Patents

Literature

410 results about "Pulp fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water dispersible, pre-saturated wiping products

A water dispersible nonwoven web is disclosed. The nonwoven web is produced in an airlaying process and contains pulp fibers mixed with water soluble fibers. The water soluble fibers may be, for instance, polyvinyl alcohol fibers. The nonwoven web may be pre-saturated with a cleaning solution. Once pre-saturated with a cleaning solution, the wiping product is particularly well suited to cleaning and / or disinfecting surfaces, such as toilet seats prior to use. Because the nonwoven web is water dispersible, the wiper may be disposed of by being flushed down a toilet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

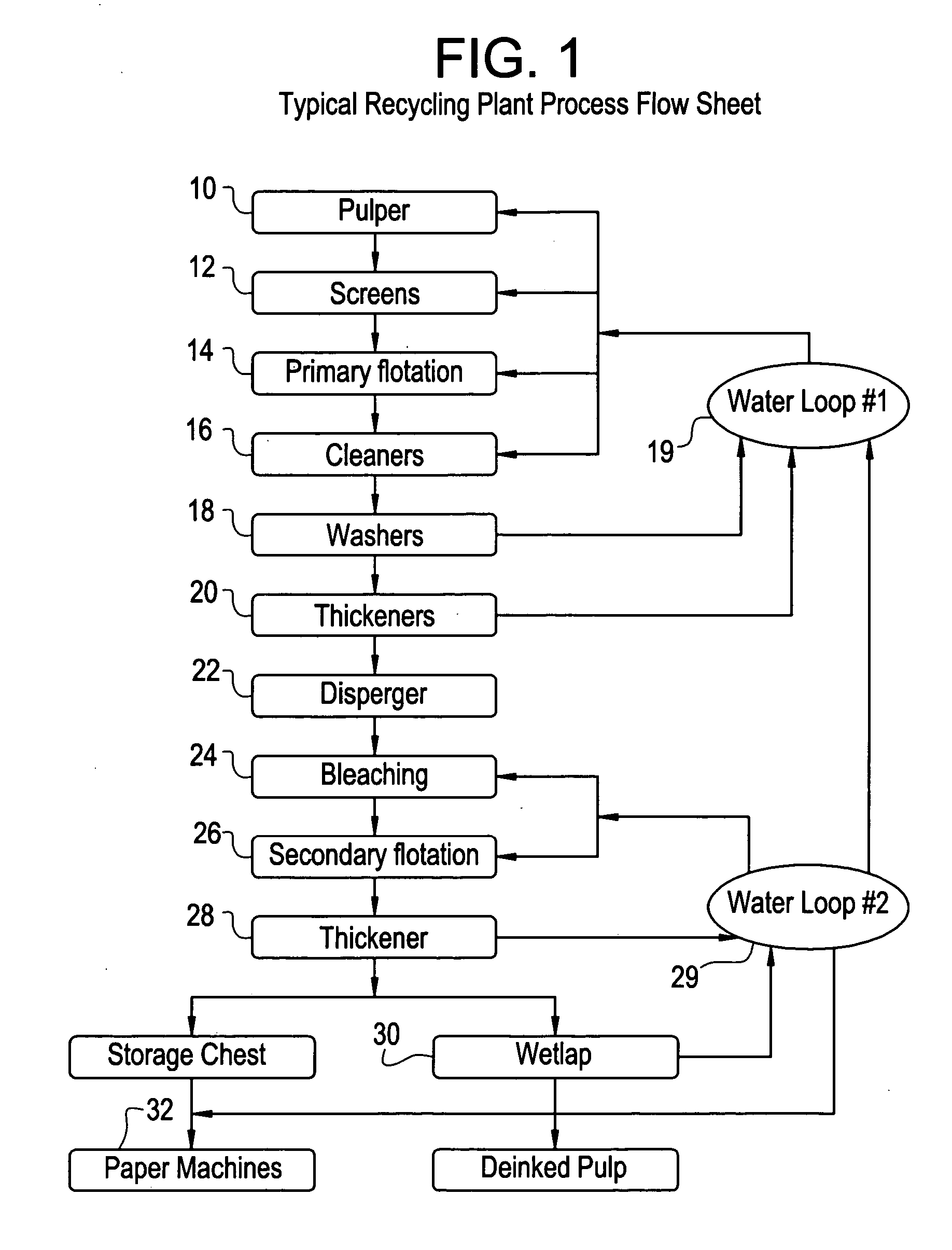

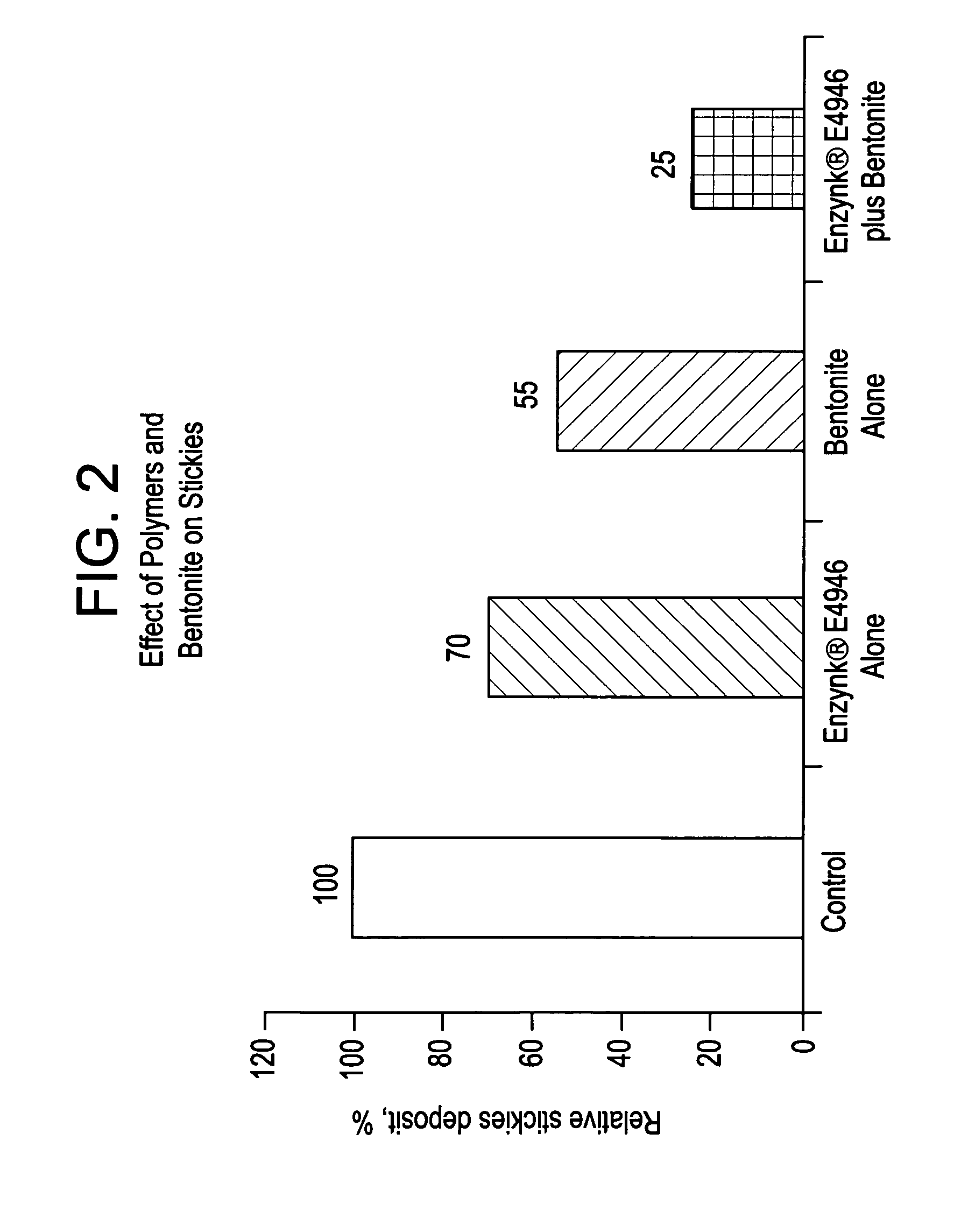

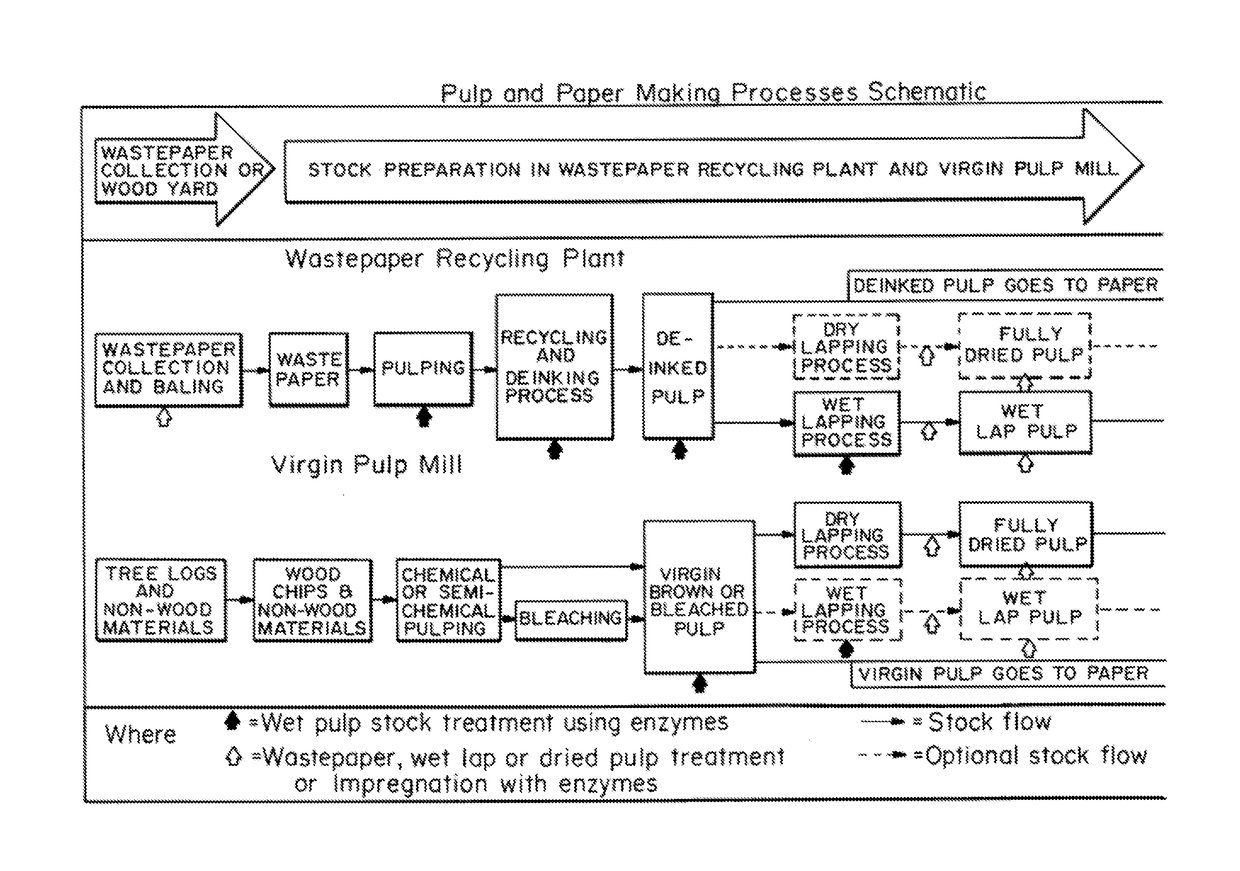

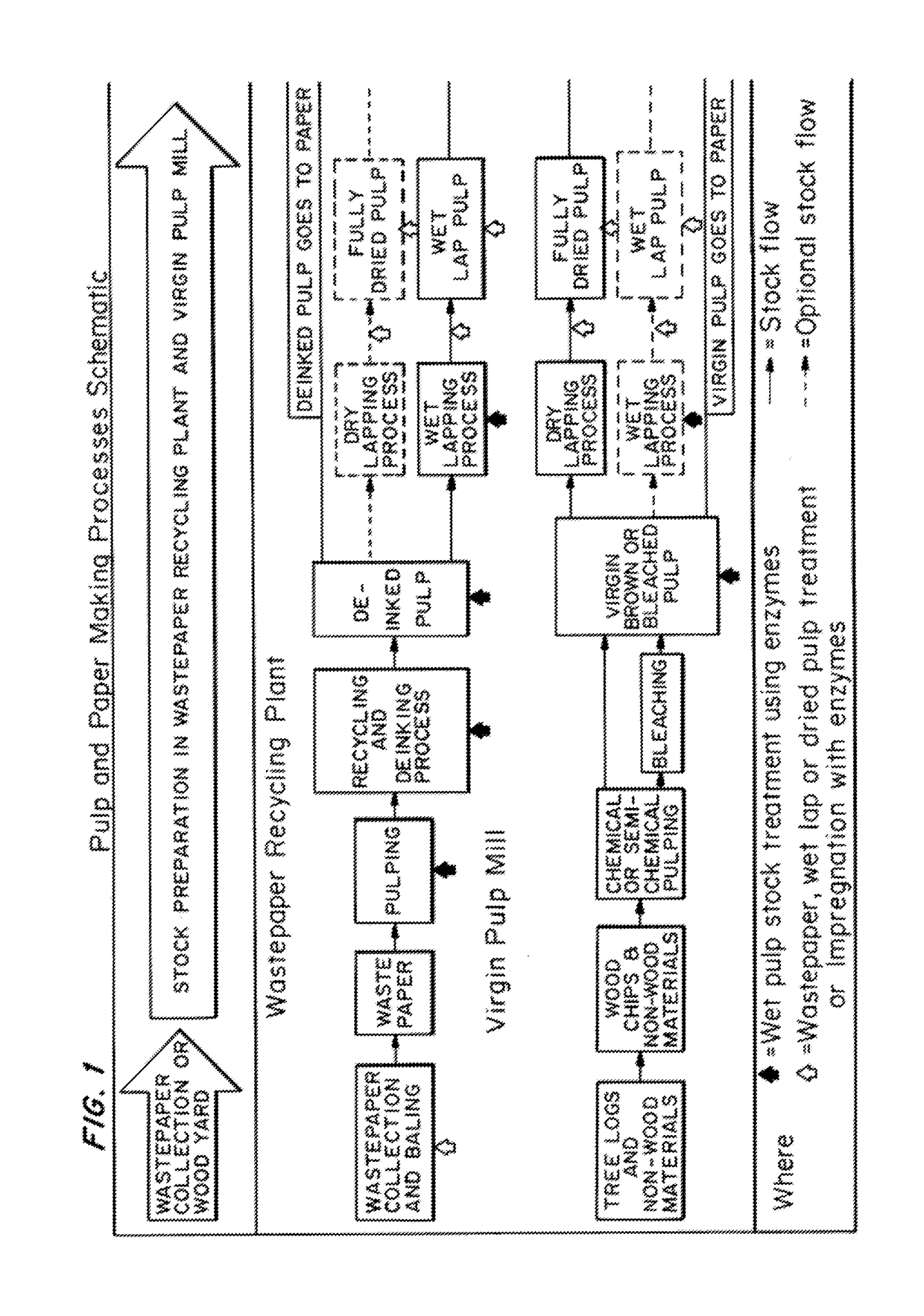

System for control of stickies in recovered and virgin paper processing

InactiveUS20060048908A1Good removal effectEasy to controlFats/resins/pitch/waxes removal in pulpMachine wet endPectinaseAmylase

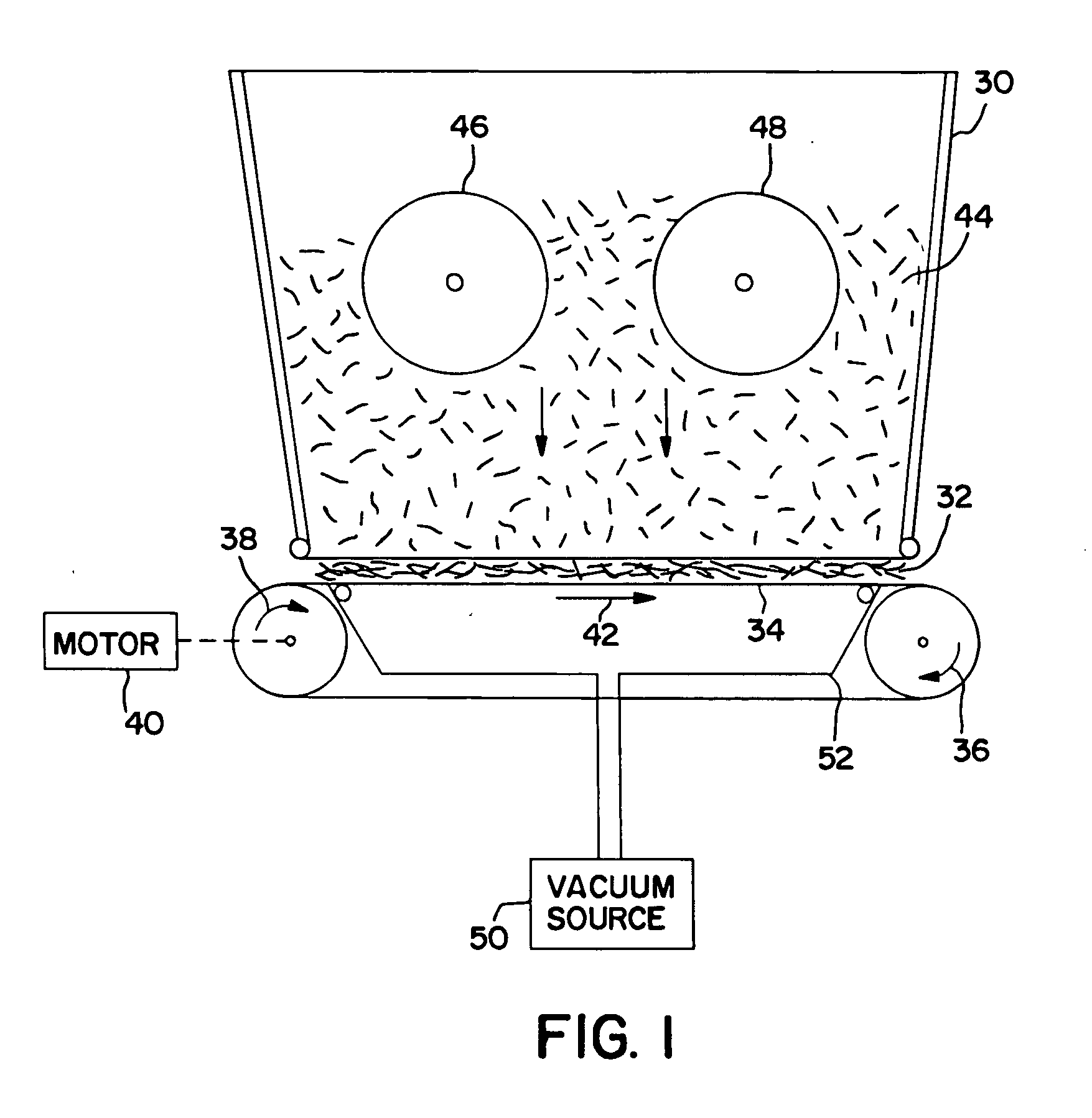

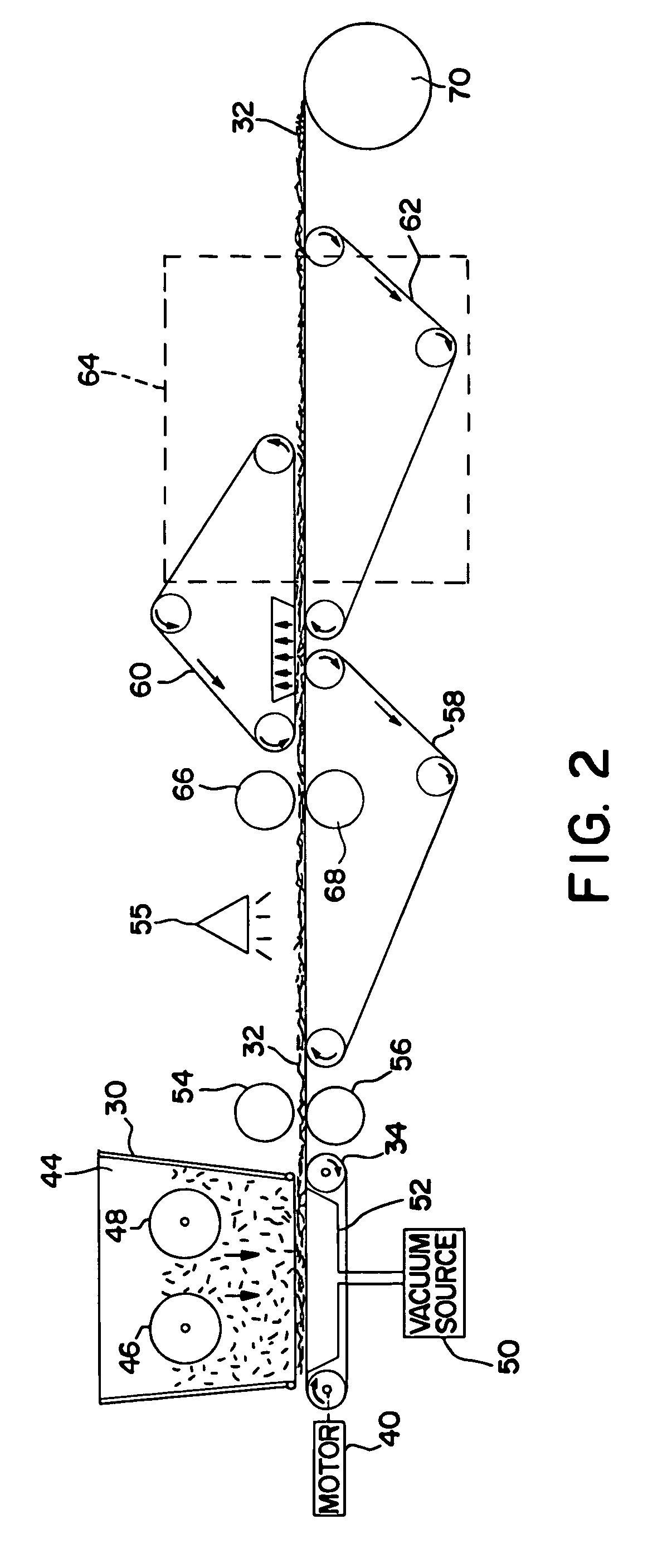

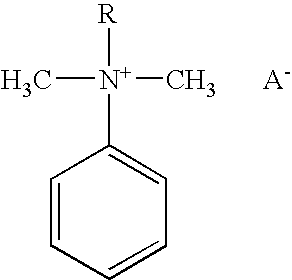

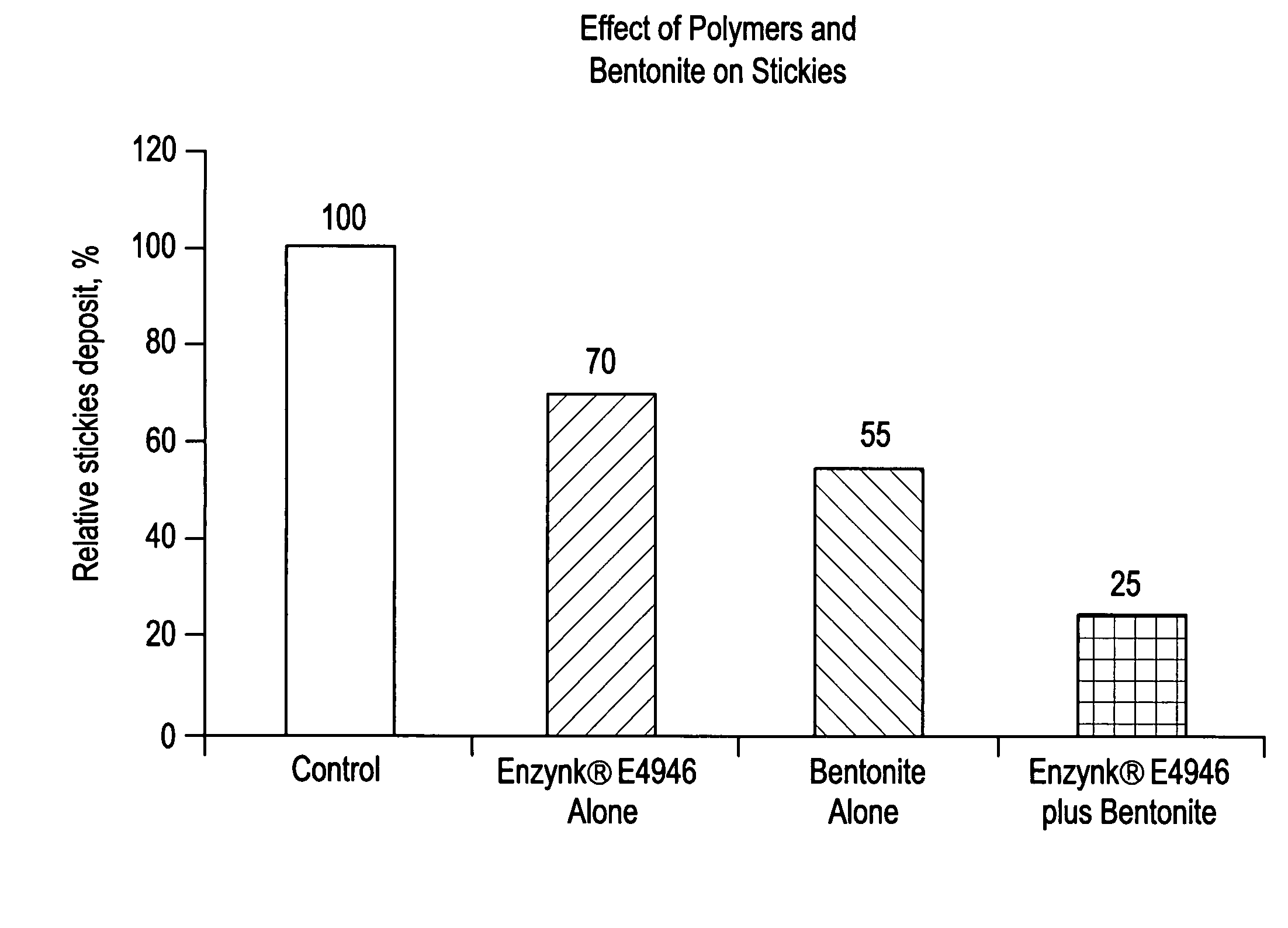

Enhanced removal and / or control of adhesives or sticky materials, “stickies”, from recovered paper stock or virgin pulp fibers is achieved using a combination of enzyme treatment with adsorbents and / or absorbents. Pulp stock to be treated is typically obtained from old magazines, newspapers, household waste, but may include corrugated boxes and office waste. Virgin pulps may include mechanical, chemical, or semi-chemical pulps. Enzymes typically include hydrolases such as cellulases, hemicellulases, pectinases, amylases, and lipases such as esterases, lyases such as pectate lyases, and oxidoreductases. Adsorbents include activated bentonite, microparticles, talc, clay and modified silica. Absorbents typically include water soluble polymers, dispersants, coagulatants and agglomerants.

Owner:ENZYMATIC DEINKING TECH LLC

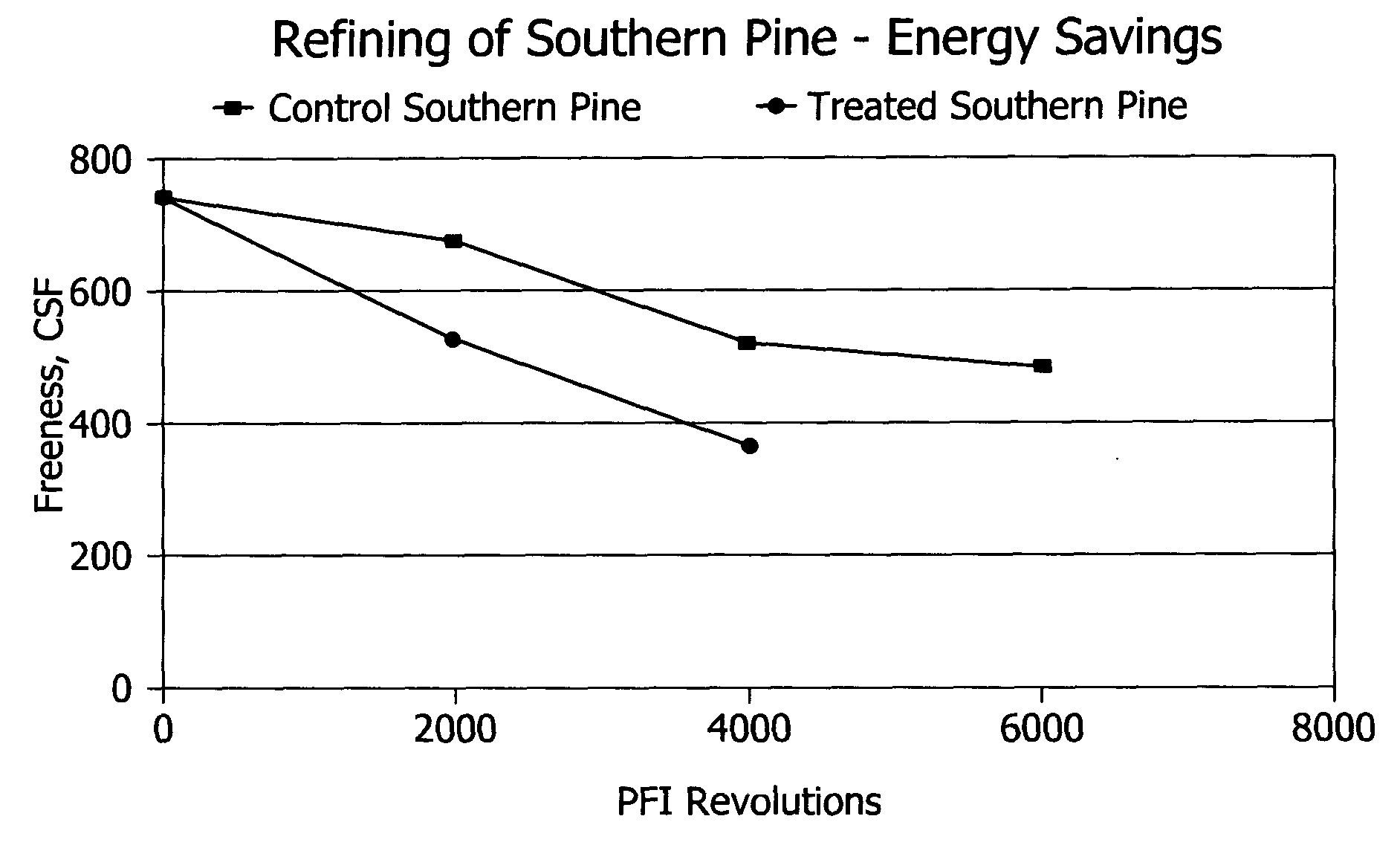

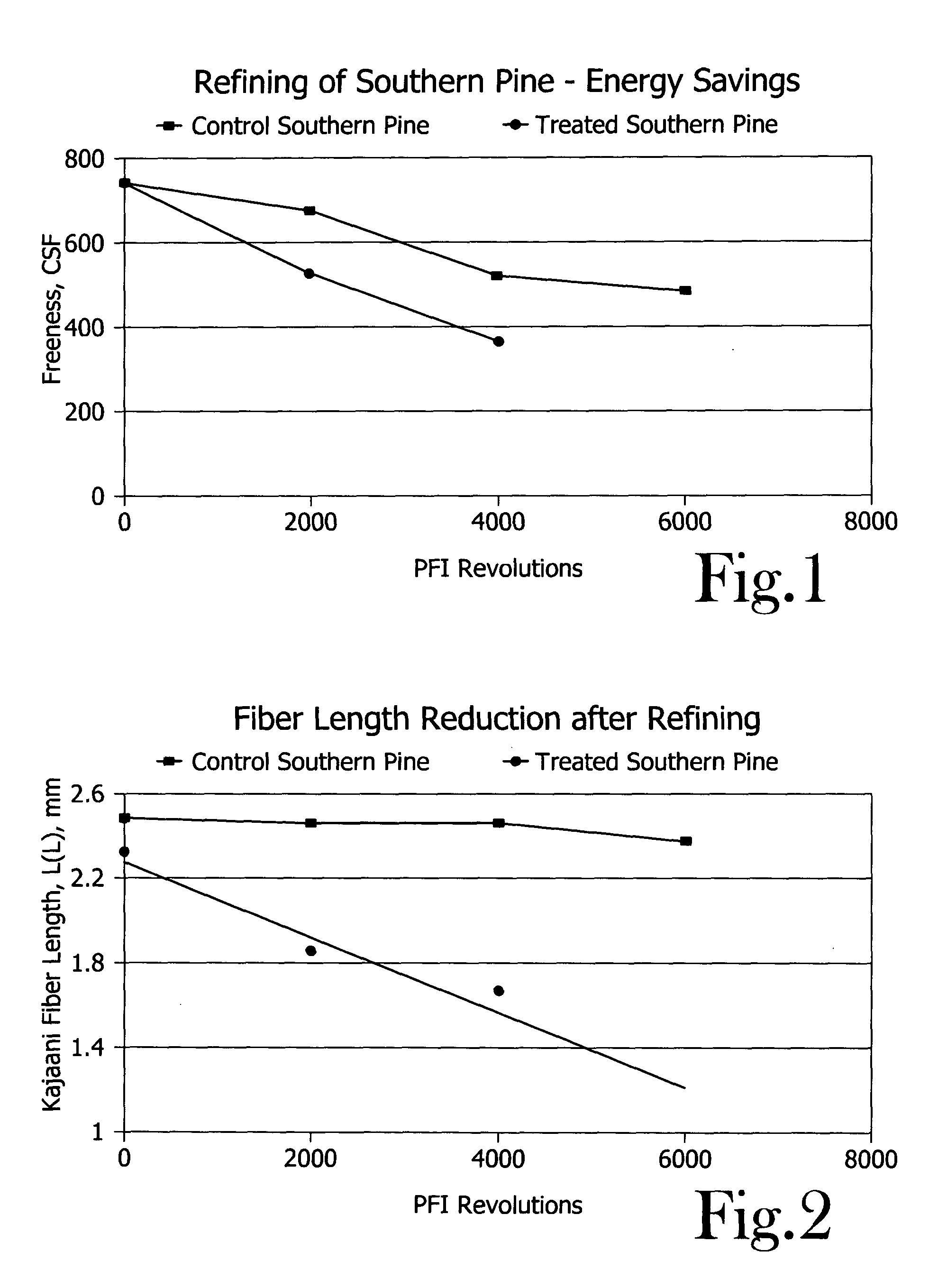

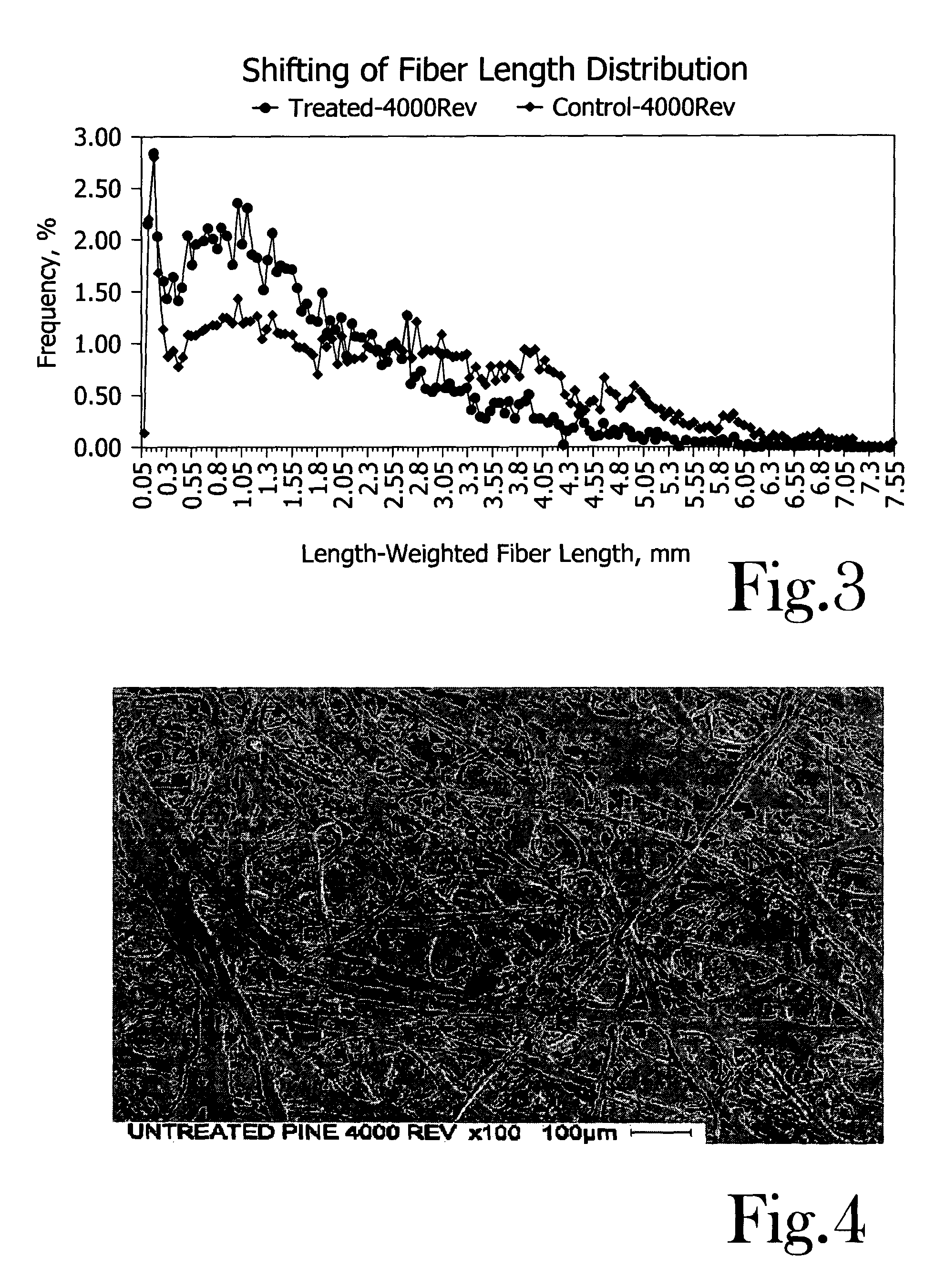

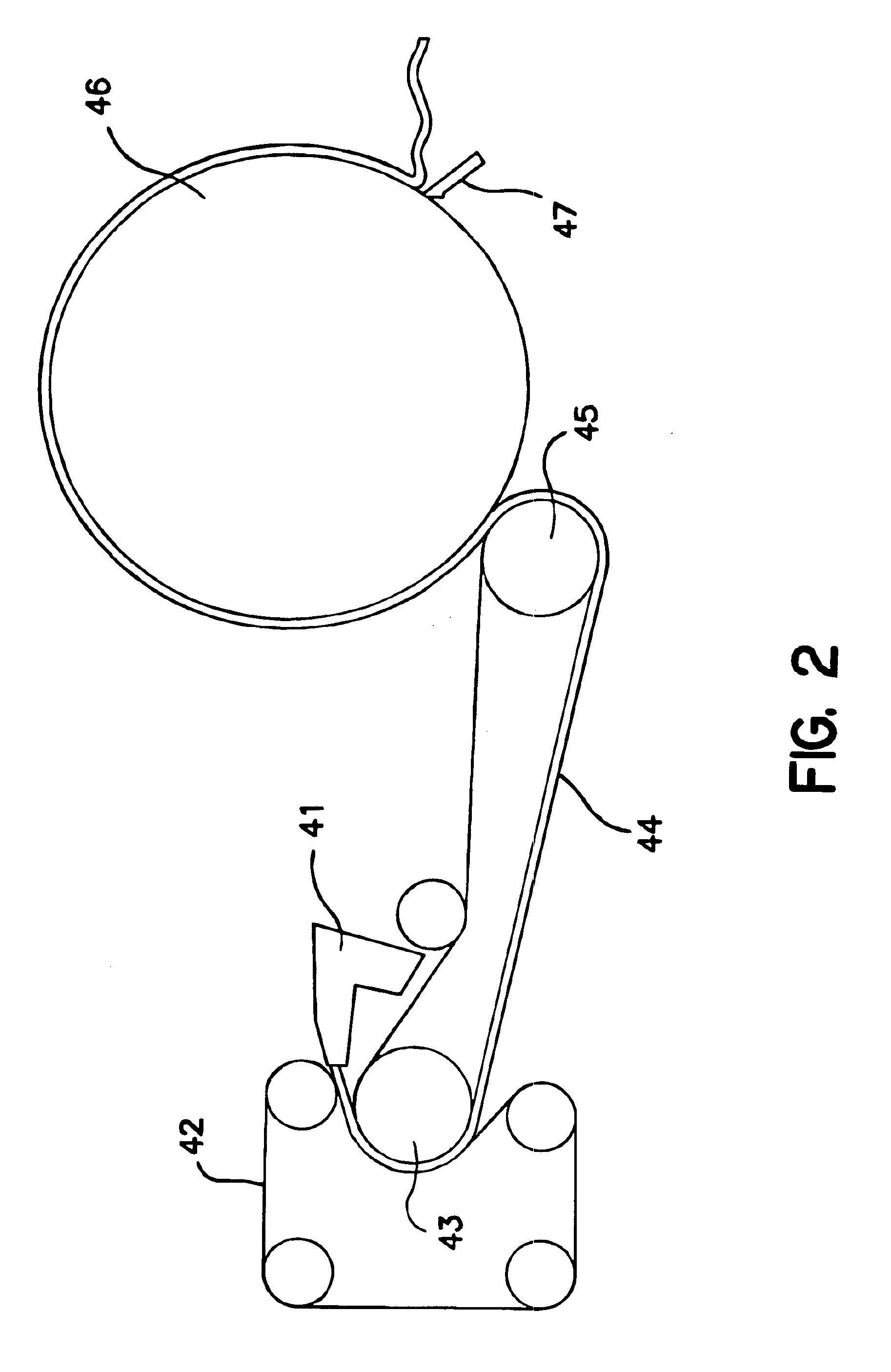

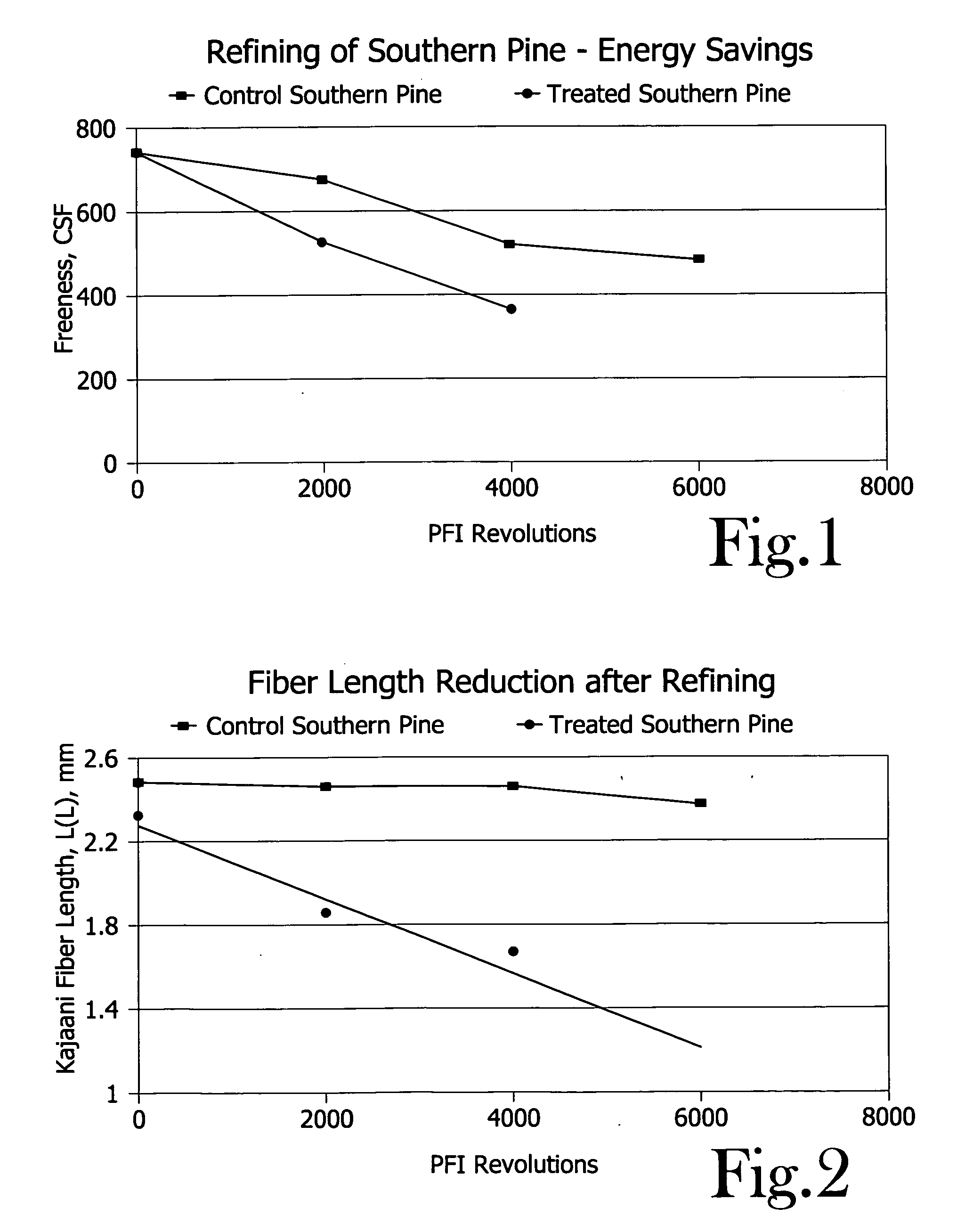

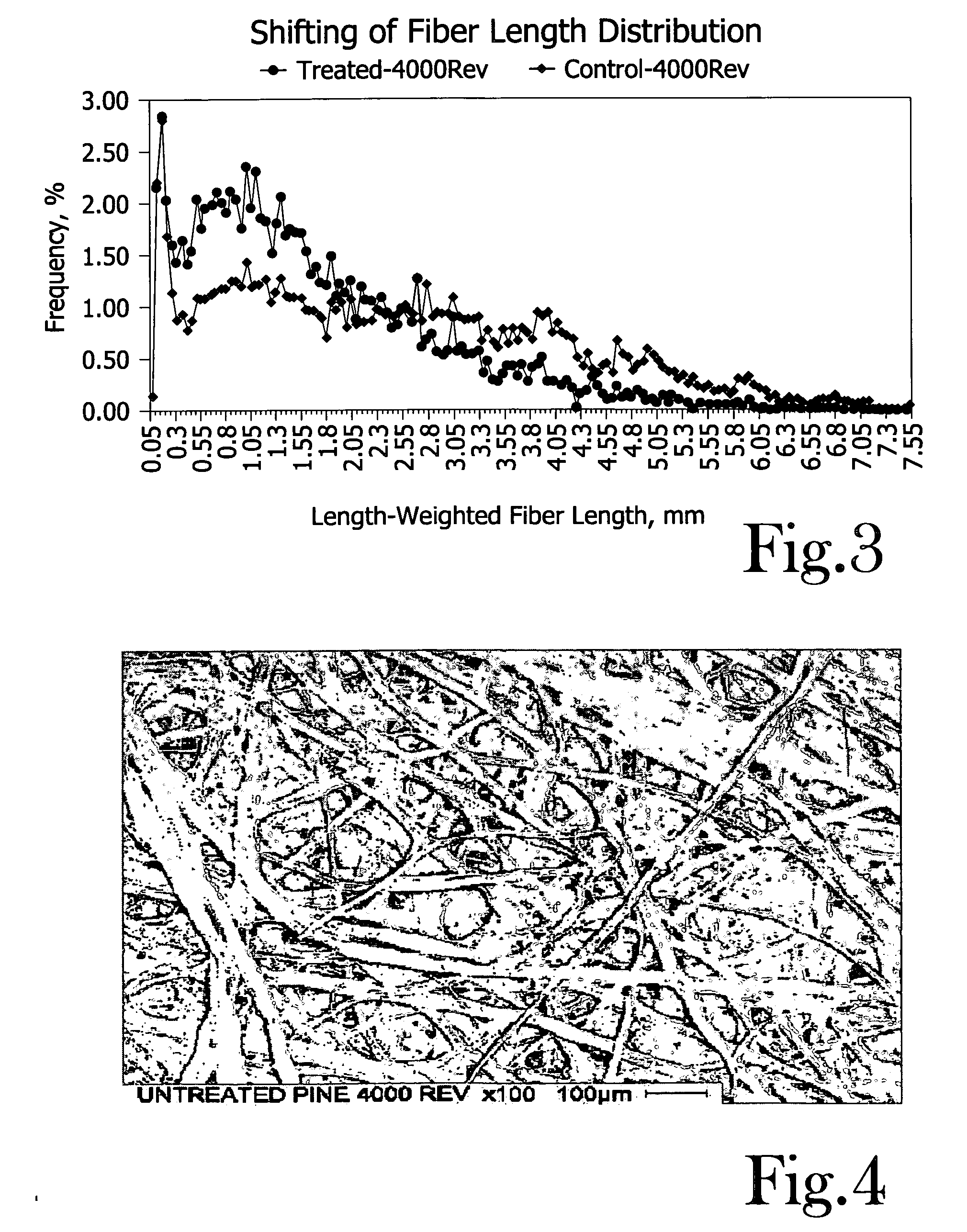

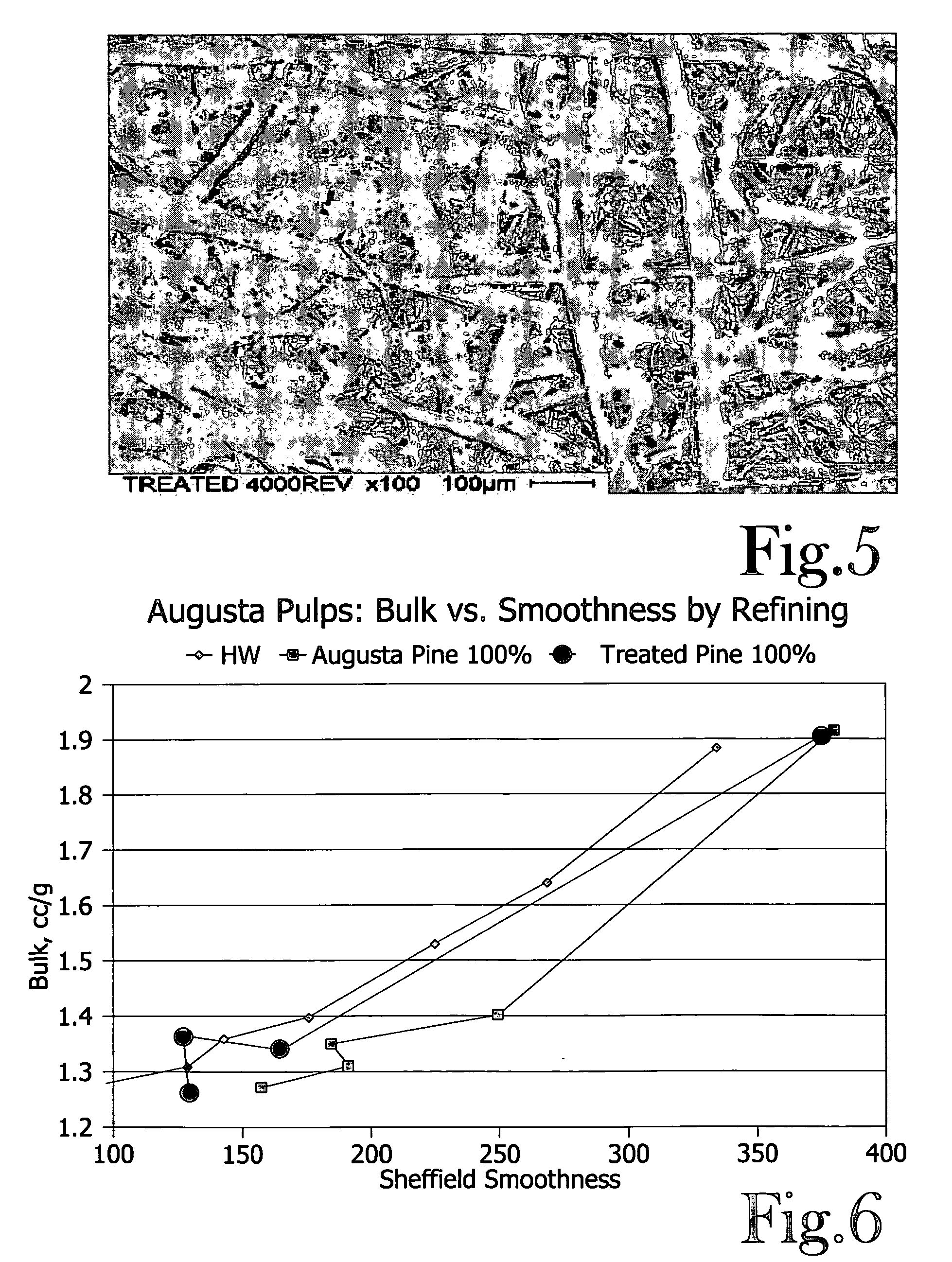

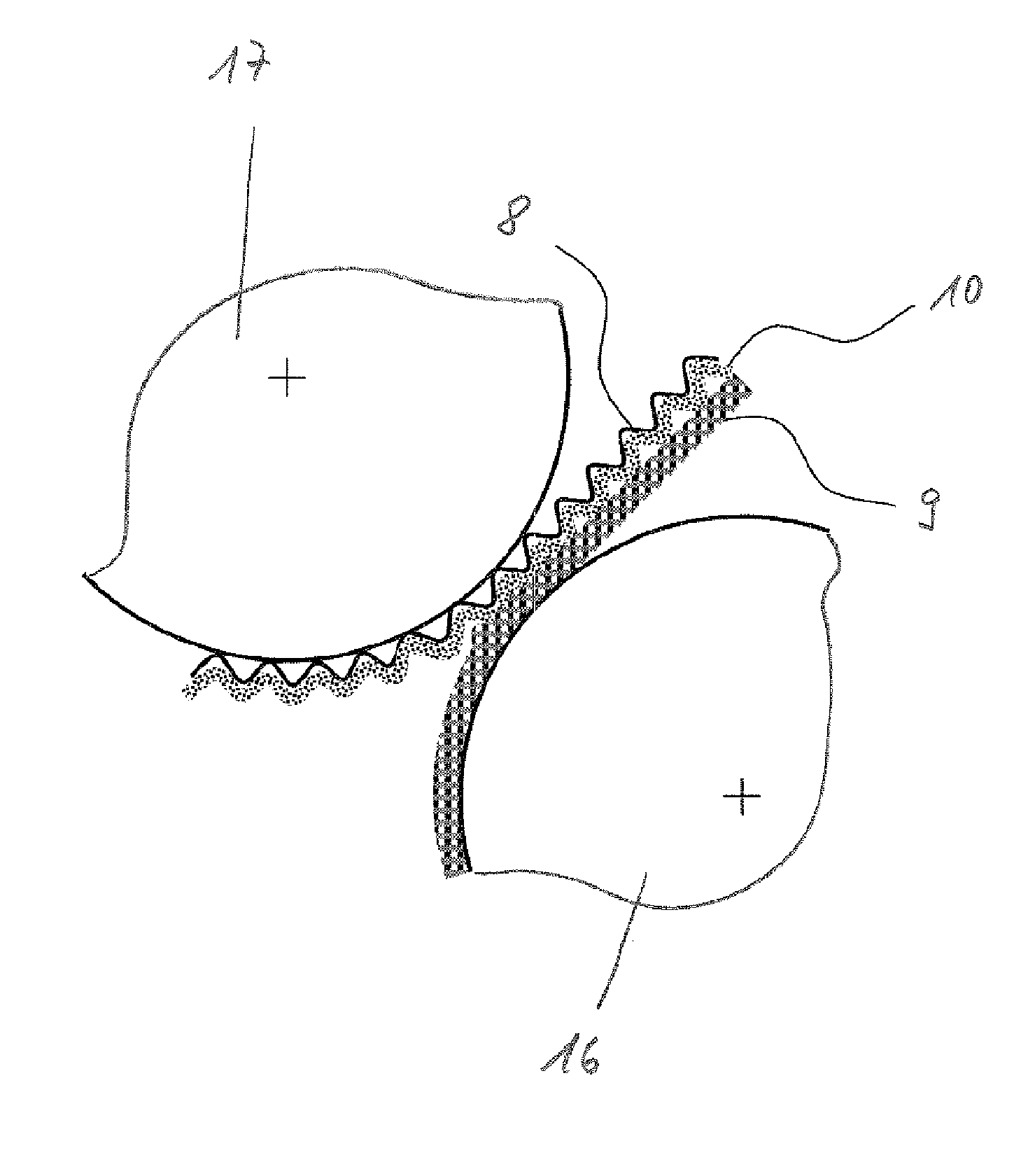

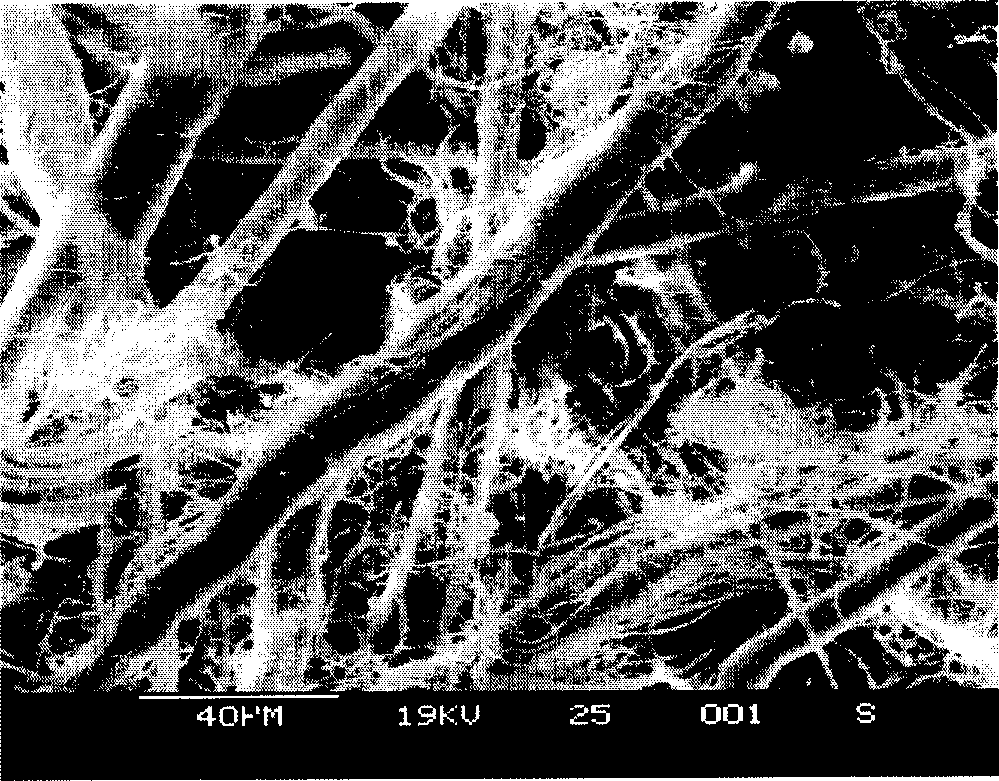

Chemical activation and refining of southern pine kraft fibers

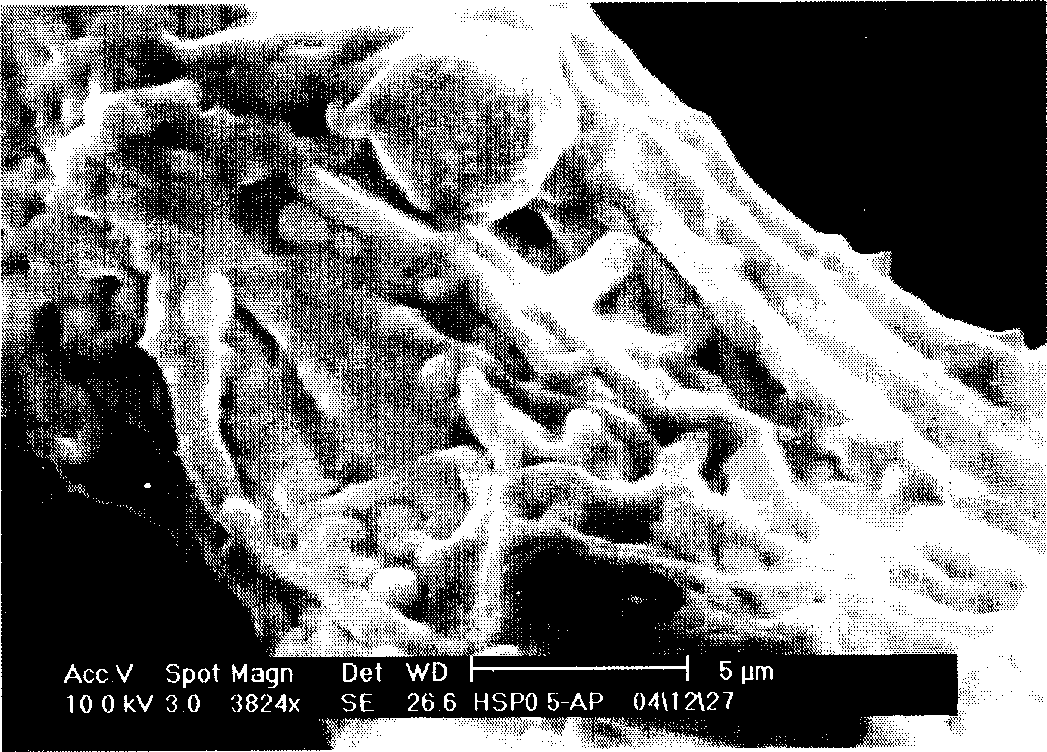

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

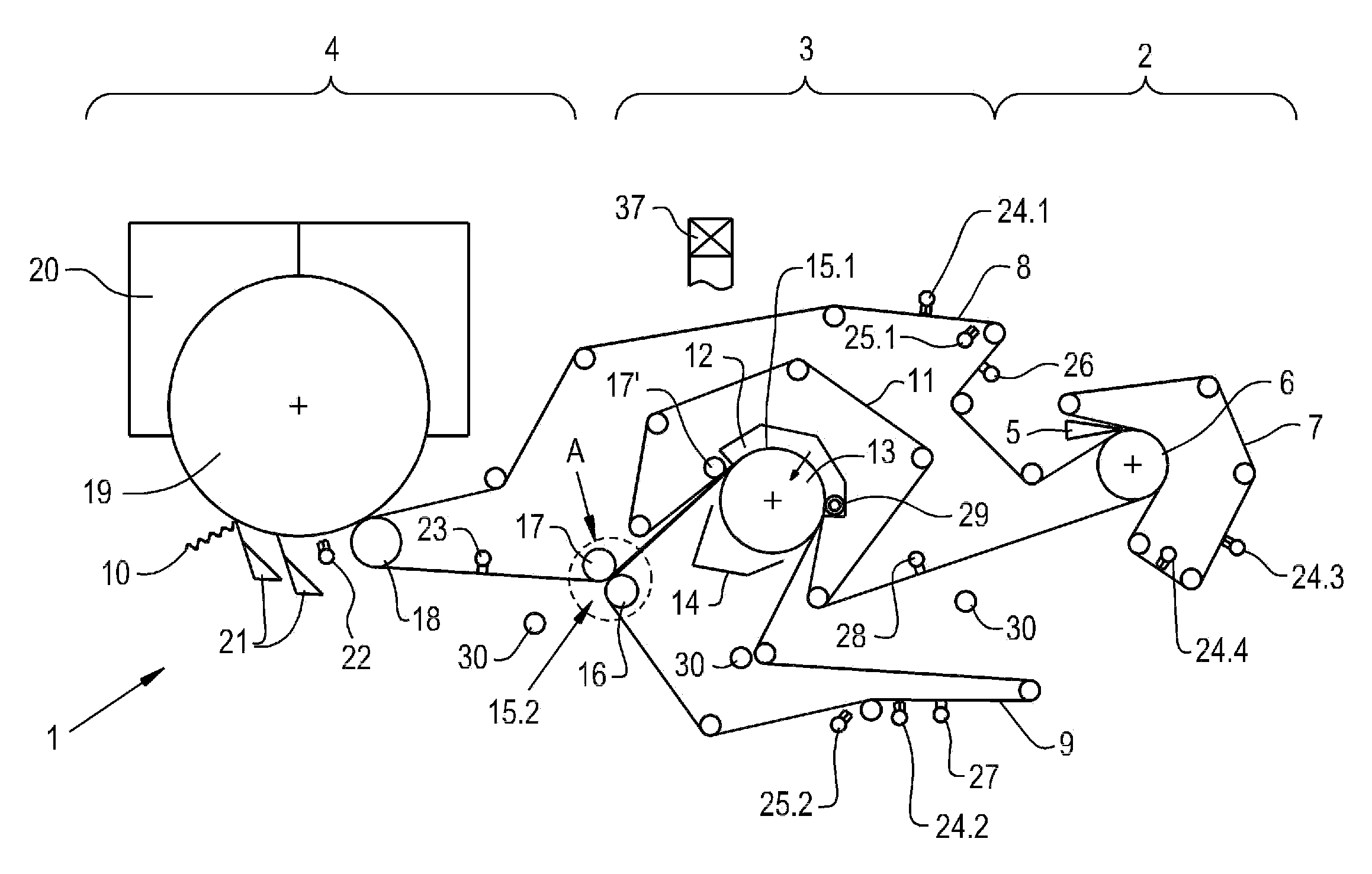

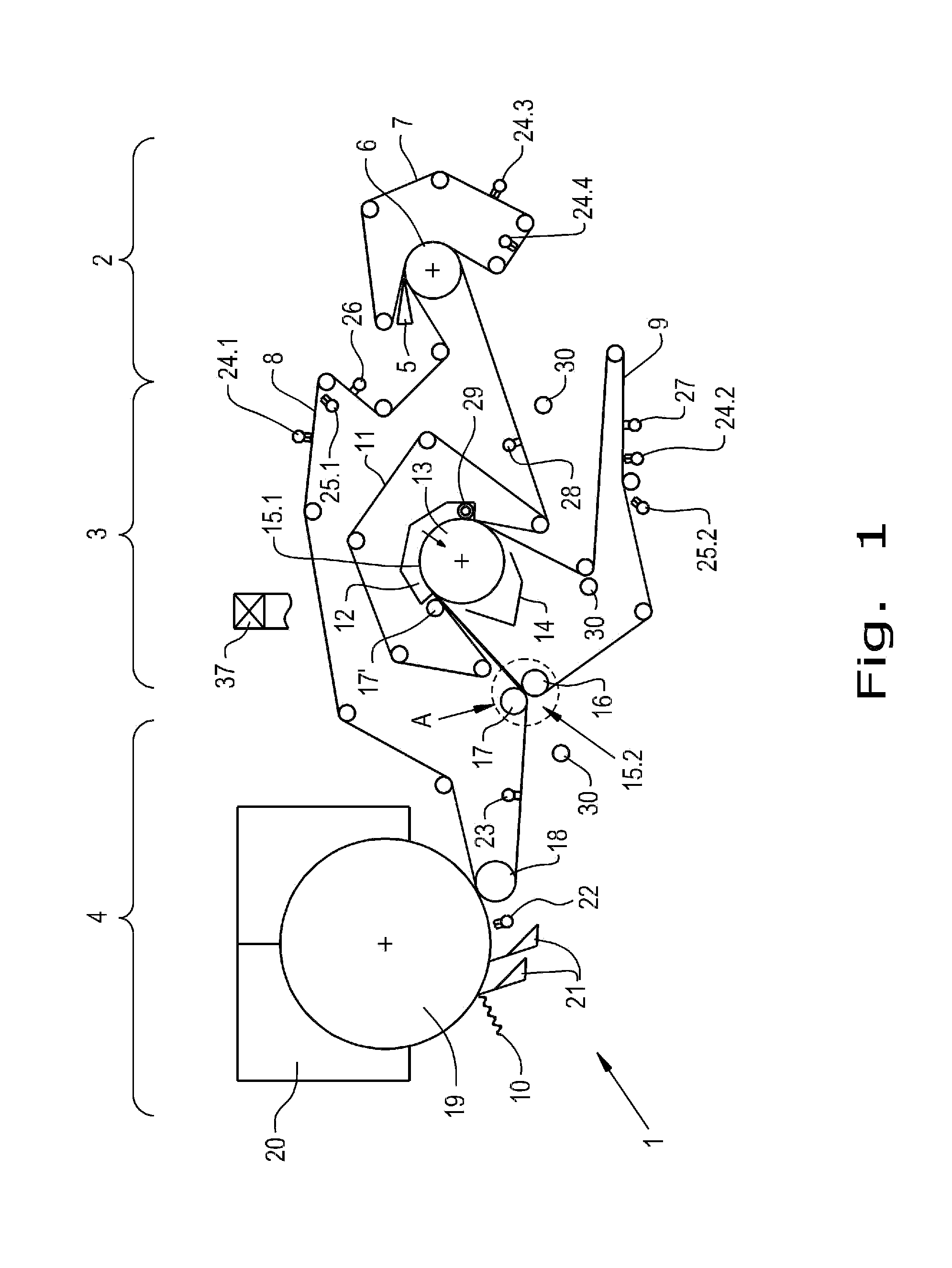

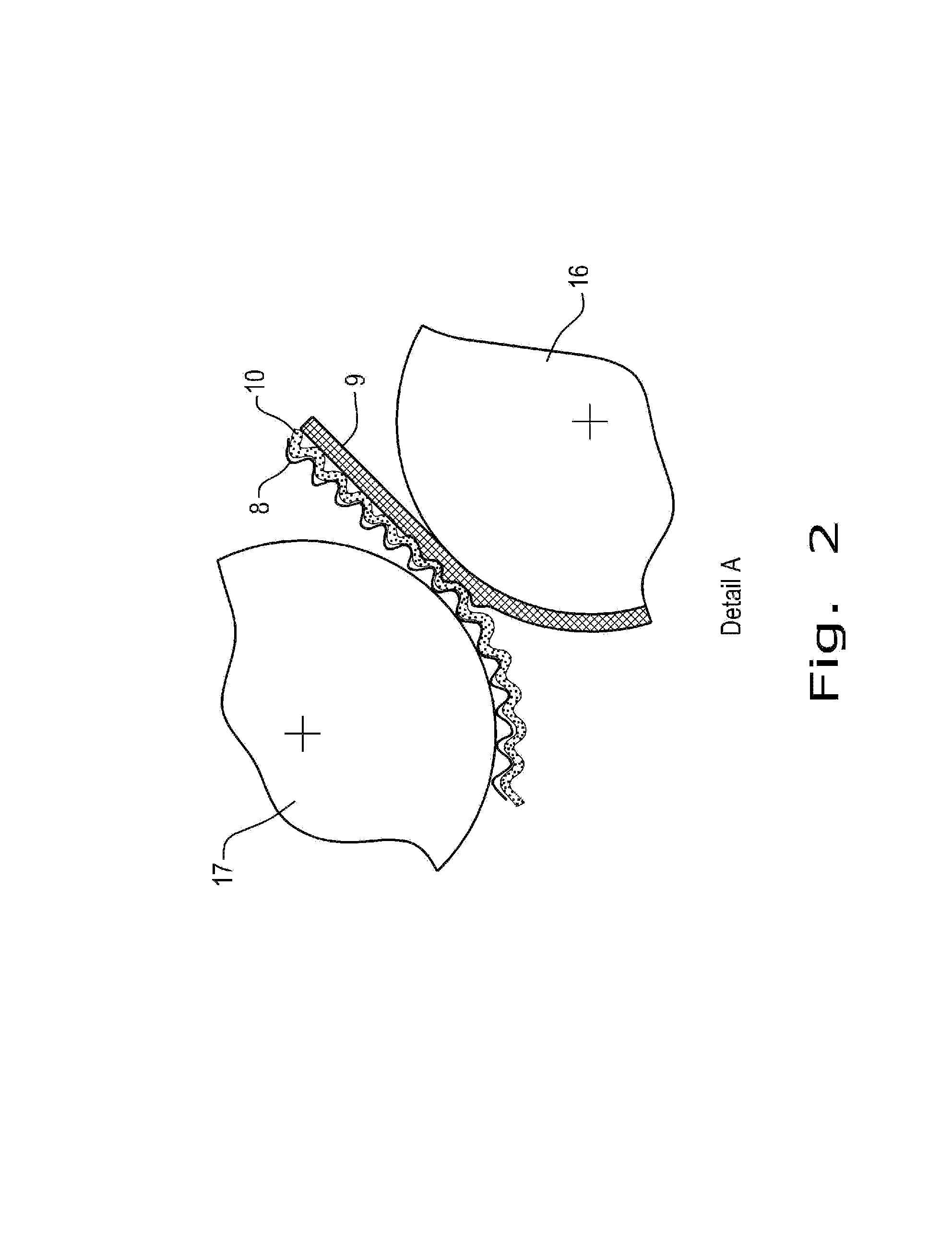

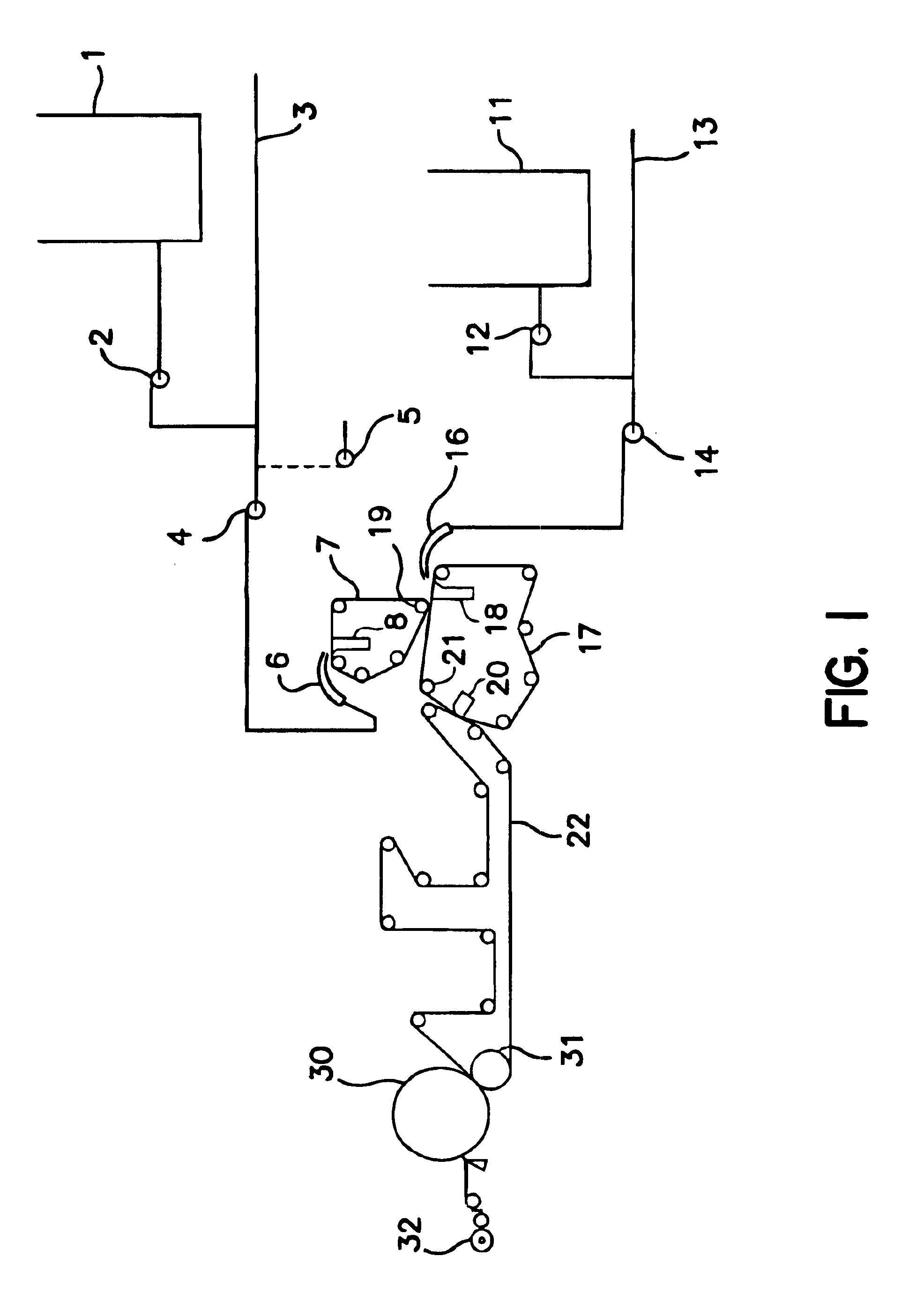

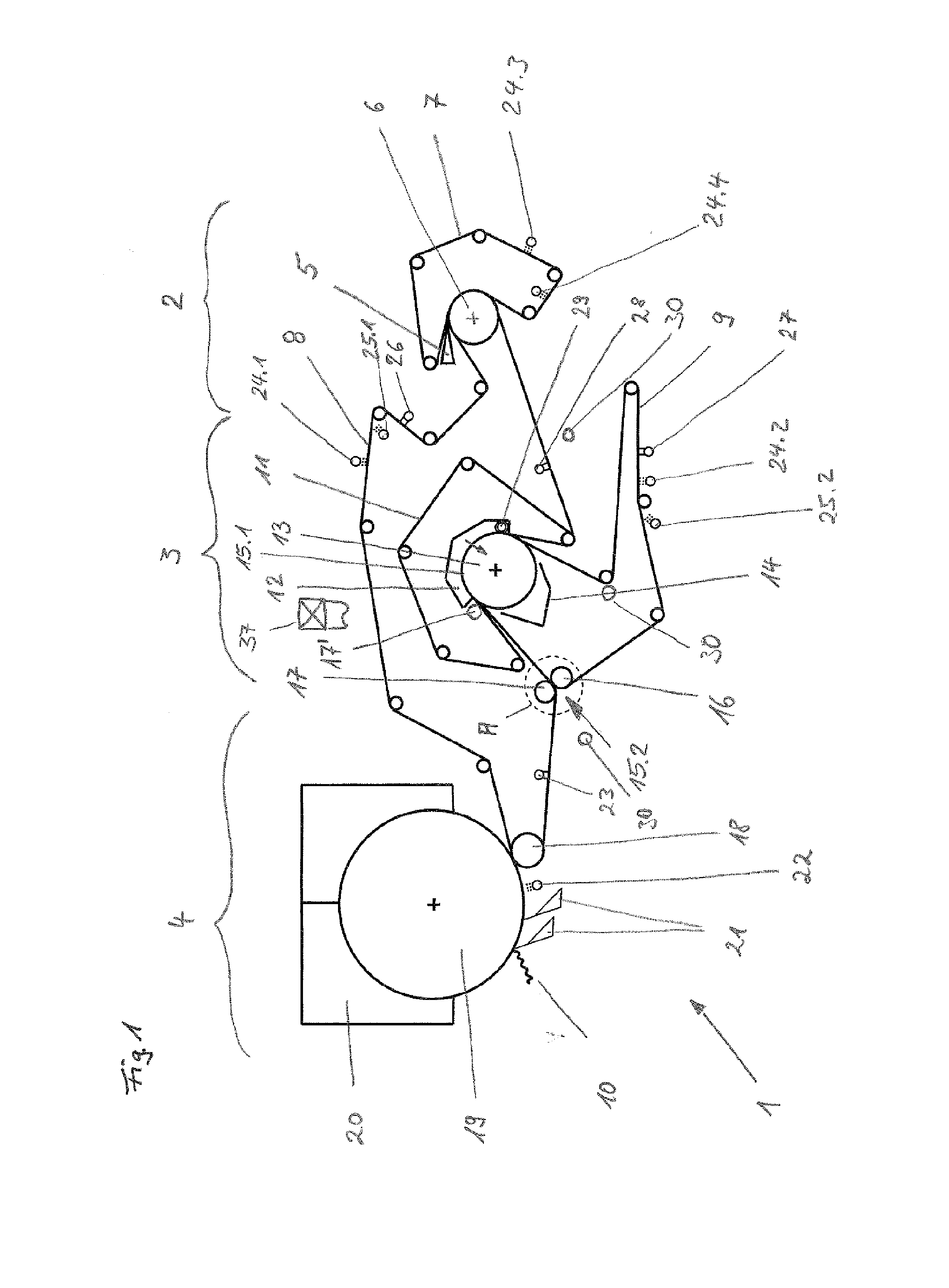

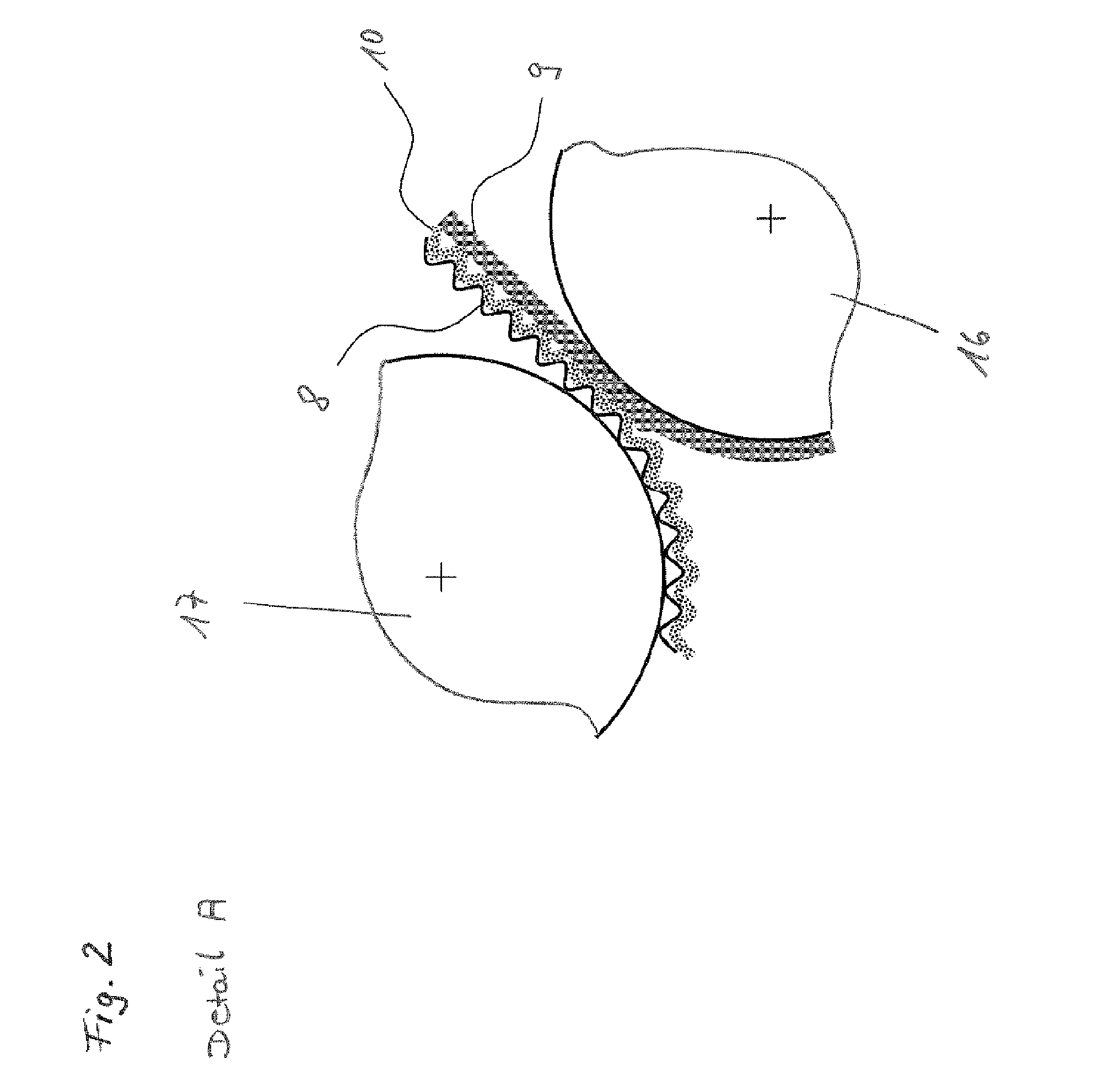

Device and method for producing a material web

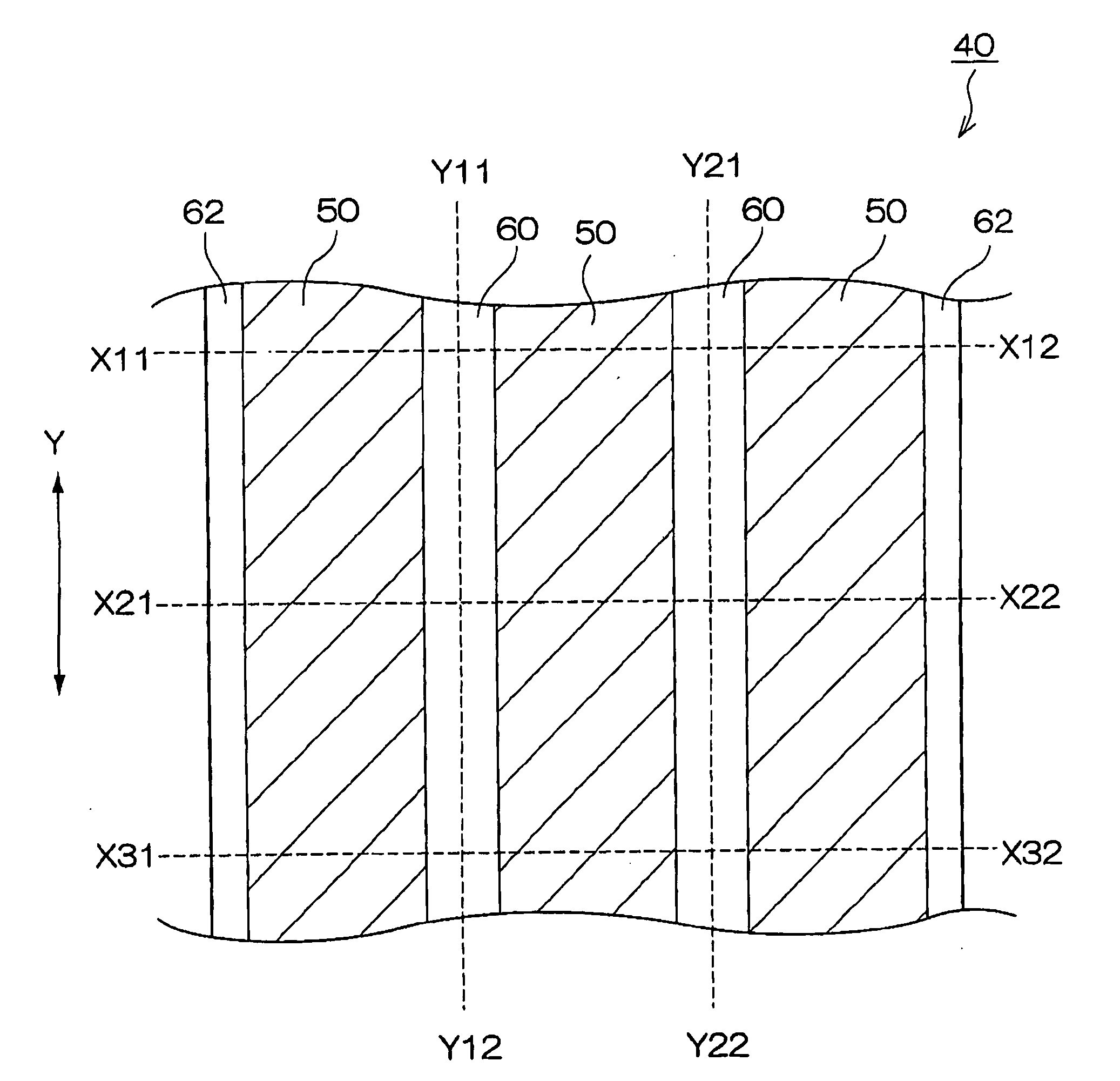

InactiveUS8382956B2Increase contentLow compressibilityDrying solid materials with heatDrying solid materials without heatTwo bandPulp and paper industry

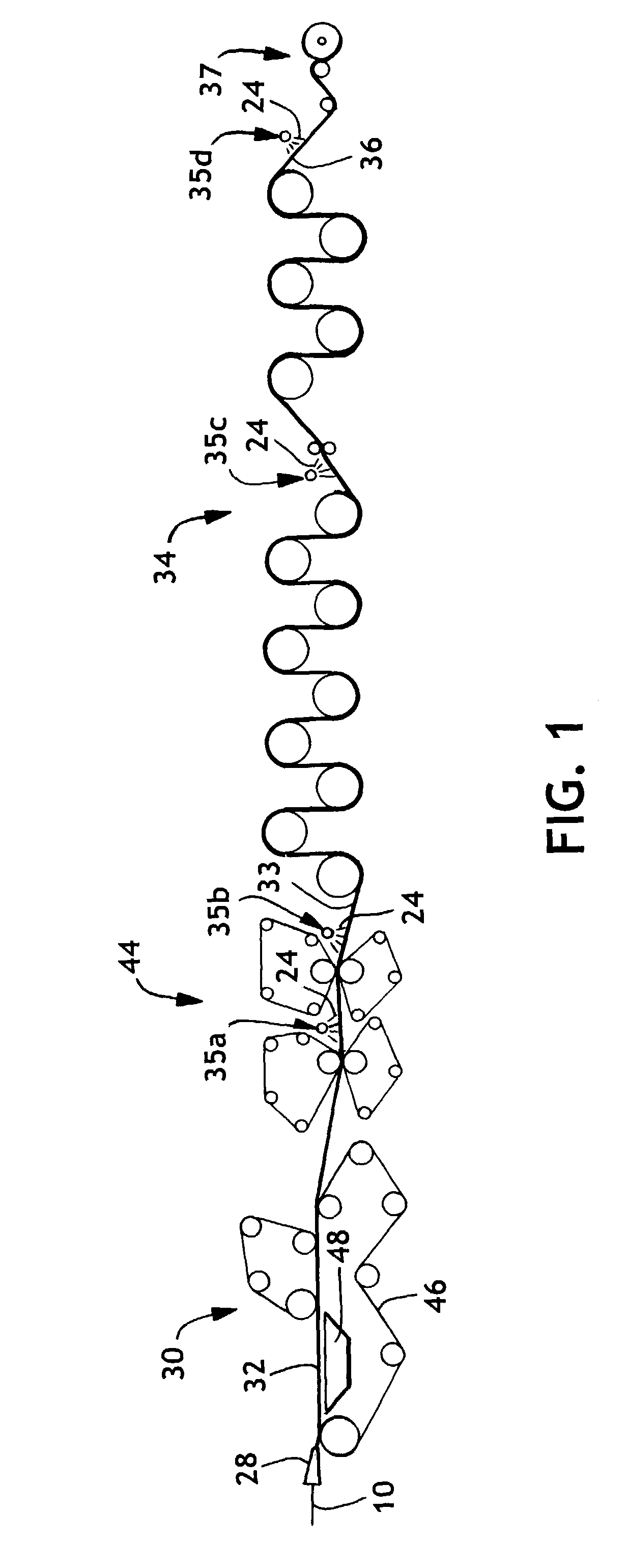

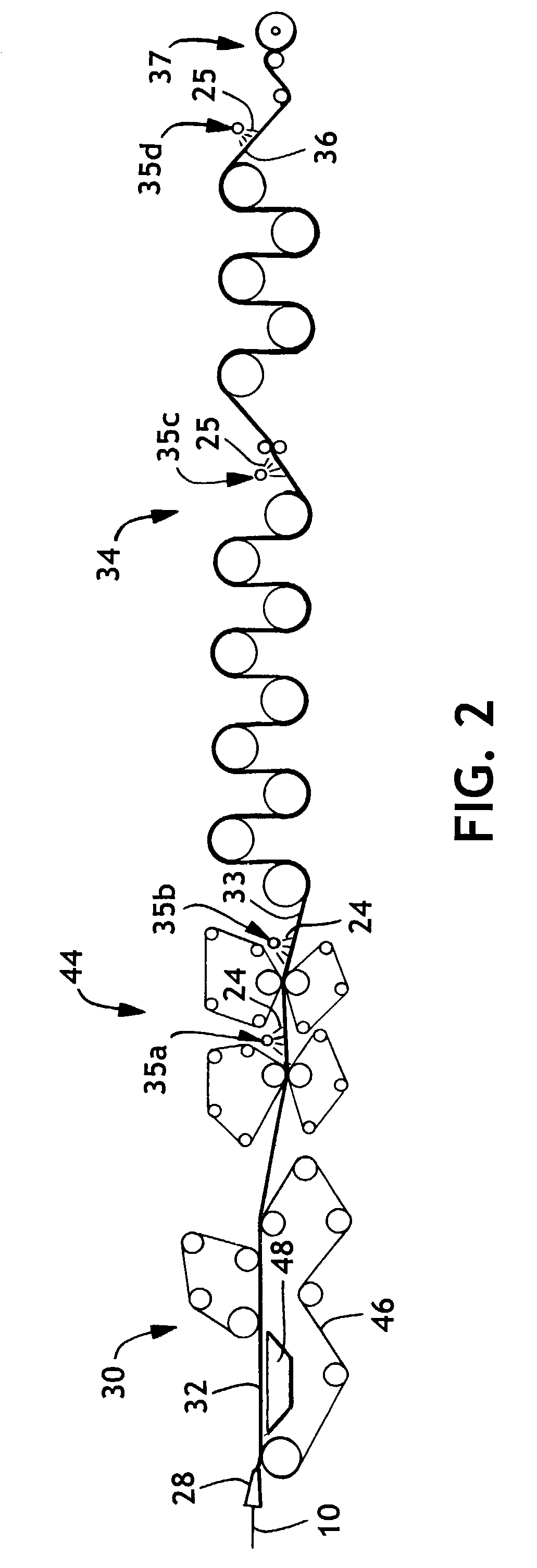

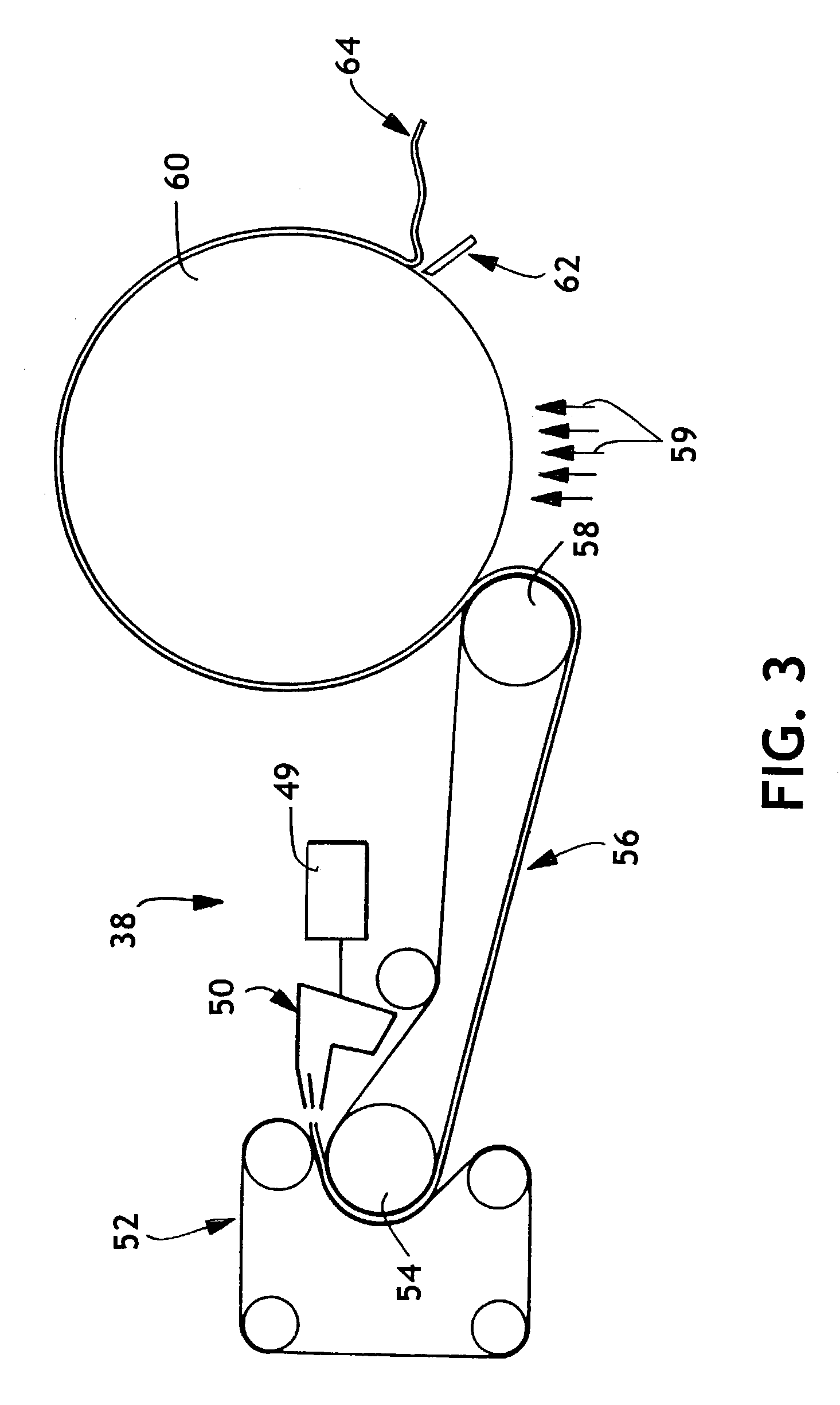

A device for drainage of a pulp web, particularly a tissue web, having a first pressing zone having a first pressing zone length through which the pulp web is fed horizontally between a circulating, permeable band and a circulating, permeable support band. The first pressing zone is designed such that a fluid can flow through the band, the pulp web and the support band at least on one part of the first pressing zone length. In addition, the device has a subsequent second pressing zone having a second pressing zone length. The pulp web is guided through the second pressing zone between two bands having differing compressibility.

Owner:VOITH PATENT GMBH

Tissue products having reduced lint and slough

InactiveUS6861380B2Long fiber lengthAvoid short lengthSpecial paperPaper/cardboardPulp fibreBiomedical engineering

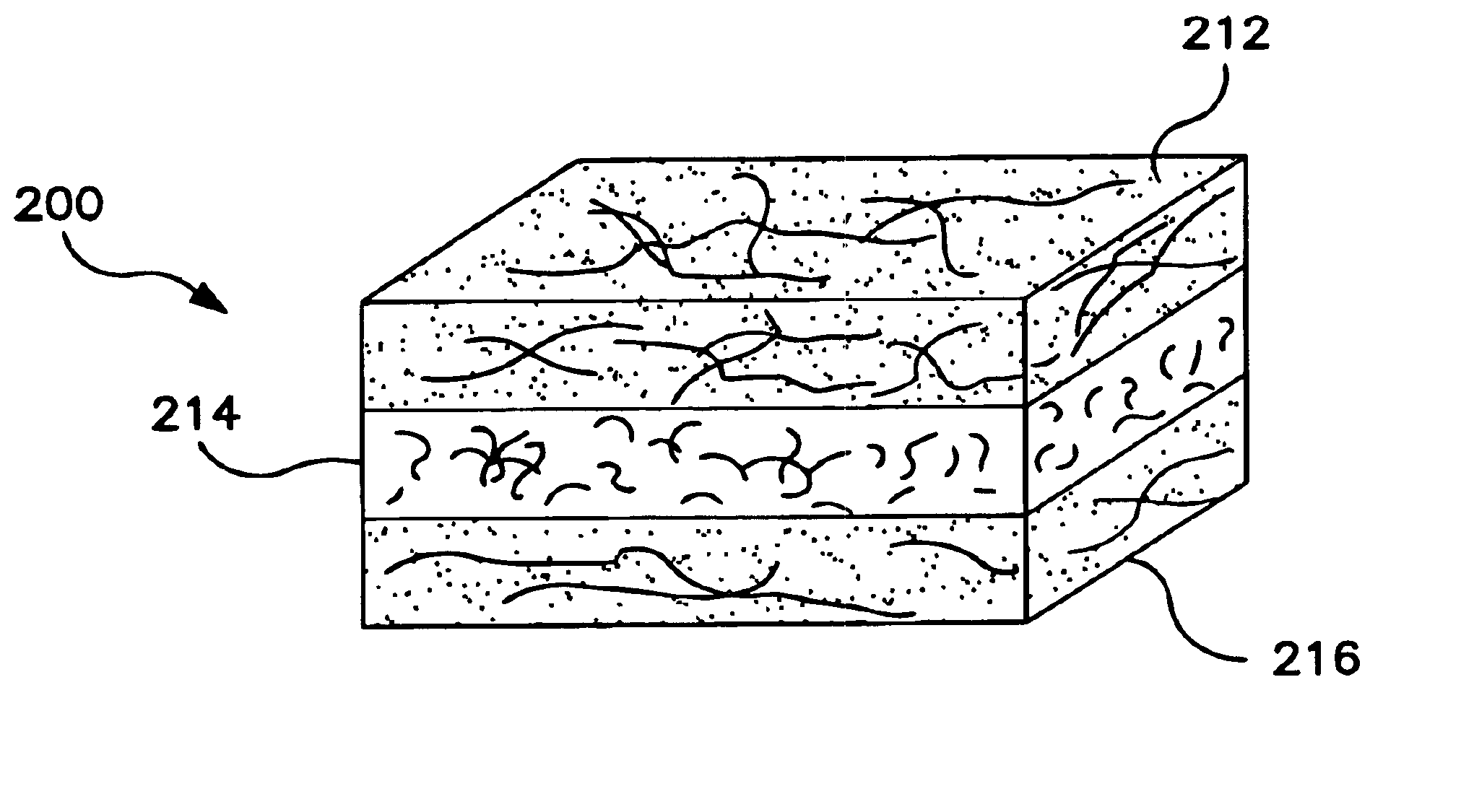

A tissue product containing a multi-layered paper web that has at least one layer formed from a blend of pulp fibers and synthetic fibers is provided. By containing at least one layer of synthetic and pulp fibers, it has been discovered that lint and slough of a tissue product formed according to the present invention can be substantially reduced. In addition, by limiting the amount and layers to which the synthetic fibers are applied, the increase in hydrophobicity and cost of the tissue product may be minimized, while still achieving the desired reduction in lint and slough. In some embodiments, the tendency of the synthetic fibers to sink or float in the fibrous furnish may be minimized to enhance processability by selecting certain types of synthetic fibers, e.g., those with a certain density imbalance.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Chemical activation and refining of southern pine kraft fibers

InactiveUS20070119556A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

Device and method for producing a material web

InactiveUS20110303379A1Increase contentLow compressibilityDrying solid materials with heatDrying solid materials without heatTwo bandPulp and paper industry

A device for drainage of a pulp web, particularly a tissue web, having a first pressing zone having a first pressing zone length through which the pulp web is fed horizontally between a circulating, permeable band and a circulating, permeable support band. The first pressing zone is designed such that a fluid can flow through the band, the pulp web and the support band at least on one part of the first pressing zone length. In addition, the device has a subsequent second pressing zone having a second pressing zone length. The pulp web is guided through the second pressing zone between two bands having differing compressibility.

Owner:VOITH PATENT GMBH

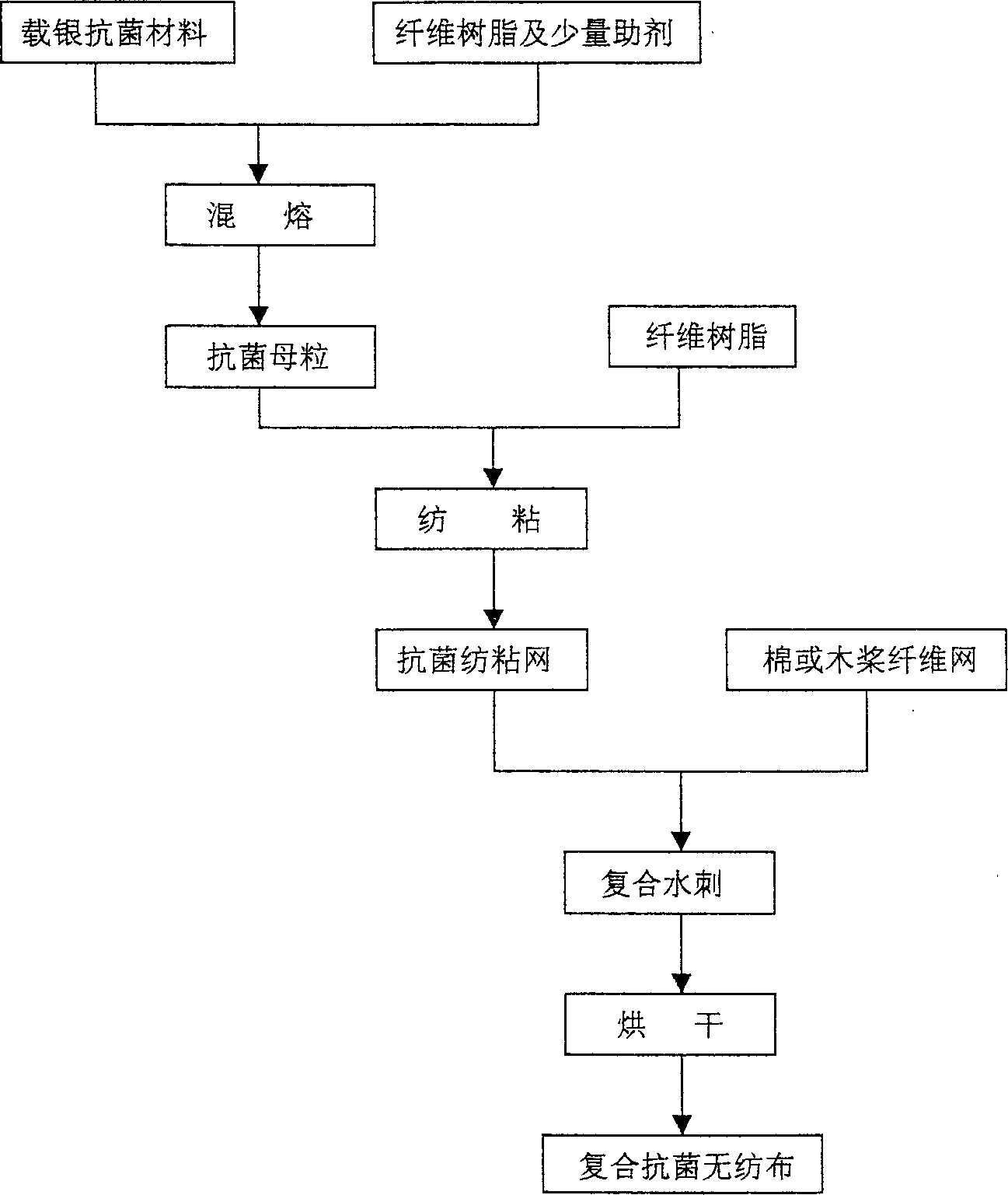

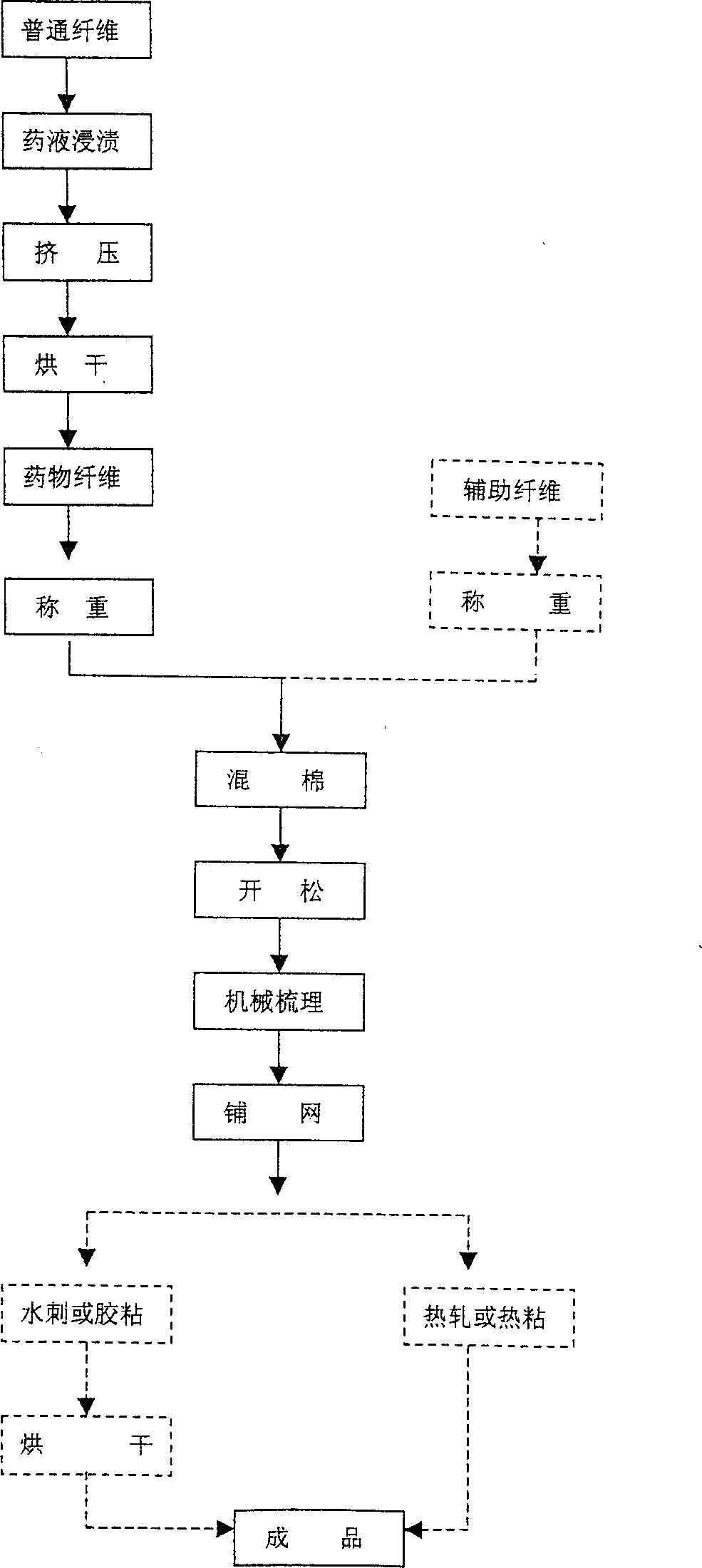

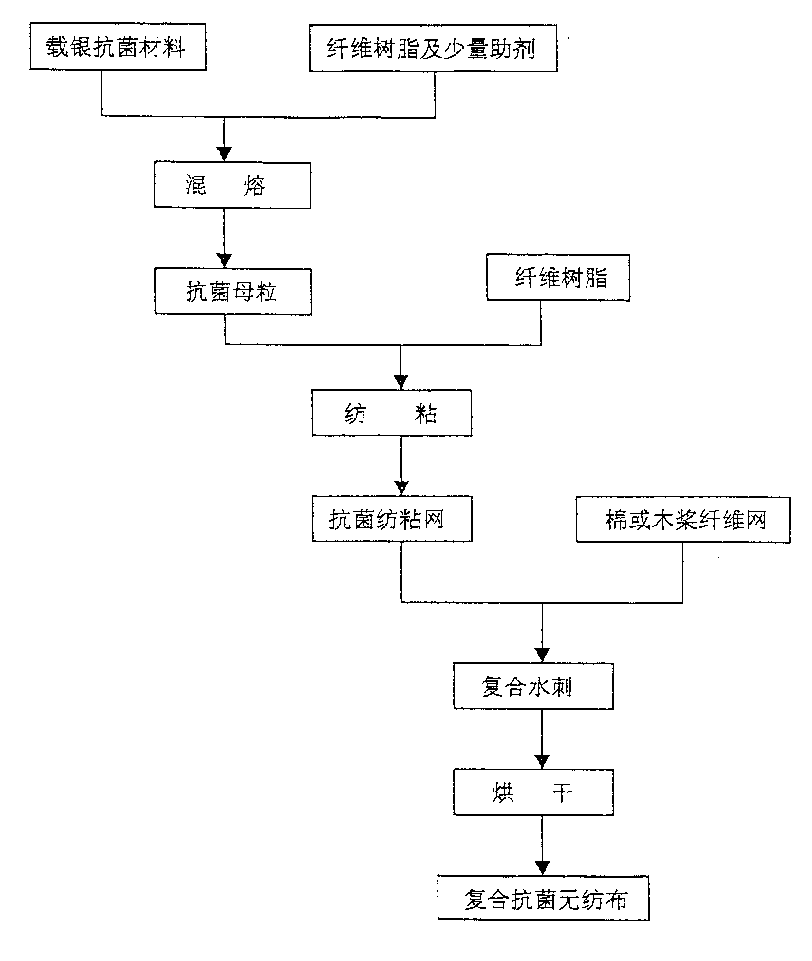

Process for preparing Ag-carried antibacterial composite non-woven fabric

InactiveCN1346905ANot easy to fall offImprove antibacterial propertiesNon-woven fabricsArtifical filament manufacturePolymer scienceCotton fibre

A process for preparing Ag-carried antibacterial composite non-woven fabric includes preparing antibacterial mother particles from Ag-carried antibacterial material, fibre resin and plastic assistant by screw extruding, preparing antibacterial spun-bonded mesh from said antibacterial mother particles and fibre resin, combining said antibacterial spun-bonded mesh with cotton fibre mesh or wood pulp fibre mesh, hydro-entangling, and drying. Its advantages are high antibacterial power and durability, and broad spectrum.

Owner:韦卫军

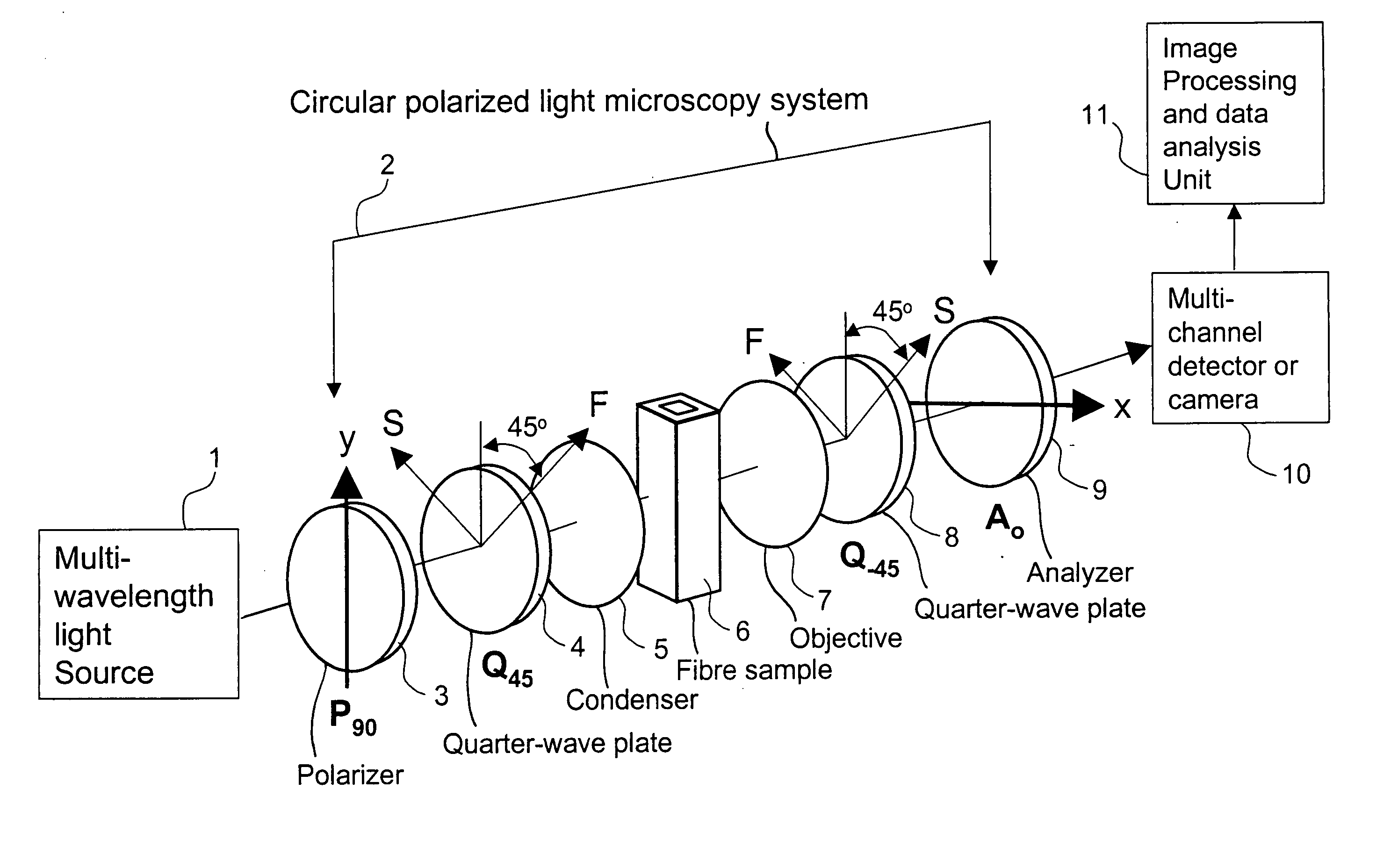

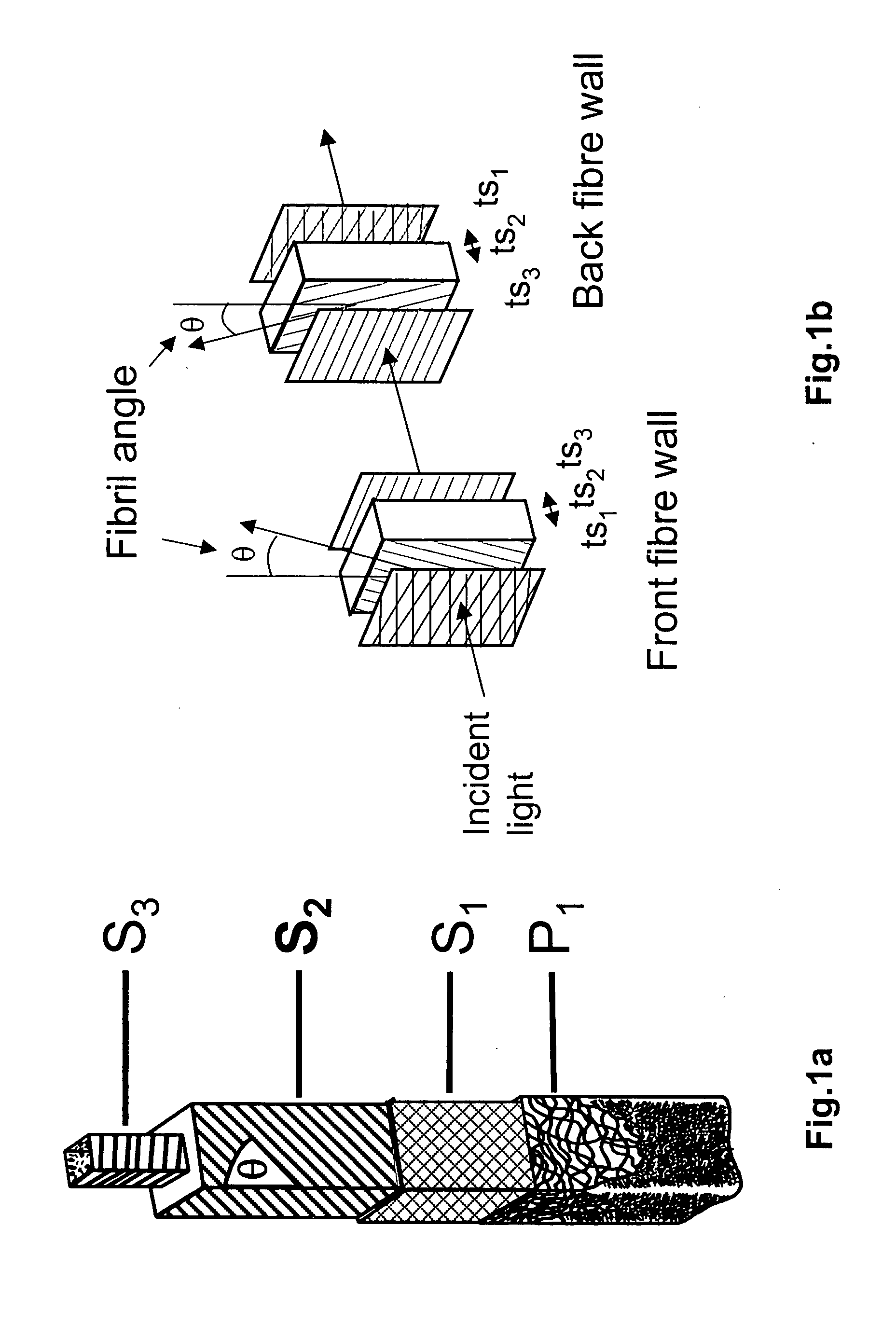

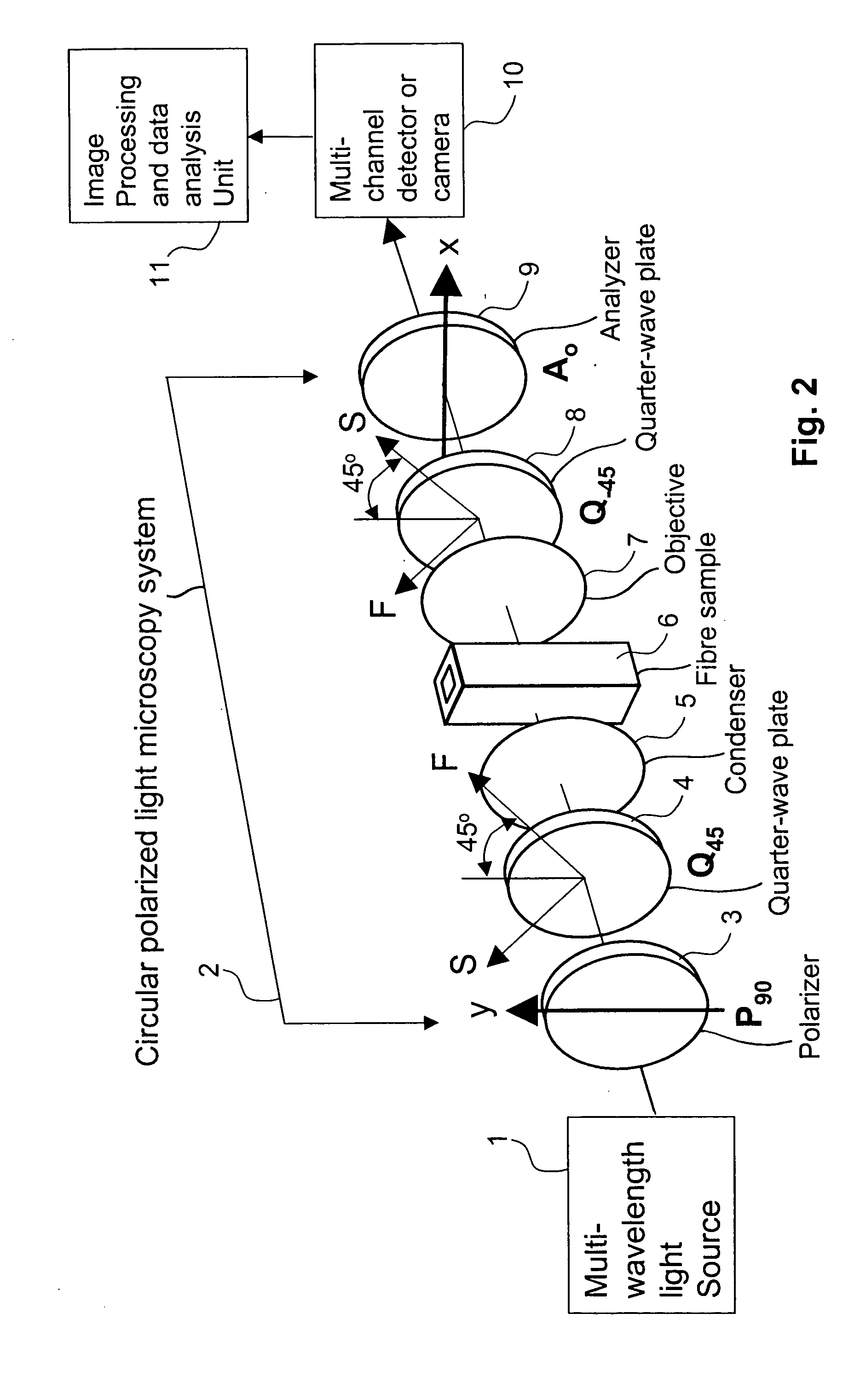

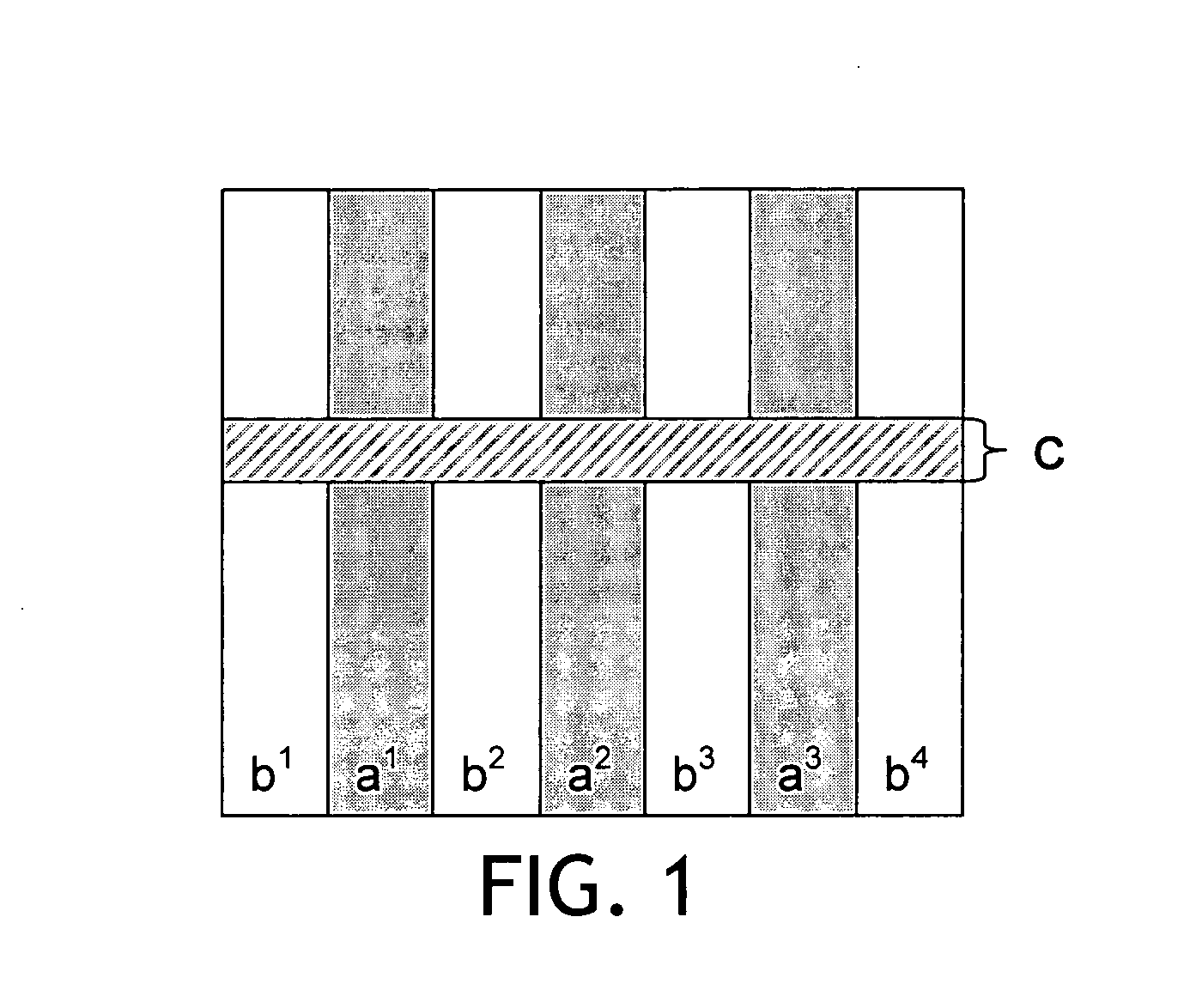

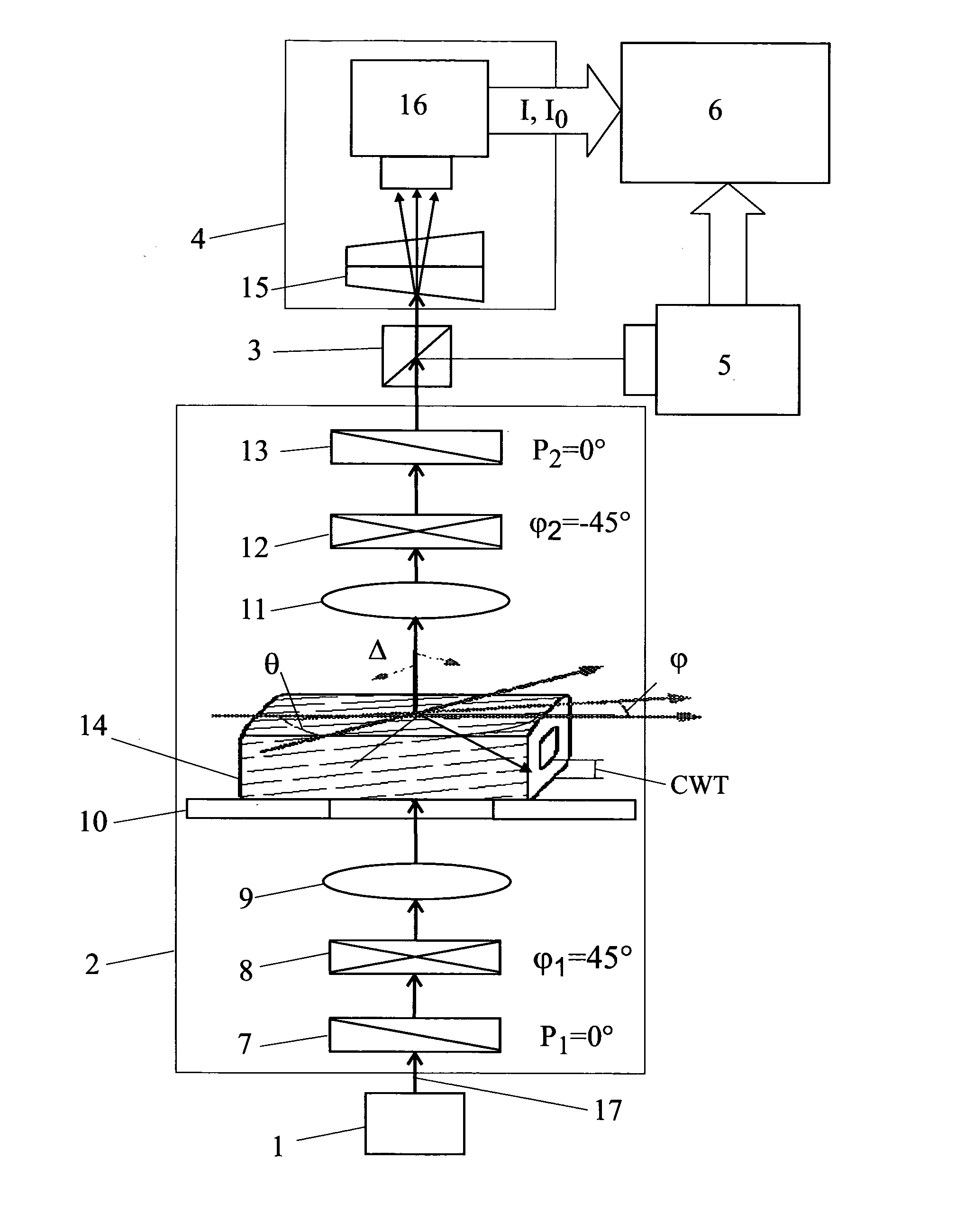

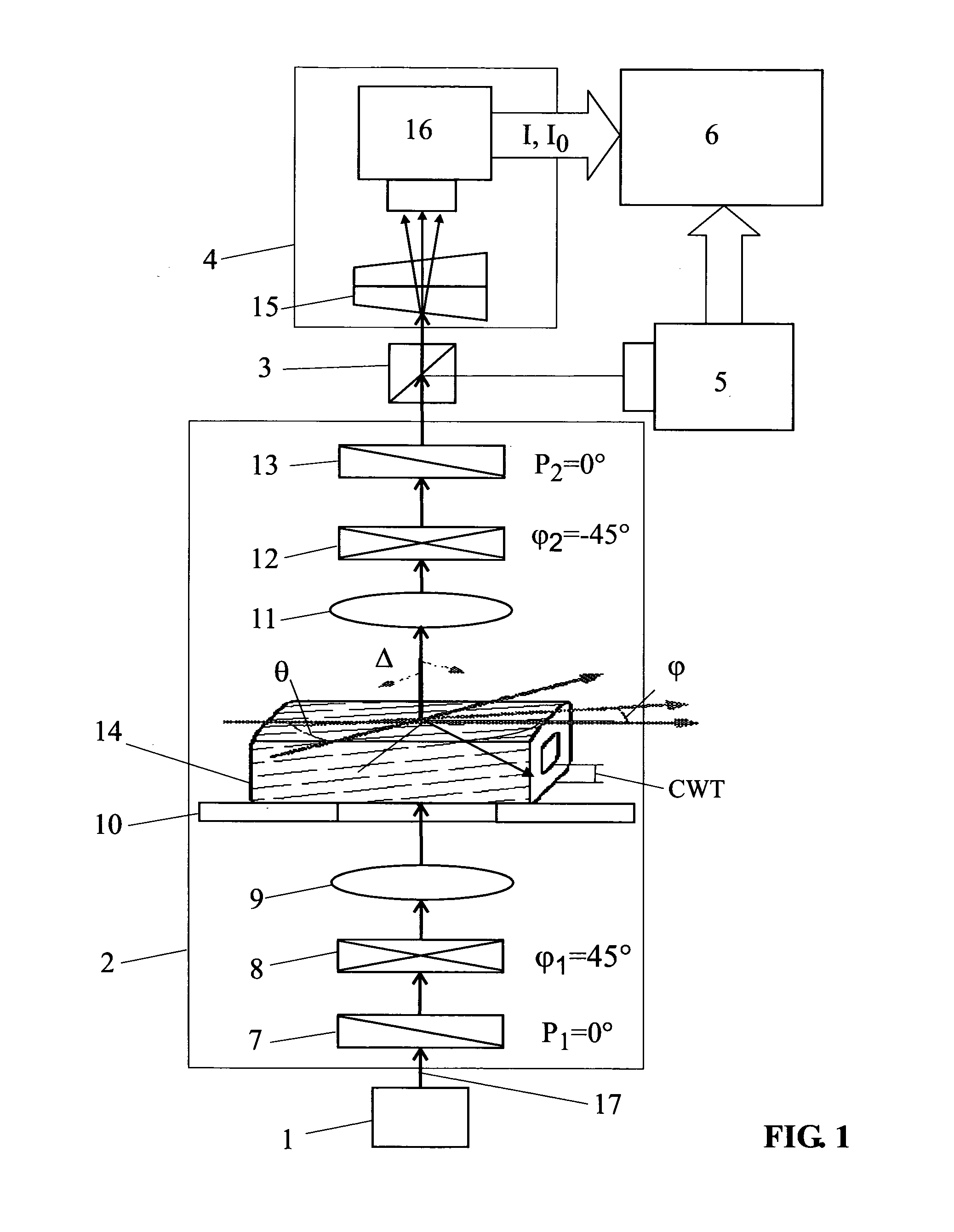

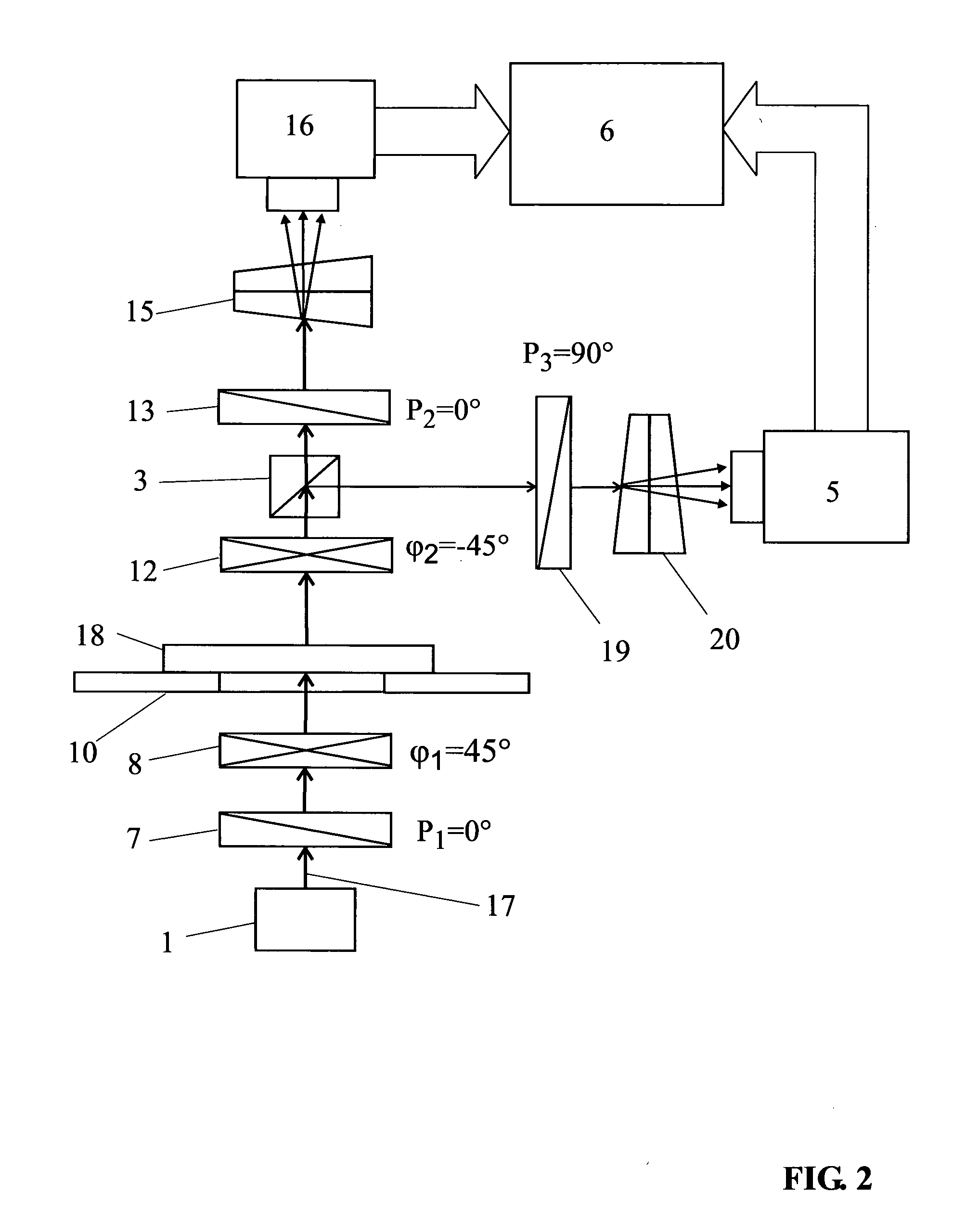

Circular polarized light method and device for determining wall thickness and orientations of fibrils of cellulosic fibres

ActiveUS20050122514A1Polarisation-affecting propertiesPhase-affecting property measurementsFibrilData analysis system

This invention provides a novel, rapid method and device for determining the relative phase retardation of a multi-layered specimen, which is related to the thicknesses of its layers and walls, and the orientations of its optical axes. An intact wood pulp fibre is a typical multi-layered birefringent specimen. This new method is based on the change of polarization of polarized light that passes through a specimen composed of birefringent layers with different optical axis orientations, such as directions of cellulosic microfibrils oriented differently in various layers of wood fibres. In particular, a novel solution is found to relate the emerging light intensity from an intact wood fibre to the incident light intensity, the wavelength of the light, and the relative phase retardations of various layers and orientations of their cellulosic microfibrils, such as fibril angle, in a circular polarized light system. This new method evaluates the transmitted light intensities of multiple predetermined wavelengths simultaneously to determine the optical and physical properties of a multi-layered specimen being measured. A device for determining the relative phase retardation (retardance) of fibre walls and the fibril angle of intact wood fibres in accordance with the presented invention comprises a light source with well defined multi-wavelengths, an achromatic circular polarized light system, appropriate imaging optics, a multi-channel camera such as a digital color camera that has two or more wavelength (color) detection channels, and an image processing and data analysis system. The measurements take advantage of the birefringence of cellulosic microfibrils, and thus require neither sample preparation nor high resolution optics. Specimen alignment is not required as specimens such as wood fibres are evaluated under circular polarized light. Compared with other methods, this invention is more rapid, accurate, and robust. This method can be automated, and implemented in a fibre flow-through system, thus allowing a rapid assessment of wood pulp fibre properties (on-line in real time).

Owner:FPINNOVATIONS INC

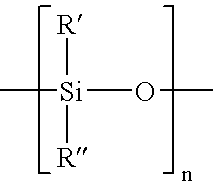

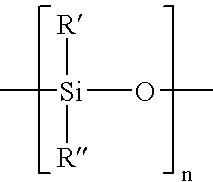

Absorbent articles comprising thermoplastic resin pretreated fibers

InactiveUS20060070712A1Good dispersionNatural cellulose pulp/paperPulp properties modificationCelluloseWater dispersible

One embodiment of the present invention is a fibrous structure that may comprise: cellulosic pulp fibers and pretreated cellulosic pulp fibers. The pretreated cellulosic pulp fiber is formed by pretreating cellulosic pulp fiber with a thermoplastic resin having a property selected from the group consisting essentially of water soluble, water dispersible, and combinations thereof.

Owner:KIMBERLY-CLARK WORLDWIDE INC

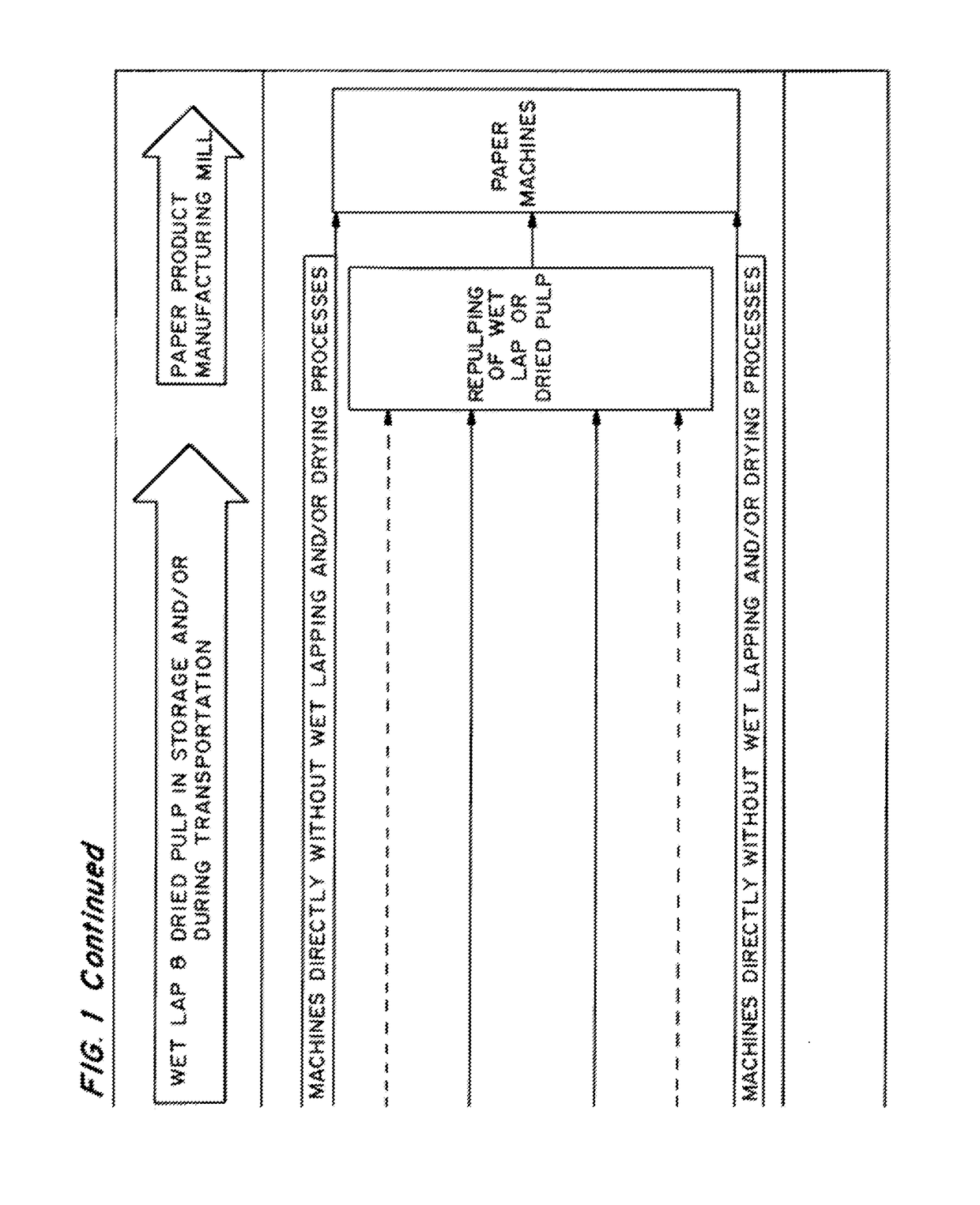

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20170328006A1Increasing pulp drainage and strength propertyQuality improvementMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Owner:ENZYMATIC DEINKING TECH LLC

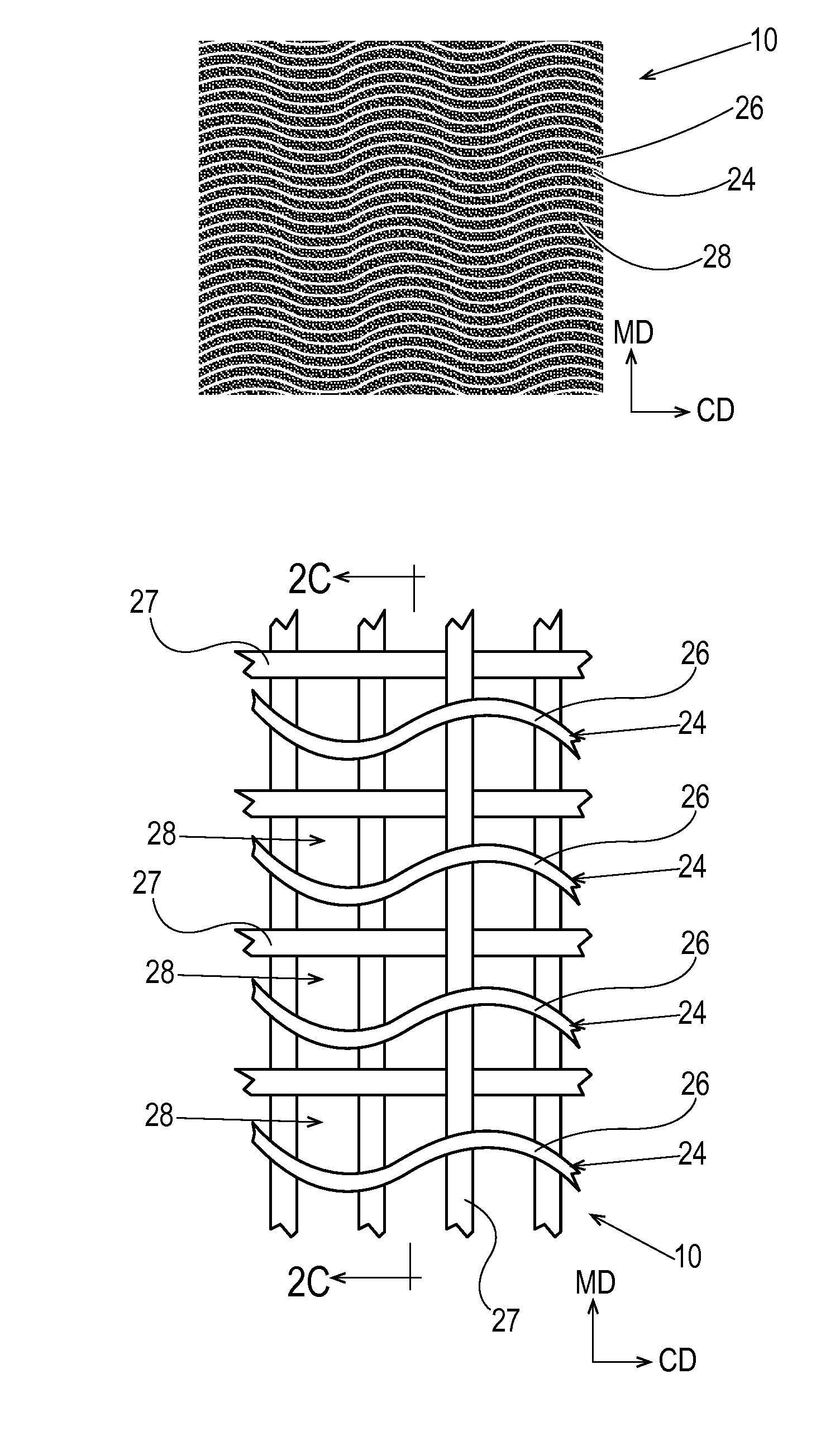

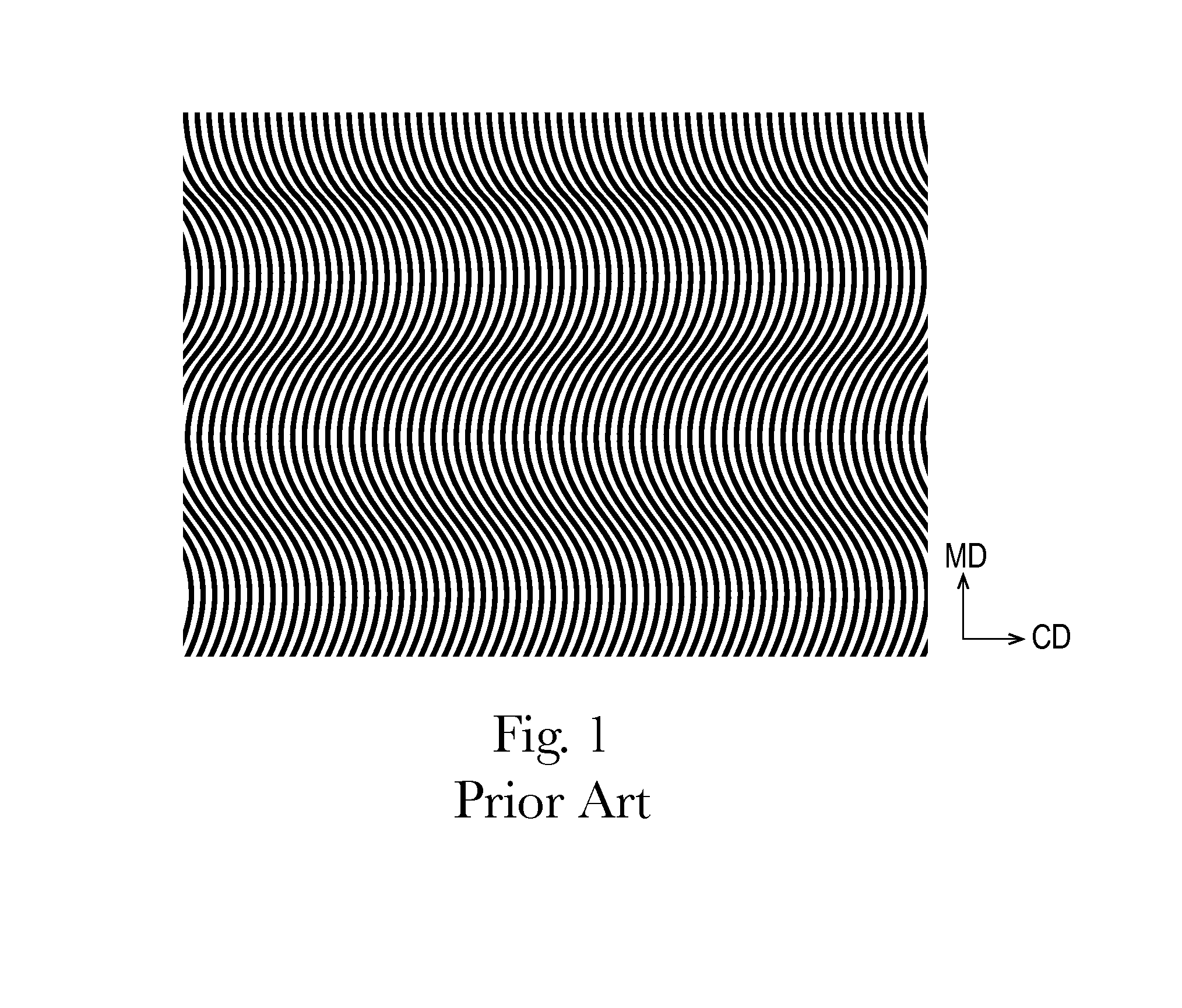

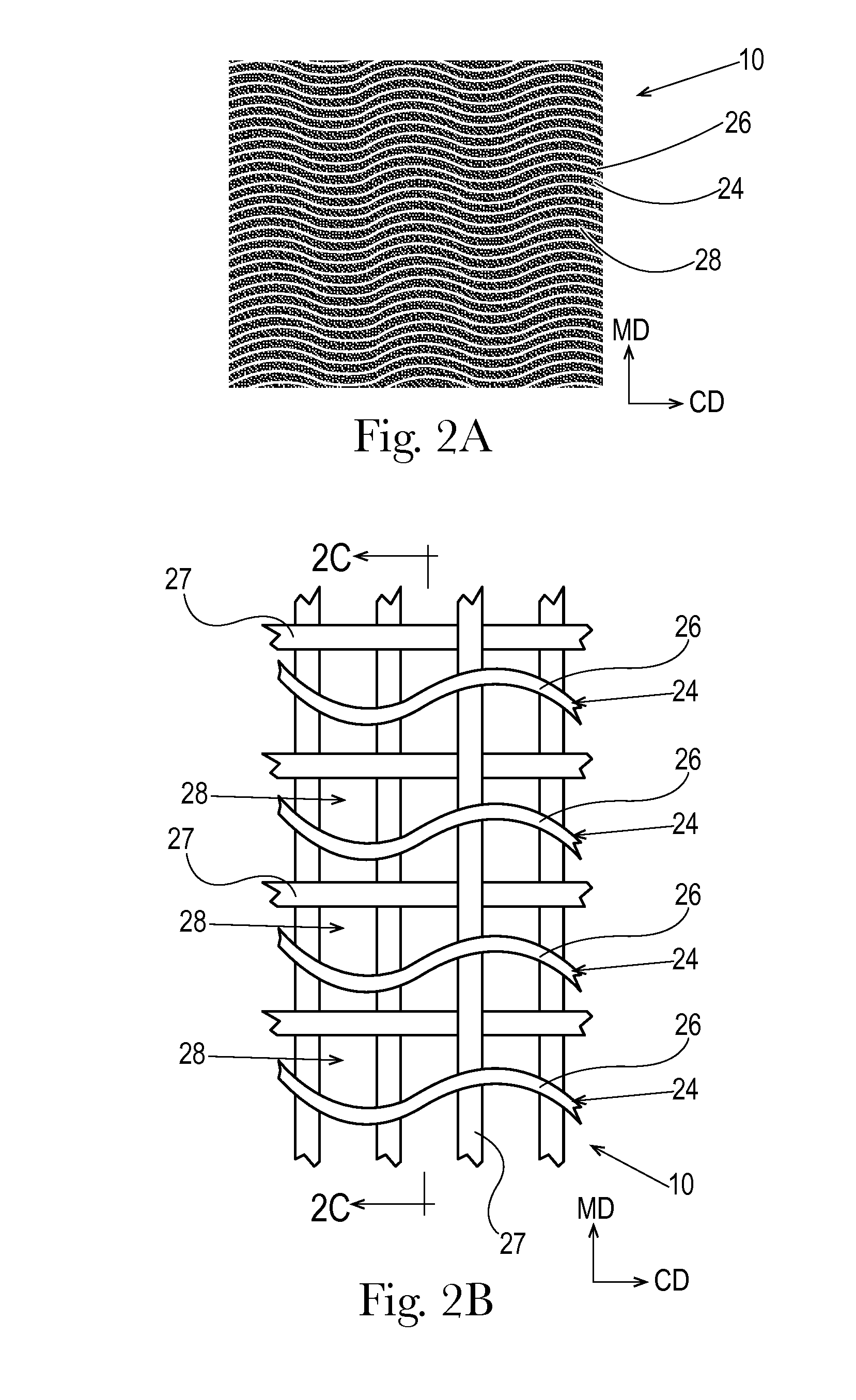

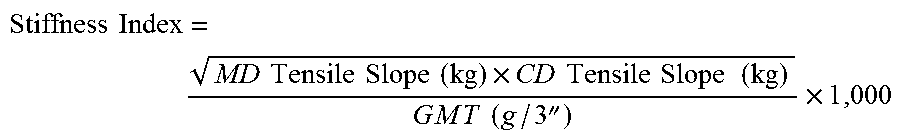

Sanitary Tissue Products with Superior Machine Direction Elongation and Foreshortening Properties and Methods for Making Same

Owner:THE PROCTER & GAMBLE COMPANY

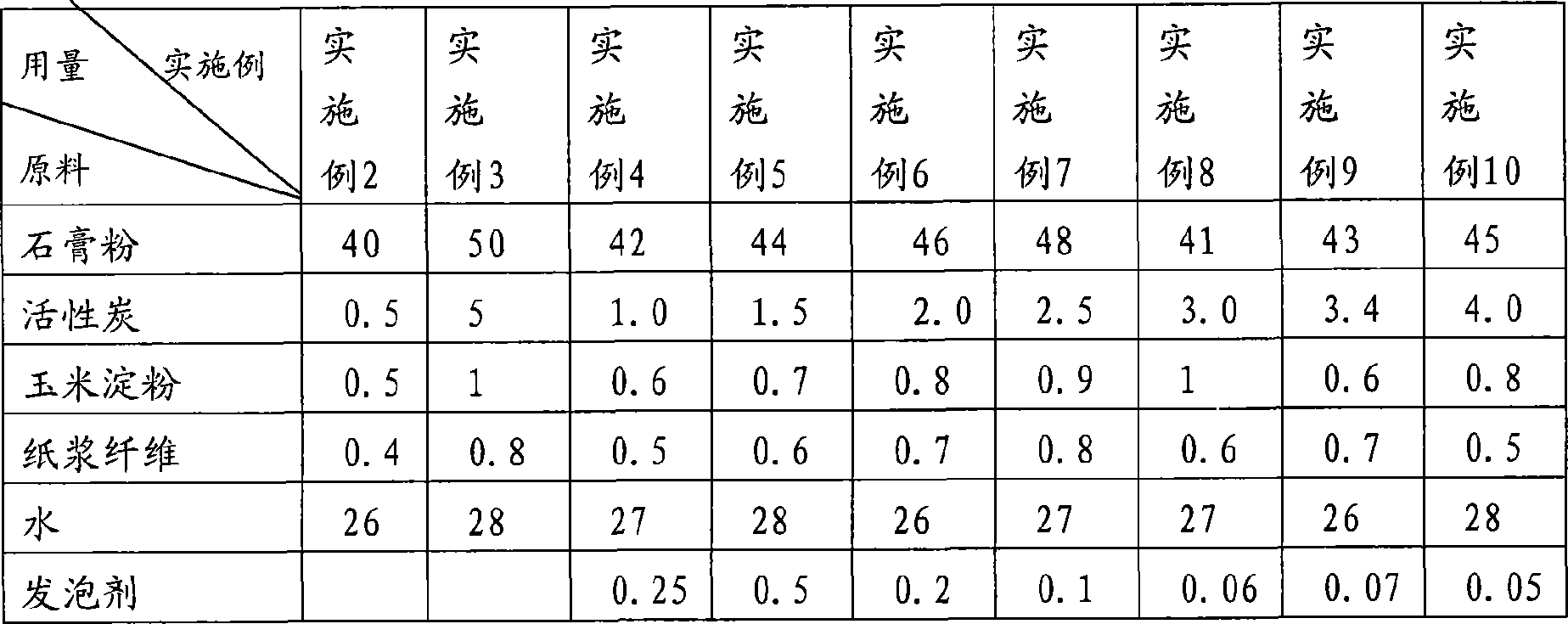

Gypsum plasterboard

InactiveCN101139199AImprove adsorption capacityReduce adverse effectsSolid waste managementCeramicwarePulp fibreGypsum

The present invention discloses a paper-surface gesso plate, which is made of the following components according to weight ratio: 40-50 percent of gesso powder, 0.5-5 percent of active carbon, 0.5-1 percent of corn amylum and 0.4-0.8 percent of paper pulp fibre. Each raw material after being matched together with water is put into a mixer for milling, and then is to be pressed into a mould; the molded gesso plate is to be dried after being cut; the gesso plate after being dried is to be made with the second cut; finally, the products are packed and stored in the warehouse. Because active carbon is added into the gesso plate, by the test and detection in the house decorated with the gesso plate, the result shows that each residual organic volatile brought from the indoor fitment and other decorative materials can be adsorbed effectively; the adsorbing effect is 2-5 times better than that of the gesso plate without added with the active carbon. Besides, the present invention has the long-term and persistent absorption function. The present can avoid the disadvantage to the body health by the deleterious volatile. The manufacturing process is simpler and the social and economical benefits are much greater.

Owner:HEBEI ANTAI PAPERBACKED PLASTERBOARD

Poly-fibre slurry cake pretreatment

InactiveCN1896369AGood dispersionUnleash the full enhancement potentialFibre typesPretreatment methodElastomer composites

The aramid pulp pretreatment process in the present invention relates to a pretreatment process insulating the surface of aramid pulp fibres with isolation medium. The used isolation medium contains inorganic isolation powder and lubricant, the inorganic isolation powder is mixed with incompact aramid pulp mixture and then with lubricant to prepare aramid pulp composite. In every 100 weight parts of aramid pulp composite, there are 20-30 parts of aramid pulp, 37.5-62.5 parts of inorganic isolation powder, and 10-40 parts of lubricant. The inorganic isolation powder is hollow glass microbeads of 1250- 5000 mesh and the lubricant is phthalate ester compound. The prepared aramid pulp composite is a homogeneous and stable fibre composite, the aramid pulp fibres in it disperse well in the elastomer matrix facilitating the enhancement of the performance of the elastomer composite materials.

Owner:BEIJING UNIV OF CHEM TECH

Method for applying water insoluble chemical additives with to pulp fiber

InactiveUS6984290B2Reduce the amount requiredNatural cellulose pulp/paperPulp properties modificationPulp fibreMaterials science

Pulp fibers can be treated with water insoluble chemical additives resulting in a minimal amount of unretained water insoluble chemical additives present after redispersing the treated pulp fibers in the process water. One embodiment of the present invention is a method for preparing chemically treated pulp fiber. A fiber slurry is created comprising process water and pulp fibers. The fiber slurry is transported to a web-forming apparatus of a pulp sheet machine thereby forming a wet fibrous web. The wet fibrous web is dried to a predetermined consistency thereby forming a dried fibrous web. The dried fibrous web is treated with a water insoluble chemical additive thereby forming a chemically treated dried fibrous web containing chemically treated pulp fibers. The chemically treated pulp fibers have an improved level of chemical retention of the water insoluble chemical additive and retain from between about 25 to about 100 percent of the applied amount of the water insoluble chemical additive when the chemically treated pulp fibers are redispersed in water.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of forming composite absorbent members

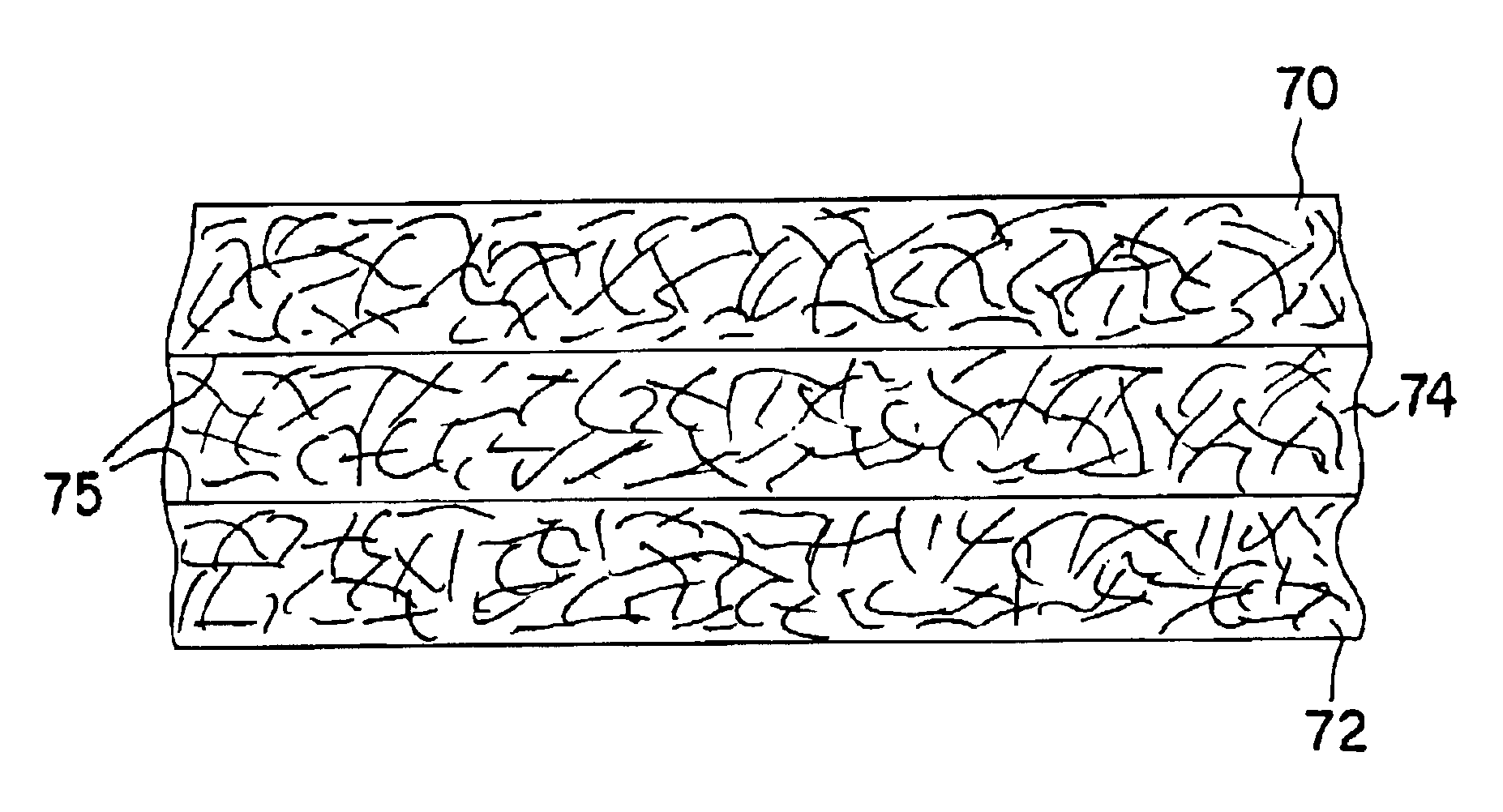

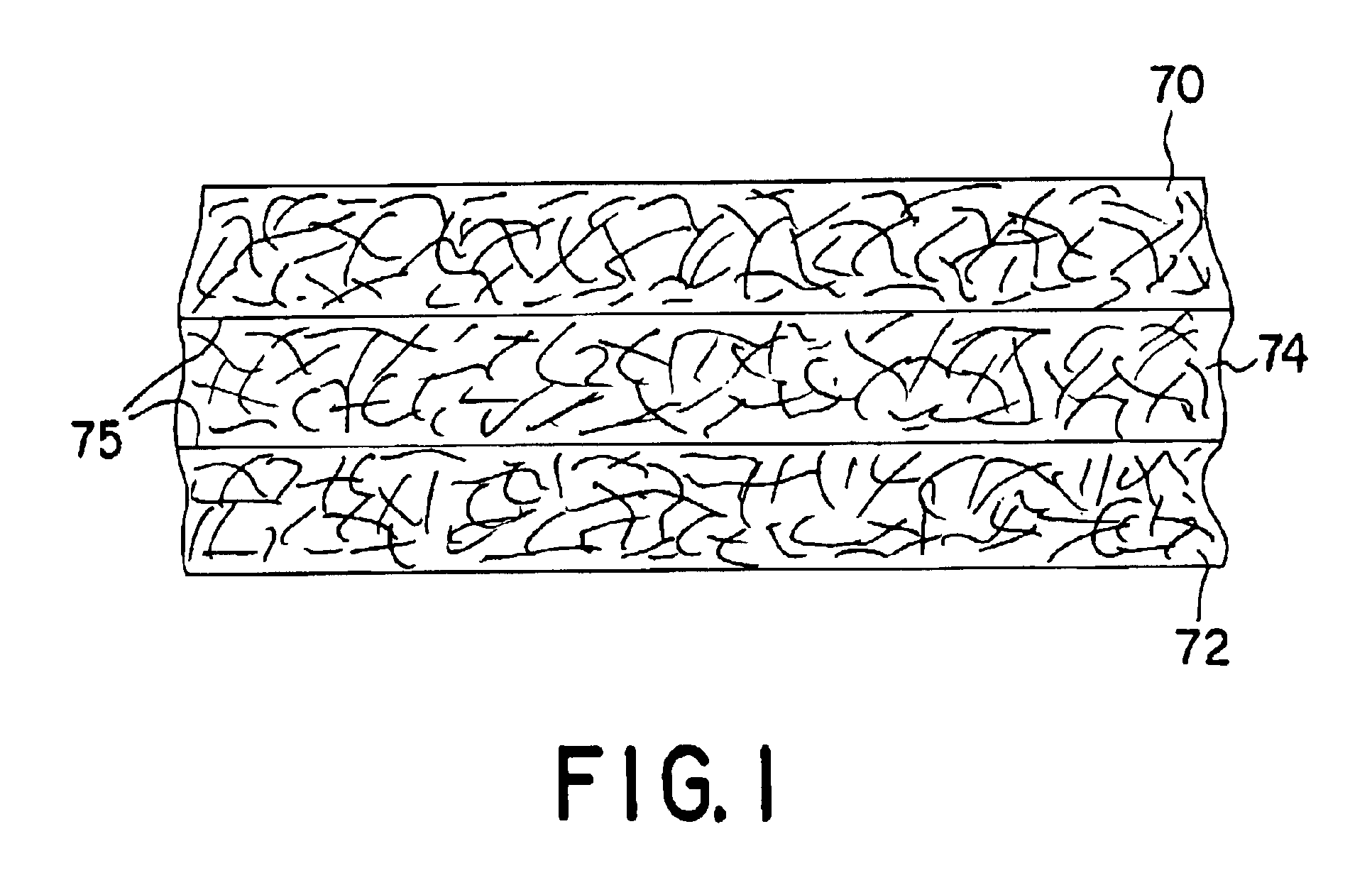

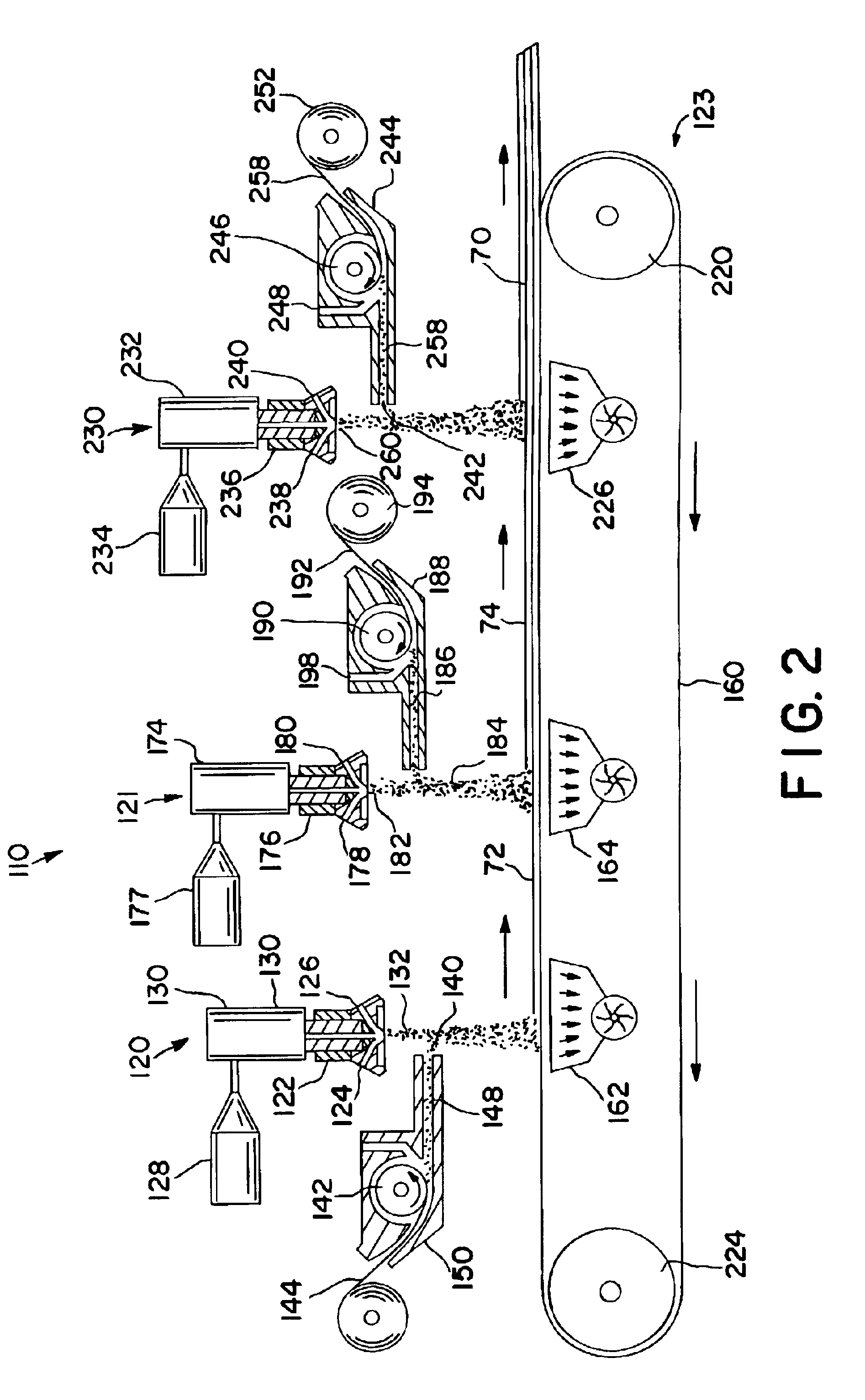

InactiveUS6932929B2High weight percentageSmall diameterCrochetingInspecting textilesFiberEngineering

A method for forming a composite absorbent member is provided that includes:a) extruding a first fibrous component through a first meltblowing die and intermingling pulp fibers with the first fibrous component to form a first admixture;b) extruding a second fibrous component through a second meltblowing die and intermingling pulp fibers with the second fibrous component to form a second admixture; andc) codepositing the first and second admixtures on a collecting surface so as to form a composite structure having at least a first layer and a second layer. The second layer has a higher weight percentage of pulp fibers than the first layer, and the average diameter of the pores within the second layer is smaller than the average diameter of the pores within the first layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Natural green health care knitwear and its mfg. method

A health-care knitting fabric is made up of hemp fibre, color cotton fibre, bamboo fibre, soybean protein fibre, chitin fibre, and natural wooden pulp fibre through twisting, knitting, boiling, softening, baking and high-pressure ironing.

Owner:王新文

Soft tissue hydrophilic tissue products containing polysiloxane and having unique absorbent properties

ActiveUS20050136265A1Improve hydrophobic stabilityReduce hydrophobicityNon-fibrous pulp additionNatural cellulose pulp/paperFiberSoft tissue

Owner:KIMBERLY-CLARK WORLDWIDE INC

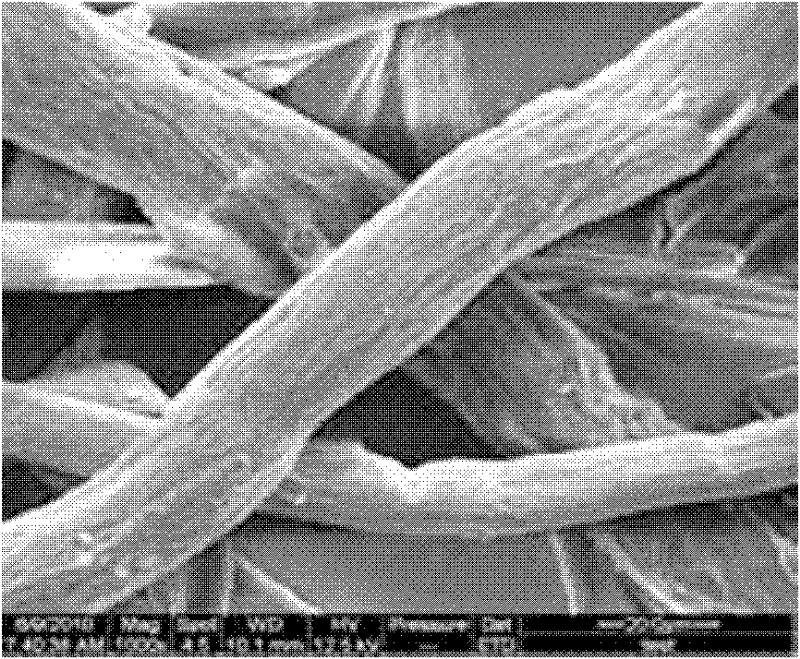

Pulp-grinding method for improving fibre brooming and application thereof in papermaking

InactiveCN101691700AEnhance brooming effectHigh strengthOther chemical processesPulp beating/refining methodsSodium BentonitePrecipitated calcium carbonate

The invention discloses a pulp-grinding method for improving fibre brooming, comprising the following steps: adding rigid filler to the pulp before grinding, and grinding after mixing the rigid filler and the pulp fibre, wherein the additive amount of the rigid filler accounts for 1%-30% of the total mass of the pulp; the rigid filler is any one or the mixture of several types of PCC, GCC, Talc, titanium pigment and bentonite of filler grade; and the rigid filler can also be fibrous mineral fibre. The adoption of the pulp-grinding method can improve devillicate brooming degree of the fibre, improve paper strength and interweaving, or can improve the ash content of paper and reduce fibre consumption under the condition of maintaining a considerable paper strength, and can reduce production cost and reduce the grinding energy consumption while protecting the environment.

Owner:GOLD EAST PAPER JIANGSU

Nonwoven fabrics of short individualized bast fibers and products made therefrom

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin having a mean length less than 6 millimeters. The nonwoven fabric can include staple fibers and / or pulp fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

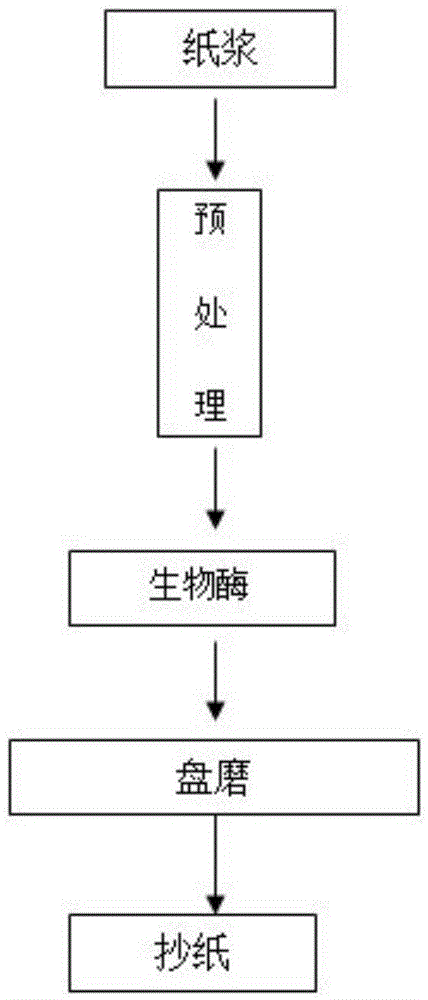

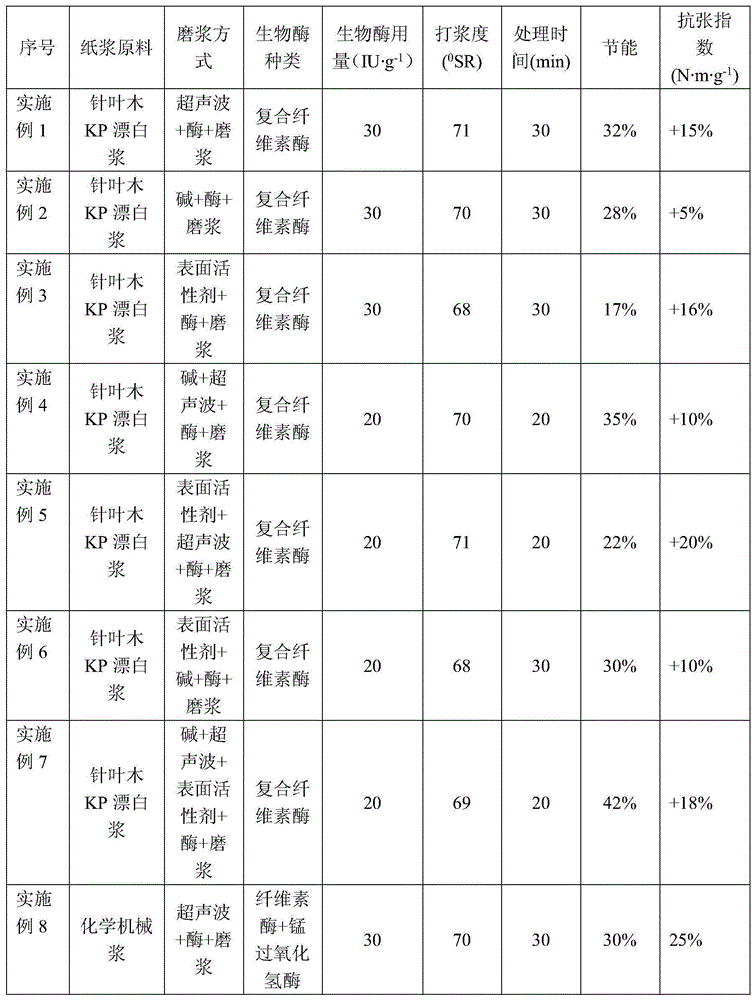

Energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp

ActiveCN104452398AImprove the physical properties of paperSave paper physical propertiesMicroorganism/enzyme additionPaper/cardboardPre treatmentPulp fibre

The invention discloses an energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp. The method comprises the following steps that (1) paper pulp fibers are dissolved in water, even defibering is carried out, and then pretreatment is carried out; (2) biological enzymes are added to the treated paper pulp for treatment, the dosage of the biological enzymes ranges from 10 IU / g to 60 IU / g, the temperature ranges from 40 degrees to 60 degrees, the pH value ranges from 6 to 9, the concentration of the paper pulp ranges from 3 wt% to 8 wt%, and treatment is carried out for 10 min to 30 min; (3) continuous millstone milling and beating are carried out on the pulp of the step (2), and the pulp is stored for standby application. The method remarkably improves the efficiency of subsequent biological enzyme treatment, and overcomes the defects that enzyme treatment time is too long in biological enzyme assistant defibrination production and energy conservation in defibrination and the physical strength of finished paper formed by fibers cannot be achieved at the same time, the defibrination energy consumption and the defibrination time for producing the viscous paper pulp are saved, the defibrination energy consumption of chemical bleached needle wood pulp and chemithermomechanical pulp of needle wood is reduced by 15%-45%, and the physical properties of finished paper formed by pulp fibers can be improved.

Owner:五洲特种纸业(龙游)有限公司

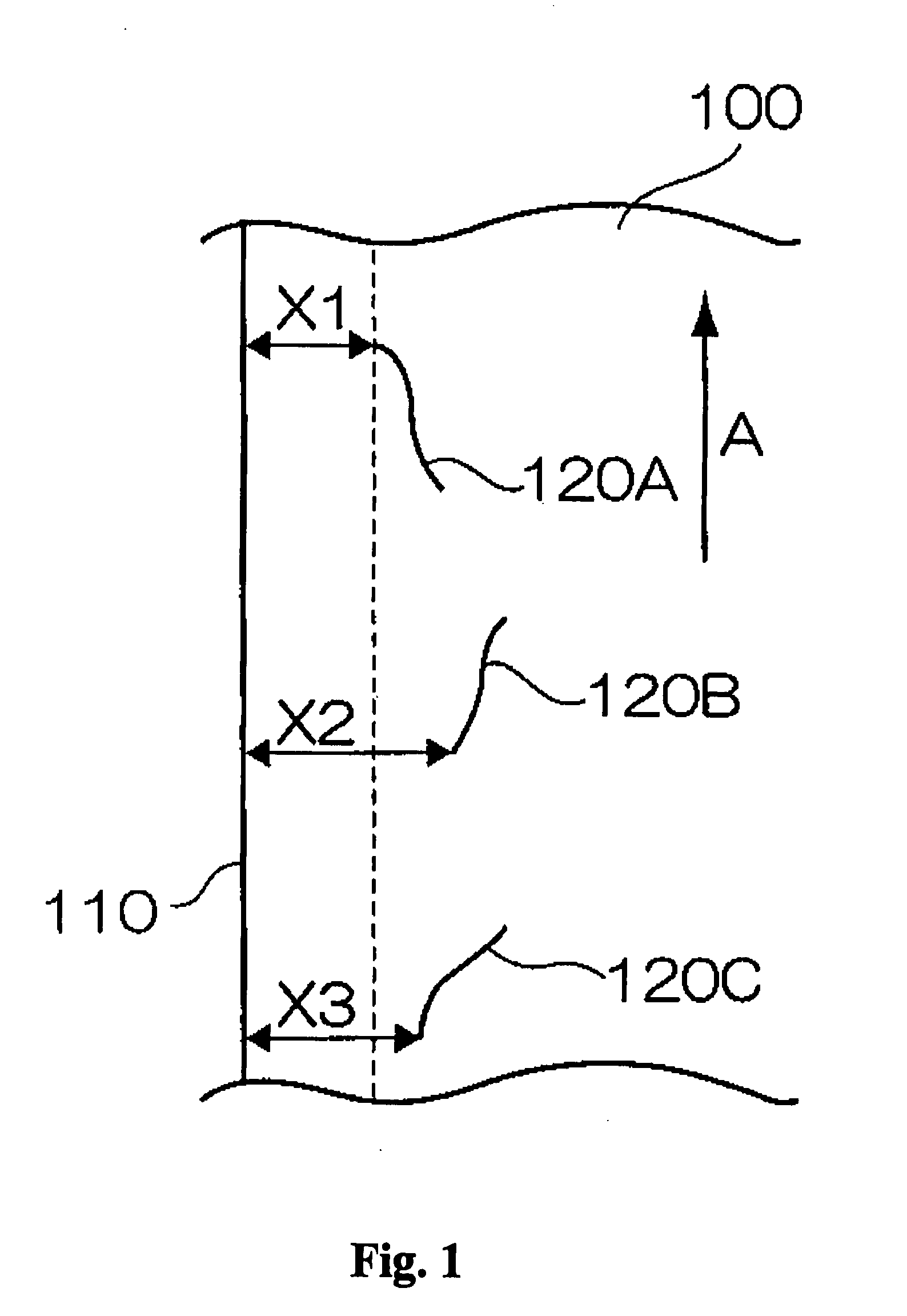

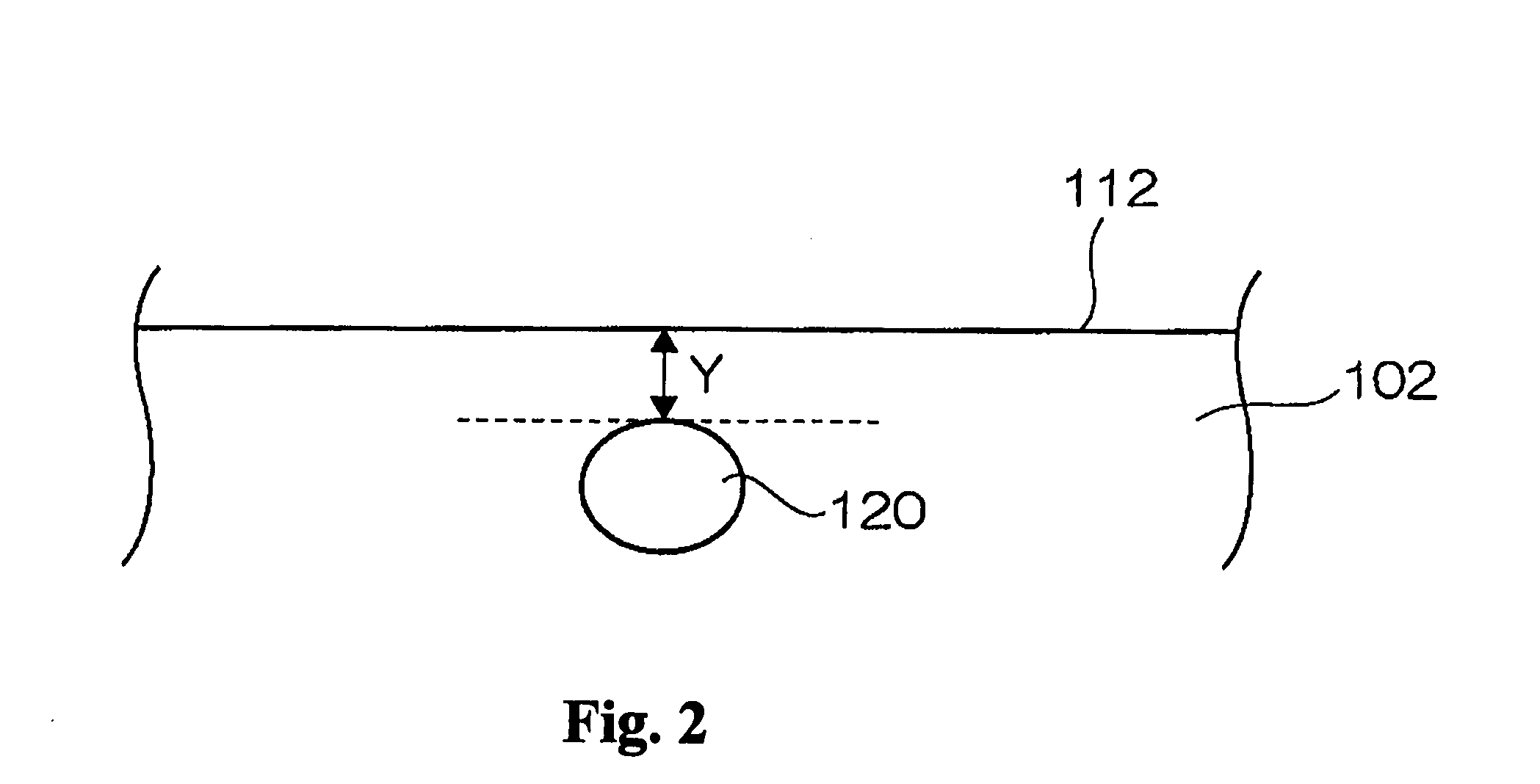

Method and equipment for measurement of intact pulp fibers

InactiveUS20100020168A1Real-time measurementAvoid dataRadiation pyrometryImage analysisNon destructiveMicrophotograph

A non-destructive method capable of real-time or on-line measurement of a wood or pulp fiber without sample pretreatment for the microfibril angle and the path difference. A circular polariscope in combination with a line spectral camera generating a micrograph insensitive to the orientation of a fiber and determined only by the fiber's properties related to polarized light. A line image across the fiber is captured and dispersed it into a spectral image to perform a real-time spectral analysis of the fiber's image.

Owner:YE CHUN

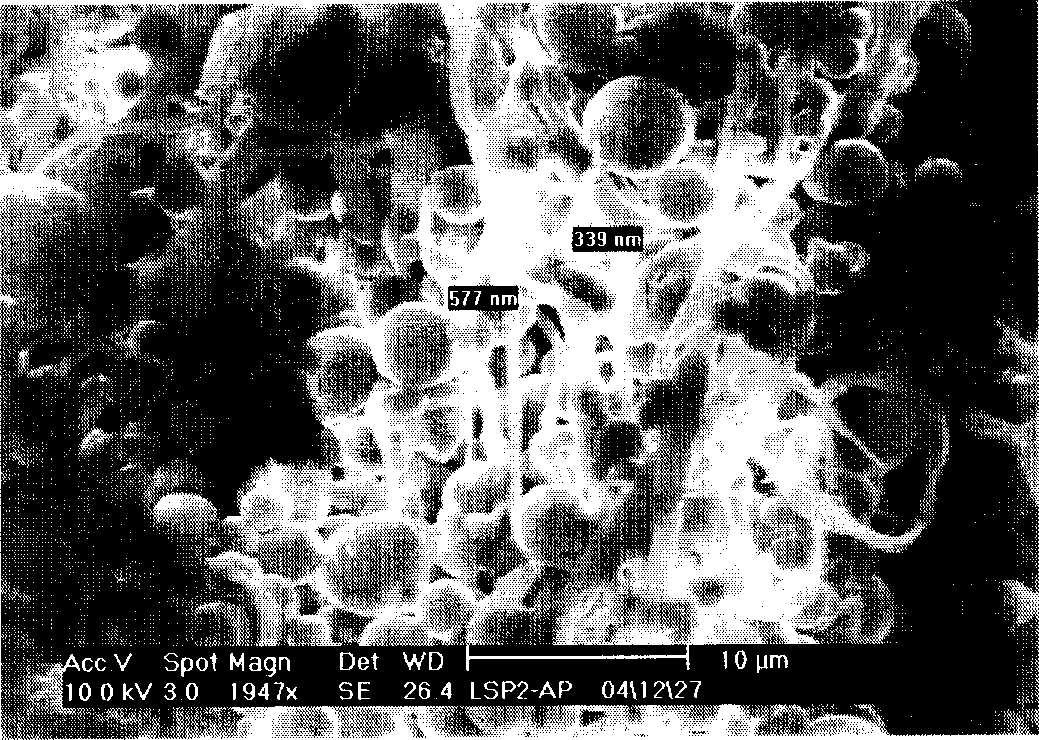

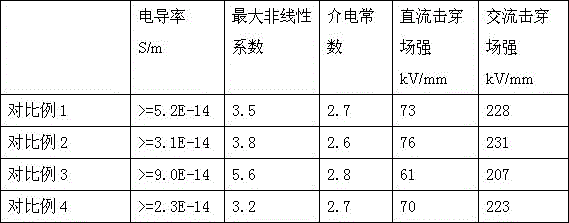

Nano modified paper based on surface modification and preparation method thereof

InactiveCN105696408AEvenly distributedNot easy to reunitePlastic/resin/waxes insulatorsDryer sectionPolymer scienceLiquid state

The invention discloses nano modified paper based on surface modification and a preparation method thereof and belongs to the technical field of conductive non-linear insulating paperboards, aiming at solving the problems that nano functional materials in modified paper are partially agglomerated and are not uniformly distributed so that the effect is difficult to exert, and the retention amount is low due to the fact that the nano functional materials are not firmly combined with paper pulp fibers and the like. The product is prepared from liquid-state paper pulp, a modifying agent solvent, a functional group modifying agent and functional fillers. The method comprises the following steps: 1, mixing the modifying agent solvent and the functional group modifying agent; 2, adding the functional fillers; and putting the mixture into a water bath and carrying out ultrasonic treatment; and 3, adding the liquid-state paper pulp; after electrically stirring and uniformly mixing, forming wet paper; and dehydrating in vacuum, hotly pressing, and drying in vacuum to obtain the nano modified paper based on the surface modification. The nano modified paper is applied to insulation in a converter transformer and a wire outlet device. With the adoption of the product disclosed by the invention, an electric field in an oil paper composite insulating structure can be uniformly distributed.

Owner:HARBIN UNIV OF SCI & TECH

Novel complex phase electromagnetic shielding-function paper and preparation method thereof

InactiveCN101994275AEvenly dispersedImprove long and short distance synergistic conduction effectSynthetic cellulose/non-cellulose material pulp/paperCarbon fibersModified carbon

The invention discloses novel complex phase electromagnetic shielding-function paper, which relates to the technical field of specific paper with the electromagnetic shielding function and is prepared by the following steps: non-deinked waste paper pulp fiber is used as matrices, carbon fiber and carbon black are dispersed among the fiber, the carbon fiber is modified through coupling agents at first, and then modified carbon fiber as surfactants is added. Compared with the traditional relevant shielding-function paper, the novel complex phase electromagnetic shielding-function paper replaces fresh pulp or resin and the like by office waste paper, conforms to the requirements of waste regeneration and reutilization, low carbon, energy saving and environment protection, does not need deinking work procedures, reserves effective electric conducting ingredients of carbon black in ink, simplifies the production process and greatly reduces the production cost. The hydrophilicity of the carbon fiber is improved through couple modification treatment, then, the dispersivity of the carbon fiber and the pulp fiber is improved through surfactants such as Tween-80 and the like, and the long-range and short-range cooperative electric conducting effect of three-dimensional networks is improved through carbon black filling. Through tests, the prepared finished paper has the advantages of high strength, low electric resistivity, low reflection, high wide-frequency absorption, low quantitative quantity, wide softness adaptability and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

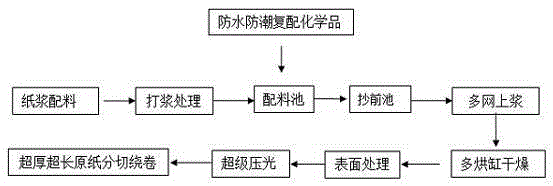

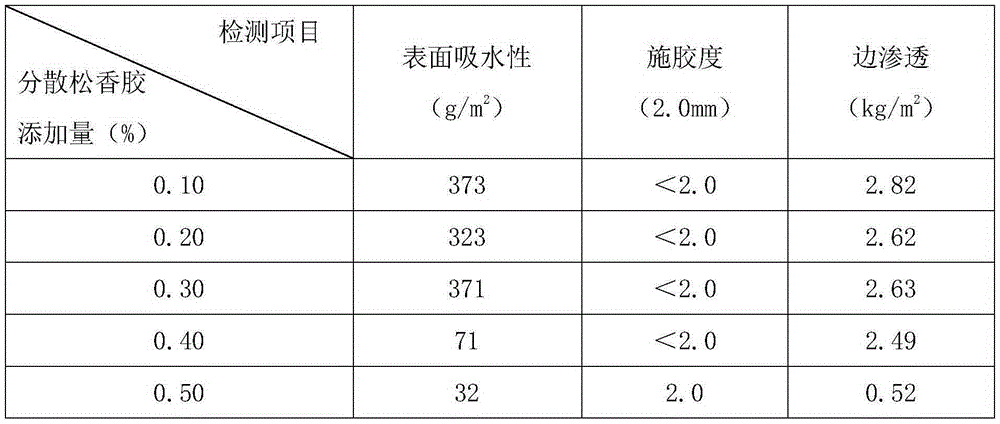

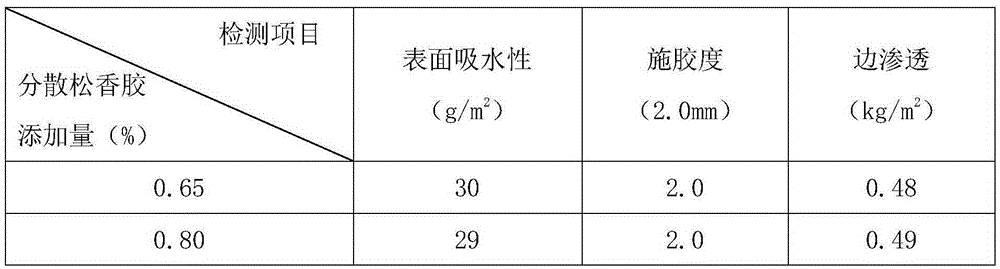

Waterproof and damp-proof raw paper dedicated for electronic paper tape, and preparation method thereof

InactiveCN105350375AGuaranteed StrengthImprove bondingWater-repelling agents additionPulp beating methodsFiberFibrillation

The present invention discloses a waterproof and damp-proof raw paper dedicated for electronic paper tapes, and a preparation method thereof. The method is characterized in that untwining and fibrillation are carried out on pulp fibers, fibrillation and cutting are further carried out so as to enable a pulp beating degree to reach 45 degree SR to 48 degree SR and a fiber wet weight to be reduced to 5.5 g to 8.0 g; and a water-resistant damp-proof composition is added in each layer, 1.0%-2.5% of the water-resistant damp-proof composition is added in relative to 100 parts of the pulp fibers, the water-resistant damp-proof composition including 0.15+-0.015 % of a wet strength agent PAE, 0.50+-0.05 % of gum rosin or an alkyl ketene dimer (AKD), 0.10+-0.01 % of silicon and fluorine type polymers, and 0.15+-0.015 % of ammonium zirconium carbonate. According to the above method, defibrination treatment is utilized, and a water-resistant damp-proof functional chemical is added in the pulp and coated on the surface of paper, surface water absorption and an edge permeation index of the raw paper are lowered than like products on the market, and water-resistance and damp-proofness of the raw paper are the best.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

Plant paper pulp fiber modifying agent and modifying method using same, and filter paper and preparation method thereof

The invention relates to a modifying method of a plant paper pulp fiber modifying, and filter paper and a preparation method thereof, belonging to the fields of modification of plant paper pulp fiber and preparation of filter paper. The invention aims to solve the problem of failure to implement modification of plant paper pulp fiber since no plant paper pulp fiber modifying agent and modifying method exist in the prior art, and the problem of high cost in the prepared filter paper in the prior art, or that the prepared filter paper can not have small pore size on the premise of ensuring high air permeability. The plant paper pulp fiber modifying method comprises the following steps: 1. preparing the modifying agent; and 2. modifying. The filter paper is prepared from the following components in parts by weight: 15-45 parts of plant paper pulp fiber modified sulfate softwood pulp, 5-15 parts of sulfate hardwood pulp and 45-75 parts of plant paper pulp fiber modified mercerized sulfate softwood pulp. The invention is used for modifying plant paper pulp fiber and preparing filter paper.

Owner:NORTHEAST FORESTRY UNIVERSITY

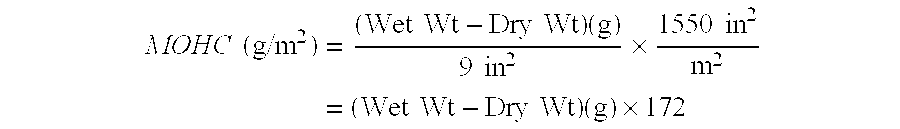

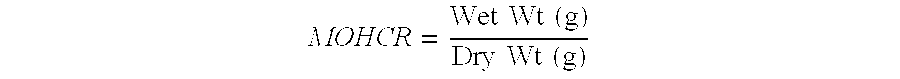

Highly durable towel comprising non-wood fibers

ActiveUS20180135249A1Strong water absorptionHigh yieldBathroom accessoriesPaper/cardboardMedicineWet strength

The present invention relates to tissue products comprising high yield hesperaloe fiber having improved wet performance, such as improved absorbency, CD Wet / Dry Ratio and CD Wet Durability. The addition of high yield hesperaloe pulp fibers surprisingly improves the CD Wet / Dry ratio without negatively affecting the absorbency of the tissue product. For example, tissue products of the present invention generally have an Absorbent Capacity greater than about 6.0 g / g, such as from about 8.0 to 8.0 g / g. As such the tissue products are durable when wet, but are still sufficiently absorbent. This balance of absorbency and wet strength is not found in the prior art without resorting to adding latex binders or the like to the tissue product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Recording medium and sheet

InactiveUS20080018674A1Non-fibrous pulp additionNatural cellulose pulp/paperShortest distanceEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

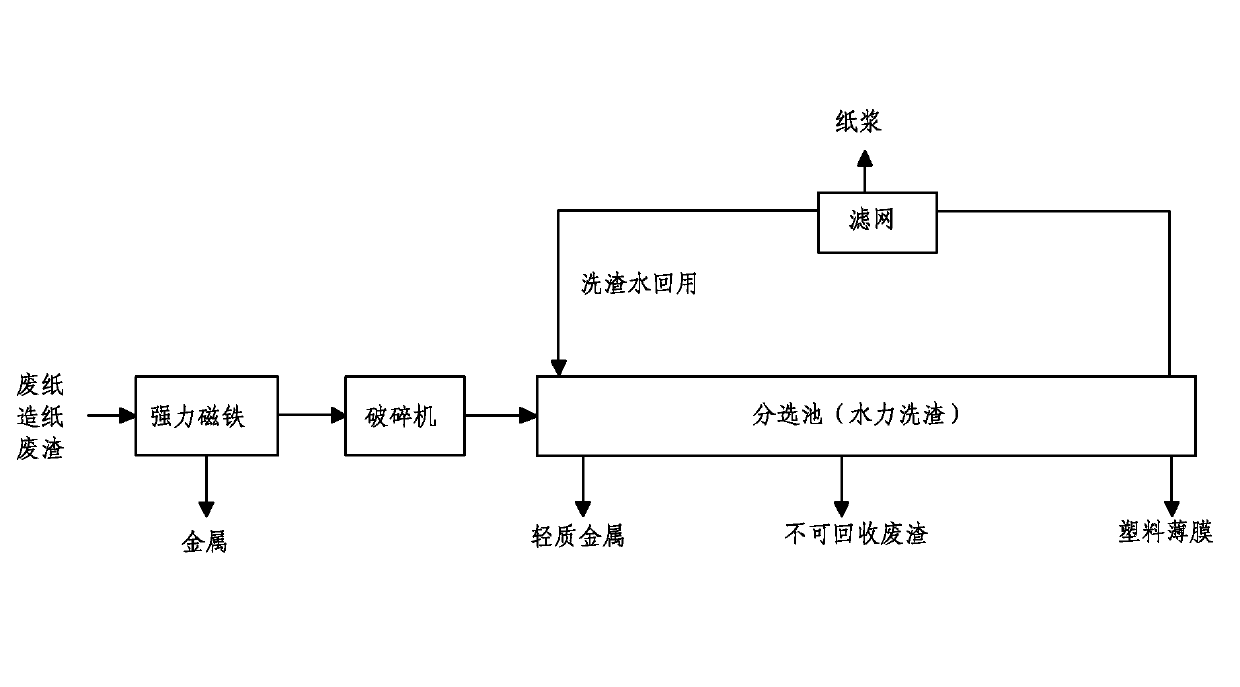

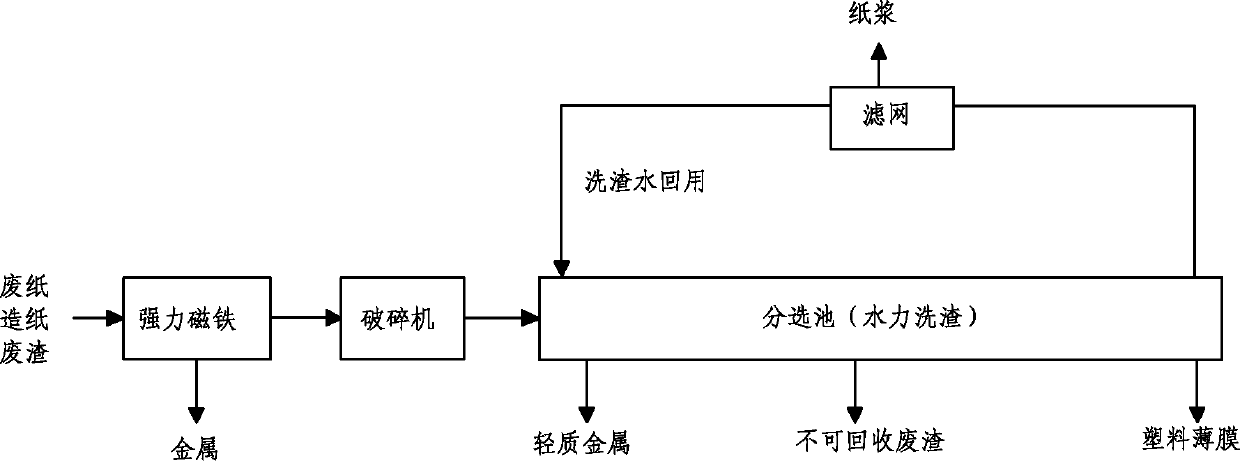

Method for recycling papermaking waste residues

InactiveCN102671922AImprove utilizationLow costSolid waste disposalPaper recyclingWastewaterProcess engineering

The invention relates to the technical field of processing of papermaking waste residues, in particular to a method for recycling papermaking waste residues. The method for recycling the papermaking waste residues comprises the processing steps of impurity removal, smashing, washing slag separation and recycling and filtering, wherein the impurity removal is performed to remove metal in the papermaking waste residues, the impurity-removed papermaking waste residues are put into a smashing machine in the smashing step to enable the papermaking waste residues to be smashed completely, a sorting pool is utilized to classify and recycle materials in the papermaking waste residues in the step of washing slag separation and recycling, and papermaking waste water produced after the separation and recycling is filtered to recycle paper pulp fiber. By means of the method for recycling the papermaking waste residues, more than 40% of materials in the waste residues can be recycled, the recycle rate of the materials in the papermaking waste residues is high, and the method has the advantages of being simple and mature in process and low in device cost and production cost and facilitating large-scale general popularization and application.

Owner:DONGGUAN NINE DRAGONS PAPER IND

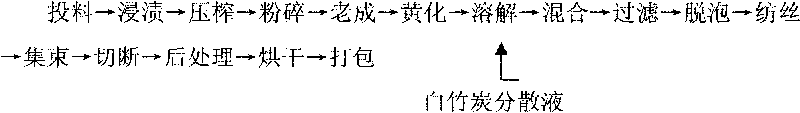

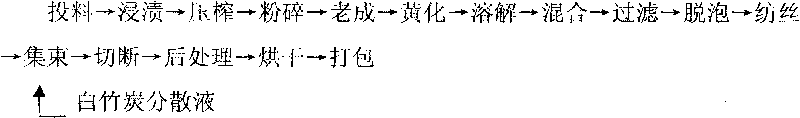

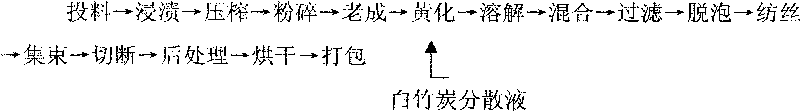

Compound function type bamboo pulp fibre and preparation method thereof

ActiveCN101724932AHigh strengthNo impact on the production processMonocomponent cellulose artificial filamentEmissivityComposite function

The invention relates to a compound function type bamboo pulp fibre prepared by taking white bamboo charcoal as a functional material and a preparation method thereof. In the prepared compound function type bamboo pulp fiber, the fiber content is as follows: absolute dried fiber content is 85-93% in terms of weight, the balance water and impurities remained in the fiber production process like water, oil, etc. In the invention, the fiber far-infrared emissivity is more than 82%, the anion concentration is over 2000 / cm<3>, the sterilizing value is larger than 0.3, and the bacteriostatic value is larger than 2.0, thus preserving the excellent performance of bamboo pulp fiber such as hygroscopicity and permeability, softness and smoothness, antibiosis and the like and creating a new field for developing functional fiber.

Owner:吉林化纤股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com