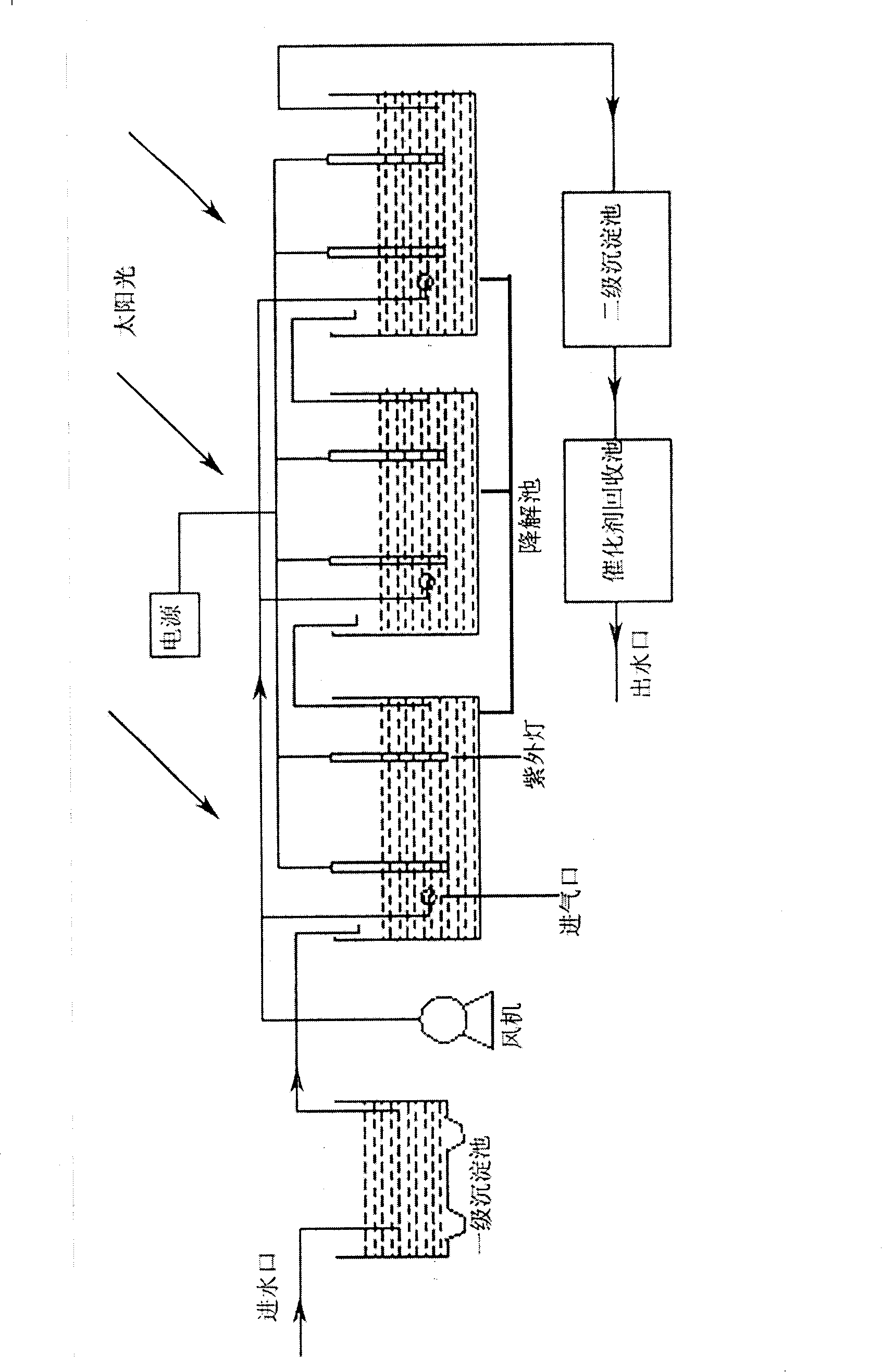

Photocatalysis oxidation treated high concentration organic trade waste

An industrial wastewater, high-concentration technology, applied in the direction of oxidized water/sewage treatment, catalyst carrier, energy wastewater treatment, etc., can solve the problems of complex components, water pollution and environmental hazards, and achieve high diffusion degree, high catalytic activity, and reduced pore size. The effect of internal surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Implementation Example 1: Measure 248.4 mL of concentrated hydrochloric acid and put it into a 500 mL volumetric flask, add water to dilute to the mark and shake well to prepare 6 mol / L hydrochloric acid. Measure 236.4mLTiCl 4 Concentrated solution, slowly added to a 2000mL beaker placed in an ice-water bath in a fume hood, and at the same time slowly added 263.60mL of prepared hydrochloric acid solution, and kept stirring rapidly until TiCl 4 All dissolved to get 4mol / L TiCl 4 solution. Accurately measure 9.37mL into a 500mL beaker, add water to 114mL, add 5mL AEO-3, 0.01mol / L FeCl 3 Solution 3.75mL, 9g activated carbon. Slowly add 3moL / lNH 3 until the pH value reaches 8-9. Aging for 10-40 hours, washed with water until Cl-free - . Exchange water with ethanol to obtain an alcohol gel, dry at 100°C, and calcinate the obtained catalyst in a muffle furnace at 600°C for 1 hour to obtain a supported nanocomposite photocatalyst. 4g of the obtained catalyst was used t...

Embodiment 2

[0032] Implementation Example 2: Accurately measure 10mL of 4mol / L TiCl 4 Put it into a 500ml beaker, add water to 120mL, add 10mL triethanolamine, stir for 1 hour; add 0.1mol / L Ce(NO 3 ) 3 solution, so that the mass percentage of Ti:Ce is 1:0.03, then add 9g of ZSM-5, and slowly add 1mol / L KOH dropwise until the pH value reaches 8-9. Then age for 10-40 hours, wash with water until it does not contain Cl - . Exchange water with ethanol to obtain an alcohol gel, move it to a high-pressure reactor for supercritical reaction, and calcinate the obtained catalyst in a muffle furnace at 550° C. for 1 hour to obtain a nanocomposite photocatalyst. The UV light was irradiated for 6 hours, and then the fluorescent lamp was irradiated for 8 hours. The amount of catalyst was 3.5g. The measured COD value in 300mL was 25000mg / L Rhodamine-6G, and the degradation rate of Rhodamine B was 98%.

Embodiment 3

[0033] Implementation Example 3: Accurately measure 9.37mL of 4mol / L TiCl 4 Put in a 500mL beaker and add water to 114mL, add 5mL AEO-9 and 0.1mol / L FeCl 3 The solution has a mass percentage of Ti:Fe of 1:0.02, then adds 9g of hollow glass beads, then slowly adds 0.1mol / L KOH until the pH value is 8-9, ages for 10-40 hours, and washes with water until there is no Cl - After that, the water was exchanged with ethanol, and supercritical drying was carried out for 0.5 hour to obtain alcohol gel. The alcohol gel was calcined at 500°C for 1.5 hours to obtain a composite photocatalyst supported by hollow glass spheres. Under the irradiation of ultraviolet light and visible light at the same time, the amount of catalyst was 2g to degrade 300mL salicylic acid with a concentration of 20000mg / L, and the COD degradation rate reached 95.5% in 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com