Herbal mixed polyamide fiber and preparation method

A nylon fiber and herbal technology, which is applied in the field of herbal mixed nylon fiber and its preparation, can solve the problems of light resistance, heat resistance and wear resistance of nylon fiber, the strength of nylon fiber cannot be guaranteed, and the practicality of fiber is affected. Fewer filaments, good fibrousness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

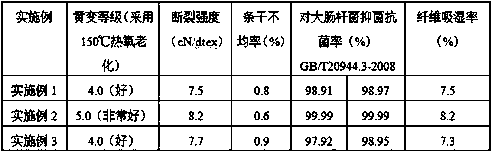

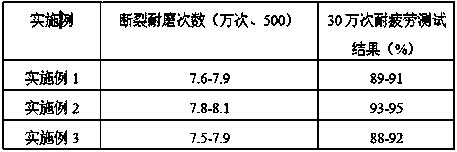

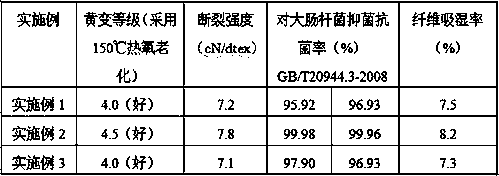

Embodiment 1

[0043] Embodiment 1 A kind of preparation method of herbal mixed nylon fiber, comprises the following steps:

[0044] Raw material selection: a herbal mixed nylon fiber, its formula raw materials include: polyamide chip, dispersant, zinc stearate, SanstabTPO330, functional fusion masterbatch, the weight percentage of each raw material is: polyamide chip 100 parts, dispersant 0.7 parts, 0.5 parts of zinc stearate, 1.6 parts of Sanstab TPO330, 20 parts of functional fusion masterbatch.

[0045] The preparation method of herbal mixed nylon fiber specifically comprises the following steps:

[0046] 1. Preparation of functional fusion masterbatch

[0047] The functional fusion masterbatch is composed of polyamide chips, microcrystalline cellulose, casein, plant extracts, modifiers, silicone powder, dilauryl thiodipropionate, and gelatin;

[0048] The mass parts of each component in the functional fusion masterbatch are: 21 parts of polyamide chips, 2 parts of microcrystalline cel...

Embodiment 2

[0073] Embodiment 2 A kind of preparation method of herbal mixed nylon fiber, comprises the following steps:

[0074] Raw material selection: a herbal mixed nylon fiber, its formula raw materials include: polyamide chip, dispersant, zinc stearate, SanstabTPO330, functional fusion masterbatch, the weight percentage of each raw material is: polyamide chip 110 parts, dispersant 0.8 parts, 0.6 parts of zinc stearate, 1.8 parts of Sanstab TPO330, 20 parts of functional fusion masterbatch.

[0075] The preparation method of herbal mixed nylon fiber specifically comprises the following steps:

[0076] 1. Preparation of functional fusion masterbatch

[0077] The functional fusion masterbatch is composed of polyamide chips, microcrystalline cellulose, casein, plant extracts, modifiers, silicone powder, dilauryl thiodipropionate, and gelatin;

[0078] The mass parts of each component in the functional fusion masterbatch are: 22 parts of polyamide chips, 2 parts of microcrystalline cel...

Embodiment 3

[0103] Embodiment 3 A kind of preparation method of herbal mixed nylon fiber, comprises the following steps:

[0104] Raw material selection: a herbal mixed nylon fiber, its formula raw materials include: polyamide chip, dispersant, zinc stearate, SanstabTPO330, functional fusion masterbatch, the weight percentage of each raw material is: polyamide chip 120 parts, dispersant 1 part, 0.8 parts of zinc stearate, 2 parts of Sanstab TPO3302, 25 parts of functional fusion masterbatch.

[0105] The preparation method of herbal mixed nylon fiber specifically comprises the following steps:

[0106] 1. Preparation of functional fusion masterbatch

[0107] The functional fusion masterbatch is composed of polyamide chips, microcrystalline cellulose, casein, plant extracts, modifiers, silicone powder, dilauryl thiodipropionate, and gelatin;

[0108] The mass parts of each component in the functional fusion masterbatch are: 25 parts of polyamide chips, 3 parts of microcrystalline cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com