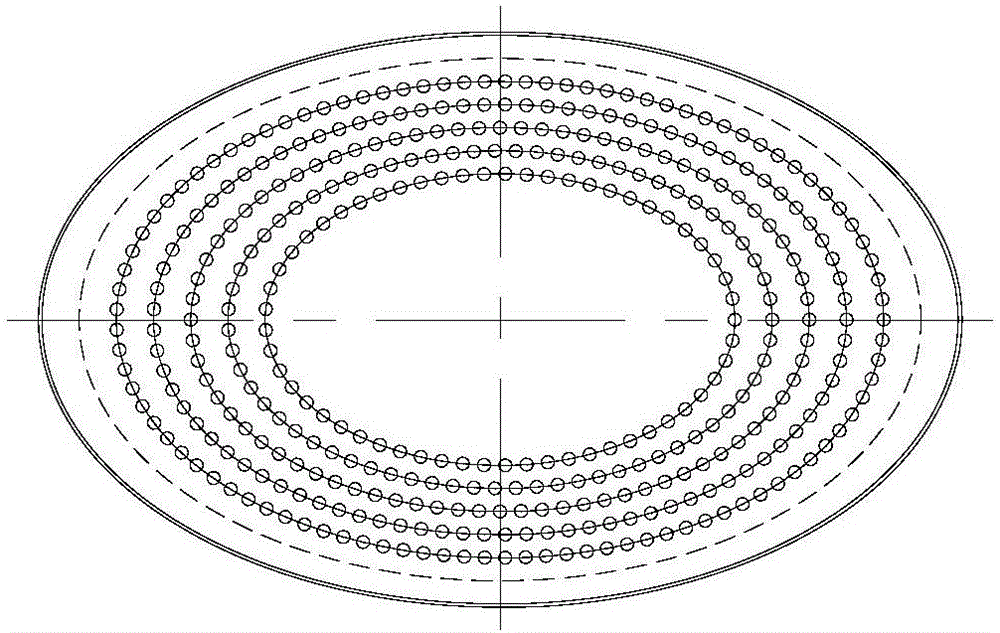

Patents

Literature

199results about How to "Increase the degree of diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

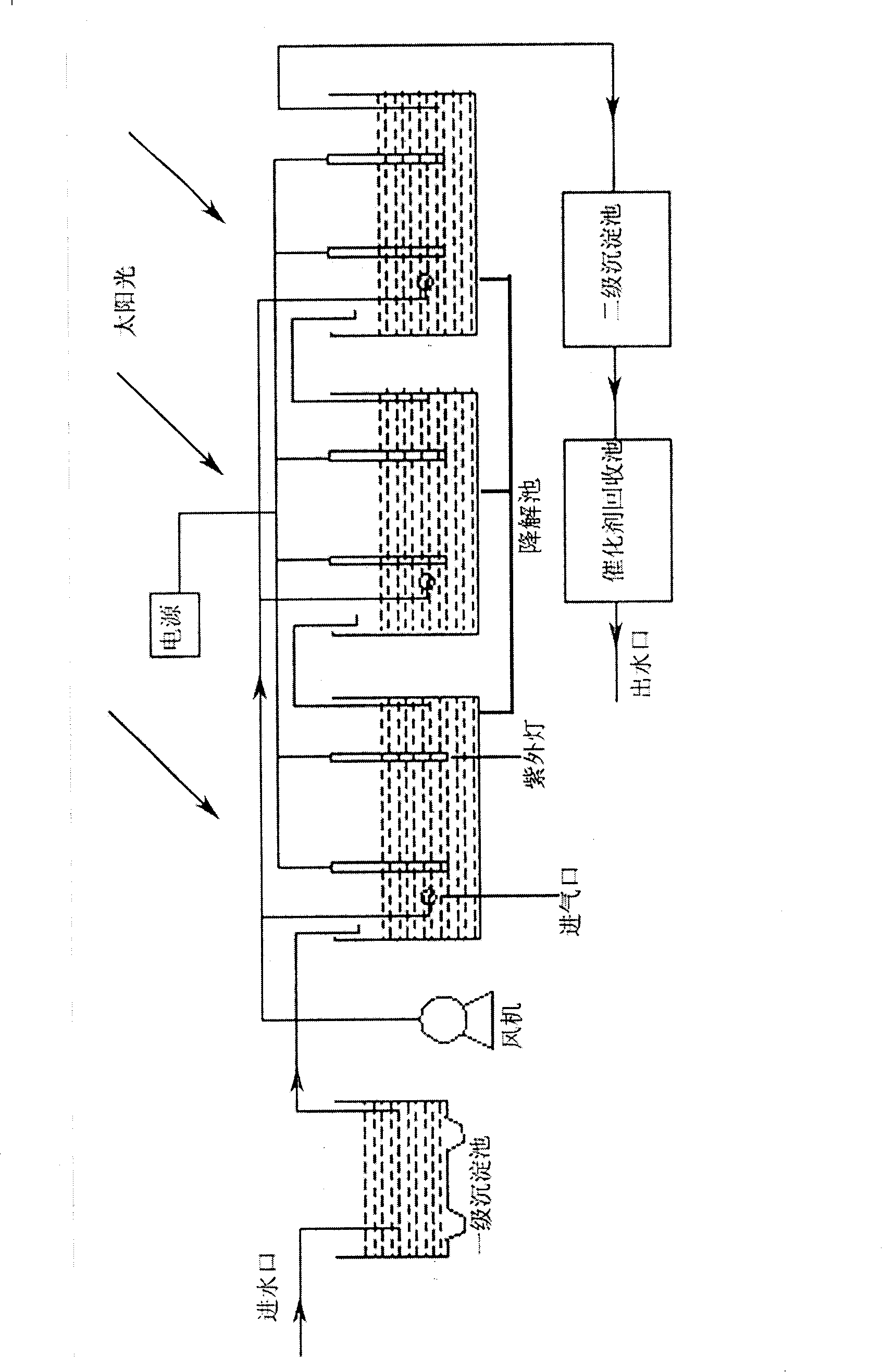

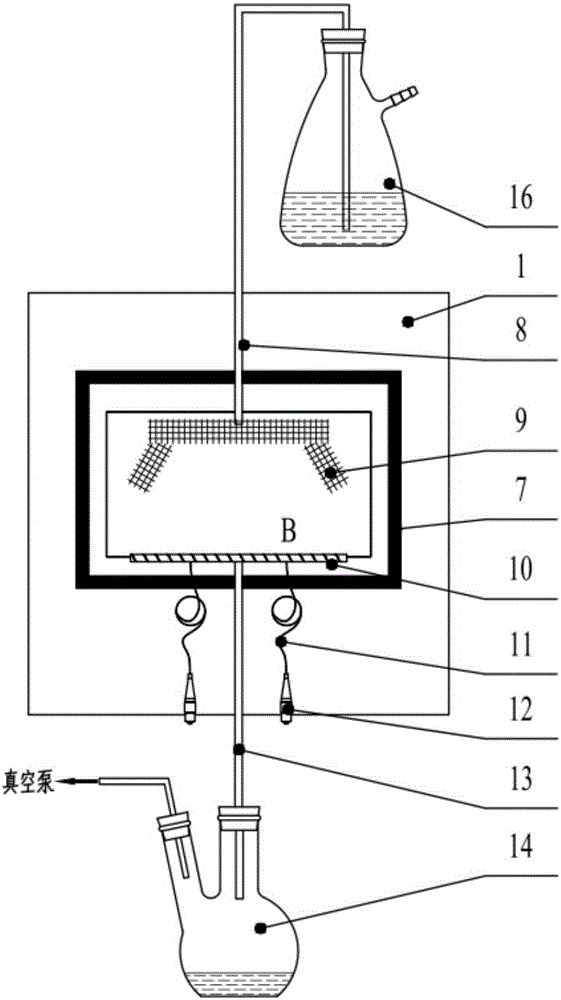

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

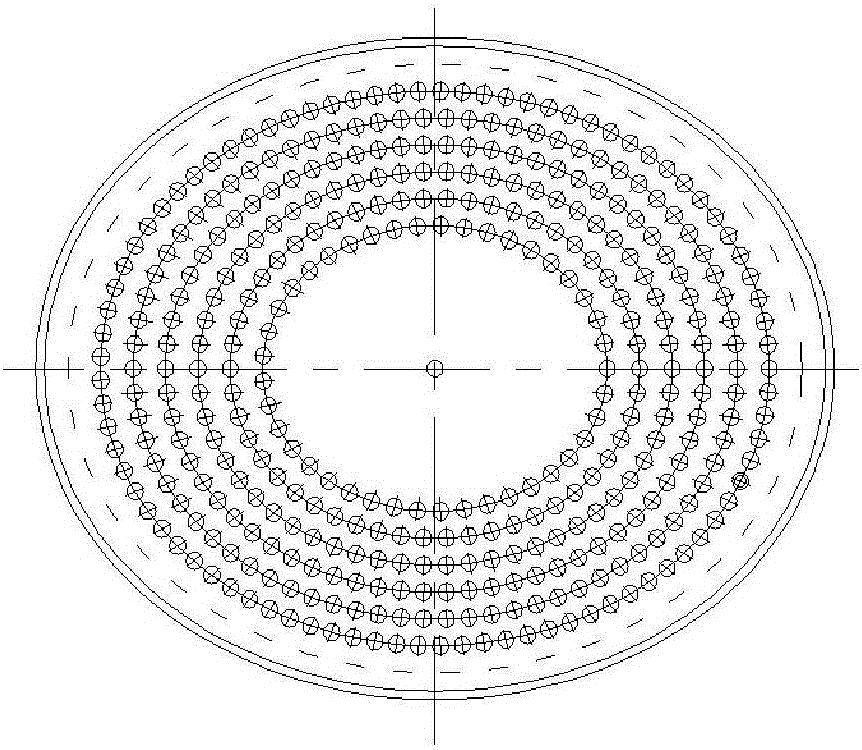

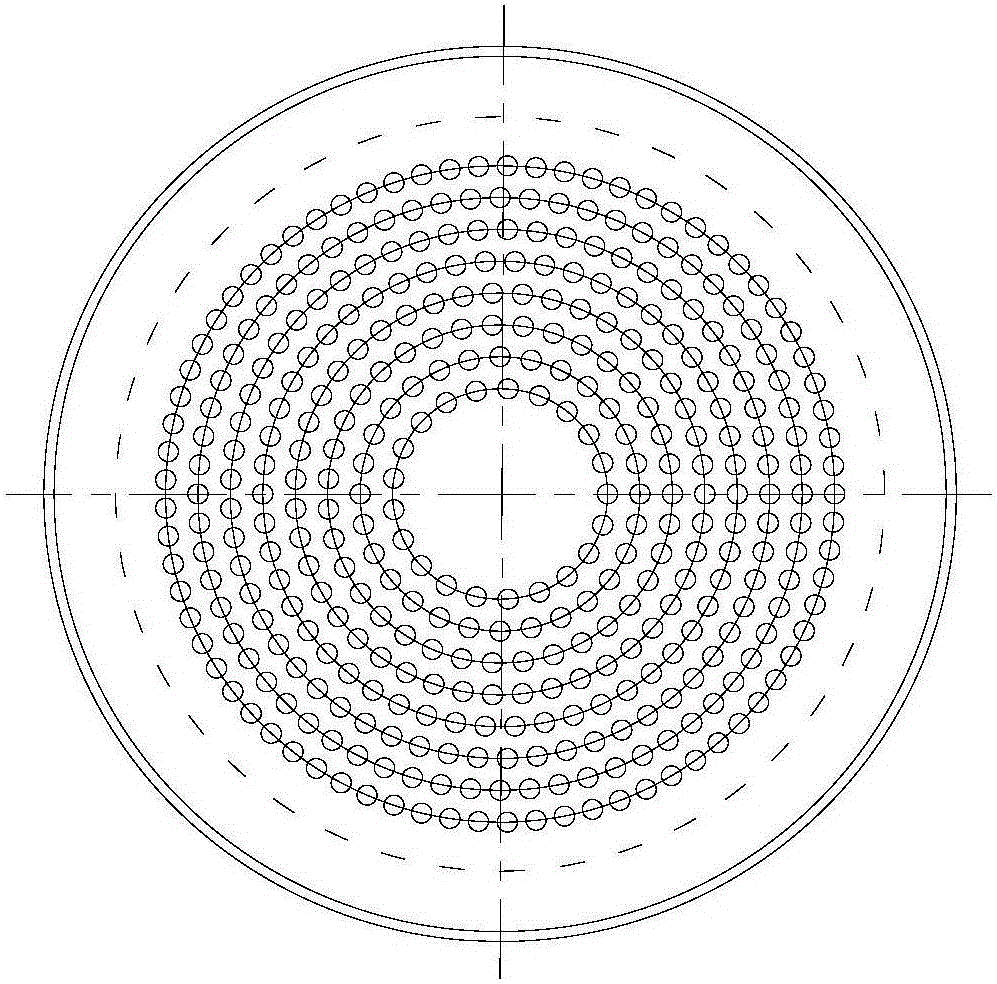

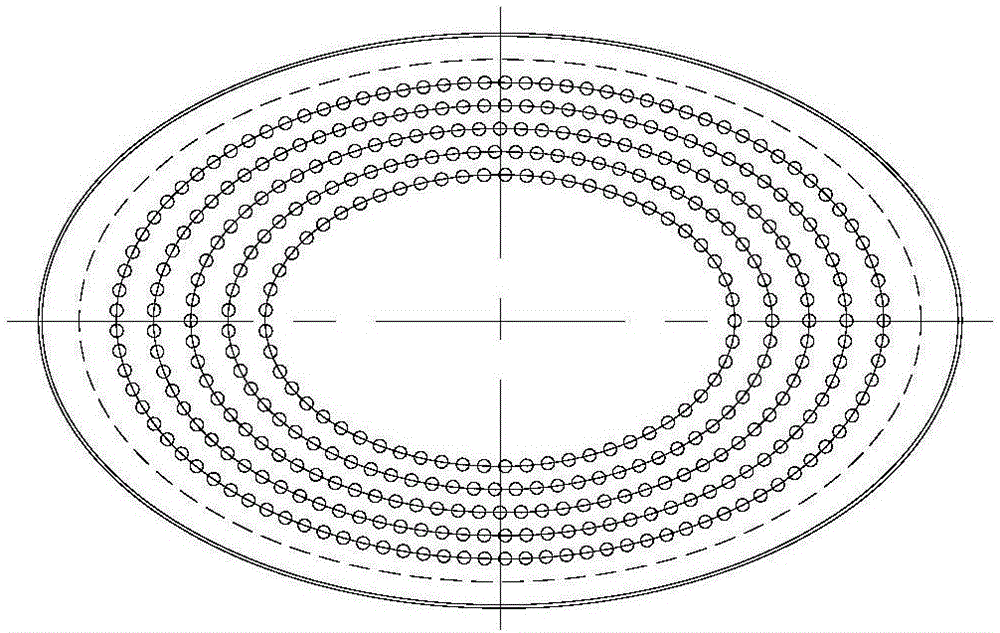

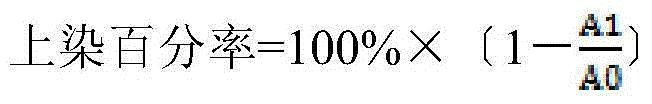

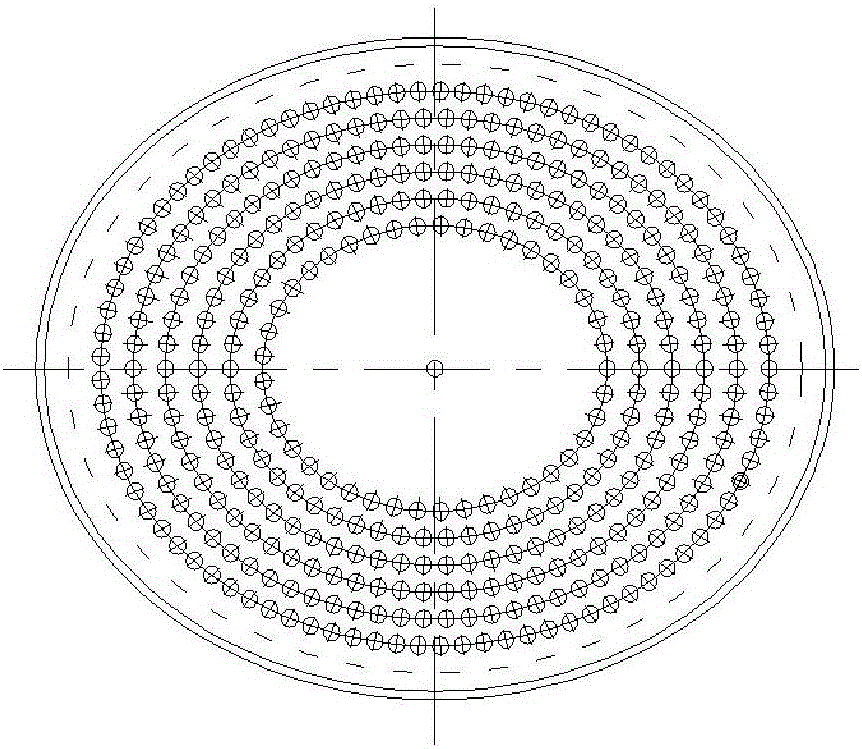

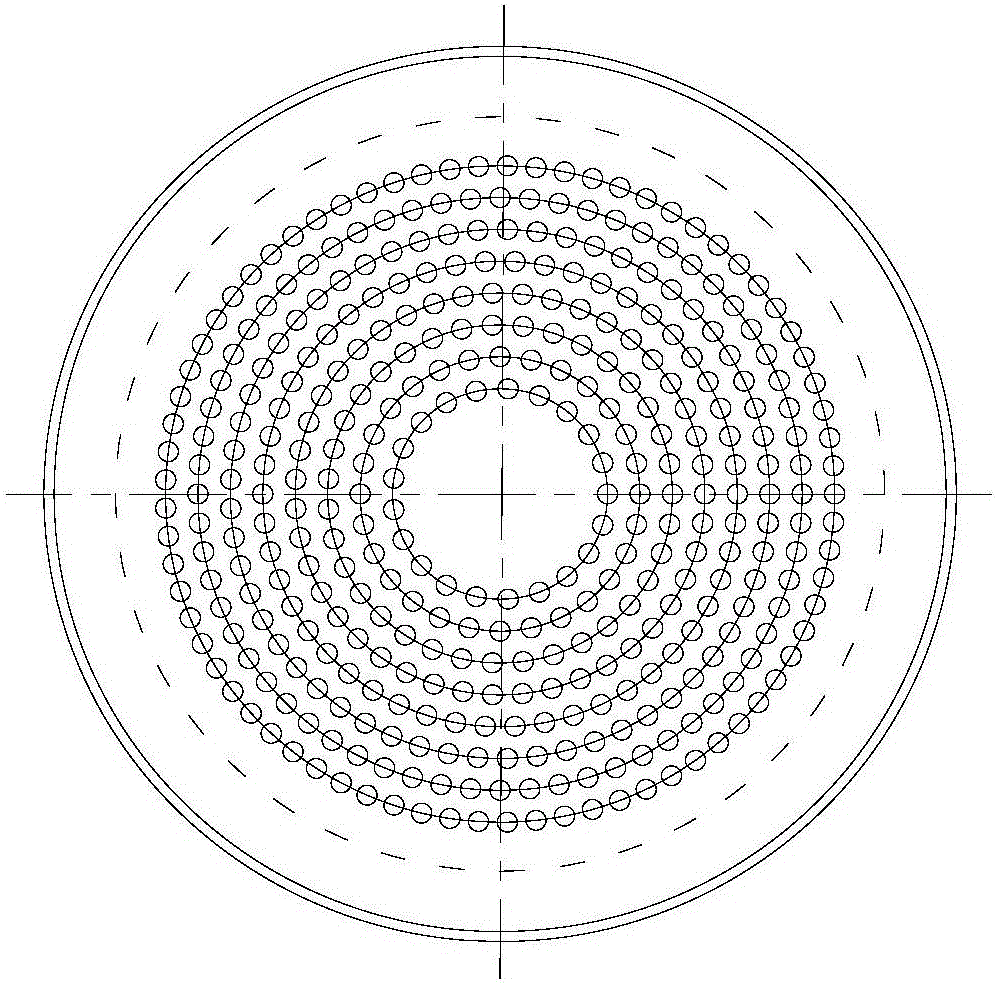

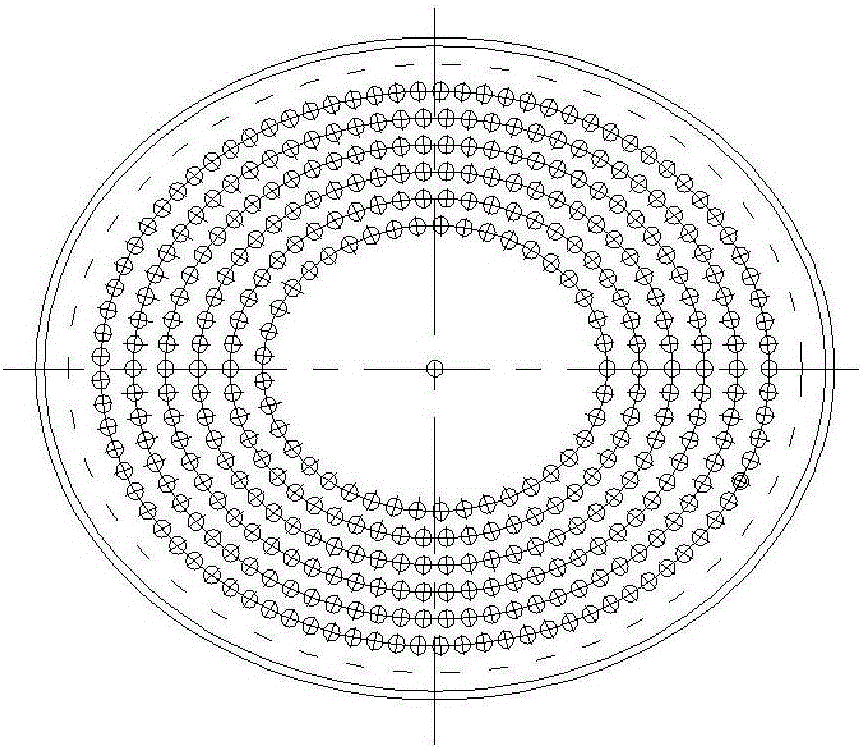

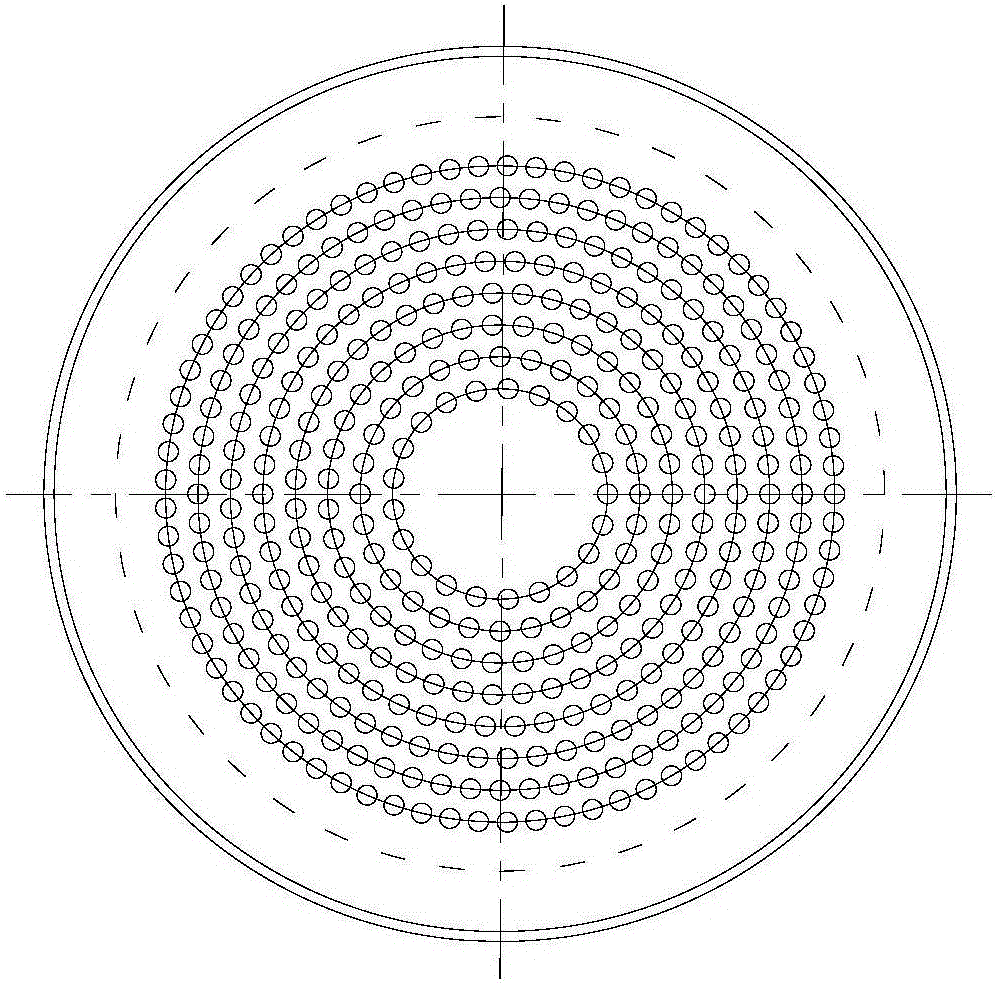

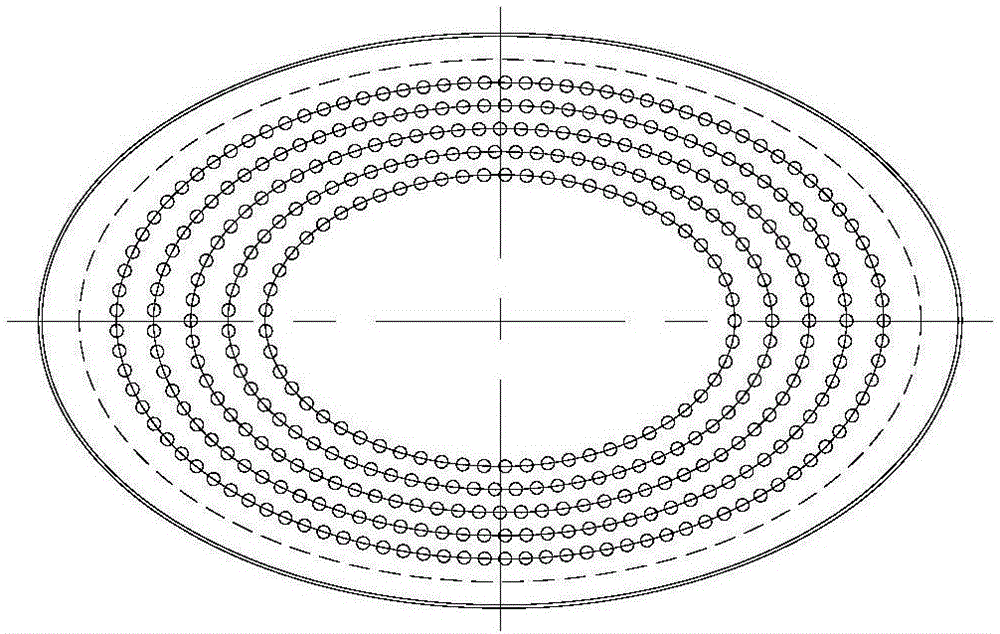

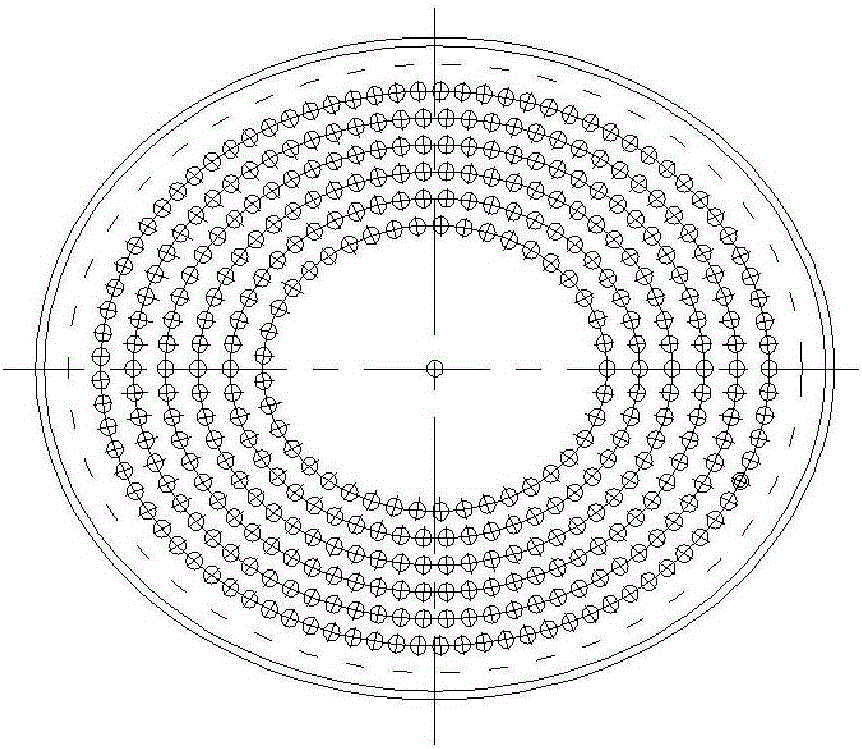

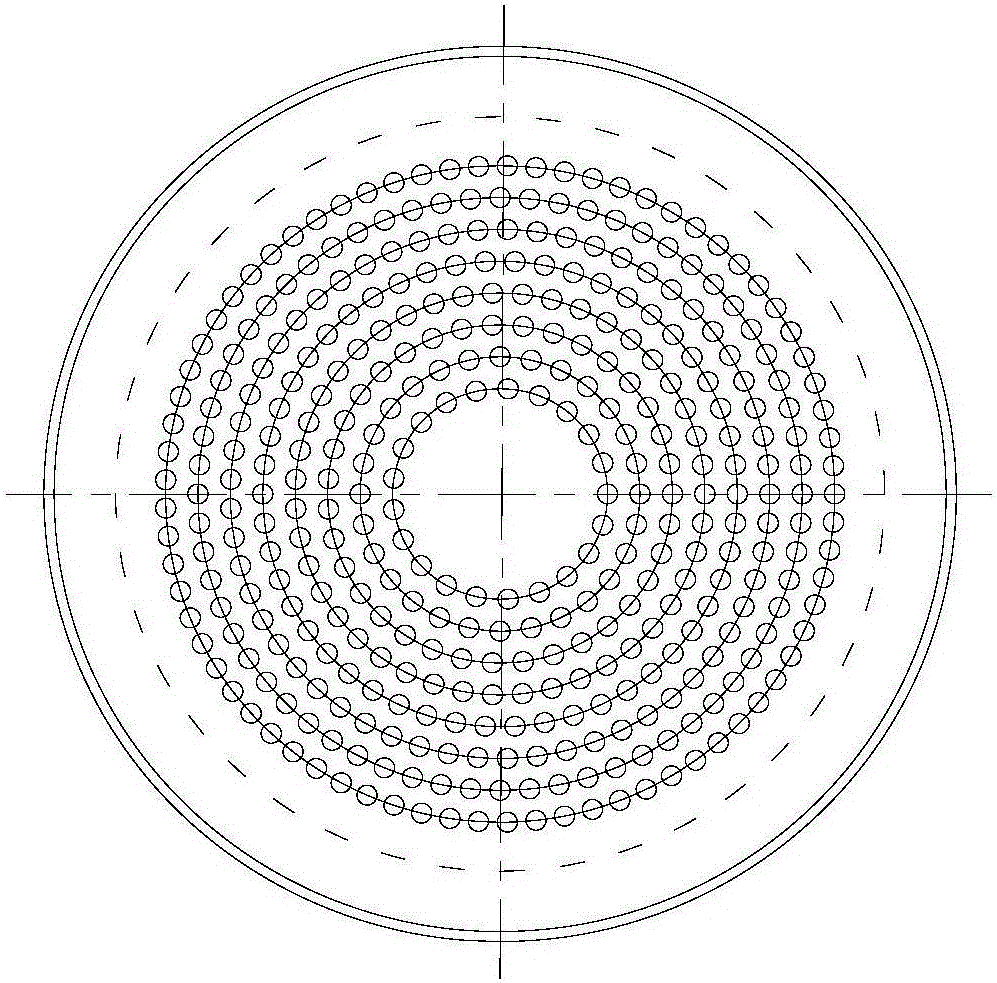

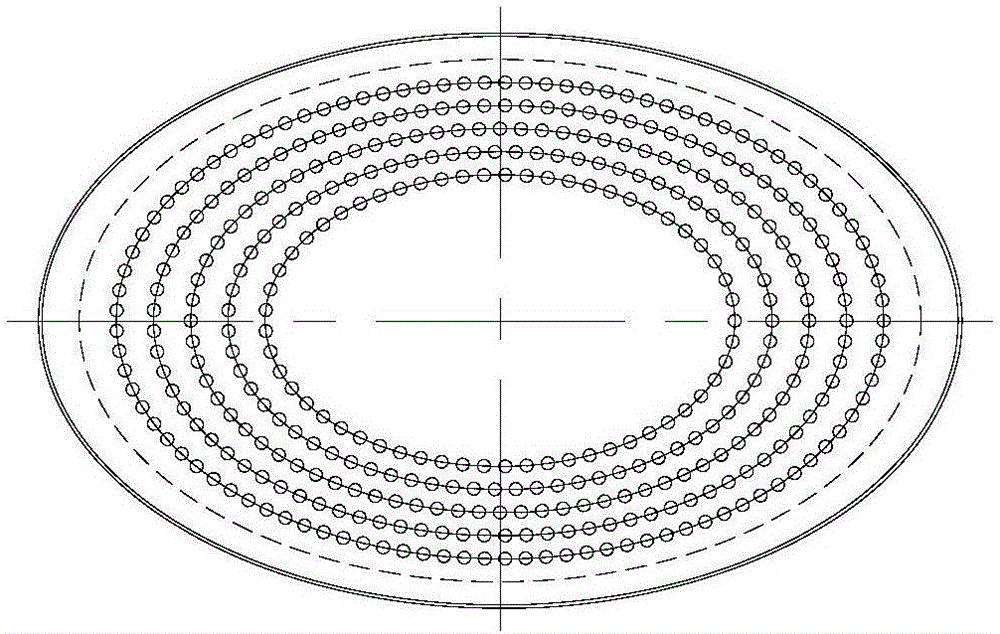

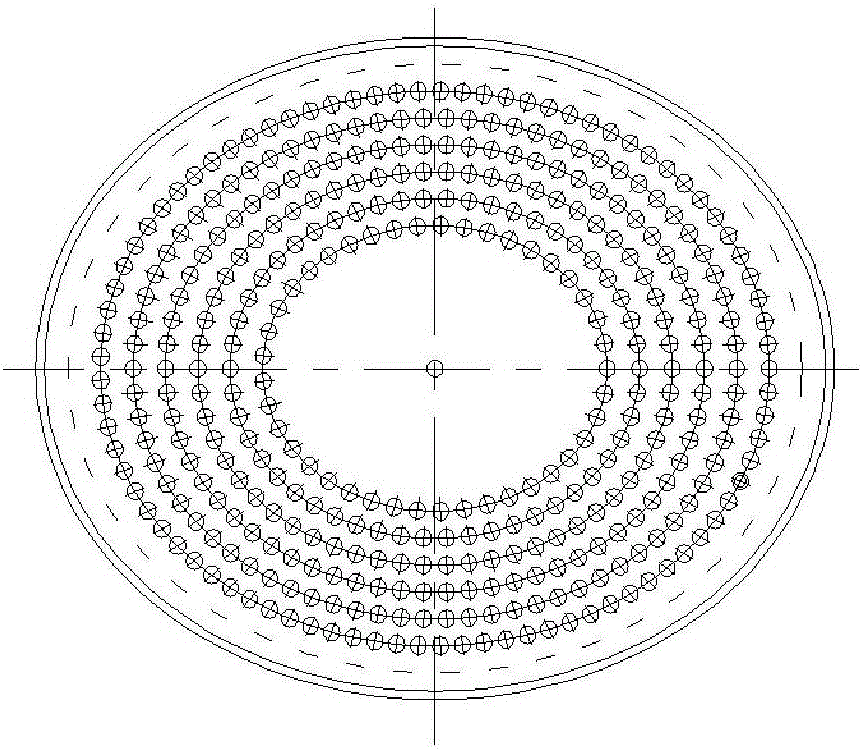

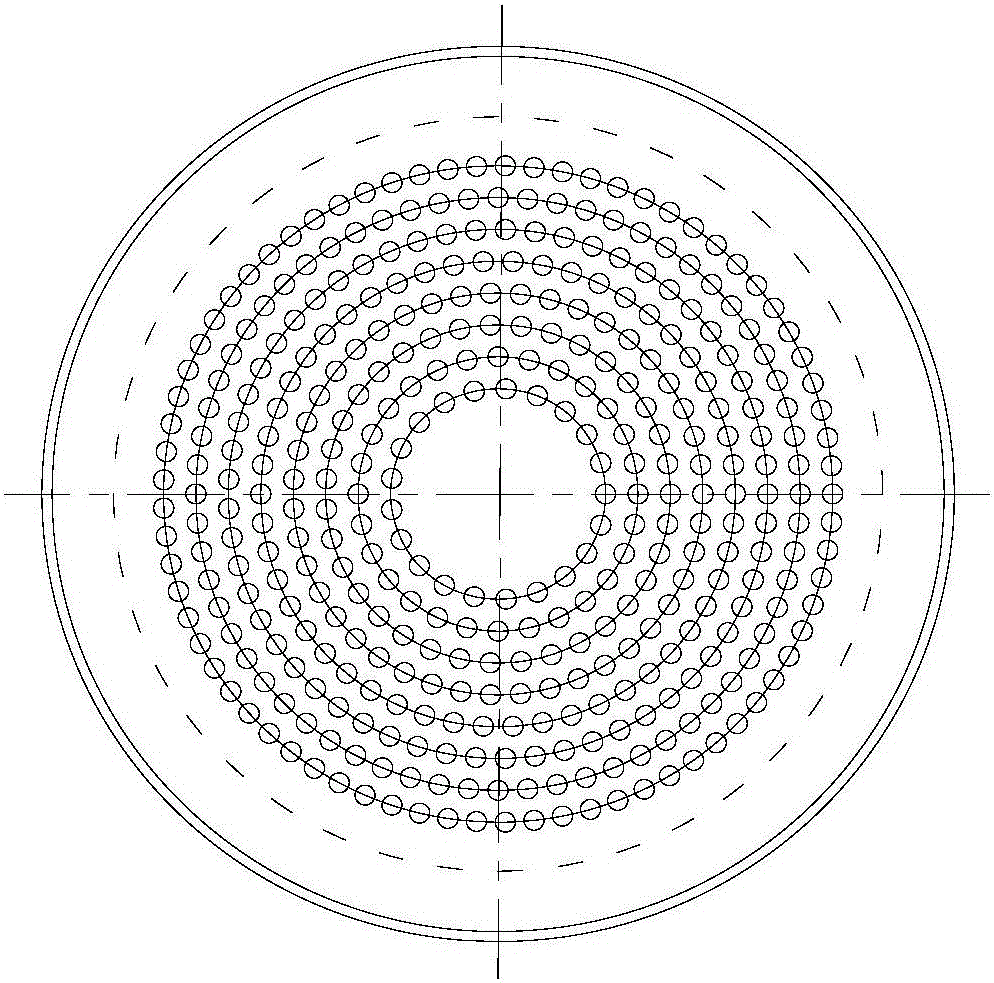

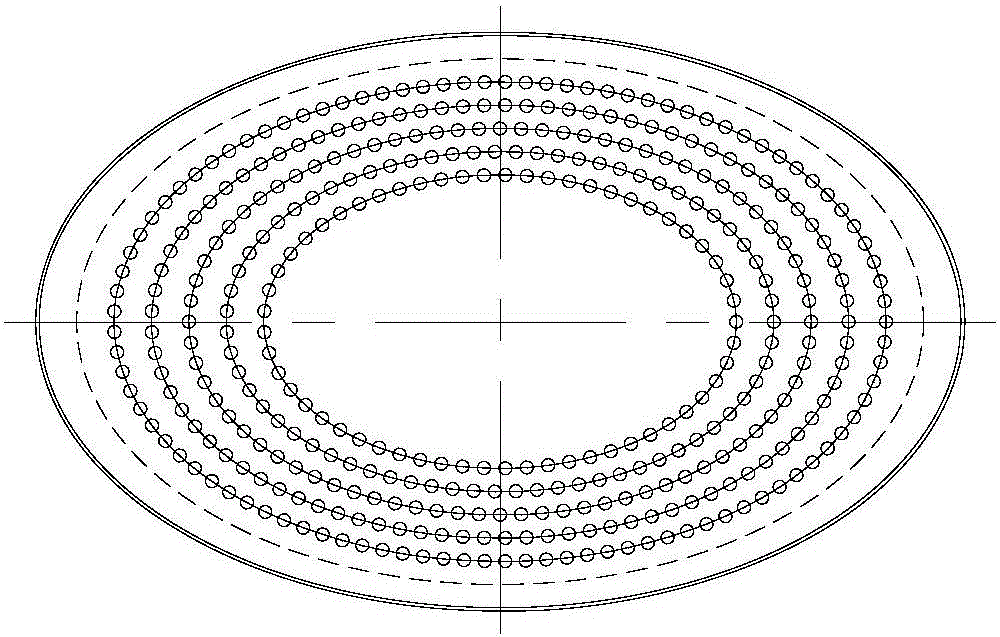

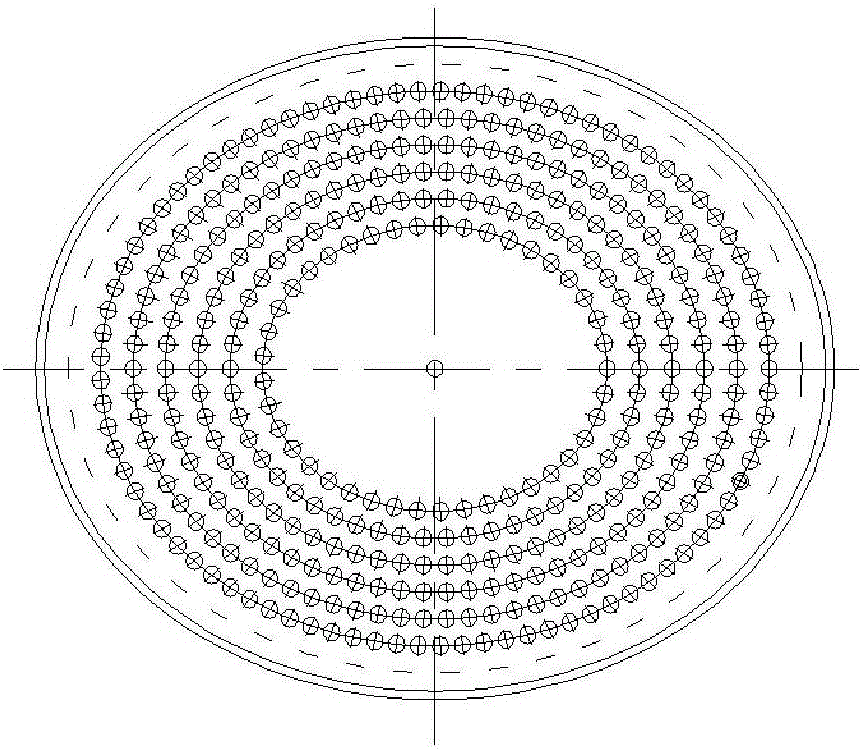

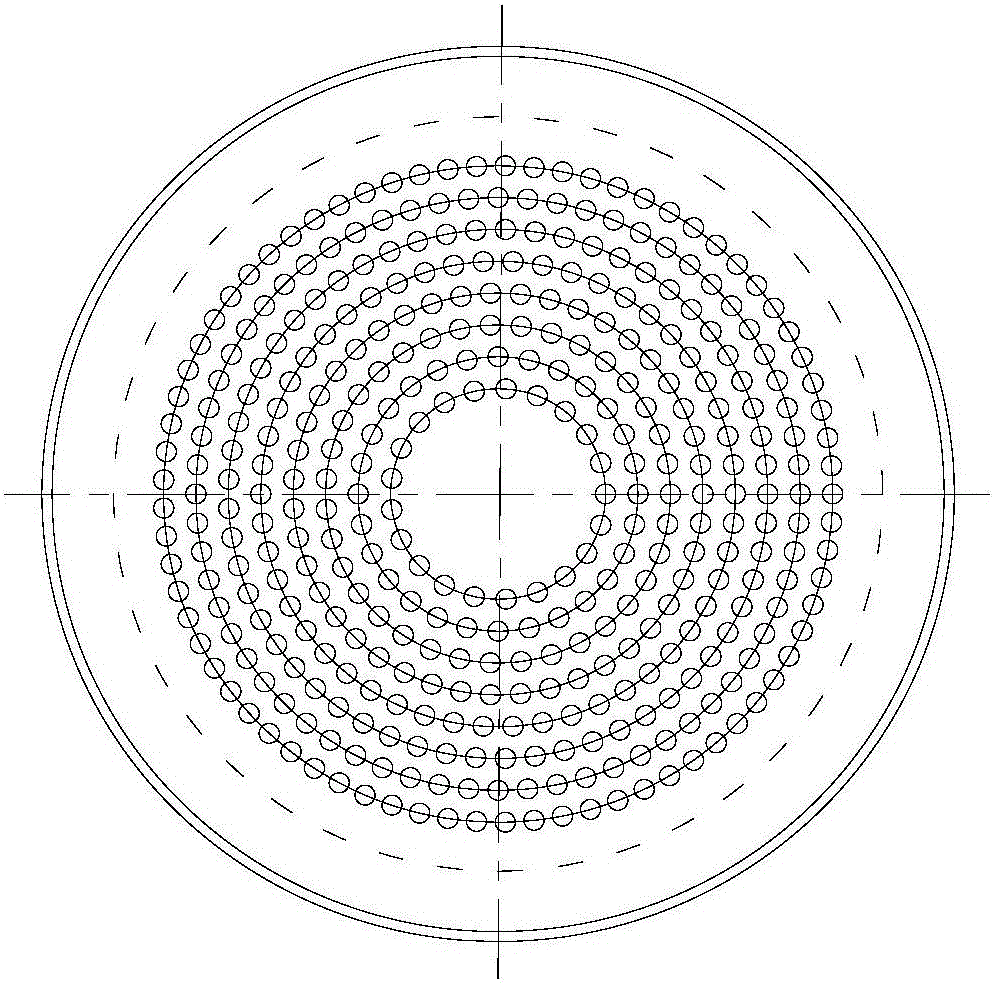

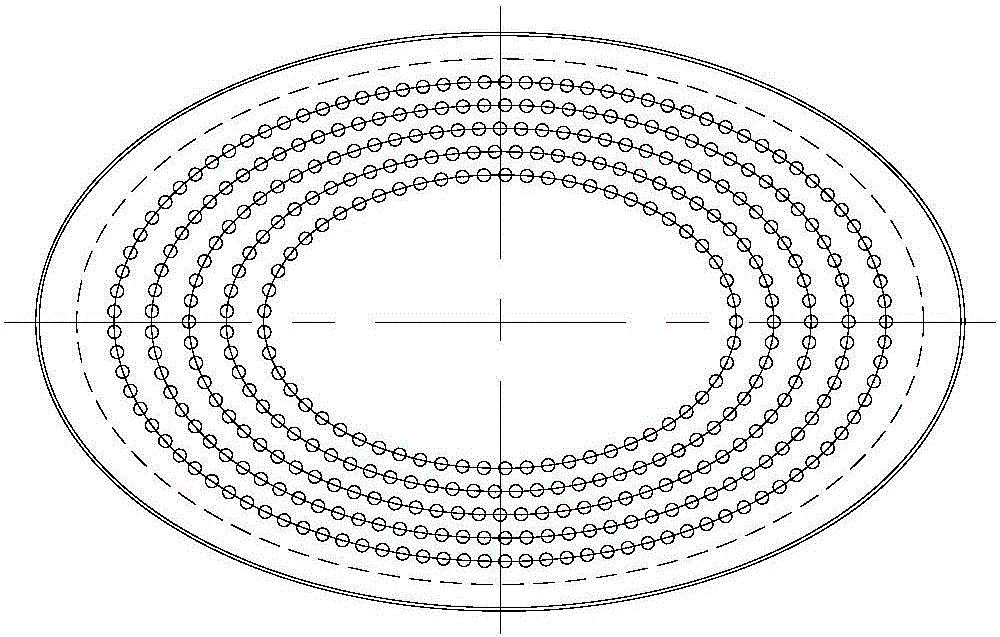

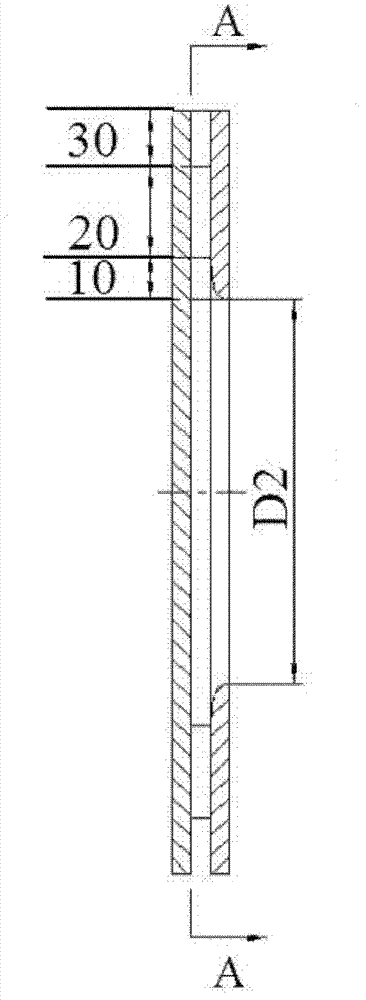

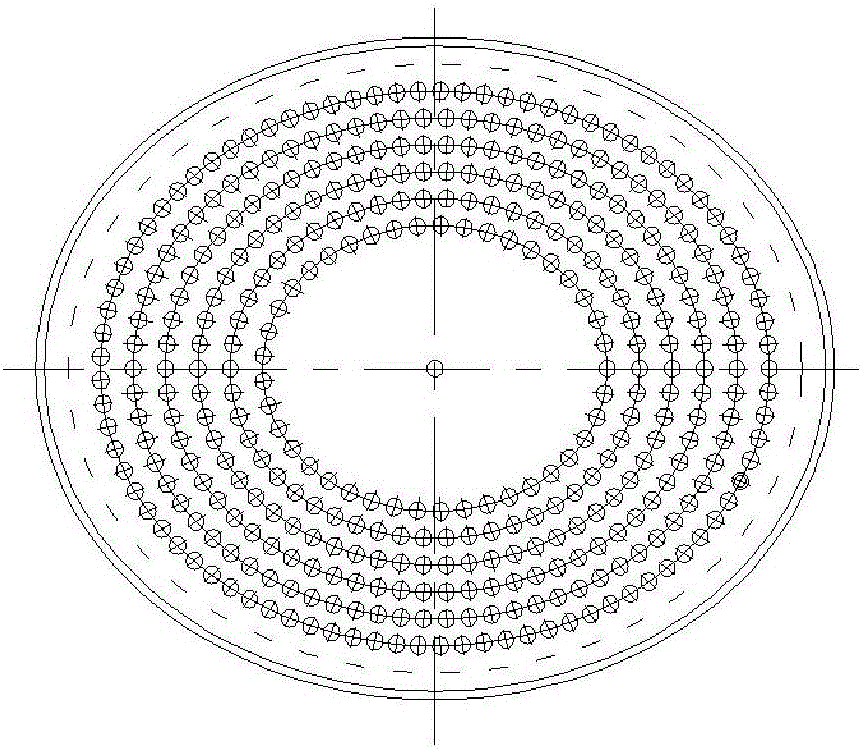

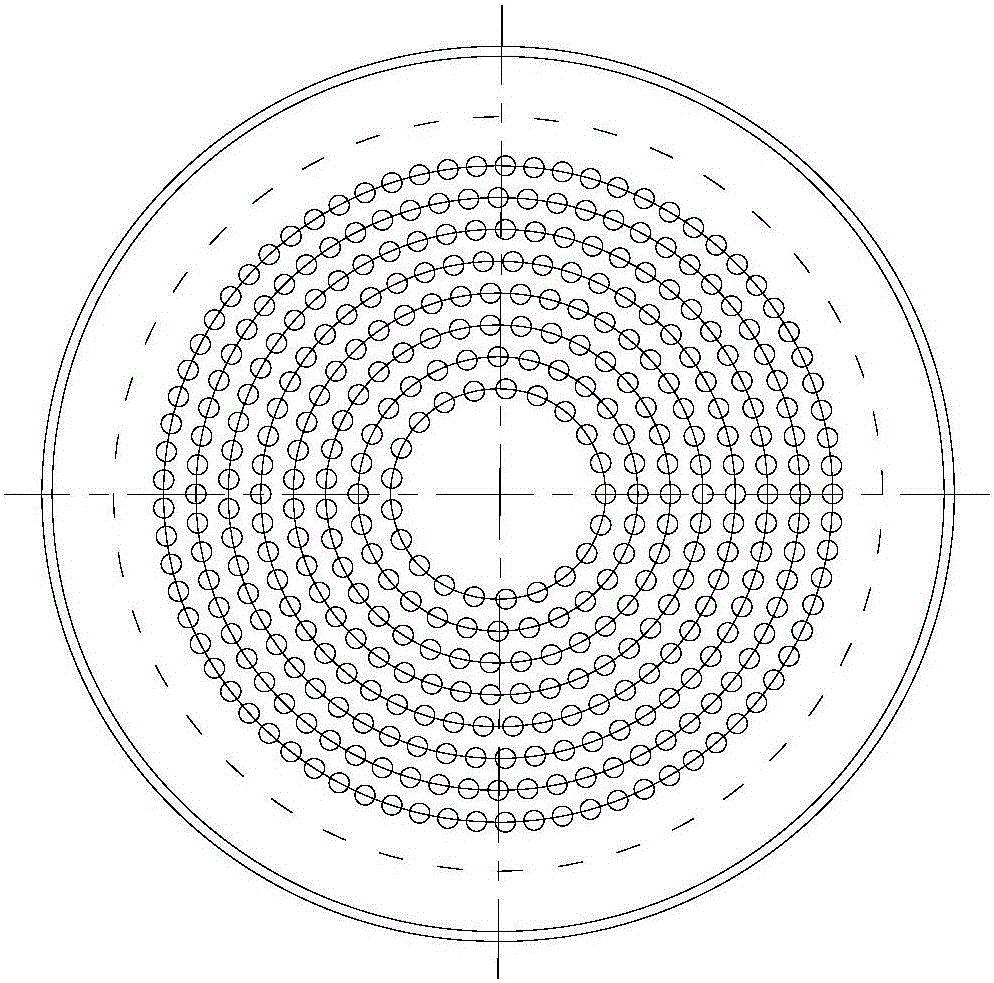

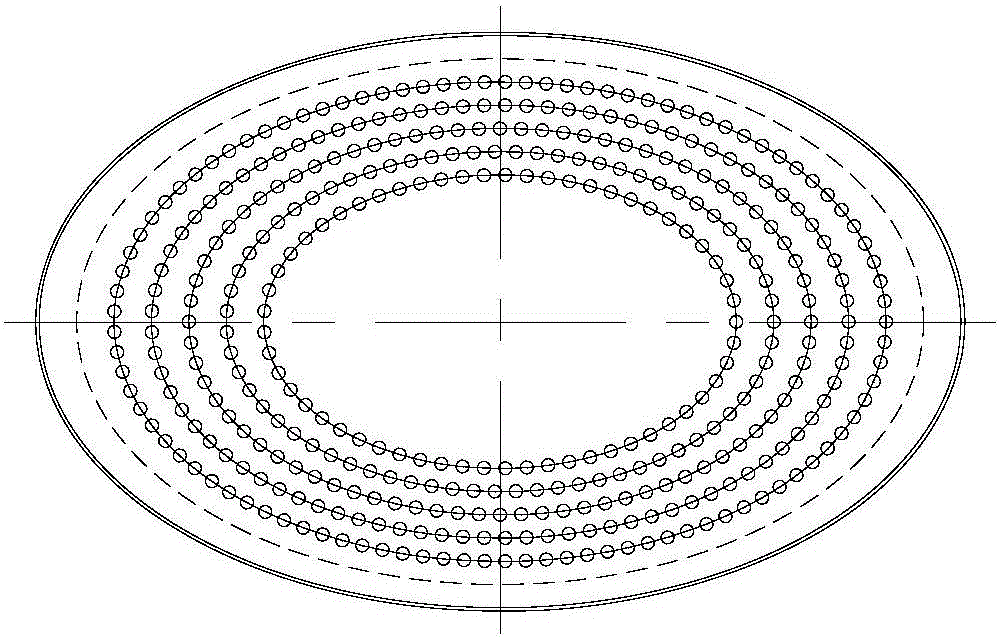

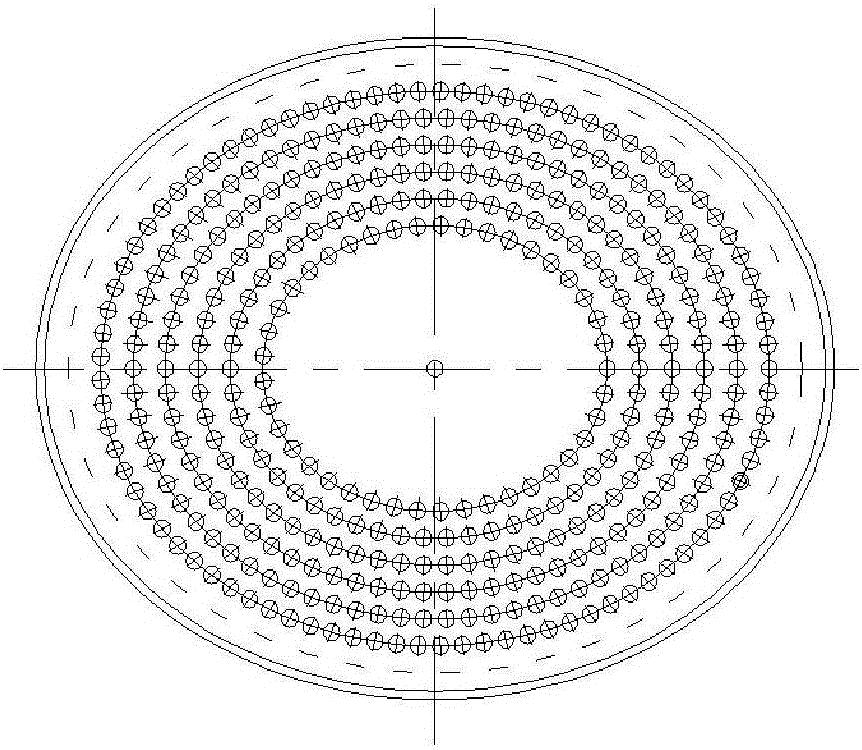

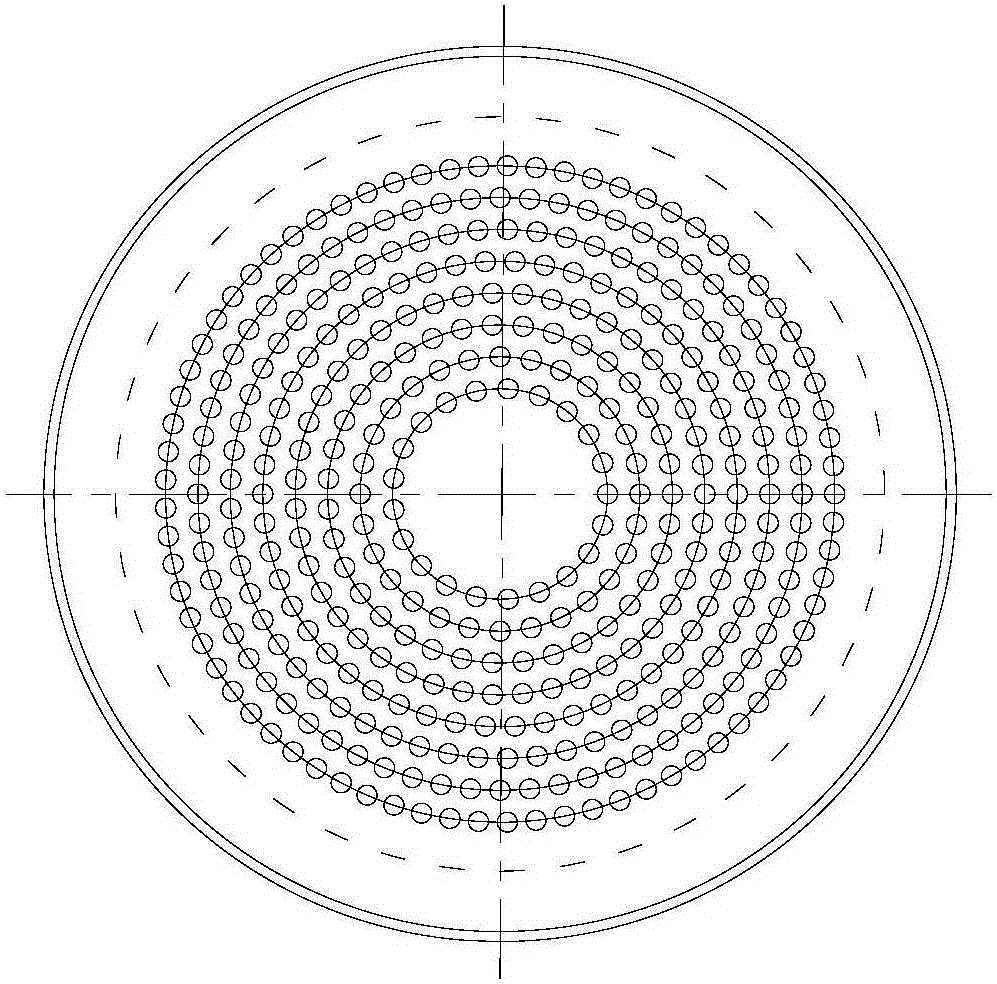

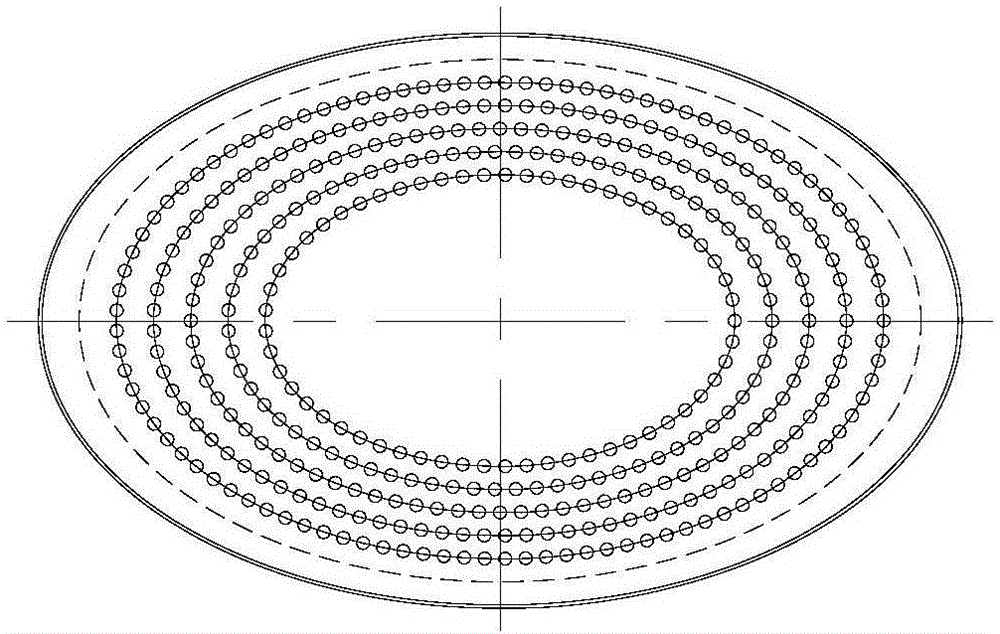

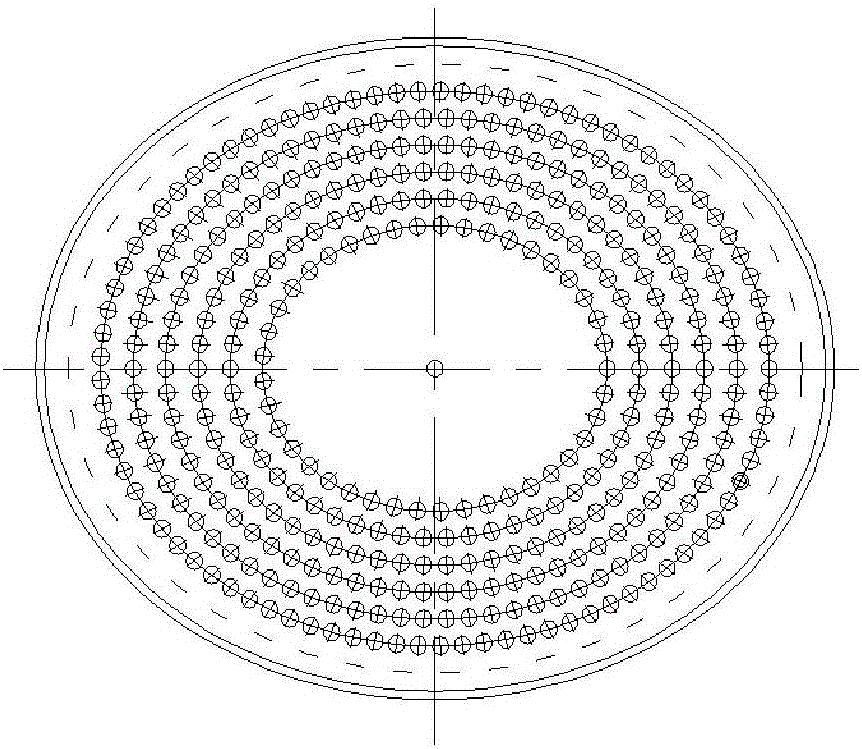

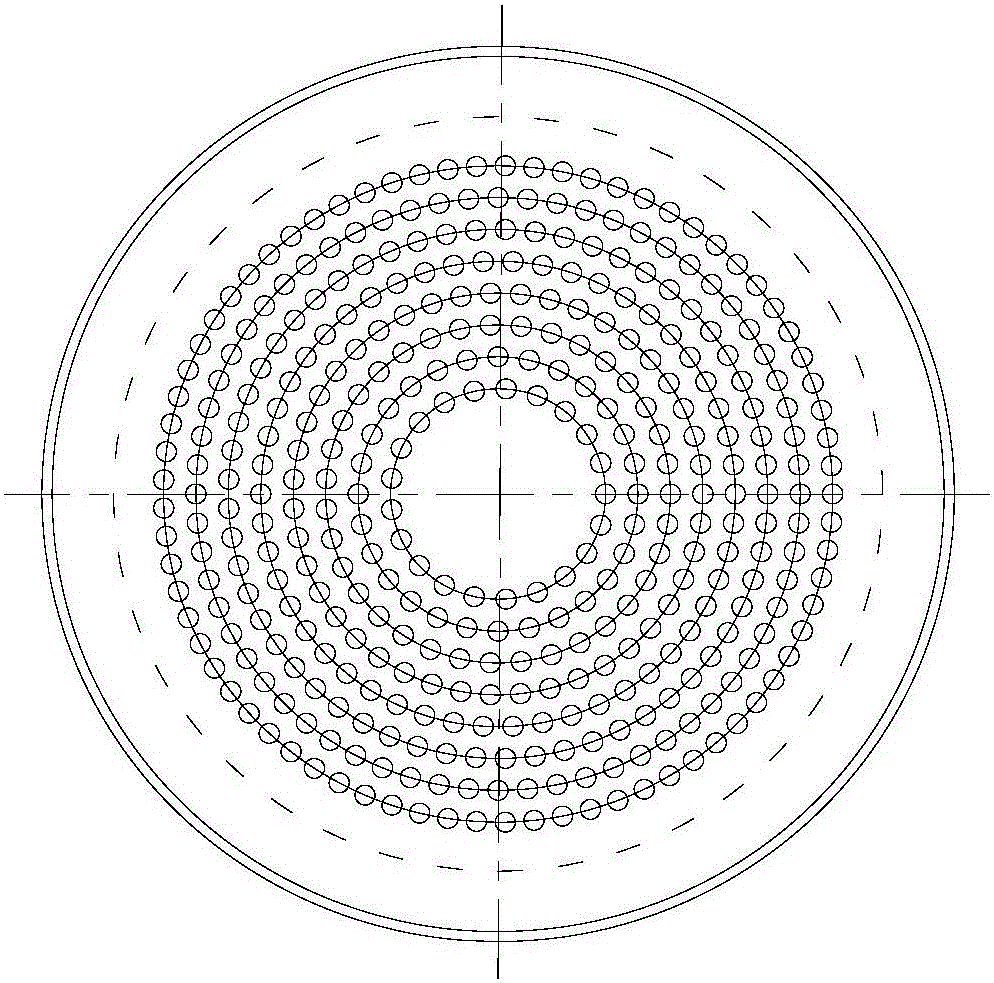

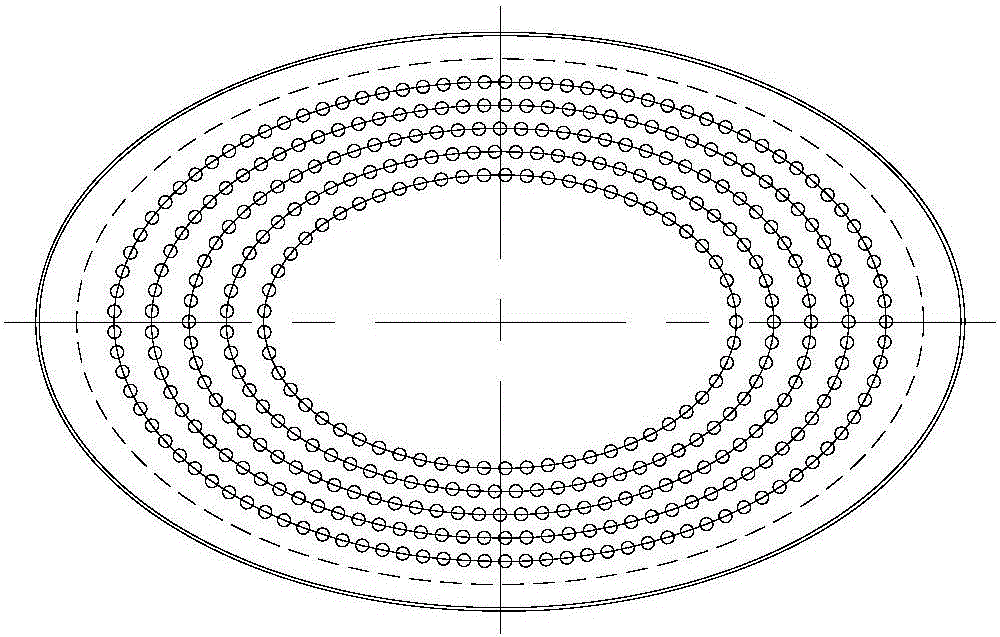

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Composite differential shrinkage yarn and preparation method thereof

The invention relates to a composite differential shrinkage yarn and a preparation method thereof. The composite differential shrinkage yarn is formed by compositing of a POY (polyester pre-oriented yarn) body and an FDY (fully drawn yarn) body, both the POY body and the FDY body are made of modified polyester by means of spinning, the modified polyester is formed by polyester and amino fatty acid gylcol ester, the amino fatty acid gylcol ester is scattered among molecular chains of the polyester, and a hydrogen-bond interaction among the amino fatty acid gylcol ester and the molecular chains of the polyester enables opposite positions of the amino fatty acid gylcol ester and the molecular chains of the polyester to be fixed; in the condition with temperature ranging from 90 DEG C to 130 DEG C, free volume spaces among molecular chains inside a fiber of the composite differential shrinkage yarn are enlarged by 20-30v / v%. The composite differential shrinkage yarn has the advantages that the free volume of polyester fibers is increased by the aid of fatty acid ester, so that diffusing degree of dye is improved, dyeing property of the polyester fibers is improved, and the composite differential shrinkage yarn is applicable to fashion fabric, decorative fabric and the like formed by means of spinning, knitting and warp knitting.

Owner:JIANGSU HENGLI CHEM FIBER

Differential-shrinkage cotton-like composite filament and preparation method thereof

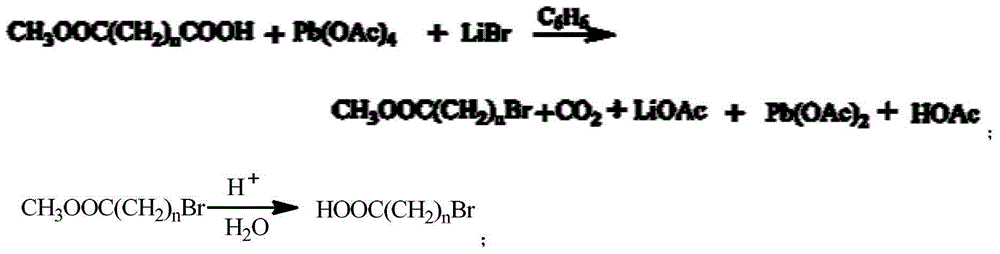

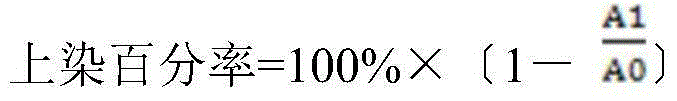

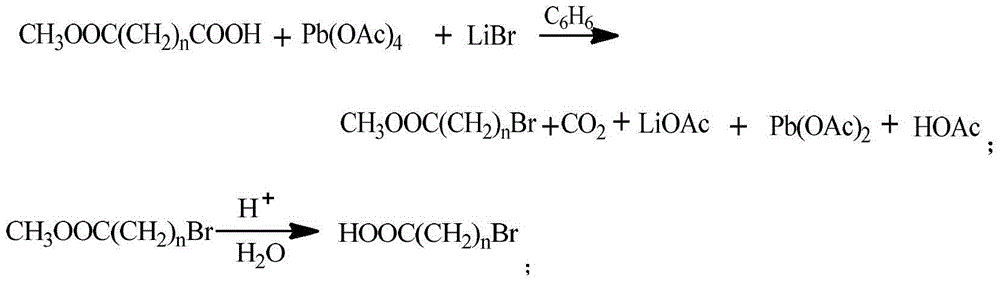

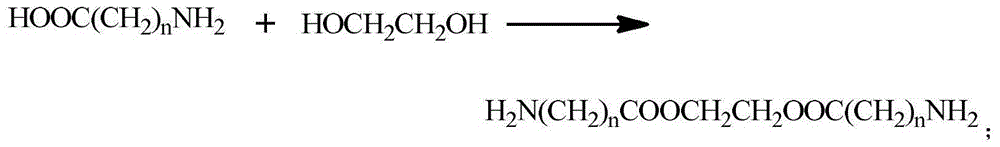

ActiveCN104562340AGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFatty acid ester

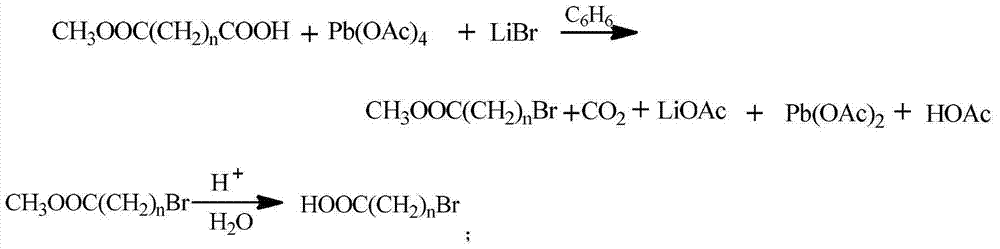

The invention relates to a differential-shrinkage cotton-like composite filament and preparation method thereof; the differential-shrinkage cotton-like composite filament is a composite filament blended by a modified polyester POY filament and a modified polyester FDY filament; the modified polyester consists of polyester and aminoadipic acid glycol ester; the aminoadipic acid glycol ester is dispersed among the molecular chains of the polyester; and the aminoadipic acid glycol ester takes effect of hydrogen bond among the molecular chains of the polyester, so as to stabilize the positions of the aminoadipic acid glycol ester with respect to the molecular chains of the polyester; in condition of the temperature is 90-130 degrees centigrade, the free volume spaces among the molecular chains inside the fiber of the differential-shrinkage cotton-like composite filament are increased by 20-30v / v%. The aliphatic ester increases the free volume of the polyester fiber in order to increase the diffusion degree of the dye, thereby increasing the dyeing performance of the polyester fiber. The differential-shrinkage cotton-like composite filament is applicable to clothes fabric, bedding article, decoration article, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Porous super-bright trilobal profiled polyester fiber and production method thereof

ActiveCN106400166AImprove dyeing effectEasy to processFilament/thread formingMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a porous super-bright trilobal profiled polyester fiber and a production method thereof. Modified polyester is spun by adopting a porous spinneret with the cross section shape of spinneret micro-pores being trilobal in order to produce the porous super-bright trilobal profiled polyester fiber; the spinneret micro-pores are arranged in the porous spinneret in an elliptical manner, the pore center of every spinneret micro-pore is positioned in a concentric ellipse, concentric ellipses are serial ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. A preparation method of the modified polyester comprises the following steps: reacting terephthalic acid with ethylene glycol to prepare ethylene terephthalate, adding diol terephthalate prepared from terephthalic acid and branched chain-containing diol, and continuously reacting to obtain the modified polyester. The porous super-bright trilobal profiled polyester fiber produced in the invention has excellent performances, the liner density deviation ratio is not greater than 0.5%, the breaking strength CV value is not greater than 4.0%, the fracture elongation CV value is not greater than 8.0%, and the yarn unevenness CV value is not greater than 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Linen-like type differential shrinkage composite filament and preparation method thereof

ActiveCN104480568AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationFiberPolyester

The invention relates to a linen-like type differential shrinkage composite filament and a preparation method thereof. The linen-like type differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the breakage elongation of the linen-like type differential shrinkage composite filament is 40.0+ / -3.0%, the network degree of the linen-like type differential shrinkage composite filament is 95+ / -5 piece / m; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the linen-like type differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The linen-like type differential shrinkage composite filament can be used in the industries such as high-class woof fabrics and clothes.

Owner:JIANGSU HENGLI CHEM FIBER

Wool-like differential shrinkage composite filament and preparation method thereof

ActiveCN104480567AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationPolyesterFiber

The invention relates to a wool-like differential shrinkage composite filament and a preparation method thereof. The wool-like differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the wool-like differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The wool-like differential shrinkage composite filament can be used in the industries such as clothes fabrics, bedding articles and decorative articles.

Owner:JIANGSU HENGLI CHEM FIBER

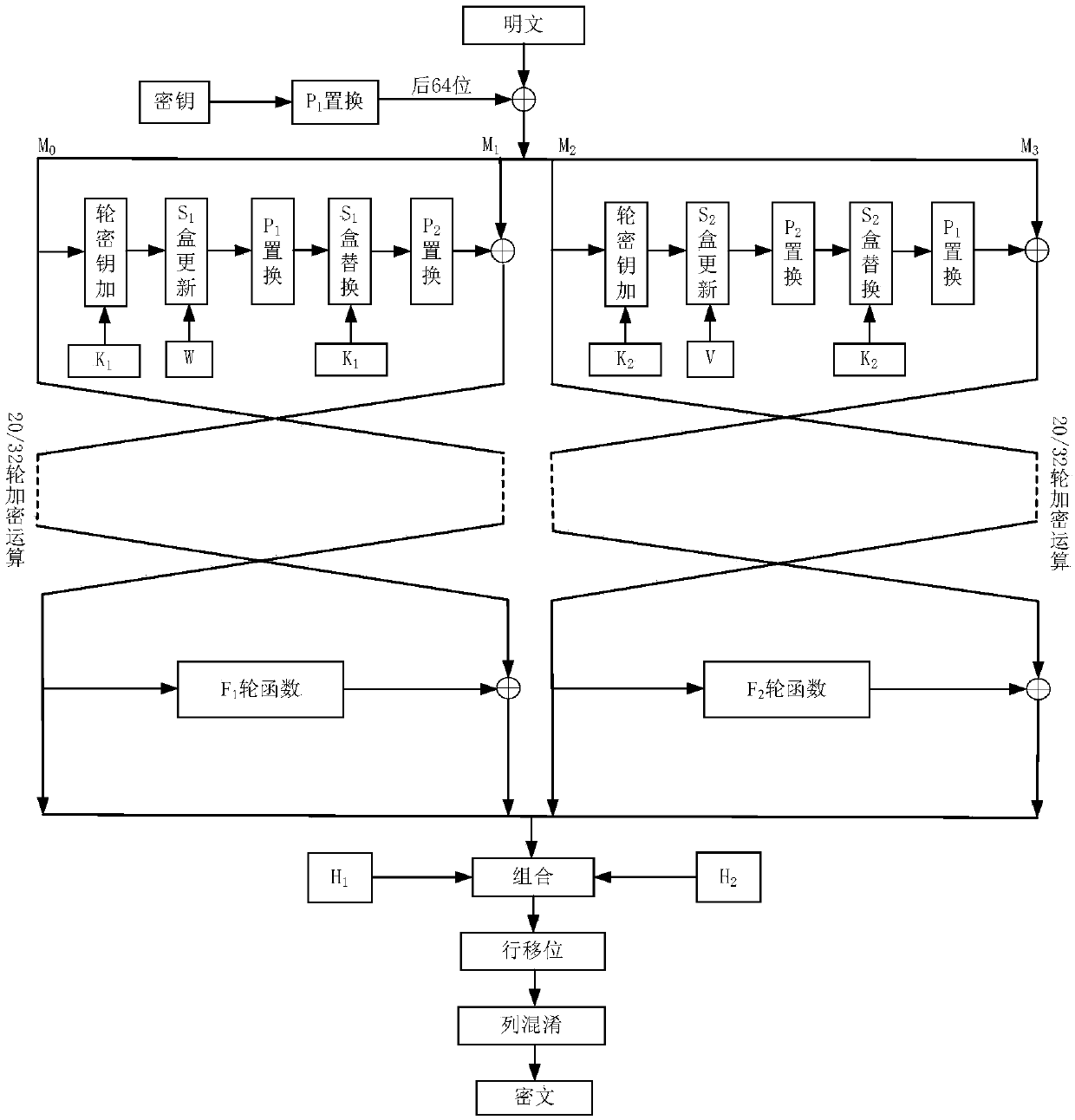

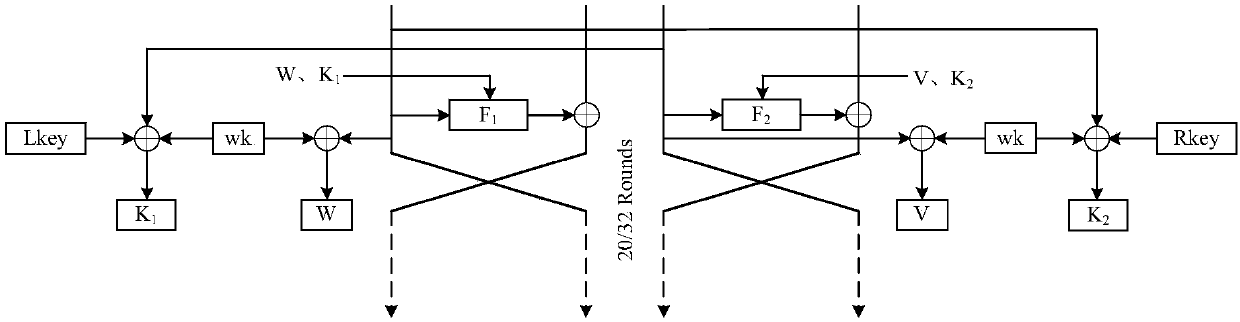

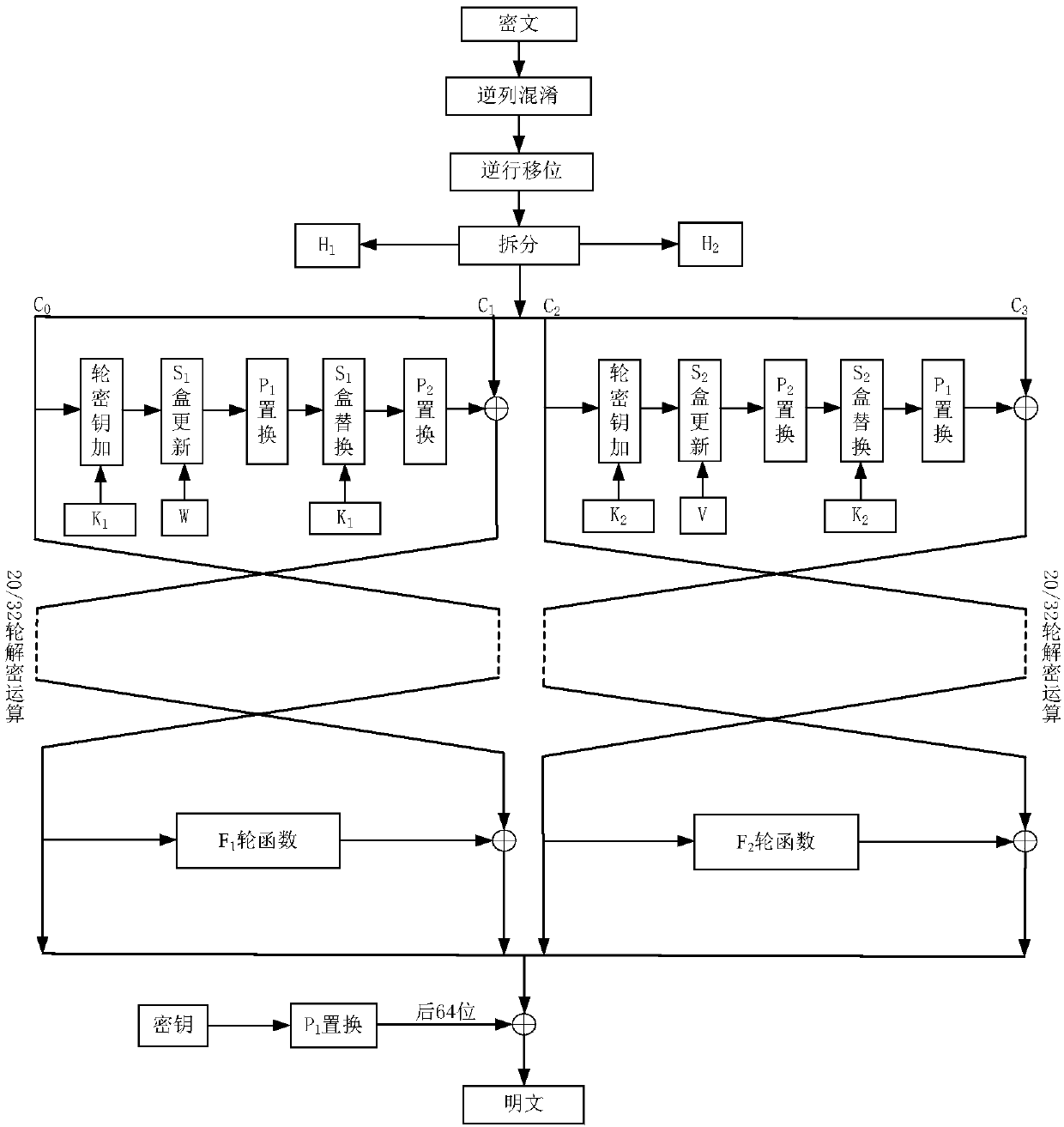

Method and apparatus for implementing lightweight block cipher SCS

ActiveCN108123791AImprove securityIncrease flexibilityKey distribution for secure communicationEncryption apparatus with shift registers/memoriesComputer hardwareDiffusion

The invention discloses a method and apparatus for implementing a lightweight block cipher SCS. A turn key and a control key are divided in keys, the round key participates in a round key adding operation, the control key controls the generation of each turn of S box to obtain a random S box, the update of the control key and the turn key is related to the operation result of the last turn, the Sbox used in each turn is random, the operation result of each turn is also random, so that the degree of confusion can be increased; in a round function, a high pseudo-random P permutation is generated by the Mason rotation algorithm in each round to achieve the diffusion, and after the end of the round function iteration, row shift and the column confusion transform are executed, so that the diffusion effect is enhanced by using the dual diffusion mode, and the security is improved. Compared with the situation that the difference between the resource consumption of fixed cipher structures isnot large, the internal structure of the device has the advantages of greatly improving the security of the scheme, and increasing the defense coefficients of linear attack, differential attack and the like to a certain extent.

Owner:HENGYANG NORMAL UNIV

Differential shrinkage composite filament and preparing method thereof

ActiveCN106381558AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberAlcohol

The invention relates to a differential shrinkage composite filament and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the differential shrinkage composite filament; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. The differential shrinkage composite filament is subjected to plying and doubling by modified polyester POY filament and FDY filament, then is composited through network, and finally reeled. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing dihydric alcohol are subjected to a reaction to obtain terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The filament has excellent fiber performance, the linear density deviation ratio is less than or equal to 2.0%, a breaking tenacity CV value is less than or equal to 4.0%, a breaking elongation CV value is less than or equal to 8.0%, and a crimp contraction variation coefficient CV value is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Manufacturing technology of glass fiber/epoxy resin composite material substrate type fiber bragg grating sensor

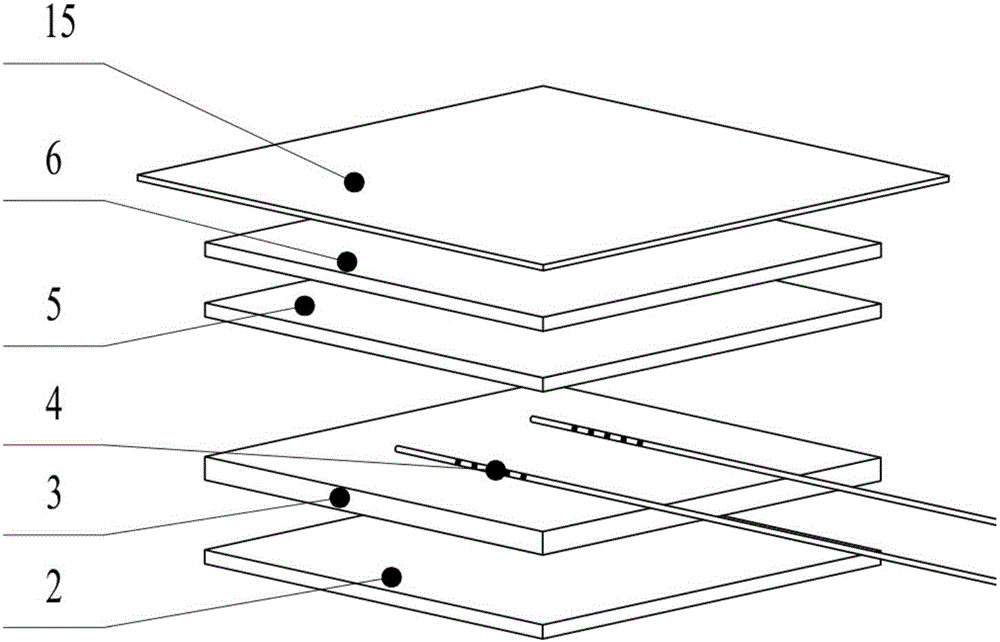

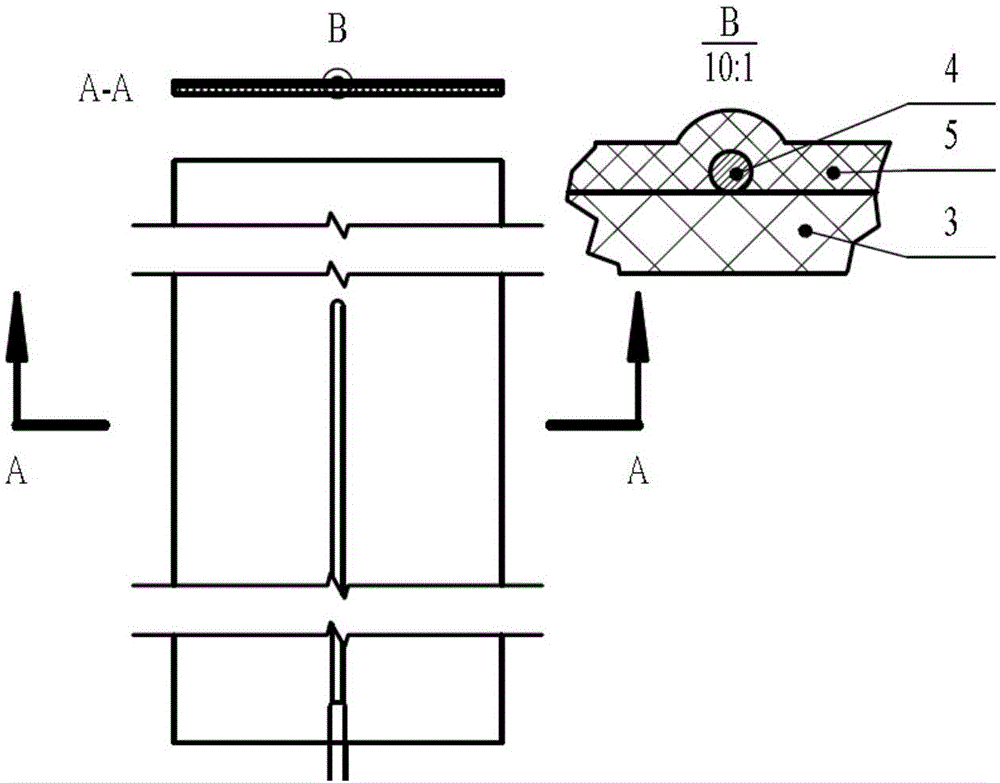

ActiveCN106633137AImprove performance and stabilityReduce internal stressMeasurement devicesOptical articlesFiberEpoxy

The invention discloses a manufacturing technology of a glass fiber / epoxy resin composite material substrate type fiber bragg grating sensor. The manufacturing technology comprises the steps that glass fiber / epoxy resin prepreg is procured to prepare a glass fiber / epoxy resin composite material substrate; a fiber bragg grating is fixed to the glass fiber / epoxy resin composite material substrate; the glass fiber / epoxy resin composite material substrate fixed with the fiber bragg grating is covered with a dry-state glass fiber cloth, vacuum aided filling of liquid epoxy resin is performed, and secondary curing molding is performed. The manufacturing technology adopts the secondary curing molding in the packaging process, the interlayer interface strength is remarkably improved, accordingly the testing precision and stability of the fiber bragg grating sensor are improved, batch production of the fiber bragg grating sensor can be achieved, and the manufacturing technology has wide market prospect and huge economic benefit.

Owner:SHANDONG UNIV

Porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and preparation method thereof

ActiveCN106283251AImprove cooling effectImprove fiber propertiesSpinnerette packsMonocomponent copolyesters artificial filamentYarnBreaking strength

The invention relates to porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and a preparation method thereof. According to the preparation method, the porous PTT-fiber HOY is prepared from modified PTT by spinning with a porous spinneret; spinneret orifices in the porous spinneret are arranged in an oval shape, that is, the centers of the spinneret orifices are located on concentric ellipses adopting series ellipses, major axes of all the ellipses are collinear, and minor axes of all the ellipses are collinear. The porous PTT-fiber HOY is prepared from modified PTT through measurement, extrusion, cooling, oiling and winding. A preparation method of modified PTT comprises the steps as follows: terephthalic acid and 1,3-propanediol react, trimethylene terephthalate is prepared, diol terephthalate prepared from terephthalic acid and branched-chain-containing diol through a reaction is added, reaction is continued, and modified PTT is obtained. The prepared HOY has excellent fiber performance, the deviation rate of linear density is lower than or equal to 0.2%, the breaking strength CV value is lower than or equal to 2.5%, and the breaking elongation CV value is lower than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

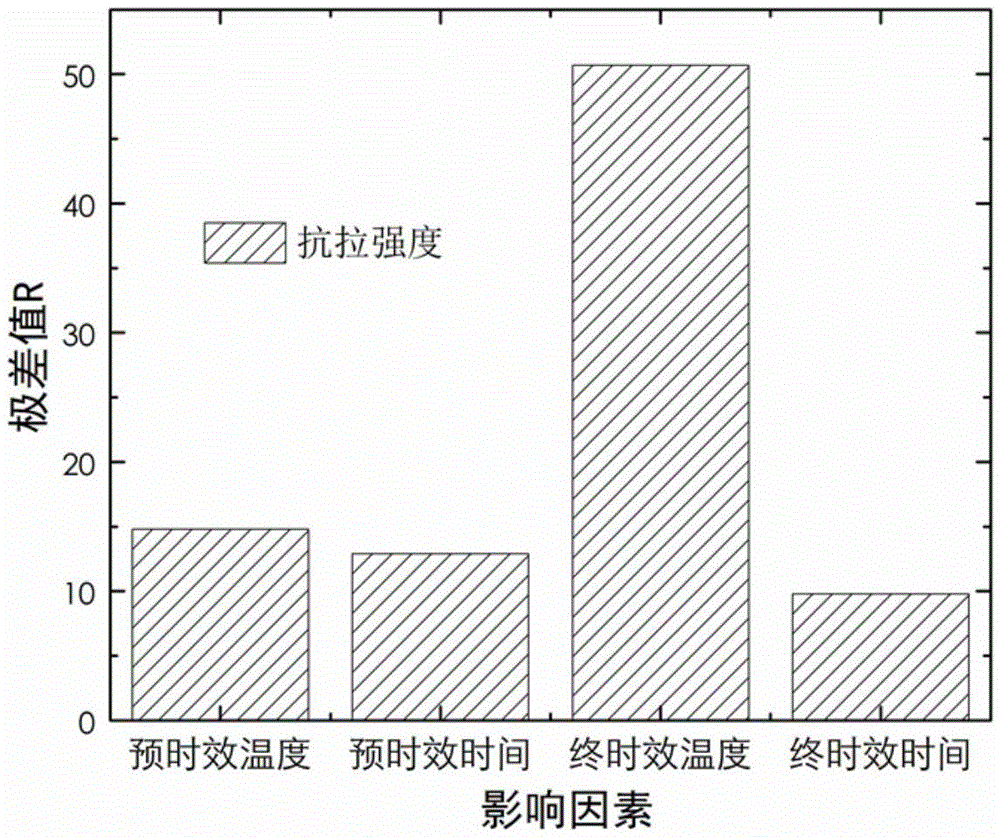

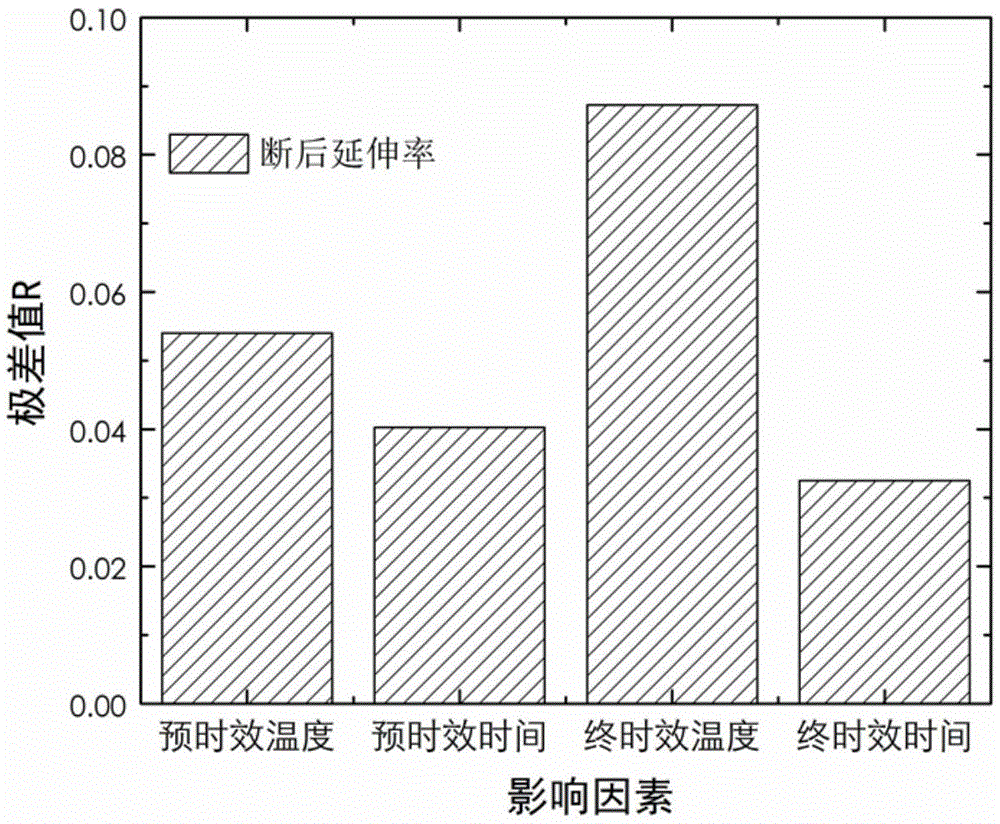

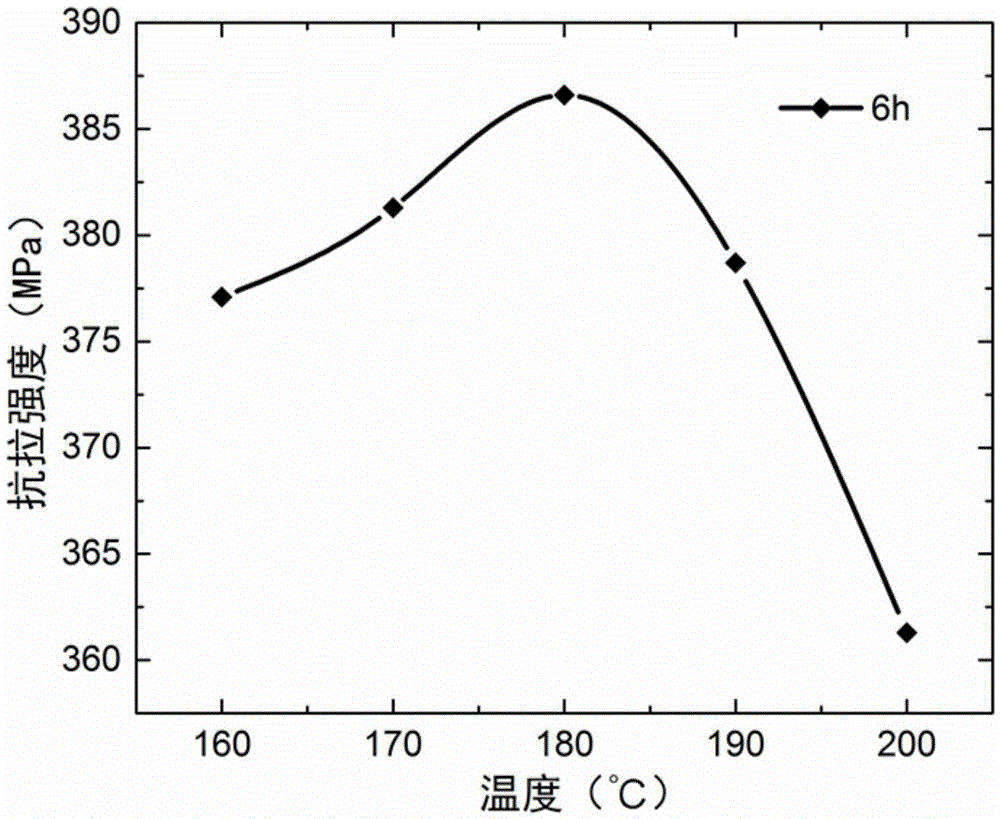

Thermo-mechanical treatment method for aluminum alloy

ActiveCN105543738ASimplify Manufacturing RoutingImprove fine dispersionPre deformationExisting Treatment

The invention discloses a novel electromagnetic forming and aging thermal treatment combined method for improving the strength and toughness of an aluminum alloy and belongs to the technical field of thermo-mechanical treatment of the aluminum alloy. The method includes the following steps of solution-and-quenching treatment, two-stage aging treatment and electromagnetic forming. Compared with an existing process including the steps of pre-deformation, solution and quenching, final deformation and artificial aging, the novel electromagnetic forming and aging thermal treatment combined method has the beneficial effects that the defects that the existing treatment process is complex, secondary deformation is likely to be caused, and use performance is lowered are overcome, the manufacturing process route for strengthening the aluminum alloy through thermal treatment is simplified, and the phenomena of secondary deformation and performance degradation in a traditional manufacturing process are avoided; and it is proved by tests that an aluminum alloy component formed through the method is free of obvious secondary deformation, and the intensity and plasticity of materials are improved compared with materials obtained through the traditional process. The thermo-mechanical treatment method of the aluminum alloy can be widely used for the fields of aerospace and the industry.

Owner:HUAZHONG UNIV OF SCI & TECH

High-modulus and low-shrinkage type activated polyester industry yarn and preparation method thereof

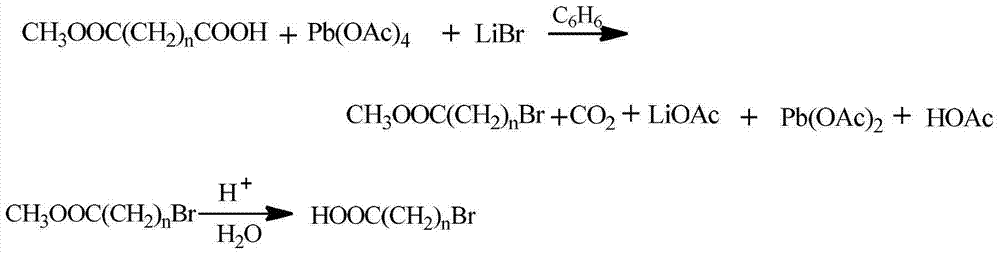

ActiveCN104499081AIncreased free volumeIncrease polarityNew-spun product collectionMelt spinning methodsPolyesterFiber

The invention relates to a high-modulus and low-shrinkage type activated polyester industry yarn and a preparation method thereof. The high-modulus and low-shrinkage type activated polyester industry yarn is prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 10-15v / v% when the high-modulus and low-shrinkage type activated polyester industry yarn is at 70-80 DEG C, a part of activating agent molecules are dispersed into fiber gaps, more -OHs and -NHs with strong activity are introduced, and the reactivity of the polyester fiber is improved; and the high-modulus and low-shrinkage type activated polyester industry yarn can be applied to light trucks, canvas conveyer belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

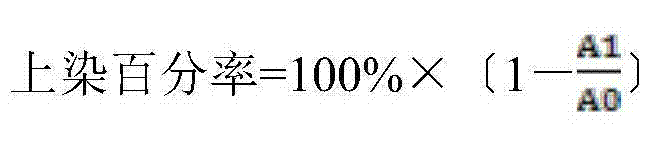

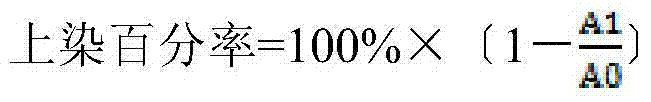

Polyester fiber DTY (draw textured yarn) with high dyeing rate and preparation method thereof

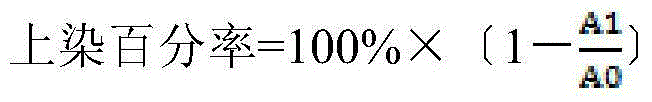

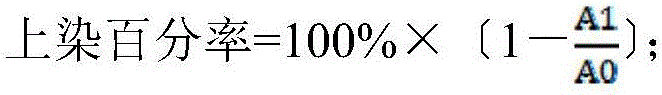

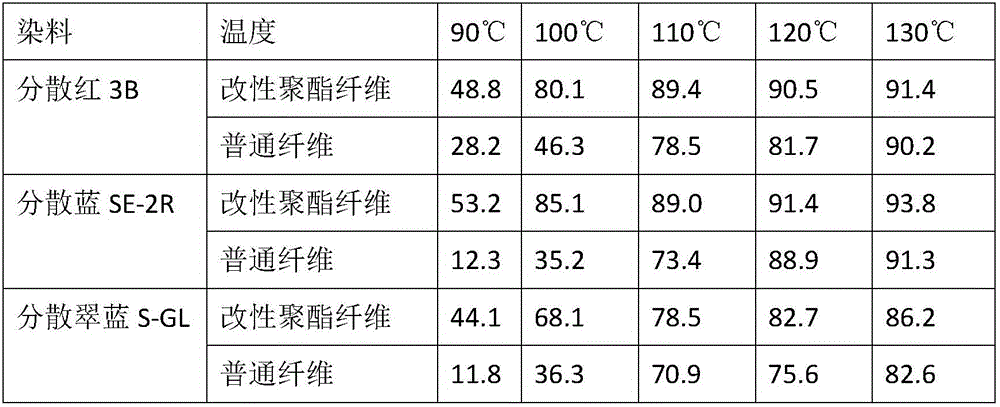

ActiveCN104499082AImprove dye uptakeGood flexibilityNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to a polyester fiber DTY (draw textured yarn) with high dyeing rate and a preparation method thereof. The polyester fiber polyester fiber DTY with high dyeing rate is made from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-30v / v% when the polyester fiber DTY with high dyeing rate is at 90-130 DEG C, the dying rate of the polyester fiber DTY with high dyeing rate is higher than that of the common fiber when the polyester fiber DTY with high dyeing rate adopts the same dyes such as disperse red 3B, disperse blue SE-2R, disperse bright blue S-GL and the like, less surface dyeing is formed after dyeing, and the polyester fiber DTY with high dyeing rate can be used for garment materials, bedding article decoration and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Porous soft polyester fiber FDY yarn and preparing method thereof

ActiveCN106381547AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureYarnFiber

The invention relates to a porous soft polyester fiber FDY yarn and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the porous soft polyester fiber FDY yarn; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. the porous soft polyester fiber FDY yarn is prepared by metering modified polyester slices, extruding, cooling, oiling, stretching, thermoforming and reeling the material. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing hexanediol are subjected to a reaction to obtain the terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The yarn has excellent fiber performance, the linear density deviation ratio is less than or equal to 0.5%, the breaking tenacity CV value is less than or equal to 4.0%, breaking elongation CV value is less than or equal to 8.0%, and a yarn unevenness CV value is less than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

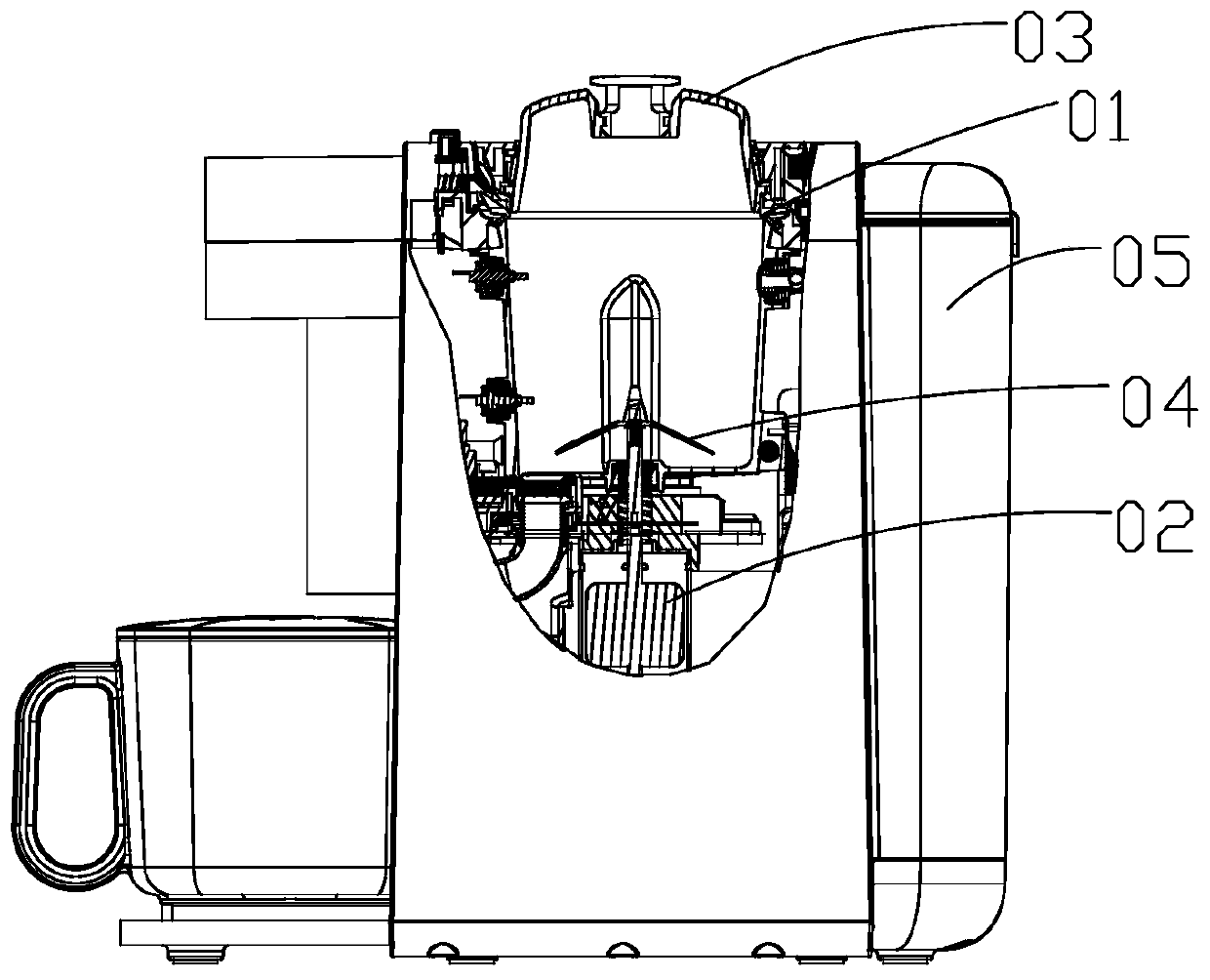

Automatic cleaning method of food processor

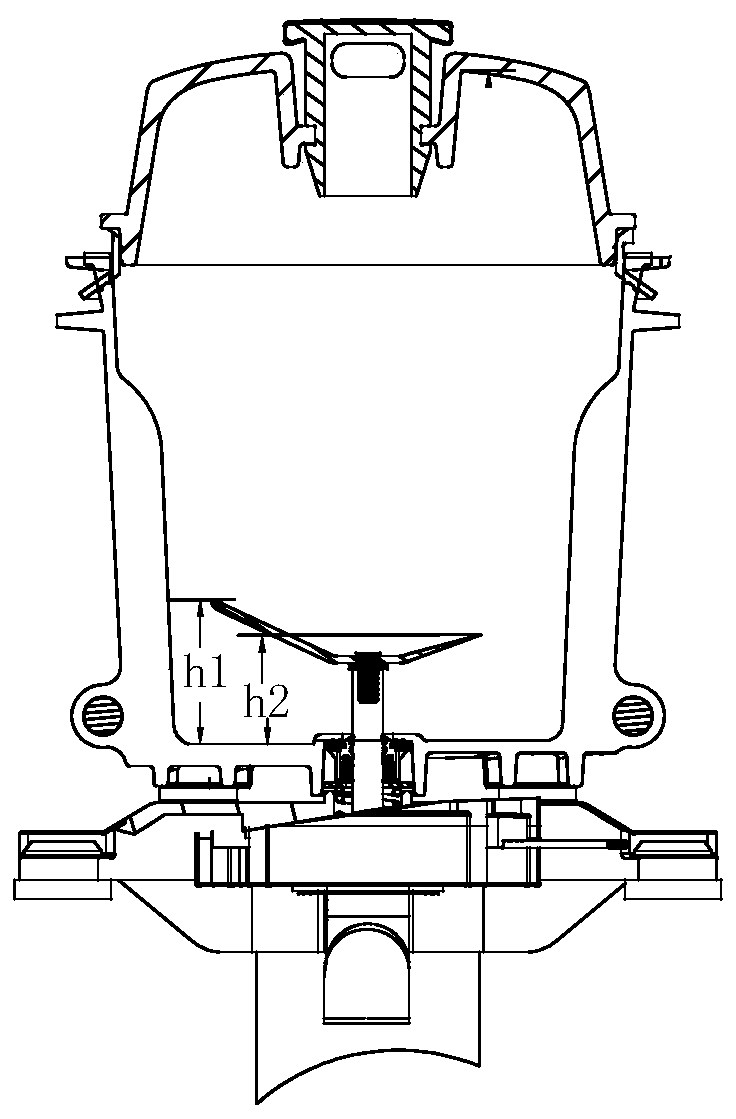

ActiveCN110236423AEasy to cleanPromote infiltrationKitchen equipmentCleaning using liquidsMechanical engineeringWater consumption

The invention discloses an automatic cleaning method of a food processor. The food processor comprises a machine body and a smashing assembly arranged on the machine body. The smashing assembly comprises a smashing cup body, a smashing cup cover, a smashing motor and smashing blades. The smashing cup cover is matched with the smashing cup body to form a smashing cavity. An output shaft of the smashing motor extends into the smashing cavity. The smashing blades are positioned in the smashing cavity and are connected to an output shaft of the smashing motor. The smashing cavity is automatically cleaned after the pulping of the food processor is completed. The automatic cleaning process at least comprises a diffusion cleaning stage and a flow gathering cleaning stage. The water consumption of the diffusion cleaning stage is V0, and the water consumption of the flow gathering cleaning stage is V1. V1 is larger than or equal to V0. In the cleaning process, the cleaning process is divided into the diffusion cleaning stage and the flow gathering cleaning stage. Based on the water amount control during the above two stages, different types of residues can be cleaned.

Owner:JOYOUNG CO LTD

Porous super-bright polyester fiber and preparation method thereof

ActiveCN104532392AGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

Owner:JIANGSU HENGLI CHEM FIBER

Porous super-soft cotton-like polyester fiber, and preparation method thereof

ActiveCN106400168AImprove cooling effectImprove fiber propertiesNew-spun product collectionHollow filament manufactureBreaking strengthYarn

The invention relates to a porous super-soft cotton-like polyester fiber, and a preparation method thereof. According to the preparation method, the porous super-soft cotton-like polyester fiber is prepared from modified polyester via porous spinneret plate spinning; spinneret orifices on a porous spinneret plate are arranged in an elliptical manner, wherein the orifice centers of the spinneret orifices are arranged in a series of concentration ellipses, the long axes of the concentration ellipses are collinear, and the short axes are collinear. The porous super-soft cotton-like polyester fiber is prepared from modified polyester POY yarn and modified polyester FDY yarn. A preparation method of the modified polyester comprises following steps: terephthalic acid is reacted with ethanediol so as to obtain ethanediol terephthalate, terephthalic acid and hexanediol containing branch chains are added are reacted so as to obtain dihydric alcohol terephthalate, and continuous reaction is carried out so as to obtain the modified polyester. The performance of the obtained porous super-soft cotton-like polyester fiber is excellent; linear density deviation ratio is equal to or less than 2.0%; breaking strength CV value is equal to or less than 4.0%; breaking elongation CV value is equal to or less than 8.0%; and crimp contraction variable coefficient CV value is equal to or less than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

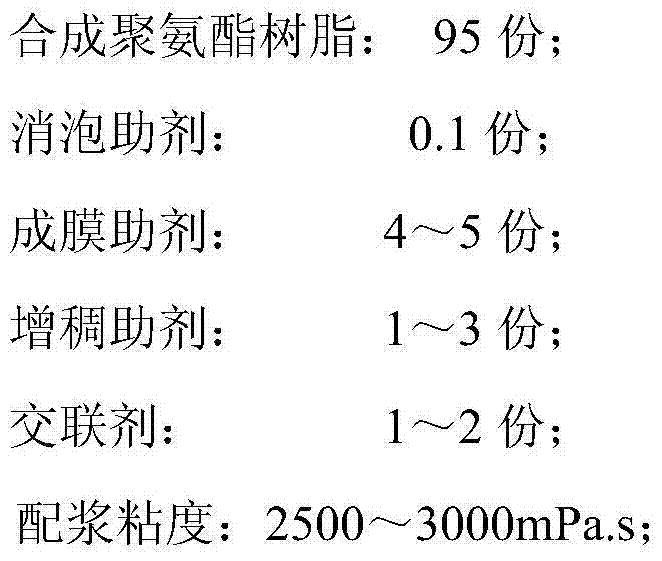

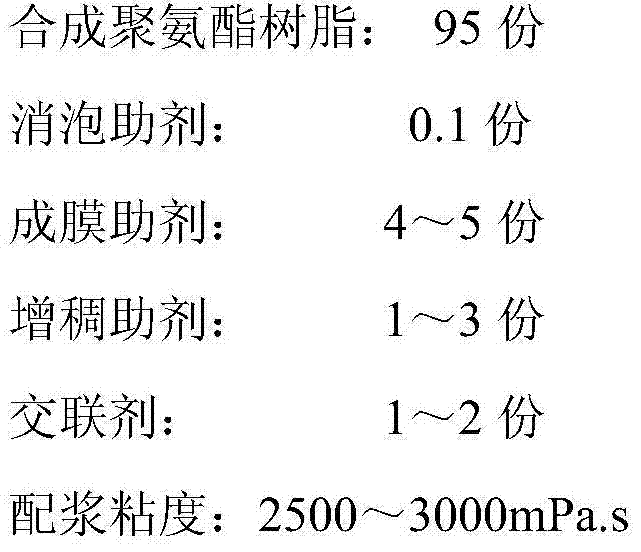

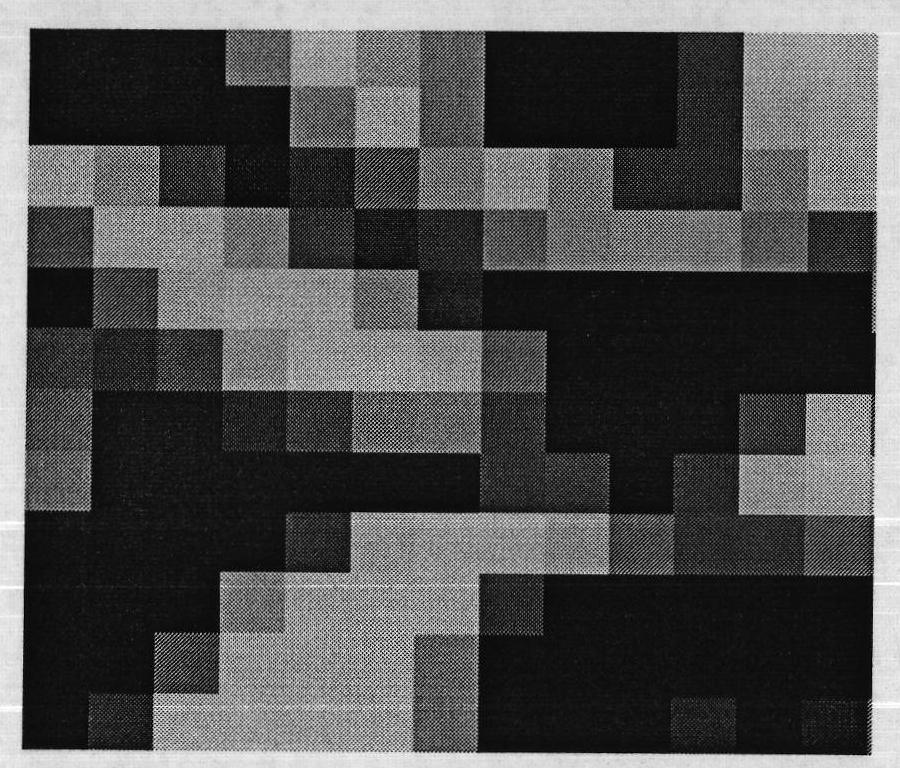

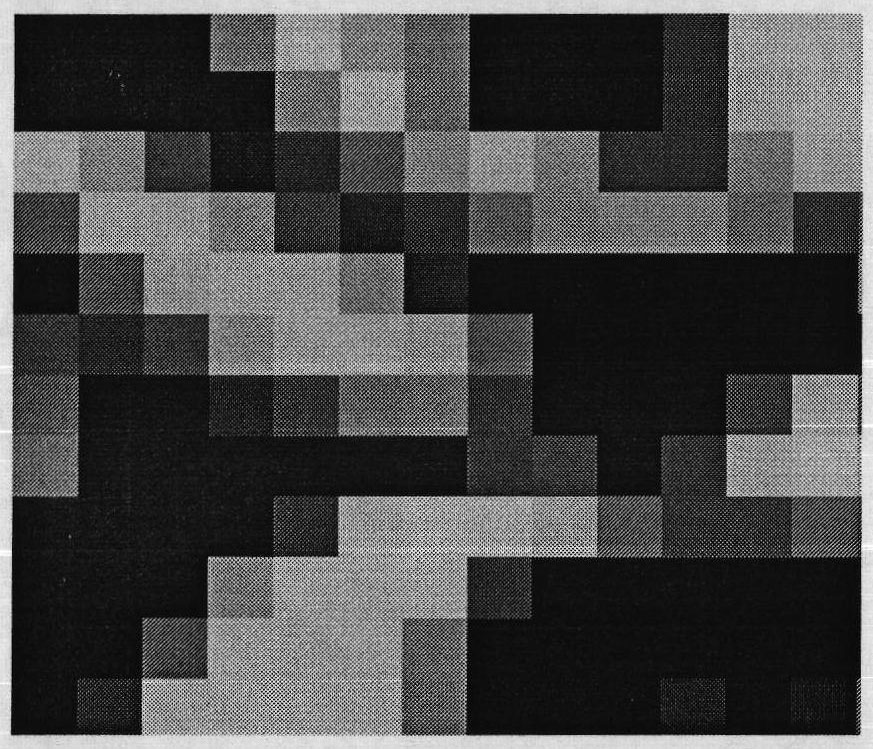

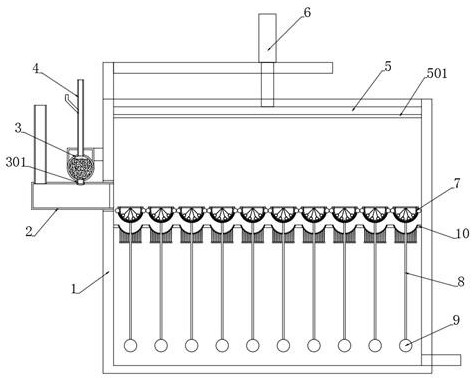

Polyurethane coated fabric and preparation method thereof

ActiveCN104499083AIncreased free volumeImprove efficiencyNew-spun product collectionFibre typesPolyesterYarn

The invention relates to a polyurethane coated fabric and a preparation method thereof. The polyurethane coated fabric comprises a fabric layer and a polyurethane coating, the warps and the wefts of the fabric layer are polyester industry yarns for the polyurethane coated fabric, the polyester industry yarns for the polyurethane coated fabric are made from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-40v / v% when the polyester industry yarns for the polyurethane coated fabric are at 100-150 DEG C, the polyurethane coated fabric and the polyurethane have good interface bonding effect, and the polyester industry yarns for the polyurethane coated fabric can be used for improving the appearance of the fabric.

Owner:JIANGSU HENGLI CHEM FIBER

Magnesium-based wear-resistant damping alloy material and preparation method thereof

InactiveCN101781729ASmall mechanical propertiesInhibit synthesisChemical compositionDamping function

The invention provides a magnesium-based wear-resistant damping alloy material and a preparation method thereof. A matrix of the alloy material is provided with a stable plate compound, the damping function of an alloy is improved. The method has the advantages of simple process, low production cost, and suitability for industrial production. In the alloy material, a magnesium alloy is taken as the matrix, and compound complexes are uniformly distributed on the matrix of the magnesium alloy. The alloy material comprises the following chemical compositions in percentage by weight: 5 to 9 percent of Al, 2 to 4 percent of Sr, 2 to 3 percent of Sn, 0.5 to 3 percent of Fe, 0.03 to 0.09 percent of C, 0.5 to 1.5 percent of Dy, 1.1 to 3 percent of Y, 0.5 to 2 percent of La, and the balance of Mg.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Superhydrophobic polyester resin powder paint

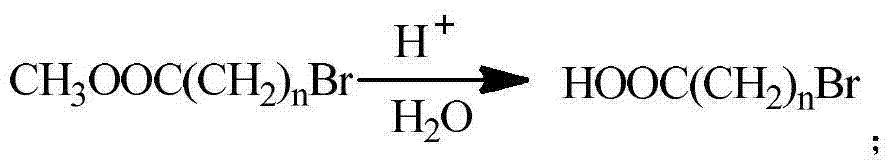

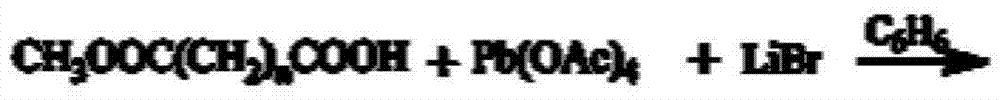

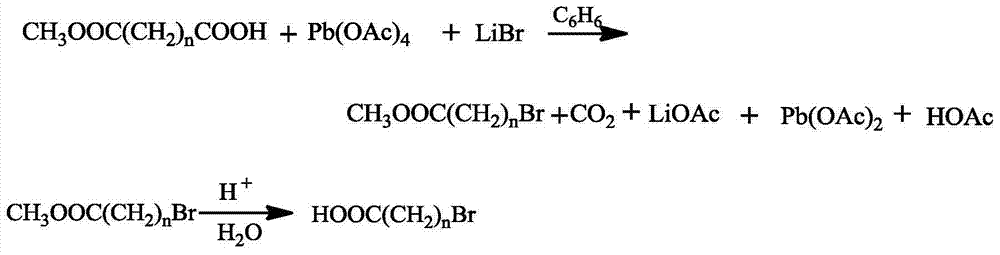

InactiveCN105694682AIncrease the degree of diffusionHigh purityPowdery paintsBituminous coatingsAluminium hydroxideAntioxidant

The invention discloses a superhydrophobic polyester resin powder coating, the raw materials of which include by weight: 45-50 parts of polyester resin, 22-26 parts of phenolic resin, 17-20 parts of hydroxyl acrylic resin, 13-20 parts of fluorine-containing hydrophobic material 16 parts, 8-12 parts of asphalt, 6-9 parts of magnesium carbonate, 6-8 parts of aluminum hydroxide powder, 1-3 parts of barium sulfate, 2-3 parts of zinc powder, 3-5 parts of curing agent, 2 parts of leveling agent -5 parts, 1-2 parts of matting agent, 1-3 parts of antioxidant, 1-2 parts of pigment dispersant. The superhydrophobic polyester resin powder coating proposed by the invention has excellent hydrophobic performance and is a powder coating with good antirust performance.

Owner:安徽圣德建材科技有限公司

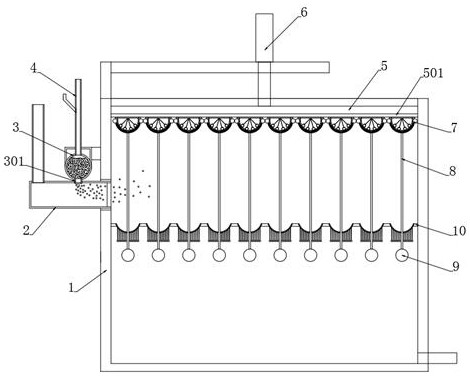

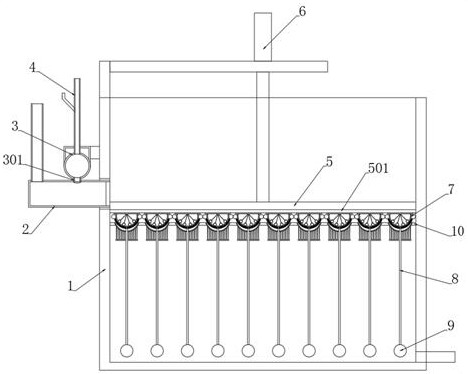

Greasy dirt flocculation deoiling device for industrial sewage

InactiveCN111606456AFully dispersedGood flocculation effectFatty/oily/floating substances removal devicesWater contaminantsEnvironmental engineeringSewage

The invention discloses a greasy dirt flocculation deoiling device for industrial sewage. The invention belongs to the technical field of sewage treatment. Upper elliptic adsorption layers coating thebottom end parts of adsorption floating balls are used for adsorbing greasy dirt flocculation particles on the water surface. After the flocculation operation is finished, sewage is discharged, the adsorption floating balls sink and abut against filtering oil guide mechanisms, meanwhile, an electric push rod presses down a sealing plate to enable the sealing plate to abut against the adsorption floating balls again, an electromagnet is electrified to magnetically attract a magnetic sealing cover plate, the electric push rod resets upward, the magnetic sealing cover plate and a gas stamping mechanism are pulled upwards, the gas stamping mechanism is separated from the filter holes of elliptic floating balls, sodium peroxide in the elliptic floating balls is diffused outwards to the upper elliptic adsorption layers through the filter holes, sodium peroxide powder generates sodium hydroxide and oxygen which can decompose greasy dirt particles when encountering water, the oxygen is used for scattering condensed particles to enable the greasy dirt particles to fall off easily, the gas stamping mechanism releases gas after being pulled to be broken, and the diffusion degree of the sodium peroxide powder is effectively improved.

Owner:施德琴

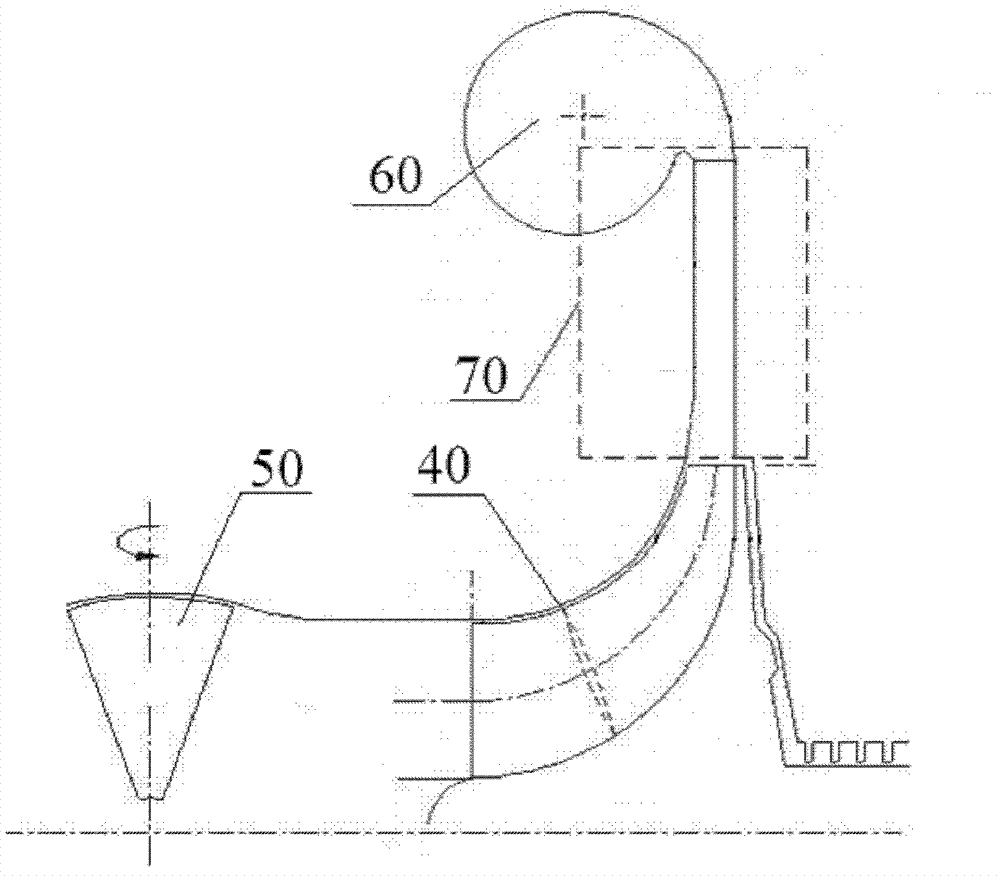

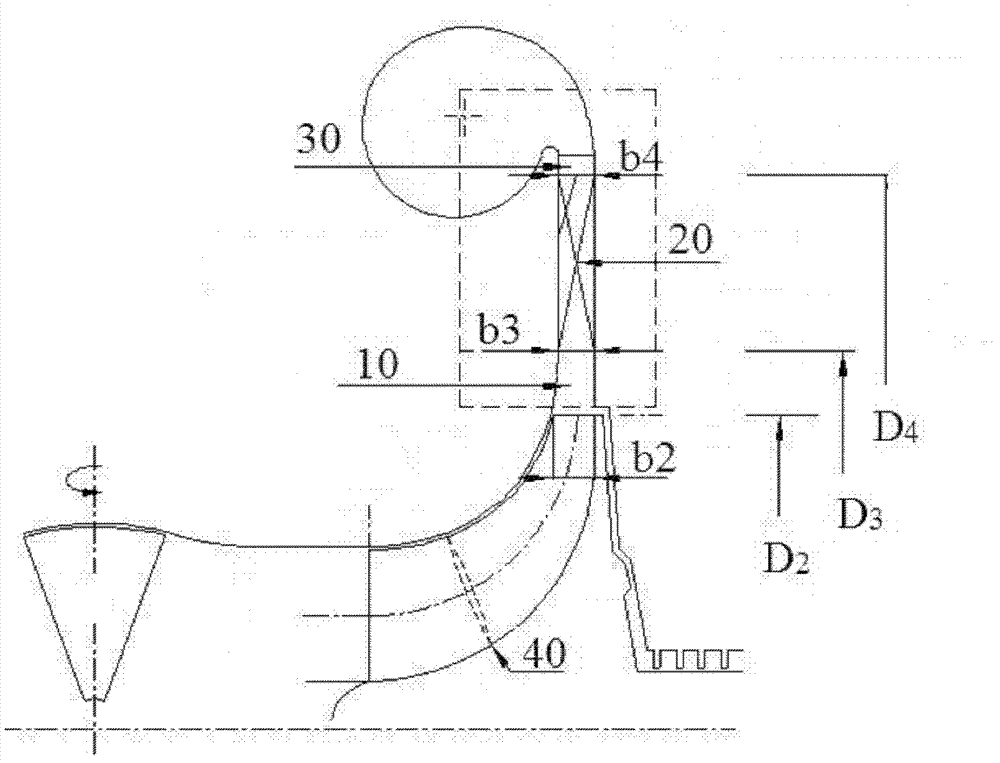

Low-denseness blade diffuser and production method thereof

ActiveCN103244461AIncrease the degree of diffusionReduce power consumptionPump componentsPumpsImpellerEngineering

The invention provides a low-denseness blade diffuser and a production method thereof. The low-denseness blade diffuser is arranged between an outlet of vane wheels and an inlet of volutes of a compressor, and comprises a non-blade inlet section, a low-denseness blade section and a non-blade outlet section. The inlet of the non-blade entrance section is communicated with the outlet of the vane wheels, blades are arranged inside the low-denseness blade section, and the inlet of the low-denseness blade section is communicated with the outlet of the non-blade inlet section, the inlet of the non-blade outlet section is communicated with the outlet of the low-denseness blade section and the outlet of the same is communicated with the inlet of the volutes. The low-denseness blade diffuser has the advantages that diffusion degree of the diffuser is improved, wasted works of the compressor is reduced and efficiency is improved by adopting the low-denseness blade; and the non-blade sections are addedly arranged on the front and back of the blade section to overcome defects of regular poor adaptability of variable working conditions of the blade diffuser, impact losses under variable working conditions are reduced, and working ranges of the compressor are widened.

Owner:GREE ELECTRIC APPLIANCES INC

Polyester paralleling composite yarn and prepared method thereof

ActiveCN104499091AGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to a polyester paralleling composite yarn. The polyester paralleling composite yarn is prepared from PBT (polybutylece terephthalate) and modified polyester PET (polyethylene terephthalate) chips through parallel composite spinning, wherein the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 20-30v / v% when the polyester of the polyester paralleling composite yarn is at 90-130 DEG C, the dying rate of the polyester paralleling composite yarn is higher than that of the common fiber when the polyester paralleling composite yarn adopts disperse red 3B and the like, less surface dyeing is formed after dyeing, and the polyester paralleling composite yarn has wide application prospect in the field of garment materials.

Owner:JIANGSU HENGLI CHEM FIBER

Porous PBT fiber DTY (drawn textured yarn) and preparation method thereof

ActiveCN106283258AImprove cooling effectImprove fiber propertiesHollow filament manufactureMelt spinning methodsFiberBreaking strength

The invention relates to porous PBT fiber DTY (drawn textured yarn) and a preparation method thereof. The porous PBT fiber DTY is prepared from modified PBT through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged in an ellipse, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The porous PBT fiber DTY is prepared from the modified PBT through metering, extruding, cooling, oiling and winding; a preparation method of the modified PBT comprises the following steps: terephthalic acid and 1,4-butanediol react to prepare butanediol 1,4-terephthalate, terephthalic acid and diol containing branched chains are added for a reaction, diol terephthalate is prepared and continuously subjected to a reaction, and modified PBT is obtained. The prepared DTY has excellent performance, the linear density deviation is lower than or equal to 0.2%, the breaking strength CV value is smaller than or equal to 2.5%, and the breaking elongation CV value is smaller than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous flax-like polyester fiber and preparation method thereof

ActiveCN106400164AIncrease the degree of diffusionImprove dyeing performanceFilament/thread formingMonocomponent copolyesters artificial filamentPropylene glycolLinear density

The invention relates to a porous flax-like polyester fiber and a preparation method thereof. The porous flax-like polyester fiber is prepared by spinning modified polyester by using a porous spinneret plate, wherein spinneret holes in the porous spinneret plate are elliptically arrayed; i.e., the centers of the spinneret holes are located on concentric ellipses which are series ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are also collinear. The porous flax-like polyester fiber is prepared from modified polyester POY yarns and modified polyester FDY yarns through process. A preparation method for the modified polyester comprises the following steps: reacting terephthalic acid with glycol to prepare ethylene terephthalate; adding dihydric alcohol terephthalate prepared through reaction of terephthalic acid with propylene glycol containing a branched chain; and continuing reaction so as to obtain the modified polyester. The fiber prepared in the invention has following excellent properties: a linear density deviation ratio of no more than 2.0%, a breaking tenacity CV value of no more than 4.0%, a breaking elongation CV value of no more than 8.0%, and a crimp contraction variation coefficient CV value of no more than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

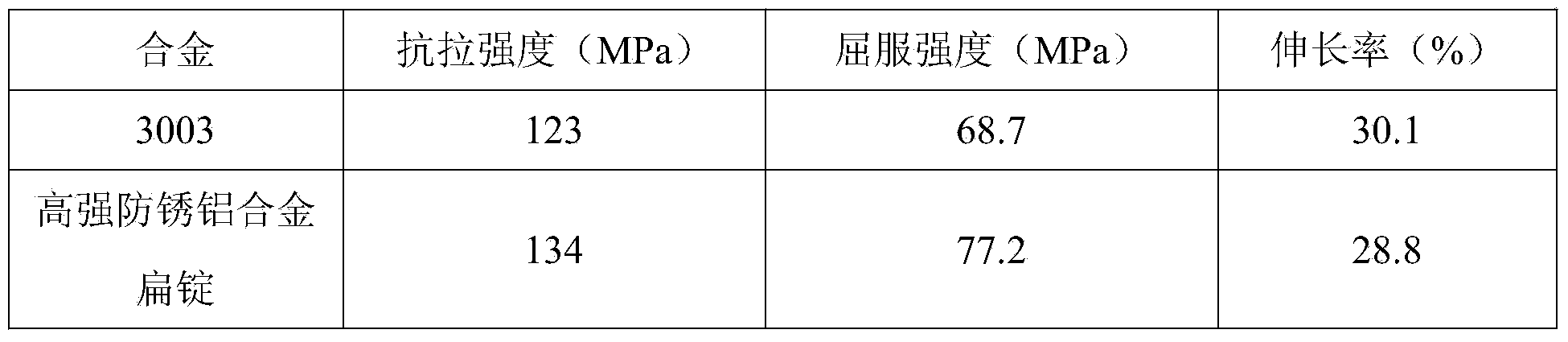

Manufacturing method of high-strength antirust aluminum alloy slab ingot

ActiveCN104264015AIncrease productivityIncrease the degree of diffusionIngotUltimate tensile strength

The invention discloses a manufacturing method of a high-strength antirust aluminum alloy slab ingot and relates to a manufacturing method of an aluminum alloy slab ingot. The manufacturing method solves the problems that a core of an existing composite material is mainly a 3003 alloy, but the 3003 alloy hardly meets the requirements of the current market on the high-performance composite material due to low alloying degree and low strength. The method comprises the following steps: 1, melting, and 2, forming, so that the high-strength antirust aluminum alloy slab ingot is obtained. The manufacturing method is used for manufacturing the high-strength antirust aluminum alloy slab ingot.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Super-soft wool-like porous polyester and preparation method thereof

ActiveCN106319678AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentWoolPropylene glycol

The invention relates to super-soft wool-like porous polyester and a preparation method thereof. The super-soft wool-like porous polyester is prepared from modified polyester through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The super-soft wool-like porous polyester is prepared from modified polyester POY and modified polyester FDY through processing; a preparation method of the modified polyester comprises the following steps: terephthalic acid and ethylene glycol react to prepare ethylene glycol terephthalate, terephthalic acid and propylene glycol containing branched chains are added for a reaction, glycol terephthalate is prepared and continuously subjected to a reaction, and modified polyester is obtained. The prepared fiber has excellent performance, the linear density deviation is lower than or equal to 2.0%, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, and the crimp contraction variation coefficient CV value is lower than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Modified polyester and preparation method thereof

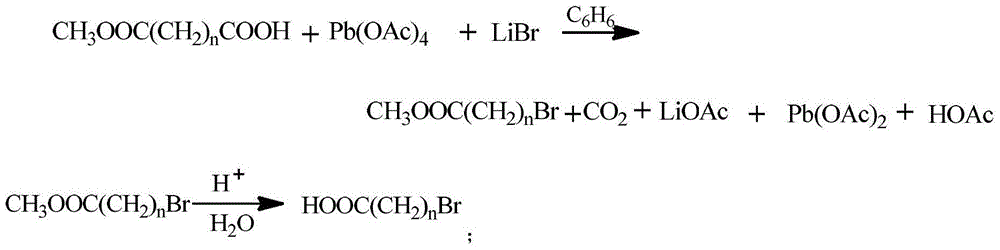

ActiveCN106380580AIncrease the degree of diffusionImprove dyeing performanceMonocomponent copolyesters artificial filamentDyeing processChemistryDyeing

The invention relates to a modified polyester and a preparation method thereof. The modified polyester is composed of a terephthalic acid segment, a glycol segment, and a branch chain containing dihydric alcohol segment. The branch chain of the branch chain containing dihydric alcohol segment is positioned on one non-terminal carbon of the branch chain containing dihydric alcohol segment, is a straight carbon chain, and contains 5 to 10 carbon atoms. The preparation method comprises the following steps: carrying out esterification reactions between terephthalic acid and branch chain containing dihydric alcohol in the presence of concentrated sulfuric acid to obtain dihydric alcohol terephthalate; then carrying out esterification reactions between terephthalic acid and glycol to obtain ethylene terephthalate; stirring and mixing dihydric alcohol terephthalate and ethylene terephthalate, in the presence of a catalyst and a stabilizing agent, and carrying out condensation reactions in a low vacuum stage and a high vacuum stage to obtain modified polyester. The increased space between the gaps among molecular chains in polyester is far greater than that of branch chain free polyester at a same temperature, so small particles such as dye can more easily enter the interior of modified polyester, and the dyeing speed is increased.

Owner:JIANGSU HENGLI CHEM FIBER

Low-shrinkage type activated polyester industrial filament and preparation method thereof

ActiveCN104480563AGood flexibilityGood compatibilityOrganic compound preparationNew-spun product collectionBreaking strengthPolyester

The invention relates to a low-shrinkage type activated polyester industrial filament and a preparation method thereof. The low-shrinkage type activated polyester industrial filament is made of modified polyester; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among molecular chains of the polyester and has hydrogen-bond interaction to the polyester, so that the relative positions of the molecular chain of the amino fatty acid gylcol ester and the polyester are fixed; under the condition of 70-80 DEG C, the free volume space of a part of the molecular chains inside the low-shrinkage type activated polyester industrial filament is increased by 10-15v / v%, the breaking strength of the low-shrinkage type activated polyester industrial filament is greater than or equal to 7.6 cN / dtex, and the core absorption height is less than or equal to 5 mm. A part of molecules of an activating agent are diffused and enter fiber gaps, and more -OH and -NH with relatively high activity are introduced into polyester molecules, so that the reactivity of the polyester fiber is improved. The low-shrinkage type activated polyester industrial filament can be used in apron fabrics, radial tire builder fabrics, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com