Soil conditioner and preparation method thereof

A technology of soil conditioner and plant growth agent, which is applied in the field of soil conditioner and its preparation, can solve the problems of lack of soil permeability, water retention and agglomeration ability improvement and regulation, short fertilizer action time, poor comprehensive functionality, etc. It can reduce soil bulk density and compactness, improve the structure of nutrient elements, and facilitate the downward movement of salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

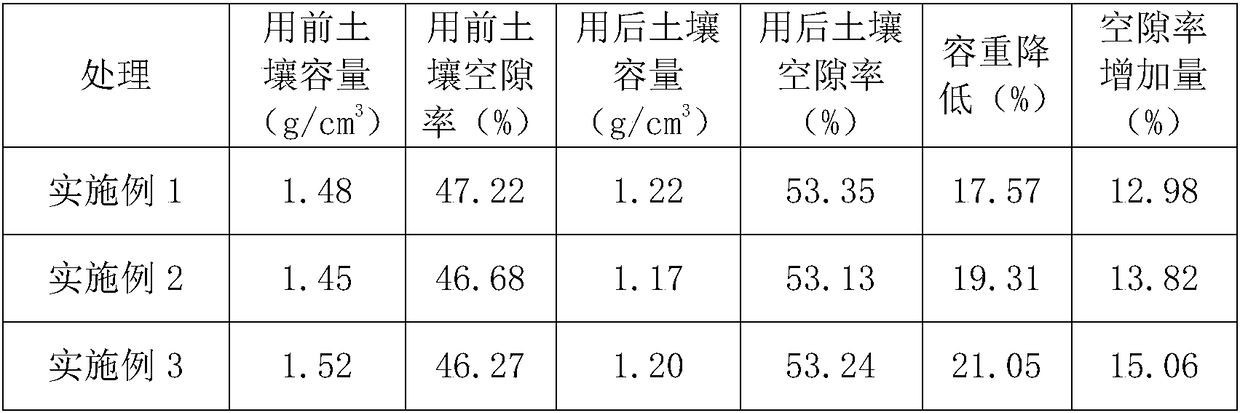

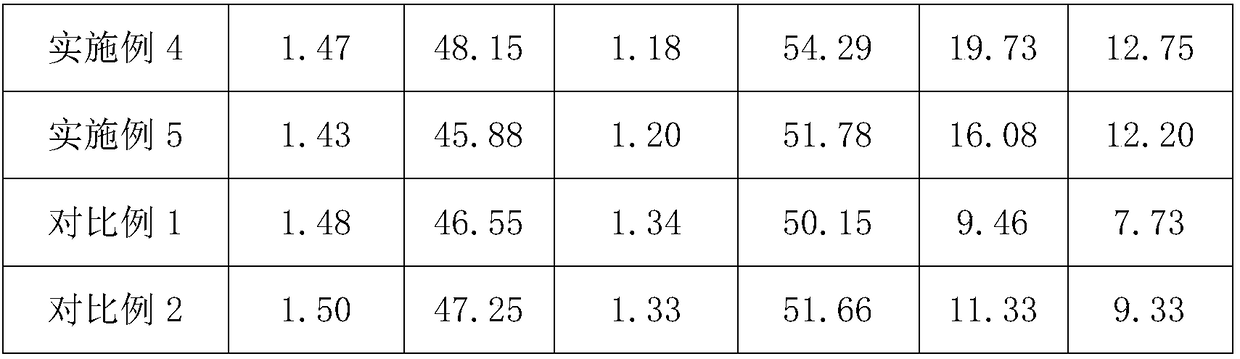

Examples

Embodiment 1

[0035] A soil conditioner, comprising the following raw materials in parts by weight:

[0036] 10 parts of straw granules, 40 parts of fermented cow dung, 3 parts of medical stone, 2 parts of dolomite powder, 5 parts of modified attapulgite, 2 parts of desulfurized gypsum powder, 4 parts of seafood shell powder, 5 parts of plant ash, 4 parts of sweet potato residue , 4 parts of fermentation residue, 1 part of shiitake mushroom extract, 1.5 parts of plant growth agent, 2 parts of amino acid salt, 1.5 parts of ferric chloride, 3 parts of ammonium dihydrogen phosphate, 2 parts of superphosphate, and 0.5 part of microbial action bacteria.

[0037] The preparation method of straw granules is as follows:

[0038] (a1) chopping the straw raw material with a pulverizer to obtain crushed straw with a length of 20 mm, and then entering the silage tank for silage fermentation treatment, drying the crushed straw after silage, and obtaining crushed straw with a water content of 10%;

[00...

Embodiment 2

[0053] A soil conditioner, comprising the following raw materials in parts by weight:

[0054] 15 parts of straw granules, 45 parts of fermented cow dung, 7 parts of medical stone, 5 parts of dolomite powder, 10 parts of modified attapulgite, 5 parts of desulfurized gypsum powder, 9 parts of seafood shell powder, 10 parts of plant ash, 9 parts of sweet potato residue , 9 parts of fermentation residue, 3 parts of shiitake mushroom extract, 3.5 parts of plant growth agent, 5 parts of amino acid salt, 3.5 parts of ferric chloride, 7 parts of ammonium dihydrogen phosphate, 5 parts of superphosphate, and 1.2 parts of microbial action bacteria.

[0055] The preparation method of straw granules is as follows:

[0056] (a1) chopping the straw raw material with a pulverizer to obtain crushed straw with a length of 50 mm, and then entering the silage tank for silage fermentation treatment, drying the crushed straw after ensilage, and obtaining crushed straw with a water content of 15%; ...

Embodiment 3

[0071] A soil conditioner, comprising the following raw materials in parts by weight:

[0072] 11 parts of straw granules, 41 parts of fermented cow dung, 4 parts of medical stone, 3 parts of dolomite powder, 6 parts of modified attapulgite, 3 parts of desulfurized gypsum powder, 5 parts of seafood shell powder, 6 parts of plant ash, 5 parts of sweet potato residue , 5 parts of fermentation residue, 1.5 parts of shiitake mushroom extract, 2 parts of plant growth agent, 3 parts of amino acid salt, 2 parts of ferric chloride, 4 parts of ammonium dihydrogen phosphate, 3 parts of superphosphate, and 0.7 part of microbial action bacteria.

[0073] The preparation method of straw granules is as follows:

[0074] (a1) Shredding the straw raw material with a pulverizer to obtain crushed straw with a length of 30 mm, and then entering the silage tank for silage fermentation treatment, and drying the crushed straw after silage to obtain crushed straw with a water content of 12%;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com