Patents

Literature

30results about How to "Improve chemical structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

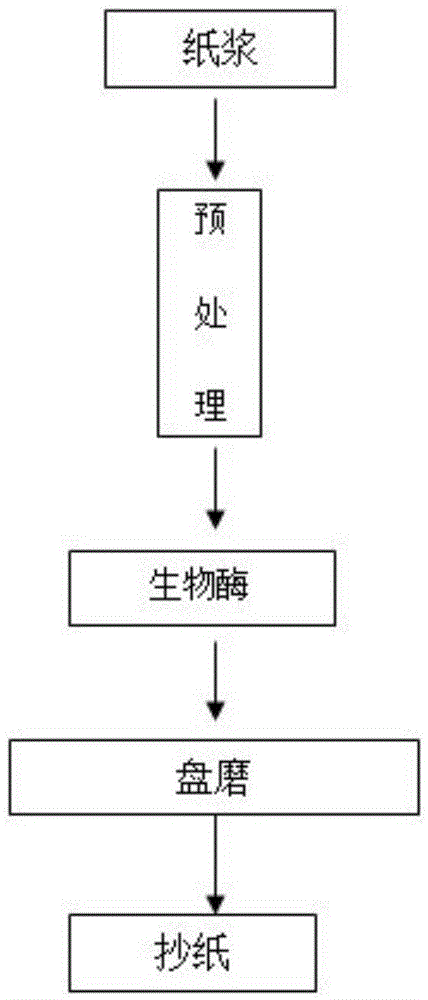

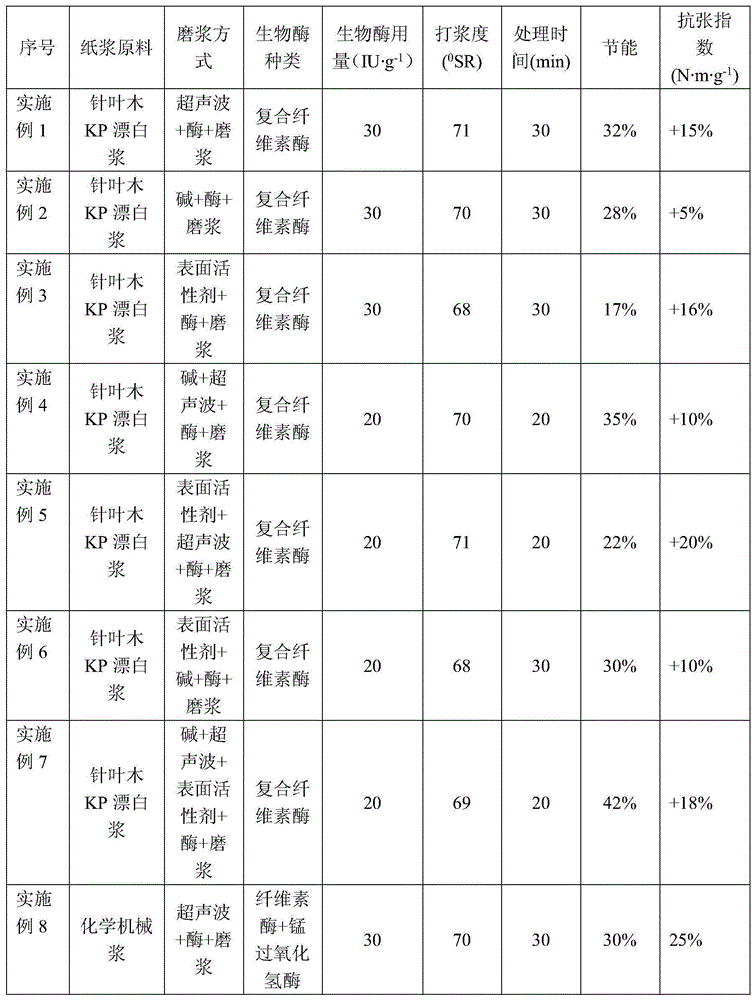

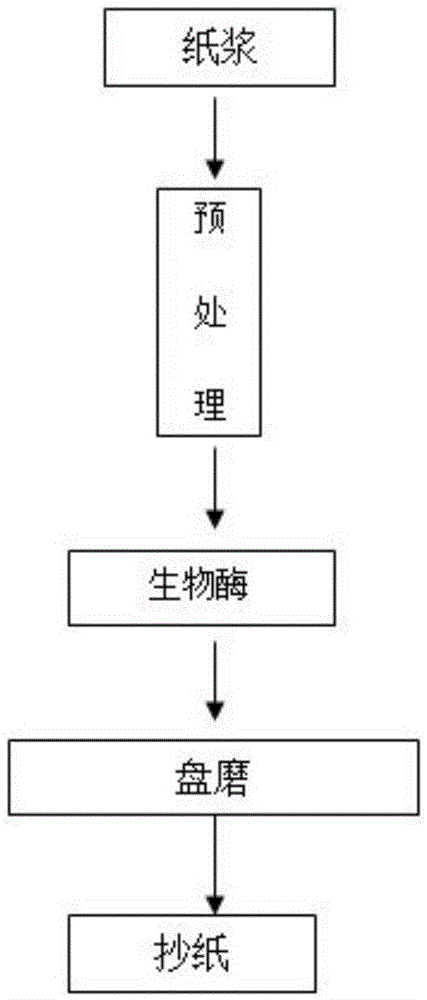

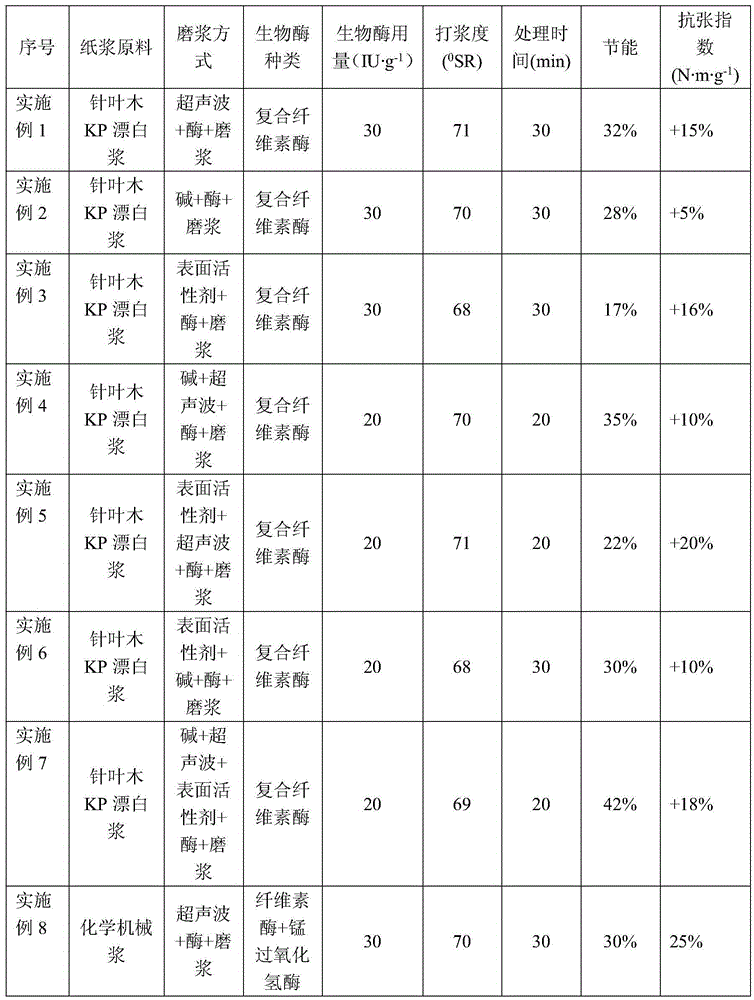

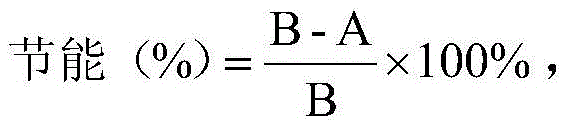

Energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp

ActiveCN104452398AImprove the physical properties of paperSave paper physical propertiesMicroorganism/enzyme additionPaper/cardboardPre treatmentPulp fibre

The invention discloses an energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp. The method comprises the following steps that (1) paper pulp fibers are dissolved in water, even defibering is carried out, and then pretreatment is carried out; (2) biological enzymes are added to the treated paper pulp for treatment, the dosage of the biological enzymes ranges from 10 IU / g to 60 IU / g, the temperature ranges from 40 degrees to 60 degrees, the pH value ranges from 6 to 9, the concentration of the paper pulp ranges from 3 wt% to 8 wt%, and treatment is carried out for 10 min to 30 min; (3) continuous millstone milling and beating are carried out on the pulp of the step (2), and the pulp is stored for standby application. The method remarkably improves the efficiency of subsequent biological enzyme treatment, and overcomes the defects that enzyme treatment time is too long in biological enzyme assistant defibrination production and energy conservation in defibrination and the physical strength of finished paper formed by fibers cannot be achieved at the same time, the defibrination energy consumption and the defibrination time for producing the viscous paper pulp are saved, the defibrination energy consumption of chemical bleached needle wood pulp and chemithermomechanical pulp of needle wood is reduced by 15%-45%, and the physical properties of finished paper formed by pulp fibers can be improved.

Owner:五洲特种纸业(龙游)有限公司

Shallow-groove improved in-situ repair saline-land vegetable planting method

InactiveCN101361421AImprove physical structureImprove chemical structurePigmenting treatmentHorticultureWet seasonBiology

The invention relates to a method for planting plants by improving a shallow groove and restoring salinate fields in situ; the method comprises the following steps: for planting different plants, shallow-groove strip tillage is carried out on the salinate; a layer of cornstalk, a layer of cow dropping and a layer of cornstalk are laid at the bottom of the groove, then a saline-alkali reducing agent is applied, and then a layer of artificially improved soil which is mixed by luvisol dug from the tillage and artificial biological substrate matured by the cornstalk and the cow dropping in advance is applied; finally, the seeds of the plants is spread into the artificially improved soil, watered and surefooted and field management is carried out; and a layer of cornstalk is laid between the adjacent shallow grooves, the luvisol is used for building a ladder-shaped drainage ditch which is communicated with a water-collecting tank, thus draining excessive water in rainy season.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Optical plastic protection coating and preparation method thereof

InactiveCN104231914AImprove chemical structureStable network structureCoatingsPtru catalystSilicic acid

The invention discloses an optical plastic protection coating and a preparation method thereof. The optical plastic protection coating comprises the following raw materials in parts by weight: 2 parts of ethyl orthosilicate, 5-6.5 parts of phenyl trimethoxy silane, 1.5-2 parts of a coupling agent, 3-4 parts of distilled water, 0.02-0.03 part of a curing agent and 0.02-0.04 part of a catalyst. The preparation method comprises the following steps: adding the raw materials into a container, stirring, standing at the room temperature for 24 hours to obtain colorless transparent liquid, coating an optical plastic plate with the liquid, and drying at 80 DEG C to form a layer of coating on the optical plastic plate, wherein the coating is the optical plastic protection coating. The optical plastic protection coating has the characteristics of high transparency, high hardness and the like, can be widely used in the field of optical plastic protection, and also can be used in the fields of coatings, printing ink and the like.

Owner:SHANGHAI INST OF TECH

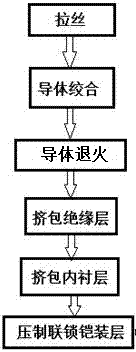

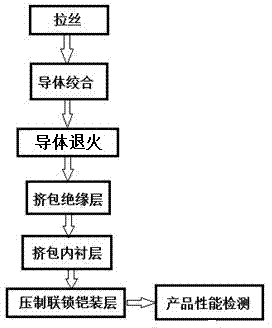

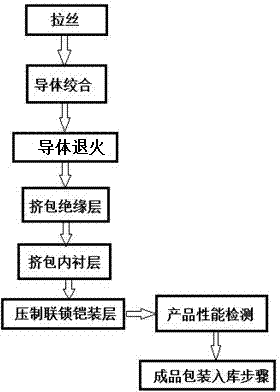

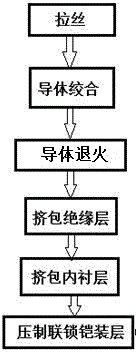

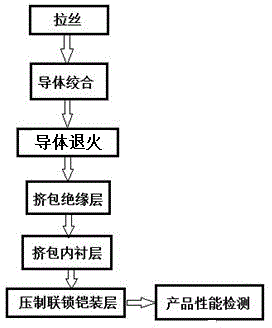

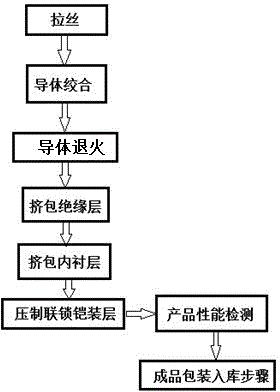

Manufacturing method for interlocked armored aluminum alloy flat cable

ActiveCN102969087APrevent disconnectionImprove conductivityFlat/ribbon cablesFlexible cablesElectrical conductorManufacturing technology

The invention discloses a manufacturing method for an interlocked armored aluminum alloy flat cable. According to the manufacturing technology, the manufacturing method comprises the following steps in sequence: drawing wires, stranding a conductor, annealing the conductor, extruding an insulating layer, extruding a lining layer, and pressing an interlocked armored layer, wherein the conductor annealing step comprises the steps: through boxcar type heating and annealing steps, heating the stranded conductor to 370-400 DEG C, lasting for 4-5 hours at the environment of 370-400 DEG C, and then naturally cooling to the room temperature; and the interlocked armored layer pressing step is that an aluminum alloy tape with the thickness of 0.5mm-0.6mm is arranged on the surface of the lining layer and pressed into a Z-shaped interlocked armored form with the arc-shaped height of 2mm-4mm according to pitches of 6mm-24mm. according to the manufacturing method, the conductivity property and creep property can be improved, the service life of the cable can be effectively prolonged, the system can have good radiating effect in short time under overload state, and can be ensured to run safely.

Owner:SICHUAN MINGXING CABLE

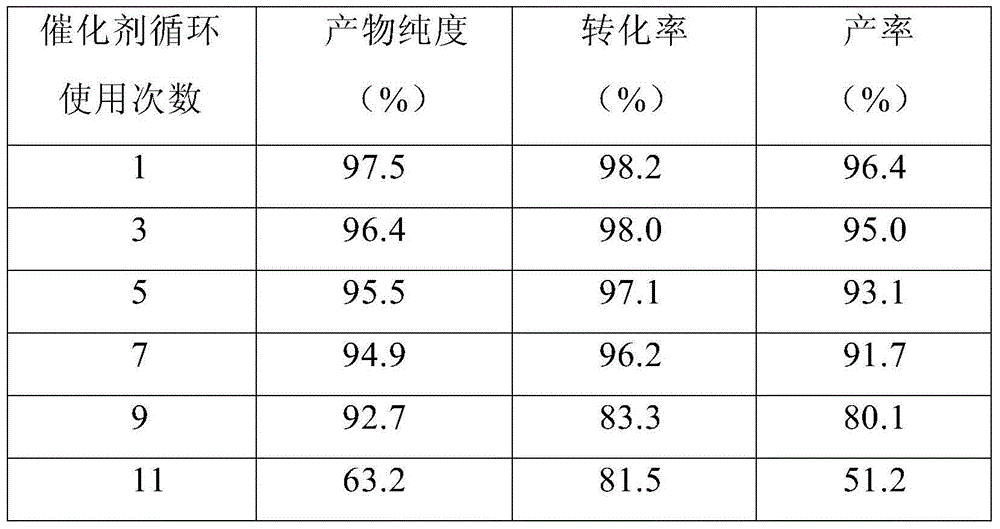

Method of producing ethylene carbonate

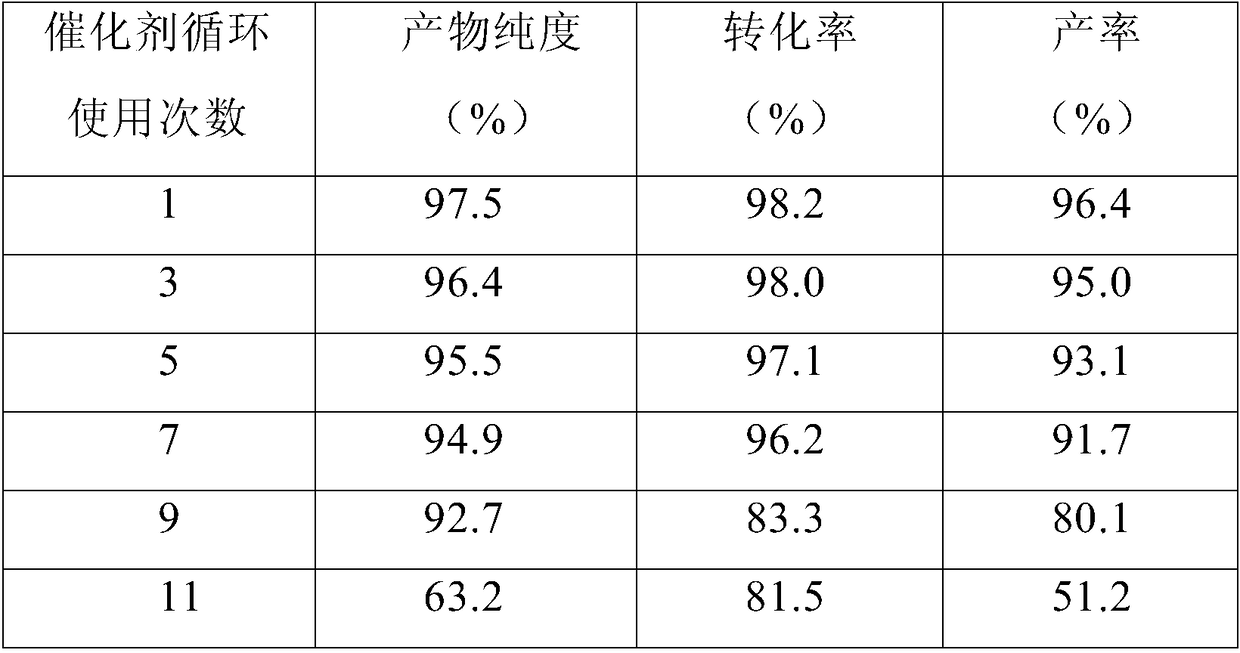

ActiveCN105732566ALess by-productsHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEthylene oxideReaction temperature

The invention relates to a method of producing ethylene carbonate by catalytic addition from ethylene oxide and CO2. In the method, under the effect of an environment-friendly ionic liquid catalyst, the CO2 and the ethylene oxide are added to prepare the ethylene carbonate. When the reaction temperature is 90-130 DEG C, the reaction pressure is 1-3 MPa, the stirring speed is 200-300 r / min and the reaction time is 1-2 h, the conversion rate of the ethylene oxide reaches more than 98% and the yield of the ethylene carbonate reaches more than 94%. Conversion rate and yield are both higher than 90% even the catalyst is repeatedly used for seven times.

Owner:PETROCHINA CO LTD

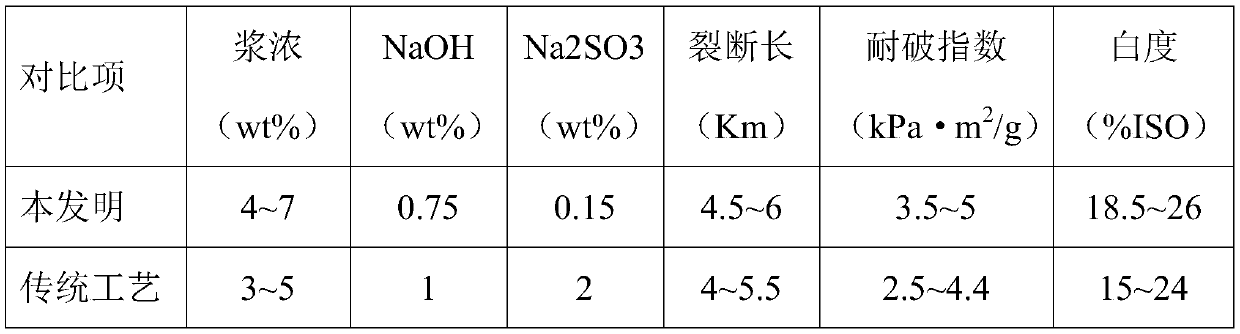

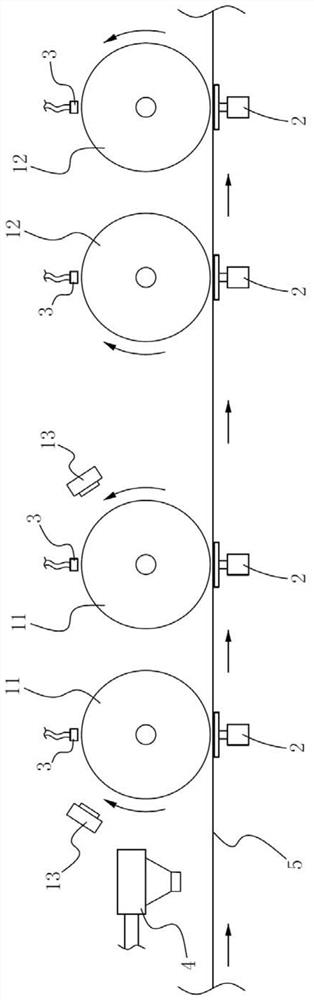

Production process for making high-strength corrugated paper from waste paper

ActiveCN110080035AIncrease the proportionHigh fiber recovery ratePaper recyclingCellulose treatment using microorganisms/enzymesState of artFiber

The invention discloses a production process for making high-strength corrugated paper from waste paper. The production process comprises the following steps: crushing, drying, carrying out ultrasonicelectrostatic sorting, repulping, diverting, carrying out step-by-step low-concentration dreg removal, carrying out step-by-step low-concentration filter pressing, carrying out step-by-step high-concentration dreg removal, carrying out distributed high-concentration filter pressing, diluting, carrying out composite pretreatment of primary slurry, pulping, screening, carrying out pulp blending, making and molding paper, carrying out intensification, drying and squeezing wet paper, carrying out surface gluing, drying finished paper, and finally coiling, thereby obtaining a finished product of corrugated paper. Compared with the prior art, the production process is capable of implementing targeted physical sorting on a waste paper material before the step of repulping, damage of paper makingfibers and amounts of chemical reagents can be further reduced, the production process is environmentally friendly, the treatment cost of paper making wastes can be reduced, the production efficiencyis improved, and the production cost of companies can be lowered.

Owner:东莞顺裕纸业有限公司

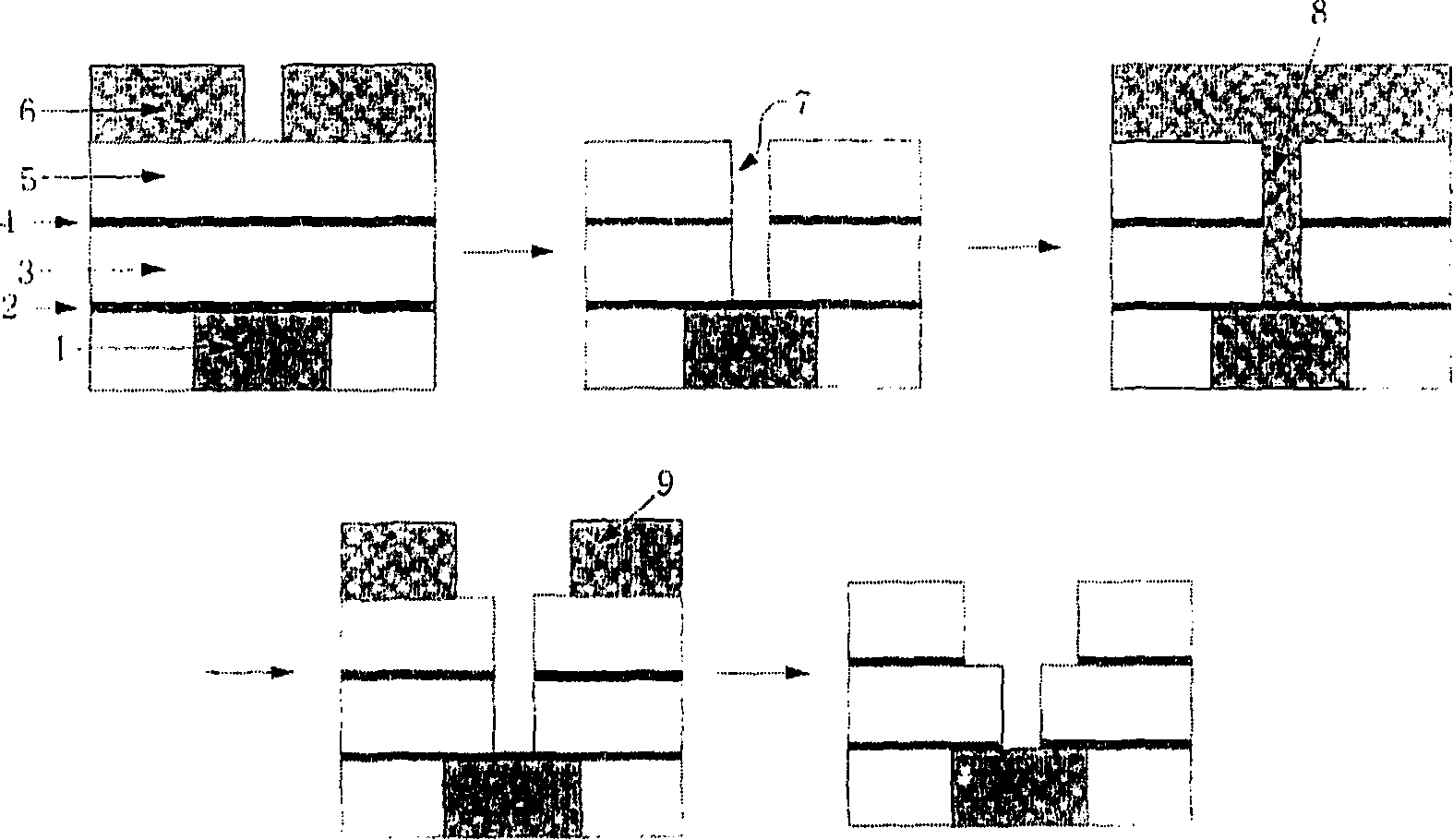

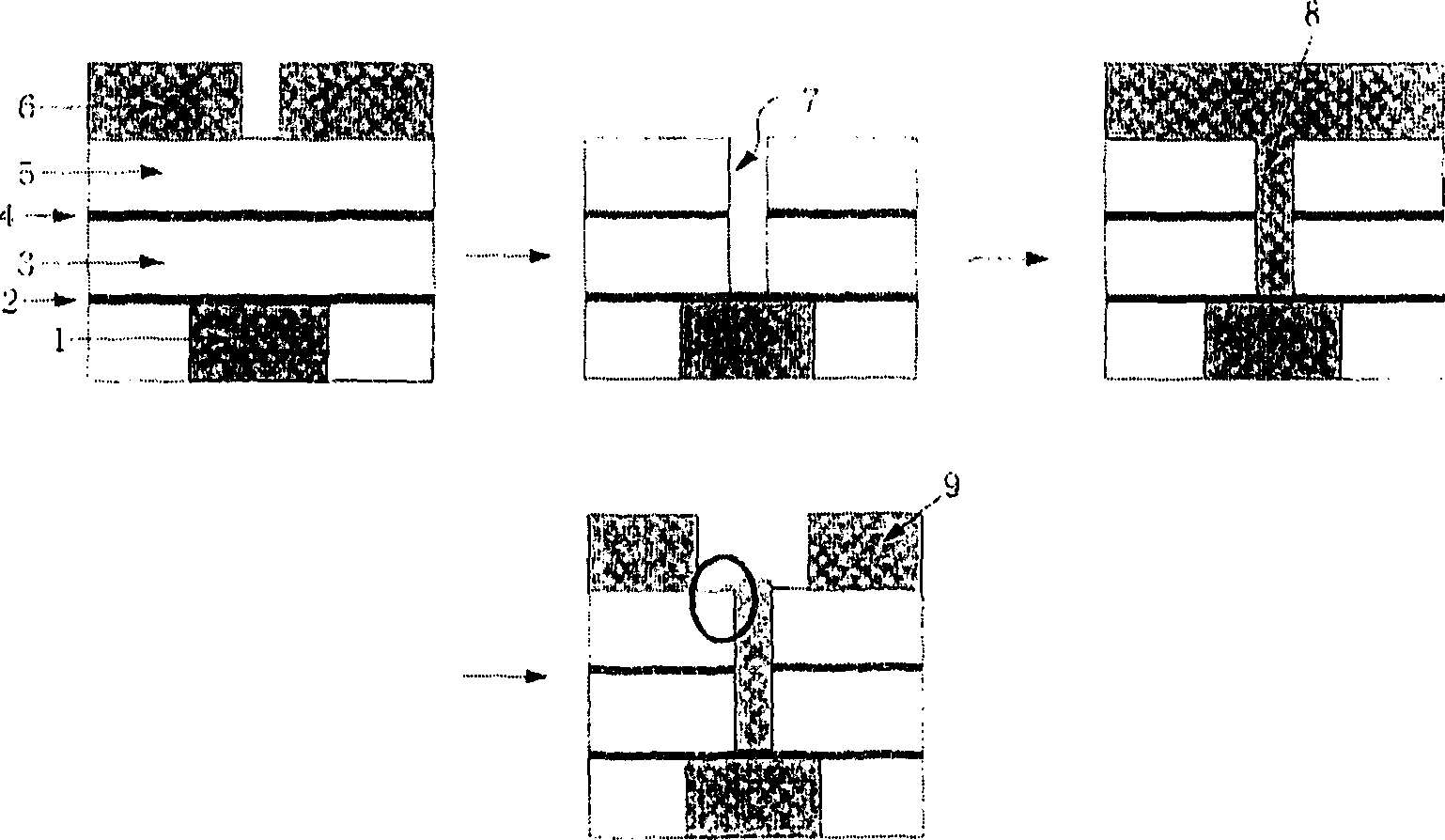

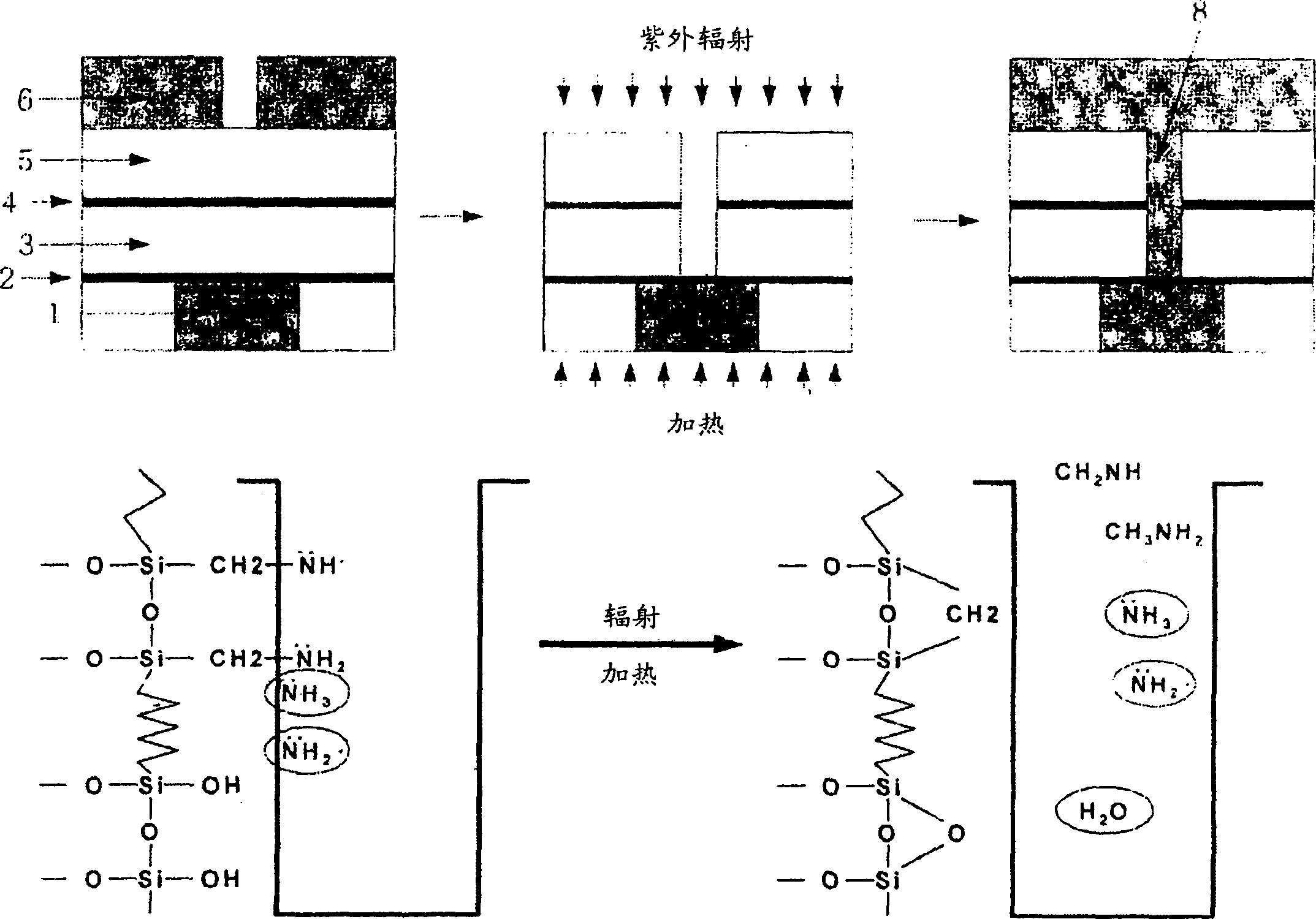

Method for constituting graph on intermetallic dielectric layer

InactiveCN1469452AImprove chemical structureEasy to removeSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDielectric layer

The method for forming a pattern of the intermetal insulating film includes (a) a stage of successively forming a lower etching preventing film 2, a lower insulating film 3, an upper etching preventing film 4, and an upper insulating film 5 on a semiconductor substrate to which lower wiring 1 is formed, (b) a stage of forming a via hole to expose the lower etching preventing film by patterning the upper insulating film, the upper etching preventing film, and the lower insulating film, (c) a stage in which the vial hole is irradiated with UV light, (d) a patterning stage by forming a photo-resist film on the whole face of the semiconductor substrate in which the via hole is formed, (e) a stage of forming a wiring groove passing through the via hole on the upper insulating film by patterning the upper insulating film by making the photo-resist pattern 6 as an etching mask, and (f) a stage of exposing the upper part of the lower wiring.

Owner:SAMSUNG ELECTRONICS CO LTD

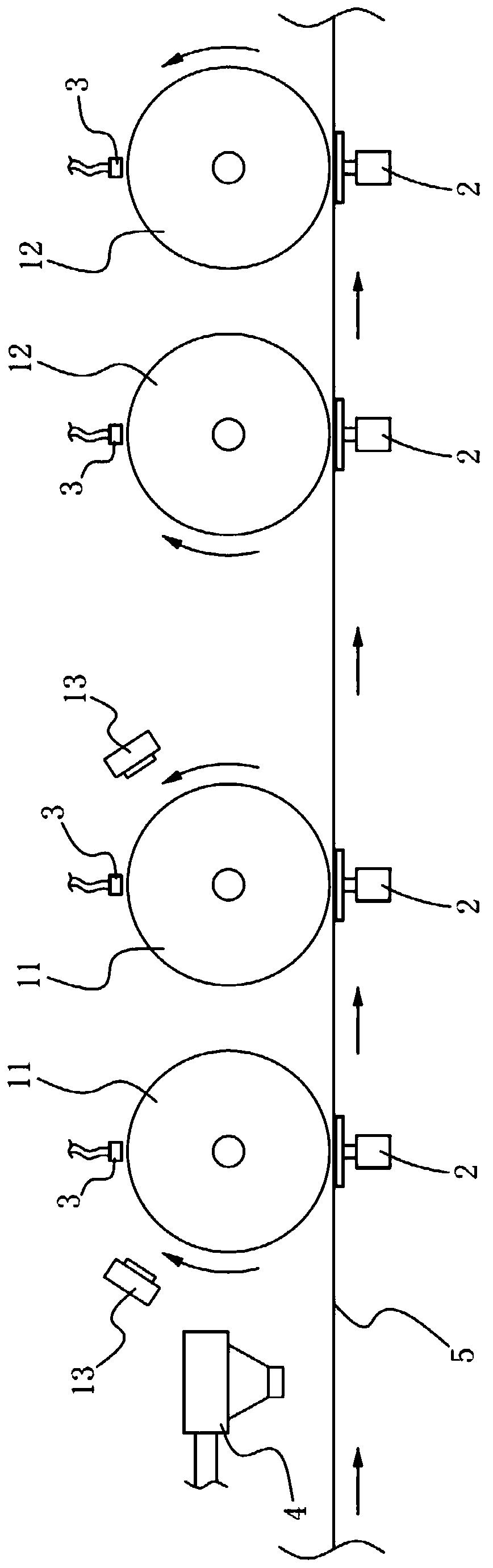

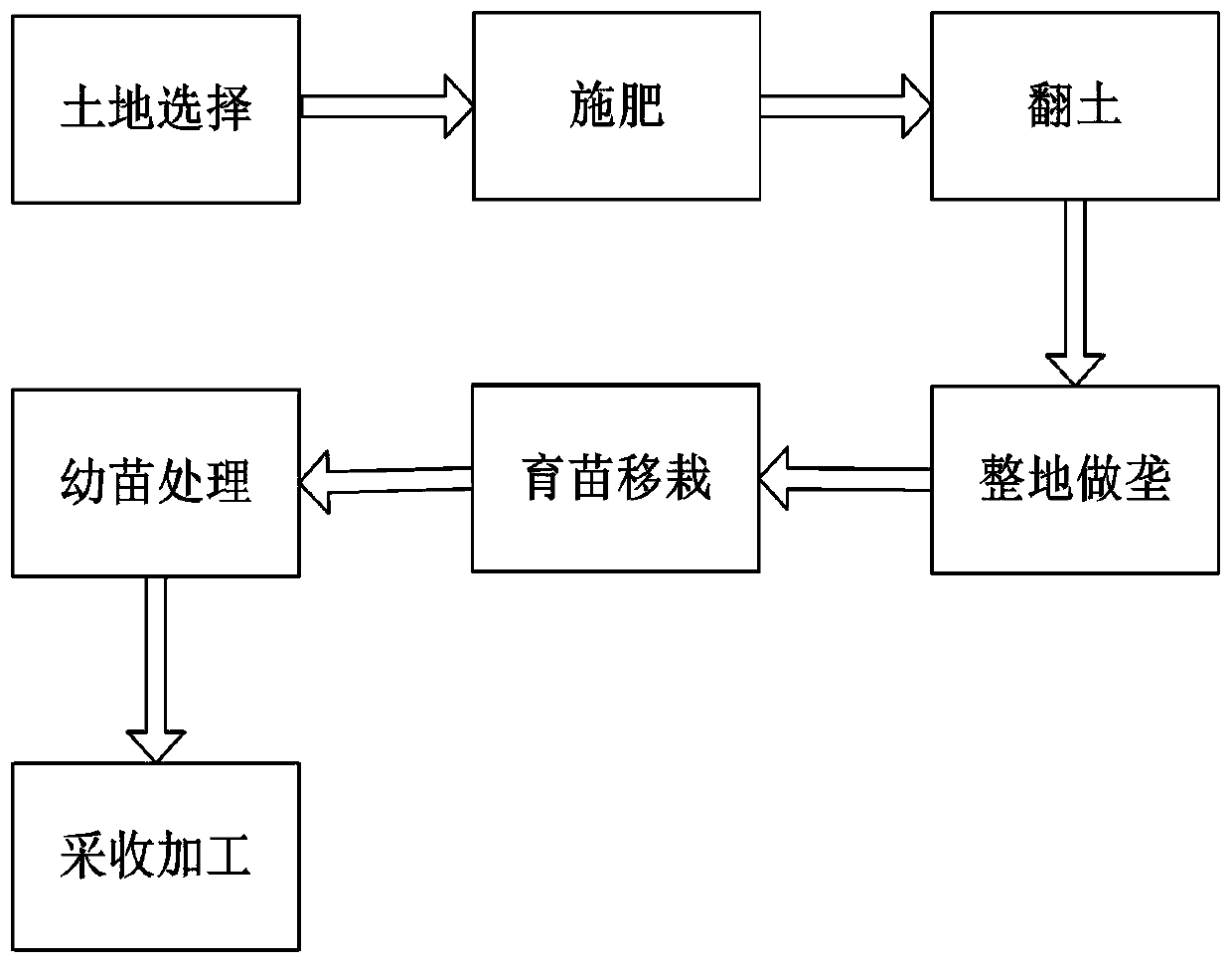

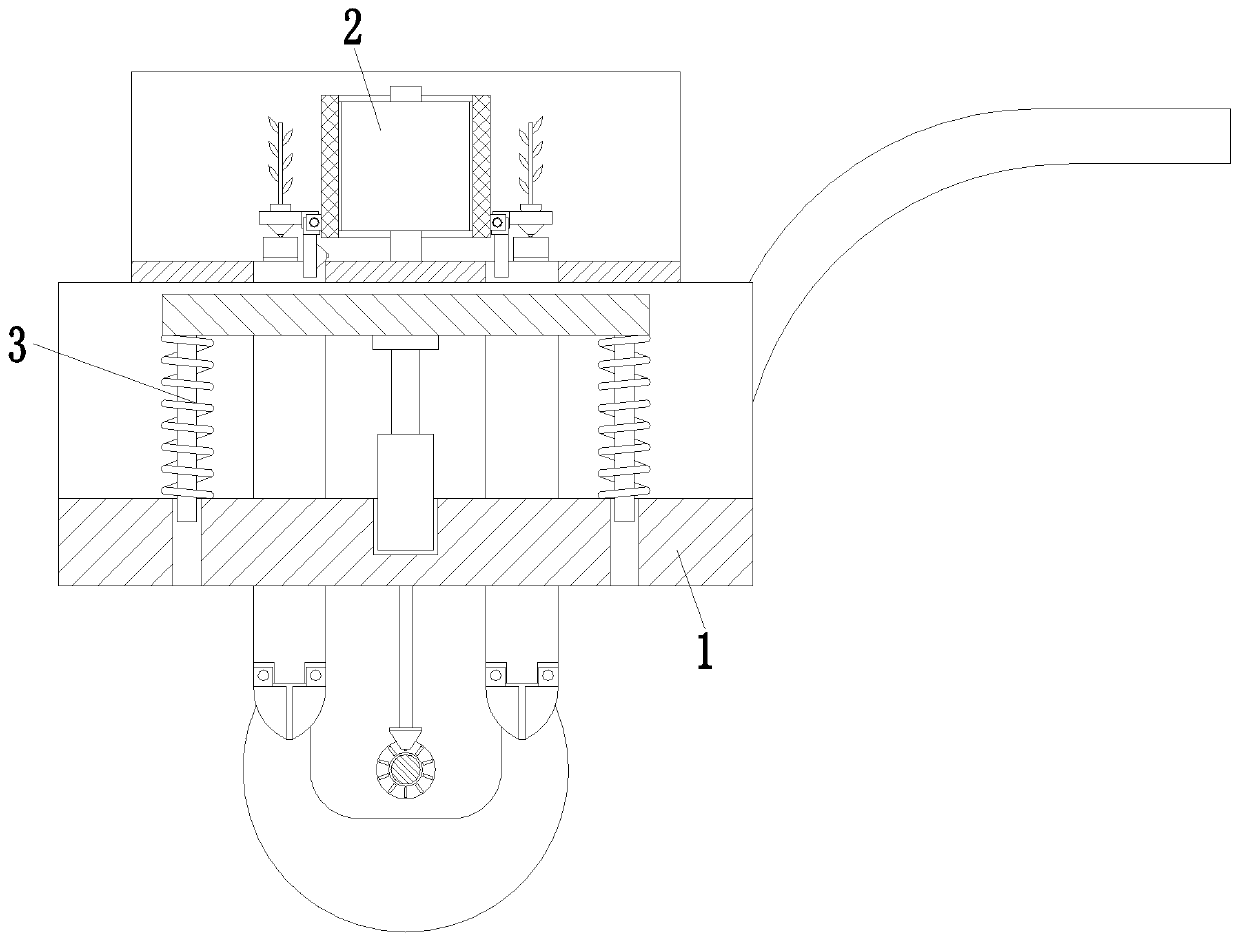

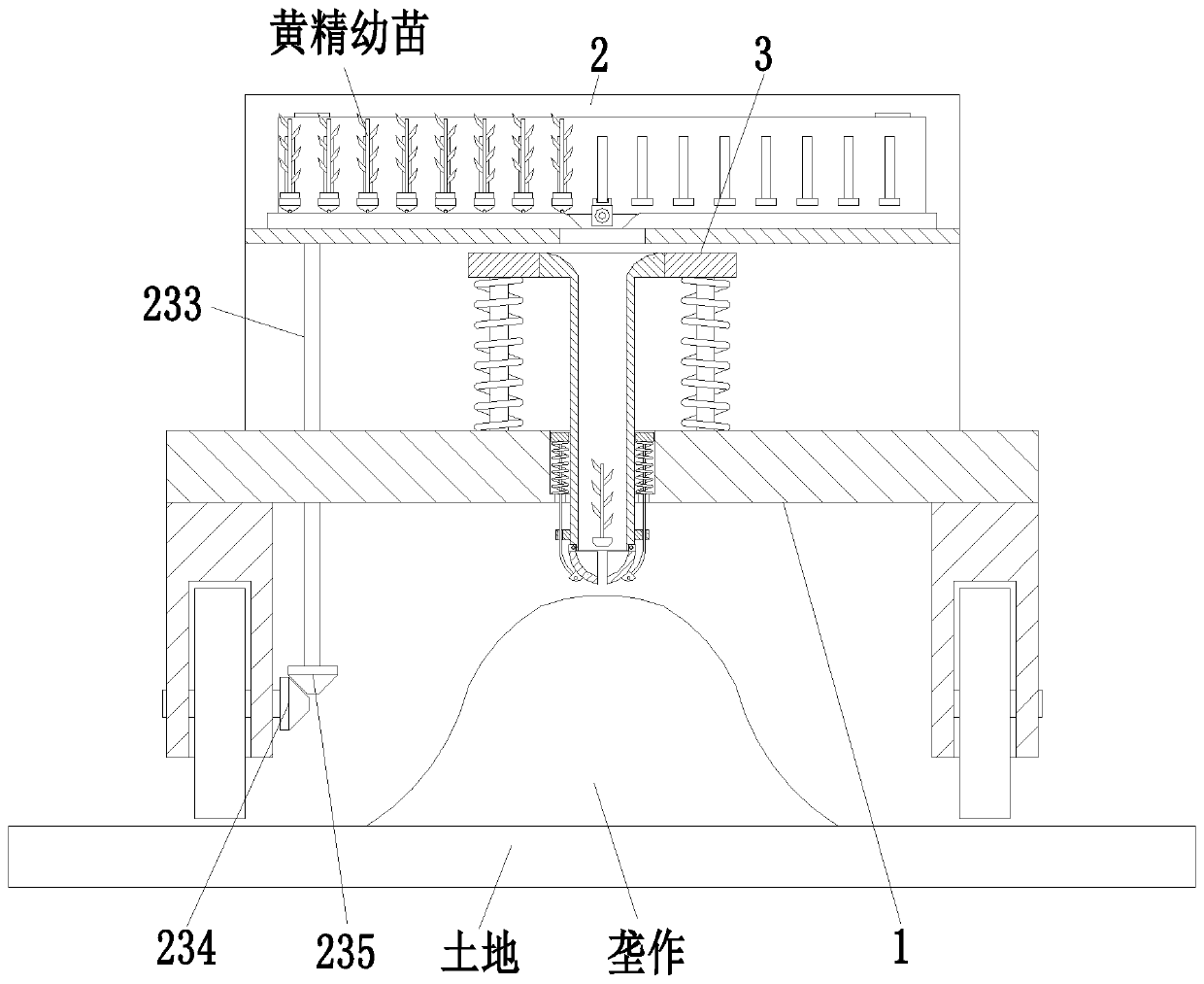

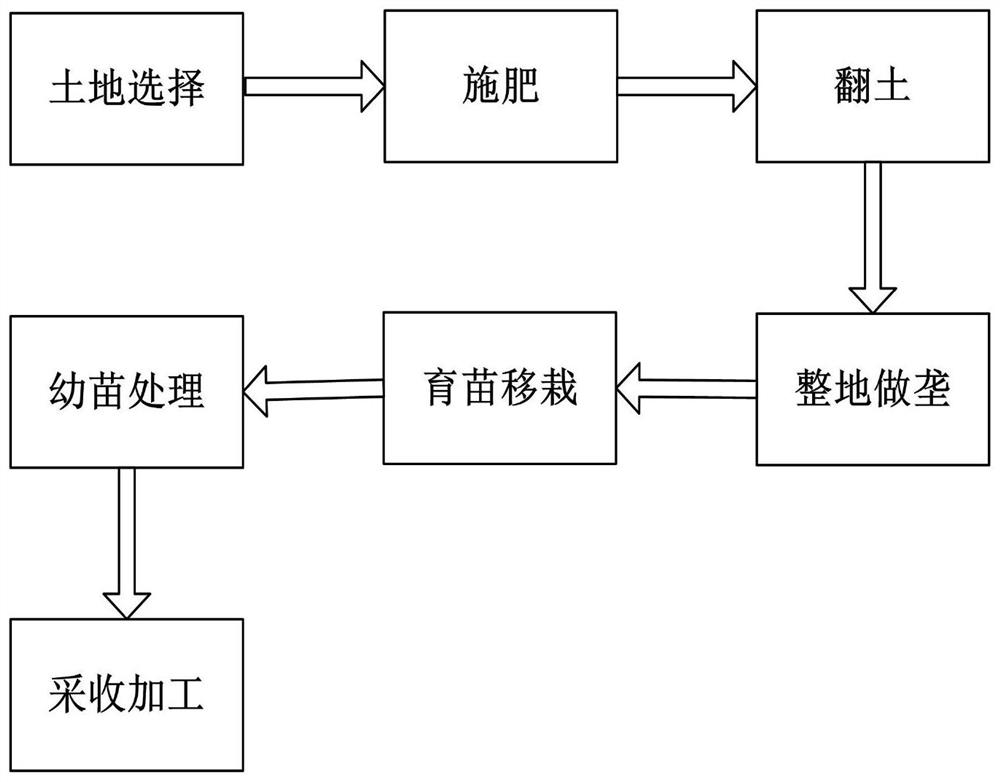

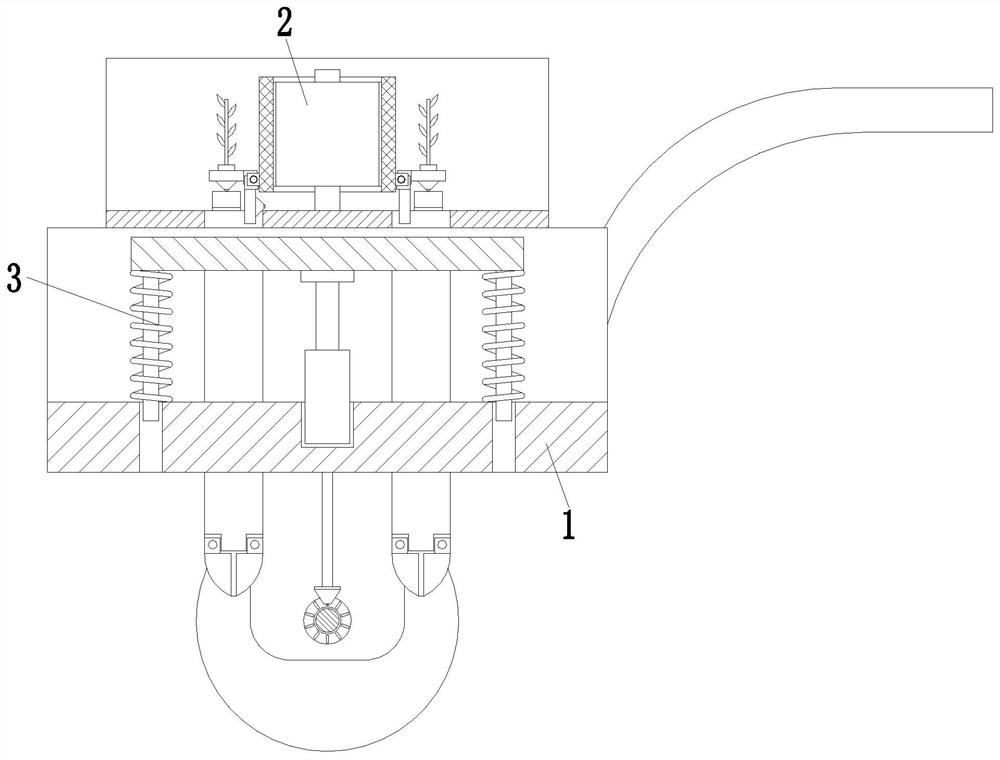

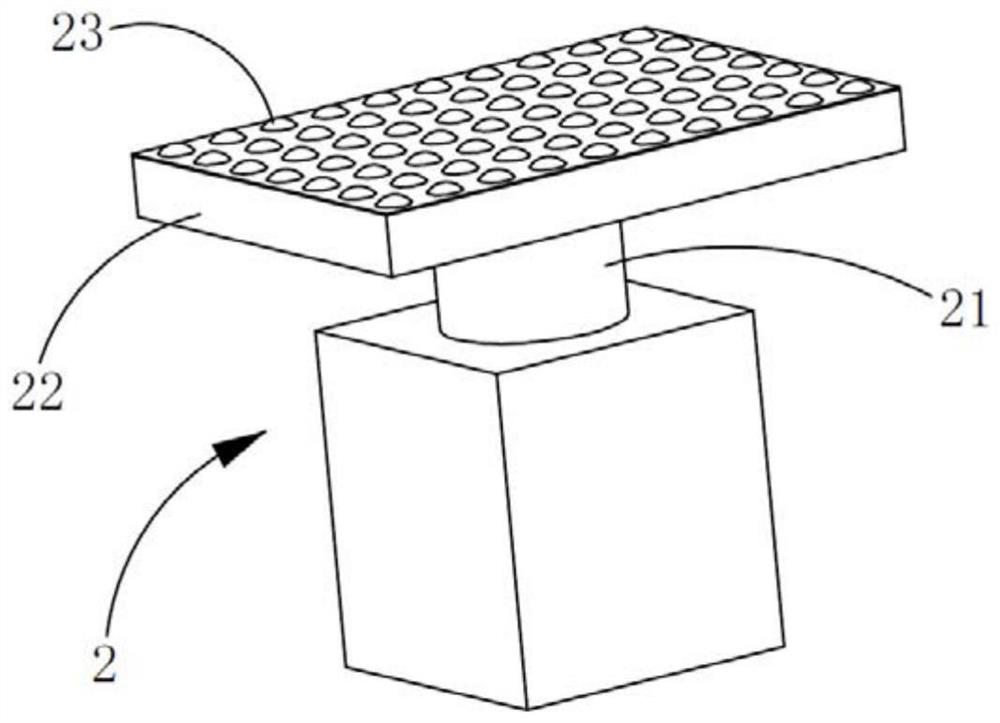

Wild planting-imitating planting method of polygonatum sibiricum

ActiveCN111567347AIncrease fertilityImprove physicsTransplantingRoot crop cultivationPolygonatum sibiricumSeedling

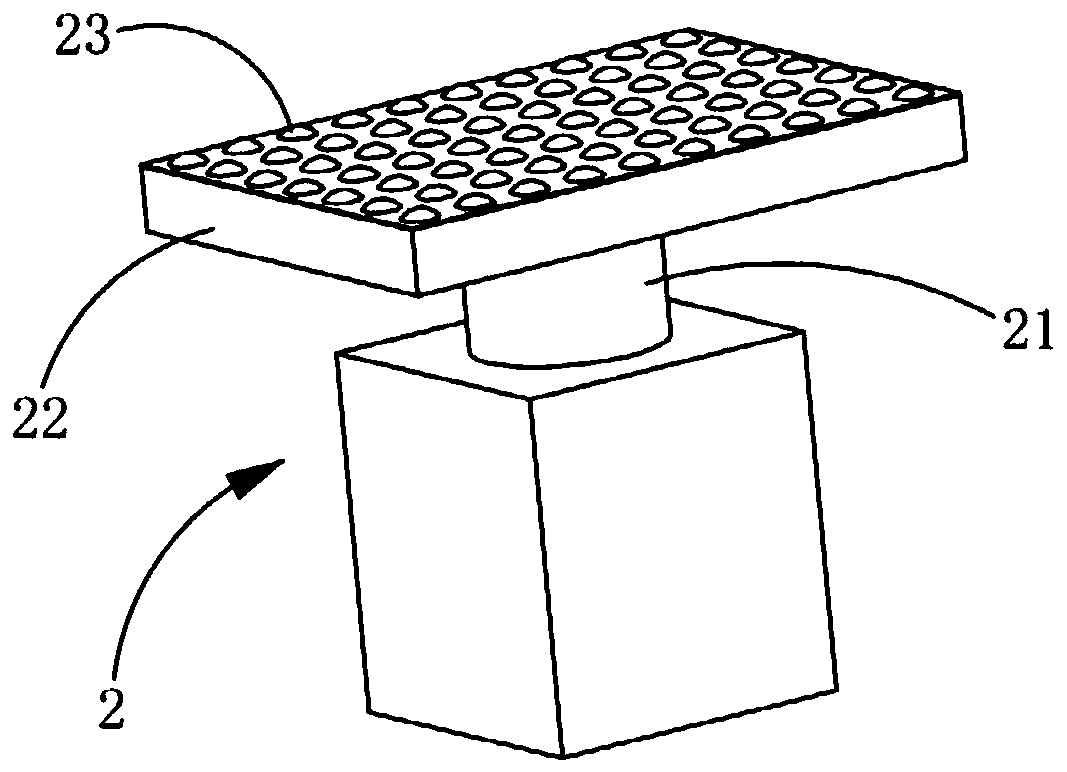

The invention relates to a wild planting-imitating planting method of polygonatum sibiricum. The wild planting-imitating planting method of polygonatum sibiricum adopts the following processing equipment, the processing equipment comprises a bottom plate frame, a material distributing device and a planting device, the bottom plate frame is of a U-shaped structure, the planting device is installedin the middle of the upper end of the bottom plate frame, the material distributing device is arranged above the planting device, and the distributing device is mounted on the bottom plate frame. Thepolygonatum sibiricum planting device can solve the problems that when existing polygonatum sibiricum is planted and processed, manual cultivation is usually carried out manually, manual planting is high in labor intensity and low in efficiency, large-scale planting of polygonatum sibiricum is not facilitated, and when existing equipment is used for planting polygonatum sibiricum, the planting effect is poor, the efficiency is low, and planted seedlings are prone to toppling, and meanwhile, in the planting process, seedlings cannot be effectively protected and are prone to being damaged, and the survival rate of the seedlings is affected.

Owner:池州市九华府金莲智慧农业有限公司

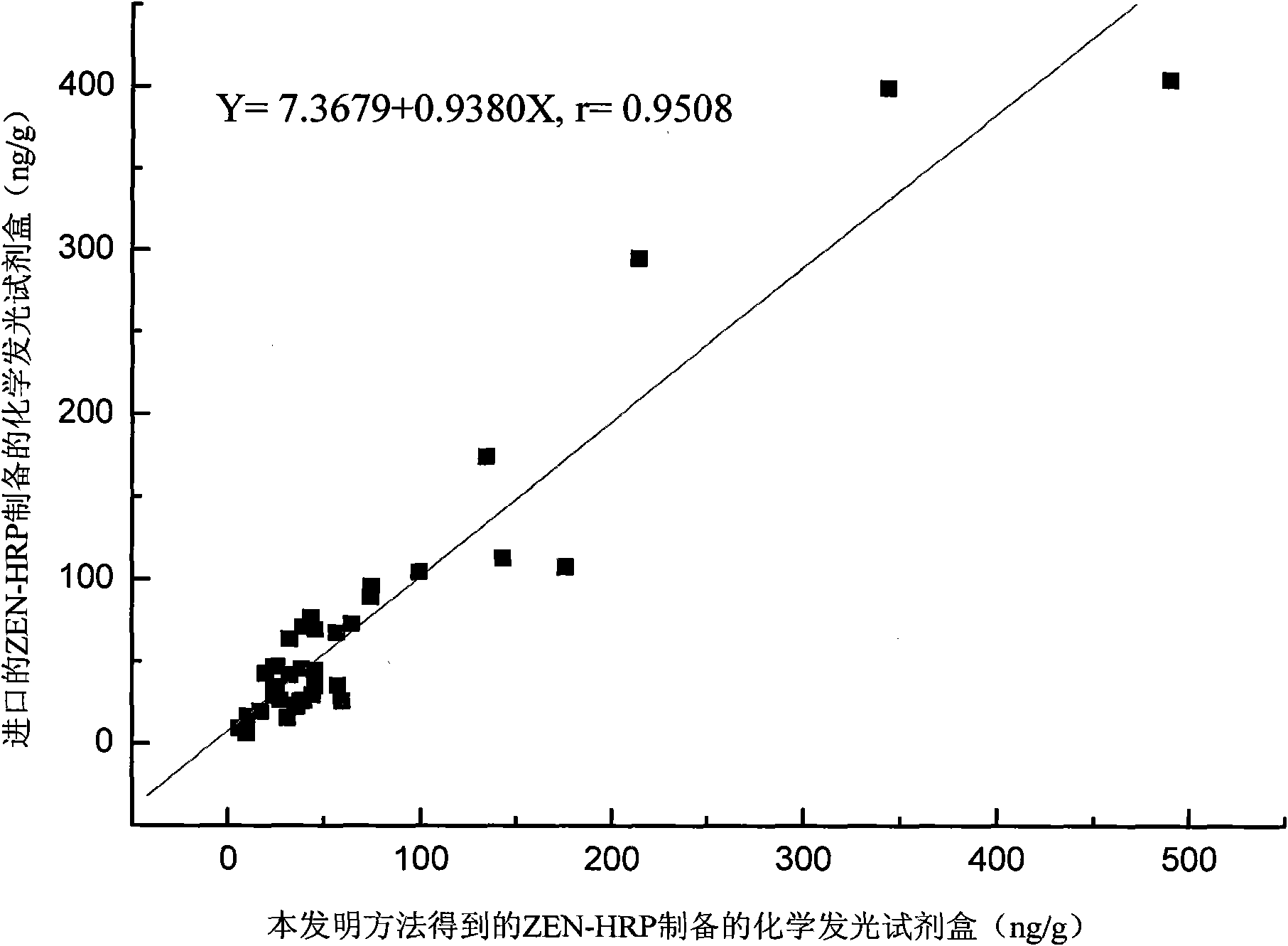

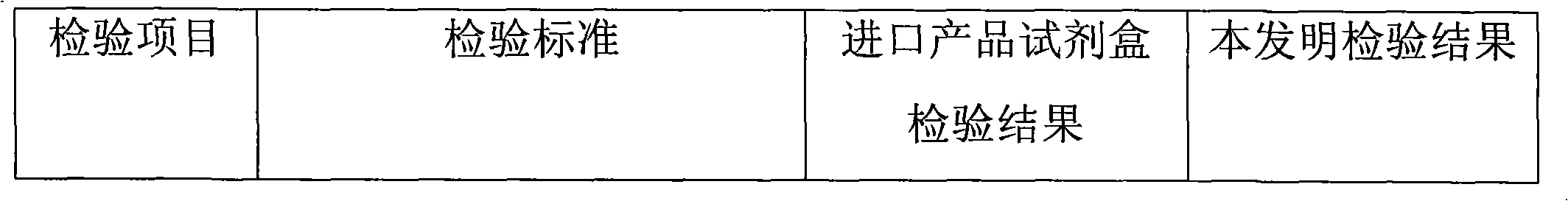

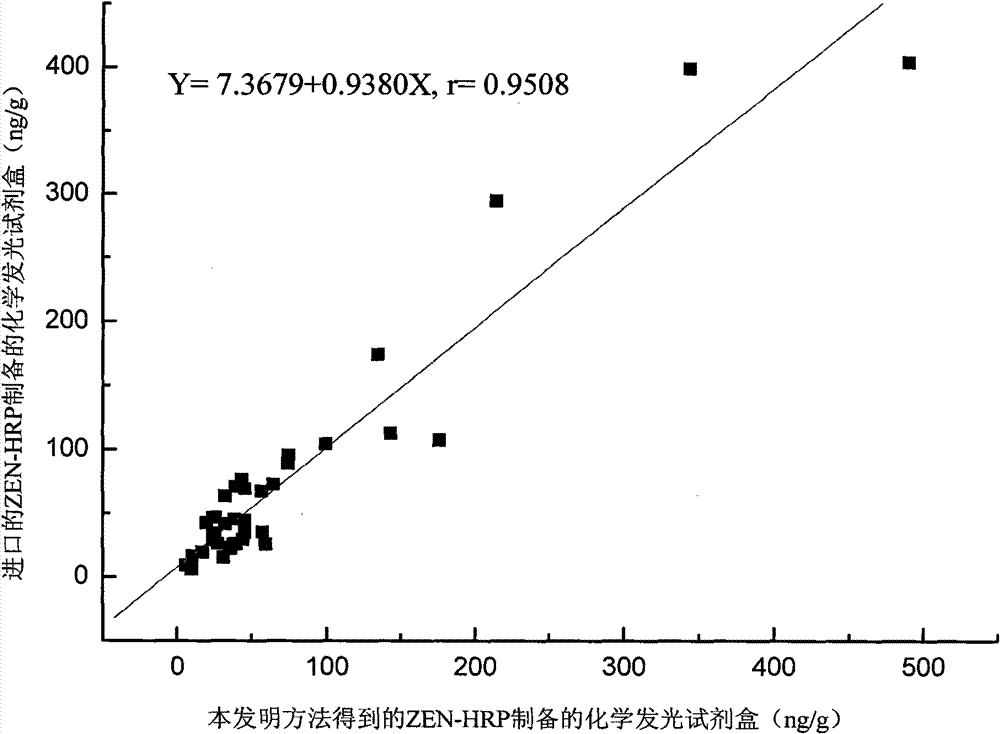

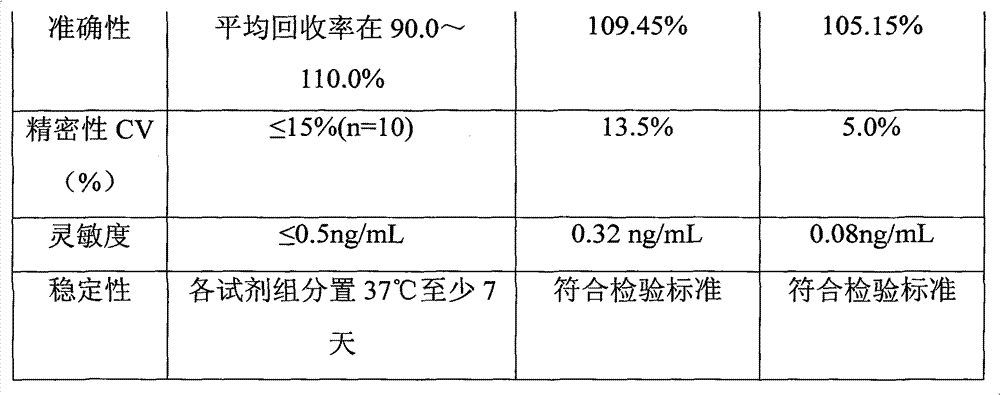

Synthesis process of horseradish peroxidase enzymelabeled zearalenone

ActiveCN102051389AImprove chemical structureImprove effectivenessFermentationPeroxidaseHorseradish peroxidase

The invention discloses a synthesis process of horseradish peroxidase enzymelabeled zearalenone. In the synthesis process, a carboxylated product is obtained by carboxylating zearalenone, and the horseradish peroxidase enzymelabeled zearalenone is obtained by a condensation reaction of the carboxylated product and horseradish peroxidase enzyme. The preparation process of detecting the key component horseradish peroxidase enzymelabeled product in the CLIA (Chemiluminescence Immunoassay) field is a formidable difficult all along. Accordingly, the synthesis process of the horseradish peroxidase enzymelabeled zearalenone, which is provided by the invention, is simple and practical and has low cost and favorable market application prospects.

Owner:CHEMCLIN DIAGNOSTICS CO LTD

Catalyst for improving desulfurization performance of calcium hydroxide

PendingCN111359601AImprove chemical structureIncrease the internal and external areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSlagCalcium hydroxide

The invention discloses a catalyst for improving the desulfurization performance of calcium hydroxide. The catalyst comprises the following components in percentage by weight: 10-20% of a catalytic component, 15-20% of an excitant, 30-40% of carbide slag and the balance being residues of manganese ores. The catalyst not only can improve the reaction rate of calcium hydroxide with SO2 and SO3, butalso can greatly improve the reaction sulfur capacity of calcium hydroxide and enhance the desulfurization performance of calcium hydroxide.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

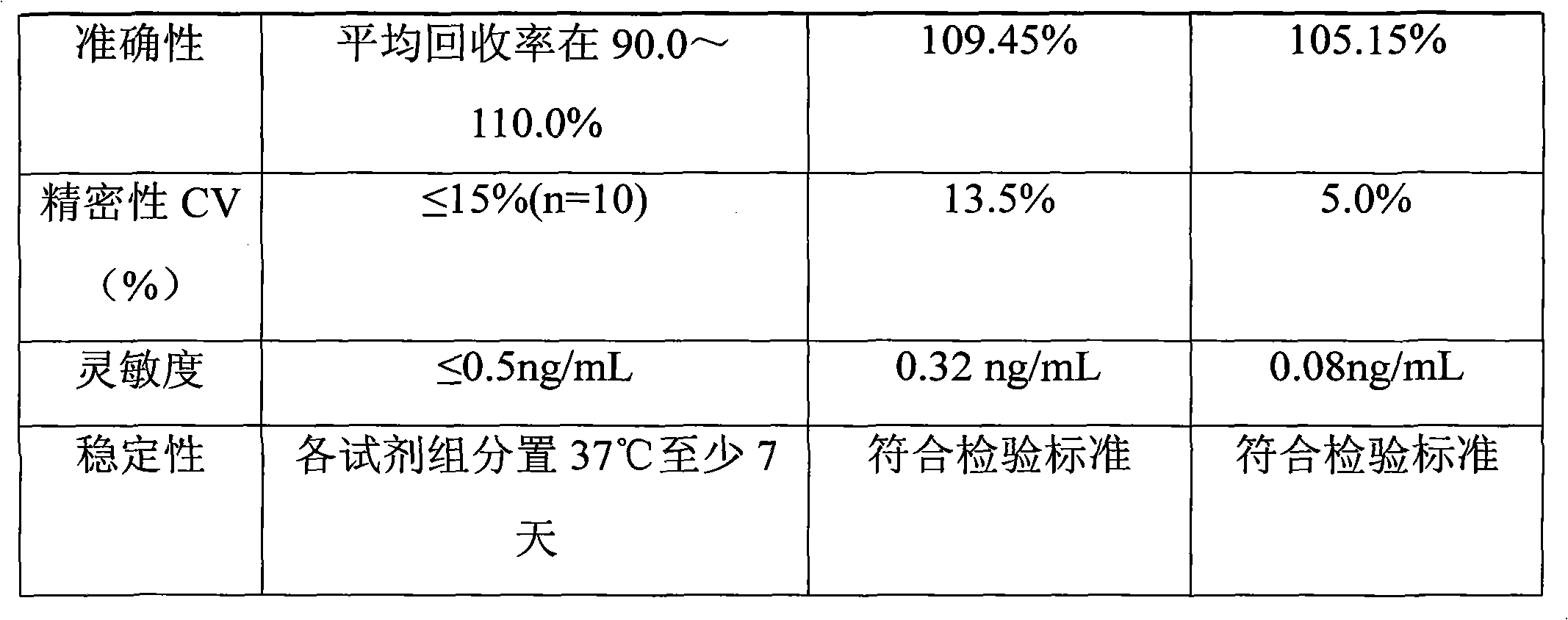

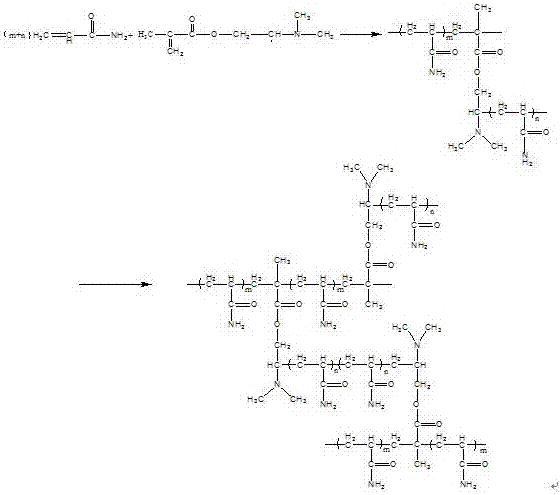

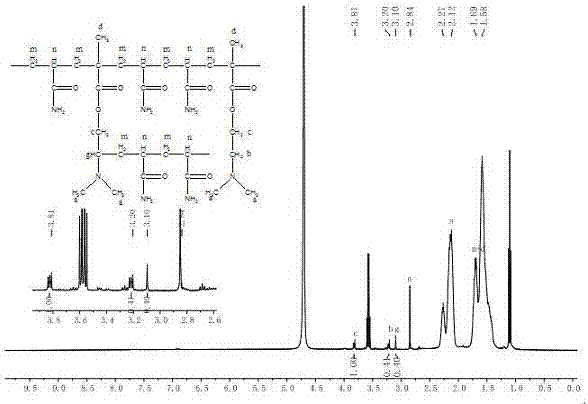

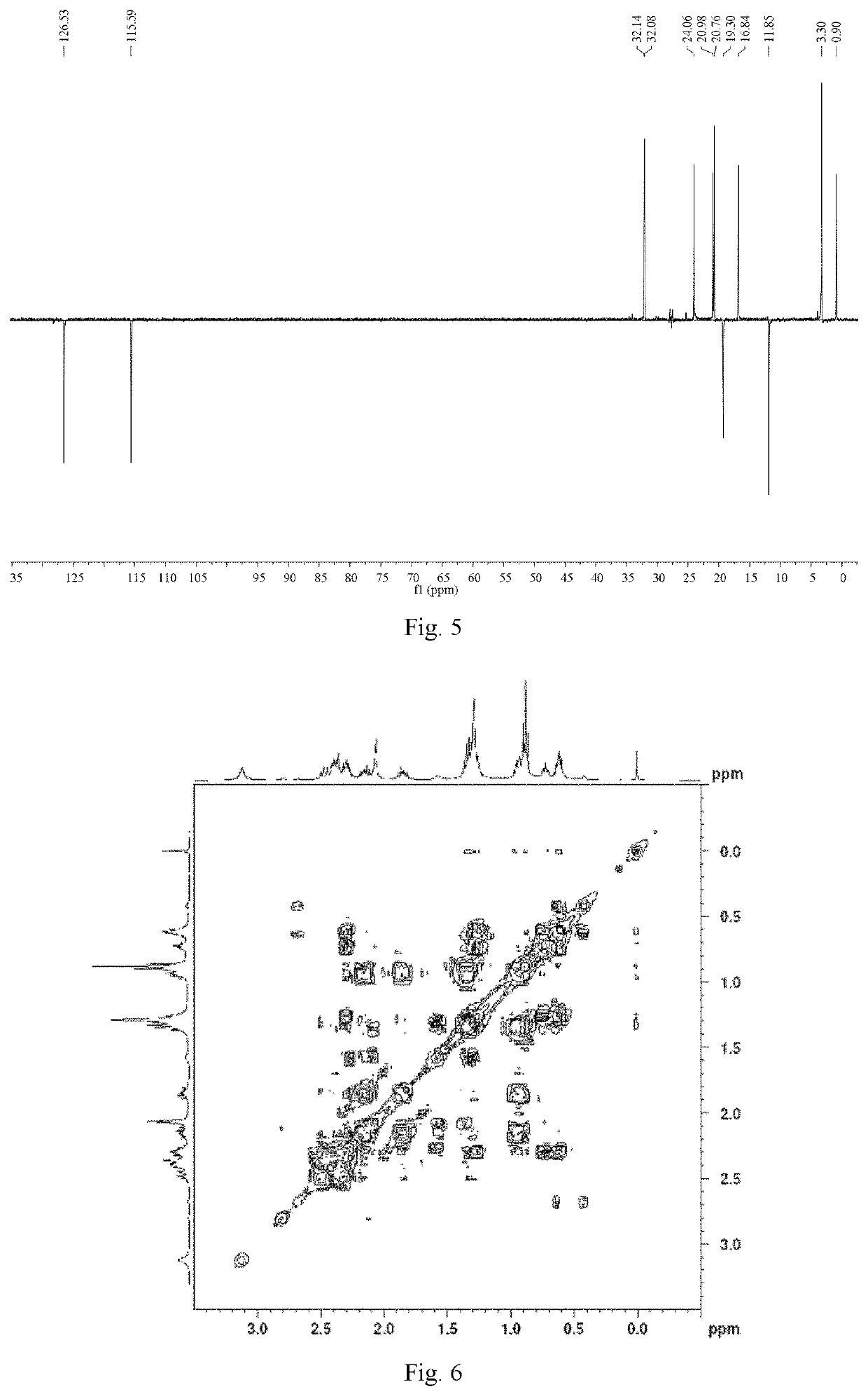

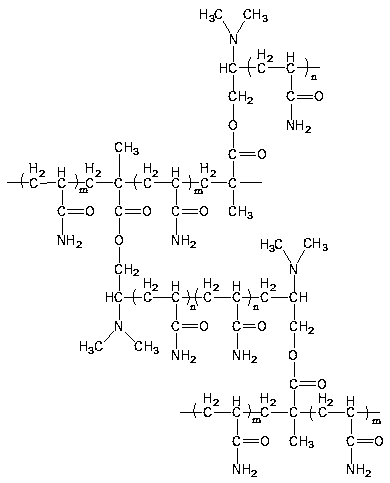

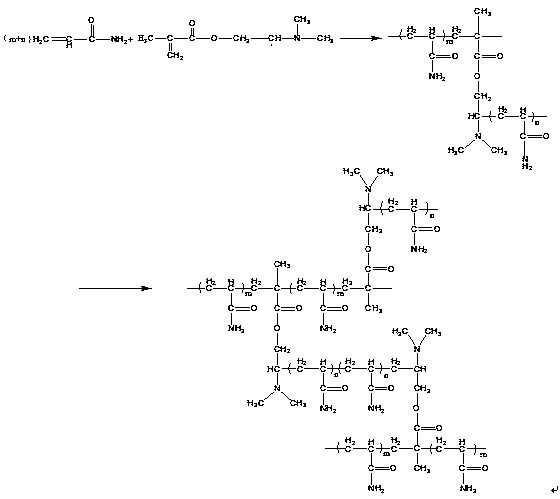

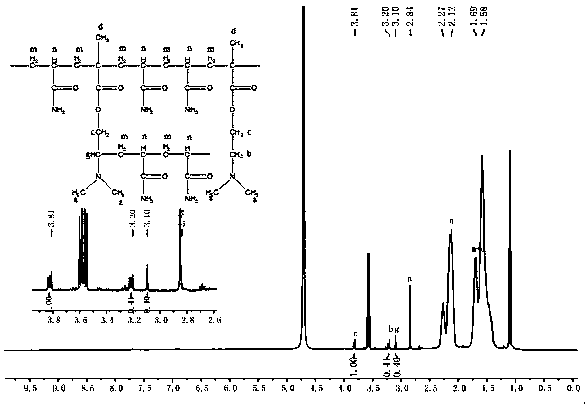

Preparation method of micro-branched micro-crosslinked polyacrylamide

ActiveCN107365402AImprove shear resistanceImprove thermal stabilityDrilling compositionHydrolysisPolyacrylamide

The invention discloses a preparation method of micro-branched micro-crosslinked polyacrylamide. The preparation method comprises the following steps: adding an acrylamide monomer of which the mass percent is 20-30% into water; then adding dimethylaminoethyl methacrylate, persulfate, a chain transfer agent, EDTA and manganese acetylacetonate, regulating the pH value to 5-8, and initiating a polymerization reaction at 20-40 DEG C; after 5-10 hours of reaction, taking out a colloid, and performing granulation; and the adding NaOH accounting for 1.5-3% of the mass of the colloid, and performing hydrolysis at 80-100 DEG C for 1-3 hours to obtain the finished product. The micro-branched micro-crosslinked polyacrylamide prepared by the method disclosed by the invention has high viscosity, and has excellent thermal stability and mechanical shearing resistance; and experiments indicate that the viscosity retention rate of the micro-branched micro-crosslinked polyacrylamide disclosed by the invention after mechanical shearing is more than 81%, and the viscosity retention rate after 90 days of aging is 79% or above. The method disclosed by the invention has the advantages of mild reaction conditions, simple operation process, low cost and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

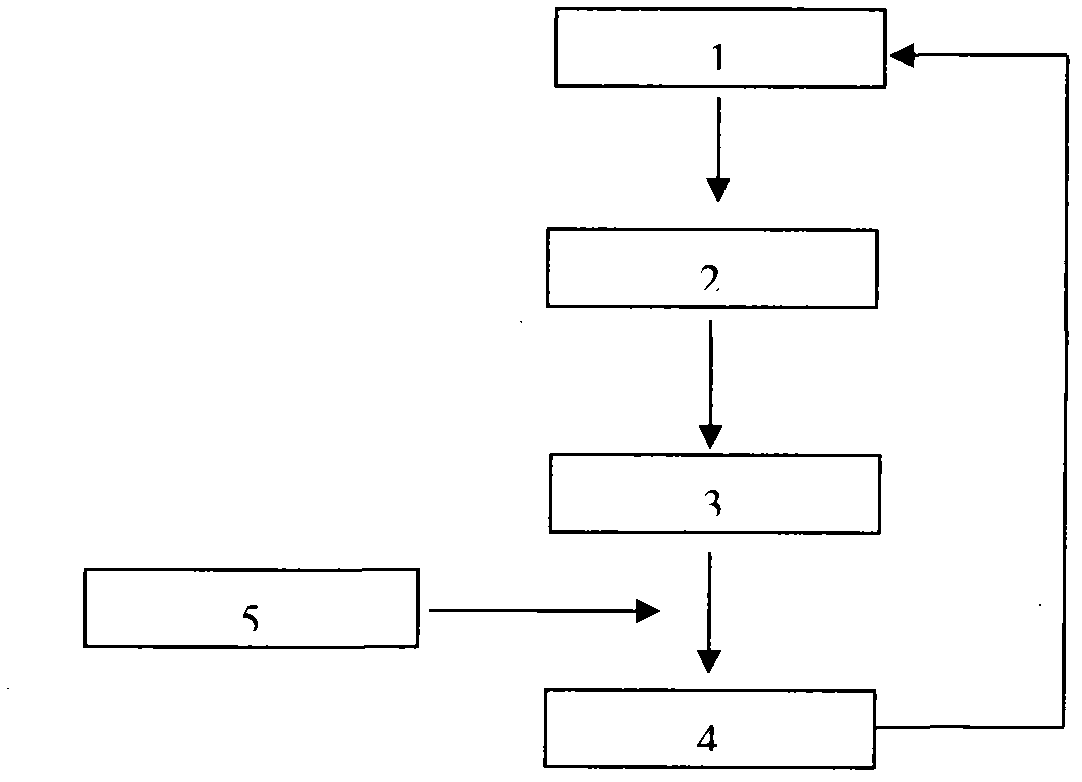

Industrial circulation water quick sterilization technology and system

InactiveCN103288253APrevent regenerationNo harmMultistage water/sewage treatmentCooling towerWater quality

The invention discloses an industrial circulation water quick sterilization technology and an industrial circulation water quick sterilization system. An ultraviolet sterilization device and chemical bactericides are combined; the ultraviolet sterilization device is used as a core device and can be arranged between a circulation pump and a cooling tower and also arranged between the circulation pump and a heat exchange device; the ultraviolet sterilization efficiency is extremely high, the chemical property of water is not changed, the water quality cannot be polluted, and damage to the heat exchange device is avoided, therefore, the industrial circulation water quick sterilization technology and the industrial circulation water quick sterilization system are very environment-friendly. Due to chemical sterilization, trace chemical bactericides are fed, so that the heat exchange device cannot be damaged, and the shortcoming that ultraviolet does not have the continuous sterilization capacity is overcome; the chemical bactericides and the ultraviolet are combined; therefore, the sterilization process is quick, high-efficiency, stable, reliable, safe and environment-friendly.

Owner:王宇

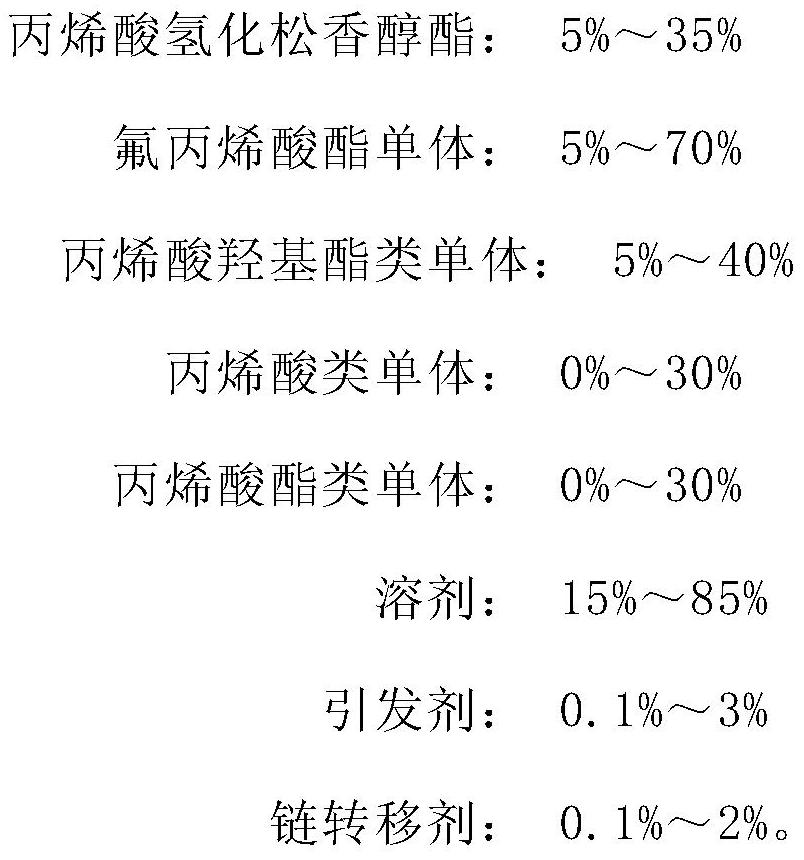

Acrylic acid hydrogenated abietinol ester modified fluorocarbon resin and preparation method thereof

PendingCN113861334AGood steric hindrance effectGood hydrophobicityAnti-corrosive paintsPolyurea/polyurethane coatingsFluorocarbon ResinsCorrosion prevention

The invention discloses an acrylic acid hydrogenated abietinol ester modified fluorocarbon resin, the molecular structure of which takes a carbon chain as a main chain structure, and a side group connected with a main chain carbon atom is composed of one or more of a hydrogenated abietinol ester group, a fluoroalkyl ester group, a hydroxyl group or an alkyl hydroxyl group, and / or a hydrogen atom, an alkyl group, an alkoxy group, a carboxyl group and an ester group; from the perspective of the molecular structure, the chemical structure of the fluorocarbon resin is designed and optimized, a large-volume rigid group is introduced into the molecular structure, the novel fluorocarbon resin is synthesized, the hydrophobicity and hardness of the fluorocarbon resin are further improved, the comprehensive performance of the fluorocarbon coating can be essentially improved, and the application of the fluorocarbon coating in the field of marine heavy corrosion prevention is further expanded.

Owner:GUANGXI UNIV FOR NATITIES

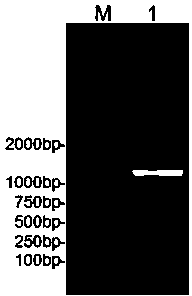

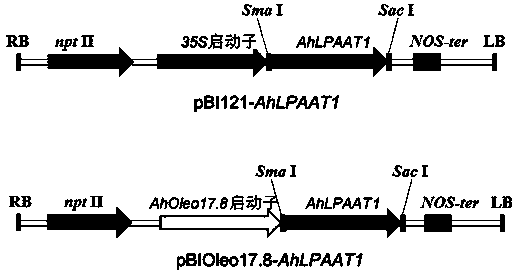

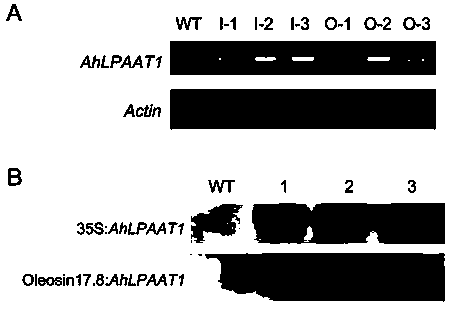

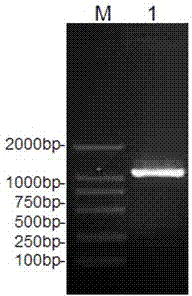

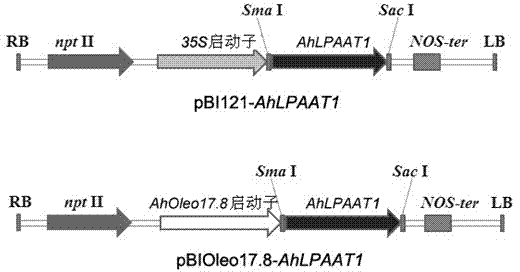

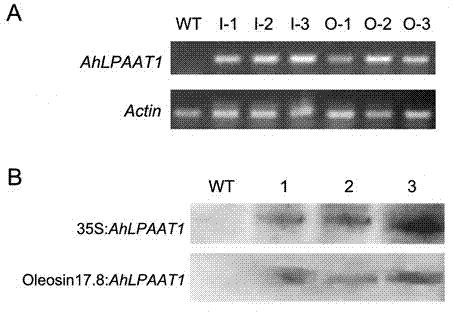

Peanut lysophosphatidic acid acyltransferase gene and application thereof

InactiveCN103725700ATotal oil content decreasedRaise the ratioBacteriaTransferasesPlant tissueNucleotide

The invention relates to a peanut lysophosphatidic acid acyltransferase gene AhLPAAT1 and application thereof, belonging to the fields of molecular biology and biotechnology. The gene cDNA nucleotide sequence of the AhLPAAT1 is disclosed as SEQ ID NO:1, and the amino acid sequence of the coding protein is disclosed as SEQ ID NO:2. The peanut lysophosphatidic acid acyltransferase gene has the actions of changing the fatty acid content in plant tissues and especially seeds and enhancing the proportion of polyunsaturated fatty acids, and has wide application prospects in the fields of plant species breeding and agricultural production. The invention also relates to a transgenic plant with AhLPAAT1 gene. The invention also relates to a method for changing the fatty acid content in plant seeds and component proportion by using the AhLPAAT1 gene.

Owner:SUN YAT SEN UNIV

A planting method imitating wild Polygonatum

ActiveCN111567347BIncrease fertilityImprove physicsTransplantingRoot crop cultivationMaterial distributionSeedling

The invention relates to a planting method of imitating wild Polygonatum, the following processing equipment is used in the planting method of imitating wild Polygonatum, the processing equipment includes a floor frame, a material distributing device and a planting device, the bottom frame is a U-shaped structure, the bottom frame A planting device is installed in the middle of the upper end, and a material distributing device is arranged above the planting device, and the material distributing device is installed on the bottom plate frame. The present invention can solve the problem that when the existing Rhizoma Polygonatum is planted and processed, manual cultivation is usually carried out manually, which has high labor intensity and low efficiency, which is not conducive to the large-scale planting of Rhizoma Polygonatum, and when the existing equipment is planting Rhizoma Rhizoma Polygonatum, planting The effect is poor, the efficiency is low, and the seedlings after planting are prone to dumping. At the same time, the seedlings cannot be effectively protected during the planting process, which is easy to cause damage to the seedlings and affect the survival rate of the seedlings.

Owner:池州市九华府金莲智慧农业有限公司

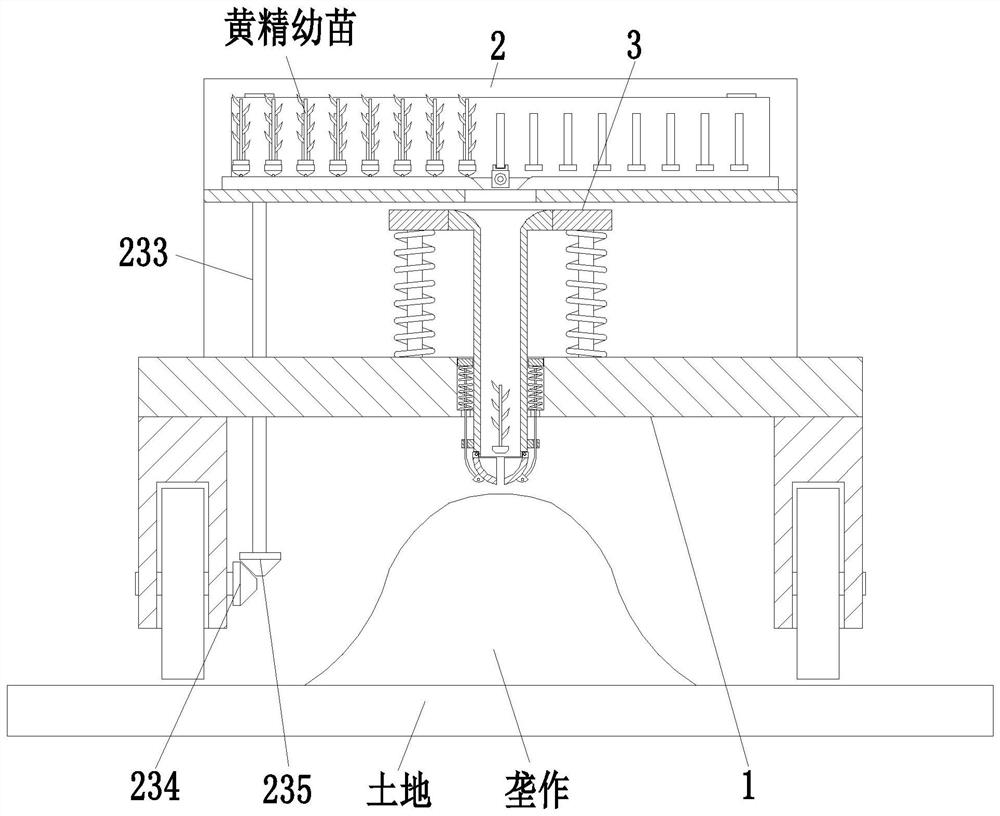

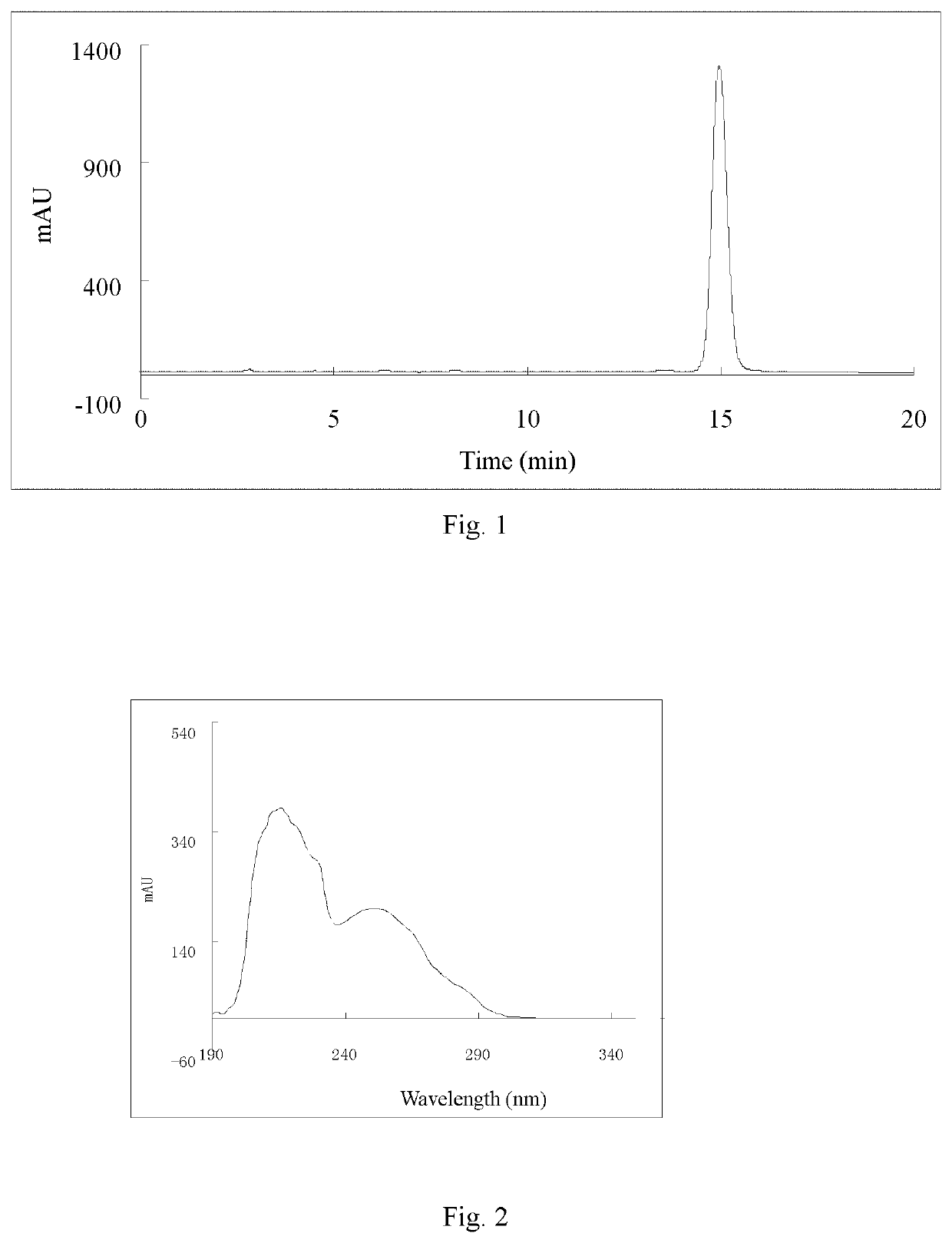

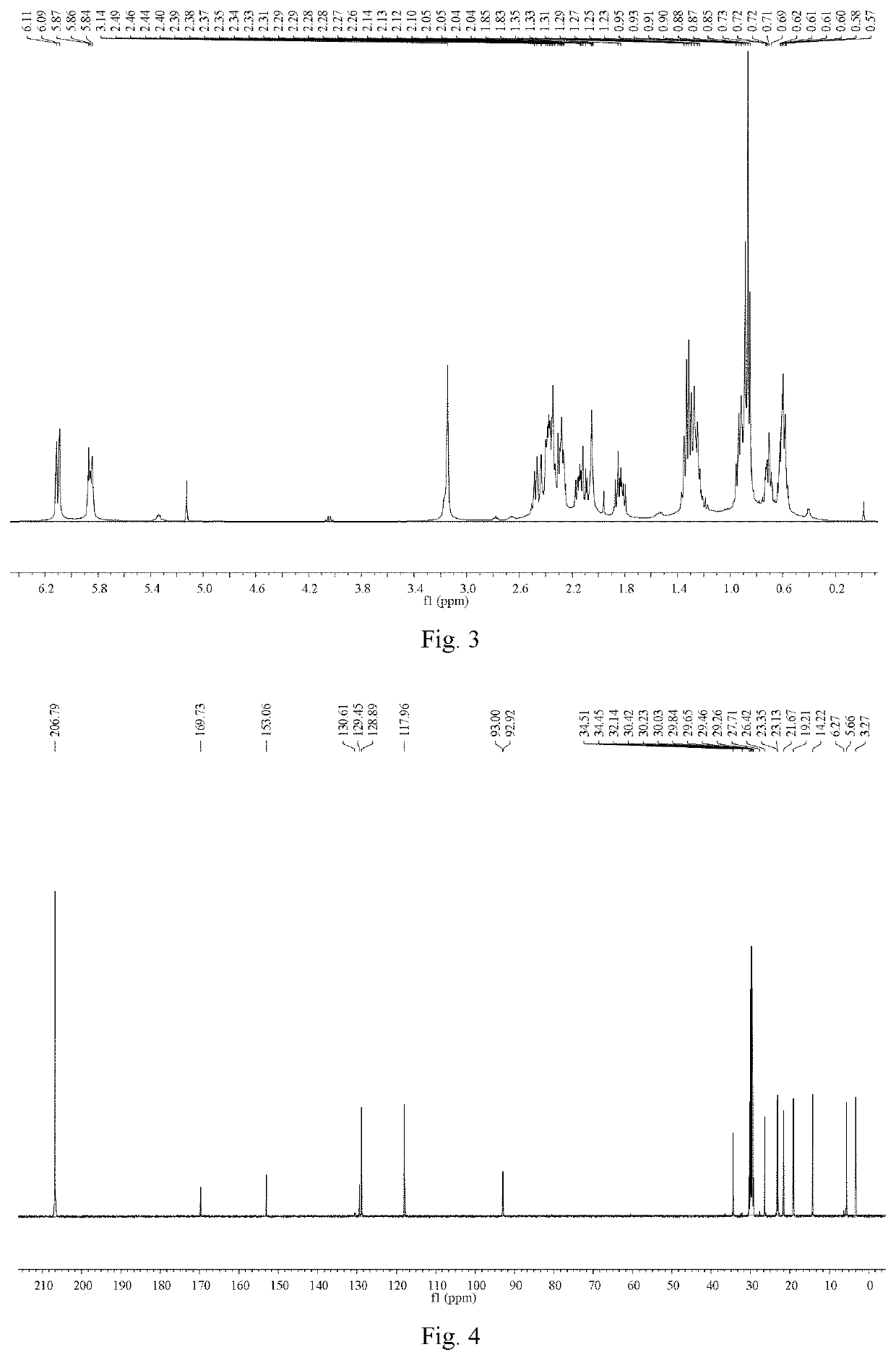

Phthalide derivative, preparation method and use thereof

PendingUS20210276953A1Good effectImprove protectionOrganic chemistry methodsAntinoxious agentsCombinatorial chemistryPerylene derivatives

The present invention discloses a phthalide derivative, the structure of said derivative is represented by Formula (I) or Formula (II). The present invention also discloses the preparation method and use of said derivative. The phthalide compound obtained through structure modifications in the present invention enhances the chemical stability and pharmacological activity of the phthalide compound, facilitating the improvement of the druggability of such compounds.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of micro-branched micro-crosslinked polyacrylamide

ActiveCN107365402BImprove thermal stabilityImprove shear resistanceDrilling compositionPolymer scienceHydrolysis

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for preparing ethylene carbonate

ActiveCN105732566BLess by-productsHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEthylene oxideReaction temperature

The invention relates to a method of producing ethylene carbonate by catalytic addition from ethylene oxide and CO2. In the method, under the effect of an environment-friendly ionic liquid catalyst, the CO2 and the ethylene oxide are added to prepare the ethylene carbonate. When the reaction temperature is 90-130 DEG C, the reaction pressure is 1-3 MPa, the stirring speed is 200-300 r / min and the reaction time is 1-2 h, the conversion rate of the ethylene oxide reaches more than 98% and the yield of the ethylene carbonate reaches more than 94%. Conversion rate and yield are both higher than 90% even the catalyst is repeatedly used for seven times.

Owner:PETROCHINA CO LTD

Large-delve improvement home-position reparation alkaline land thick-planting building method of man-made forest

InactiveCN101379940BImprove convenienceImprove survival rateClimate change adaptationContaminated soil reclamationAlkali soilLand preparation

The invention discloses a method for afforesting an artificial forest by closely planting trees on an in-situ repaired saline land with improved great holes. In order to afforest the artificial forest by closely planting trees, firstly, the saline land is prepared with holes dug, and then the eluvial soil dug out for land preparation is mixed with an artificial biological matrix prepared by curing corn stalks and cow dung to prepare the standby artificial improved soil. A layer of corn stalks is spread on the bottom of the holes, then a layer of cow dung is added to the corn stalks, and successively a layer of corn stalks is spread on the cow dung. Then the artificially improved soil is applied to the holes, and a saline alkali soil amendment is poured on the artificially improved soil. After selected seedlings are planted in the holes, the artificially improved soil is used for fixing root systems and water is irrigated to the soil. Finally, the artificially improved soil is stacked on the planting holes until a trapezium shape is formed, and a surface soil film former is spread on the artificially improved soil. A perforated feeding channel is dug between every two holes, and isfilled with the artificially improved soil.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Synthesis process of horseradish peroxidase enzymelabeled zearalenone

ActiveCN102051389BImprove chemical structureImprove effectivenessFermentationPeroxidaseHorseradish peroxidase

The invention discloses a synthesis process of horseradish peroxidase enzymelabeled zearalenone. In the synthesis process, a carboxylated product is obtained by carboxylating zearalenone, and the horseradish peroxidase enzymelabeled zearalenone is obtained by a condensation reaction of the carboxylated product and horseradish peroxidase enzyme. The preparation process of detecting the key component horseradish peroxidase enzymelabeled product in the CLIA (Chemiluminescence Immunoassay) field is a formidable difficult all along. Accordingly, the synthesis process of the horseradish peroxidase enzymelabeled zearalenone, which is provided by the invention, is simple and practical and has low cost and favorable market application prospects.

Owner:CHEMCLIN DIAGNOSTICS CO LTD

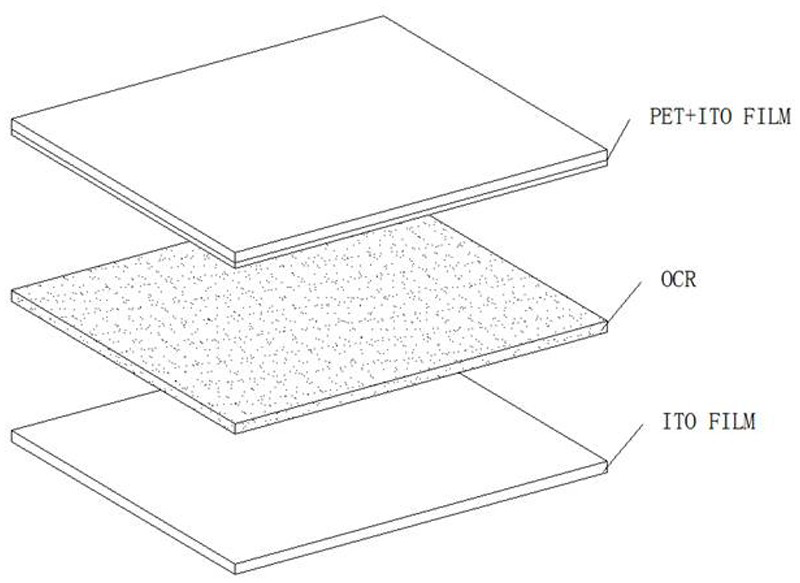

Manufacturing process of FF touch screen

PendingCN112114712ALow costHigh strengthInput/output processes for data processingLaser etchingPolyethylene terephthalate glycol

The invention relates to the technical field of touch screen manufacturing, in particular to an FF touch screen manufacturing process which includes the steps: (1) firstly, electroplating or coating an ITO (indium tin oxide) conductive layer on the back of a PET (polyethylene terephthalate) material to serve as an upper conductive material of a touch screen; (2) etching a preset conductive patternand a preset circuit on the ITO conductive layer on the back surface of the PET material through a laser etching machine; (3) carrying out surface treatment on the front surface of the PET material to enable the surface hardness of the PET material to reach more than 3H, and supporting touch writing of human fingers; and (4) finally, enabling the conductive surface of the ITO film on the middle and lower layers of the touch screen to face upwards, and adhering the ITO film in the middle through transparent optical cement OCA, so as to form the FF touch screen with the cover plate effect. According to the touch screen, the upper-layer material can reach the surface hardness of 3H or above, the PET material with the ITO conducting layer attached to the back face can also be taken into consideration, the PET material without the conducting layer in the prior art is replaced, and therefore two attaching procedures and two layers of materials can be reduced, and the cost is reduced.

Owner:东莞探未光电有限公司

An energy-saving and enhanced refining method for producing sticky pulp by composite pretreatment

ActiveCN104452398BImprove the physical properties of paperSave paper physical propertiesMicroorganism/enzyme additionPaper/cardboardPre treatmentUltimate tensile strength

The invention discloses an energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp. The method comprises the following steps that (1) paper pulp fibers are dissolved in water, even defibering is carried out, and then pretreatment is carried out; (2) biological enzymes are added to the treated paper pulp for treatment, the dosage of the biological enzymes ranges from 10 IU / g to 60 IU / g, the temperature ranges from 40 degrees to 60 degrees, the pH value ranges from 6 to 9, the concentration of the paper pulp ranges from 3 wt% to 8 wt%, and treatment is carried out for 10 min to 30 min; (3) continuous millstone milling and beating are carried out on the pulp of the step (2), and the pulp is stored for standby application. The method remarkably improves the efficiency of subsequent biological enzyme treatment, and overcomes the defects that enzyme treatment time is too long in biological enzyme assistant defibrination production and energy conservation in defibrination and the physical strength of finished paper formed by fibers cannot be achieved at the same time, the defibrination energy consumption and the defibrination time for producing the viscous paper pulp are saved, the defibrination energy consumption of chemical bleached needle wood pulp and chemithermomechanical pulp of needle wood is reduced by 15%-45%, and the physical properties of finished paper formed by pulp fibers can be improved.

Owner:五洲特种纸业(龙游)有限公司

Manufacturing method for interlocked armored aluminum alloy flat cable

ActiveCN102969087BPrevent disconnectionImprove conductivityFlat/ribbon cablesFlexible cablesElectrical conductorManufacturing technology

The invention discloses a manufacturing method for an interlocked armored aluminum alloy flat cable. According to the manufacturing technology, the manufacturing method comprises the following steps in sequence: drawing wires, stranding a conductor, annealing the conductor, extruding an insulating layer, extruding a lining layer, and pressing an interlocked armored layer, wherein the conductor annealing step comprises the steps: through boxcar type heating and annealing steps, heating the stranded conductor to 370-400 DEG C, lasting for 4-5 hours at the environment of 370-400 DEG C, and then naturally cooling to the room temperature; and the interlocked armored layer pressing step is that an aluminum alloy tape with the thickness of 0.5mm-0.6mm is arranged on the surface of the lining layer and pressed into a Z-shaped interlocked armored form with the arc-shaped height of 2mm-4mm according to pitches of 6mm-24mm. according to the manufacturing method, the conductivity property and creep property can be improved, the service life of the cable can be effectively prolonged, the system can have good radiating effect in short time under overload state, and can be ensured to run safely.

Owner:SICHUAN MINGXING CABLE

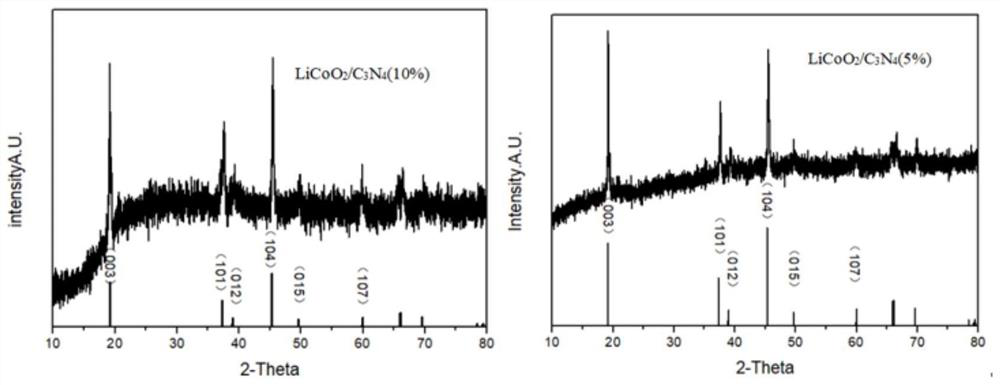

Lithium ion battery

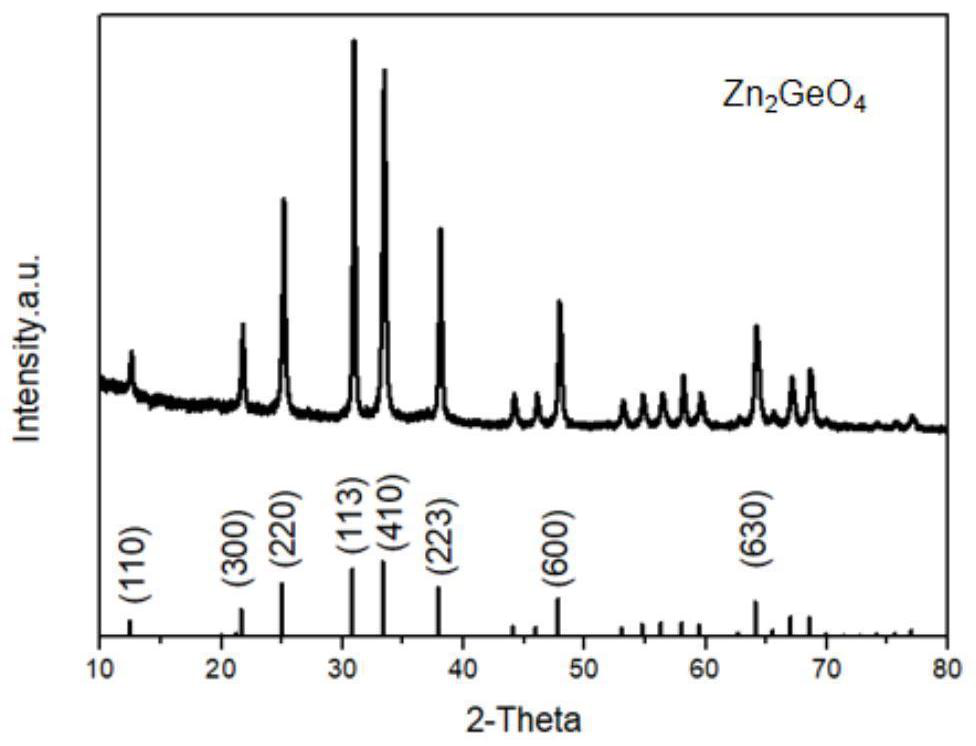

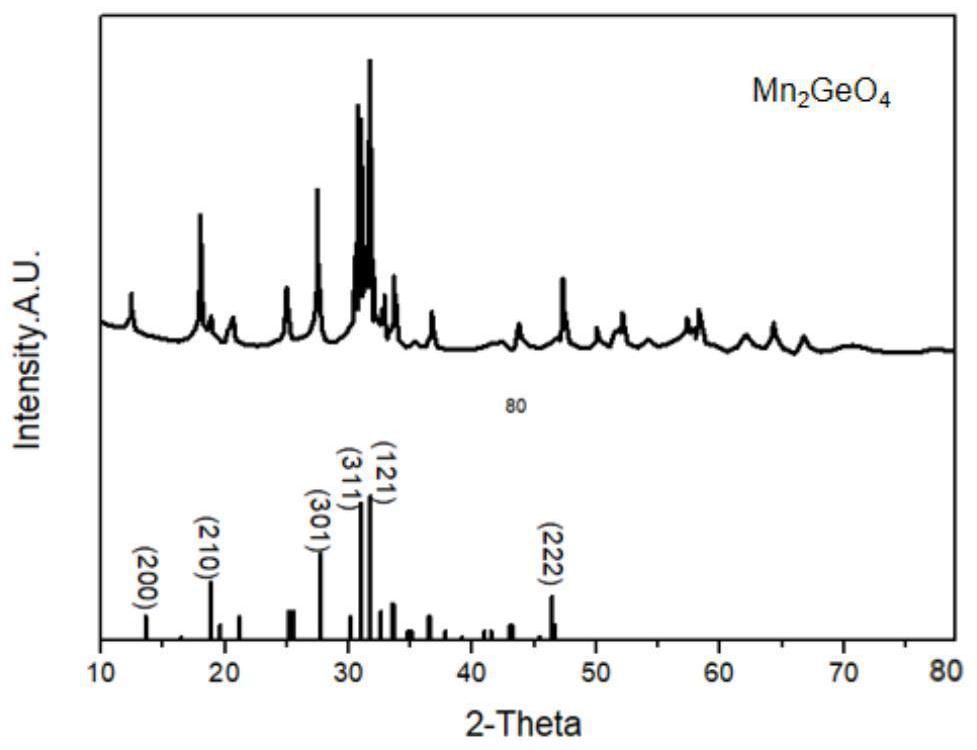

PendingCN114843486AEasy to prepareEasy to operateFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention relates to a lithium ion battery, which comprises the following structures: a winding battery cell assembly, electrolyte for impregnating the winding battery cell assembly, a metal shell for loading the winding battery cell assembly and the electrolyte, and a sealing cover for sealing the metal shell, the winding cell assembly comprises a positive electrode foil, a negative electrode foil and a diaphragm for separating the positive electrode foil from the negative electrode foil; the positive electrode foil comprises a positive electrode active material, and the positive electrode active material is a LiCoO2 / C3N4 composite material; the negative electrode foil comprises a negative electrode active substance, the negative electrode active substance is an M2GeO4 material, and M is selected from one or more of Zn, Mn, Co and Cd, specifically one of Zn2GeO4, Mn2GeO4, Co2GeO4 and Zn1. 8Cd0. 2GeO4; the battery provided by the invention has relatively high reversible capacity, relatively good cycle performance and rate capability, and relatively stable fast charging performance.

Owner:JIANGSU UNIV OF TECH

Optical plastic protective coating and preparation method thereof

InactiveCN104231914BImprove chemical structureStable network structureCoatingsPtru catalystSilicic acid

The invention discloses an optical plastic protective coating and a preparation method thereof. The optical plastic protective coating is calculated in parts by weight, that is, 2 parts of ethyl orthosilicate, 5-6.5 parts of phenyltrimethoxysilane, 1.5-2 parts of coupling agent, 3-4 parts of distilled water, 0.02 ~0.03 parts of curing agent and 0.02~0.04 parts of catalyst were added to the container in turn, stirred and left at room temperature for 24 hours, the obtained colorless and transparent liquid was coated on the optical plastic plate and dried at 80°C, and then placed on the optical plastic plate The resulting layer of coating is the optical plastic protective coating. The optical plastic protective coating has the characteristics of high light transmittance, high hardness, etc., and can be widely used in the field of optical plastic protection, and can also be used in the fields of coatings, inks, and the like.

Owner:SHANGHAI INST OF TECH

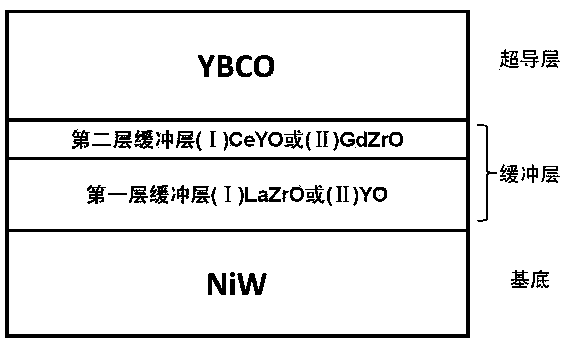

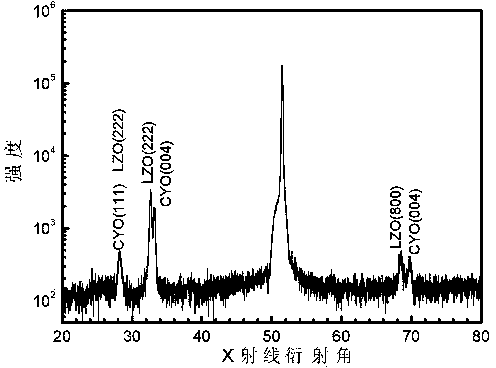

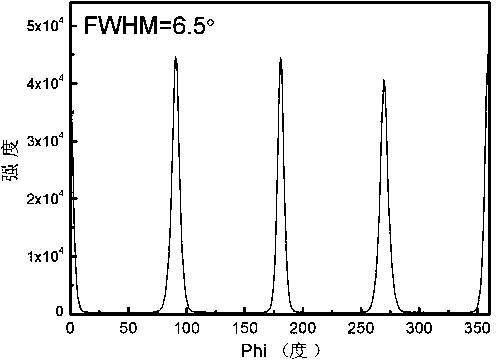

High-temperature superconductive coating conductor dual-layer buffering layer structure and dynamic deposition method thereof

ActiveCN102610322BLess componentsSimple manufacturing processSuperconductors/hyperconductorsVacuum evaporation coatingElectrical conductorChemical physics

The invention relates to a high-temperature superconducting coating conductor double-layer buffer layer structure and a dynamic deposition method thereof. Simplified double-layer rare earth oxide buffer layer structures, including (I) La2Zr2O7 / Ce2Y2O7 and (II) Y2O3 / La2Zr2O7, were epitaxially grown on Ni-5%W substrates with biaxial texture orientation by reactive sputtering. That is, the first buffer layer (lower buffer layer) and the second buffer layer (upper buffer layer) form a high-temperature superconducting coating conductor double-layer buffer layer structure. The metallic NiW substrate was pretreated before the reactive sputter deposition process. Carry out heat treatment on the metal substrate at a temperature of 700°C and in an ArH2 atmosphere; vacuum the back of the cavity to below 10-5Pa; inject water vapor during sputtering, and control the water pressure at 2.1×10-2Pa; the total pressure of the entire cavity Control at 1Pa; temperature at 800°C; after full pre-sputtering, power control at 160W. Sputtering deposition first deposits the first layer and then deposits the second layer. Finally, a double-layer rare earth oxide buffer layer is obtained.

Owner:SHANGHAI UNIV

A production process for reproducing high-strength corrugated paper from waste paper

ActiveCN110080035BIncrease the proportionHigh fiber recovery ratePaper recyclingCellulose treatment using microorganisms/enzymesFiberProcess engineering

The invention discloses a production process for remanufacturing high-strength corrugated paper by using waste paper. Filtration step, step-by-step high-consistency slag removal step, distributed high-consistency filter press step, dilution step, primary pulp compound pretreatment step, refining step, screening step, pulp blending step, sheet-making step, strengthening step, wet paper Drying and pressing steps, surface sizing steps, paper drying steps, etc., and finally winding to obtain finished corrugated paper. Compared with the existing technology, it enables directional physical separation of waste paper materials before the pulping step, which further reduces the damage of papermaking fibers and reduces the use of chemical agents. It is environmentally friendly and reduces the treatment cost of papermaking waste , Improve production efficiency and reduce the production cost of the enterprise.

Owner:东莞顺裕纸业有限公司

A peanut lysophosphatidic acid acyltransferase gene and its application

InactiveCN103725700BTotal oil content decreasedRaise the ratioBacteriaTransferasesPlant tissueNucleotide

The invention relates to a peanut lysophosphatidic acid acyltransferase gene AhLPAAT1 and application thereof, belonging to the fields of molecular biology and biotechnology. The gene cDNA nucleotide sequence of the AhLPAAT1 is disclosed as SEQ ID NO:1, and the amino acid sequence of the coding protein is disclosed as SEQ ID NO:2. The peanut lysophosphatidic acid acyltransferase gene has the actions of changing the fatty acid content in plant tissues and especially seeds and enhancing the proportion of polyunsaturated fatty acids, and has wide application prospects in the fields of plant species breeding and agricultural production. The invention also relates to a transgenic plant with AhLPAAT1 gene. The invention also relates to a method for changing the fatty acid content in plant seeds and component proportion by using the AhLPAAT1 gene.

Owner:SUN YAT SEN UNIV

Preparation method of novel composite board used for furniture

The invention discloses a preparation method of a novel composite board used for furniture. The preparation method comprises the following operation steps: (1) carrying out extrusion pelletizing on thermoplastic resin for later use; (2) after plant fibers are smashed, carrying out surface activation treatment by adopting activation solution, so that activated plant fibers are obtained; (3) mixing the plant fibers with the pelletized thermoplastic resin, adding additives into the obtained mixture, preheating the obtained mixture to 70-80 DEG C, and carrying out heat preservation for 30 minutes; and (4) heating the preheated mixture, and pressing, so that the novel composite board used for the furniture is obtained. By adopting the preparation method of the novel composite board used for the furniture, the obtained composite board not only has excellent mechanical properties, but also is almost odorless, and causes no harm to health of a consumer.

Owner:安徽宏润工艺品有限公司

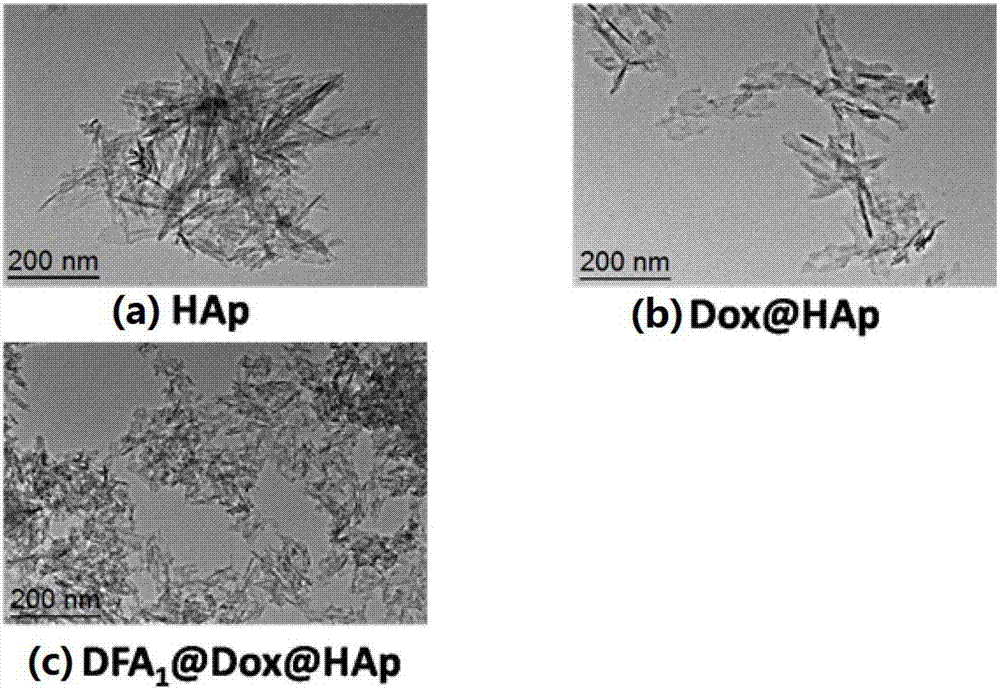

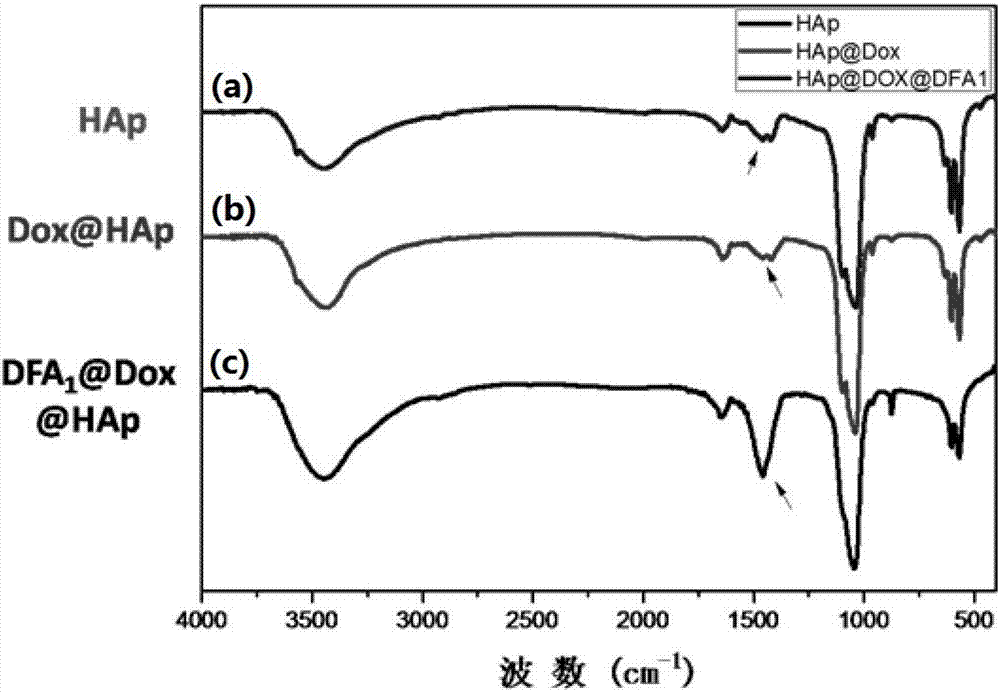

Target fluorescent dye and application thereof

ActiveCN106995442AGood biocompatibilityPromote degradationOrganic chemistryInorganic non-active ingredientsAbnormal tissue growthSide effect

The invention discloses a target fluorescent dye and application thereof. The target fluorescent dye has a structure of a general formula I. On the basis of the target fluorescent dye, the invention further discloses drug-loading hydroxyapatite subjected to surface modification through the dye and a preparation method of the drug-loading hydroxyapatite. A target compound material prepared through the method can be sensitively recognized, and is combined with glutamine transaminase highly expressed in most tumor cell membranes so as to penetrate through a cell membrane through an endocytosis manner, so that slow targeting release of an anti-cancer drug is realized. The coating rate of the anti-cancer drug can be improved, and normal and tumor cells are effectively distinguished, so that the release efficiency and the local concentration of the anti-cancer drug are effectively improved, and the dosage and the toxic and side effects of the anti-cancer drug are reduced; the compound material can quickly penetrate into tumor tissues, is combined with cell toxin, and has great research value and application prospect in the field of cancer treatment.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com