Automatic cleaning method of food processor

A food processing machine, automatic cleaning technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of non-detachable cups, easy breeding of bacteria, and hidden food safety hazards, etc., to achieve Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

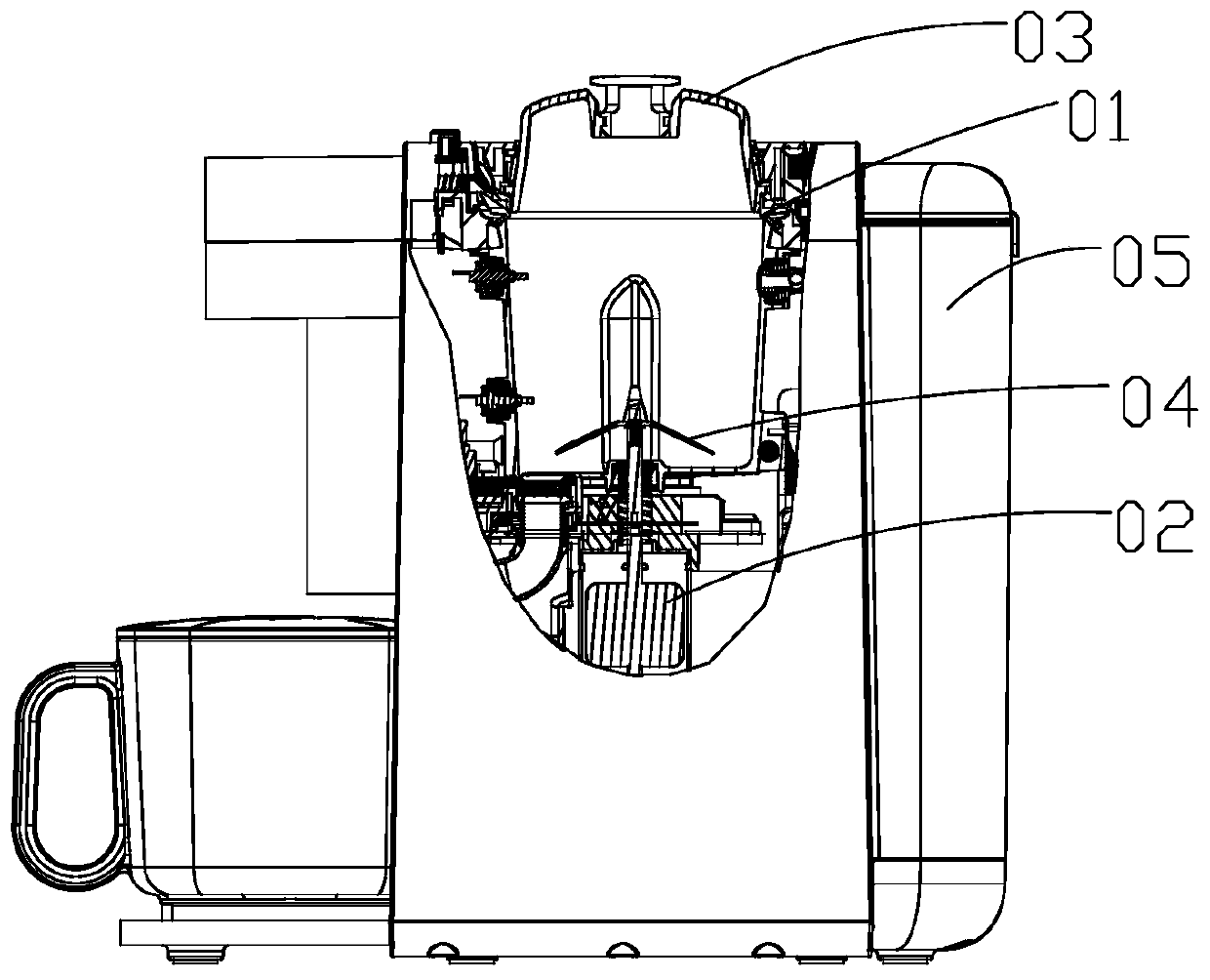

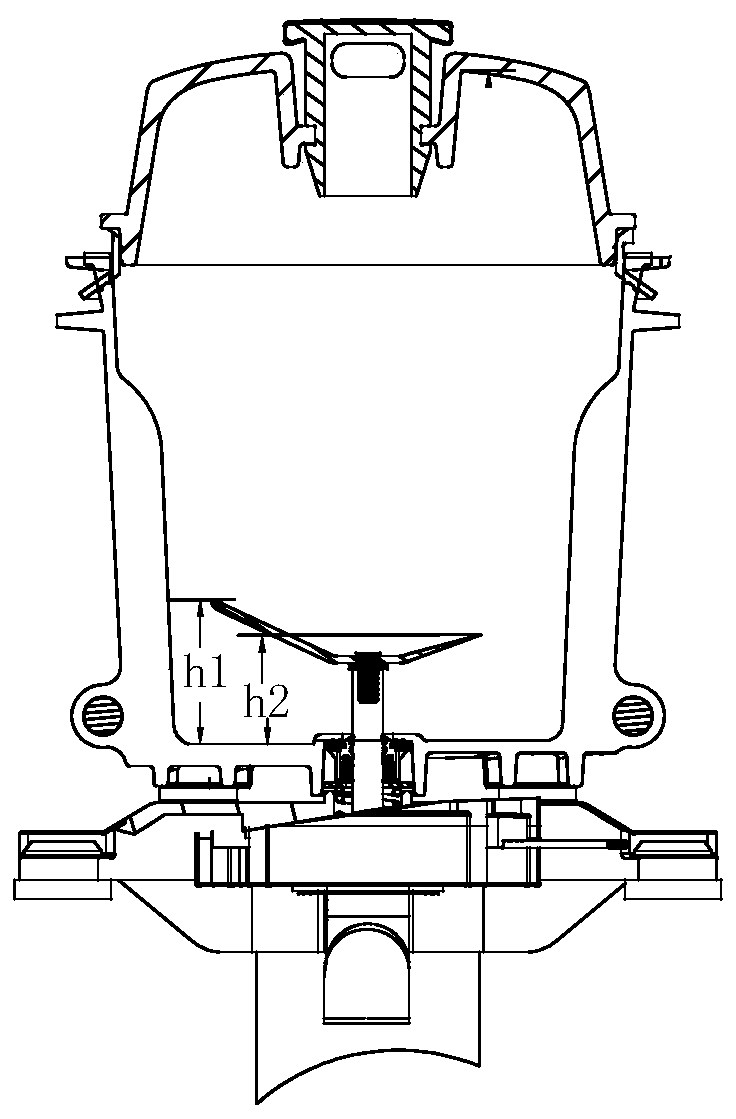

[0023] Such as figure 1 Shown is the structural representation of the food processing machine in the present invention. Including the machine body and the crushing assembly located on the body, the crushing assembly includes a crushing cup body 01, a crushing cup cover 03, a crushing motor 02 and a crushing blade 04, the crushing cup cover 03 and the crushing cup body 01 cooperate to form a crushing chamber, and the output of the crushing motor 02 The shaft extends into the crushing chamber, and the crushing blade 04 is located in the crushing chamber and connected to the output shaft of the crushing motor 02. The food processor is also provided with a water tank 05, and the water tank 05 supplies water to the crushing cup body 01. When the material is crushed to form a slurry, in addition, water can be supplied for cleaning the area of the food processor, that is, the crushing chamber.

[0024] The food processing machine automatically cleans the crushing cavity after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com