Gypsum plasterboard

The technology of gypsum board and gypsum powder is applied in the field of decoration materials, which can solve the problems of human health threats, and achieve the effects of significant social and economic benefits, avoiding adverse effects, and good prospects for promotion and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Pour 45Kg of 200-250 mesh gypsum powder, 3.5Kg of 60-100 mesh activated carbon powder, 0.7Kg of corn starch, 0.5Kg of pulp fiber and 28Kg of water into the mixer at the same time. After the gypsum board is cut, it is dried in a drying furnace. The drying is divided into a preheating zone, a high temperature zone and a low temperature zone. The drying temperature is 80-90°C, and the dried gypsum boards are cut for the second time and packed into storage.

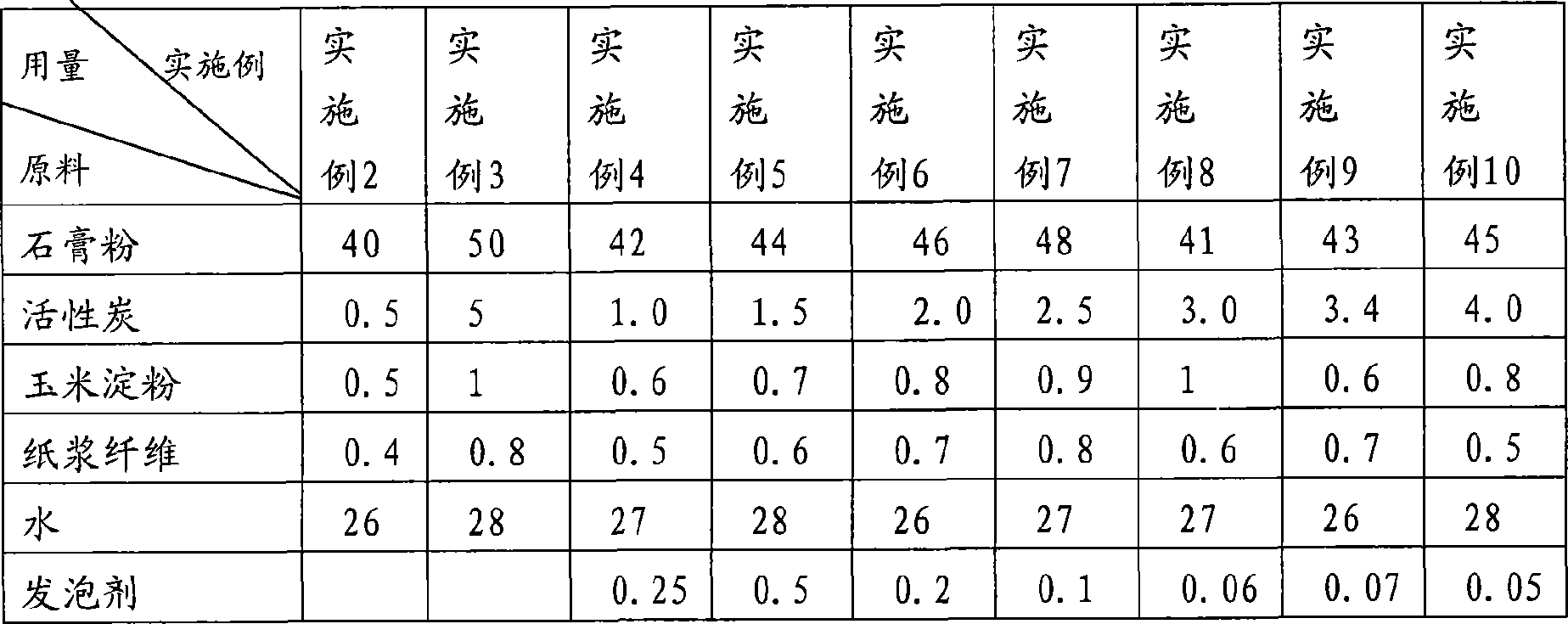

[0019] The difference between other embodiments and embodiment 1 is shown in the table below.

[0020] Unit: (Kg)

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com