Patents

Literature

113results about How to "Reduce firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

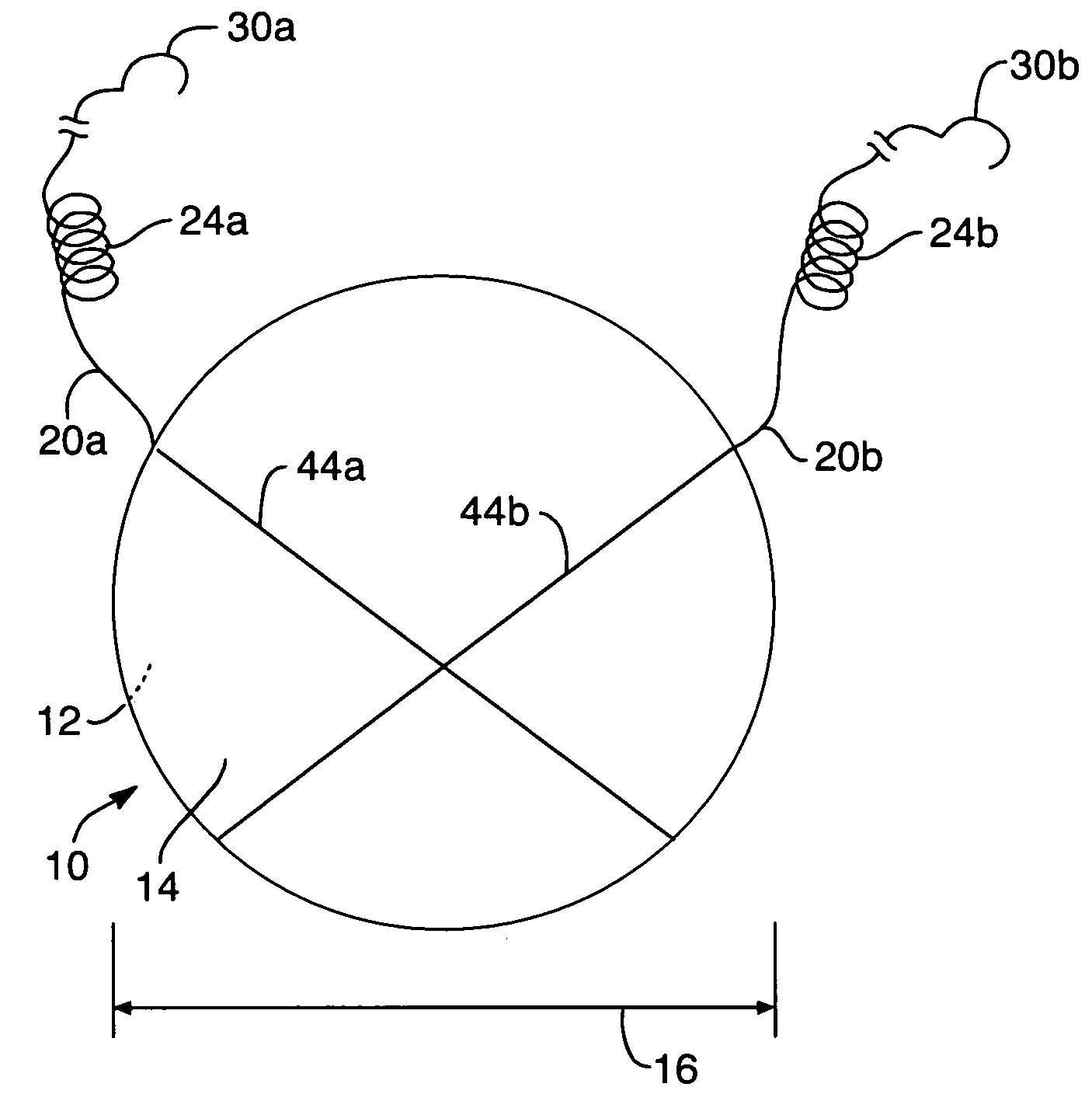

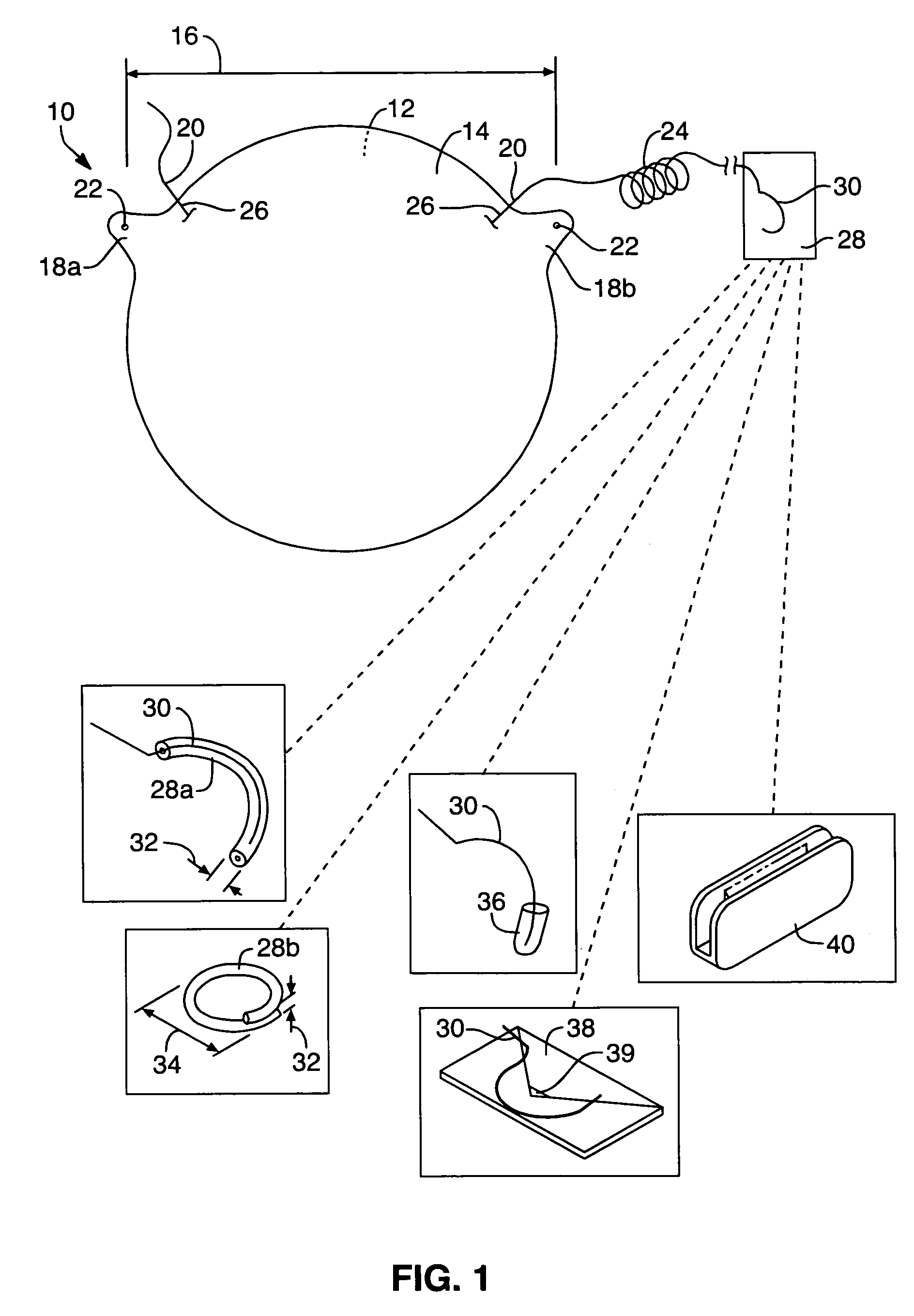

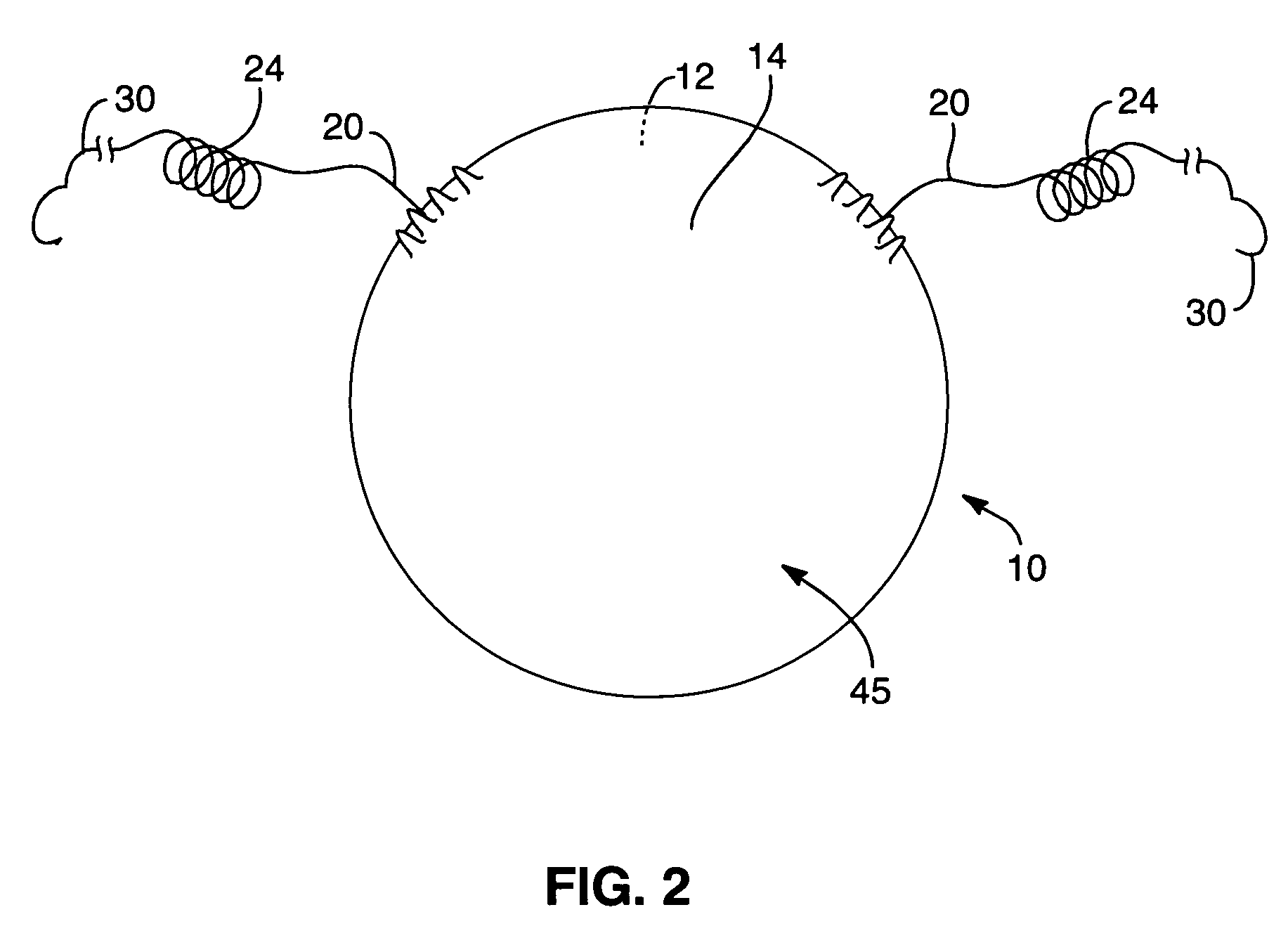

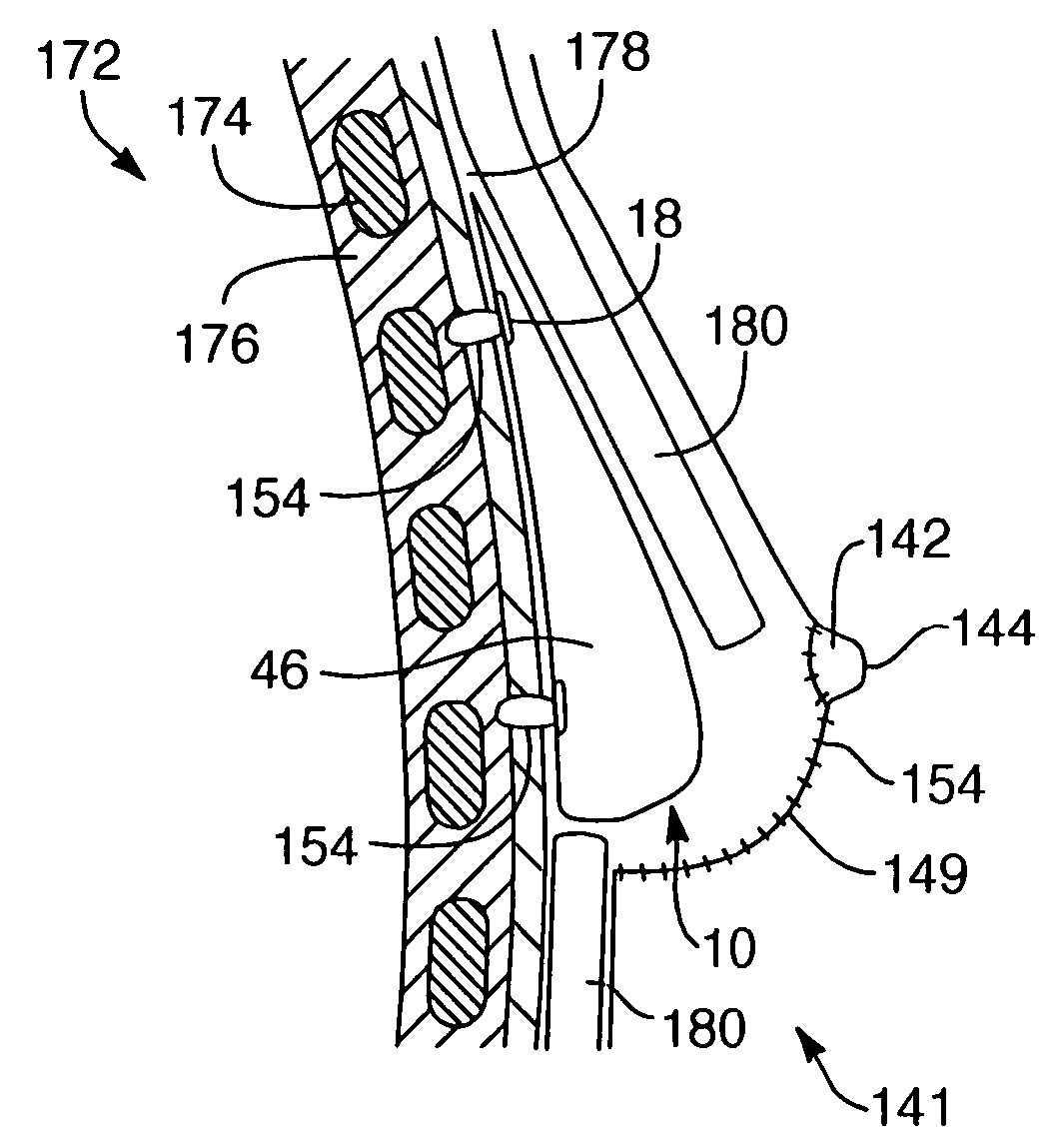

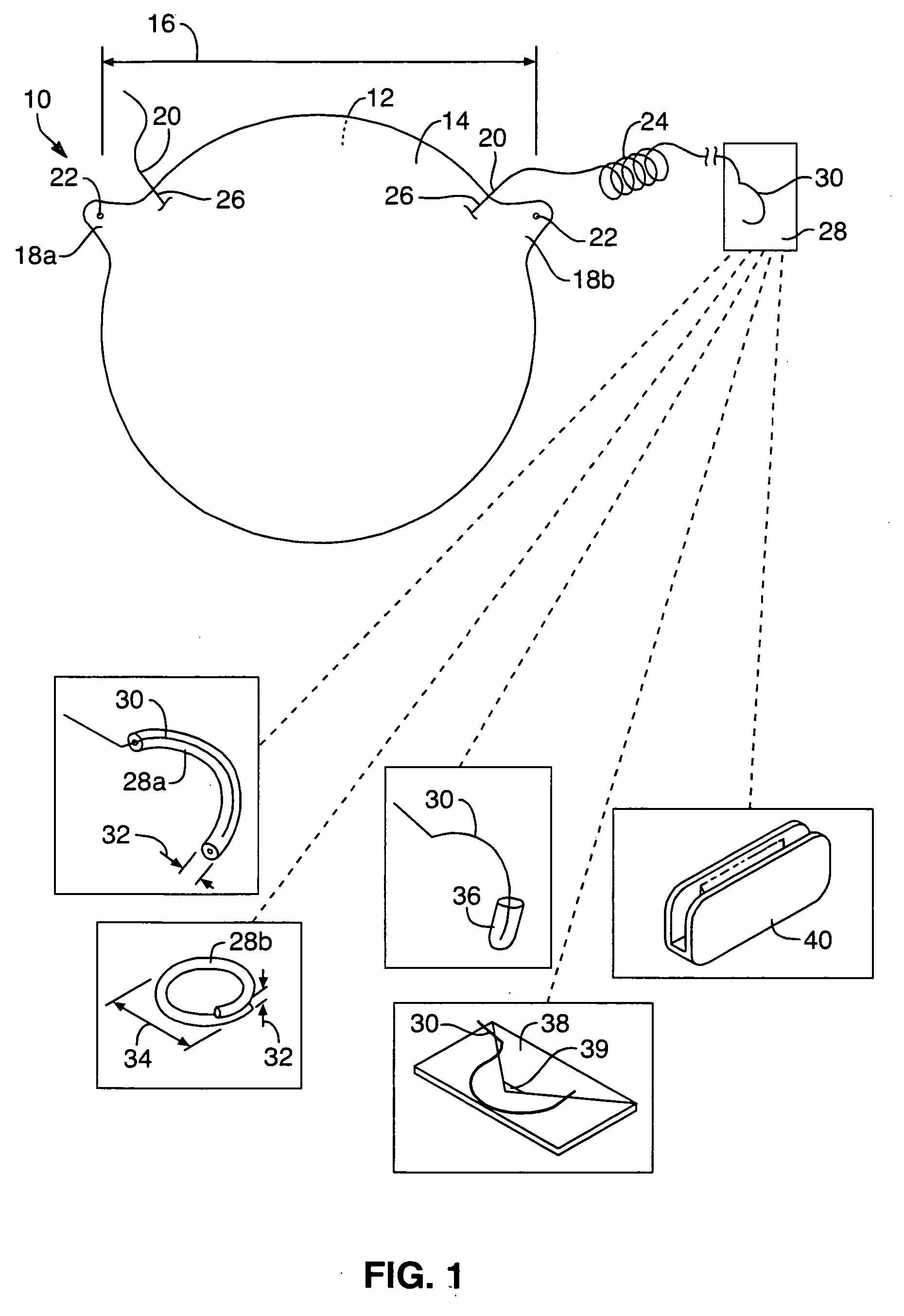

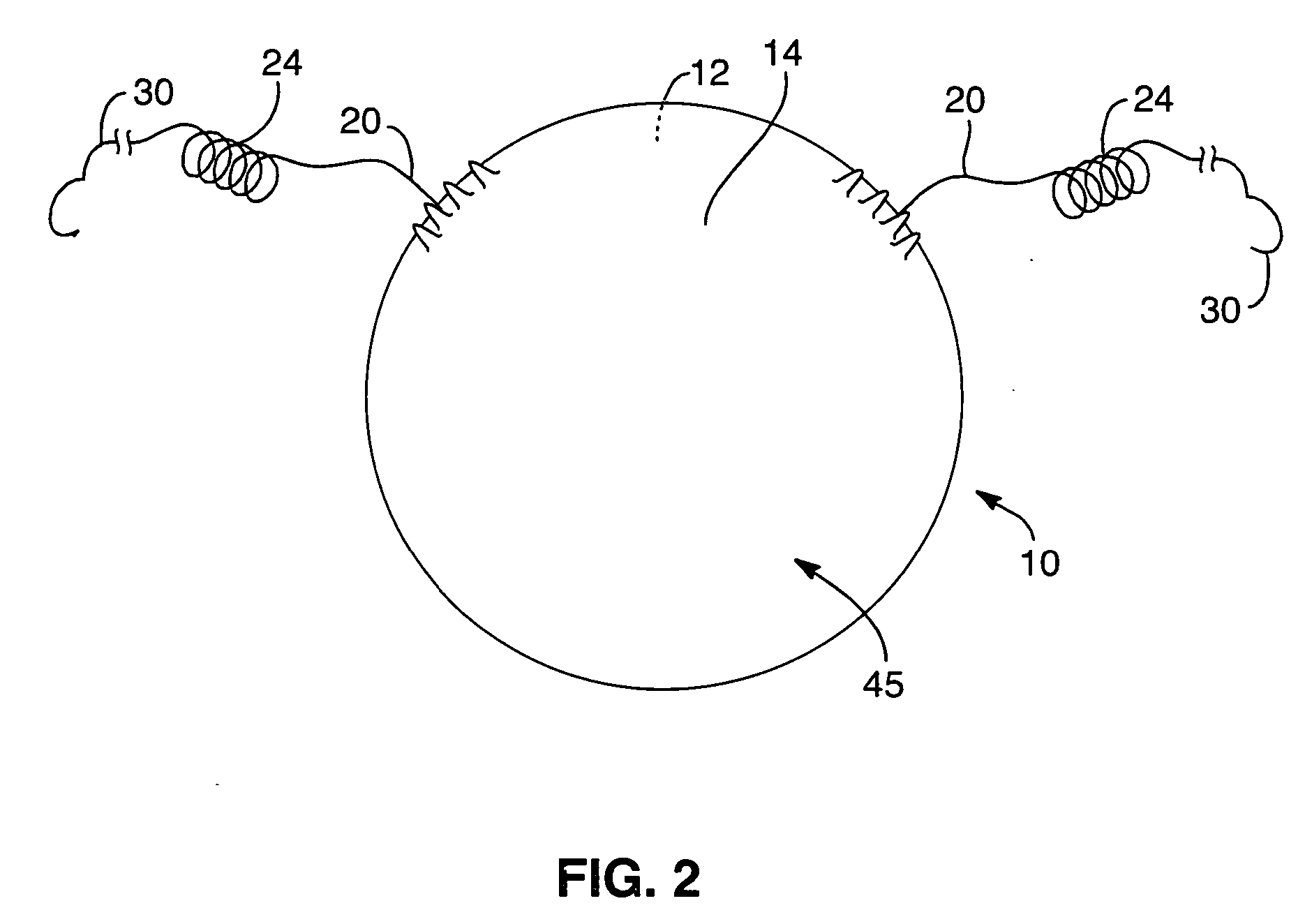

Mastopexy stabilization apparatus and method

An apparatus and method for mastopexy surgeries correcting a ptosis condition caused by tissue stretching, in the breast as a result of pregnancy, time, aging, and the effects of gravity and athletic activity provide an implant having homogeneously formed connectors extending from inside an implant wall for anchoring to the chest wall or chest muscles of a patient. Embedded reinforcements and anchoring tabs or sutures may be readily oriented along a rib or other defining physiological location in order to provide immediate, permanent, and symmetric installation of implants in a mastopexy reconstruction.

Owner:SMITH LANE FIELDING +1

Fertilizer for saline-alkali soil and preparation method of fertilizer

InactiveCN104262046AHigh in nutrientsLow bulk densitySuperphosphatesCalcareous fertilisersAlkali soilSoil organic matter

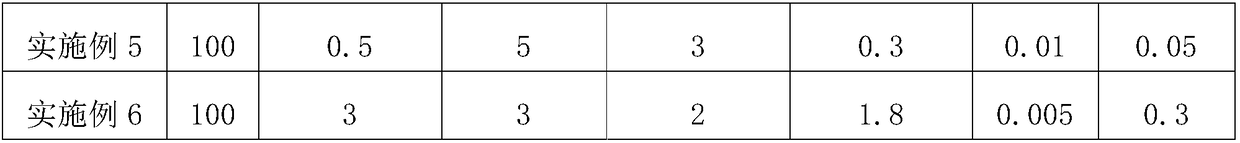

The invention relates to a fertilizer for saline-alkali soil. The fertilizer is prepared from the following raw materials in parts by weight: 5-20 parts of humic acid, 0.3-1 part of microorganisms, 6-16 parts of farmyard manure, 15-40 parts of straws, totally 5-10 parts of calcium superphosphate, ferrous sulfate, coal ash, furfural residues and flue gas desulfurization gypsum, 6-14 parts of a nitrogen fertilizer, 2-4 parts of a phosphatic fertilizer and 2-3 parts of a potassic fertilizer. The invention further relates to a preparation method of the fertilizer for saline-alkali soil. The fertilizer for saline-alkali soil, which is provided by the invention, has the beneficial effects that the fertilizer for saline-alkali soil has the characteristics of being low in cost and simple in preparation method, can be used for effectively improving the condition of saline-alkali soil, reducing the content of salt of soil and the pH value and increasing the content of organic matters in soil, and is particularly suitable for being applied to the saline-alkali soil.

Owner:瑞昊(北京)环境工程集团有限公司

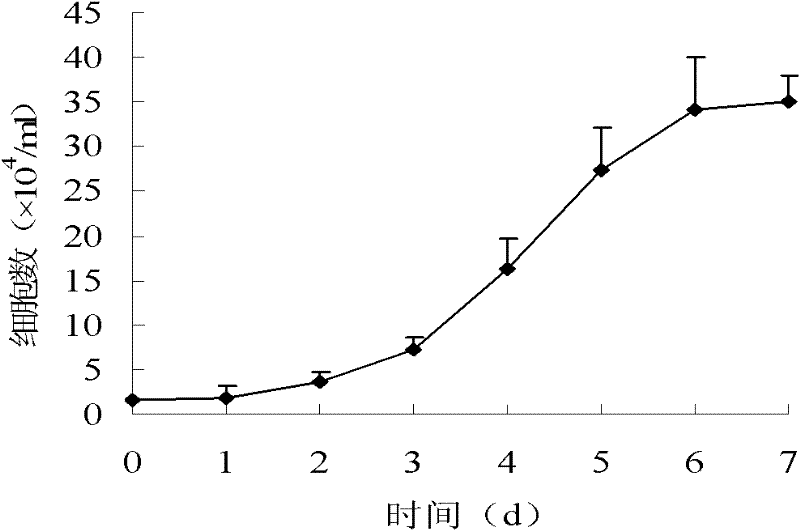

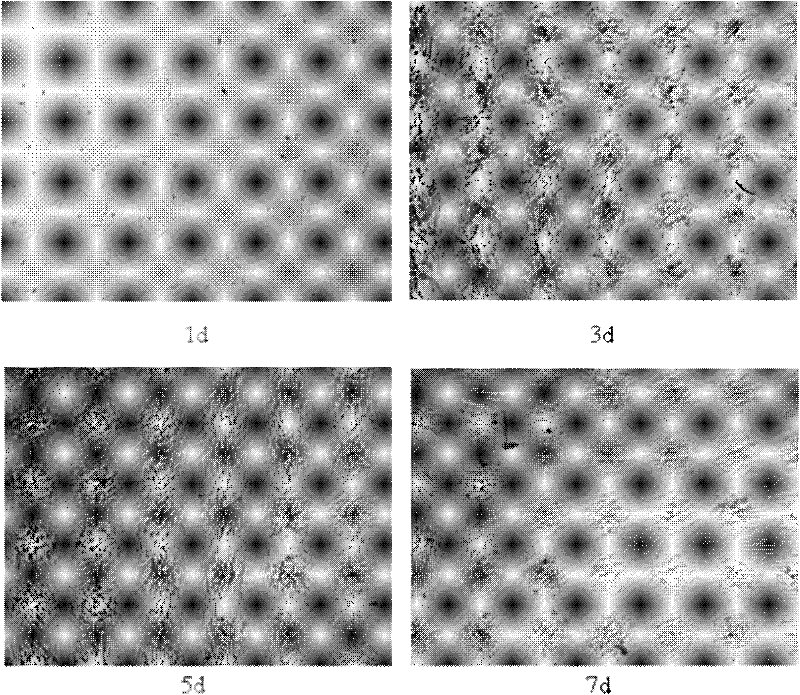

Complete medium and human amnion-derived mesenchymal stem cell culture method

The invention discloses a complete medium and a human amnion-derived mesenchymal stem cell (hAMSCs) culture method. The complete medium is prepared by adding 3 to 10 percent of autologous umbilical cord blood serum into low-sugar Dulbecco minimum essential medium solution according to a volume ratio. The culture method comprises: (1) separation; (2) primary culture; and (3) subculture. The methodusing the complete medium in the hAMSCs culture has the advantages that: the risk of using fetal calf serum is avoided; although the need of adding L-glutamine, non-essential amino acid, 2-mercapitoethanol, pyruvic acid and the like is obviated, the high proliferation properties and phenotypic characteristics of the hAMSCs and expression of multilineage differentiation marker genes sand proteins of some stem cells can still be retained; and in subculture, the wall adherence fastness of the hAMSCs is much lower than that in fetal bovine serum (FBS) culture, the digestion time is reduced obviously, and the damage of trypsinization to cells and loss of cells are reduced.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

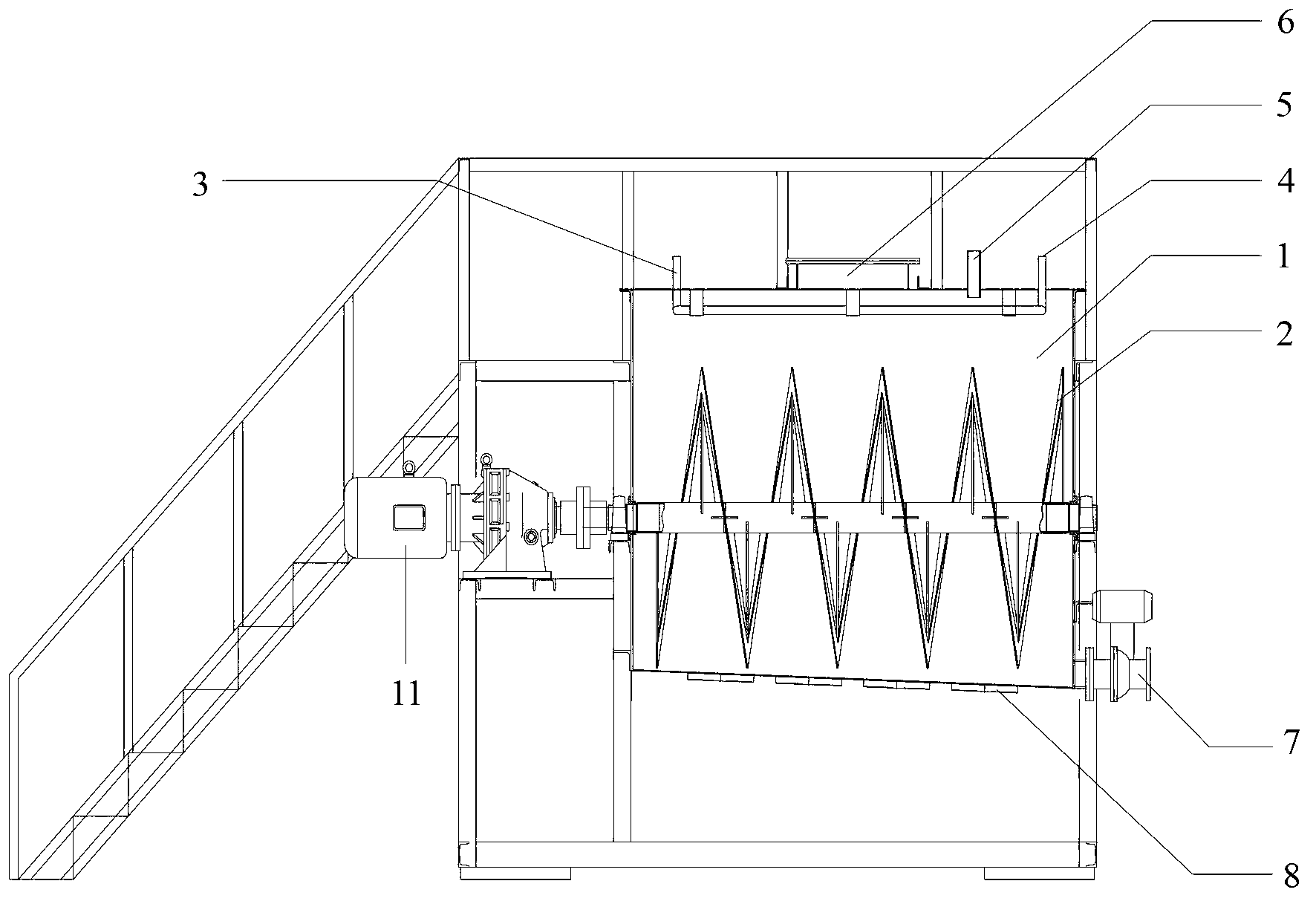

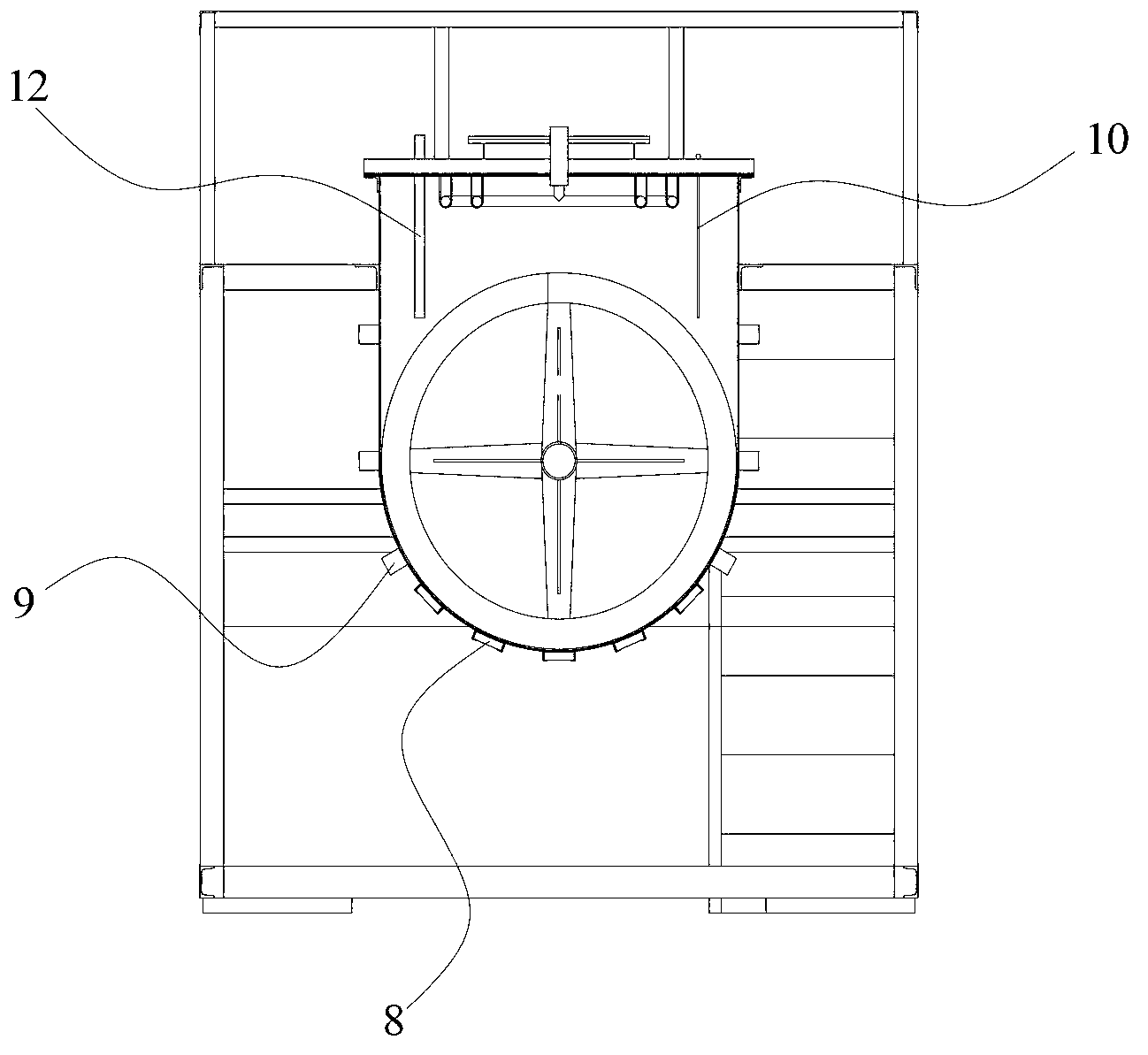

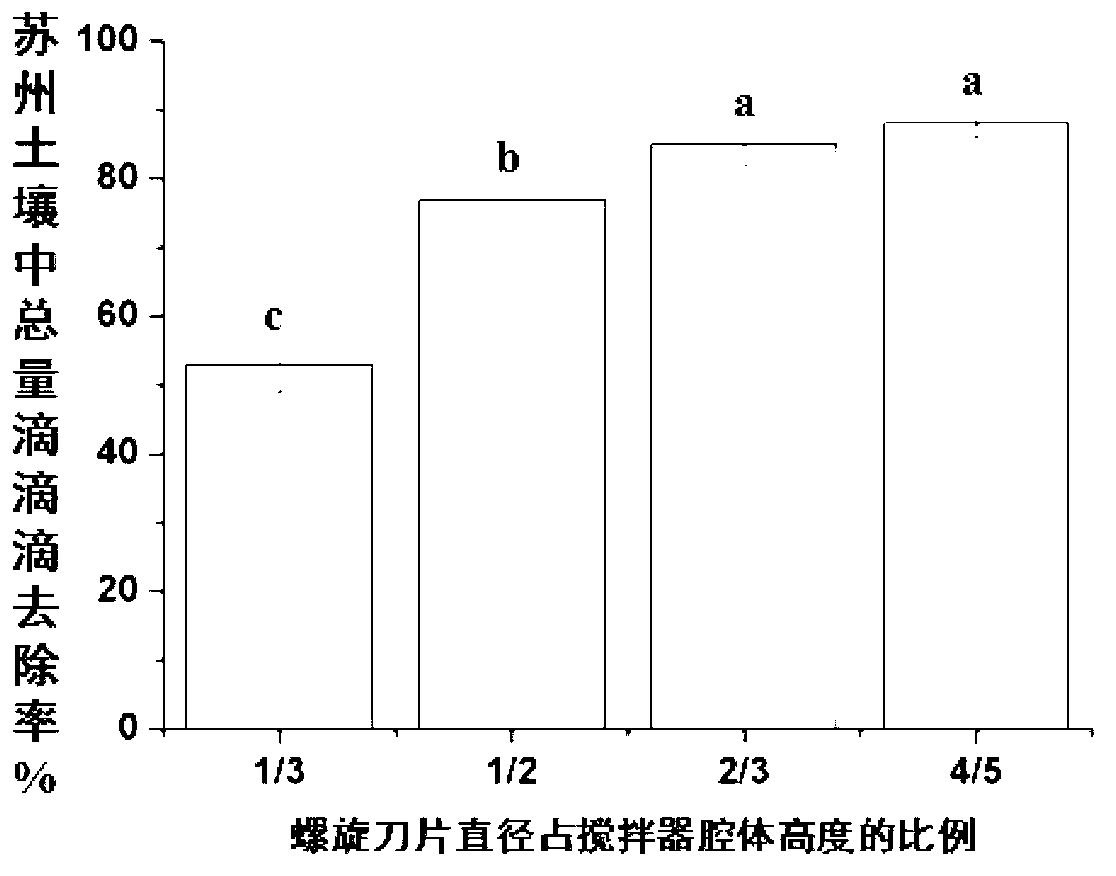

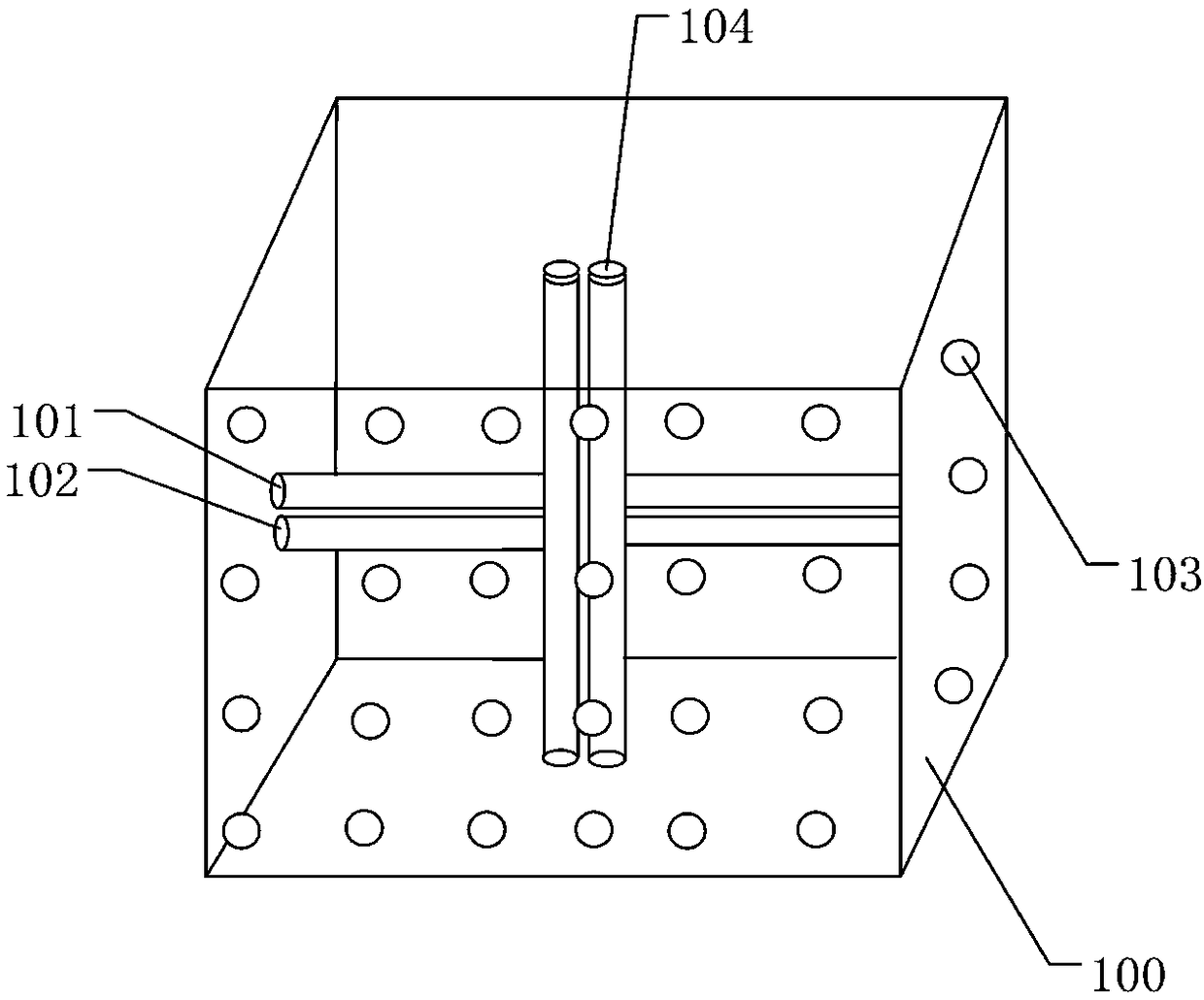

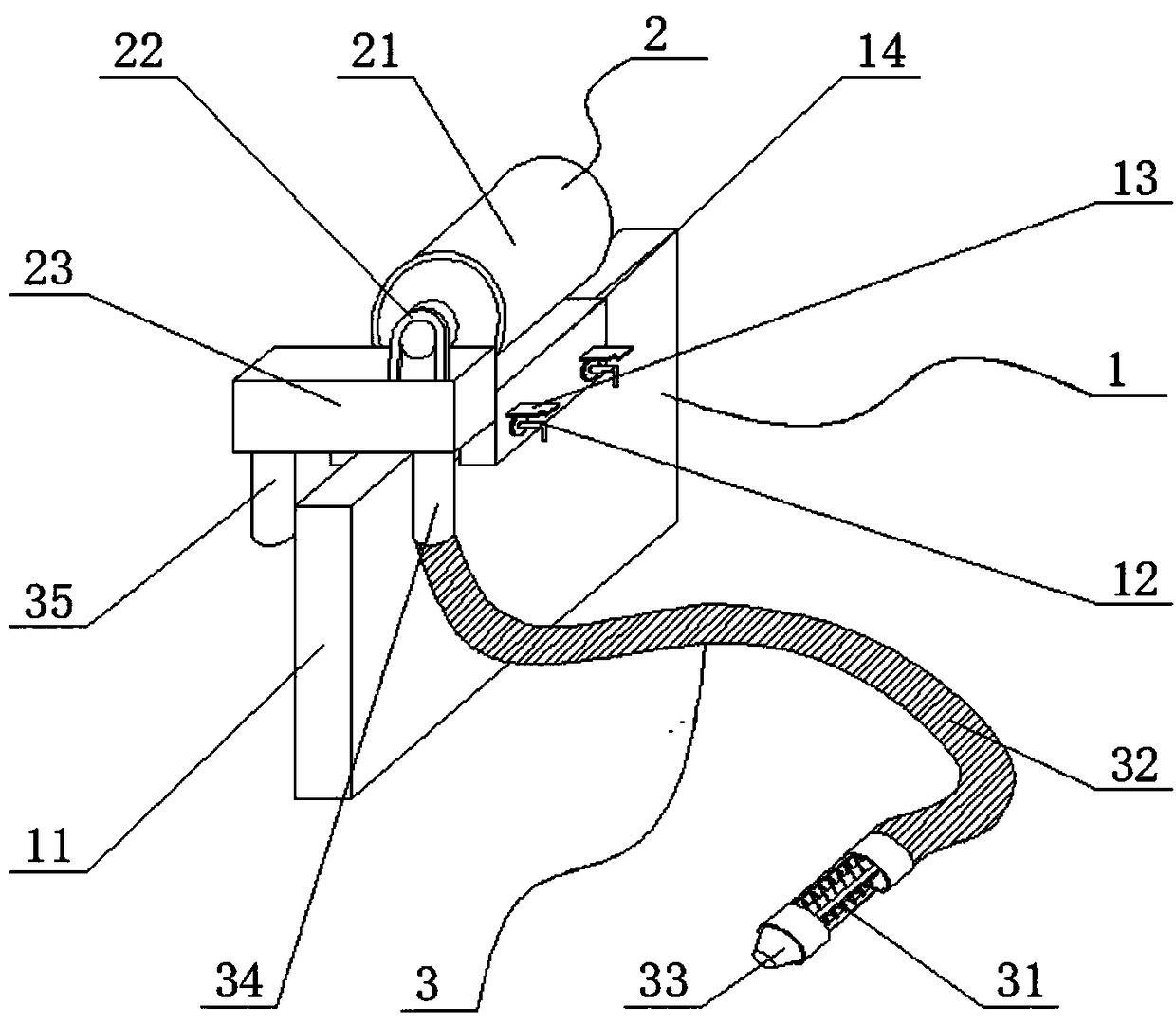

Multielement ex-situ remediation equipment and method used for organo-chlorine pesticide contaminated soil

InactiveCN103182394AWell mixedUniform heating effectContaminated soil reclamationSoil organic matterElution

The invention discloses multielement ex-situ remediation equipment and method used for organo-chlorine pesticide contaminated soil, belongs to the technical field of materializing remediation equipment for contaminated sites. The equipment comprises a stirring device, an eluent injecting device, an eluent recovery device, an ultrasonic generator and a heater. The equipment has extremely strong remediation broad-spectrum performance for organo-chlorine pesticide site soil with different characteristics such as organo-chlorine pesticide substance types, soil contamination incidents, soil contamination concentration, soil organic matter content, soil texture and the like, and a removal rate by single or repeated continuous elution is higher (larger than or equal to 85%); the equipment can form a good matching technology with a patent eluent (ZL201010547630.2), and is developed specially aiming at solving actual contamination situation of organo-chlorine pesticide sites in our country; and during a process of manufacturing the equipment, on the basis of synergistic effects generated by multielement strengthening components such as stirring, ultrasonic, heating and the like, the parameter condition design is optimized, the distribution is scientific and reasonable, and the optimal integration of multielement strengthening components is reflected.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

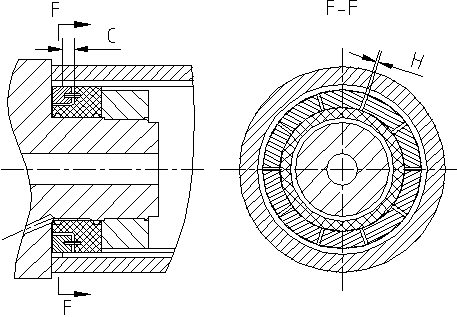

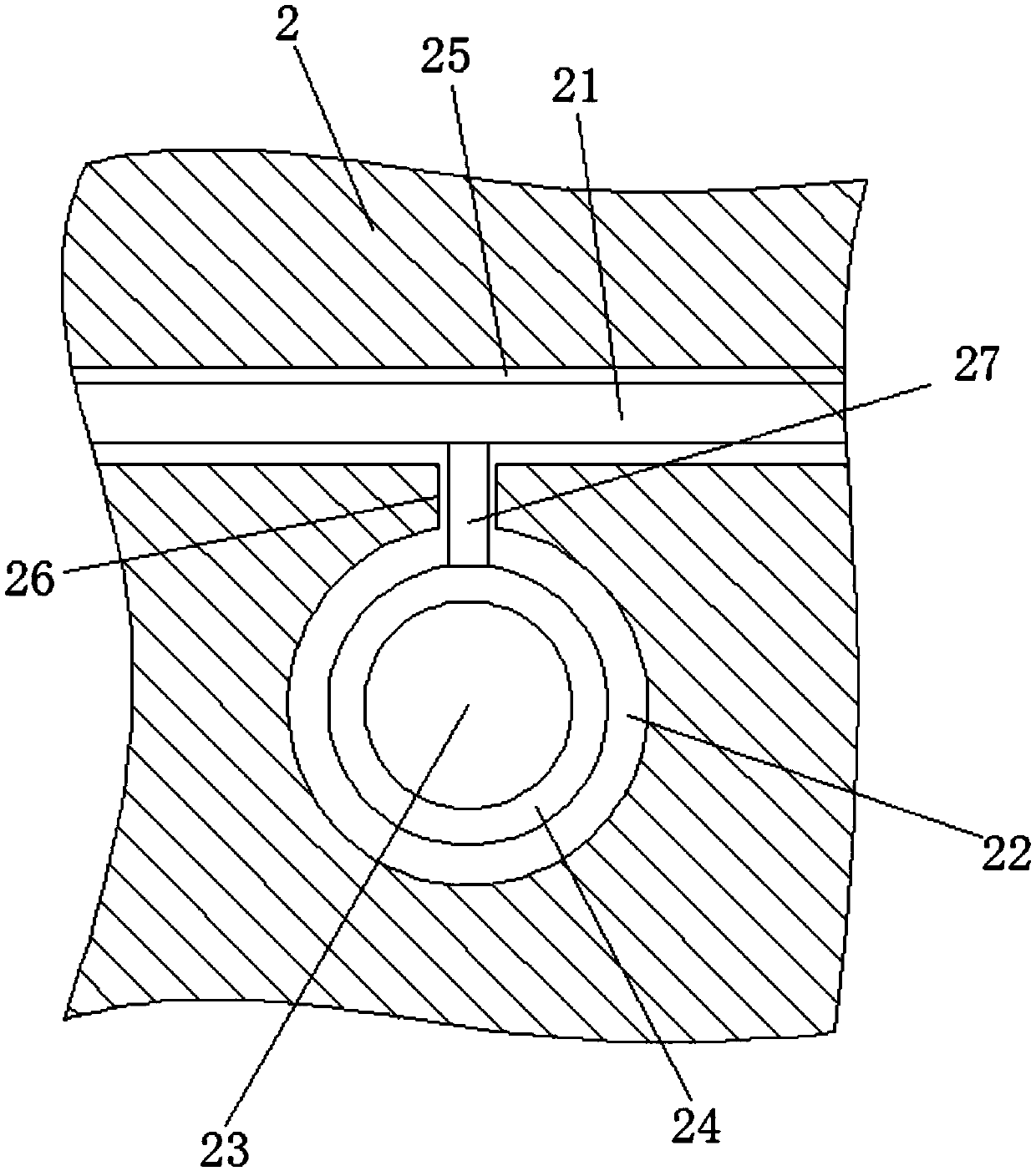

Mastopexy stabilization apparatus and method

InactiveUS20060036333A1Guaranteed uptimeShape stableMammary implantsTubular organ implantsPregnancyMastopexy

An apparatus and method for mastopexy surgeries correcting a ptosis condition caused by tissue stretching, in the breast as a result of pregnancy, time, aging, and the effects of gravity and athletic activity provide an implant having homogeneously formed connectors extending from inside an implant wall for anchoring to the chest wall or chest muscles of a patient. Embedded reinforcements and anchoring tabs or sutures may be readily oriented along a rib or other defining physiological location in order to provide immediate, permanent, and symmetric installation of implants in a mastopexy reconstruction.

Owner:SMITH LANE FIELDING +1

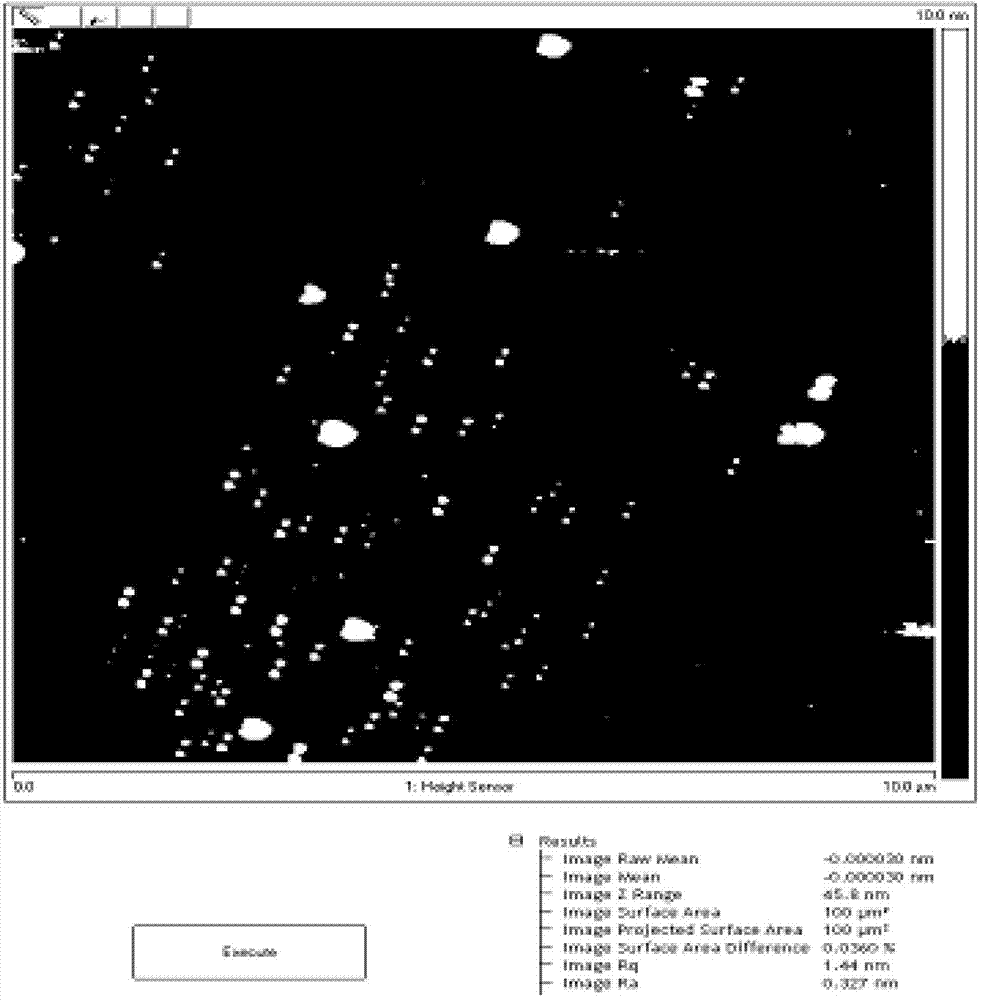

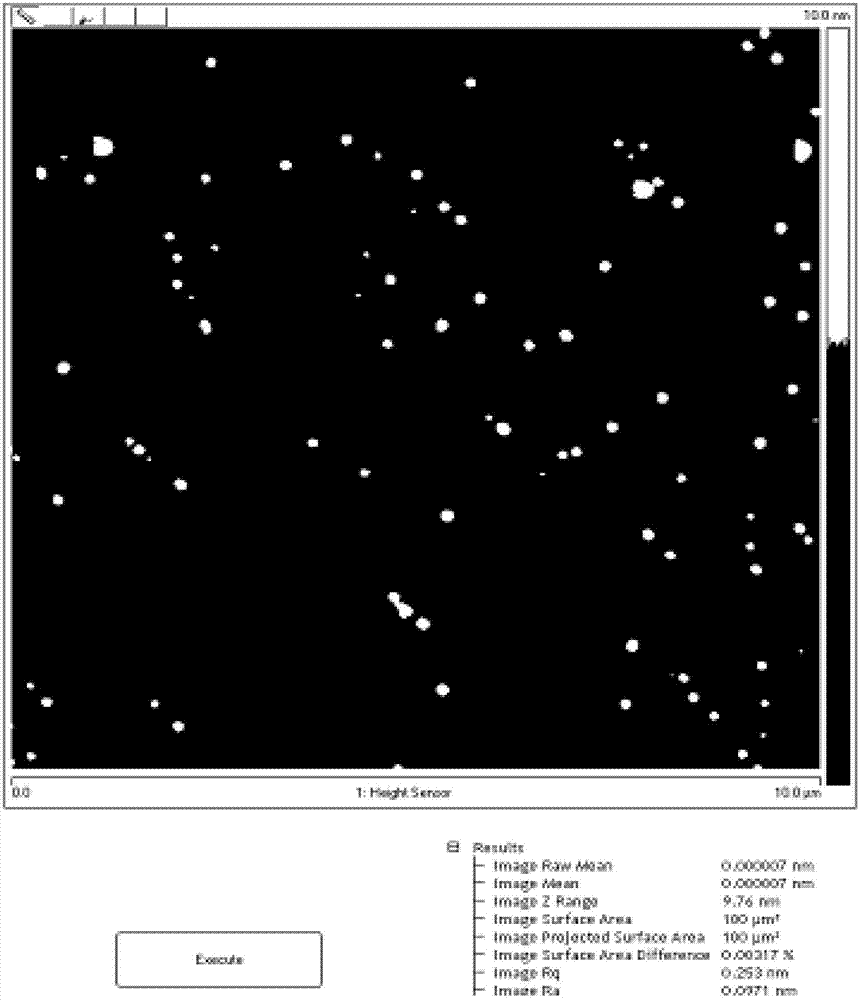

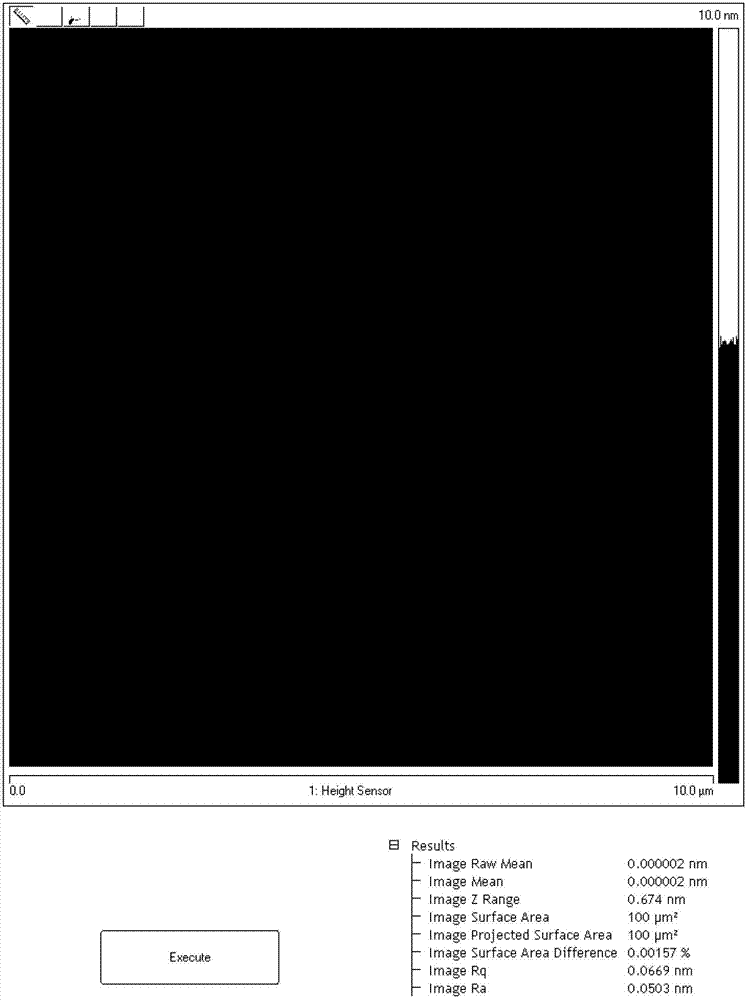

Silicon wafer fine polishing combined solution capable of inhibiting particle deposition and preparation method thereof

InactiveCN102775915AAvoid depositionResidue reductionPolishing compositions with abrasivesHydrogenPhysical chemistry

The invention relates to a silicon wafer fine polishing combined solution capable of inhibiting particle deposition and a preparation method thereof, belonging to the field of CMP (chemical mechanical polishing). The silicon wafer fine polishing combined solution capable of inhibiting particle deposition is prepared by using silicon dioxide / water-soluble polymer composite abrasive particles, hydroxyl-containing and / or amino-containing surface protecting agent, alkali compound, surfactant and deionized water. The pH (potential of hydrogen) of the silicon wafer fine polishing combined solution is 8-12. Compared with the prior art, the deposition of particles is effectively inhibited, and the precision and the quality of polished silicon wafer surfaces are improved. The silicon wafer fine polishing combined solution provided by the invention has the advantages that the used raw materials are easy to obtain, the silicon wafer fine polishing combined solution is pollution free, the requirements on environmental protection are satisfied and the large-scale industrial production is easy to realize.

Owner:SHENZHEN LEAGUER MATERIAL +2

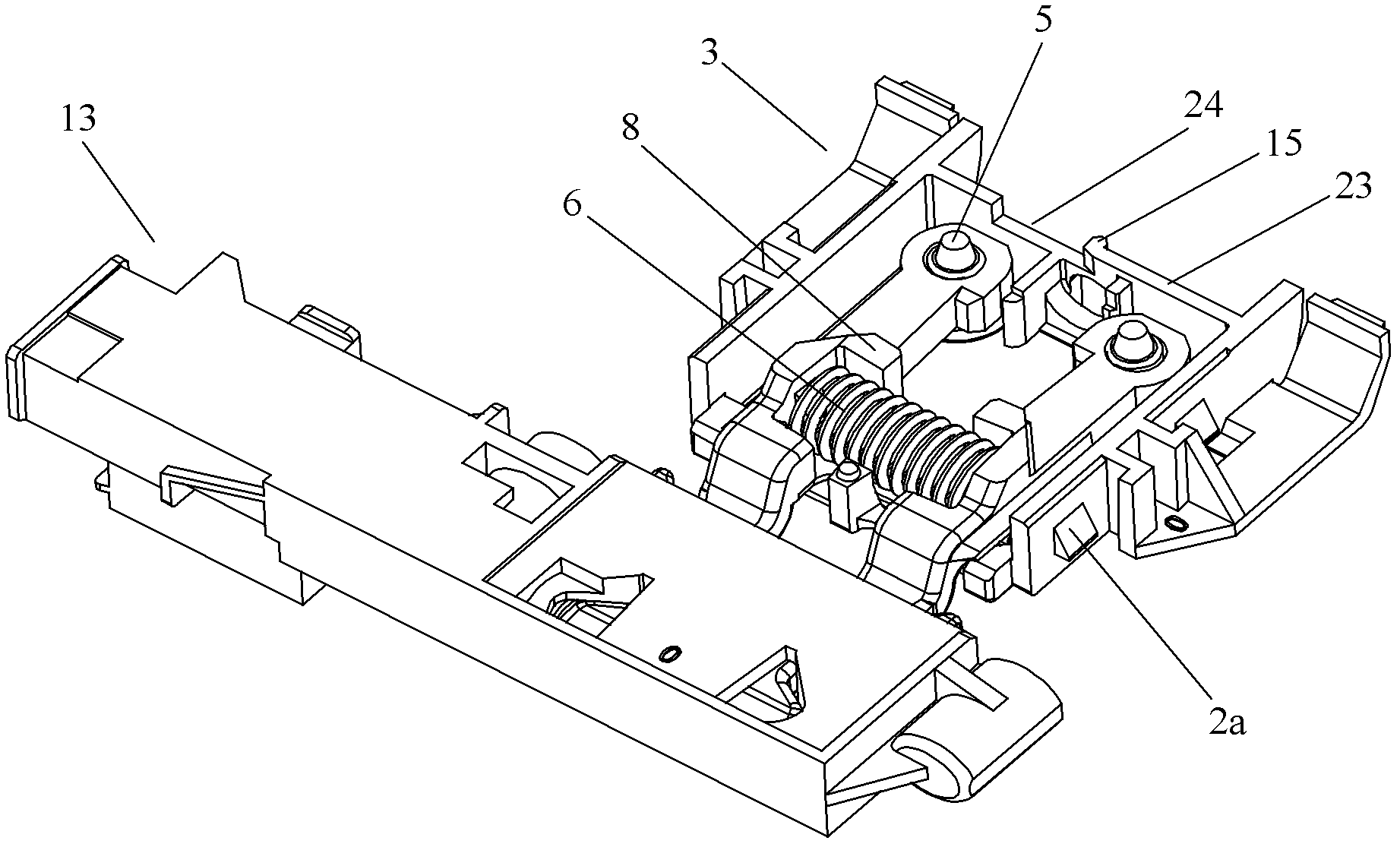

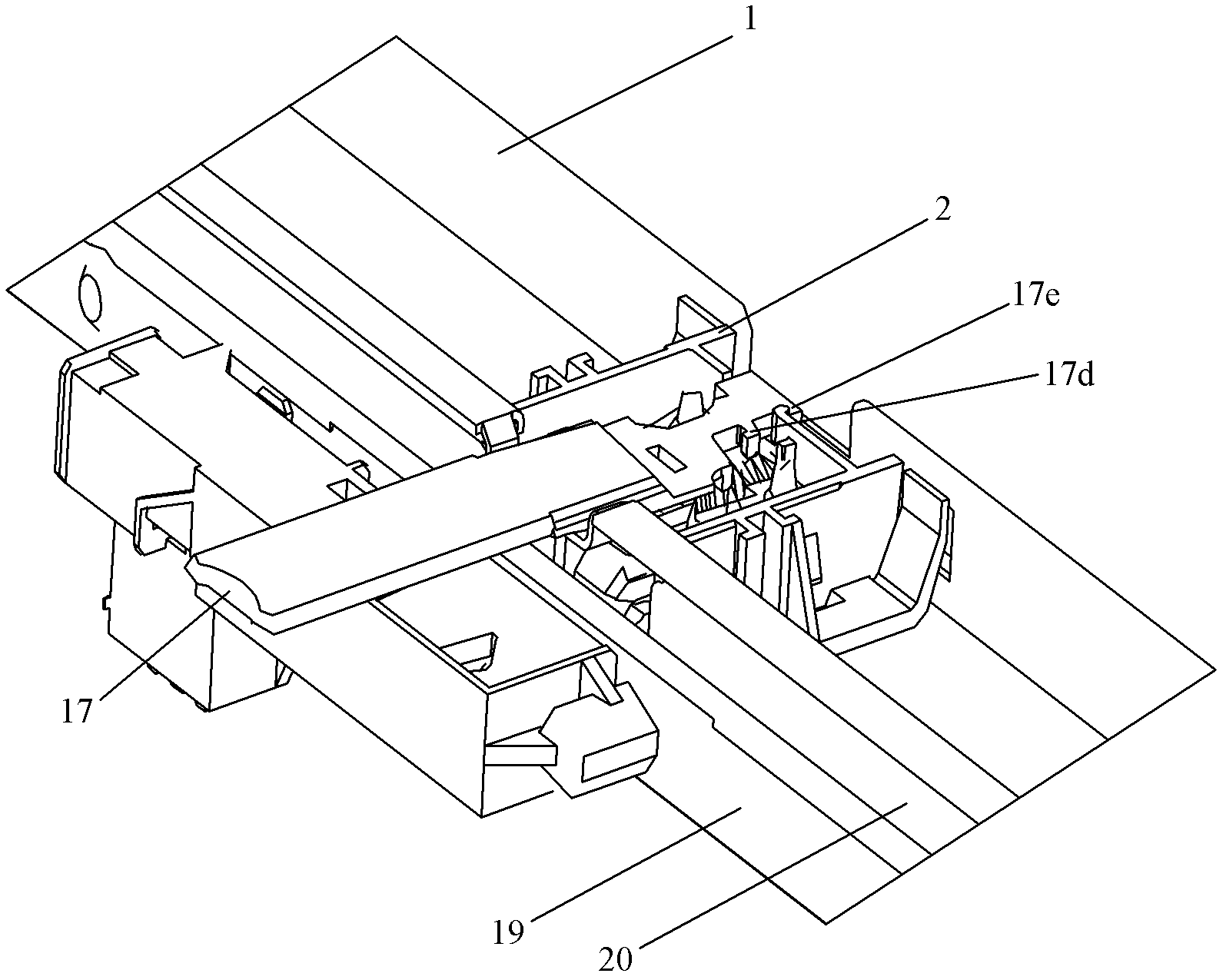

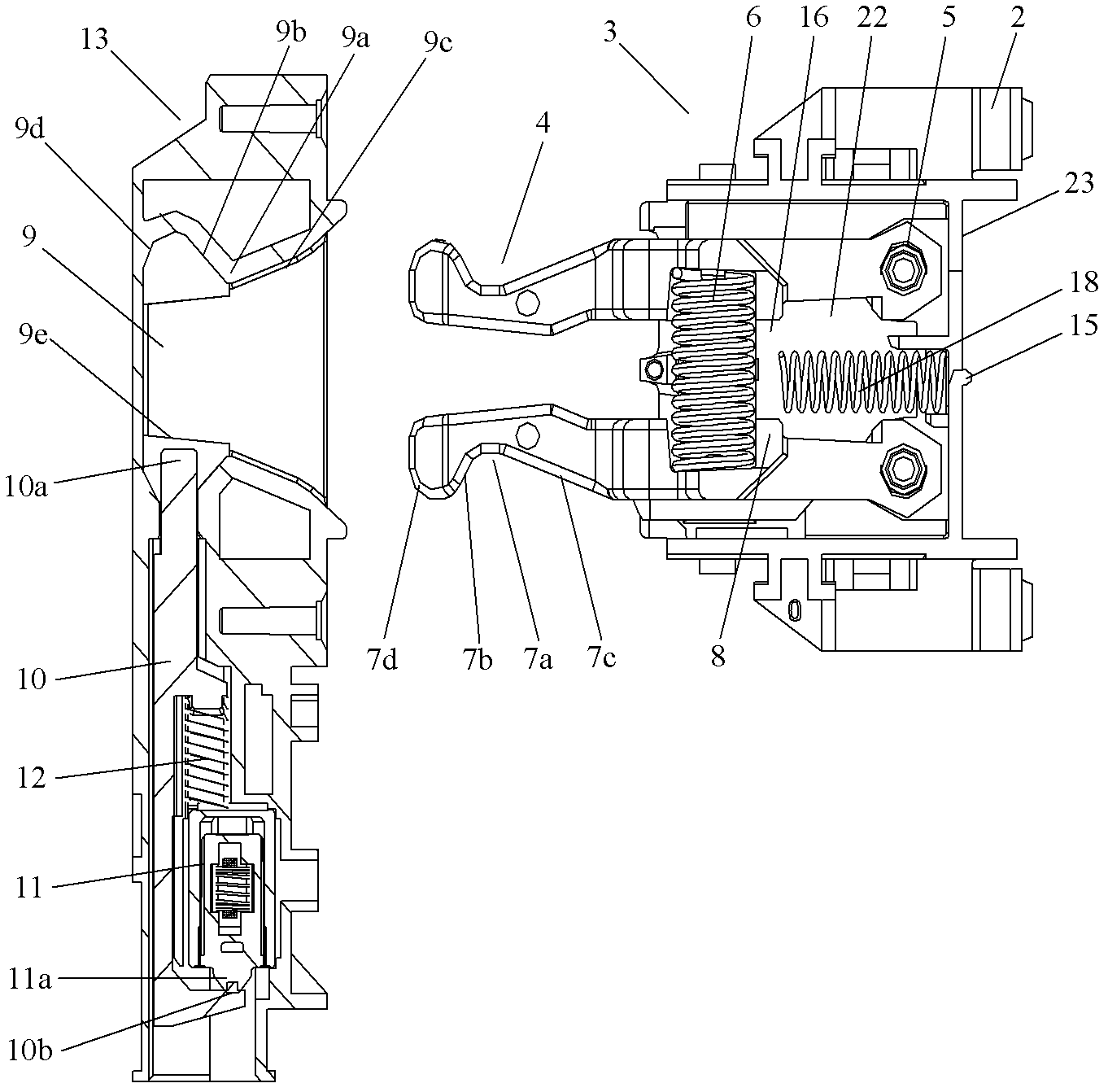

Door lock device and dish-washing machine with same

ActiveCN102525371AGuaranteed sealingReduce intervalTableware washing/rinsing machine detailsEngineeringElectrical and Electronics engineering

The invention relates to a door lock device and a dish-washing machine with the same. The door lock device comprises a lock body and a lock catch box, bolts which are arranged at intervals side by side are disposed in the lock body, resetting springs are arranged among the bolts, the bolts can rotate around rotating shafts, and lock holes which can be snapped with the bolts are arranged on the lock catch box. As the bolts are arranged at intervals side by side, the resetting springs are disposed among the bolts, when snapped with the lock holes, the bolts compress the resetting springs so that the intervals among the bolts are decreased, and the bolts enter the lock holes and are snapped with the lock holes. Accordingly, when the bolts are snapped with the lock holes, firmness of closing of a door body cannot be reduced even if the bolts have an elastic deformation characteristic.

Owner:HAIER GRP CORP +1

Shallow-groove improved in-situ repair saline-land vegetable planting method

InactiveCN101361421AImprove physical structureImprove chemical structurePigmenting treatmentHorticultureWet seasonBiology

The invention relates to a method for planting plants by improving a shallow groove and restoring salinate fields in situ; the method comprises the following steps: for planting different plants, shallow-groove strip tillage is carried out on the salinate; a layer of cornstalk, a layer of cow dropping and a layer of cornstalk are laid at the bottom of the groove, then a saline-alkali reducing agent is applied, and then a layer of artificially improved soil which is mixed by luvisol dug from the tillage and artificial biological substrate matured by the cornstalk and the cow dropping in advance is applied; finally, the seeds of the plants is spread into the artificially improved soil, watered and surefooted and field management is carried out; and a layer of cornstalk is laid between the adjacent shallow grooves, the luvisol is used for building a ladder-shaped drainage ditch which is communicated with a water-collecting tank, thus draining excessive water in rainy season.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

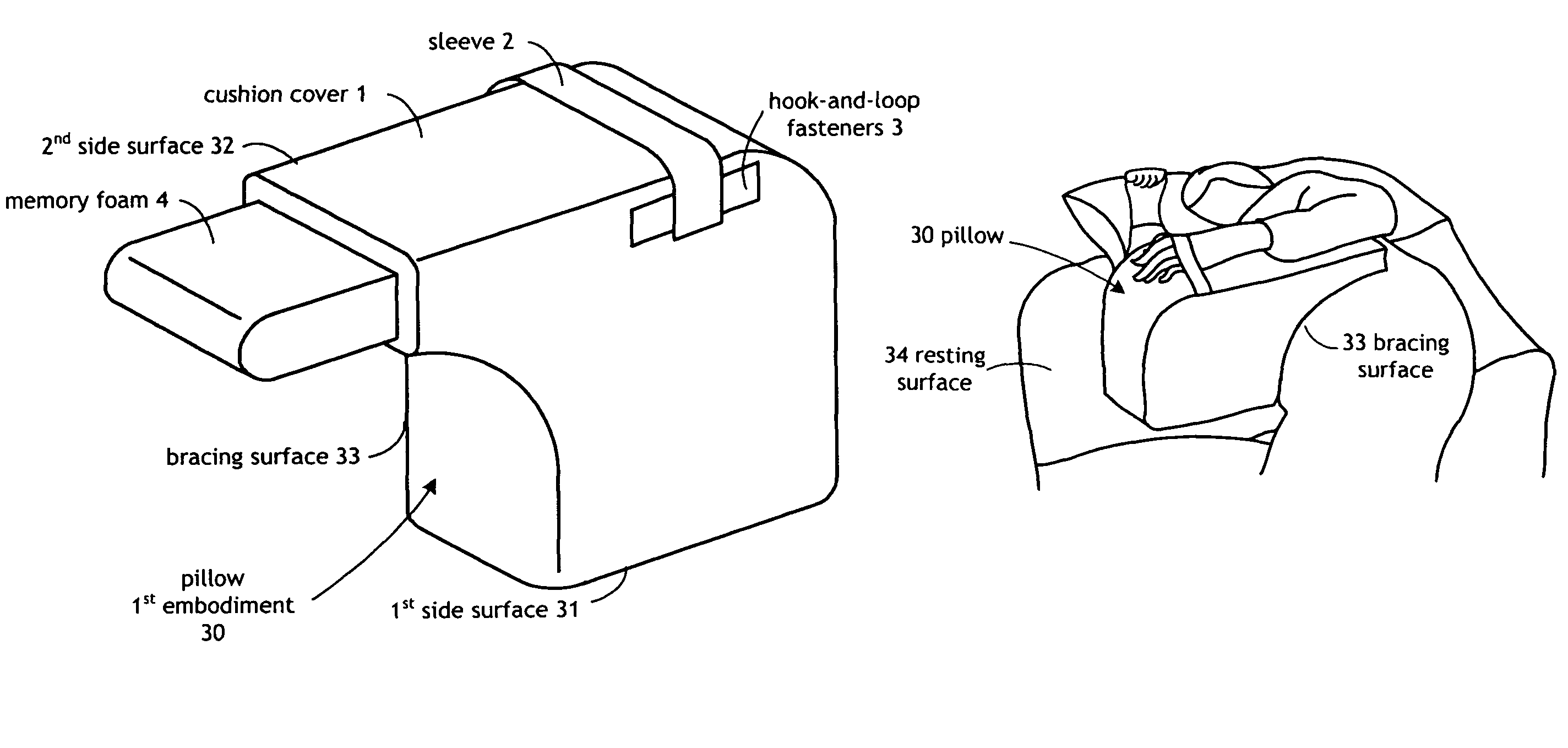

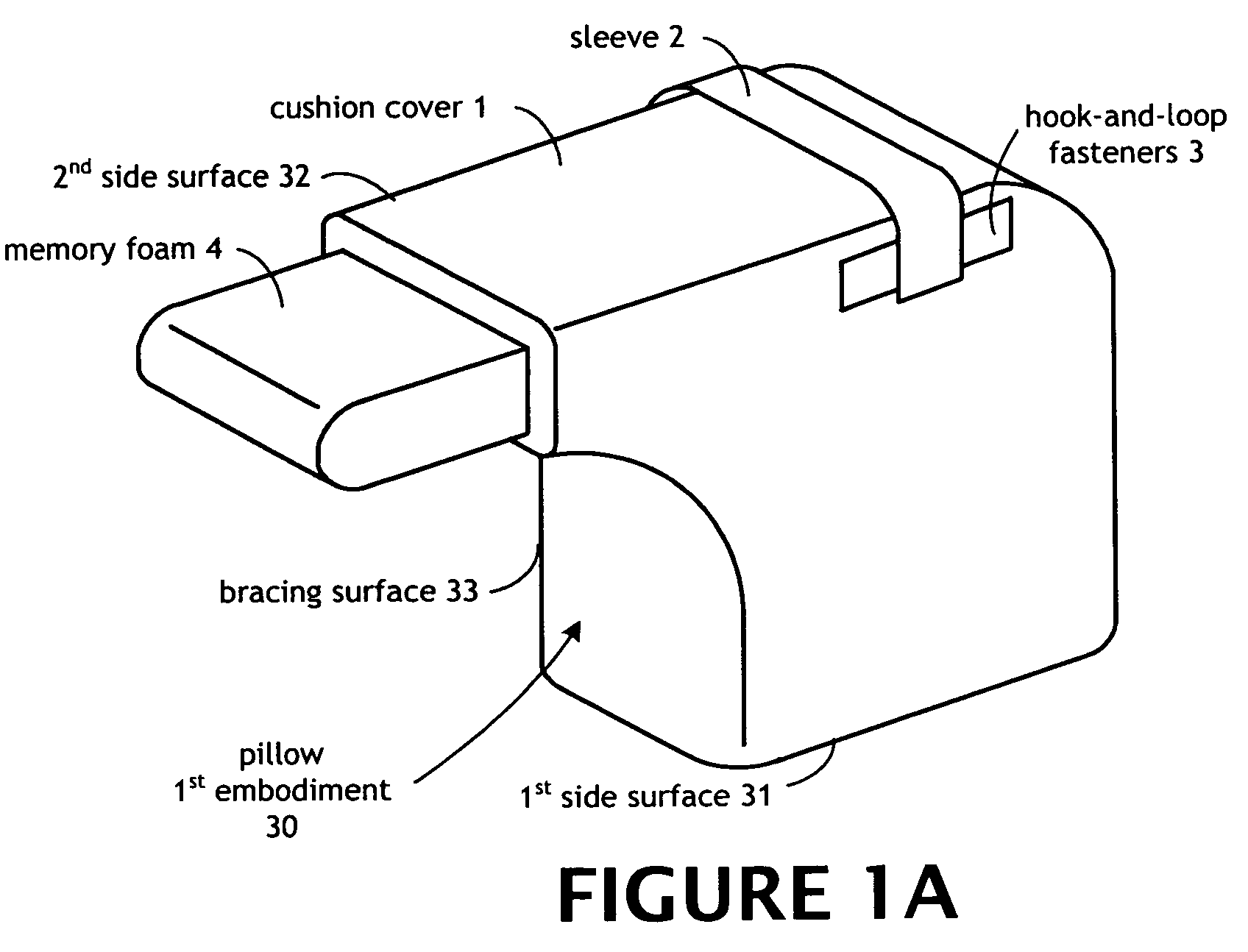

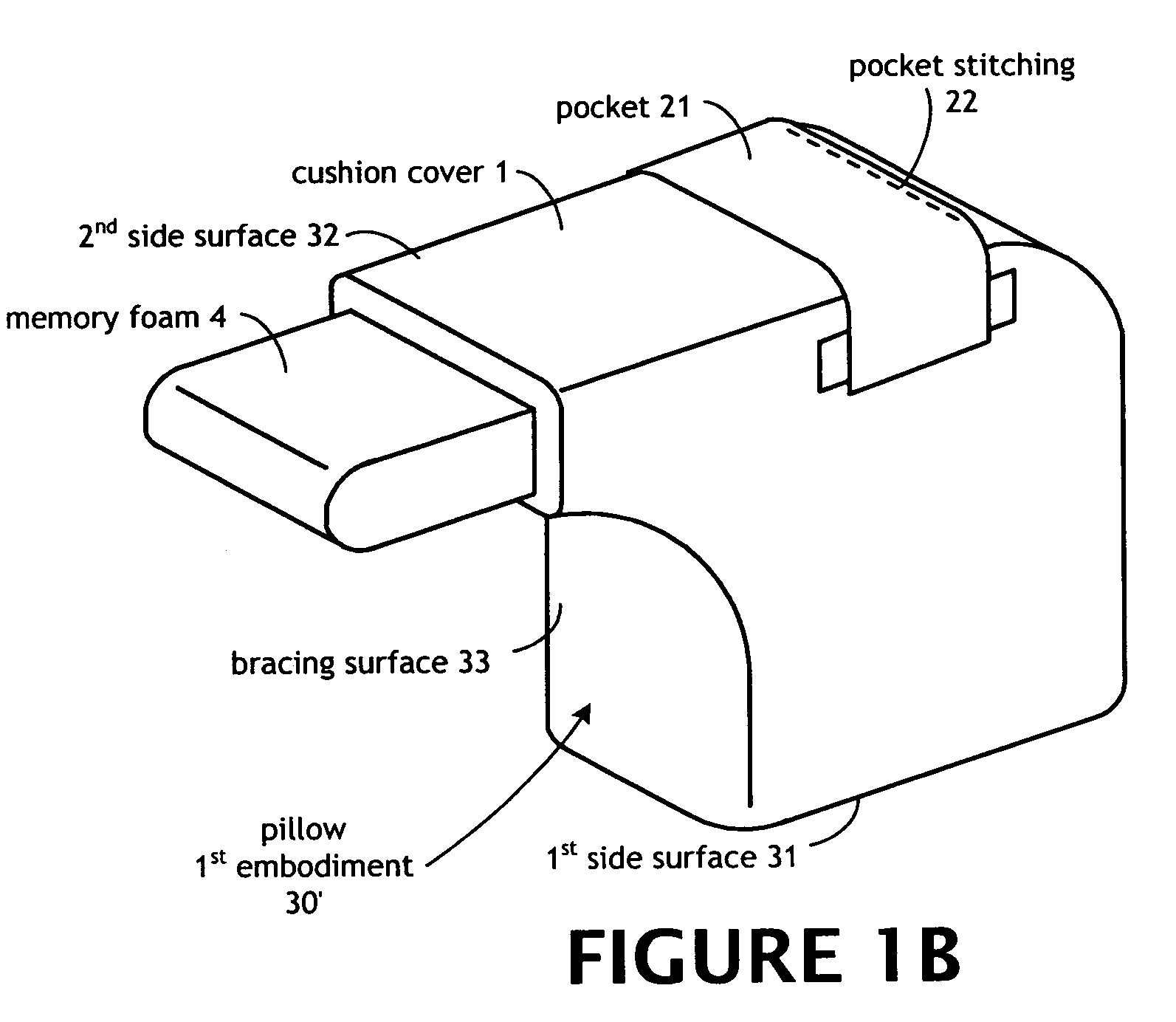

Orthopedic support pillow

InactiveUS8286285B2Increasing height and firmnessDecreasing height and firmnessRestraining devicesSofasOrthopedic pillowProne position

The orthopedic support pillow is for use by a patient having a retained arm while the patient is lying in a generally prone position sideways on a resting surface. The orthopedic support pillow comprises two side surfaces, the two side surfaces opposing each other, and a bracing surface. The second side surface accommodates the retained arm of the patient and is at least as wide as the ailing forearm of the patient. The bracing surface is disposed between the two side surfaces, and has a generally concave shape. The abdominal section of the patient abuts against the bracing surface of the orthopedic support pillow when the patient is lying in the prone position sideways. The orthopedic support pillow provides stability and support to the retained arm in an elevated position while the patient is in the generally prone position on the resting surface. The orthopedic support pillow includes a strap or pocket positioned for retaining the hand of retained arm of the patient. The orthopedic support pillow is either made of a resilient foam material, or has an inflatable pillow body with an interior that is adapted to be filled with air inflate the pillow body, enabling firmness of the orthopedic support pillow to be adjusted for comfort by each patient.

Owner:MAHLER SHEILA J

Graphene-organosilicon modified urethane resin synthetic leather

InactiveCN106702750AGood high and low temperature resistanceLower surface energyPolyurea/polyurethane coatingsTextiles and paperWater basedAMMONIUM STEARATE

The invention relates to a graphene-organosilicon modified urethane resin synthetic leather, which is prepared from the following ingredients: graphene-organosilicon modified urethane resin, fluorine-modified alkide resin, propylene glycol n-butyl ether, a flatting agent, a thickening agent, a foaming agent, a filler, a water-based color paste, a plasticizer, an ammonium stearate emulsion and de-ionized water, wherein the graphene-organosilicon modified urethane resin is prepared through reaction of polyisocyanate, polyhydric alcohol, a polybasic amine chain extender, oligomer polyhydric alcohol, dimethylolpropionic acid, organosilicon, graphene, a neutralizer and de-ionized water; the synthetic leather prepared by the invention is capable of effectively preventing statical electricity, and has the characteristics of good abrasion resistance, high crosslinking density, good chemical resistance and no pollution.

Owner:康伦国

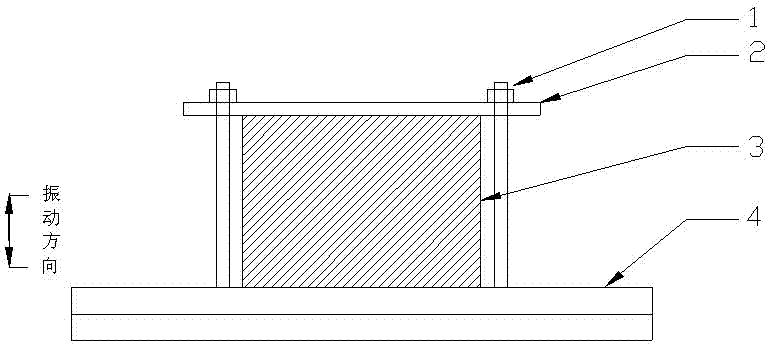

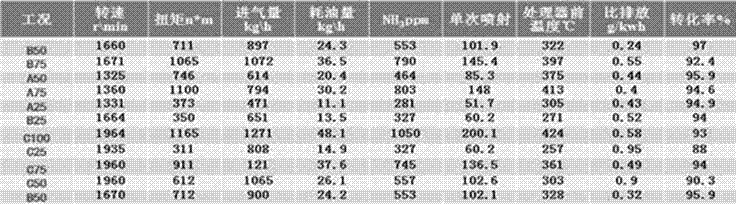

Preparation method of non-noble metal containing monolithic supported catalyst

ActiveCN107442163AImprove loading efficiencyImprove high temperature resistanceGas treatmentMolecular sieve catalystsActive componentBench test

The invention relates to a preparation method of a non-noble metal containing monolithic supported catalyst. The prepared non-noble metal containing monolithic supported catalyst is characterized by being uniformly loaded in active components, high in firmness of a coating and a carrier, and simple in preparation technological process; engine bench test results show that the conversion rate of NOx reaches 97% under the working condition of B50; furthermore, a non-noble metal system is adopted, so that the non-noble metal containing monolithic supported catalyst is low in preparation cost.

Owner:CHINA FIRST AUTOMOBILE

Curd type broccoli cultivation method

The invention discloses a curd type broccoli cultivation method. The method includes the following steps that an appropriate variety, appropriate planting time and an appropriate planting place are selected; strong seedlings are cultivated; field management is performed and includes the steps of fertilization, land preparation, field planting, nutrient and water management, hormone spraying and shading treatment. Extension of curds and floral axes are promoted through spraying GA3, the curds become loose, and taste and quality become better; then through shading, the temperature is appropriately lowered, besides, lighting time can be shortened, in this way, when the extension of the curds and the floral axes is promoted, growth and development of flower buds can be delayed, and therefore the purpose of cultivating the curd type broccoli is achieved; through combination treatment of the multiple procedures, the compactness of the broccoli is lowered, the taste is improved, and the yield is increased.

Owner:江苏句农生态农业发展有限公司

Composite pipe hydraulic expansion method, manufacturing device and obtained composite pipe

ActiveCN103629445AGood removal effectGuaranteed bonding qualityPipe elementsRigid pipesEngineeringScrew thread

The invention provides a composite pipe hydraulic expansion method, which comprises the following steps that (1) a plug provided with a sealing ring in the circumferential direction is inserted into an inner pipe; (2) sealing pressure liquid is introduced to a position between the plug and an inner ring of the sealing ring for sealing the end part of the inner pipe; (3) the expansion is carried out, before the expansion, a sleeve ring with the same inner diameter as an outer pipe of a composite pipe is arranged in a way of tightly pasting the end surface of the outer pipe of the composite pipe requiring the expansion, and in addition, the innermost end of the sealing ring is arranged outside the end surface of the outer pipe of the composite pipe. The sealing position exceeds the end surface of the outer pipe, so the pressure inside an inner pipe cavity can reach the end part of the outer pipe, and the combining quality is ensured. The defect of composite blind region reservation at the end part of the composite pipe manufactured in the prior art is overcome, and the composite pipe can be used without cutting off the blind region, so the cost is reduced in aspects of both materials and the process. The cutting is not needed, so great convenience is brought for the subsequent processing of external screw threads formed at the pip end of the composite pipe before the expansion.

Owner:QINGDAO ZHONGRUITAI MESNAC TECH CO LTD

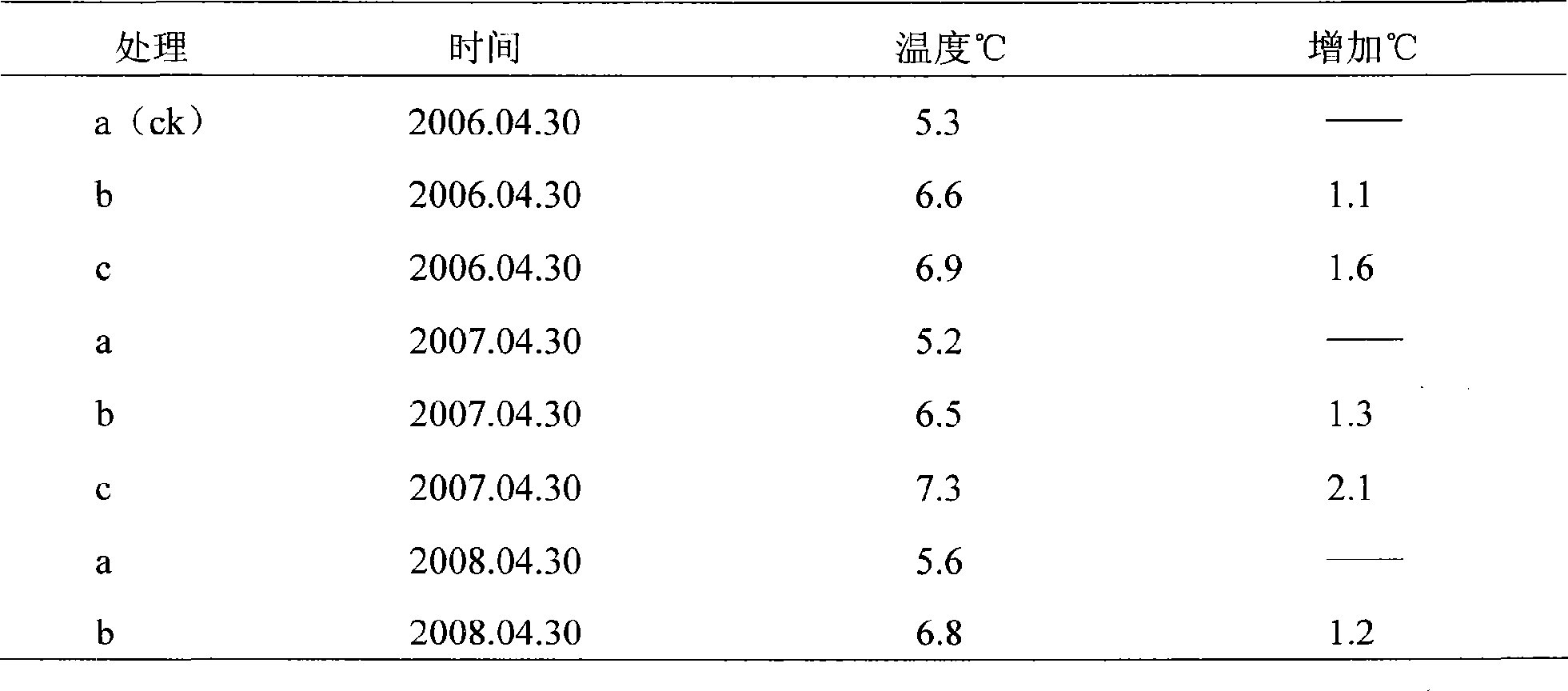

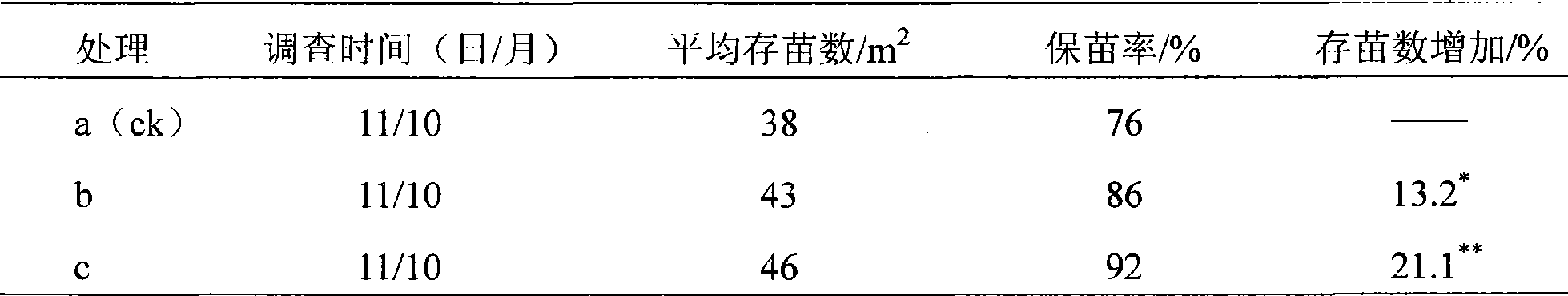

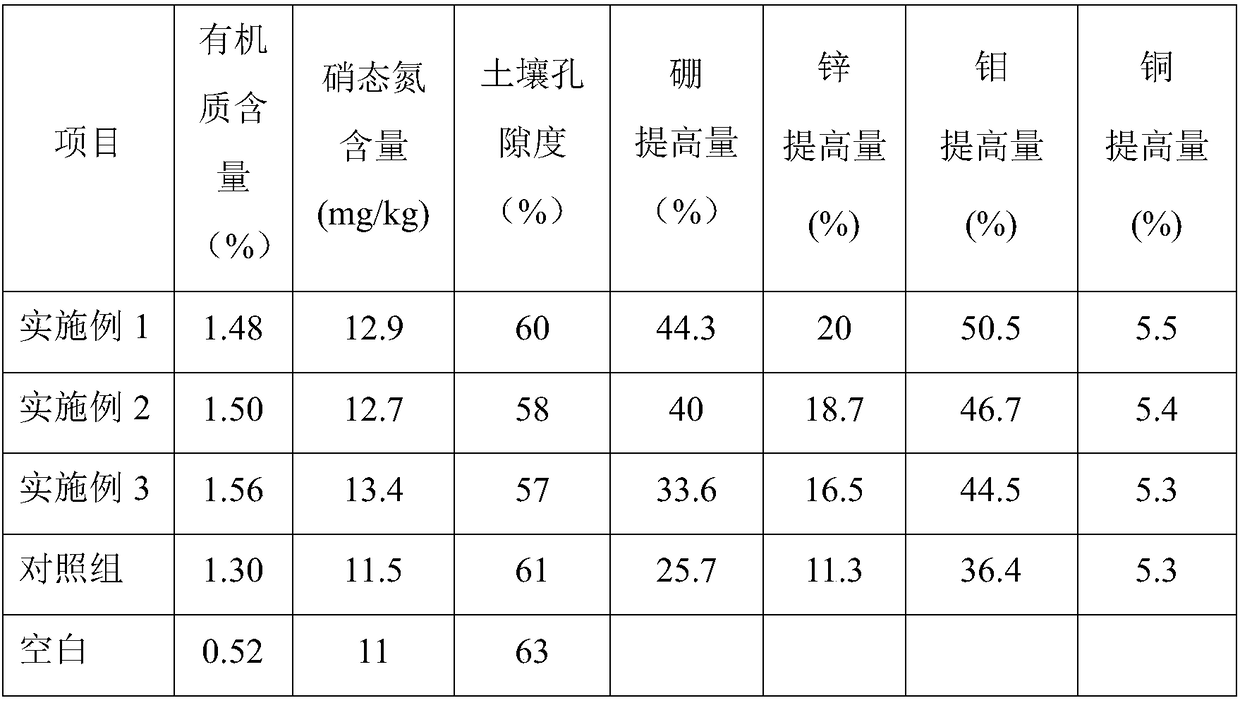

Nourishing type soil temperature raising agent for ginseng land

InactiveCN101481618AComponent content is reasonableModerate amountAgriculture tools and machinesOrganic fertilisersNitrohumic acidMonopotassium phosphate

Nutritional type ginseng land soil thermogenic agent belongs to the technical field of agriculture, and solves the problem that the root system suffers from serious frozen injury, and the survival rate of seedling is low when in the growing process of ginseng. The soil water retention agent is prepared by mixing 40.0-60.0% of pulverized fuel ash, 30.0-50.0% of crushed crop straw (with the water content of 60%), 0.30-0.50% of nitrohumic acid, 0.30-0.60% of monopotassium phosphate, 0.05-0.15% of boric acid, 0.10-0.30% of zinc sulfate, and 0.05-0.15% of ammonium molybdate based on the weight percentage. When in the land preparation, the nutritional type ginseng land soil thermogenic agent is evenly sprinkled on the soil, and the soil is ploughed for three times; when the soil water retention agent is uniformly mixed with ginseng bed soil with the depth of 30cm, the ginseng is transplanted. The invention is used for heating the ginseng land soil, and can raise the soil temperature. Meanwhile, the survival rate of seedling and the yield of the ginseng can be remarkably improved.

Owner:JILIN AGRICULTURAL UNIV

Chitosan-coated controlled release fertilizer for saline-alkaline soil

InactiveCN106365833AIncrease profitGood water permeabilityCalcareous fertilisersMagnesium fertilisersControlled releaseCitric acid

The invention discloses a chitosan-coated controlled release fertilizer for saline-alkaline soil and relates to the field of agriculture. The chitosan-coated controlled release fertilizer for saline-alkaline soil is made from chitosan, flyash, stalks, animal waste, furfural residue, citric acid residue, distillers' grains, desulfurization gypsum and the like, via the steps of fermenting, mixing, crushing, granulating, dissolving, spraying, perforating and the like; the wastes such as stalks, animal waste and furfural residue are fermented and then coated with chitosan such that the fertilizer may be released slow, fertility period is extended, fertilizer utilization rate is increased, saline-alkaline soil is better improved, and salt damage is relieved.

Owner:滁州朝昱农业科技有限公司

Soil conditioner and preparation method thereof

InactiveCN108558535AImprove fertilityImprove compactionCalcareous fertilisersSuperphosphatesAlkali soilShiitake mushroom extract

The invention discloses a soil conditioner and a preparation method thereof and relates to the field of soil conditioners. The soil conditioner is prepared from the following raw materials in parts byweight: 10 to 15 parts of straw particles, 40 to 45 parts of fermented cow dung, 3 to 7 parts of medical stone, 2 to 5 parts of dolomite powder, 5 to 10 parts of modified attapulgite, 2 to 5 parts ofdesulphurization gypsum powder, 4 to 9 parts of seafood shell powder, 5 to 10 parts of plant ash, 4 to 9 parts of sweet potato waste, 4 to 9 parts of fermented residue, 1 to 3 parts of shiitake mushroom extract, 1.5 to 3.5 parts of plant growth agent, 2 to 5 parts of amino acid salt, 1.5 to 3.5 parts of ferric chloride, 3 to 7 parts of ammonium dihydrogen phosphate, 2 to 5 parts of calcium superphosphate and 0.5 to 1.2 parts of microorganism acting bacteria. According to the soil conditioner, the soil fertility can be improved and a soil caking phenomenon is improved; the breathability, seepage, fertilizer-keeping and water retention capabilities of salt-alkali soil are remarkably enhanced; the physical-chemical properties of the soil are effectively improved.

Owner:合肥市风达农业有限责任公司

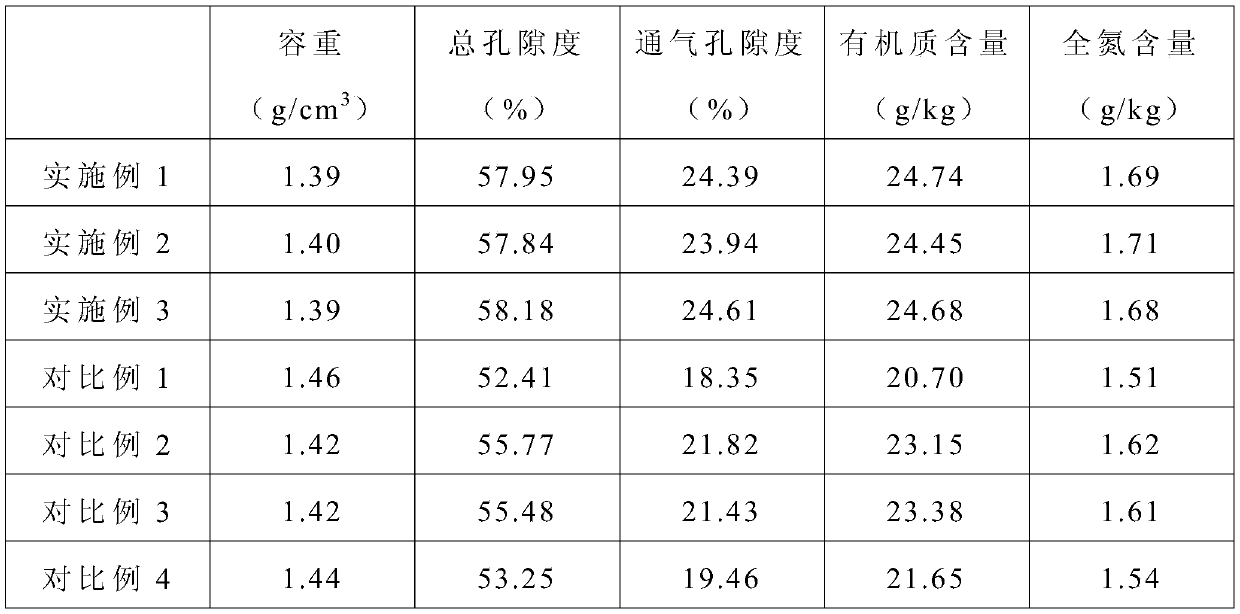

Organic compost capable of repairing soil and preparation method of organic compost

InactiveCN109369294AReduce firmnessImprove water retentionBio-organic fraction processingAnimal corpse fertilisersOrganic basePorosity

The invention discloses a preparation method of organic compost capable of repairing soil. The organic compost is prepared from the following components in parts by weight: 95-102 parts of an organicbase material, 8-13 parts of microbial liquid and 3-5 parts of a bulk material, wherein the organic base material is prepared from the following components in parts by weight: 20-30 parts of plant branches and trunks, 10-18 parts of plant fallen leaves, 5-10 parts of seed shells, 10-15 parts of animal waste and 5-10 parts of animal bones; the microbial liquid is prepared from the following microbial agents in parts by weight: 2-5 parts of bacillus subtilis, 2-5 parts of bacillus sporothermodurans, 0.5-1.5 parts of mycorrhiza fungi, 1-3 parts of saccharomycetes, 0.5-1 part of streptomyces rimosus and 1-3 parts of bacillus laterosporus; and the bulk material is prepared from the following components in parts by weight: 3-5 parts of dried chicken manure and 2-4 parts of flour weevil manure. The invention further provides the preparation method of the organic compost, the porosity of the organic base material and microelements required by microorganisms are increased advantageously by adding the bulk material, dominant bacteria are strengthened through alternate cooling and heating treatment, the humification degree is increased advantageously, and nutritional ingredient are retained advantageously.

Owner:晁伟岩

Sugar-producing and texture-improving bakery methods and products formed therefrom

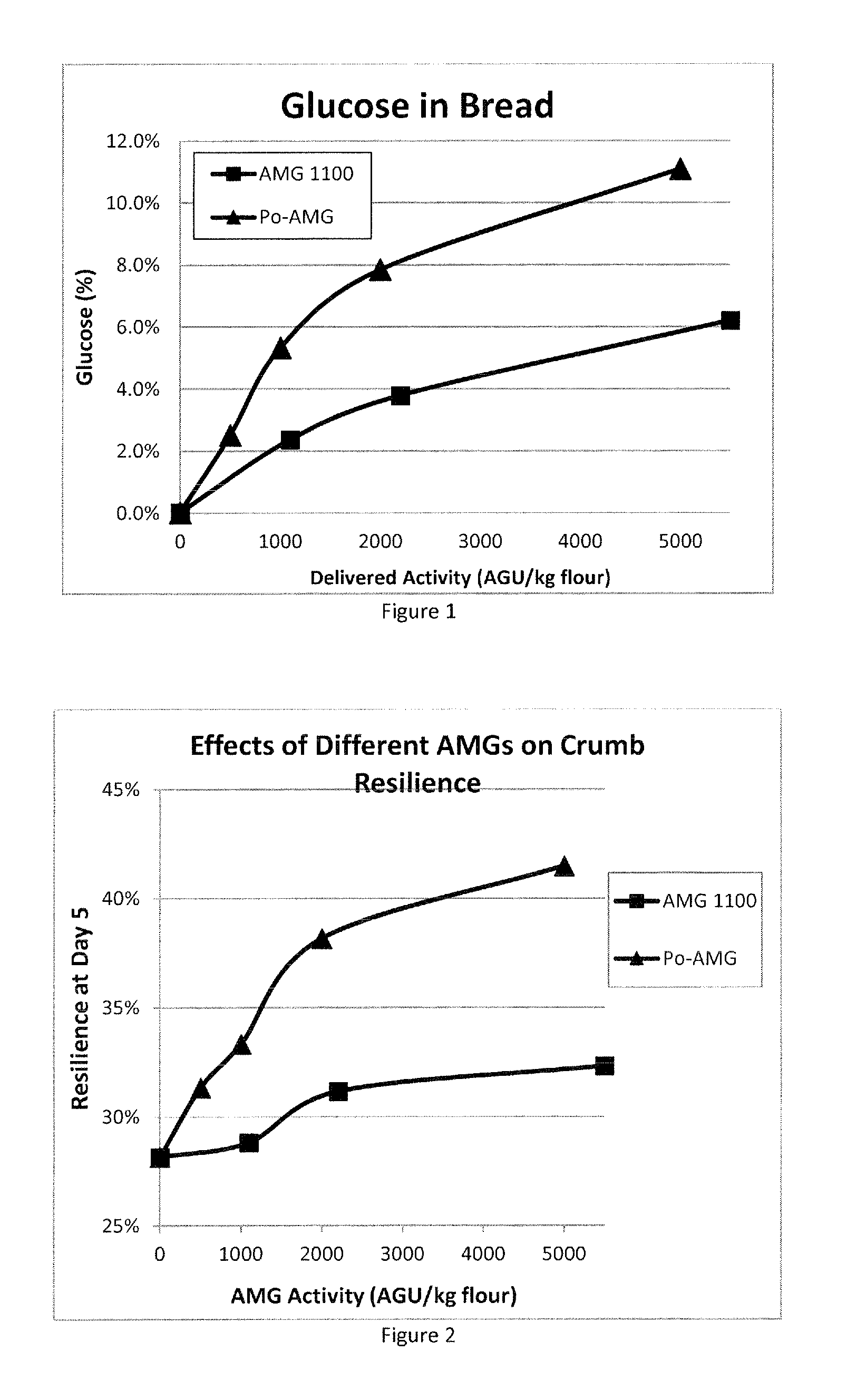

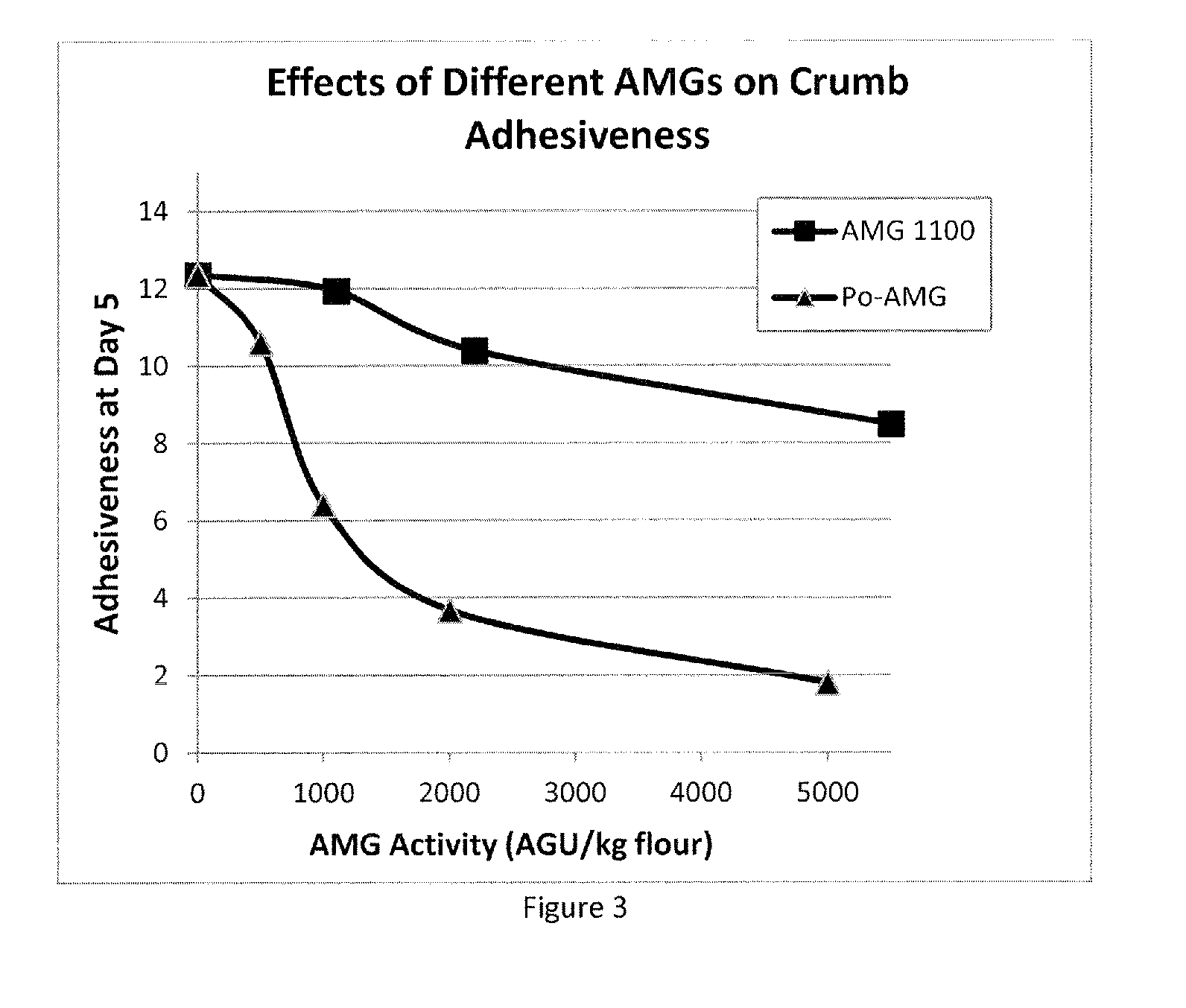

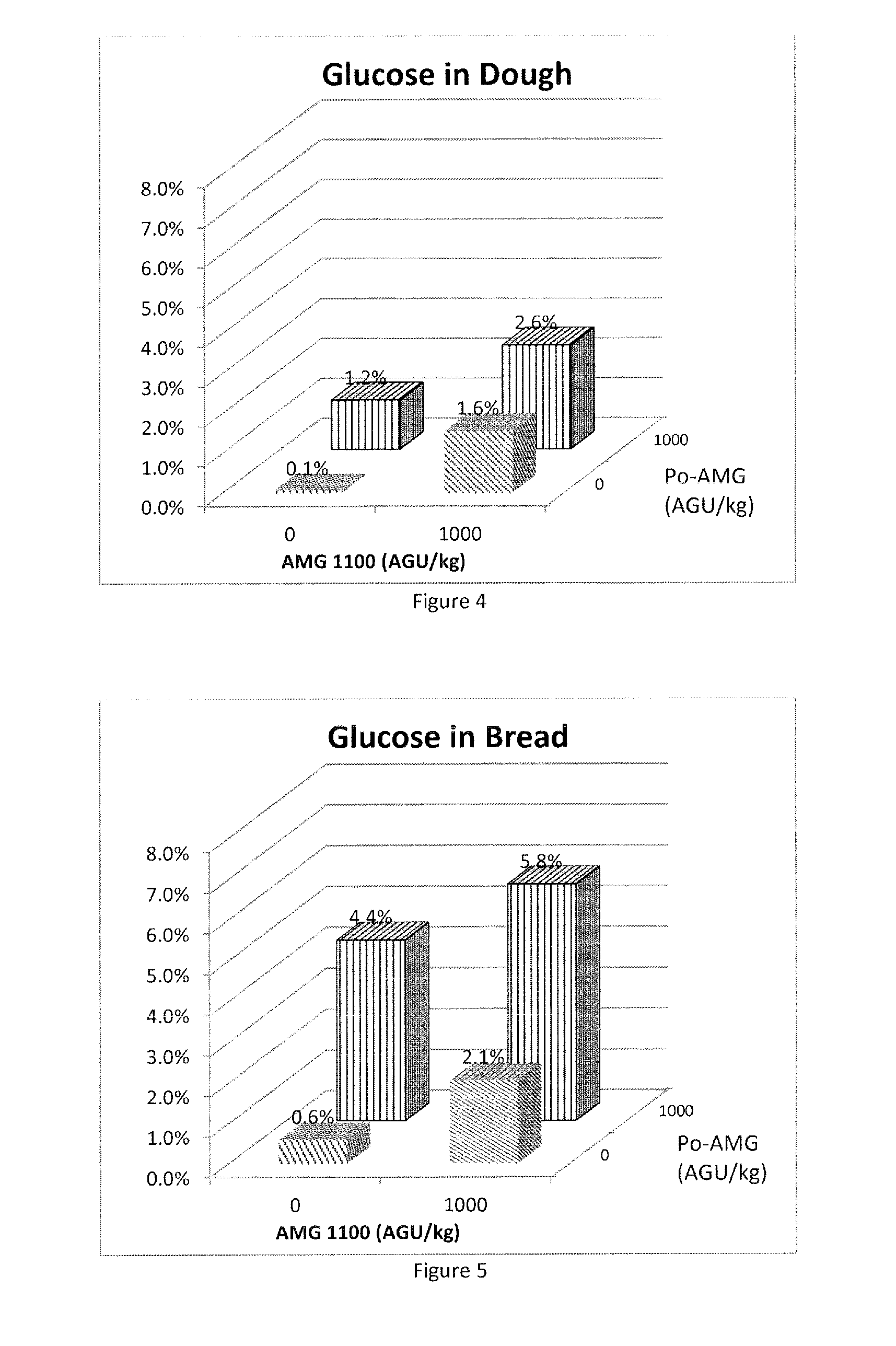

InactiveUS20160007618A1Function increaseImprove performanceMilk preparationDough treatmentAlgluceraseAdded sugar

Novel yeast-raised and other bakery products and methods of making those products are provided. The products are formed from dough comprising a thermally-stable amyloglucosidase, and a raw starch degrading amyloglucosidase and / or an anti-staling amylase. The level of added sugar included in the dough can be substantially reduced, and even eliminated, while still achieving a sweet product. Additionally, the resulting bakery product is free of, or at least substantially free of, fructose. The final baked product will also have improved texture properties, including superior firmness, resilience, and adhesiveness and can be made with a reduced amount of yeast.

Owner:CARAVAN INGREDIENTS

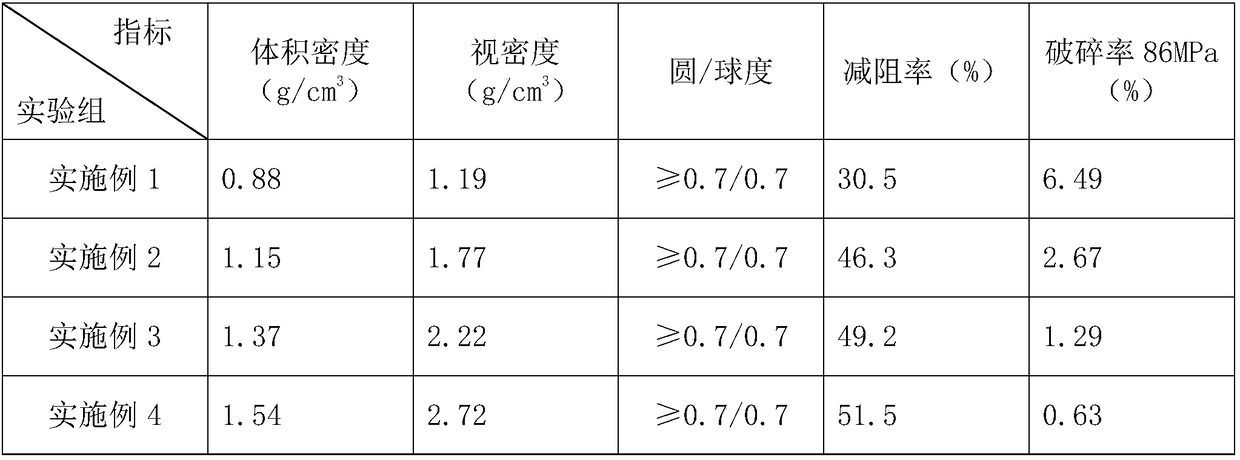

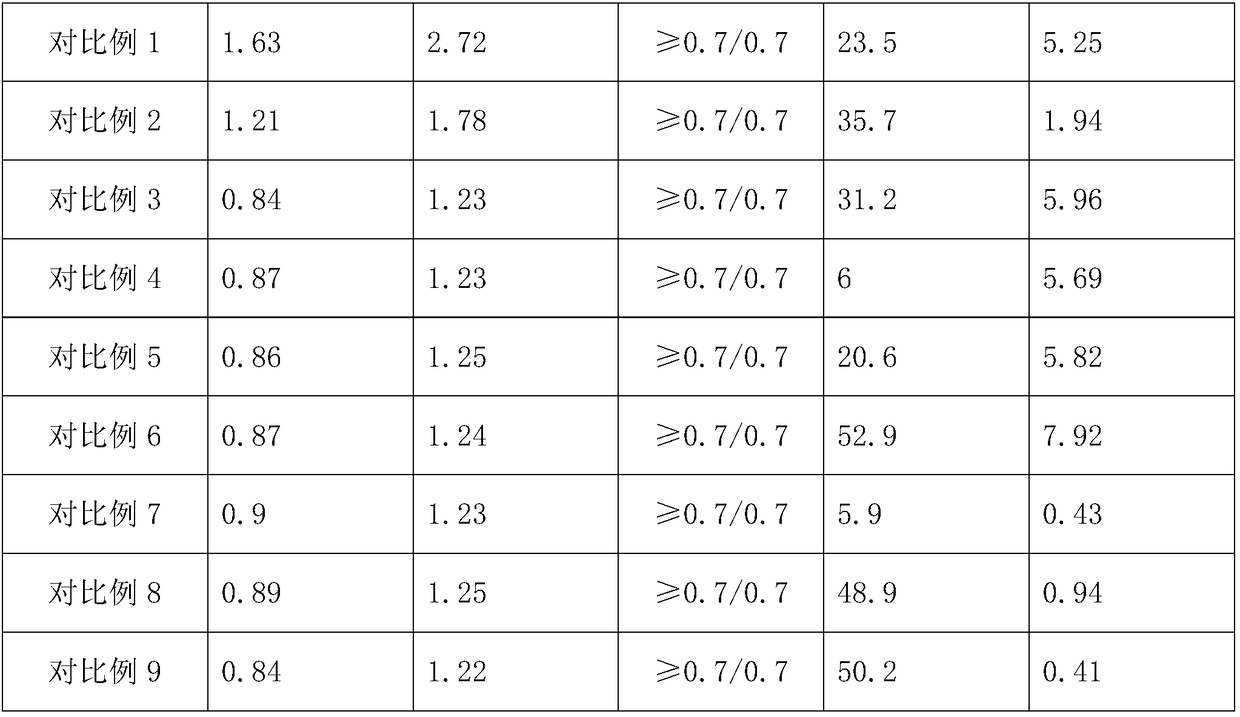

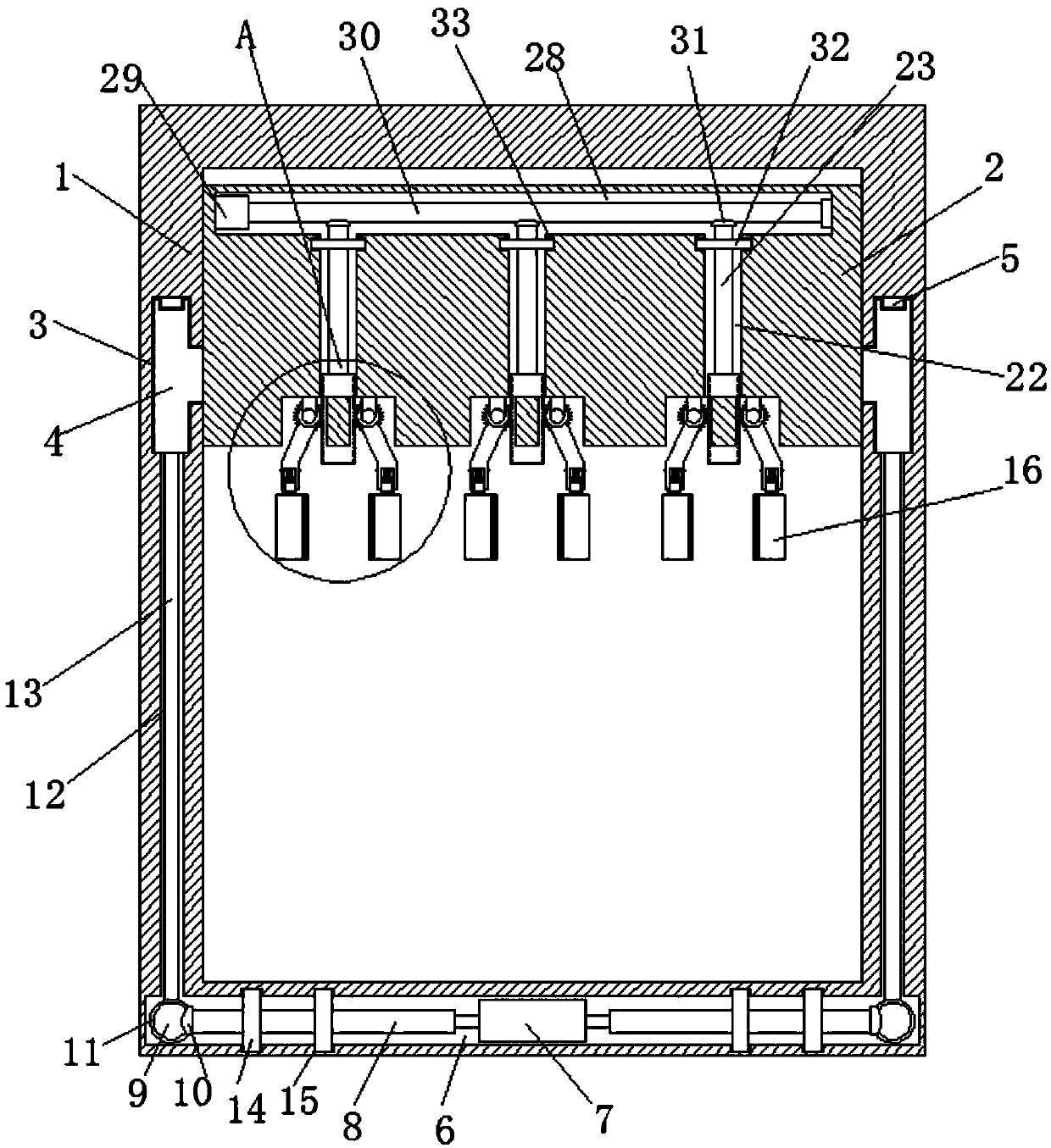

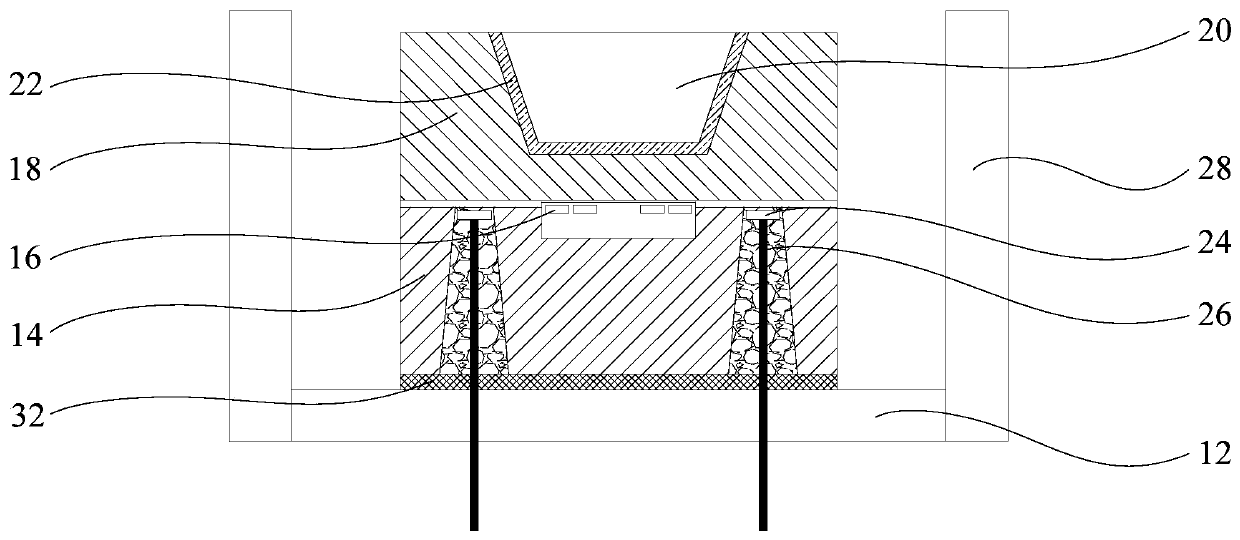

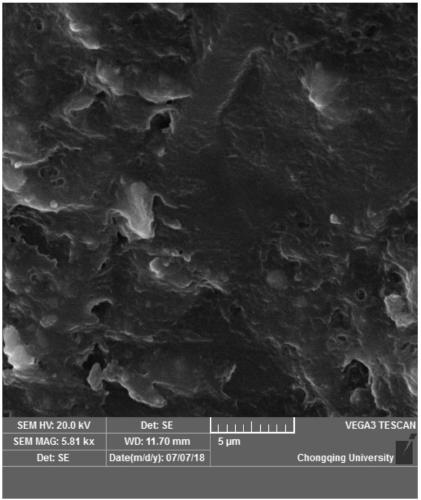

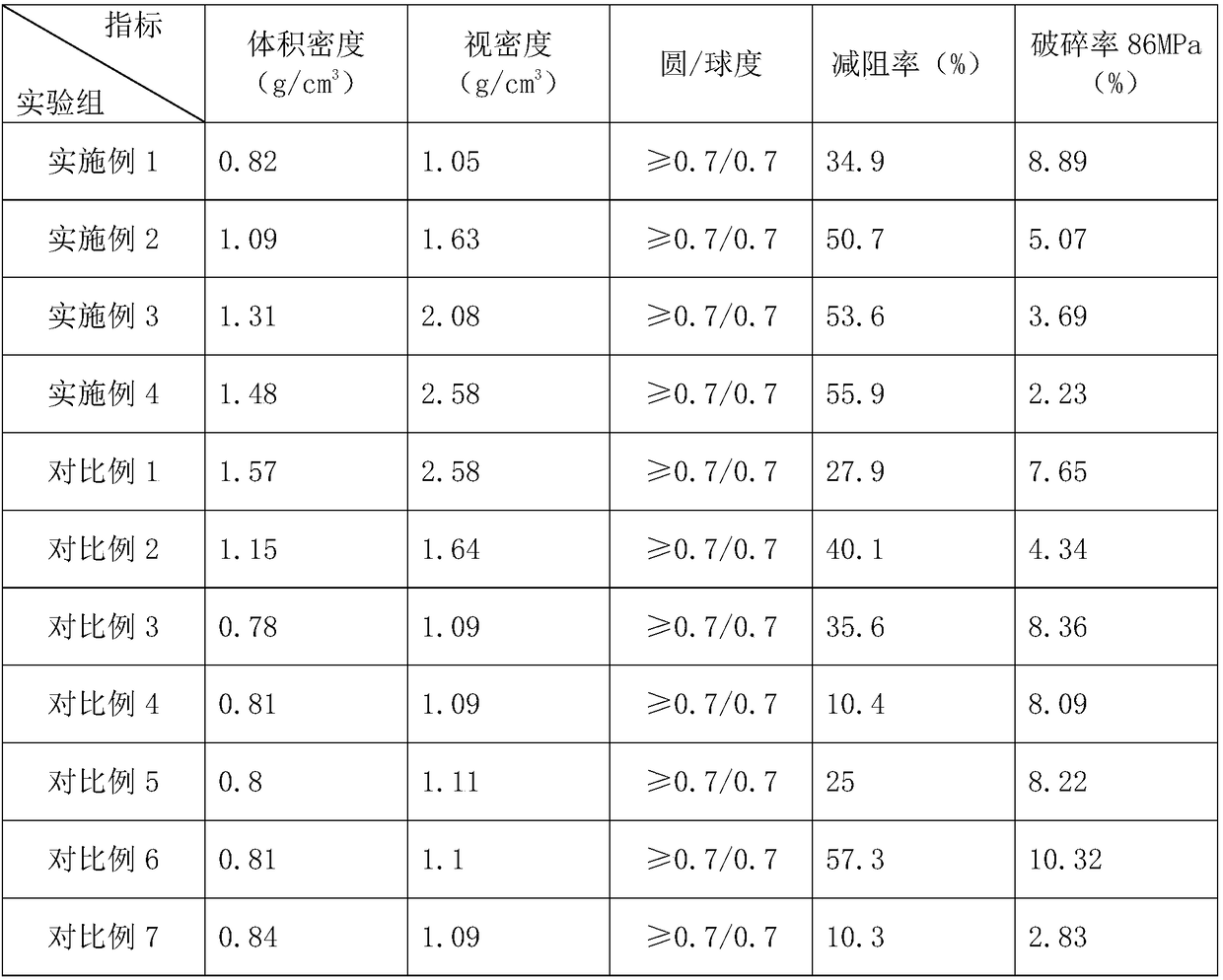

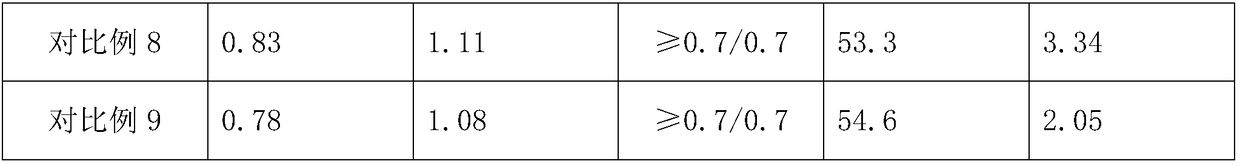

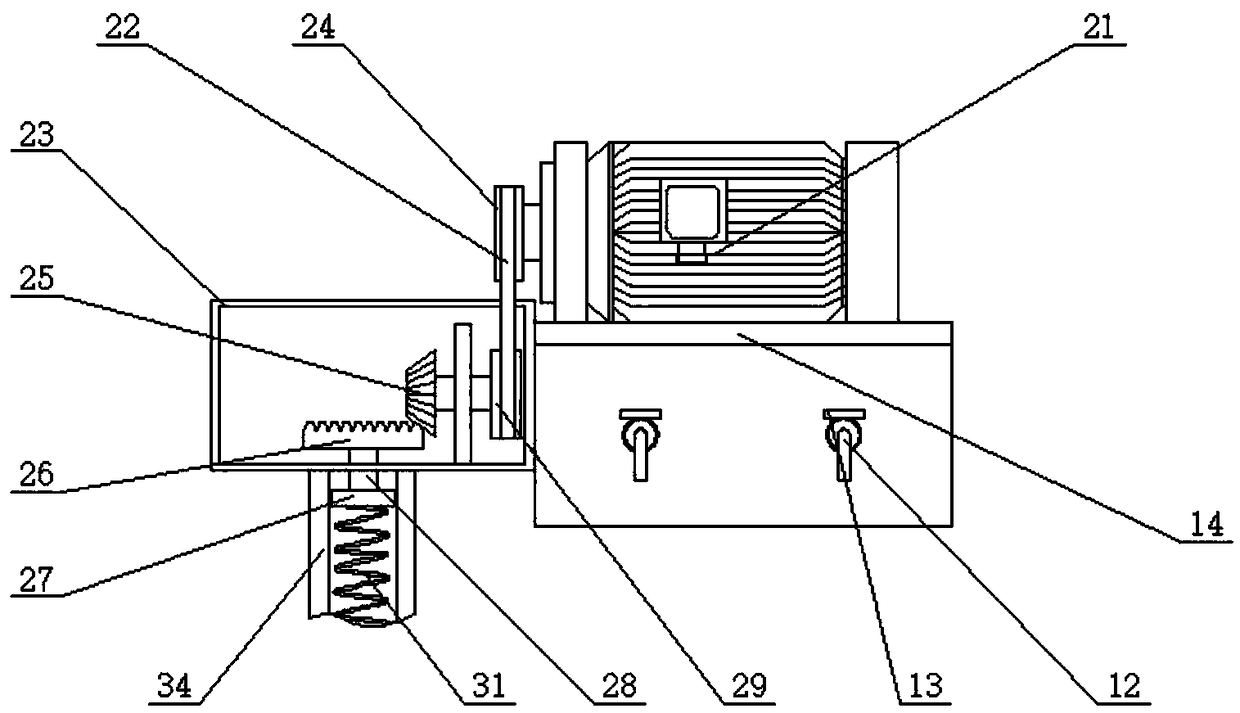

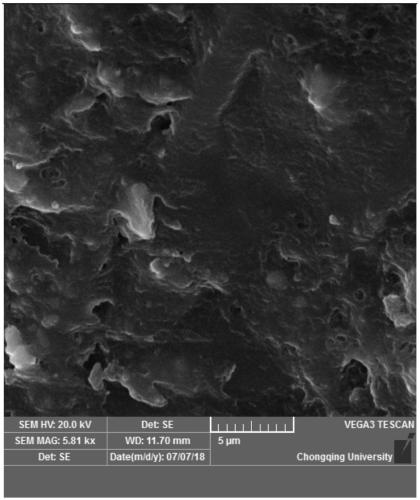

Preparation technology of self-suspension coated support material

InactiveCN109111911AGood drainageFast dissolution rateFluid removalDrilling compositionApparent densityReducer

The invention belongs to the technical field of production of fluid ores of petroleum, natural gas, shale gas and the like, and particularly discloses a preparation technology of a self-suspension coated support material. The preparation technology comprises the following steps: (1) heating aggregate to the temperature of 80 to 230 DEG C, and stirring and mixing the heated aggregate; (2) cooling to the temperature of 75 to 200 DEG C, adding inner resin and a curing agent of the inner resin, and stirring, thus forming an inner coating layer; (3) cooling to the temperature of 65 to 190 DEG C, adding a drag reducer, and stirring; (4) cooling to the temperature of 55 to 130 DEG C, adding a catalyst, outer resin, an amine additive and a curing agent of the outer resin, and stirring, thus forming an outer coating layer; (5) cooling to the temperature of 40 to 80 DEG C, adding a blocking agent, and stirring; (6) cooling to the temperature of 30 to 70 DEG C, discharging out of a pot, and controlling the apparent density of a low-density support agent within the range of 1.05 to 2.60g / cm<3>. The self-suspension coated support material prepared by the preparation technology has the advantages that the flow guide property is good, the self-suspension property is good, and the friction drag is low.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

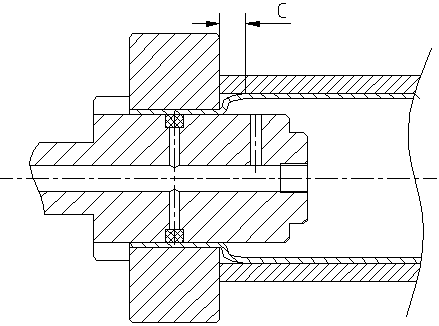

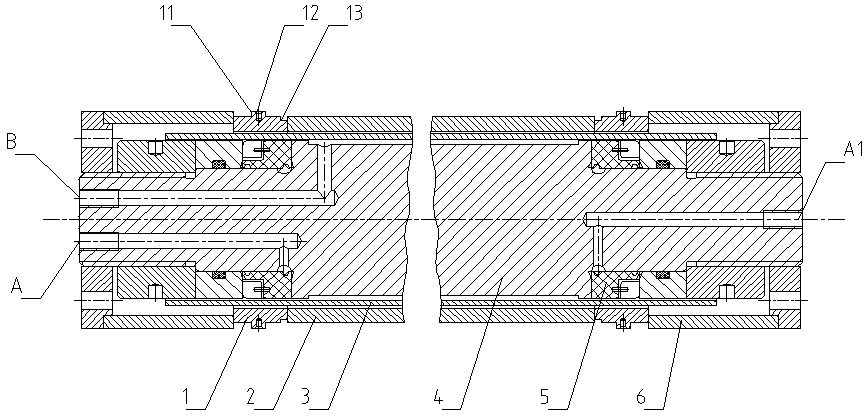

Multistage cold former mechanical arm transmission mechanism

ActiveCN107900273AEasy to disassemble and replaceAvoid wear and tearForging/hammering/pressing machinesElectric machineryManipulator

Owner:宁波华力兴紧固件有限公司

Method for integrated repairing alkali spot soil by furfural slag and Atriplex hortensis

InactiveCN1857046AReduce repair costsLight weightSoil lifting machinesSoil-working methodsMagnesium saltSlag

The present invention relates to soil improvement method, and is especially method for repairing alkali spot soil with furfural slag and Atriplex hortensis. Furfural slag as a kind of acid biomass contains rich organic matter, humic acid, nitrogen fertilizer, phosphate fertilizer, potash fertilizer and trace elements essential for plant to grow and has excellent effect of lowering soil pH value, activating calcium and magnesium salt and improving soil physical and chemical properties. The present invention repairs alkali spot soil through turning over soil, adding furfural slag, banking, leaching, seeding Atriplex hortensis, field management and other steps. The present invention has the advantages of environment friendship, low cost, fast effect, etc.

Owner:NORTHEAST NORMAL UNIVERSITY

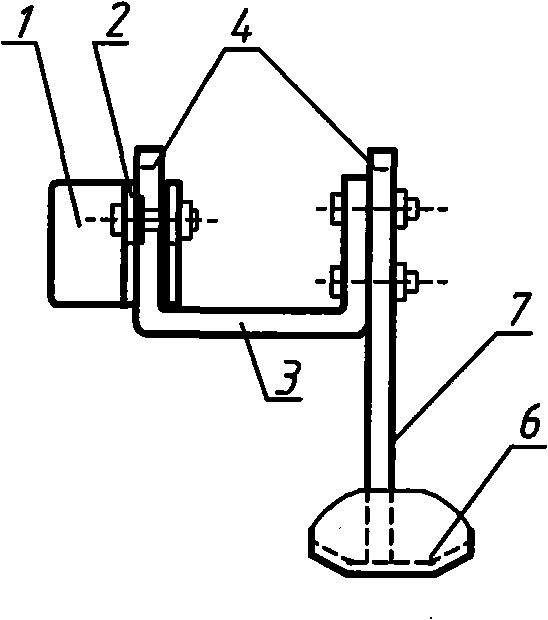

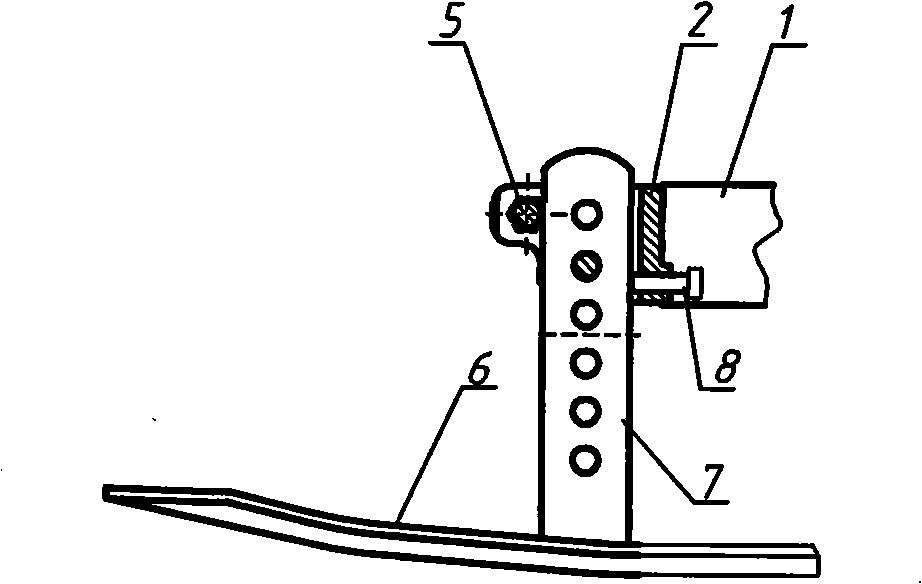

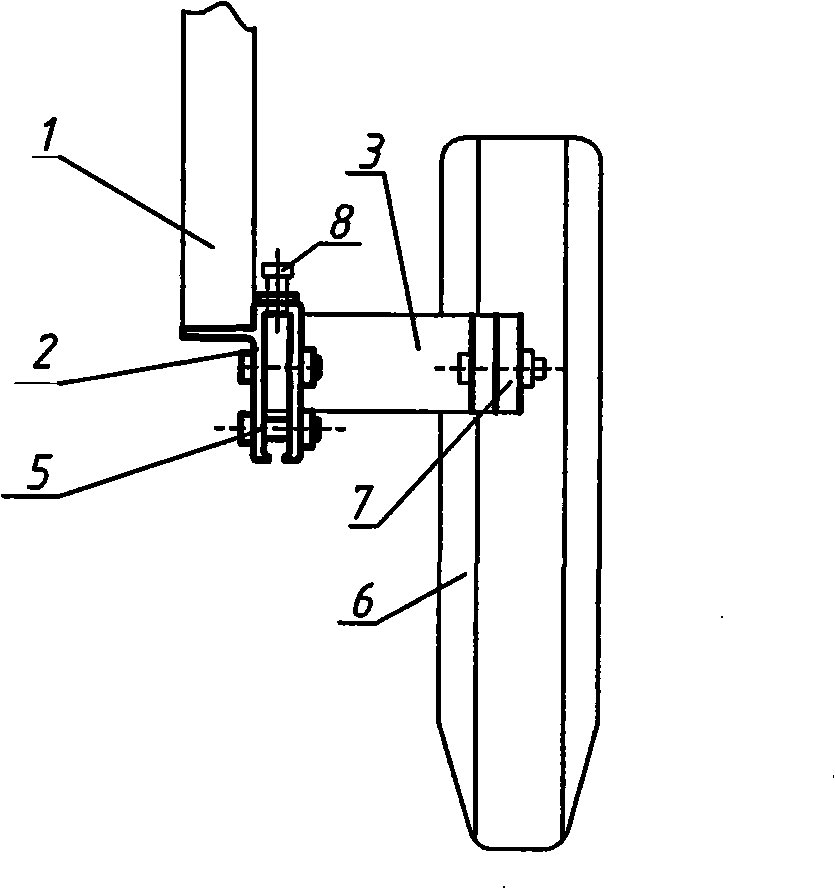

Sliding-raising mechanism of ditcher

InactiveCN101278617ASmall firmnessReduce cutting resistancePlantingFurrow making/coveringEngineering

The invention discloses a skidding mechanism of a ditcher, including an enclosed sleeve or a skidding clip which is arranged at the front end of a frame arm of the ditcher and a skidding plate; one side surface of the enclosed sleeve is provided with a bolt hole, a skidding pillar of the skidding plate is provided with a plurality of bolt holes; the skidding mechanism is characterized in that: a U-shaped joint block is additionally arranged, two vertical posts of the U-shaped joint block are equipped with the bolt holes; either the skidding pillar is directly fixed on the enclosed sleeve or the skidding clip by a bolt, or the U-shaped joint block is firstly fixed on the enclosed sleeve or the warping clip by the bolt and then the skidding pillar is fixed on the other vertical post of the U-shaped joint block by the bolt. The mechanism of the invention not only is adaptable for trenching new ditches on a common field, but also can solve the problem of broadening and deepening and repeated ditch in old ditches.

Owner:葛玉明

Pressure sensor

PendingCN109883578AImprove stabilityAchieve protectionFluid pressure measurement by electric/magnetic elementsForce measurementSlurryEngineering

The invention provides a pressure sensor, which comprises a lining board, a glass foundation bed, a chip, a silicon substrate, a pressing groove, a silicon elastic film, electrodes, pins and glass slurry, wherein the glass substrate is arranged on the lining board; the chip is embedded into the upper wall of the glass foundation bed; the silicon substrate is arranged on the top of the glass foundation bed; the pressing groove is arranged on the upper wall surface of the silicon substrate, and the pressing groove is sunken to the bottom of the silicon substrate; the silicon elastic film is attached to the inner wall of the pressing groove; the electrodes and the chip are electrically connected, and the electrodes are embedded into the upper wall surface of the glass substrate; the pins andthe electrodes are connected, and the pins penetrate through the foundation bed and the lining board; and the glass slurry is embedded into the glass foundation bed, and the glass slurry covers the outer sides of the electrodes and the pins. Pin holes are processed on the corresponding positions of the glass foundation bed and the electrodes, the pins and the electrodes are connected, the pins penetrate through the glass foundation bed and the lining board, and therefore, a required space for the horizontal direction of the chip is reduced.

Owner:CHARODEN IND TECH (SHANGHAI) CO LTD

Preparation process of auto-suspension coating material

PendingCN109135721AGood drainageFast dissolution rateFluid removalDrilling compositionShale gasPetroleum

The invention belongs to the technical field of fluid mineral exploitation of oil, natural gas, shale gas and the like, and particularly discloses a preparation process of an auto-suspension coating material. The preparation process comprises the following steps: (1) heating aggregate to 80-230 DEG C, and stirring and mixing the heated aggregate; (2) reducing the temperature to 75-200 DEG C, adding inner layer resin and a curing agent of the inner layer resin, and carrying out stirring to form an inner coating layer; (3) reducing the temperature to 40-130 DEG C, adding a catalyst, outer layerresin, an amine additive and a curing agent of the outer layer resin, and carrying out stirring to form an outer coating layer; (4) reducing the temperature to 35-90 DEG C, adding a drag reducer and carrying out stirring, wherein the mass of the drag reducer is 0.5-1.5% of that of the aggregate; and (5) reducing the temperature to 30-70 DEG C, taking the mixture out, and controlling the apparent density range of the auto-suspension coating material to be 1.05-2.60g / cm<3>. The auto-suspension coating material prepared by the preparation process has good flow conductivity, good auto-suspension performance and reduced friction resistance.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

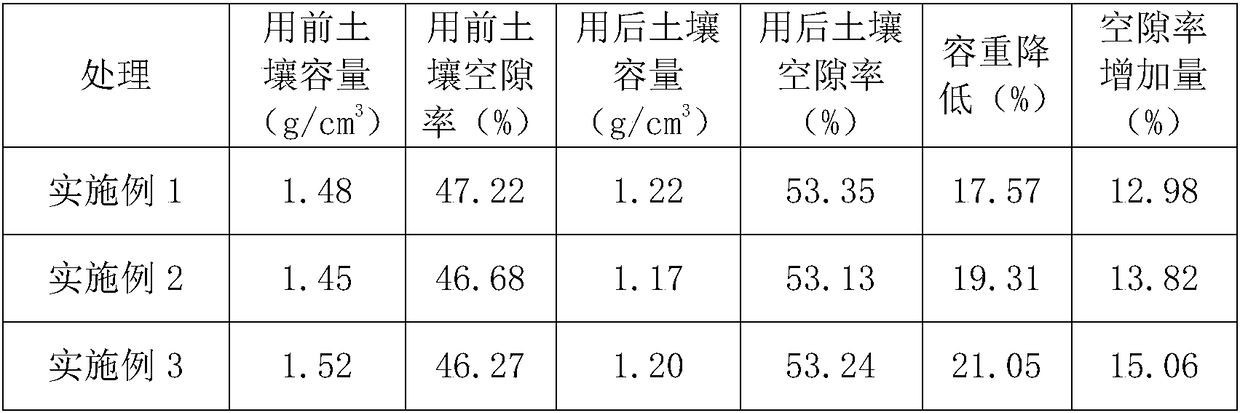

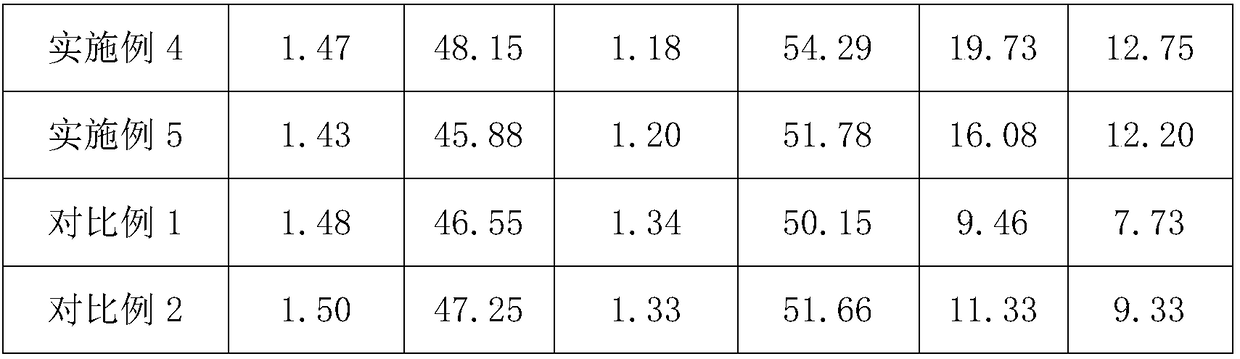

Method for improving hardened tobacco planting soil

ActiveCN110115126AReduce pollutionReduce applicationsTobacco cultivationHorticulture methodsMicroorganismPorosity

The invention relates to the technical field of soil improvement, in particular to a method for improving hardened tobacco planting soil. The method includes the steps of firstly, planting tobacco; secondly, planting paddy rice; thirdly, applying materials and performing smoldering, to be more specific, furrowing the field after paddy rice harvesting, sequentially filling paddy rice straw, soil particles, paddy rice straw, the mixture of tobacco straw and rice hulls, soil particles, rice hulls and soil particles into furrows in a layered manner, and performing smoldering after the materials are applied, wherein the thickness of each layer is different; fourthly, finishing the soil. By the method, soil bulk density can be lowered evidently, soil total porosity and ventilation porosity can be increased, soil organic matter and total nitrogen content can be increased, the activity of soil microorganisms can be increased, the hardening condition of the tobacco planting soil can be improved, and soil permeability can be evidently increased.

Owner:HUNAN AGRICULTURAL UNIV

High-binding-force graphite film metal composite material and preparation method thereof

ActiveCN107809885AImprove thermal conductivityImprove cooling effectLamination ancillary operationsMagnetic/electric field screeningCarbonizationGraphite

The invention relates to the technical field of graphite film metal composite material and discloses a high-binding-force graphite film metal composite material and a preparation method thereof. The high-binding-force graphite film metal composite material comprises a graphite layer, a metal transition layer and a surface metal layer. The graphite layer is a graphite film obtained only after carbonization and graphitization treatment. The preparation method comprises the following steps: preparing the graphite layer, preparing the metal transition layer through a melting method, carrying out calendaring and pickling, preparing the surface metal layer and carrying out anti-oxidation treatment in sequence. The high-binding-force graphite film metal composite material is convenient to prepare, is high in binding force between the graphite layer and the metal layer, and has excellent conductive performance and heat radiation performance.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

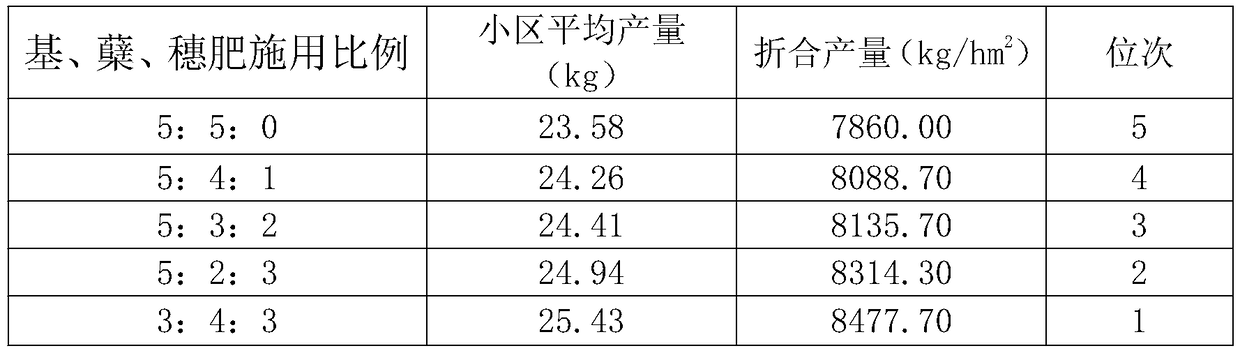

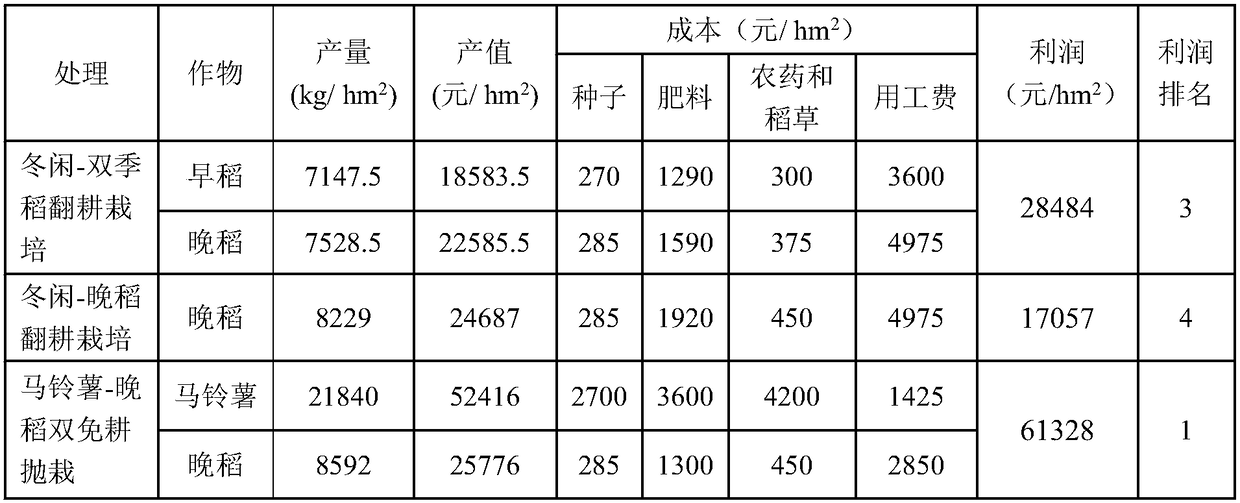

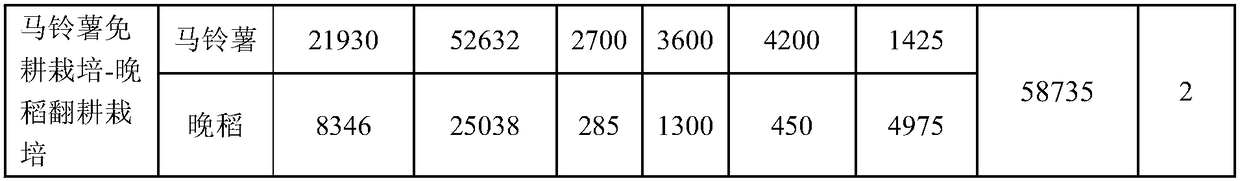

Potato and late rice double-no-tillage cast transplanting planting method

PendingCN108967100AAlleviate the tension in the connectionEfficient use ofRoot crop cultivationPlant protective coveringsEconomic benefitsSolanum tuberosum

The invention discloses a potato and late rice double-no-tillage cast transplanting planting method, belonging to the field of agricultural production. The method mainly comprises the following stepsof (1) potato no-tillage cultivation including (a) fine breed selection, (b) ditching and raking, (c) potato seed processing, (d) reasonable close planting and the application of enough base fertilizer, (e) covering with straws, (f) field management, and (g) timely harvest, and (2) late rice no-tillage cast transplanting including (a) breed selection, (b) seedling cast transplanting, (c) field management including scientific fertilization, reasonable irrigation, timely weeding and the prevention and control of pests and diseases, and (d) timely harvest. The method provided by the invention hasan obvious influence on the economy, yield and economic benefit of rice, the yield of late rice can be obviously increased, and the method has the characteristics of reducing labor intensity, savingcost and increasing efficiency, increasing production and income, and being simple and easy.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

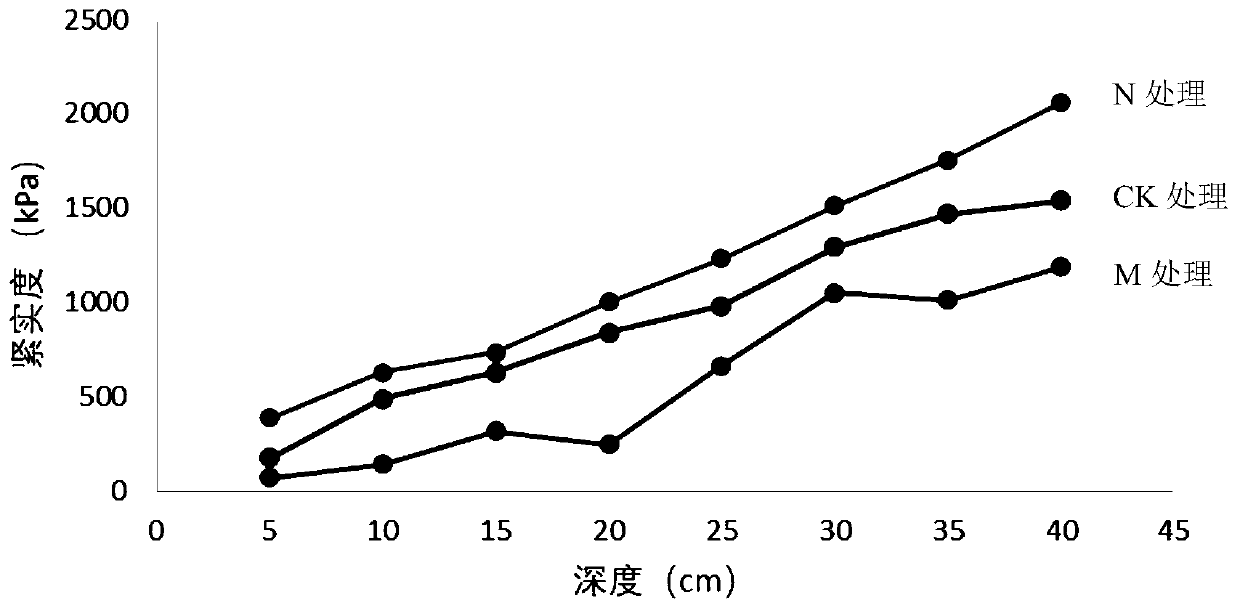

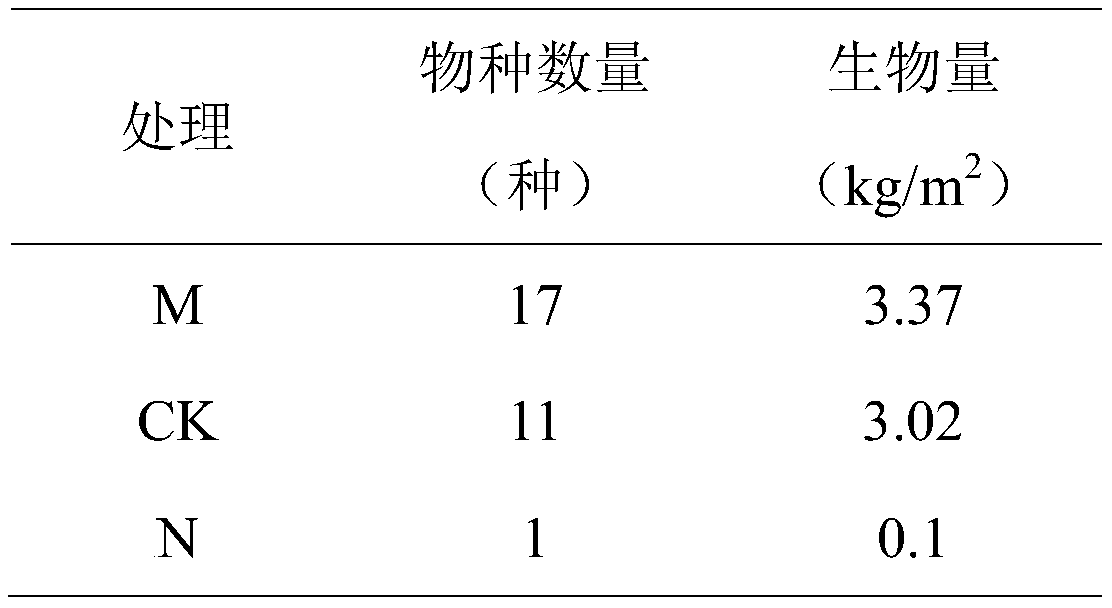

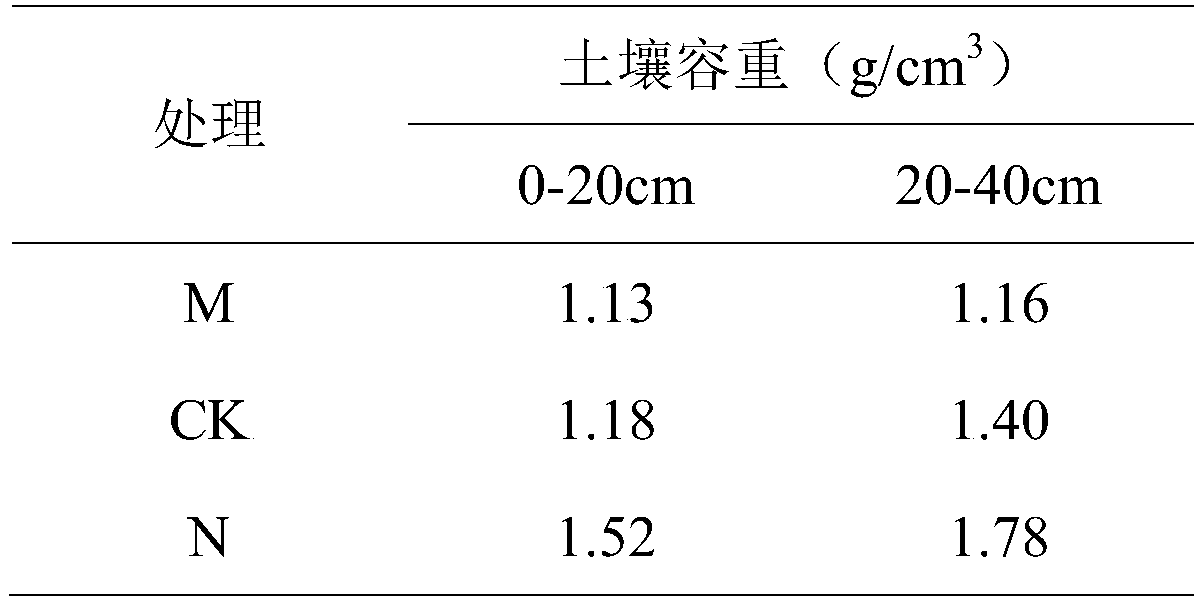

Improved method for compacted soil in surface mine dump

ActiveCN111165113AReduce firmnessUnderground miningFabaceae cultivationArbuscular mycorrhizal fungiAgrostocrinum

The invention discloses an improved method for compacted soil in a surface mine dump. According to the method, perennial gramineous plants including BromusinermisLeyss., Agropyroncristatum(L.)Gaertn,FestucaelataKeng ex E.Alexeev and Leymuschinensis(Trin.)Tzvel. are mixed with leguminous plants including Medicago falcata L. and Melissilusruthenicus(L.)Peschkova(TrigonellaruthenicaL.) to serve as acolonization plant which cooperates with arbuscular mycorrhizal fungi. The method provided by the invention can provide effective help for vegetation ecological restoration of the surface mine dump and can significantly reduce the compaction degree of the compacted soil, so that the method can be popularized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Grain elevator fixed firmly

The invention is suitable for the technical field of agricultural machinery, and provides a grain elevator fixed firmly. The grain elevator fixed firmly comprises a locking assembly, a transmission assembly and a grain elevating assembly, wherein the locking assembly comprises a car hopper side plate, locking rods, locking sheets, a support, clamping blocks, locking plates and pressure springs; the support is fixedly connected to the locking sheets; the locking sheets are positioned on the right side of the support; a locking hole is formed in the outer surface of each locking sheet; and the locking rods rotate clockwise, at the moment, each pressure spring drives the corresponding locking plate to be firmly abutted against the car hopper side plate through the corresponding clamping block, and thus, the grain elevator and the car hopper side plate are fixed firmly. Compared with an existing small grain elevator, the small portable grain elevator has the advantages that the grain elevator and the car hopper side plate can be fixed firmly, thus, when the grain elevator is used, the firmness cannot be relieved by vibration generated during running of the grain elevator, accidents areavoided effectively while the grain elevator is used simply and conveniently, and the safety of the grain elevator during use is improved.

Owner:蓝文文

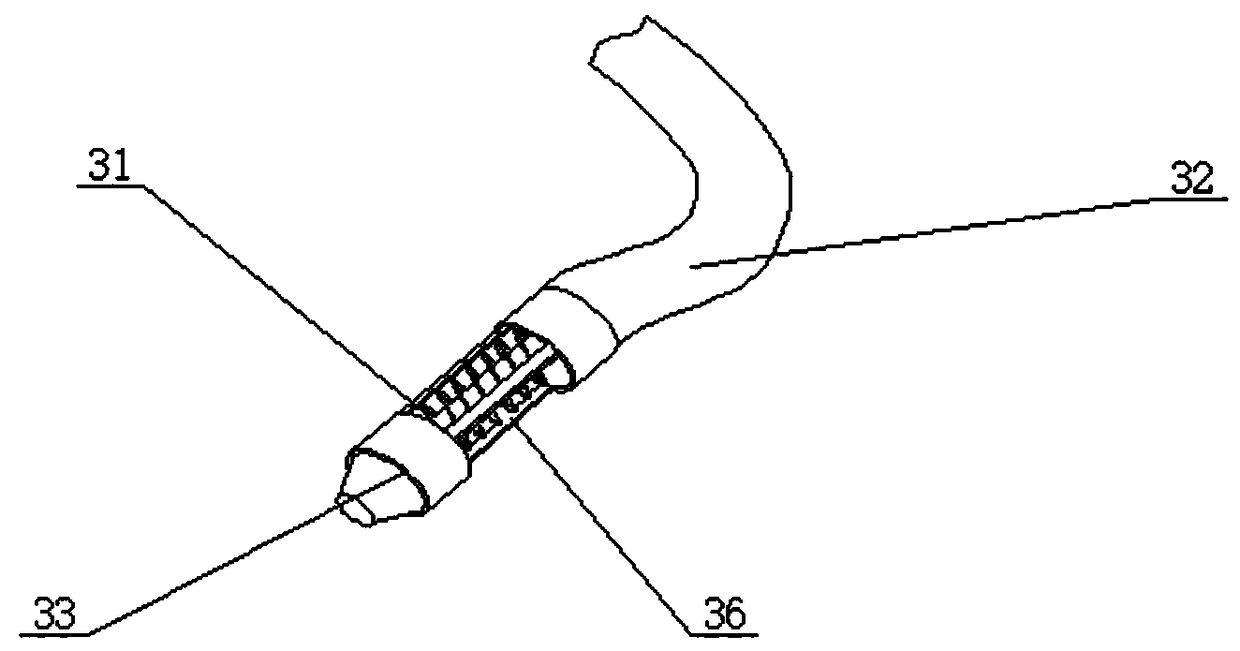

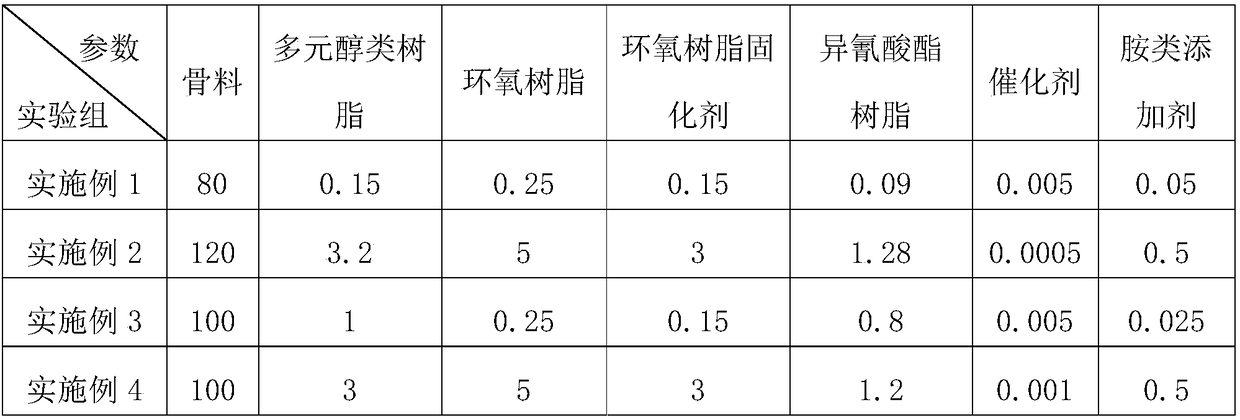

Preparation method of coated proppant

PendingCN109294552AIncrease buoyancyRelative density is smallFluid removalDrilling compositionIsocyanateChemistry

The invention belongs to the field of mixtures for hole drilling or well drilling, and concretely discloses a preparation method of a coated proppant. The preparation method comprises the following steps: (1) preparation of the following raw materials: aggregates, polyol resin, epoxy resin, an epoxy resin curing agent, isocyanate resin, a catalyst and an amine additive, wherein the hydroxyl equivalent of the polyol resin is 60-300, and the mass of the isocyanate resin is 2 / 5 to 4 / 5 of the amount of the polyol resin; (2) heating; (3) sand mixing; (4) primary coating; (5) secondary coating; and(6) sand production. The proppant prepared by the preparation method can naturally suspend in clear water, and can meet the fracturing index requirement of conventional proppants without adding any thickener in the fracturing process, so the fracturing cost is reduced, the fracturing process is simplified, and the pollution to the environment is reduced.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com