Waterproof and damp-proof raw paper dedicated for electronic paper tape, and preparation method thereof

A technology of paper tape and base paper, applied in pulp beating method, pulp beating/refining method, papermaking, etc., to achieve the effect of low cost, high bonding strength and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

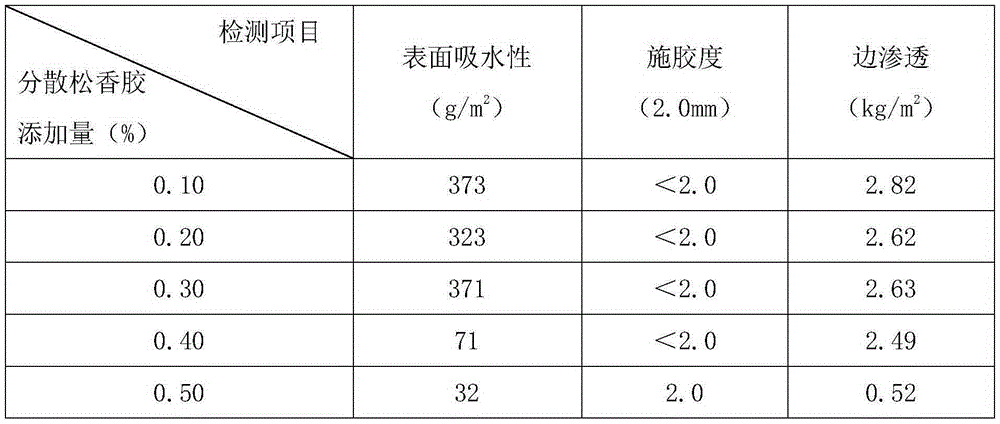

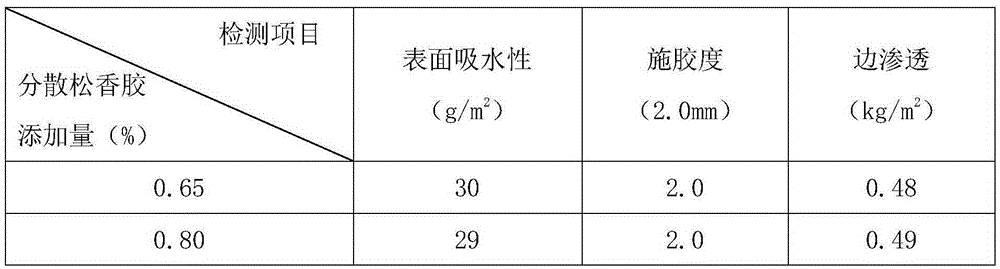

Examples

Embodiment 1

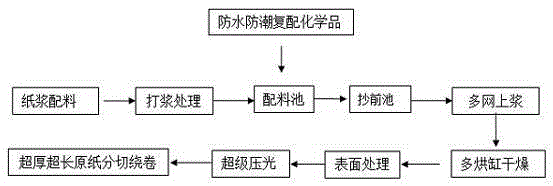

[0041] 1. Process flow

[0042] (1) Pulp ratio and additives: In consideration of the stiffness and interlayer bonding of the base paper for electronic special paper tapes, we choose a high proportion of coniferous wood fiber and a low proportion of hardwood fiber, and use a combination of water and moisture resistance material, to ensure the bonding force between the base paper layers.

[0043] For example, to produce 0.60mm base paper, 65% of softwood pulp and 35% of hardwood pulp; to produce 0.40mm base paper, 75% of softwood pulp and 25% of hardwood pulp; to produce 0.75mm base paper, 60% of softwood pulp and 35% of broadleaf pulp Leaf pulp 20%, recycled waste paper 20%, etc.

[0044] (2) Beating control process: beating determines the product performance of base paper. In this process, we will strictly control the beating process, and formulate corresponding beating treatment processes for different production specifications to ensure the bonding ability and other proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com