Patents

Literature

140results about How to "Improve fiber properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

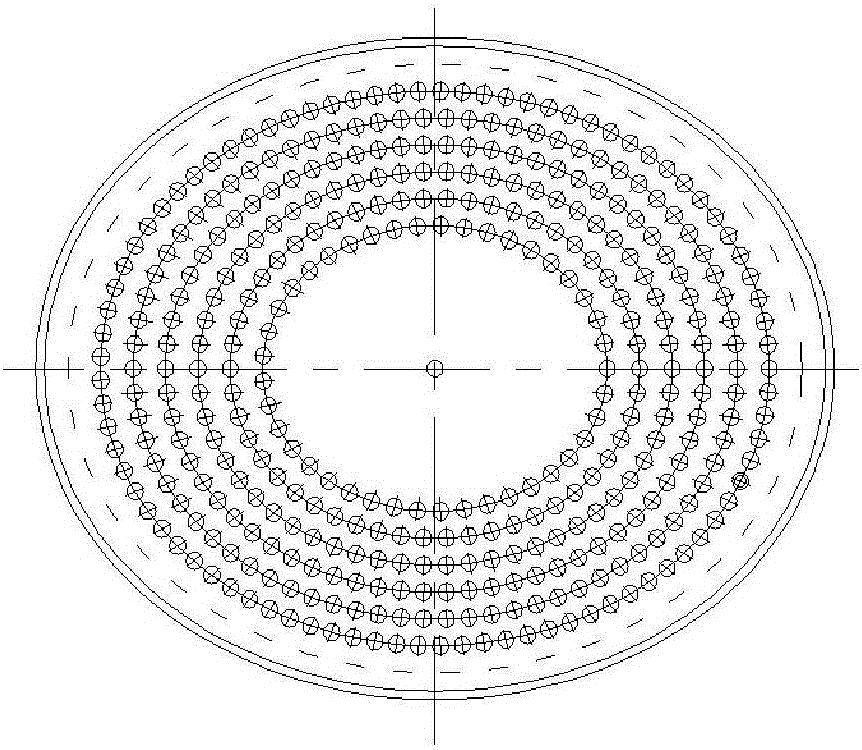

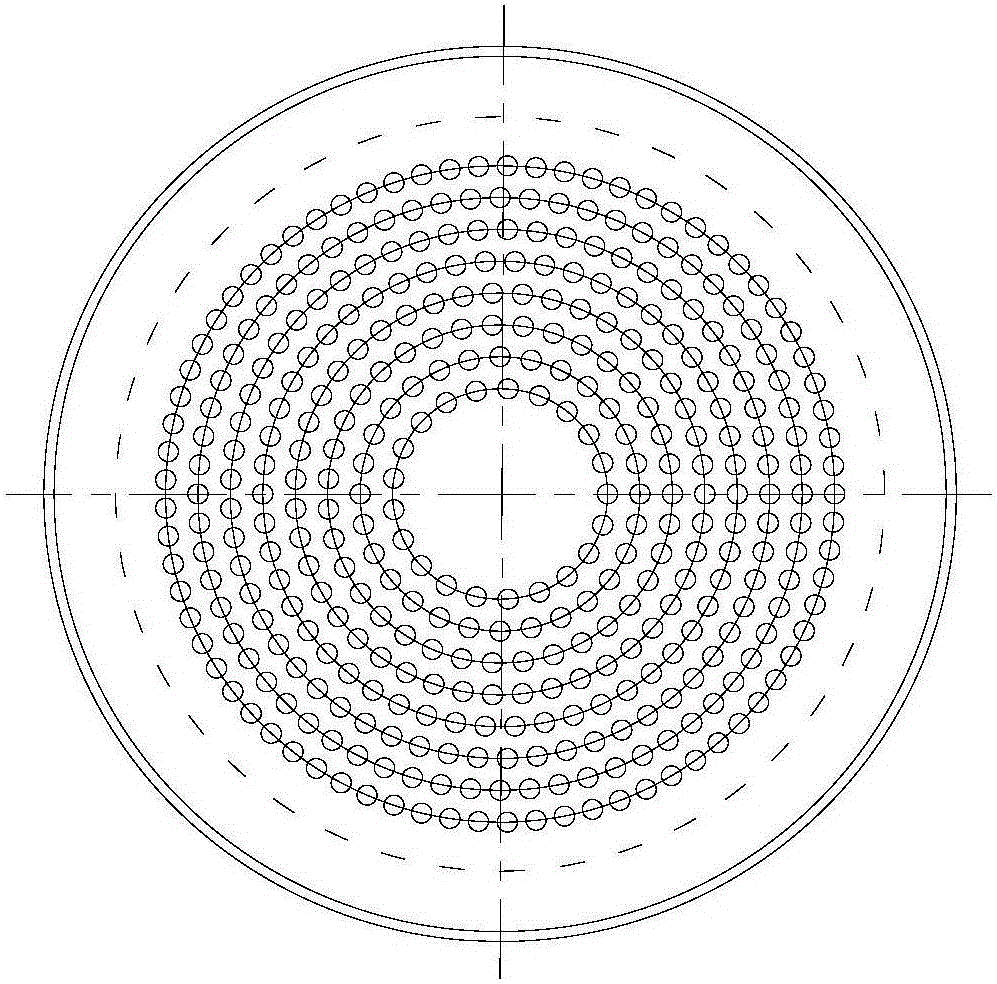

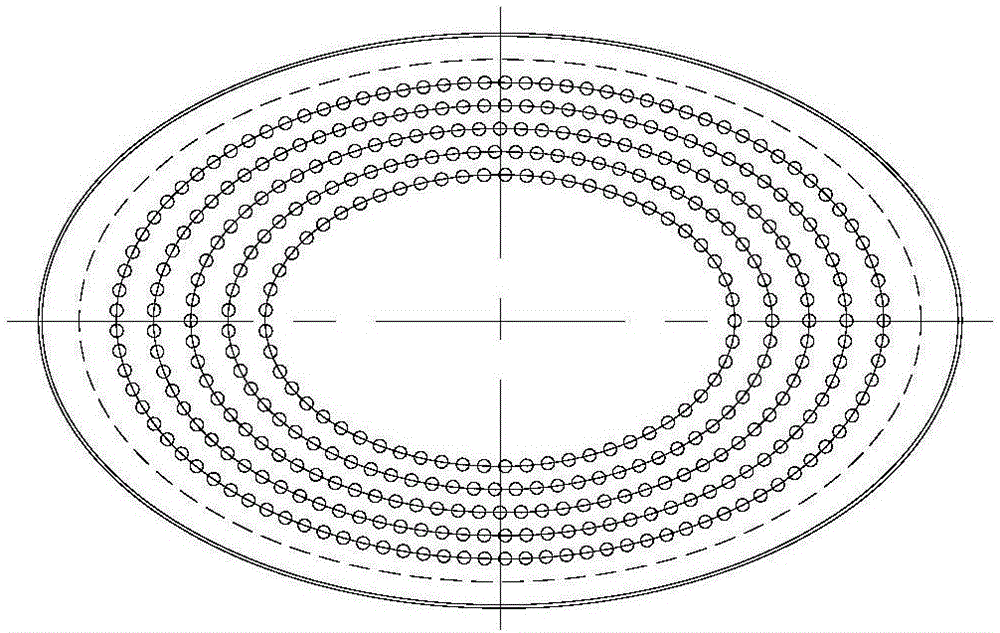

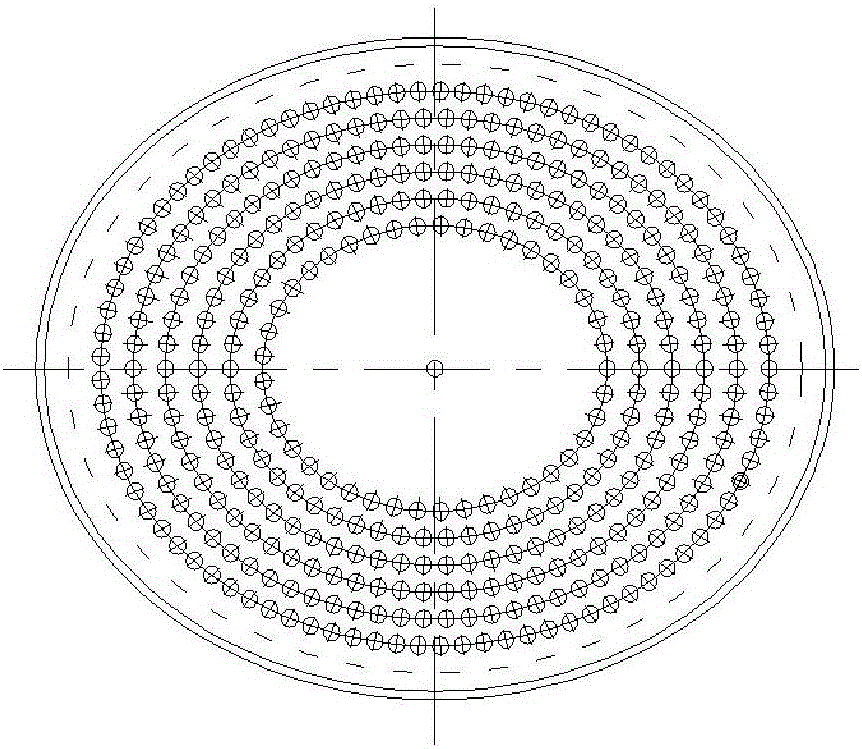

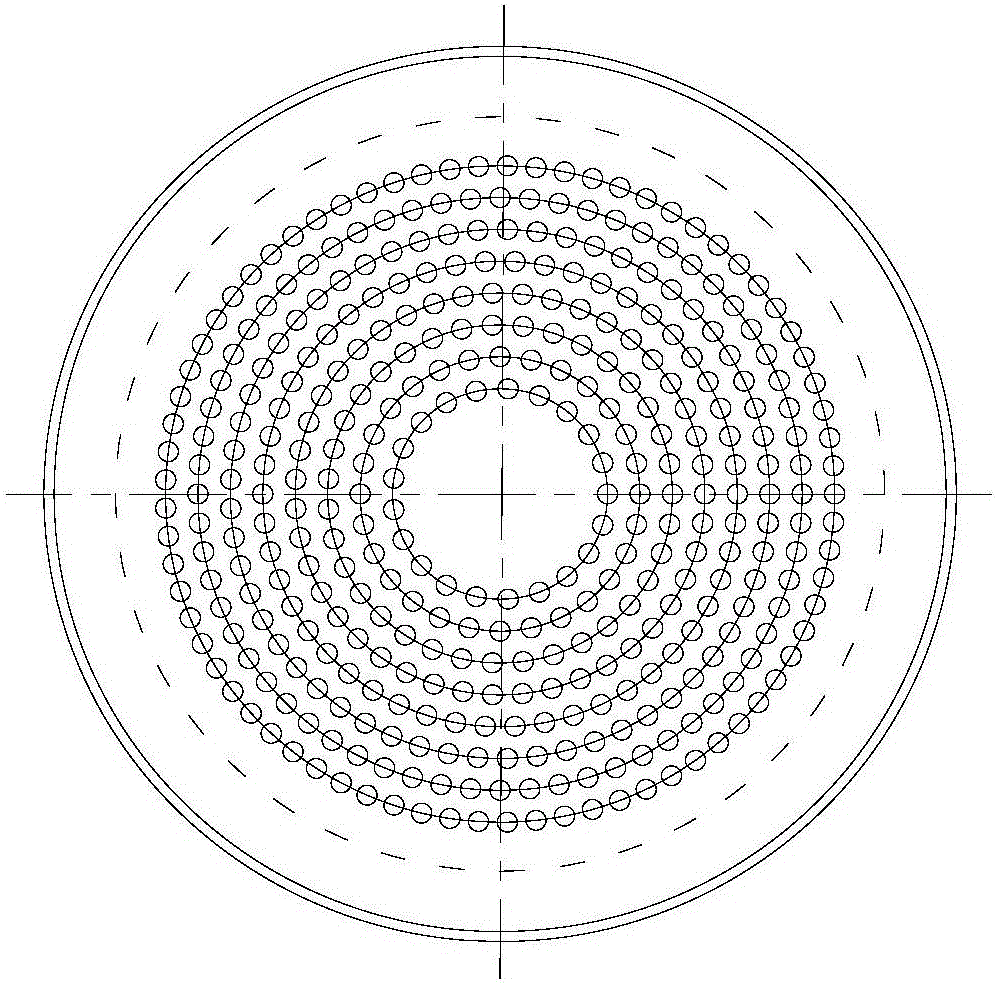

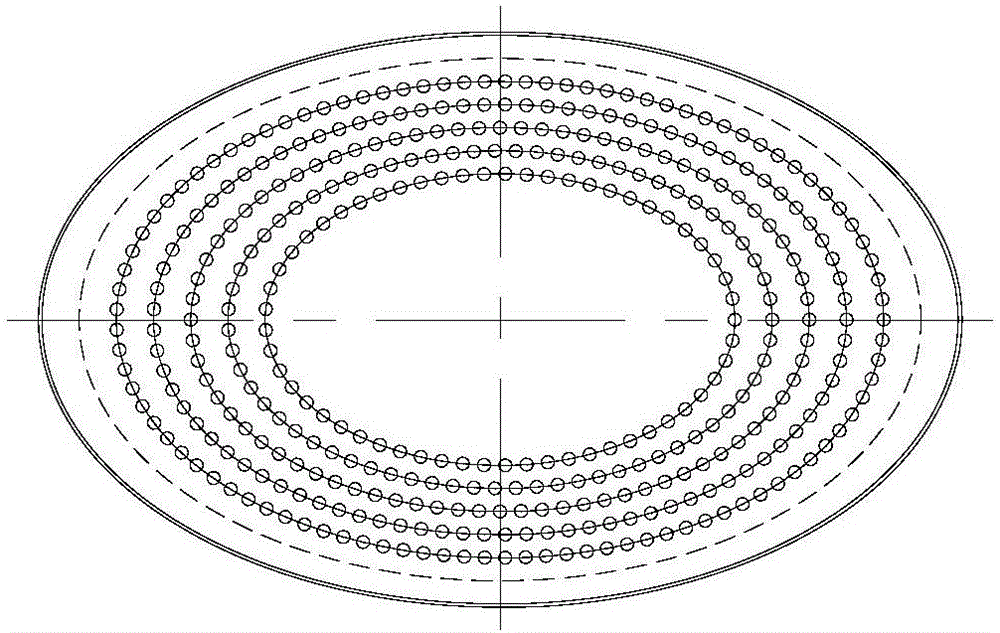

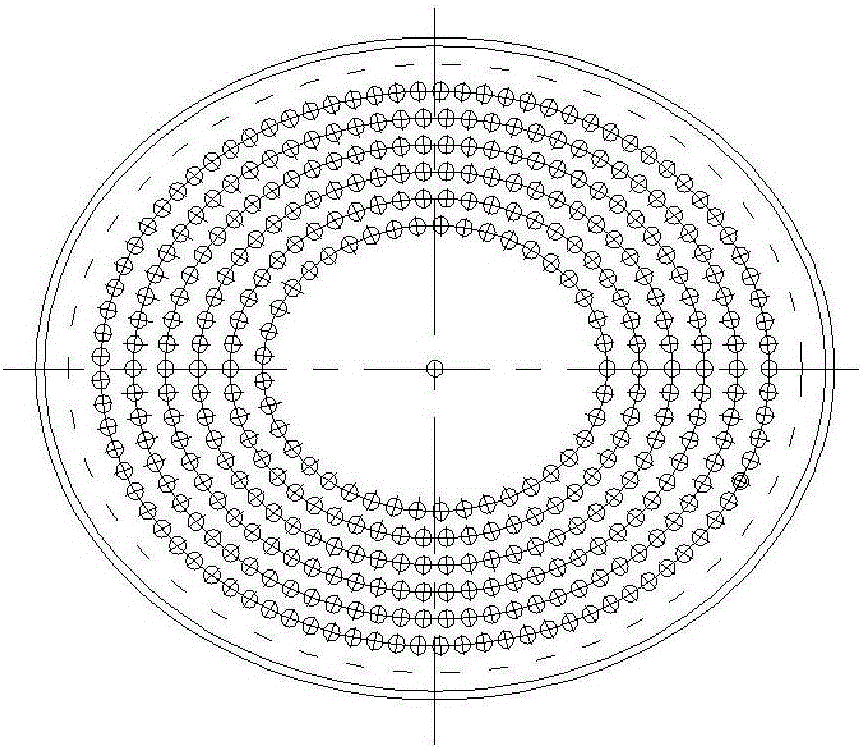

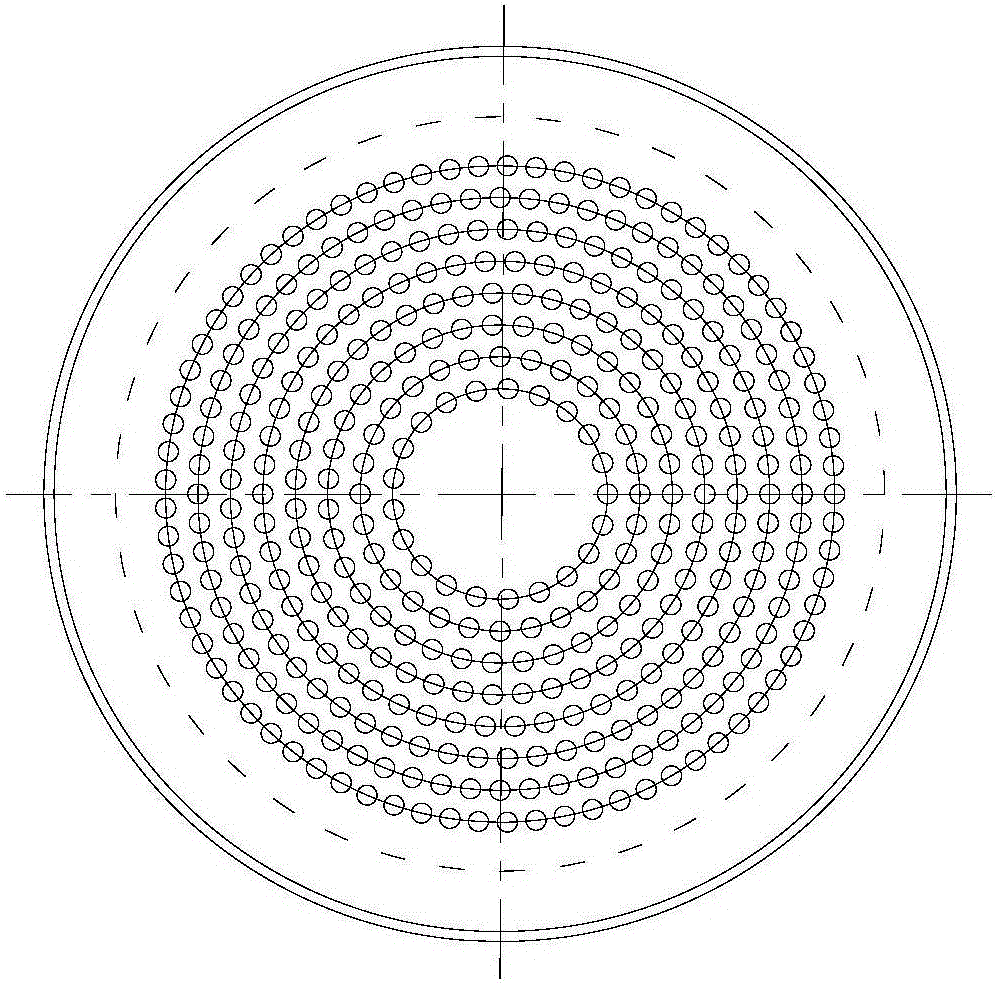

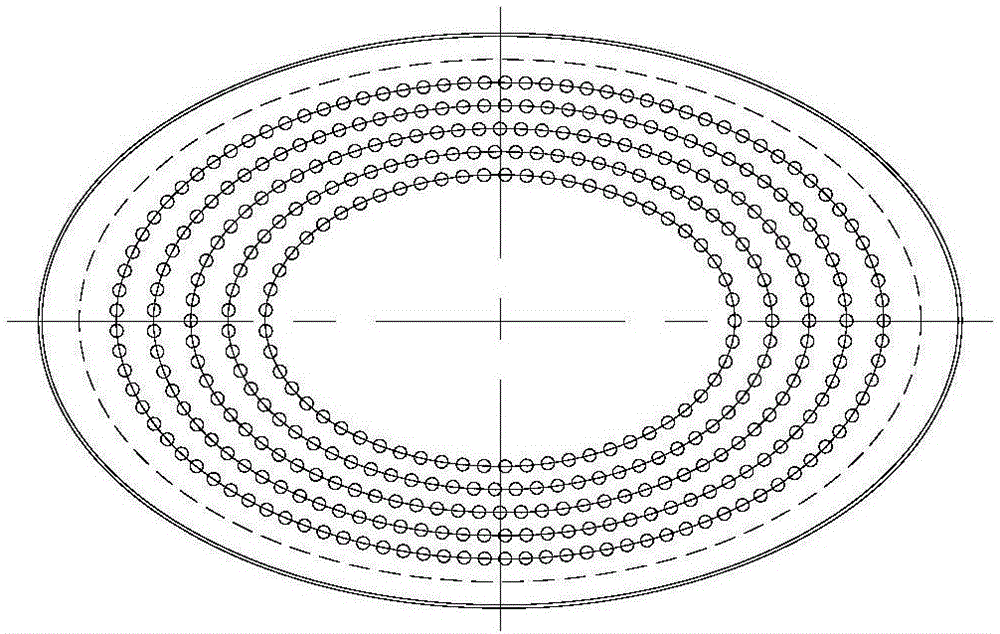

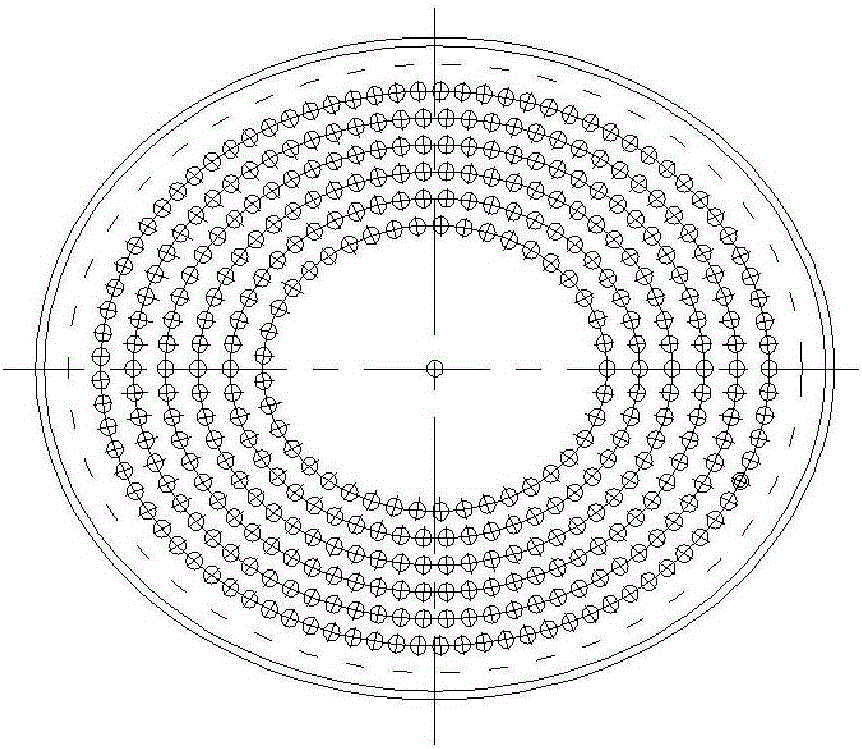

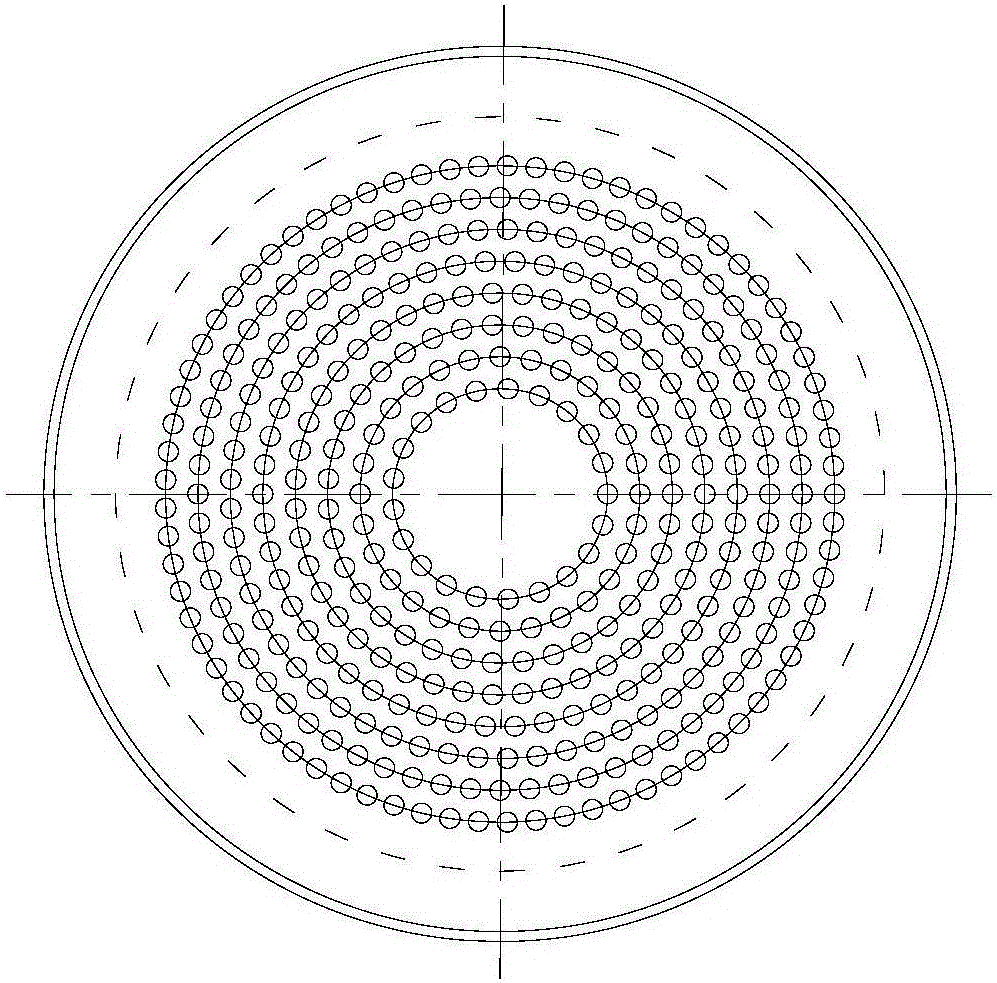

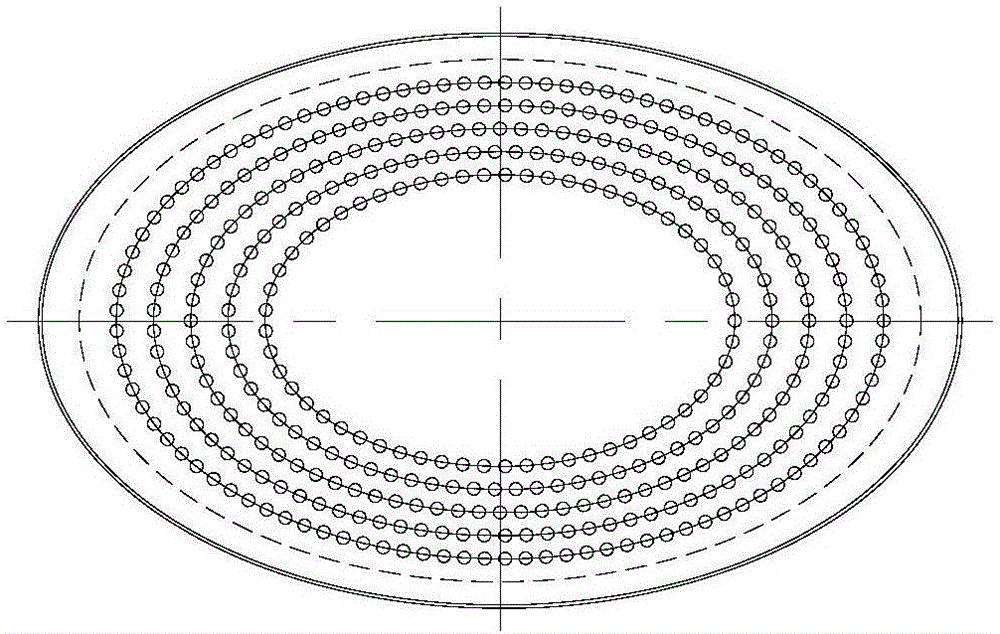

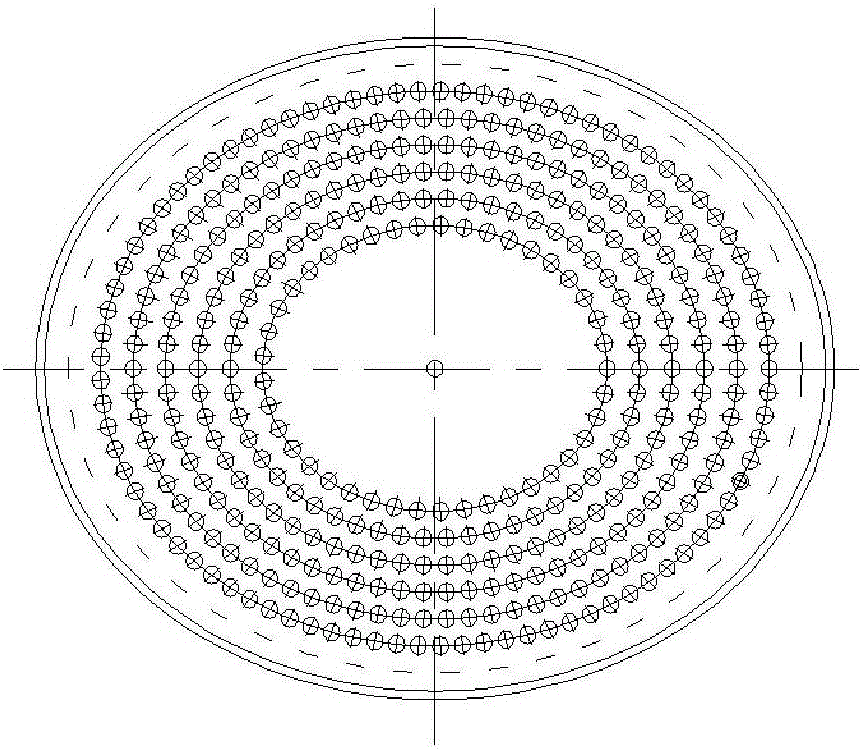

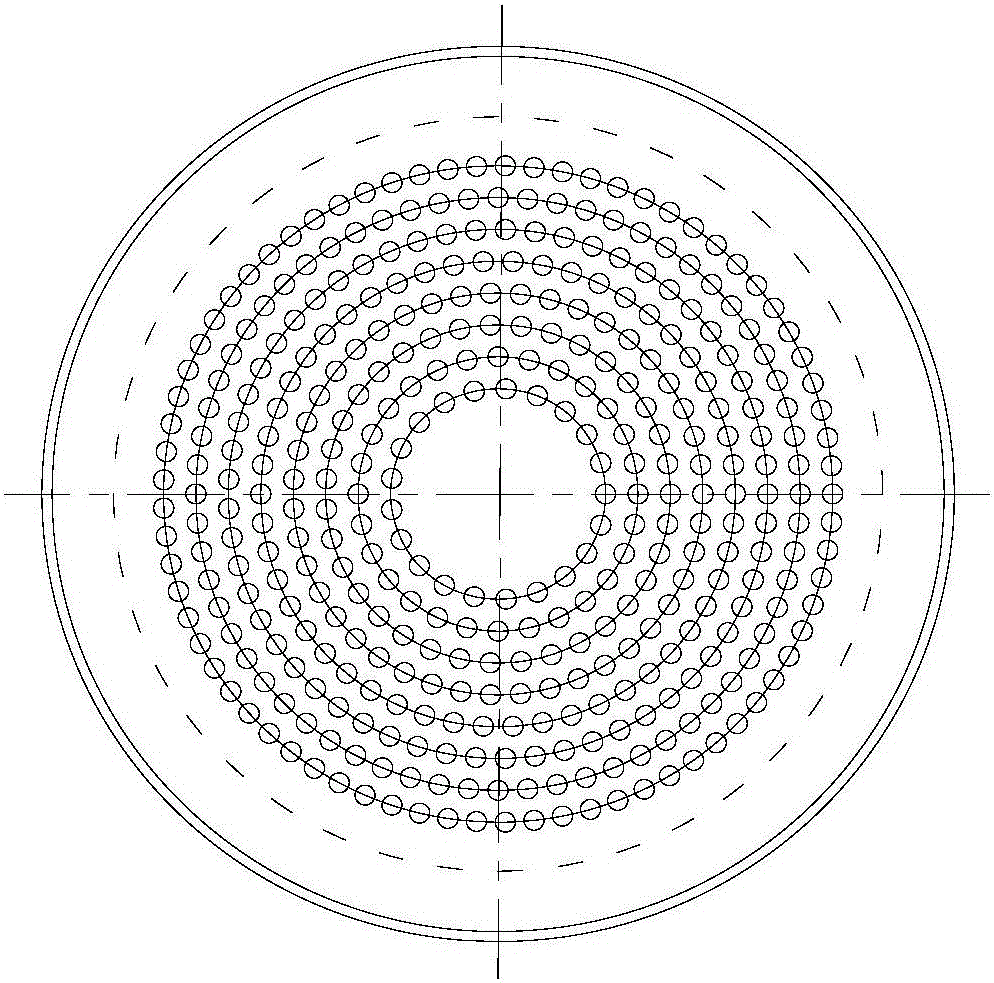

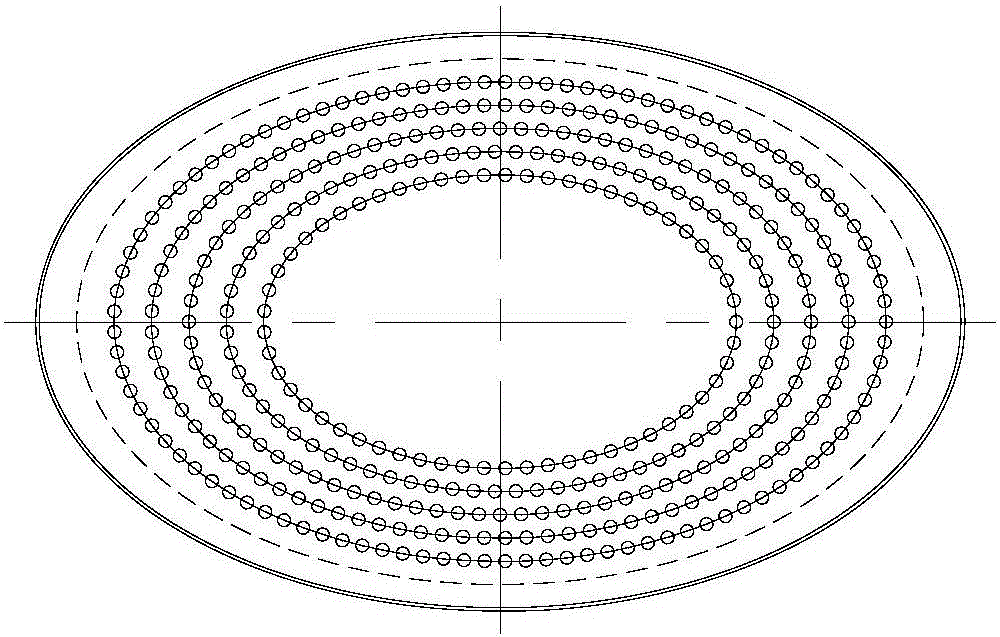

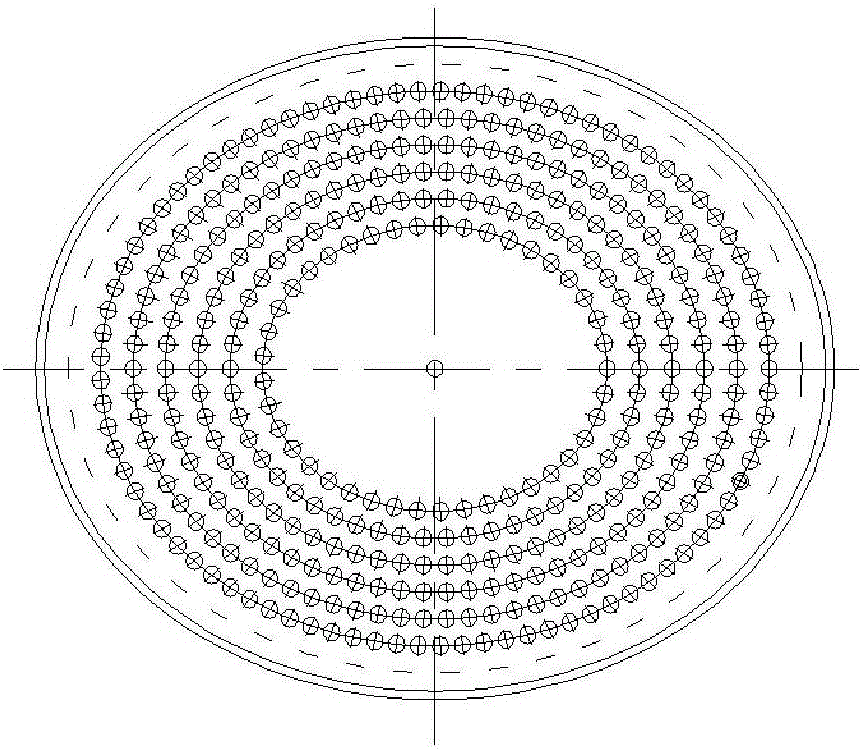

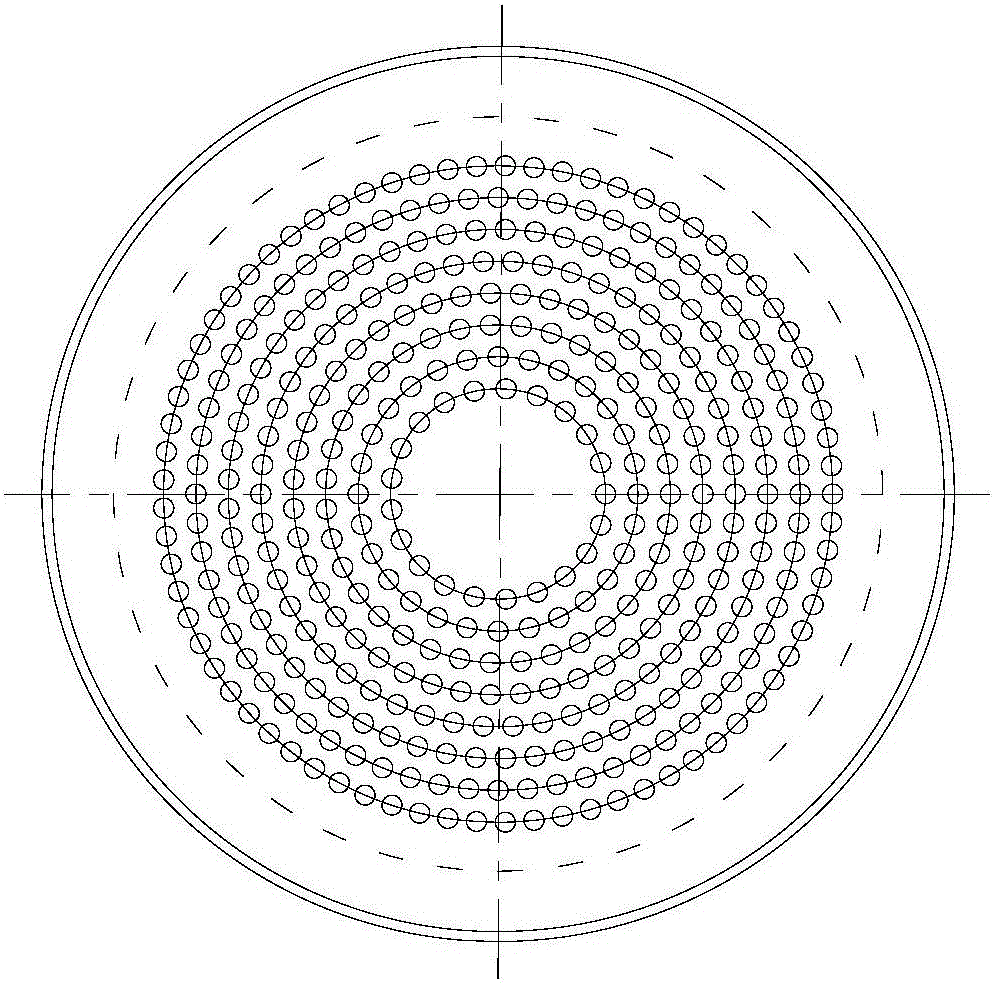

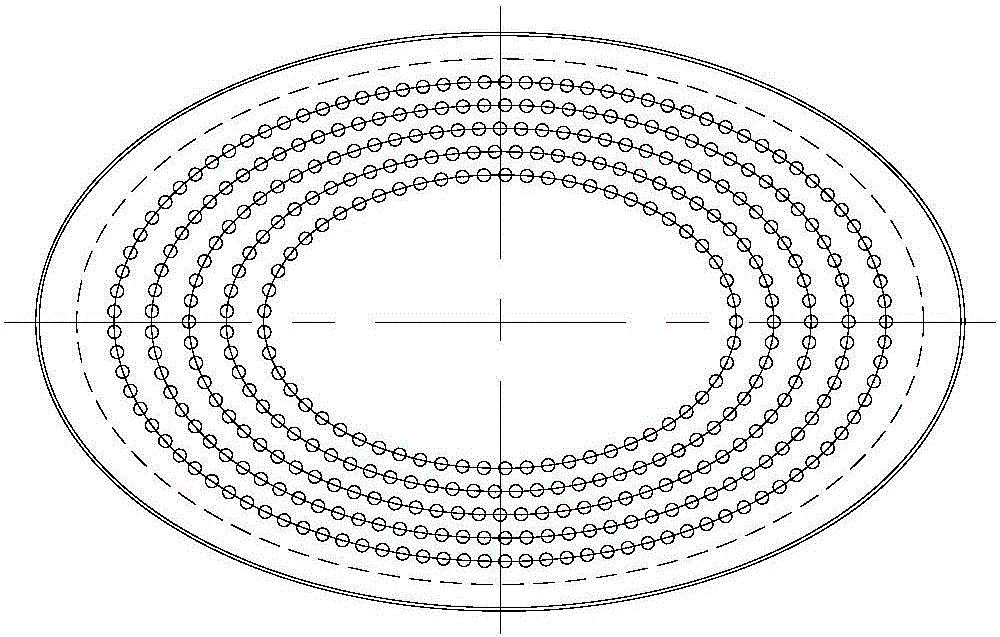

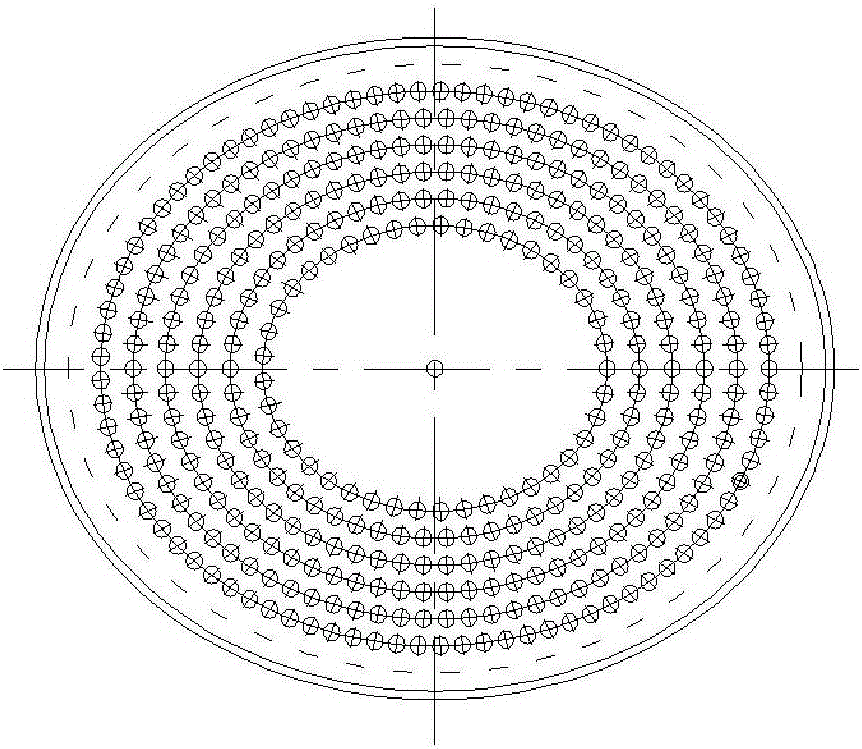

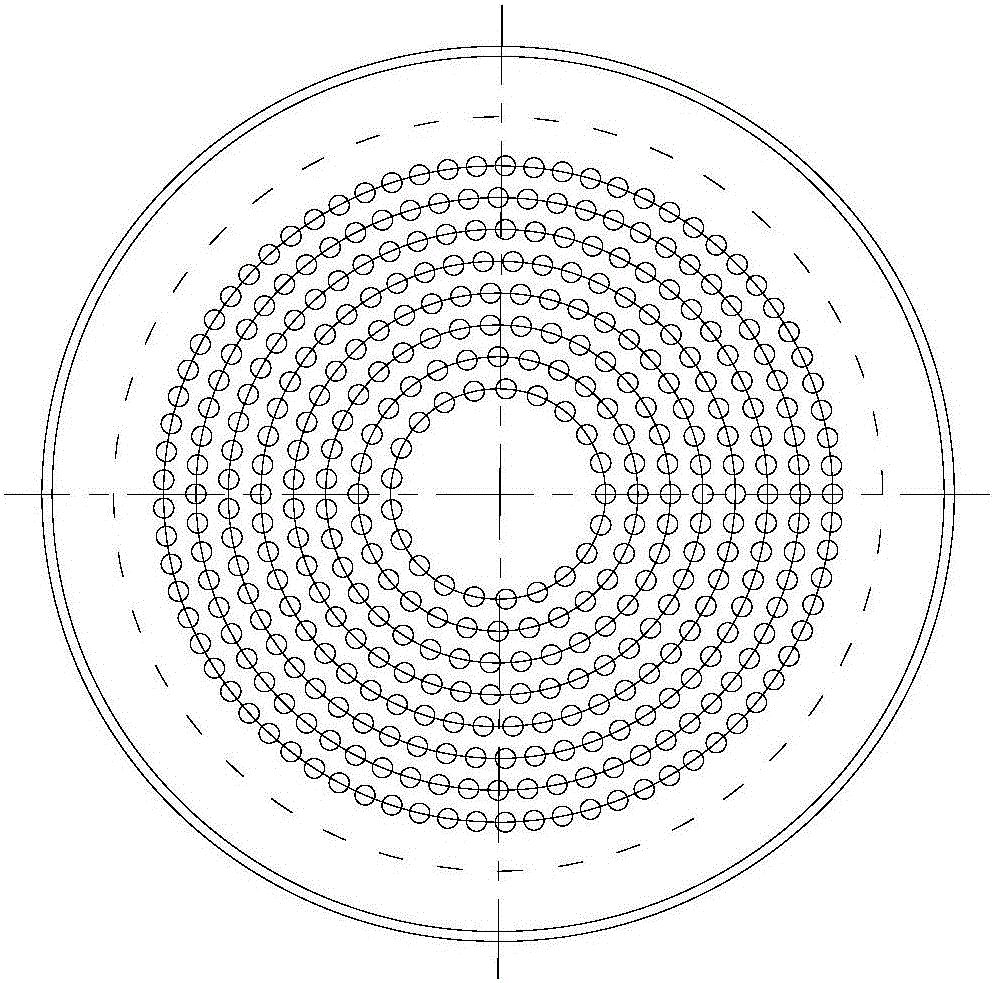

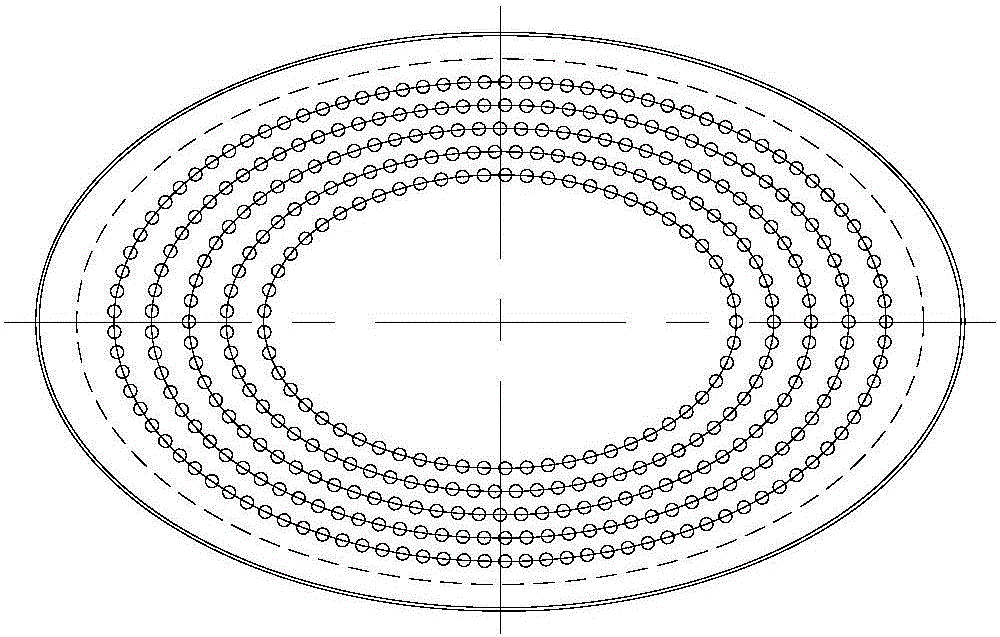

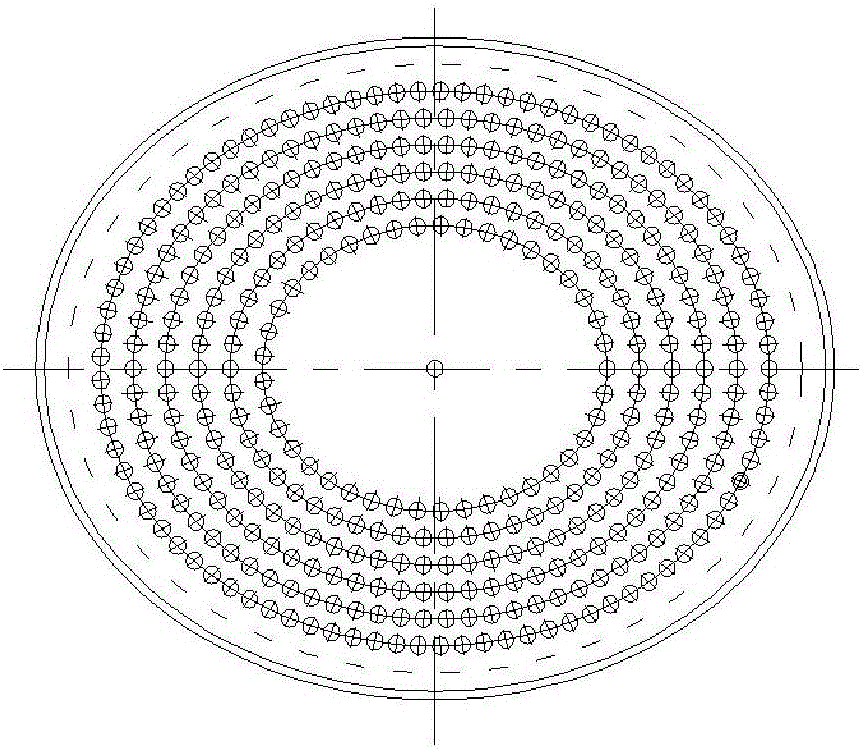

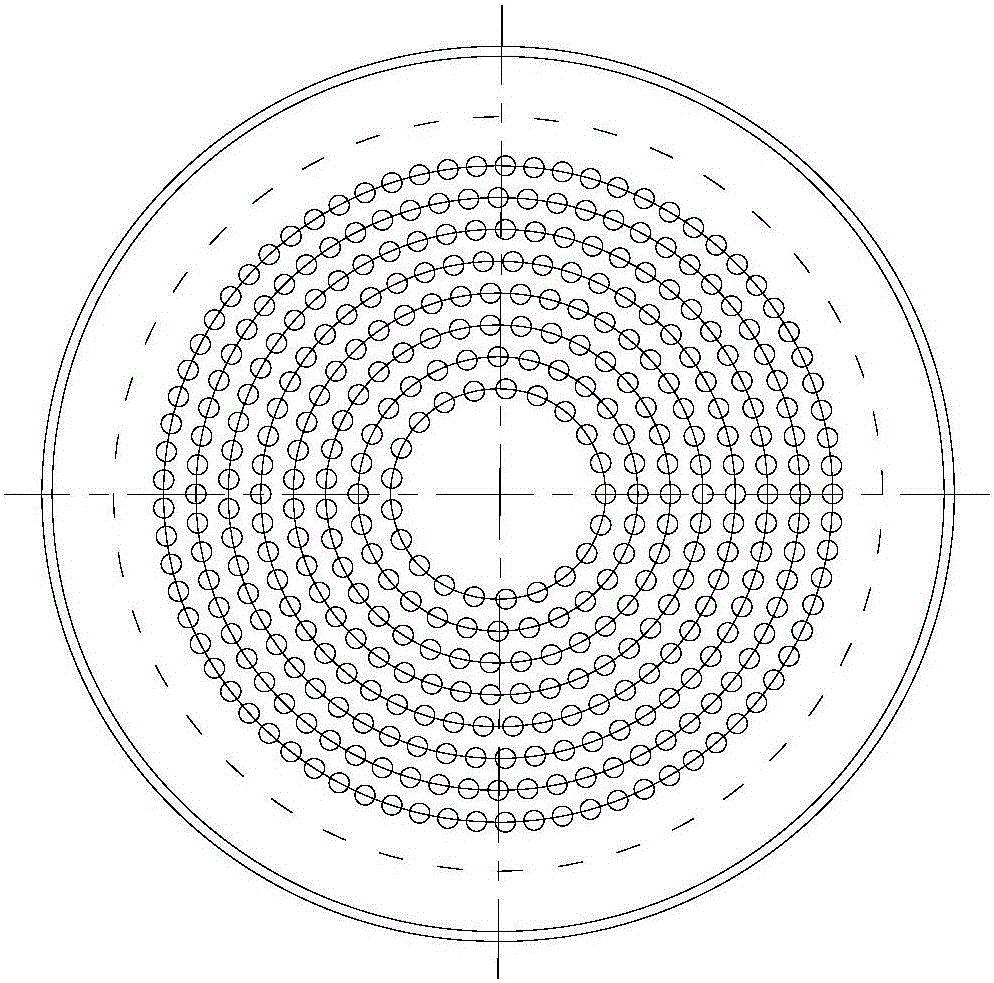

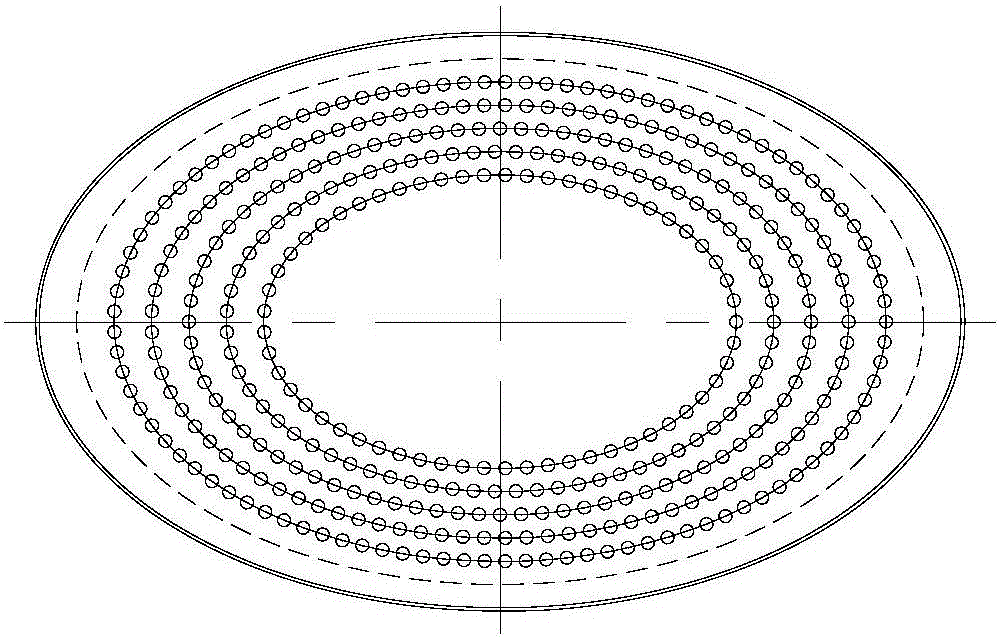

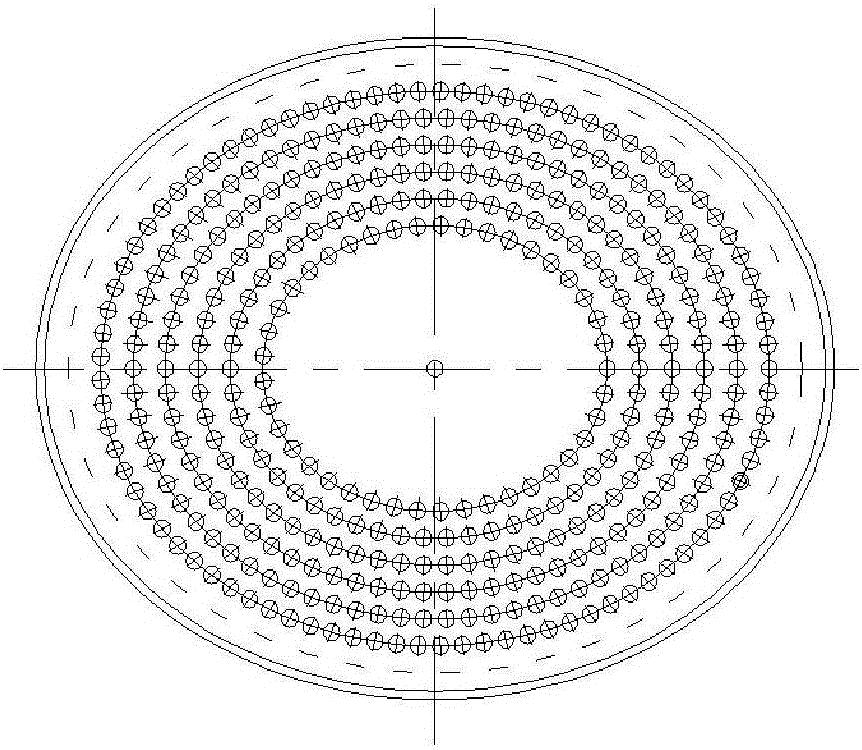

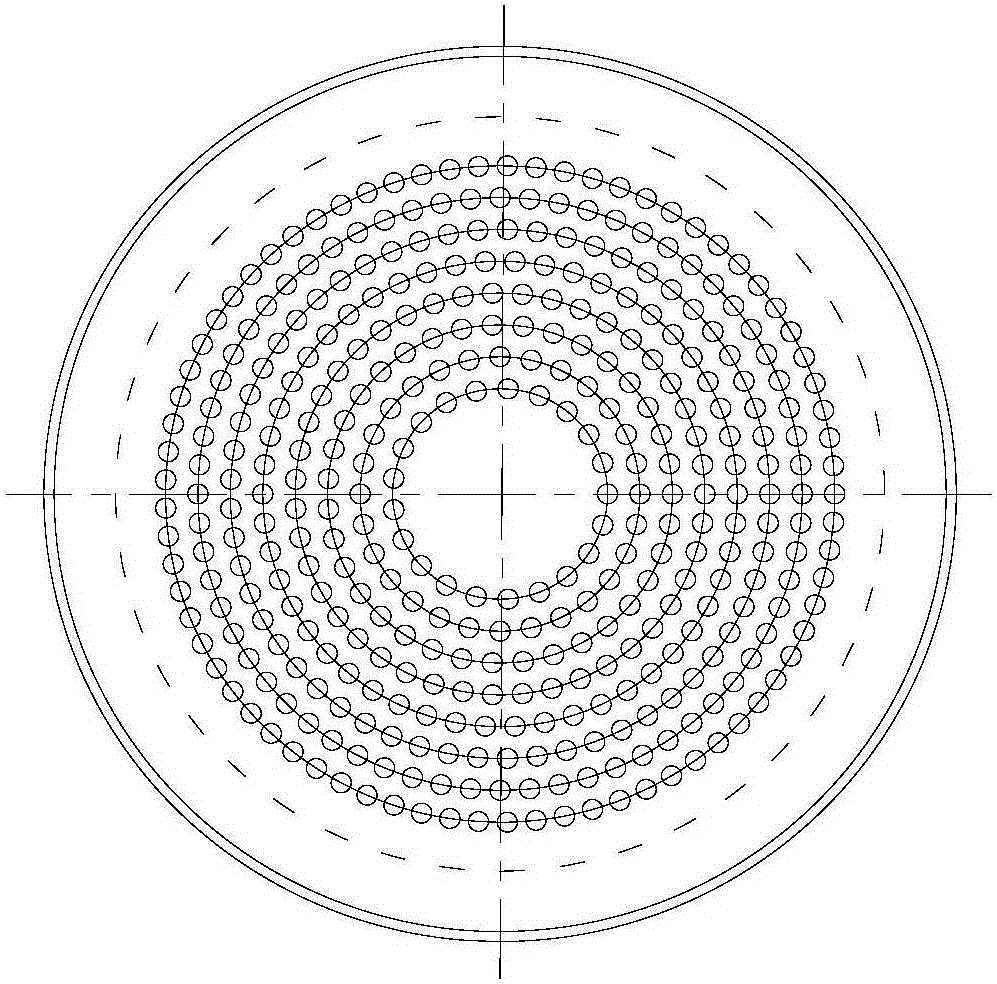

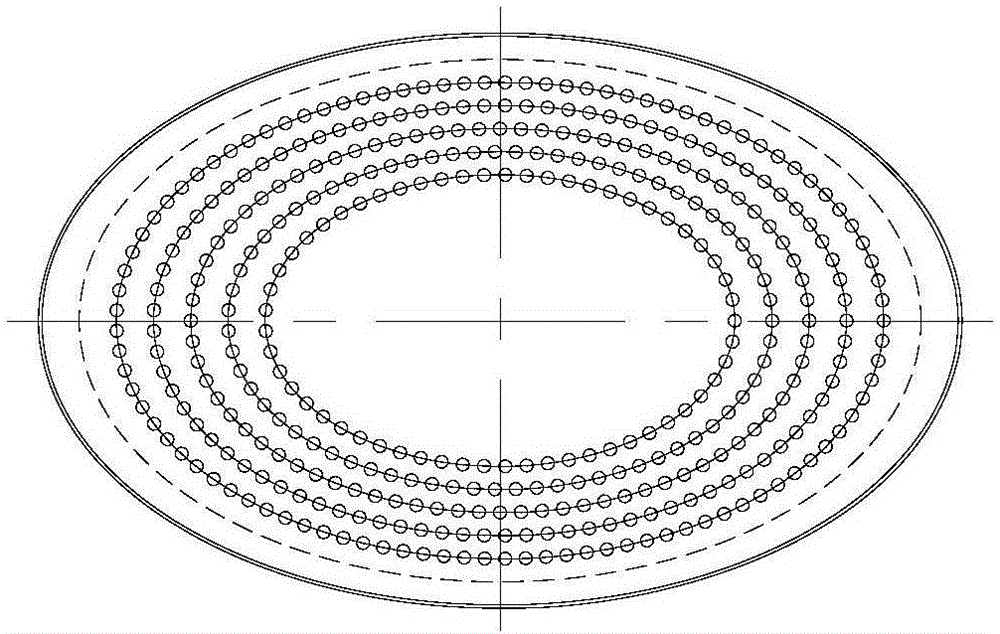

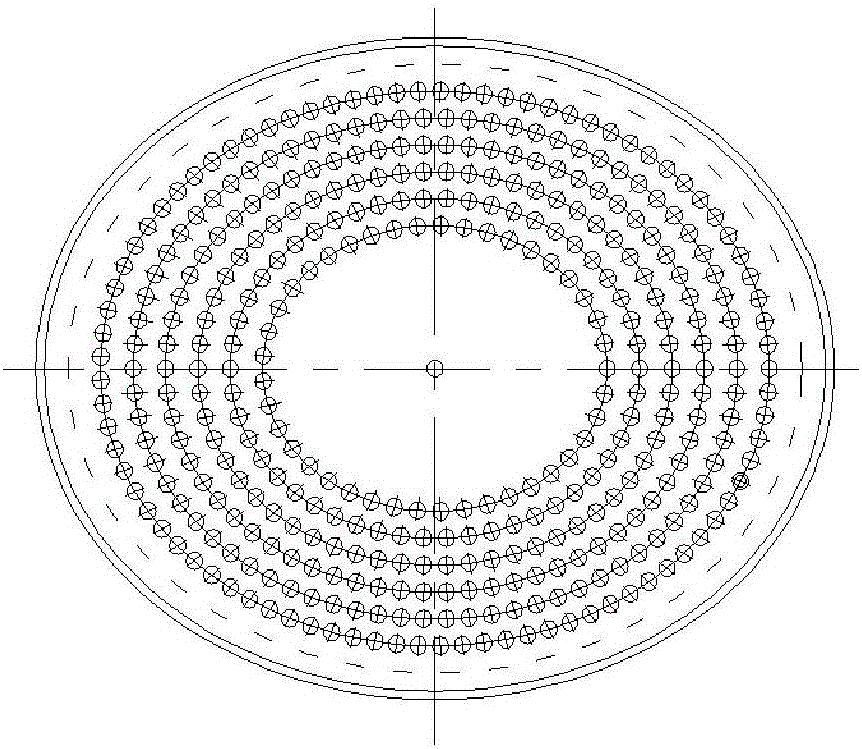

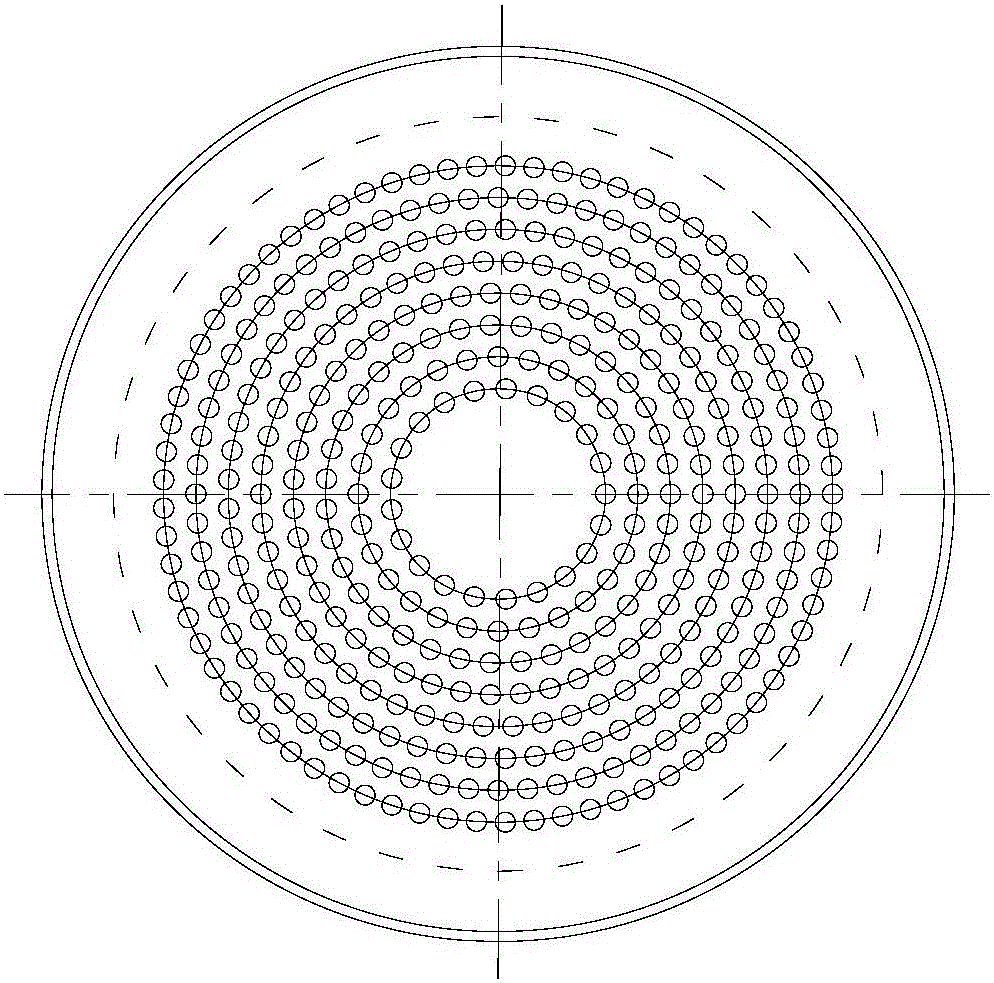

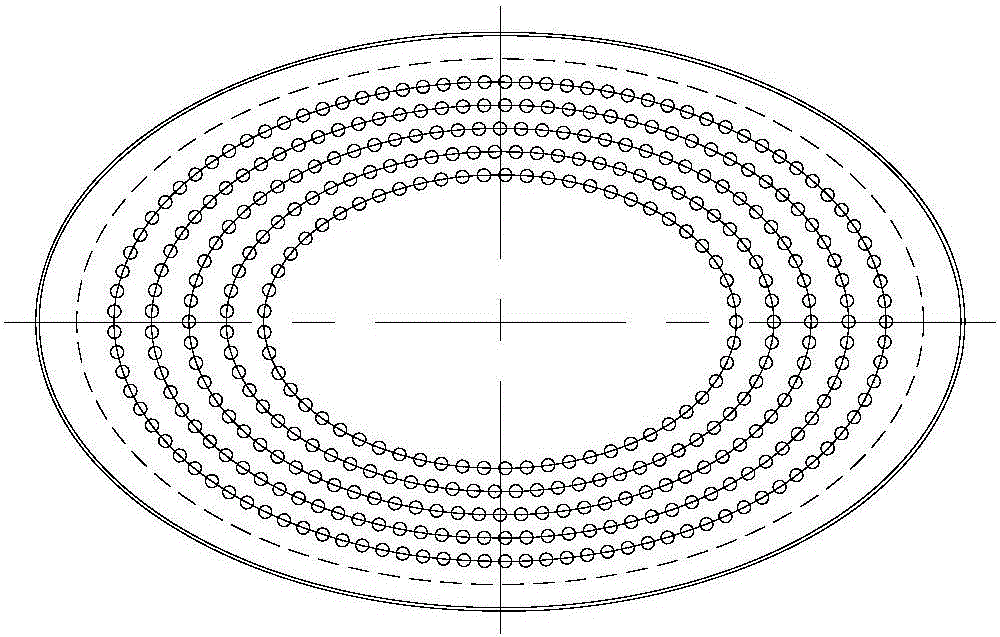

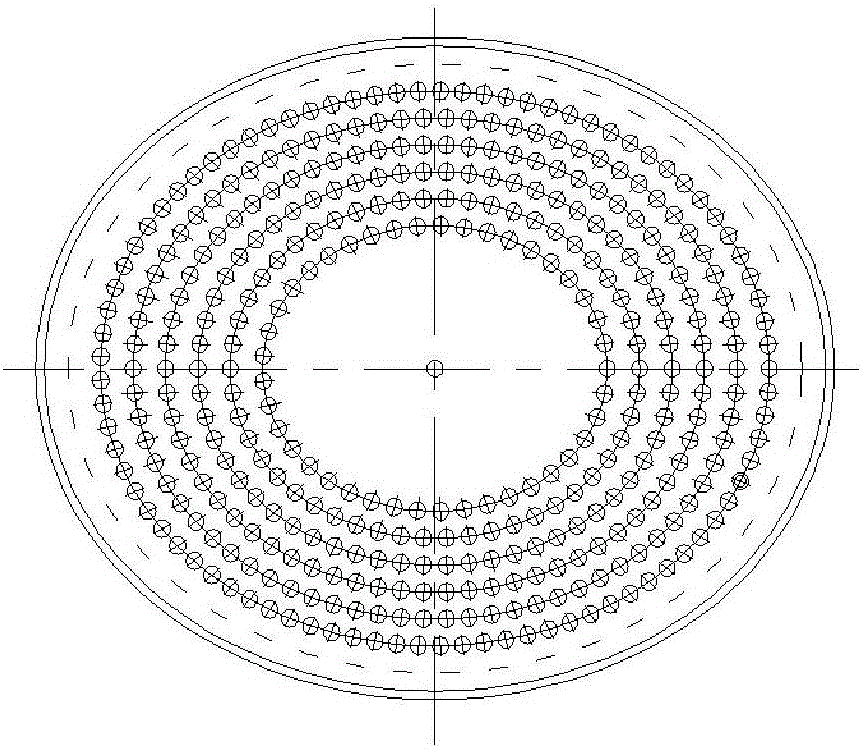

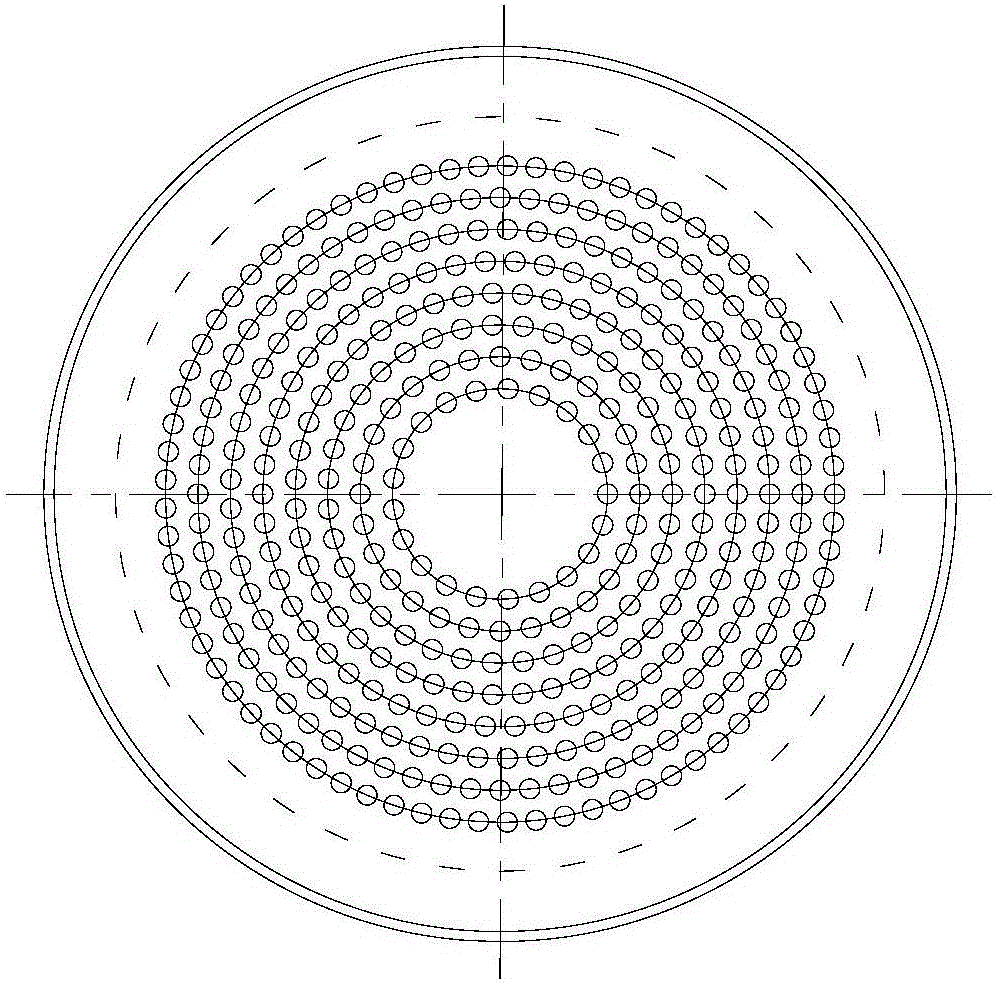

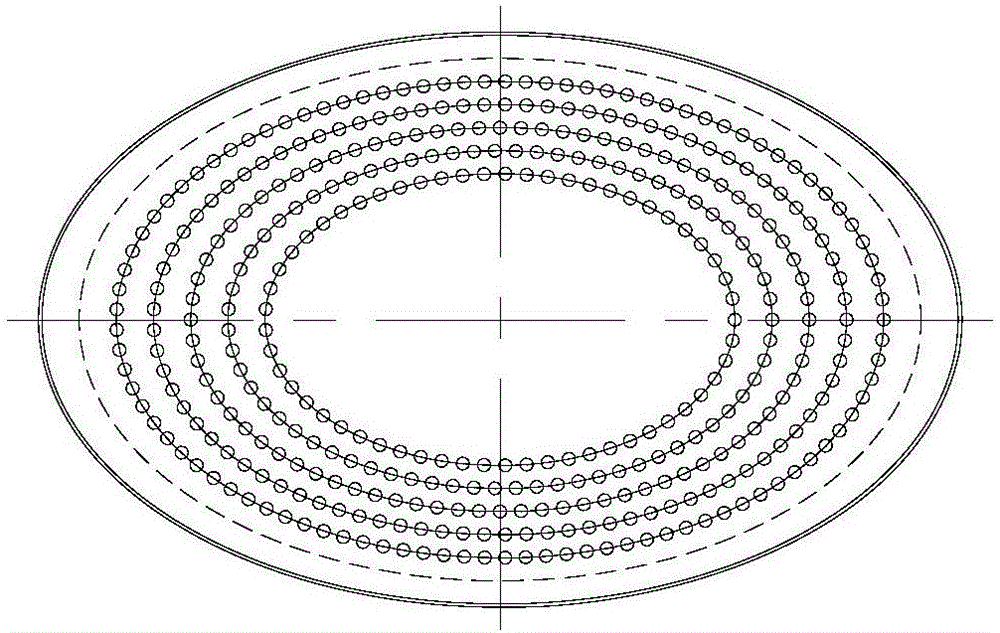

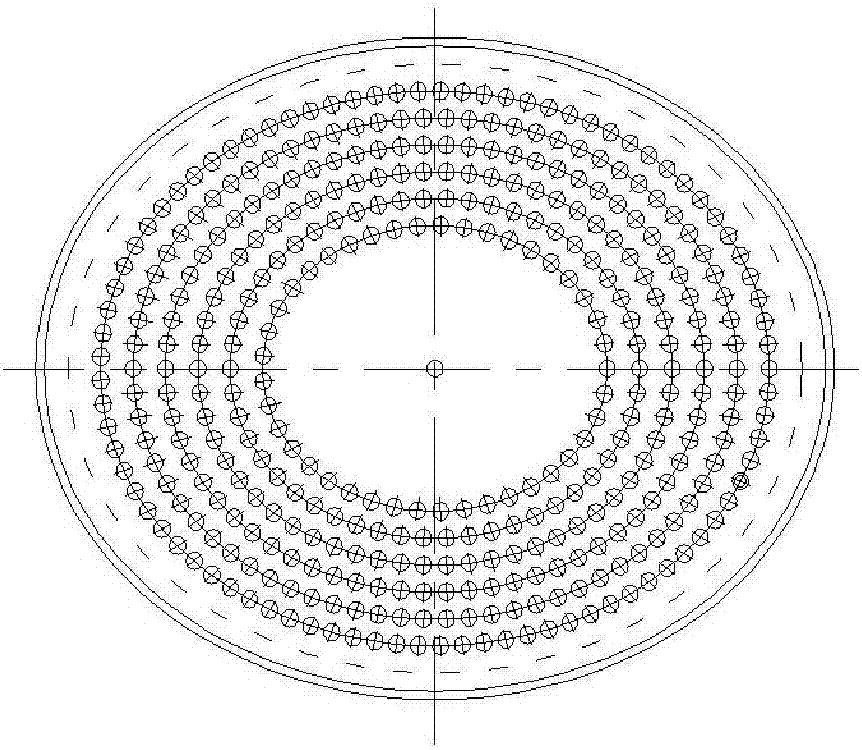

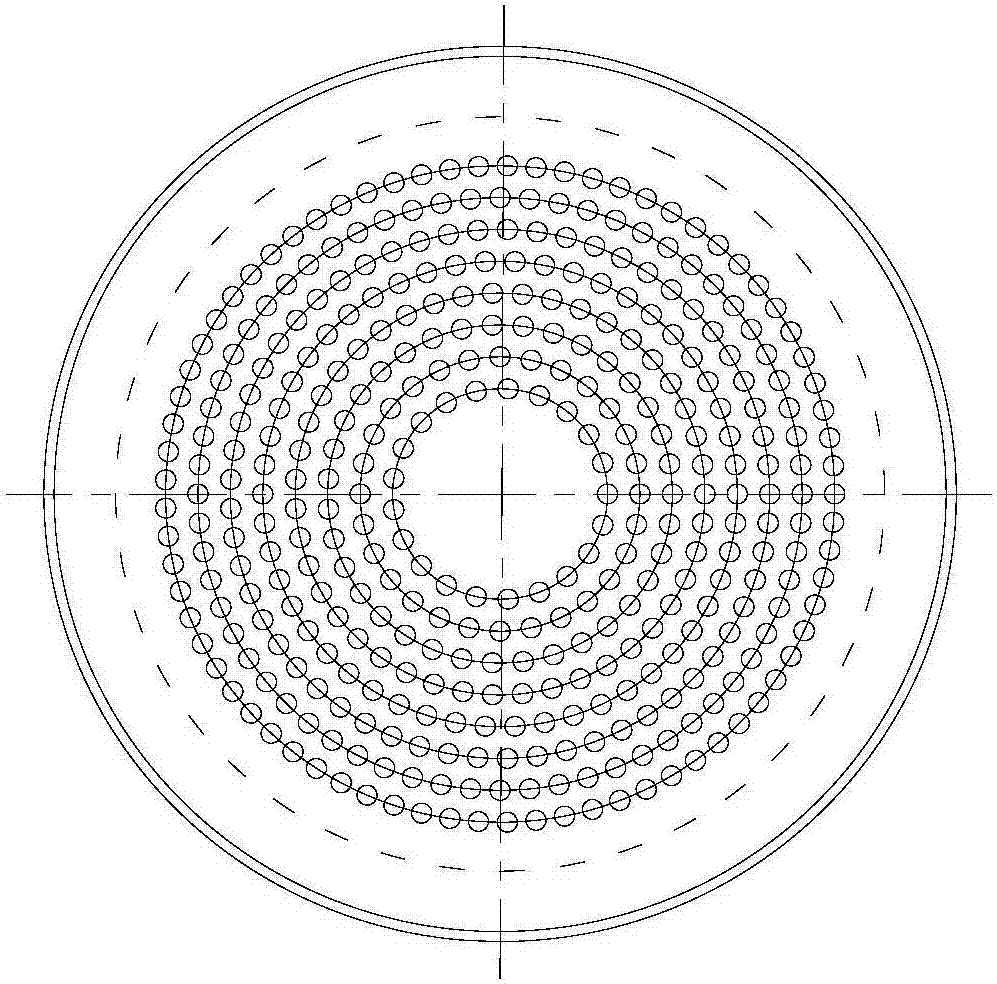

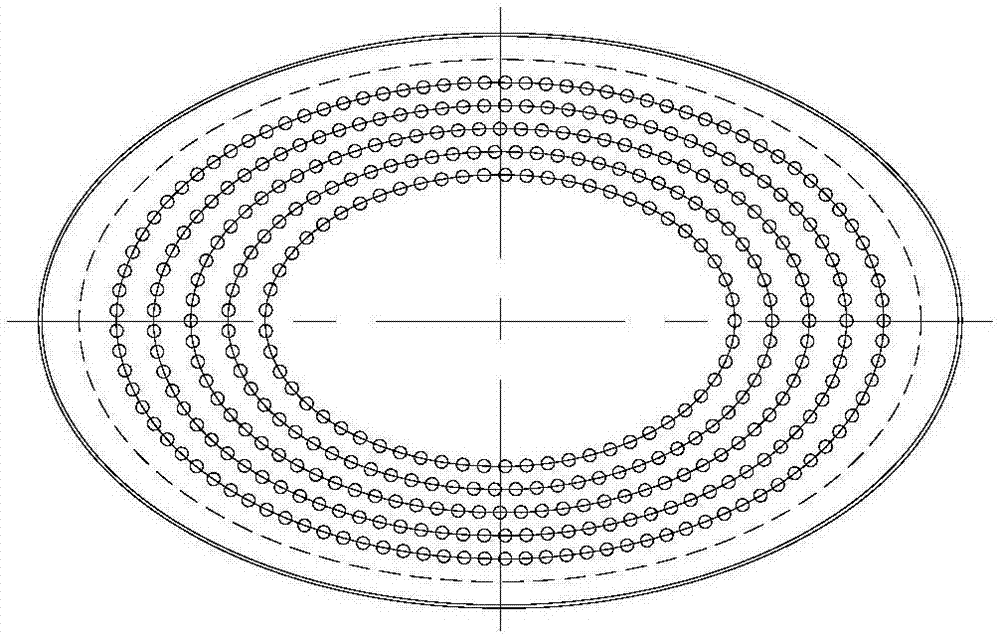

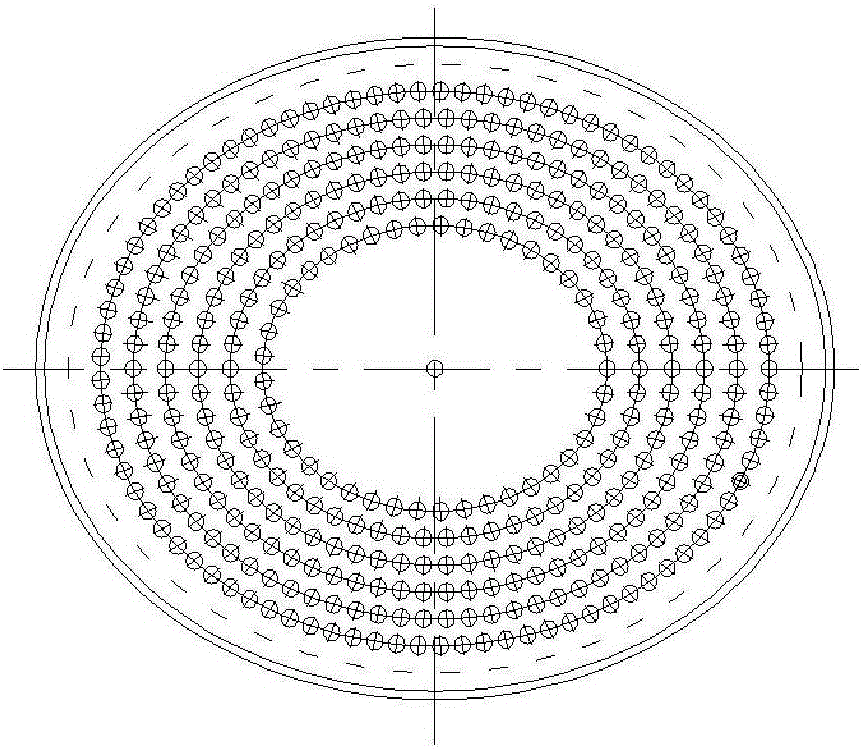

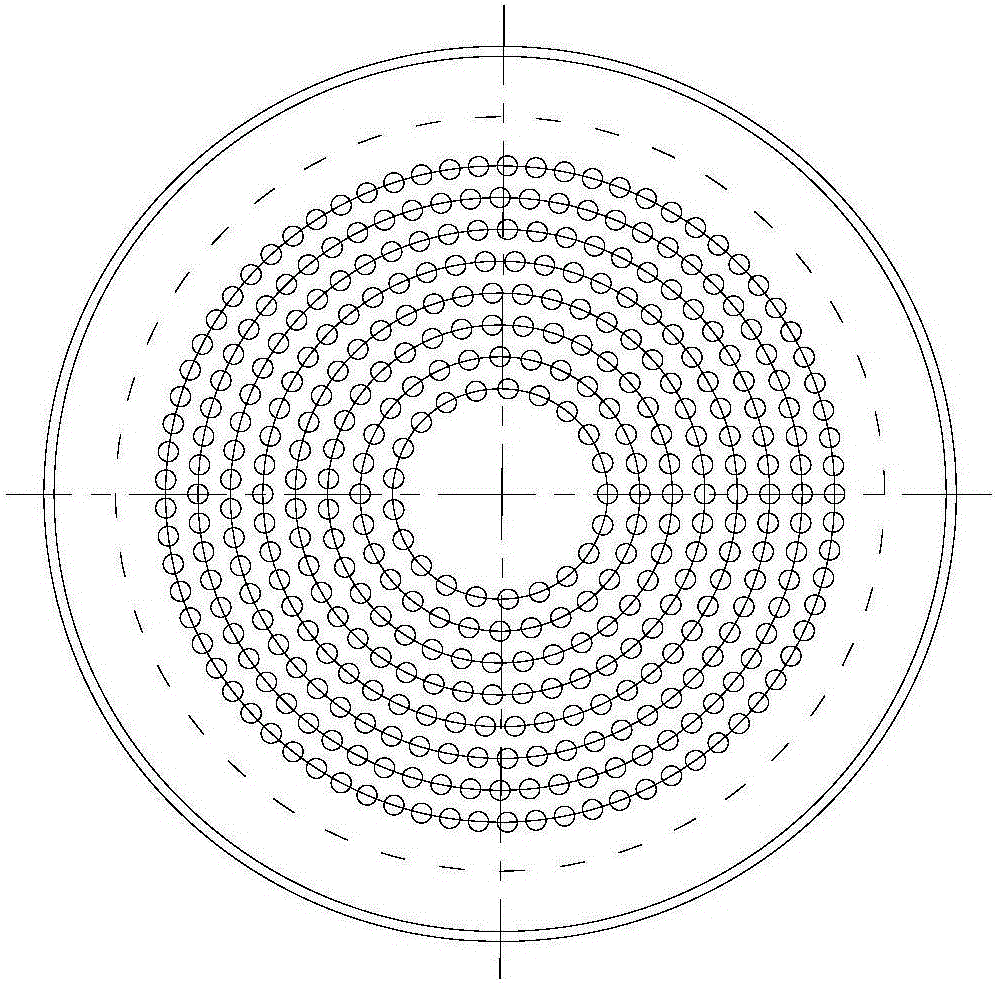

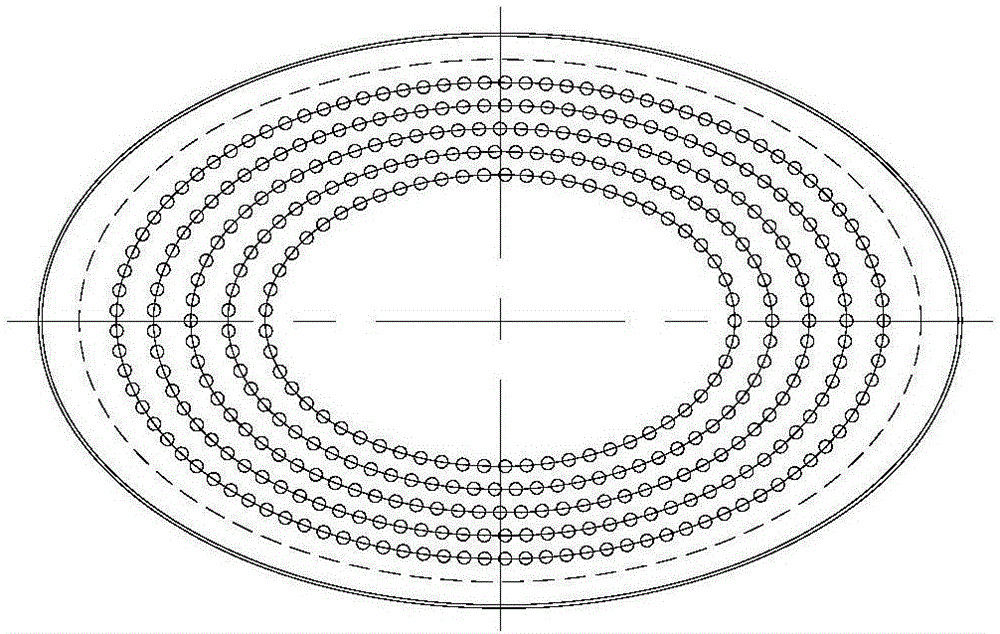

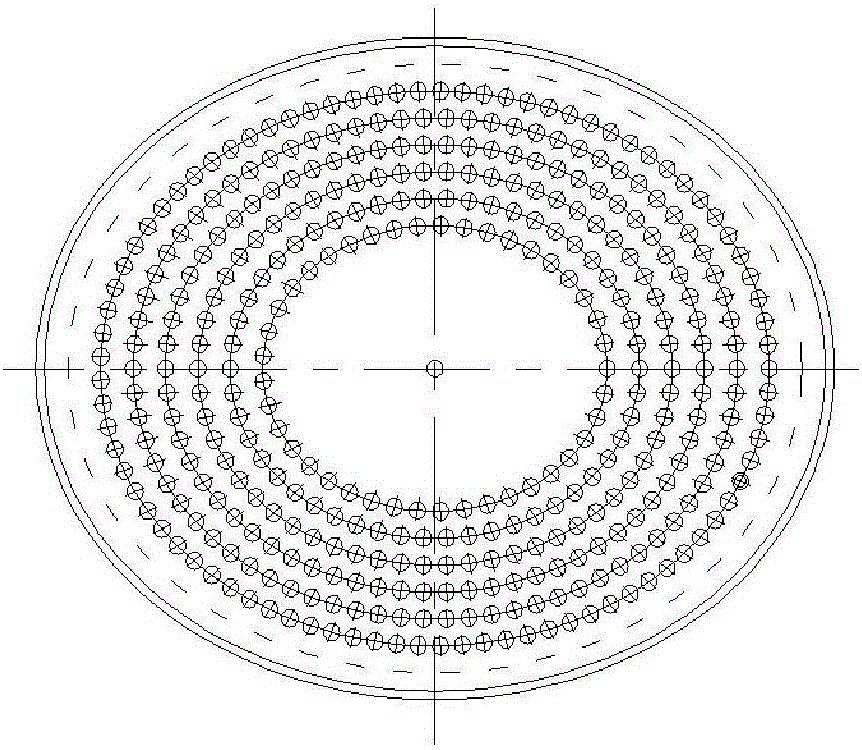

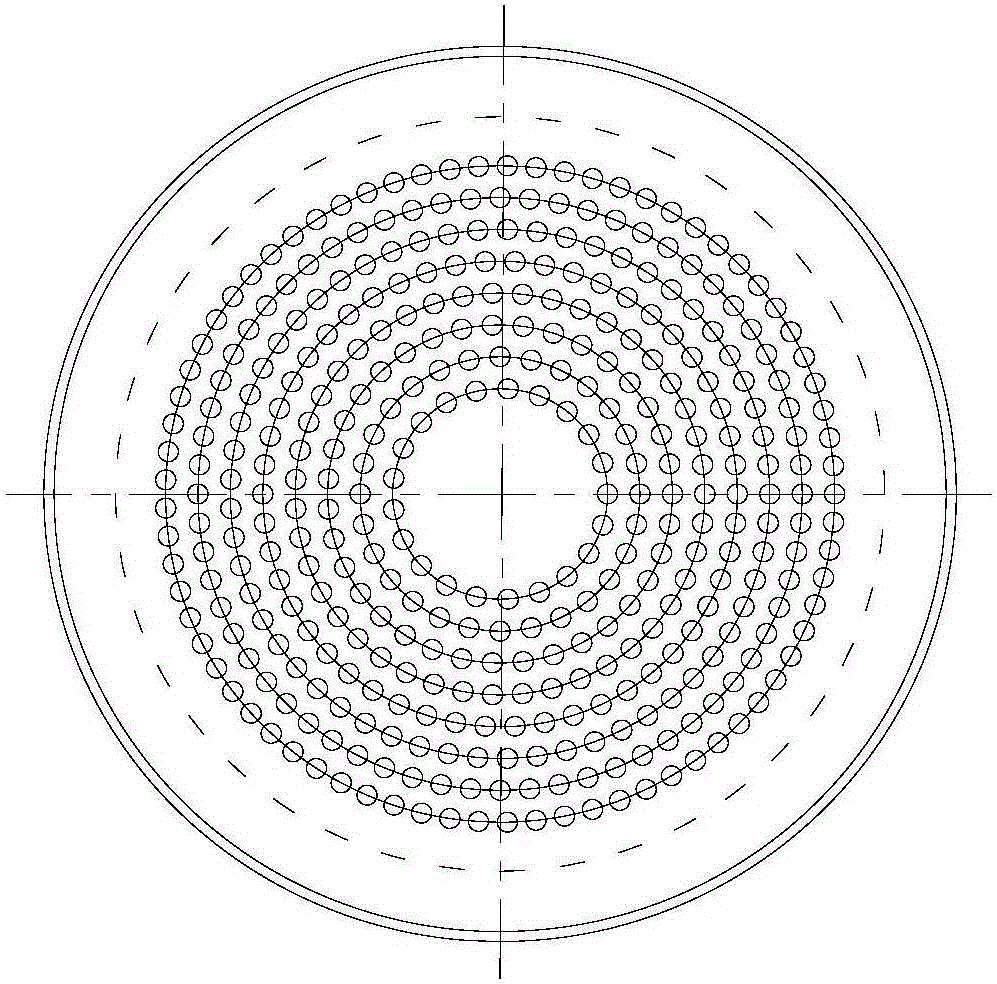

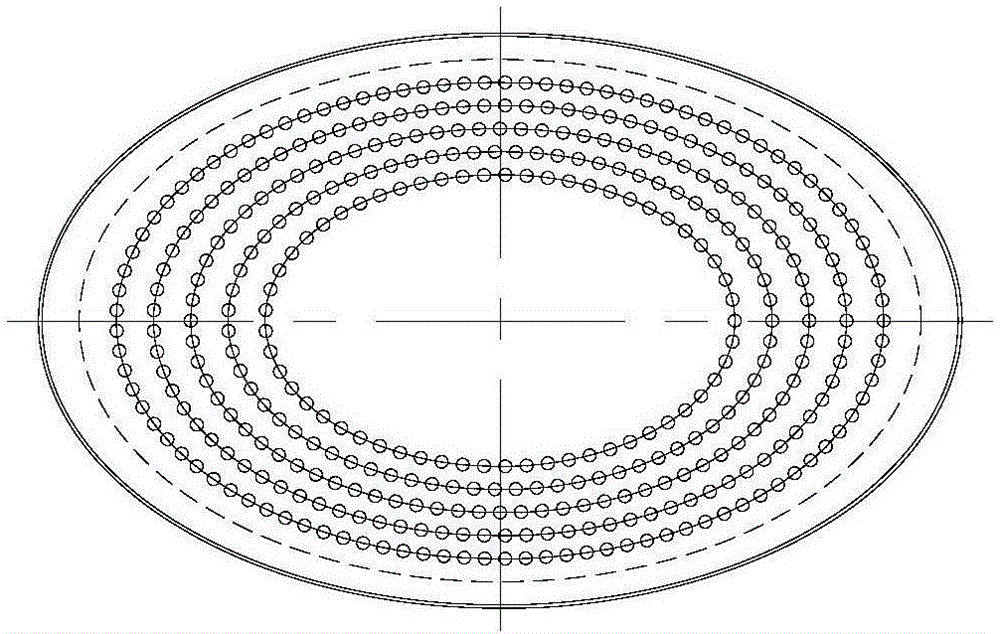

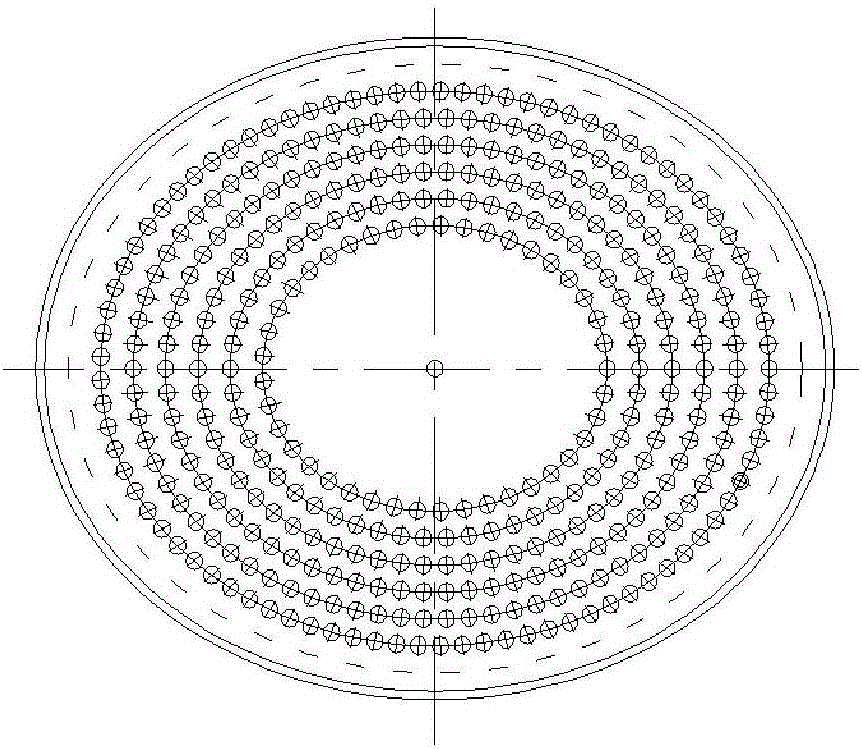

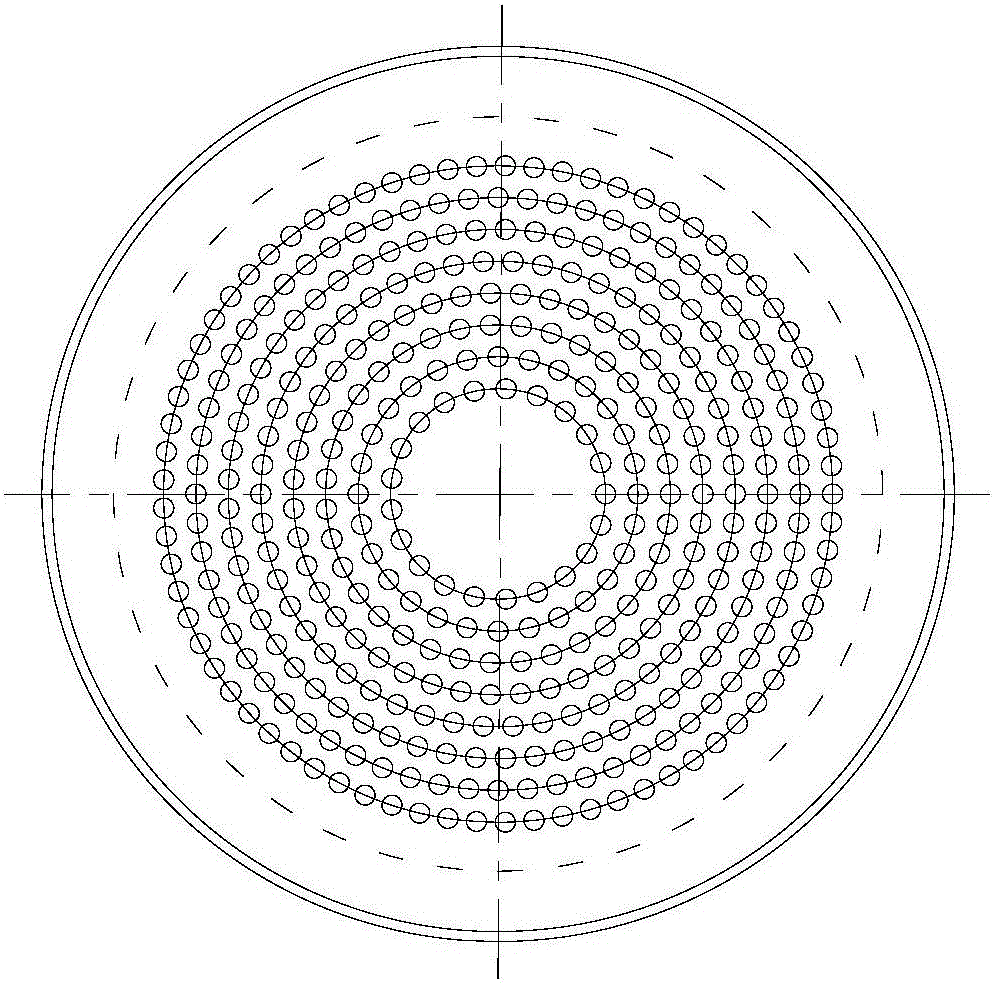

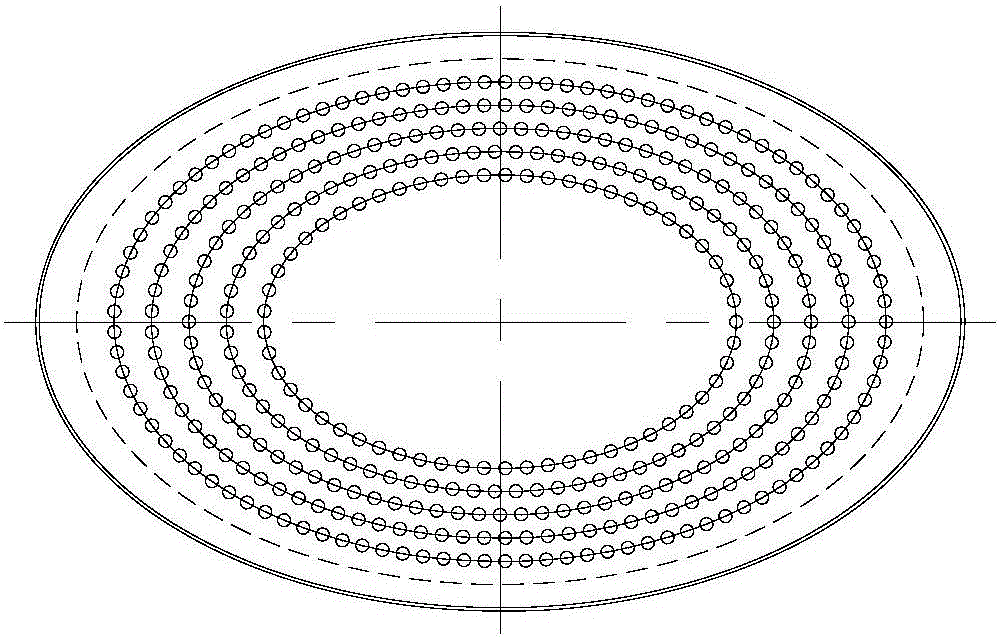

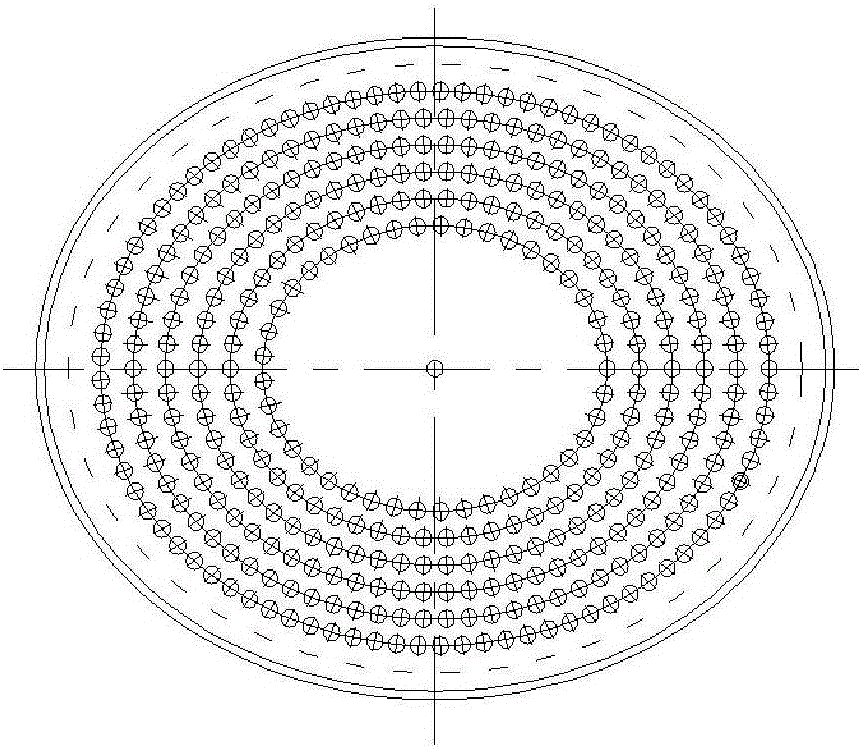

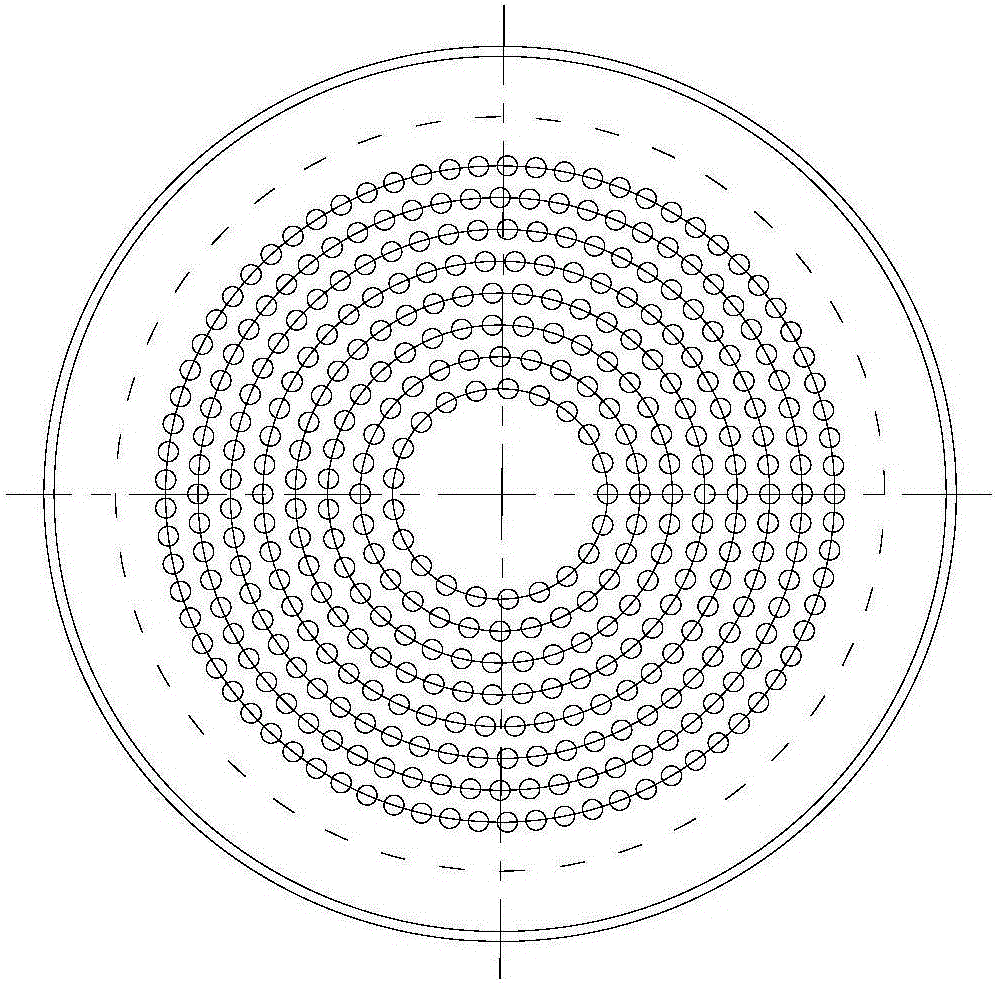

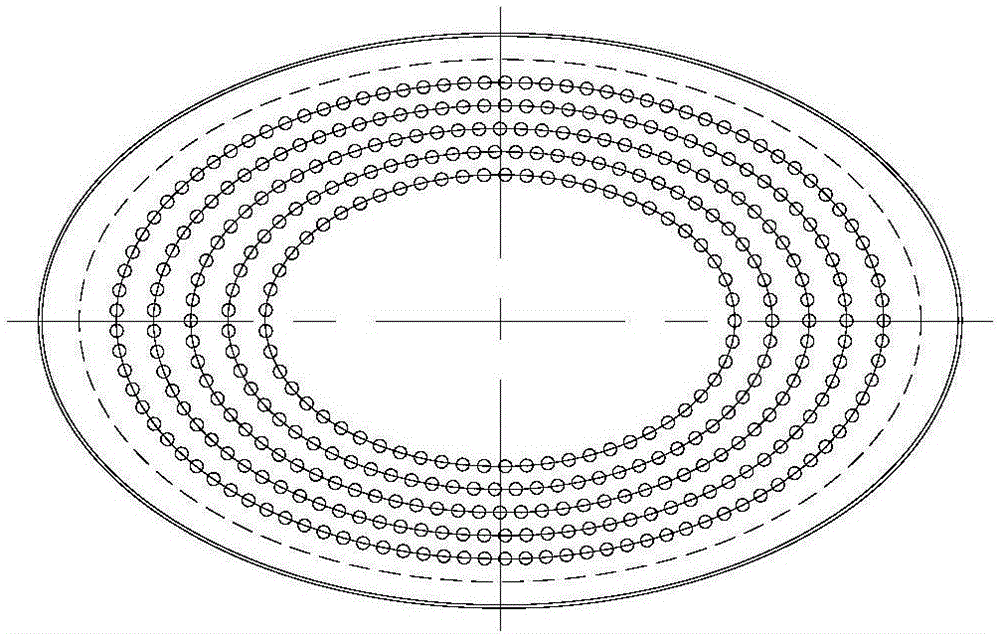

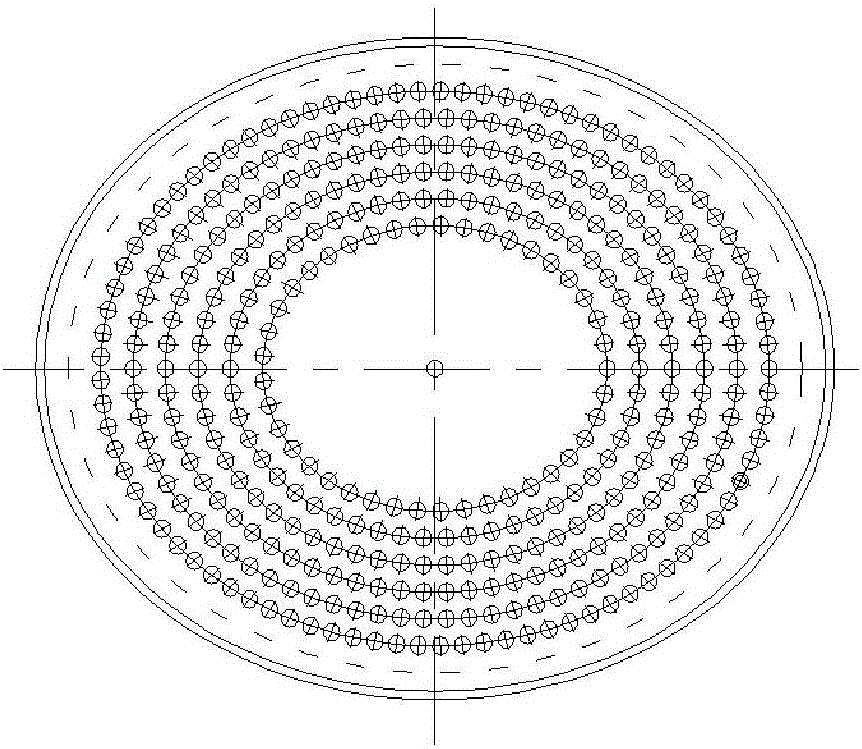

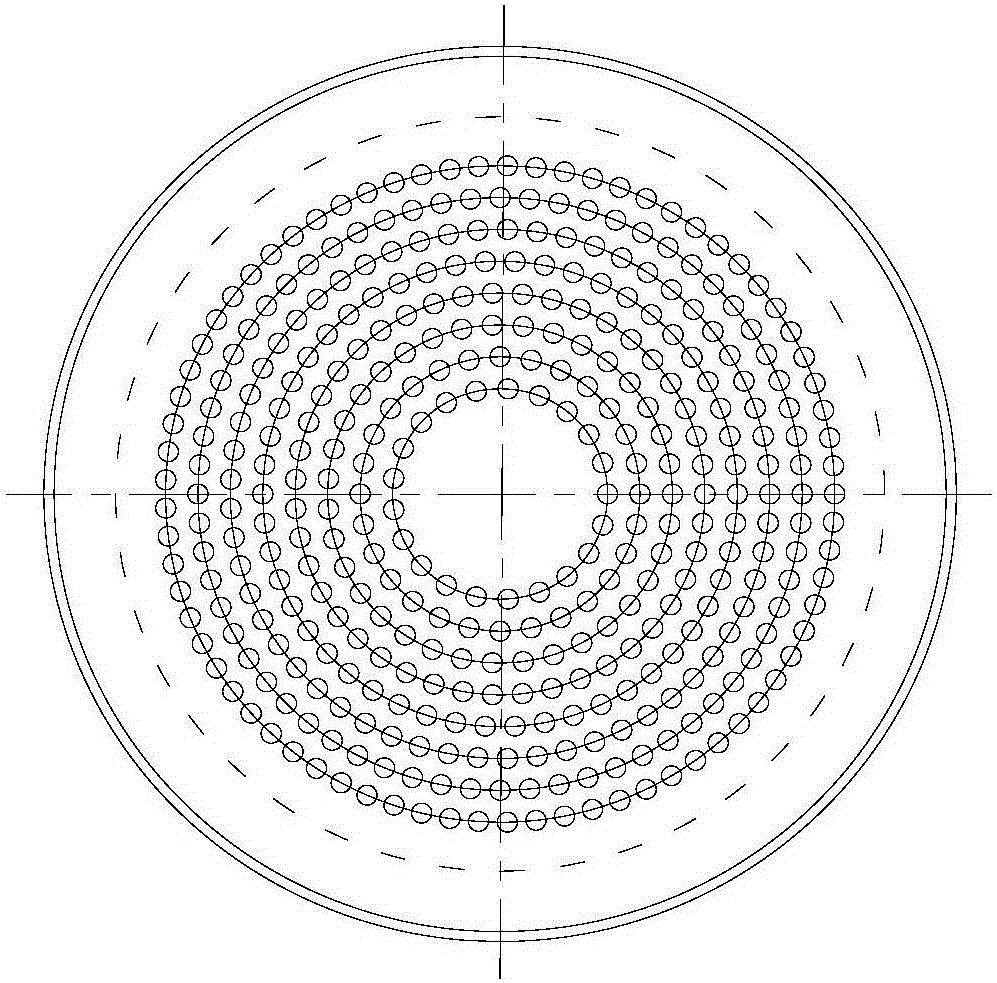

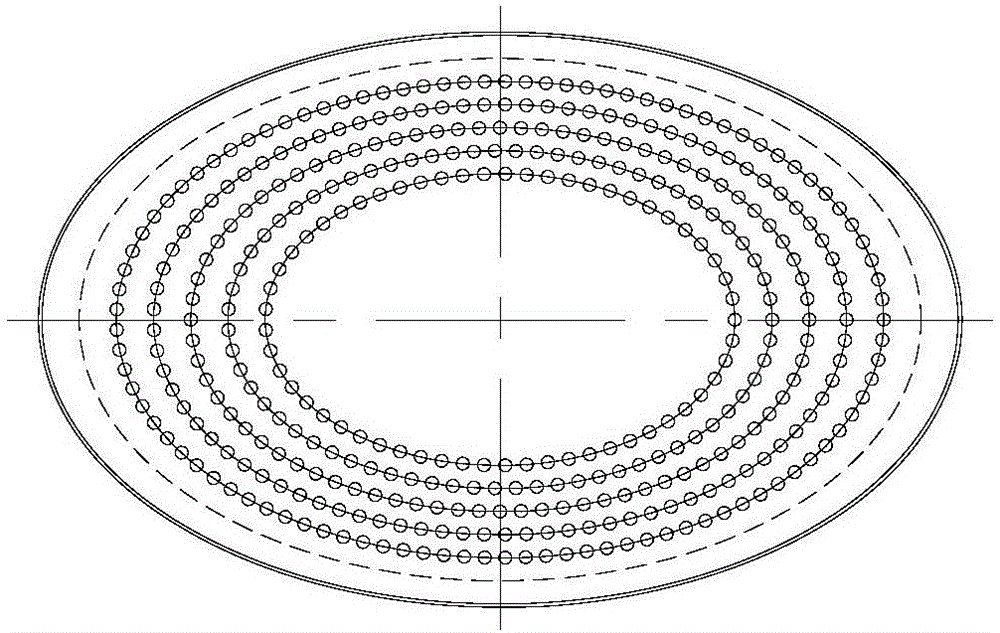

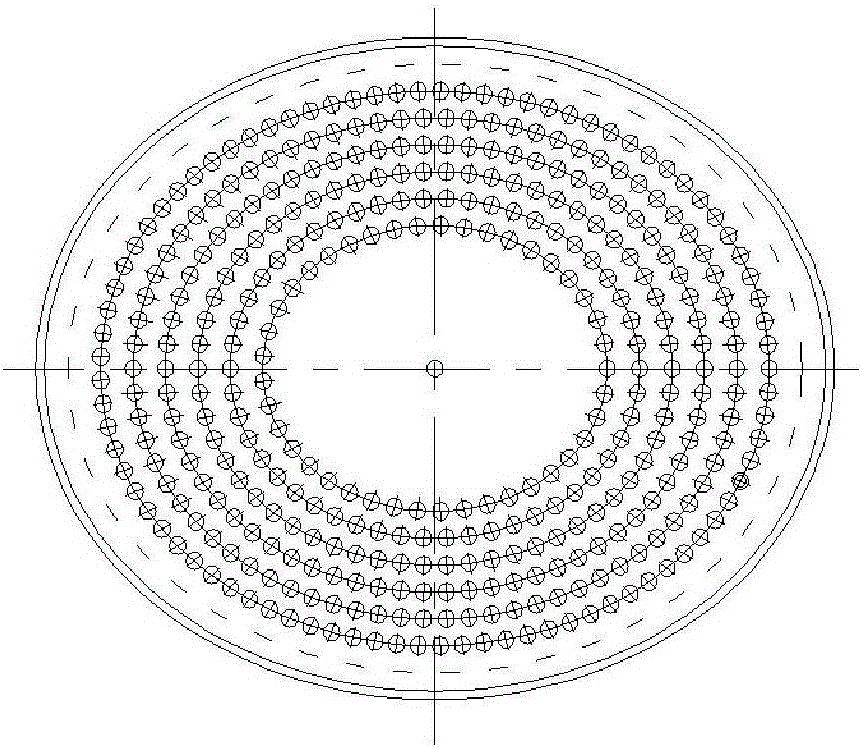

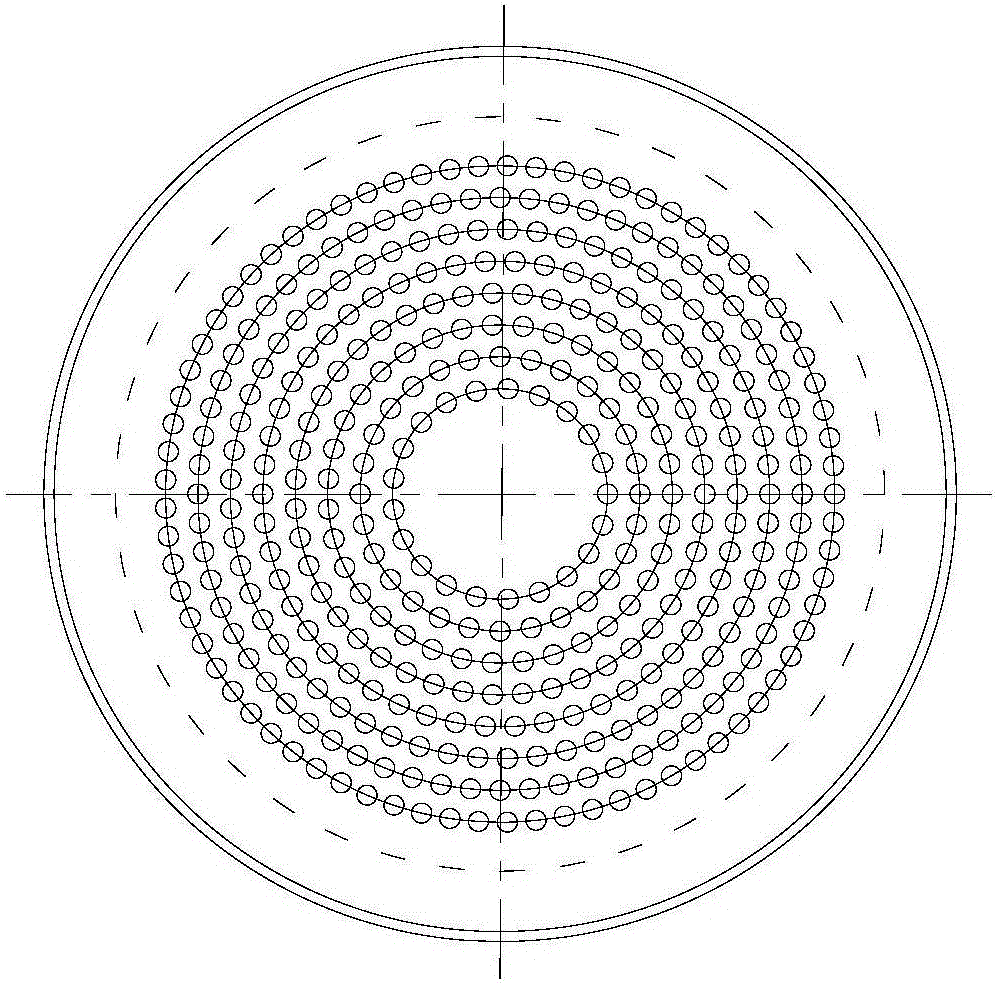

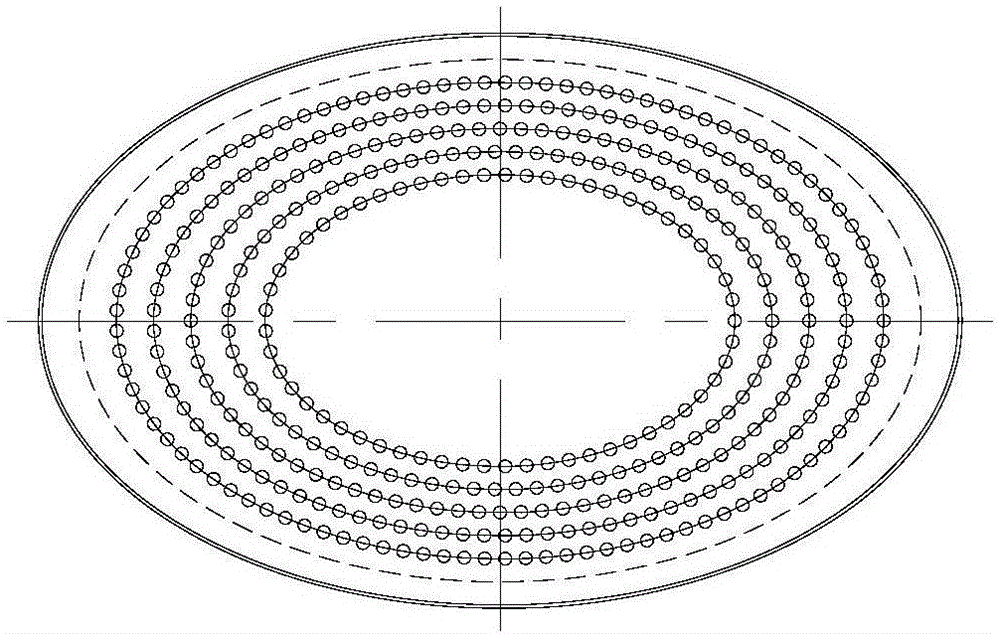

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous super-bright trilobal profiled polyester fiber and production method thereof

ActiveCN106400166AImprove dyeing effectEasy to processFilament/thread formingMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a porous super-bright trilobal profiled polyester fiber and a production method thereof. Modified polyester is spun by adopting a porous spinneret with the cross section shape of spinneret micro-pores being trilobal in order to produce the porous super-bright trilobal profiled polyester fiber; the spinneret micro-pores are arranged in the porous spinneret in an elliptical manner, the pore center of every spinneret micro-pore is positioned in a concentric ellipse, concentric ellipses are serial ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. A preparation method of the modified polyester comprises the following steps: reacting terephthalic acid with ethylene glycol to prepare ethylene terephthalate, adding diol terephthalate prepared from terephthalic acid and branched chain-containing diol, and continuously reacting to obtain the modified polyester. The porous super-bright trilobal profiled polyester fiber produced in the invention has excellent performances, the liner density deviation ratio is not greater than 0.5%, the breaking strength CV value is not greater than 4.0%, the fracture elongation CV value is not greater than 8.0%, and the yarn unevenness CV value is not greater than 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Base cloth for filter material and method of manufacturing the same

InactiveCN101108288AWill not deteriorateStrong drug resistanceFiltration separationVolumetric Mass DensityFilter material

The invention discloses a cheb used on filtering material and the production method. When the measured pressure of the product is 125Pa according to JIS L 1096 8.27.1A standard, the venting quality value of the cheb is 300cc / cm2 / s to 600cc / cm2 / s; according to JIS L 1096 8. 12. 1A standard, the warp direction of the tensile strength of the cheb is 500N / 5cm to 1000N / 5cm, and the direction of weft is 300N / 5cm to 800N / 5cm. The production method comprises the procedures of choosing warp and weft yarn fiber, weaving and so on; During the process of weaving, the yarn before weaving and the cheb after weaving is processed by heat setting and controls the indexes of warp and weft density, tilter and twist. The invention has good tension strength and venting quality, which improves the filtering performance of the filtering material and prolongs the service life of the filtering material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Differential shrinkage composite filament and preparing method thereof

ActiveCN106381558AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberAlcohol

The invention relates to a differential shrinkage composite filament and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the differential shrinkage composite filament; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. The differential shrinkage composite filament is subjected to plying and doubling by modified polyester POY filament and FDY filament, then is composited through network, and finally reeled. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing dihydric alcohol are subjected to a reaction to obtain terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The filament has excellent fiber performance, the linear density deviation ratio is less than or equal to 2.0%, a breaking tenacity CV value is less than or equal to 4.0%, a breaking elongation CV value is less than or equal to 8.0%, and a crimp contraction variation coefficient CV value is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Production process of low-quantitative straw wrapping paper

InactiveCN102002892AGuaranteed StrengthImprove fiber propertiesFlexible coversWrappersSizingChemical pulp

The invention discloses a production process of low-quantitative straw wrapping paper. The process comprises the following steps of: (1) smashing bleached sulphate needle leave wood chemical pulp, adding calcium carbonate, and grinding the mixture; (2) smashing bleached sulphate broad leaf wood chemical pulp, adding calcium carbonate, and grinding the mixture; (3) uniformly blending and stirring the pulp treated in the step (1) and the step (2), and diluting the pulp; (4) preparing auxiliary materials by using cationic starch and a retention aid respectively; and (5) adding the auxiliary materials prepared in the step (4) into the diluted pulp in the step (3) respectively, preparing netting pulp by using the mixture, performing fourdrinier wire dehydration, squeezing dehydration, drying, surface sizing, drying and finishing, and rolling to obtain the straw wrapping paper. The production process has low cost, high opacity, high degree of finish and high flexibility and is environmentally friendly.

Owner:WELBON SPECIAL MATERIALS CO LTD

Porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and preparation method thereof

ActiveCN106283251AImprove cooling effectImprove fiber propertiesSpinnerette packsMonocomponent copolyesters artificial filamentYarnBreaking strength

The invention relates to porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and a preparation method thereof. According to the preparation method, the porous PTT-fiber HOY is prepared from modified PTT by spinning with a porous spinneret; spinneret orifices in the porous spinneret are arranged in an oval shape, that is, the centers of the spinneret orifices are located on concentric ellipses adopting series ellipses, major axes of all the ellipses are collinear, and minor axes of all the ellipses are collinear. The porous PTT-fiber HOY is prepared from modified PTT through measurement, extrusion, cooling, oiling and winding. A preparation method of modified PTT comprises the steps as follows: terephthalic acid and 1,3-propanediol react, trimethylene terephthalate is prepared, diol terephthalate prepared from terephthalic acid and branched-chain-containing diol through a reaction is added, reaction is continued, and modified PTT is obtained. The prepared HOY has excellent fiber performance, the deviation rate of linear density is lower than or equal to 0.2%, the breaking strength CV value is lower than or equal to 2.5%, and the breaking elongation CV value is lower than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous soft polyester fiber FDY yarn and preparing method thereof

ActiveCN106381547AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureYarnFiber

The invention relates to a porous soft polyester fiber FDY yarn and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the porous soft polyester fiber FDY yarn; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. the porous soft polyester fiber FDY yarn is prepared by metering modified polyester slices, extruding, cooling, oiling, stretching, thermoforming and reeling the material. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing hexanediol are subjected to a reaction to obtain the terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The yarn has excellent fiber performance, the linear density deviation ratio is less than or equal to 0.5%, the breaking tenacity CV value is less than or equal to 4.0%, breaking elongation CV value is less than or equal to 8.0%, and a yarn unevenness CV value is less than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

Process for manufacturing an optical fiber and an optical fiber so obtained

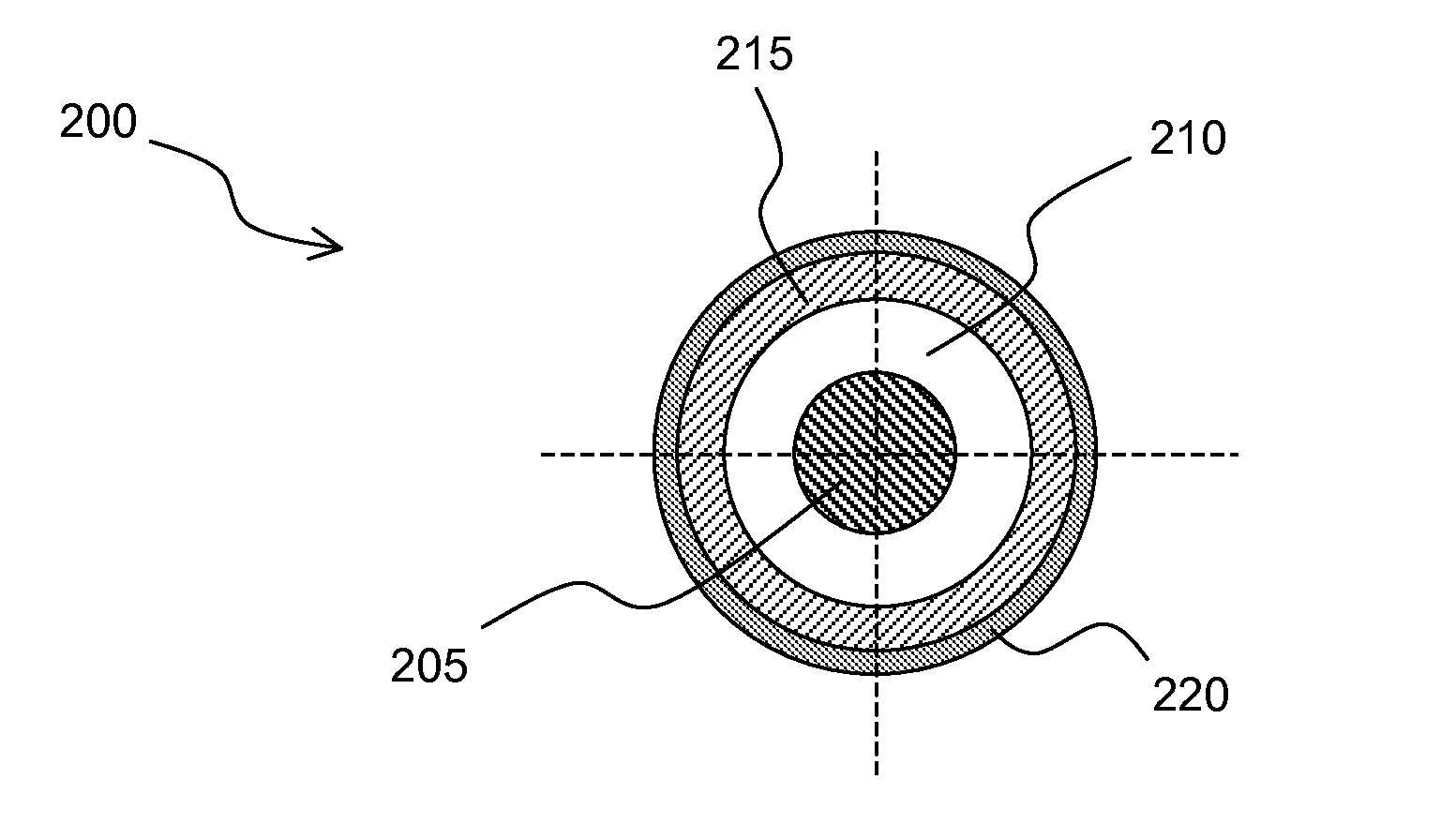

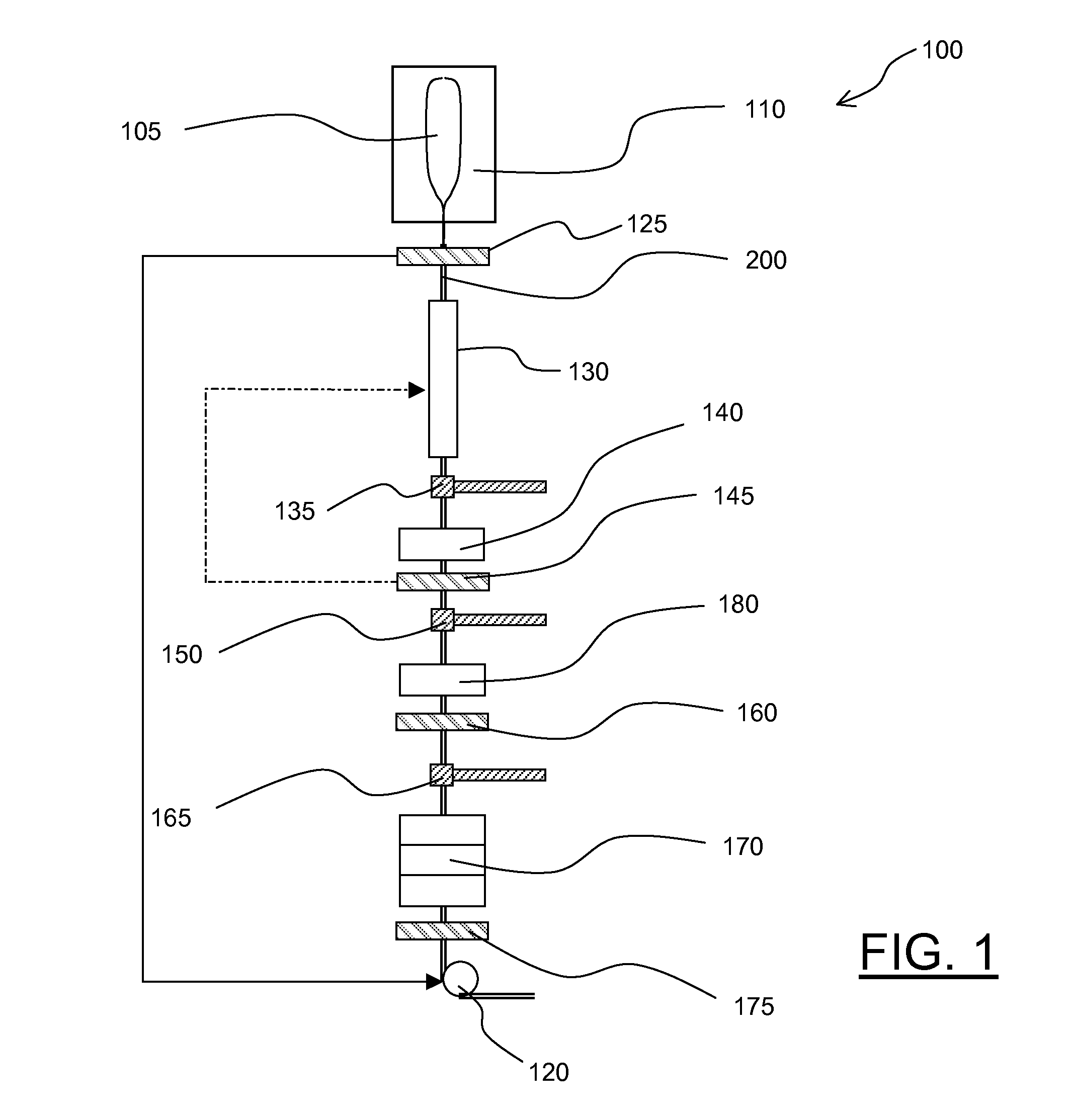

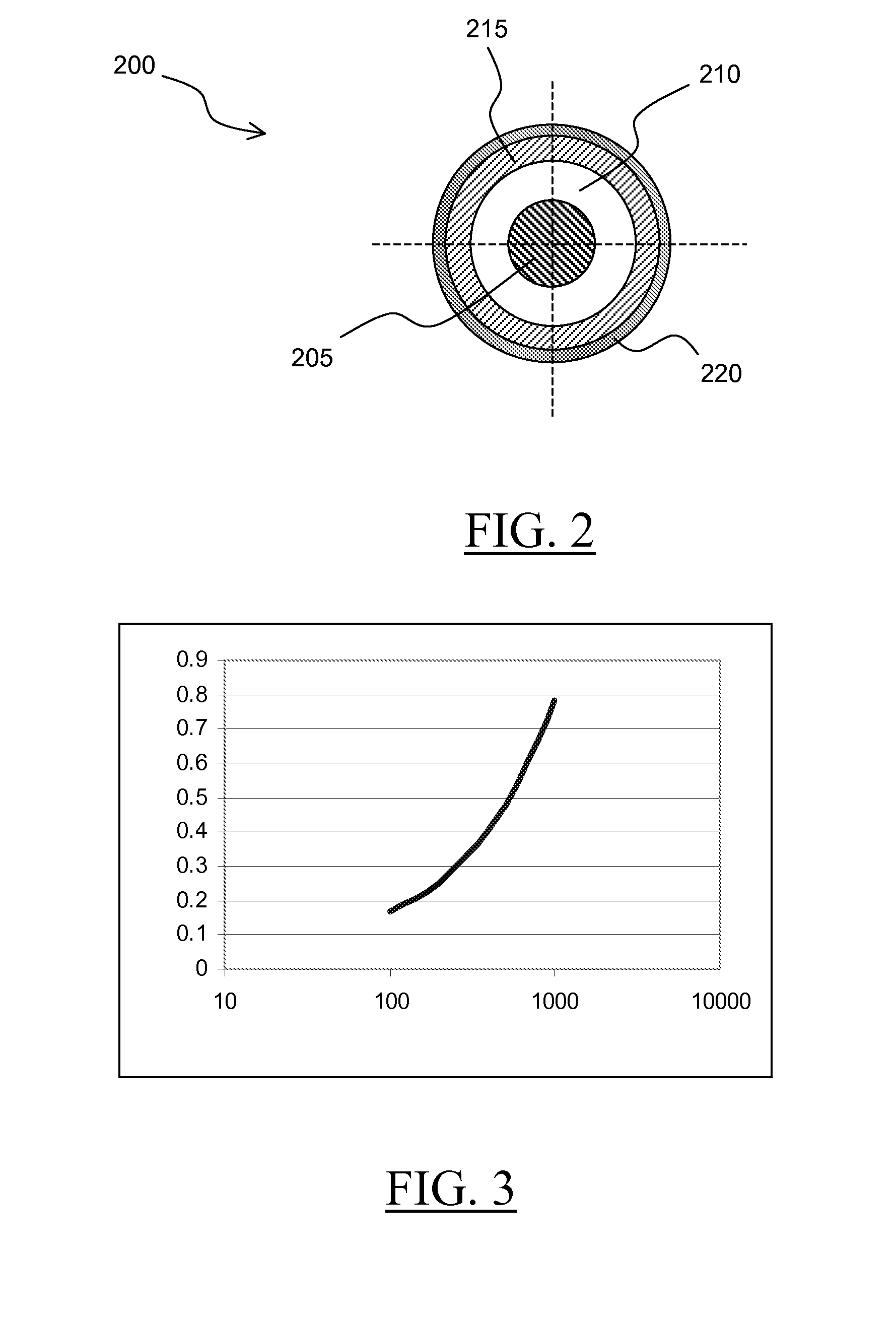

ActiveUS20100296780A1High degree of curingImprove featuresGlass optical fibreLiquid surface applicatorsWaveguideOptical fiber cable

A process for manufacturing an optical fiber includes: drawing an optical waveguide from a glass preform; applying a layer of a first coating material on the optical waveguide; curing the first coating layer material to obtain a first coating layer; applying a layer of a second coating material onto the first coating layer; applying a layer of colored coating material onto the second coating layer; curing the second coating material and the colored coating material in a single step to obtain a second coating layer superposed on the first coating layer and a colored coating layer superposed on the second coating material layer, the obtained second coating layer having an elastic modulus higher than that of the first coating layer and lower than that of the colored coating layer. An optical fiber and an apparatus for producing it are also provided.

Owner:PRYSMIAN SPA

High-shrinkage ultrafine polyester-polyamide composite fiber and production method thereof

ActiveCN103290520AImprove fiber propertiesEmbody elastic functionFilament/thread formingConjugated synthetic polymer artificial filamentsElastomerNylon 6

The invention discloses a high-shrinkage ultrafine polyester-polyamide composite fiber which comprises an ultrafine polyester-polyamide composite fiber, wherein the ultrafine polyester-polyamide composite fiber is formed in a manner that an ultrafine modified polyester fiber serves as a core wire and a modified nylon fiber layer is coated outside the ultrafine modified polyester fiber, and the ultrafine modified polyester fiber core wire is characterized in that the polyester fiber contains a polyurethane and silicon dioxide nano-powder material; and the modified nylon fiber layer is characterized in that nylon 6 contains a Vistamaxx propenyl elastomer. The high-shrinkage ultrafine polyester-polyamide composite fiber obtained through the production method disclosed by the invention has good fiber properties of both the polyester fiber and polyamide fiber and embodies the elastic functions of polyurethane and the Vistamaxx propenyl elastomer; shown by experimental tests, the elastic recovery ratio is 100% when the elongation percentage is 10%; and furthermore, the strength of the composite fiber reaches 7.5-8.0 cN / dtex.

Owner:NINGBO SANBANG MICROFIBER

Porous super-soft cotton-like polyester fiber, and preparation method thereof

ActiveCN106400168AImprove cooling effectImprove fiber propertiesNew-spun product collectionHollow filament manufactureBreaking strengthYarn

The invention relates to a porous super-soft cotton-like polyester fiber, and a preparation method thereof. According to the preparation method, the porous super-soft cotton-like polyester fiber is prepared from modified polyester via porous spinneret plate spinning; spinneret orifices on a porous spinneret plate are arranged in an elliptical manner, wherein the orifice centers of the spinneret orifices are arranged in a series of concentration ellipses, the long axes of the concentration ellipses are collinear, and the short axes are collinear. The porous super-soft cotton-like polyester fiber is prepared from modified polyester POY yarn and modified polyester FDY yarn. A preparation method of the modified polyester comprises following steps: terephthalic acid is reacted with ethanediol so as to obtain ethanediol terephthalate, terephthalic acid and hexanediol containing branch chains are added are reacted so as to obtain dihydric alcohol terephthalate, and continuous reaction is carried out so as to obtain the modified polyester. The performance of the obtained porous super-soft cotton-like polyester fiber is excellent; linear density deviation ratio is equal to or less than 2.0%; breaking strength CV value is equal to or less than 4.0%; breaking elongation CV value is equal to or less than 8.0%; and crimp contraction variable coefficient CV value is equal to or less than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

High-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn and preparation method thereof

ActiveCN106283250AIncreased free volumeReduce melt viscositySpinnerette packsMonocomponent copolyesters artificial filamentYarnAlcohol

The invention relates to high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn and a preparation method thereof. The high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn is prepared from modified polyester formed by terephthalic acid chain segments, glycol chain segments and branch-containing dihydric alcohol chain segments. The preparation method of the high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn includes the steps that terephthalic acid and branch-containing dihydric alcohol are subjected to an esterification reaction under catalysis of concentrated sulfuric acid to obtain terephthalic acid dihydric alcohol ester; then terephthalic acid and glycol are matched for an esterification reaction, and terephthalic acid gylcol ester is obtained; finally, terephthalic acid dihydric alcohol ester and terephthalic acid gylcol ester are stirred and mixed, polycondensation at a low-vacuum stage and a high-vacuum stage is carried out under the effects of a catalyst and a stabilizer, modified polyester is prepared and subjected to metering, porous spinneret plate extrusion, cooling, oiling, stretching, heat setting and winding, and the high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn is prepared.

Owner:JIANGSU HENGLI CHEM FIBER

Wet process of fabricating fiber wall panels

InactiveUS20120193828A1Low costHigh strengthWood working apparatusCeramic shaping apparatusFiberSlurry

This invention discloses a wet process of fabrication of fiber wall panel, which includes the following steps: 1) slurry making: mix nontimber type natural plant fiber slurry with grass family slurry according to 1:0˜1.5 dry weight ratio, and add water to dilute this slurry; 2) slurry storage: pour the mixed slurry into slurry storage tank and add water for dilution; 3) suction straining and forming: pour slurry into mold cavity for cold pressing, dewatering, and forming, to yield wet blanks; 4) hot pressing, forming, and drying: move the wet blanks to the hot pressing mold for hot pressing and remove moisture generated during hot pressing, to yield fiber wall panel. Fiber wall panel made by this process features environment friendliness and high strength.

Owner:NANJING UNIV OF TECH DAFENG INST OF MARINE IND

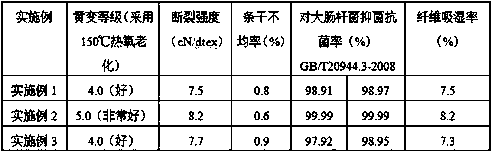

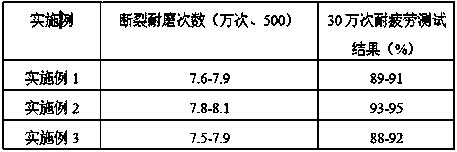

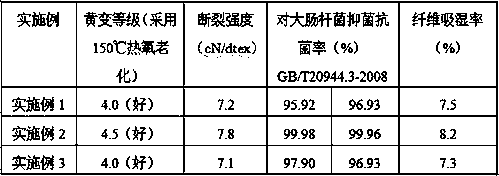

Herbal mixed polyamide fiber and preparation method

InactiveCN108998852AExtended service lifeGood antioxidantArtifical filament manufactureMonocomponent polyamides artificial filamentOxidation resistantChemistry

The invention provides herbal mixed polyamide fiber, and belongs to the field of textile fibers. The polyamide fiber comprises the following formulating raw materials in parts by weight: 100-120 partsof polyamide slice, 0.5-1 part of a dispersant, 0.2-0.8 part of zinc stearate, 1.5-2 parts of SanstabTPO330 and 15-25 parts of functional fusion masterbatches. The herbal mixed polyamide fiber prepared by a preparation method provided by the invention has the advantages of good antioxidation and heat resistance, and under the condition of 150 DEG C thermal oxidation treatment, the yellowing gradeis higher than 4.0. During preparation of the herbal mixed polyamide fiber prepared by the preparation method provided by the invention, a herbal plant-sourced component is added, and the prepared herbal mixed polyamide fiber has the functionality of a plant extract itself, has moisture-absorbing and antistatic effects, and also has the characteristics of antioxidation, light resistance, heat resistance and long service life.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

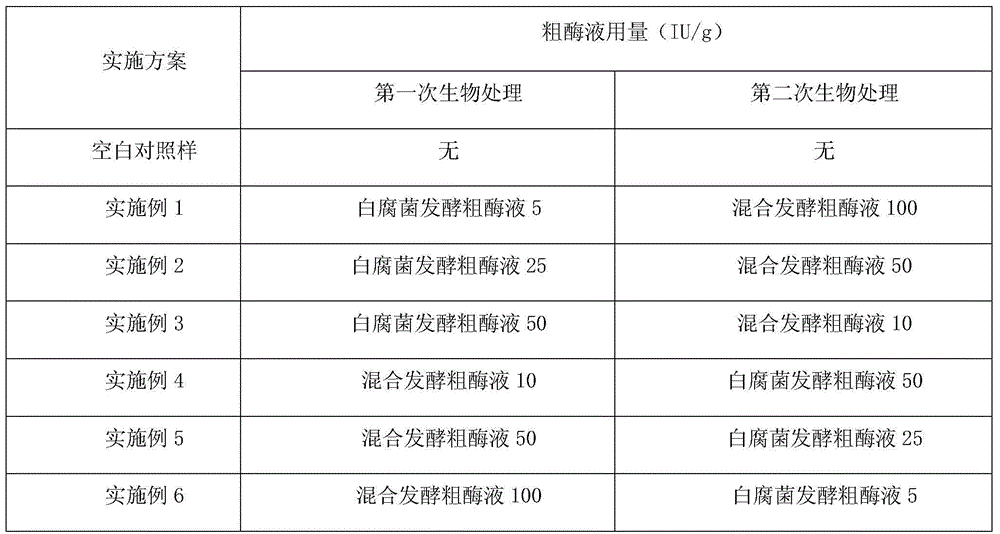

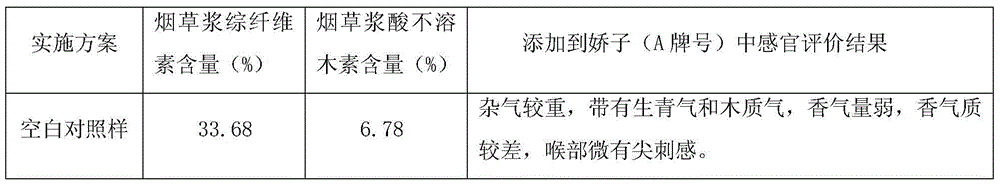

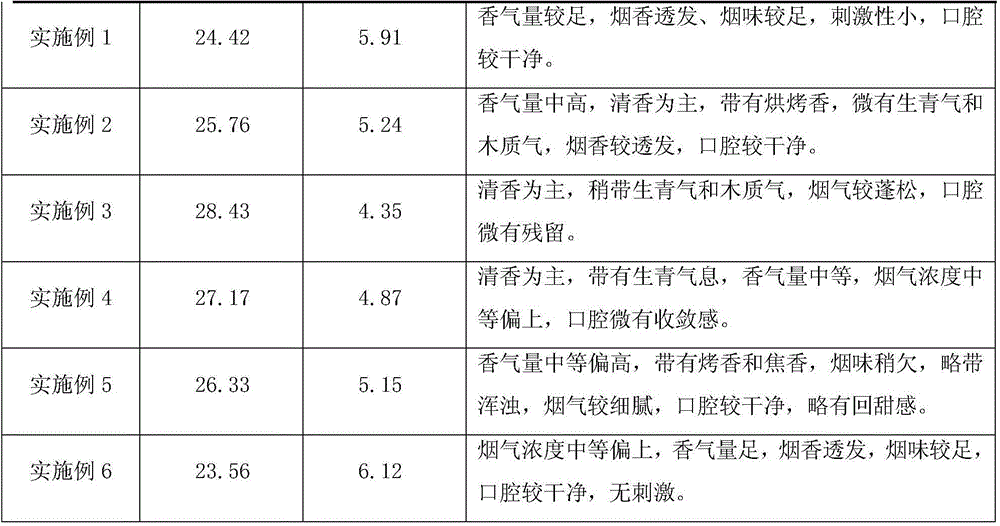

Method for improving sensory quality of tobacco reconstituted through papermaking method

The invention discloses a method for improving the sensory quality tobacco reconstituted through a papermaking method. Biotreatment is conducted twice on raw materials and sizing agents of the tobacco which is reconstituted through the papermaking method through crude enzyme obtained through microbial fermentation, the object of the primary biotreatment is raw materials obtained after extraction and tobacco rod rolling are conducted, biological enzyme penetrates through the surfaces of tobacco stems and shredded tobacco leaves obtained after extraction and tobacco rod rolling are conducted and the surface of tobacco powder and enters cell walls and middle lamella to act on chemical connection among lignin, cellulose and hemicellulose, and enzyme-promoting and defibrination functions are achieved while macromolecule matter is degraded. Secondary biotreatment is conducted in the latency process conducted before low-concentration defibrination and after high-concentration defibrination, the biological enzyme acts on sizing agent fiber, and the lignin, cellulose, hemicellulose, pectin, protein and other macromolecule matter are further degraded effectively. After biotreatment is conducted twice, cell wall matter in raw materials and the sizing agent and undissolved macromolecule matter can be degraded effectively, and the sensory quality of the tobacco reconstituted through the papermaking method is improved remarkably.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +2

Porous PBT fiber DTY (drawn textured yarn) and preparation method thereof

ActiveCN106283258AImprove cooling effectImprove fiber propertiesHollow filament manufactureMelt spinning methodsFiberBreaking strength

The invention relates to porous PBT fiber DTY (drawn textured yarn) and a preparation method thereof. The porous PBT fiber DTY is prepared from modified PBT through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged in an ellipse, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The porous PBT fiber DTY is prepared from the modified PBT through metering, extruding, cooling, oiling and winding; a preparation method of the modified PBT comprises the following steps: terephthalic acid and 1,4-butanediol react to prepare butanediol 1,4-terephthalate, terephthalic acid and diol containing branched chains are added for a reaction, diol terephthalate is prepared and continuously subjected to a reaction, and modified PBT is obtained. The prepared DTY has excellent performance, the linear density deviation is lower than or equal to 0.2%, the breaking strength CV value is smaller than or equal to 2.5%, and the breaking elongation CV value is smaller than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous flax-like polyester fiber and preparation method thereof

ActiveCN106400164AIncrease the degree of diffusionImprove dyeing performanceFilament/thread formingMonocomponent copolyesters artificial filamentPropylene glycolLinear density

The invention relates to a porous flax-like polyester fiber and a preparation method thereof. The porous flax-like polyester fiber is prepared by spinning modified polyester by using a porous spinneret plate, wherein spinneret holes in the porous spinneret plate are elliptically arrayed; i.e., the centers of the spinneret holes are located on concentric ellipses which are series ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are also collinear. The porous flax-like polyester fiber is prepared from modified polyester POY yarns and modified polyester FDY yarns through process. A preparation method for the modified polyester comprises the following steps: reacting terephthalic acid with glycol to prepare ethylene terephthalate; adding dihydric alcohol terephthalate prepared through reaction of terephthalic acid with propylene glycol containing a branched chain; and continuing reaction so as to obtain the modified polyester. The fiber prepared in the invention has following excellent properties: a linear density deviation ratio of no more than 2.0%, a breaking tenacity CV value of no more than 4.0%, a breaking elongation CV value of no more than 8.0%, and a crimp contraction variation coefficient CV value of no more than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Method for improving mechanical wood pulp fibre performance

InactiveCN1786339AImprove fiber propertiesImprove whiteness and strength propertiesNon-macromolecular organic additionPulp bleachingGrindstoneLacquer

The invention relates to a method of improving mechanical pulp fibre capability. It belongs to pulping paper technology field. It includes enzyme treatment and bleaching. The enzyme treatment is adding 0.5-50LAMU / g laccase and 0.1%-4%mediator to mechanical pulp container; inputting oxygen; controlling treating pulp density between 1% and 20%, temperature 20-70 degree centigrade, treatment time 20-120min. The invention is used to teat not bleached Massoní»s pine grindstone ground pulp to obviously improve its fiber capability, paper pulp whiteness and fatigue resistance. Compared with the comparison pulp, the whiteness can be improved 2.0%; fracture length 58%. And the fiber capability is obviously improved.

Owner:QILU UNIV OF TECH

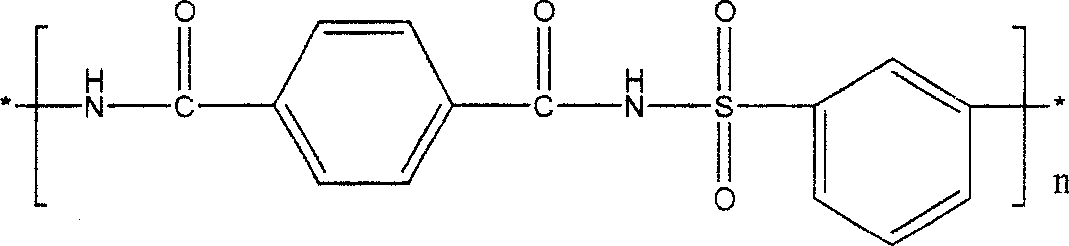

PET/PA6 (Polyethylene Terephthalate/Poly Amide 6) double-component hollow orange peel fiber and production process thereof

InactiveCN102733094APromote formationImprove fiber propertiesHollow filament manufactureFilament/thread formingIntegrated technologyFineness

The invention discloses a PET / PA6 (Polyethylene Terephthalate / Poly Amide 6) double-component hollow orange peel fiber, comprising a PET single-fiber fiber and a PA6 single-fiber fiber, wherein the PET single-fiber fiber and the PA6 single-fiber fiber are mutually wound to form the orange peel fiber; a circular blank is formed at the center of the orange peel fiber; the single-fiber finenesses of the PET single-fiber fiber and the PA6 single-fiber fiber are 0.08-0.13 dtex; and the whole fineness of the orange peel fiber is 0.18-0.28 dtex. The invention further discloses a production process of the PET / PA6 double-component hollow orange peel fiber. A double-component spun-bond composite spinning technology is adopted and the PET single-fiber fiber and the PA6 single-fiber fiber are used as raw materials; a structural design of a multi-layer step spinning plate is adopted and a multi-channel low induced draft controllable uniform net forming technology and a fiber surface splitting and hydroentangle reinforcing integrated technology are adopted, so that the production cost is reduced, the process flow is shortened, the production speed and the formation rate are improved; and a product with small fiber diameter, high strength, good tear resistance and abrasion resistance, and difficulty of dropping chips in a use process is produced.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

Super-soft wool-like porous polyester and preparation method thereof

ActiveCN106319678AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentWoolPropylene glycol

The invention relates to super-soft wool-like porous polyester and a preparation method thereof. The super-soft wool-like porous polyester is prepared from modified polyester through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The super-soft wool-like porous polyester is prepared from modified polyester POY and modified polyester FDY through processing; a preparation method of the modified polyester comprises the following steps: terephthalic acid and ethylene glycol react to prepare ethylene glycol terephthalate, terephthalic acid and propylene glycol containing branched chains are added for a reaction, glycol terephthalate is prepared and continuously subjected to a reaction, and modified polyester is obtained. The prepared fiber has excellent performance, the linear density deviation is lower than or equal to 2.0%, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, and the crimp contraction variation coefficient CV value is lower than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous polyester fiber FDY and preparation method thereof

ActiveCN106283262AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentBreaking strengthYarn

The invention relates to porous polyester fiber FDY and a preparation method thereof. The porous polyester fiber FDY is prepared by spinning modified polyester through a porous spinneret plate; spinneret holes formed in the spinneret plate are arranged in an oval shape, that is to say, hole centers of the spinneret holes are located on concentric ellipses which are series ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. The porous polyester fiber FDY is prepared from modified polyester slices through metering, extruding, cooling, oiling, stretching, heat setting and winding; a preparation method of modified polyester comprises the steps that terephthalic acid reacts with ethylene glycol to obtain ethylene terephthalate, terephthalic acid dihydroxy alcohol ester which is prepared through a reaction of terephthalic acid and terephthalic acid containing is added, reacting is conducted continuously, and porous polyester is obtained. The fiber prepared through the method is excellent in performance, the linear density deviation rate is smaller than or equal to 0.5%, the breaking strength CV value is smaller than or equal to 4.0%, the breaking elongation CV value is smaller than or equal to 8.0%, and the yarn unevenness CV is smaller than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

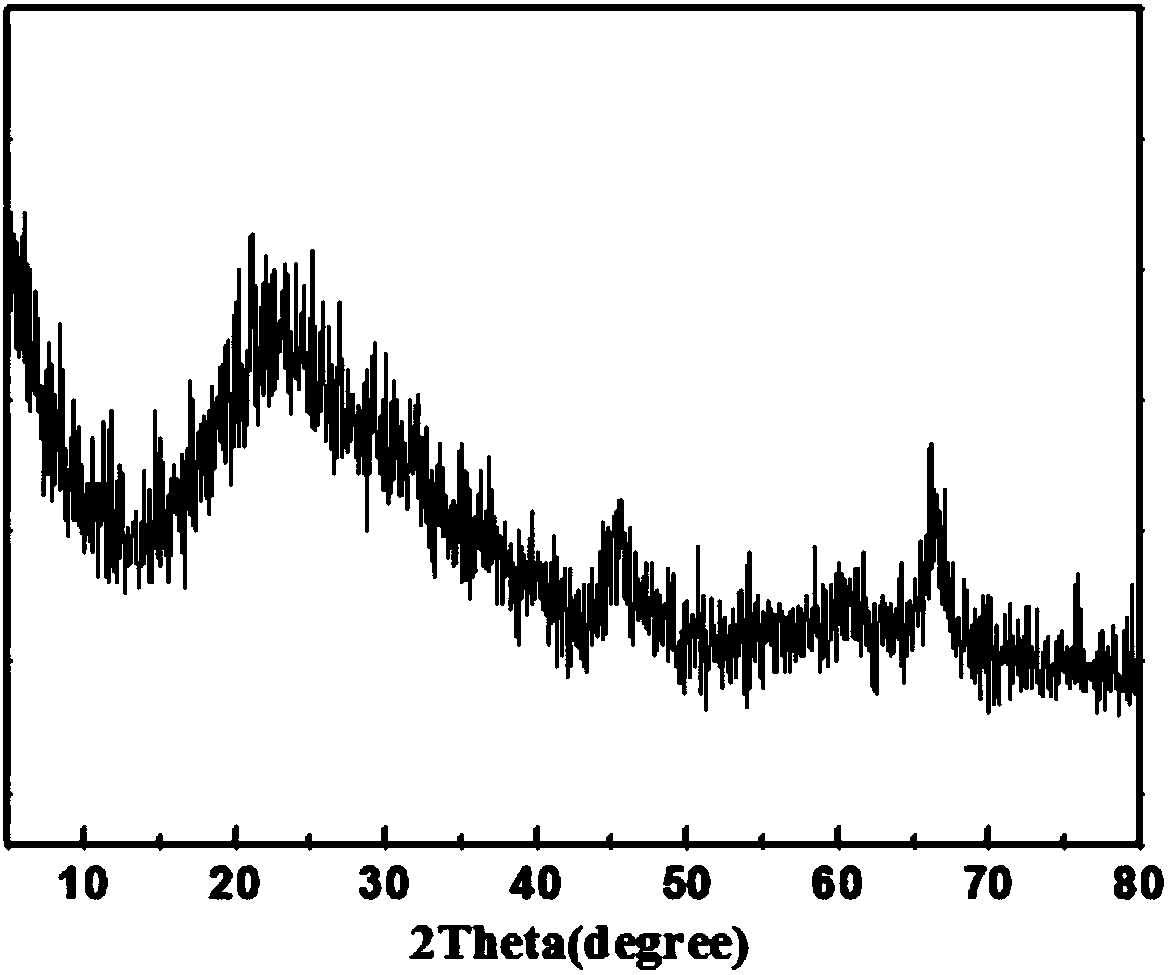

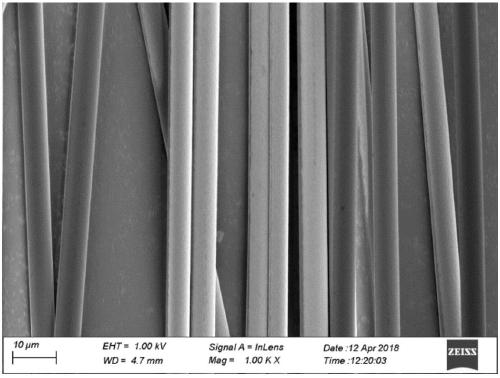

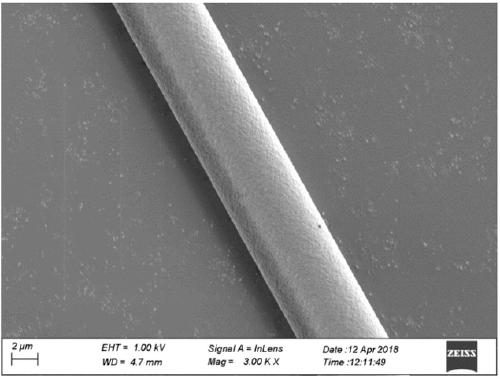

Preparation method for aluminum oxide-based ceramic continuous fiber containing 1-5 wt% of B2O3

ActiveCN109437862AImprove stabilityImprove tensile propertiesInorganic material artificial filamentsFiberTemperature resistance

The invention provides a preparation method for an aluminum oxide-based ceramic continuous fiber containing 1-5 wt% of B2O3. The method comprises the following steps that alumina sol containing Al13 colloidal particles, a pseudo-boehmite nano-dispersion, silica sol, a boric acid aqueous solution and a high-molecular spinning auxiliary are mixed so as to obtain a mixed solution; then aging and concentrating are carried out until the viscosity of a system is 500-1000 Pa*s so as to obtain spinnable precursor sol; and dry spinning, drying and calcining are carried out so as to obtain the aluminumoxide-based ceramic continuous fiber. According to the preparation method, the electron deficiency effect of boron is utilized, and addition reaction of water is carried out on the boric acid to formB(OH)4<->, so that the boric acid can be stably combined with polyhydroxyl pseudo-boehmite nano-particles so as to prepare the spinnable precursor sol and the fiber with excellent properties. The method has the advantages that the raw materials are easy to obtain, and industrialized application is easy to realize; and the diameter of the prepared fiber is 5-8 microns, the strength of the single fiber can reach 2.0 GPa, the modulus can reach 149 GPa, and various excellent performances such as high temperature resistance, flexibility and spinnability are achieved.

Owner:SHANDONG UNIV

High uniformity high modulus low shrinkage type polyester industrial yarn and preparation method thereof

ActiveCN107059152AIncreased free volumeReduce melt viscosityFilament/thread formingMonocomponent copolyesters artificial filamentYarnLow vacuum

The present invention relates to a high uniformity high modulus low shrinkage type polyester industrial yarn and a preparation method thereof, wherein the raw material of the high uniformity high modulus low shrinkage type polyester industrial yarn is a modified polyester comprising a terephthalic acid chain segment, an ethylene glycol chain segment and a branch chain-containing diol chain segment. The preparation method comprises: carrying out an esterification reaction on terephthalic acid and a branch chain-containing diol under the catalysis of concentrated sulfuric acid to obtain terephthalic acid diol ester, carrying out an esterification reaction on terephthalic acid and ethylene glycol to obtain ethylene glycol terephthalate, carrying out stirring mixing on the terephthalic acid diol ester and the ethylene glycol terephthalate, carrying out a low vacuum stage condensation polymerization reaction and a high vacuum stage condensation polymerization reaction under the effects of a catalyst and a stabilizer to prepare a modified polyester, metering the modified polyester, extruding with a porous spinning plate, cooling, oiling, drawing, carrying out thermal shaping, and winding to prepare the high uniformity high modulus low shrinkage type polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

Porous PTT (polytrimethylene terephthalate) fiber FDY (fully drawn yarn) and preparation method thereof

ActiveCN106319677AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnBreaking strength

The invention relates to porous PTT (polytrimethylene terephthalate) fiber FDY (fully drawn yarn) and a preparation method thereof. The porous PTT fiber FDY is prepared from modified PTT through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The porous PTT fiber FDY is prepared from the modified PTT through processing; a preparation method of the modified PTT comprises the following steps: terephthalic acid and 1,3-propanediol react to prepare 1,3-propanediol terephthalate, terephthalic acid and diol containing branched chains are added for a reaction, diol terephthalate is prepared and continuously subjected to a reaction, and modified PTT is obtained. The prepared fiber has excellent performance, the linear density deviation is lower than or equal to 0.5%, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, and the yarn unevenness CV is lower than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

Automatic production equipment for 3.2-meter wide non-woven fabrics

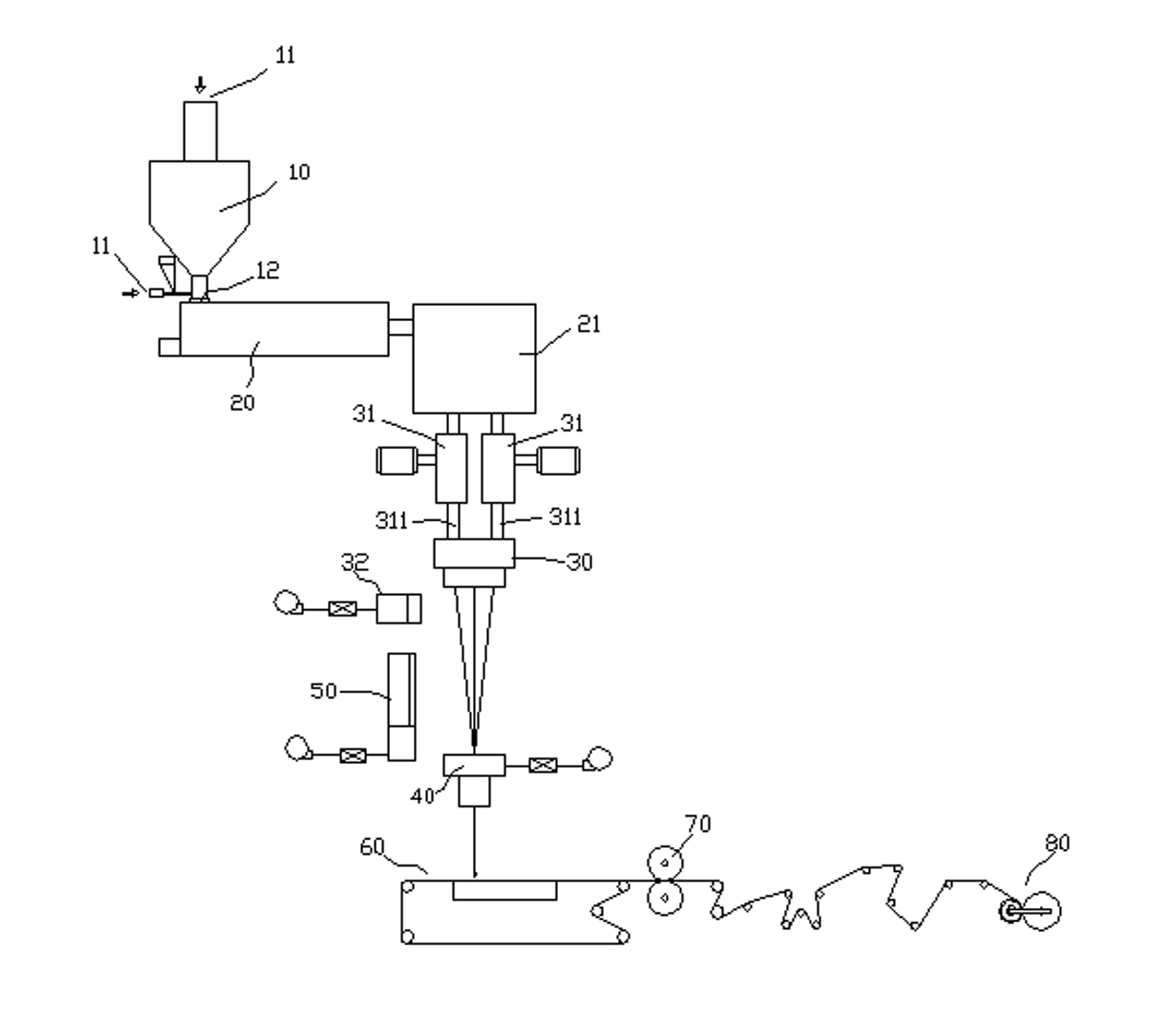

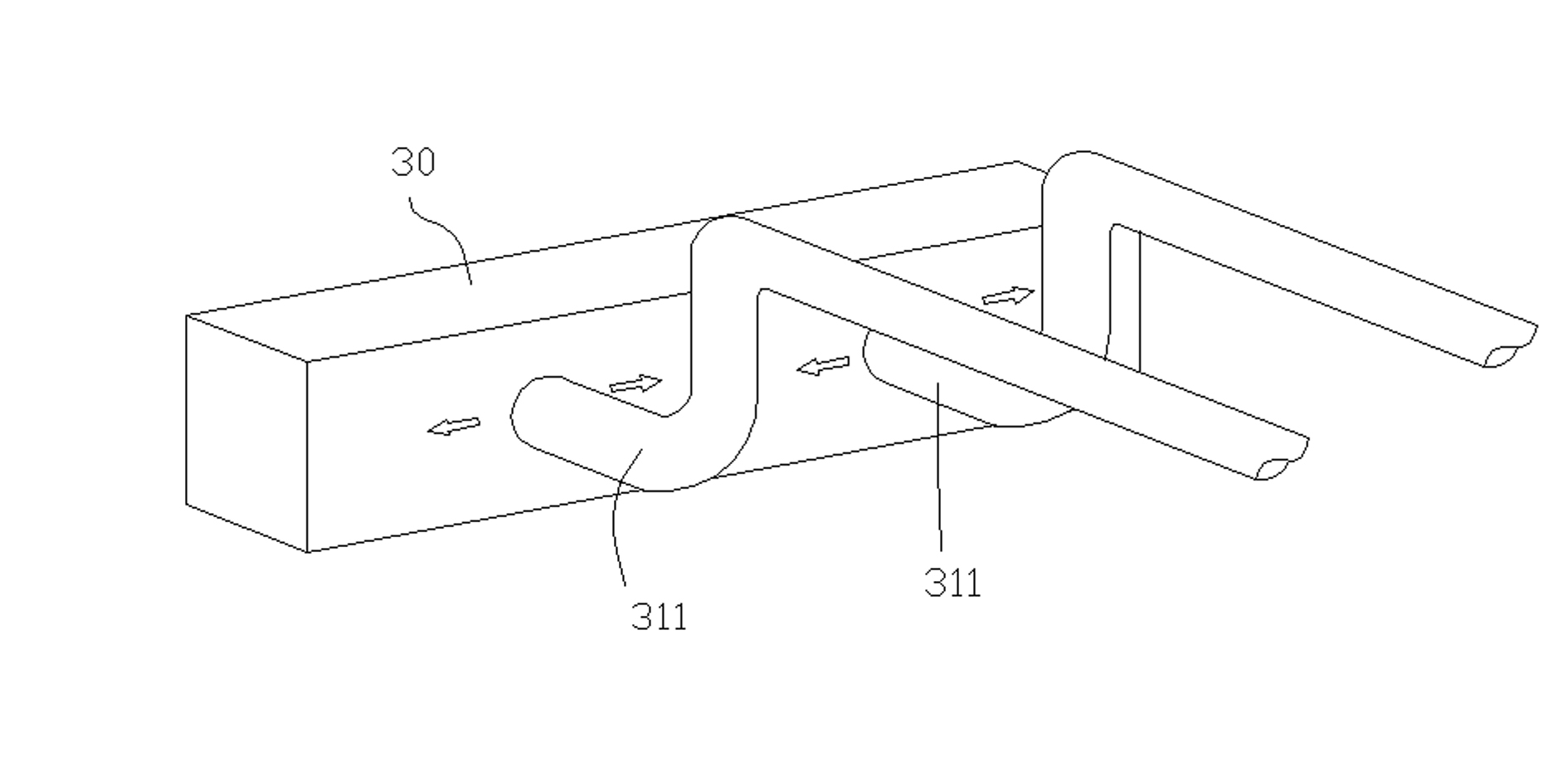

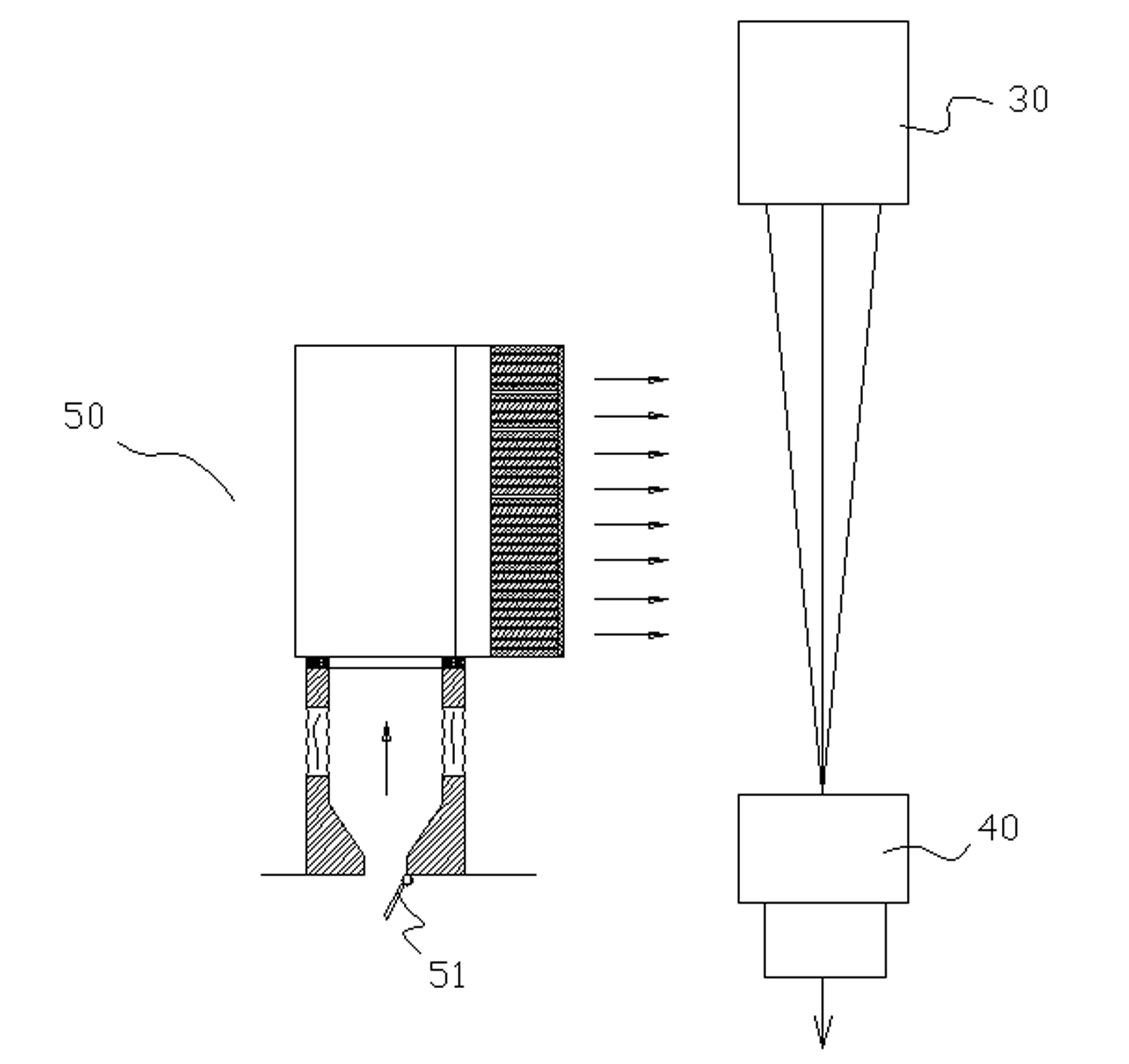

ActiveCN101979744ASimple structureLow investment costNon-woven fabricsAir volumeProgrammable logic controller

The invention relates to the technical field of non-woven fabrics, in particular to manufacturing equipment for the non-woven fabrics. The equipment is controlled by the program of a programmable logic controller (PLC) and comprises a feeding unit, a screw extruder, an extension box body, an airflow drafting unit, a cooling side-blowing unit, a wet forming unit, a rolling mill and a winding unit,wherein the screw extruder is used for extruding raw materials by heating; a filter is arranged at the extrusion port of the screw extruder; the input end of the extension box body is connected to the filter through at least two counters which are connected in parallel; the airflow drafting unit is in vertical butt joint with the output end of the extension box body; a single body drawn by the extension box body is intertwined and staggered by the airflow drafting unit; the cooling side-blowing unit is arranged on the side of a single body drafting region between the extension box body and the airflow drafting unit; and a regulating valve capable of regulating air quantity is arranged on an air channel of the cooling side-blowing unit. The equipment can produce 3.2-meter wide non-woven fabrics, meets new state requirements of non-woven fabric industries and has a simple, scientific and reasonable structure.

Owner:东莞市威骏不织布有限公司

Soft wool-like porous polyester and preparation method thereof

ActiveCN106319679AImprove cooling effectImprove fiber propertiesSpinnerette packsMelt spinning methodsFiberTerephthalic acid

The invention relates to soft wool-like porous polyester and a preparation method thereof. The soft wool-like porous polyester is prepared from modified polyester through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The soft wool-like porous polyester is prepared from modified polyester POY and modified polyester FDY through processing; a preparation method of the modified polyester comprises the following steps: terephthalic acid and ethylene glycol react to prepare ethylene terephthalate, terephthalic acid and propylene glycol containing branched chains are added for a reaction, glycol terephthalate is prepared and continuously subjected to a reaction, and modified polyester is obtained. The prepared fiber has excellent performance, the linear density deviation is lower than or equal to 2.0%, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, and the crimp contraction variation coefficient CV value is lower than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Feed for improving meat quality of yellow-head catfish and preparation method thereof

InactiveCN107183412AIncrease the fragranceImprove fibrosisFood processingClimate change adaptationAstaxanthinChemistry

The invention provides feed for improving the meat quality of yellow-head catfish and a preparation method thereof. The feed is characterized by being prepared from the following ingredients in percentage by mass: 0.08 to 0.1 percent of choline chloride, 0.2 to 0.5 percent of lutein, 0.05 to 0.1 percent of astaxanthin, 2 to 3 percent of pine needle powder, 2 to 3 percent of monocalcium phosphate, 10 to 15 percent of bean pulp, 5 to 10 percent of peanut meal, 10 to 15 percent of chellocken meal, 15 to 20 percent of imported fish meal, 3 to 4 percent of fish oil, 25 to 30 percent of flour, 15 to 20 percent of miscellaneous meal, 0.1 to 0.3 percent of trace elements and 0.1 to 0.15 percent of vitamins. The trace elements are formed by mixing iron methionine, zinc methionine and manganese methionine; the vitamins are formed by mixing vitamin A, vitamin D, vitamin E, vitamin K, vitamin C and vitamin B.

Owner:TIANJIN CHENHUI FEED

Porous super-soft linen-like polyester fiber and preparation method thereof

ActiveCN106400170AImprove cooling effectImprove fiber propertiesFilament/thread formingMonocomponent copolyesters artificial filamentYarnFiber

The invention relates to a porous super-soft linen-like polyester fiber and a preparation method thereof. Modified polyester is spun by a porous spinneret plate to prepare the porous super-soft linen-like polyester fiber. The spinneret orifices in the spinneret plate are arranged in an oval shape. The center of the spinneret orifices is positioned on the center of concentric ellipses; the concentric ellipses are a series of ellipses, long axes of all ellipses are collinear, and moreover, short axes of all ellipses are collinear. The porous super-soft linen-like polyester fiber is prepared from modified polyester POY yarns and modified polyester FDY yarns. The modified polyester preparation method comprises the following steps: reacting terephthalic acid with glycol to obtain ethylene glycol terephthalate, reacting ethylene glycol terephthalate with added branch chain containing hexylene glycol to generate dihydric alcohol terephthalate, and keeping on reactions to obtain modified polyester. The prepared fiber has excellent performances: the linear density deviation ratio is not more than 2.0%, the breaking strength CV value is not more than 4.0%, the breaking elongation CV value is not more than 8.0%, and the crimp contraction variable coefficient CV value is not more than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous PBT fiber POY yarn and preparation method thereof

ActiveCN106350887AImprove dyeing effectDestruction of structural regularityMonocomponent copolyesters artificial filamentMelt spinning methodsFiberBreaking strength

The invention relates to porous PBT fiber POY yarn and a preparation method thereof. Modified PBT polyester is spun through a porous spinneret plate, so that the porous PBT fiber POY yarn is obtained; the arrangement mode of spinneret orifices on the porous spinneret plate adopts elliptic arrangement, that is, the centers of the spinneret orifices are positioned in concentric ellipses, the concentric ellipses adopt series ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are also collinear. The porous PBT fiber POY yarn is formed by performing metering, extruding, cooling, oiling and coiling on the modified PBT polyester; the preparation method of the modified PBT polyester comprises the following steps: terephthalic acid and 1, 4-butanediol are reacted, so that terephthalic acid 1, 4-butylene terephthalate is obtained; terephthalic acid is added and reacted with dihydric alcohol containing branches, so that terephthalic acid dihydric alcohol ester is obtained; reaction is continued, so that the modified PBT polyester is obtained. The fiber prepared through the method is excellent in properties, the linear density variation rate is smaller than or equal to 0.2 percent, the breaking strength CV value is smaller than or equal to 2.5 percent, and the breaking elongation CV value is smaller than or equal to 5.0 percent.

Owner:JIANGSU HENGLI CHEM FIBER

Porous polyester fiber HOY filaments and preparation method thereof

ActiveCN106400161AImprove dyeing effectEasy to processFilament/thread formingMonocomponent copolyesters artificial filamentFiberBreaking strength

The invention relates to porous polyester fiber HOY filaments and a preparation method thereof; the porous polyester fiber HOY filaments are prepared by spinning modified polyester through a porous spinneret plate; an arrangement way of spinneret holes in the porous spinneret plate is in oval arrangement, that is to say, a hole center of the spinneret holes is located in concentric ellipses, the concentric ellipses are a series of ellipses, the long axes of all the ellipses are collinear, and the short axes are collinear. The porous polyester fiber HOY filaments are prepared by metering, extruding, cooling, oiling and high-speed coiling of the modified polyester, wherein a preparation method for the modified polyester comprises the steps: carrying out a reaction of terephthalic acid and ethylene glycol to prepare ethylene glycol terephthalate, adding terephthalic acid and branched chain-containing dihydric alcohol, carrying out a reaction to prepare dihydric alcohol terephthalate, and continuing to carry out a reaction to obtain the modified polyester. The prepared fiber is excellent in properties, the linear density deviation rate of the porous polyester fiber HOY filaments is less than or equal to 0.2%, the CV value of breaking strength is less than or equal to 2.5%, and the CV value of breaking elongation is less than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous superfine denier flat yarn and preparation method thereof

ActiveCN106400167AGuaranteed stabilityIncrease space volumeMonocomponent copolyesters artificial filamentMelt spinning methodsYarnFiber

The invention relates to a porous superfine denier flat yarn and a preparation method thereof. Modified polyester is spun by a porous spinneret plate to prepare the porous superfine denier flat yarn; the arrangement form of spinneret holes in the porous spinneret plate is in an ellipse, namely that the hole center of each spinneret hole is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. The modified polyester is subjected to slicing, solid-phase polycondensation and viscosity increasing, so as to prepare the porous superfine denier flat yarn. A preparation method of the modified polyester comprises the following steps of reacting terephthalic acid and ethylene glycol to prepare ethylene terephthalate; adding ethylene terephthalate prepared by reaction of terephthalic acid and branch chain-containing ethylene glycol, and continuously reacting, so as to prepare the ethylene terephthalate; continuing to react, so as to obtain the modified polyester. The porous superfine denier flat yarn has the advantages that the prepared fiber property is excellent; the linear density deviation is smaller than or equal to 0.5%, a break strength CV (coefficient of variation) value is smaller than or equal to 4.0%, a break elongation CV value is smaller than or equal to 8.0%, and a yarn unevenness CV value is smaller than or equal to 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com