Thermo-mechanical treatment method for aluminum alloy

A technology of deformation heat treatment and aluminum alloy, which is applied in the field of electromagnetic forming and aging composite, can solve the problems of heat treatment difficulty, application range limitation, and performance degradation of aluminum alloy formed components, so as to avoid heat treatment, secondary deformation and performance reduction, and simplify Manufacturing process route, effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0026] Take 2 groups of tensile samples (two samples in each group) for solution quenching treatment, and keep the samples in a heating furnace at a temperature of 535°C for 40min. Then double-stage aging treatment, wherein the pre-aging temperature is 140°C, the pre-aging time is 2h, the final aging temperature is 180°C, and the final aging time is 6h. The last group of samples was placed into the mold for electromagnetic uniaxial stretching, with a discharge energy of 10.63kJ and a deformation of 20%. Throughout the process see Figure 6 shown. The aluminum alloy member processed and formed was tested, and its tensile strength was 441MPa, and its elongation after fracture was 21%. Prior Art The 2219 aluminum alloy studied by An Lihui et al. (Trans.NonferrousMet.Soc.China., 2012, 370(75)) is obtained by pre-deformation-solution quenching-final deformation-artificial aging process scheme, according to the same specification Tested, the tensile strength of its components is ...

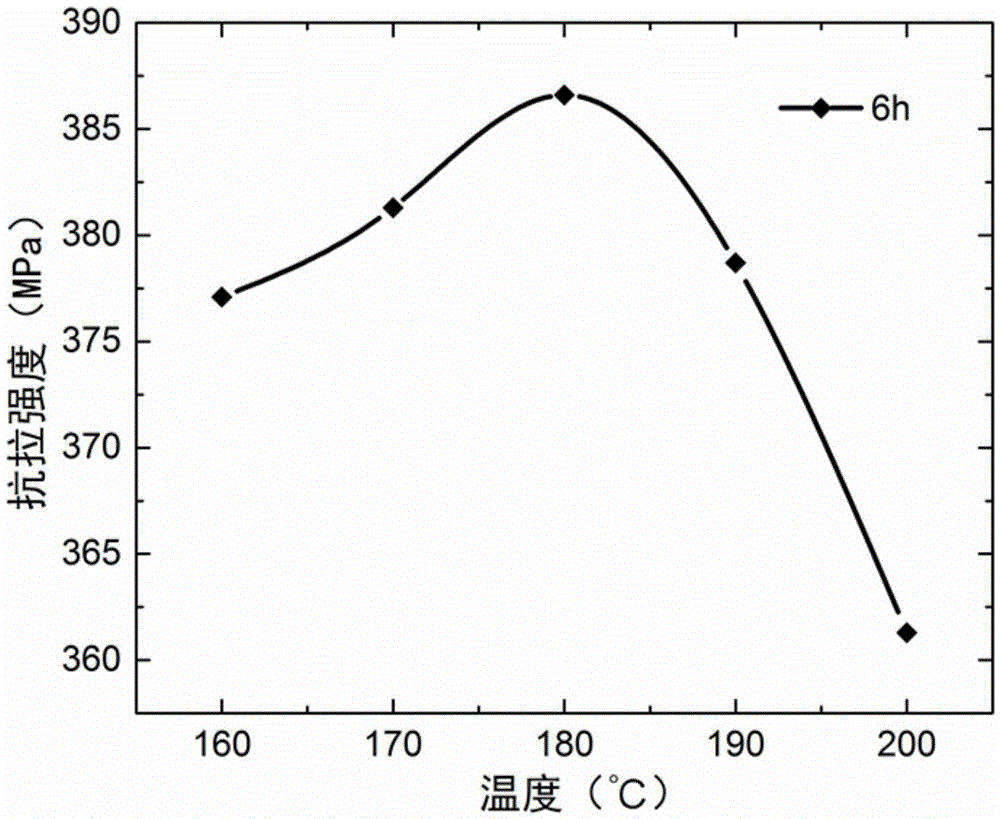

Embodiment 2

[0028] A group of tensile samples were taken for solution quenching treatment, and the samples were kept in a heating furnace at a temperature of 530°C for 45 minutes. Then double-stage aging treatment, wherein the pre-aging temperature is 100°C, the pre-aging time is 2h, the final aging temperature is 170°C, and the final aging time is 4h. Finally, put it into the mold for electromagnetic uniaxial stretching, the discharge energy is 8.63kJ, and the deformation is 10%. The aluminum alloy member tested and formed has a tensile strength of 384MPa and an elongation after fracture of 27.3%. Compared with the existing technology, the strength is only slightly reduced, but the plasticity is greatly improved.

Embodiment example 3

[0030] Two tensile samples were taken for solution quenching treatment, and the samples were kept in a heating furnace at a temperature of 540°C for 35 minutes. Then double-stage aging treatment, wherein the pre-aging temperature is 160°C, the pre-aging time is 8h, the final aging temperature is 230°C, and the final aging time is 12h. Finally, put it into a mold for electromagnetic uniaxial stretching, with a discharge energy of 15.34kJ and a deformation of 24%. The aluminum alloy component formed by testing was tested, and its tensile strength was 390MPa, and its elongation after fracture was 15.2%. The strength is improved compared to the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com