Energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp

A pretreatment and pulping technology, applied in pulp beating/refining method, fiber raw material treatment, paper, etc., can solve the problems of long processing time, high-speed continuous production, reduction of physical strength of paper, and low efficiency of biological enzyme treatment, etc. Achieve the effects of overcoming long processing time, improving the physical properties of paper, and improving the physical properties of fiber paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

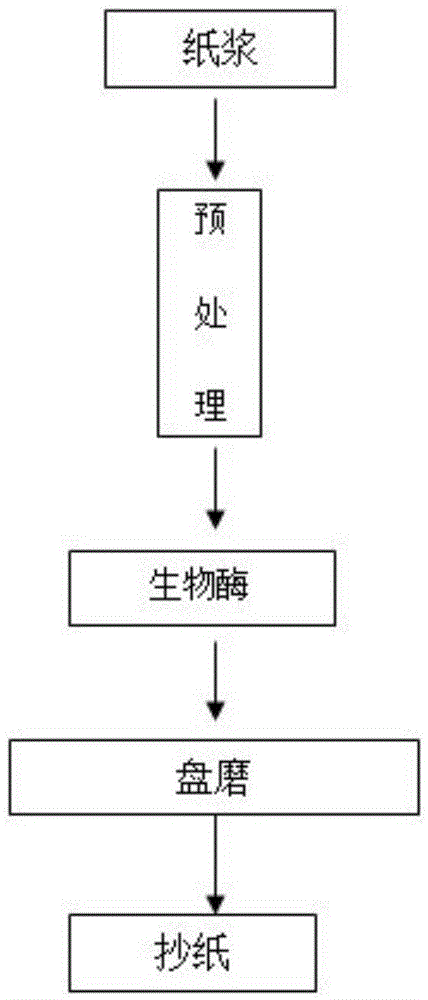

Method used

Image

Examples

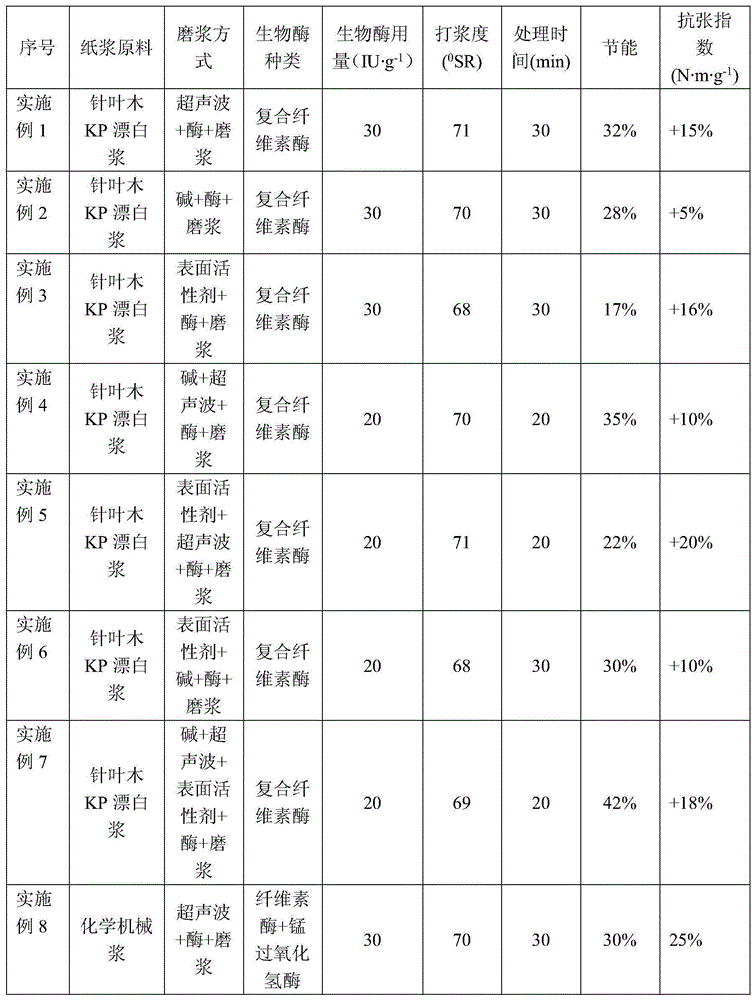

Embodiment 1

[0024] Dissolve the pulp fibers in water, place them in an ultrasonic oscillator, and stir to process: the long-fiber KP bleached pulp concentration is 4.2%, pH=7.7, temperature 23°C, ultrasonic power 250W, ultrasonic frequency 40kHz, and treatment time is 5min. After adding cellulose composite enzyme 30IU / g, temperature 40°C, pH=6.5, pulp concentration 4.2%, treatment for 30min; PFI refining to 71°SR. Pulp energy consumption is saved by 32% and tensile index is increased by 15%.

Embodiment 2

[0026] Dissolve pulp fiber in water, add sodium hydroxide aqueous solution for pretreatment: long fiber KP bleached pulp concentration is 6%, sodium hydroxide dosage is 0.5%, temperature is 35°C, and treatment time is 10min; add cellulose to the treated pulp Compound enzyme 30IU / g, temperature 40°C, pH=6.5, slurry concentration 4.3%, treatment for 30min; PFI refining to 70°SR. Pulp energy consumption is saved by 28% and tensile index is increased by 5%.

Embodiment 3

[0028] Dissolve pulp fibers in water, add surfactant for pretreatment: long fiber KP bleached pulp concentration is 6%, pH=7.2, temperature 25°C, surfactant dosage 0.15%, stirring for 15min; surfactant is carboxymethyl Base cellulose: cationic starch: sodium dodecyl benzene sulfonate = 1:1:0.2; add cellulose composite enzyme 30IU / g to the treated pulp, temperature 40°C, pH = 6.5, pulp concentration 4.3%, process 30min; PFI refining to 68°SR. Pulp energy consumption is saved by 17% and tensile index is increased by 16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com