Low-denseness blade diffuser and production method thereof

A manufacturing method and low-consistency technology, applied to machines/engines, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problems of low efficiency and poor adaptability of vane diffusers, and achieve The effect of widening the working range, improving efficiency and increasing the degree of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

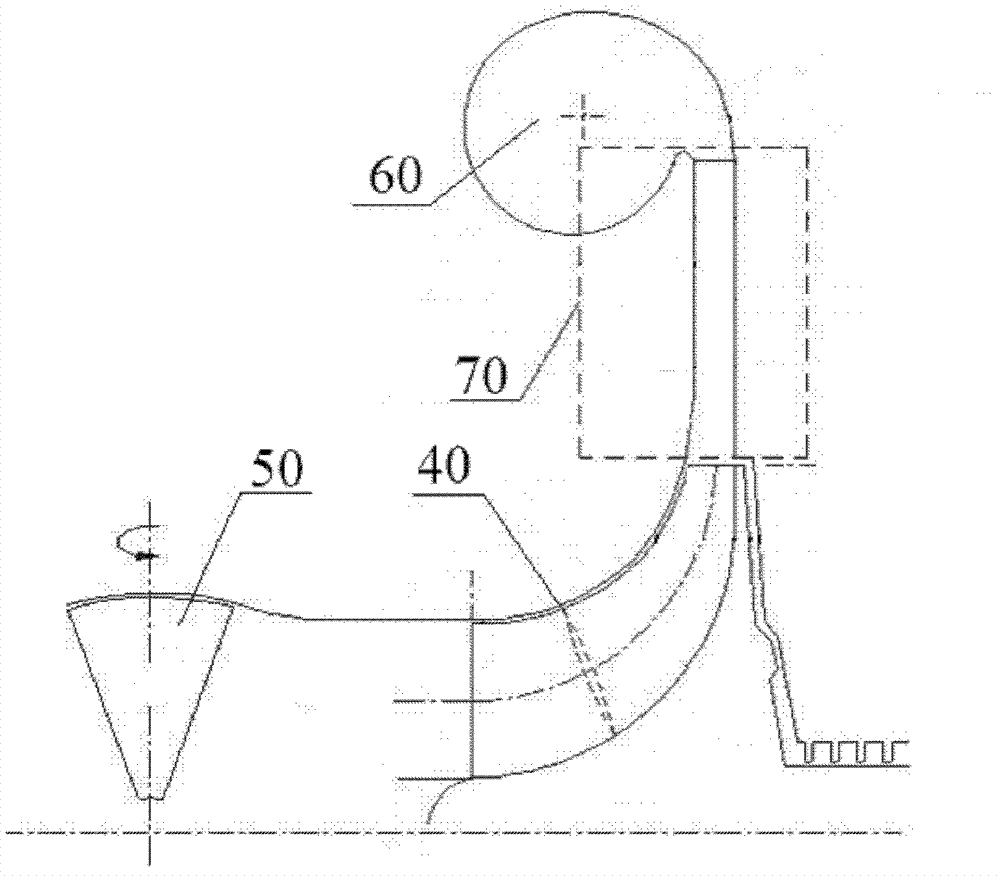

[0027] The invention adopts low-consistency blades to mainly increase the diffusion degree, and adopts a bladeless diffuser to evenly flow the airflow before the airflow enters the blades and after it flows out of the blades, so that the entire diffuser can work normally in a wide operating range , and obtain high-efficiency diffusion, thereby reducing compressor power consumption.

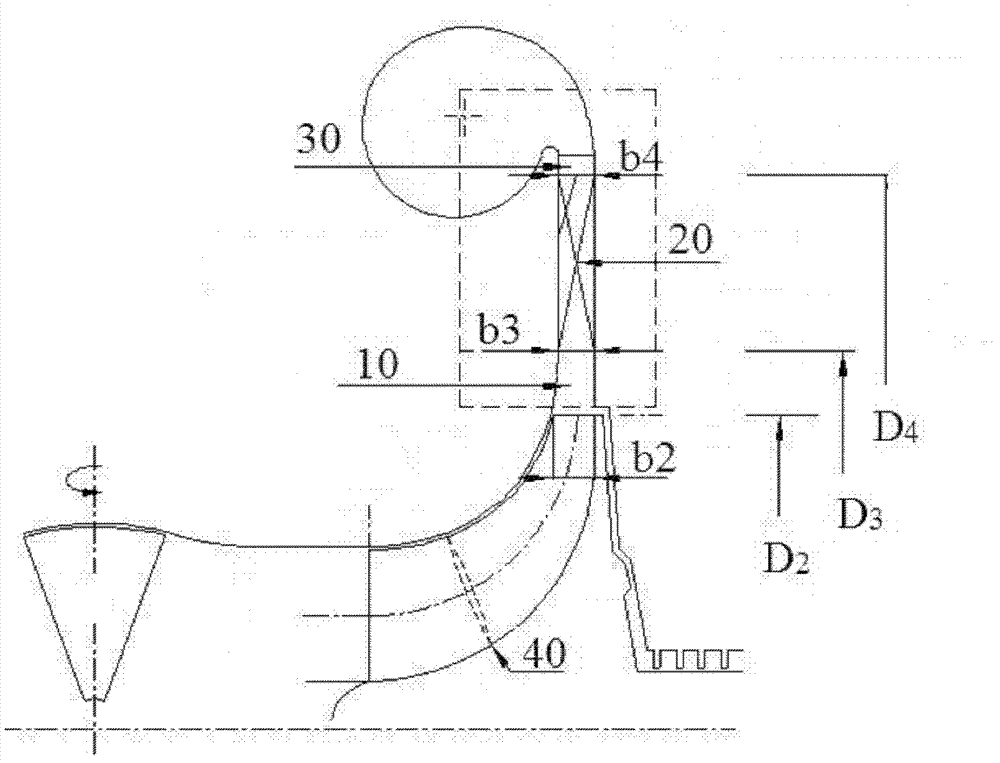

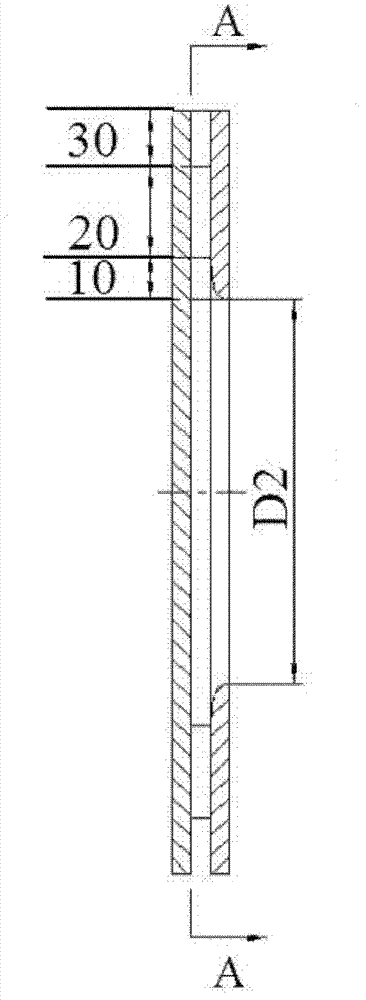

[0028] Such as figure 2 , image 3 As shown, the low-consistency vane diffuser of the present invention consists of an inlet vaneless section 10 , a low-consistency vane section 20 and an outlet vaneless section 30 . The low-consistency blade diffuser of the present invention mainly has the following characteristics:

[0029] The inlet bladeless section 10 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com