Patents

Literature

137 results about "Grain elevator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grain elevator is an agrarian facility complex designed to stockpile or store grain. In grain trade, the term grain elevator also describes a tower containing a bucket elevator or a pneumatic conveyor, which scoops up grain from a lower level and deposits it in a silo or other storage facility.

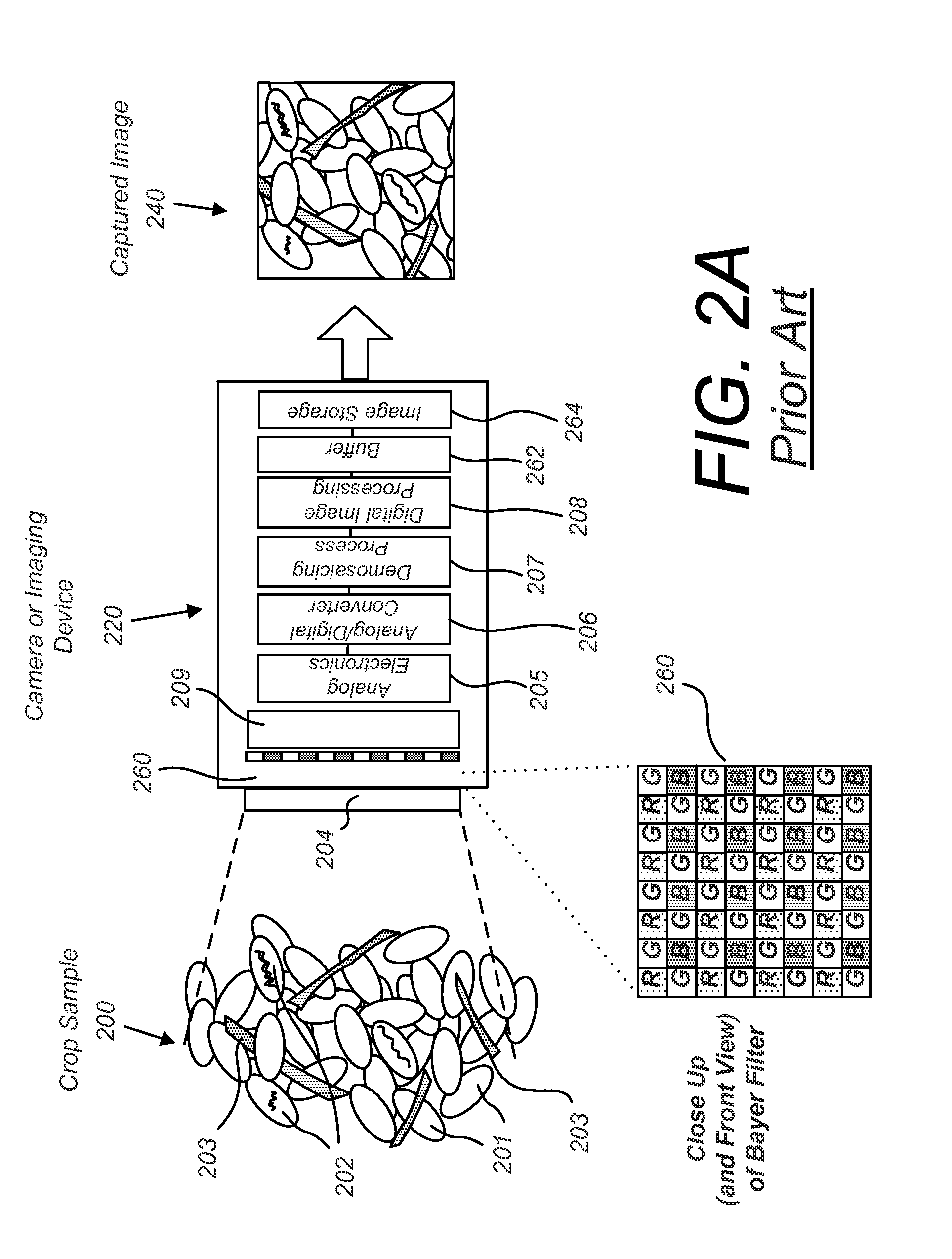

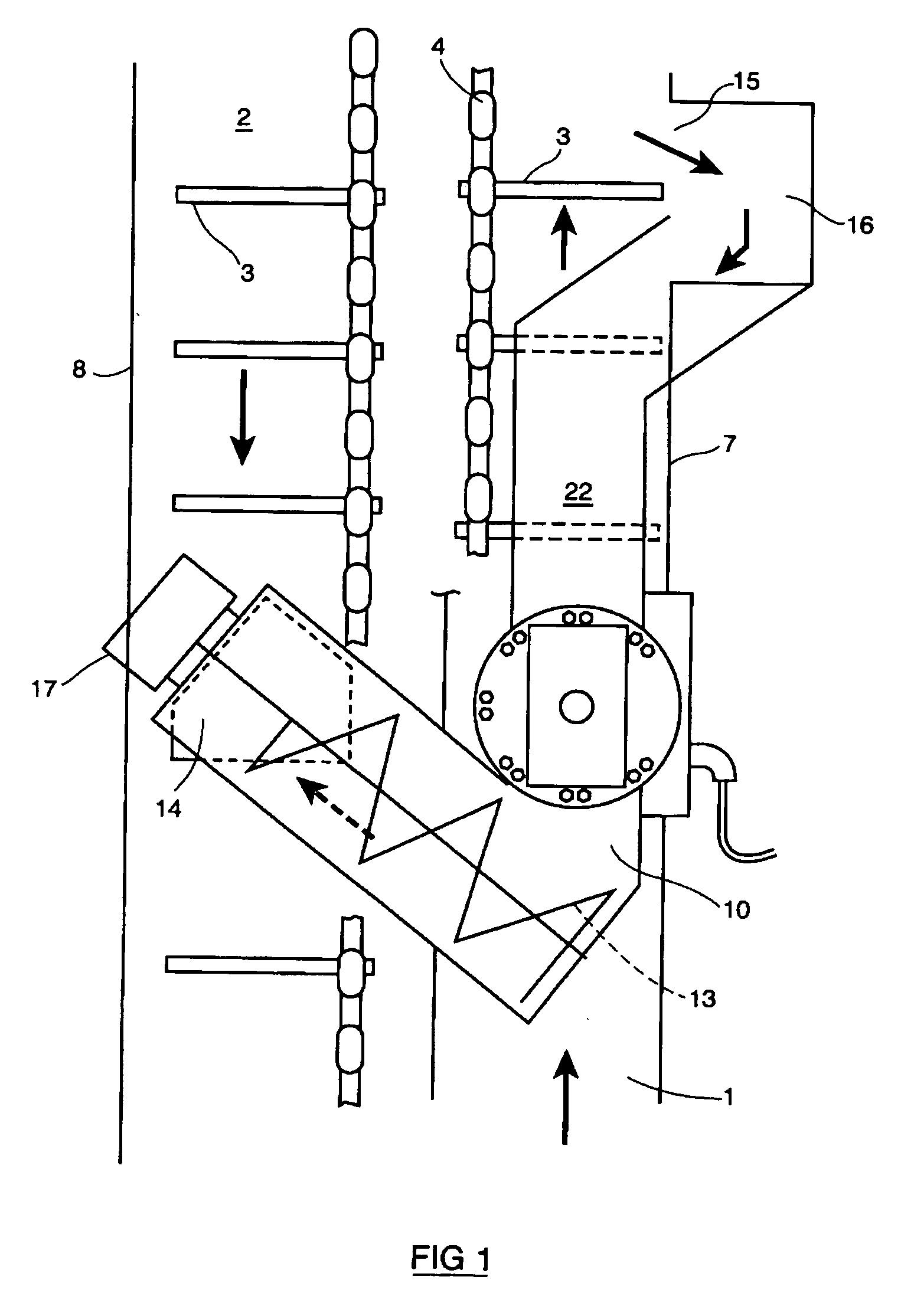

Device for detection and determination of the composition of bulk material

ActiveUS20120004815A1Easy to detectAnalogue computers for trafficMowersGrain elevatorImage recording

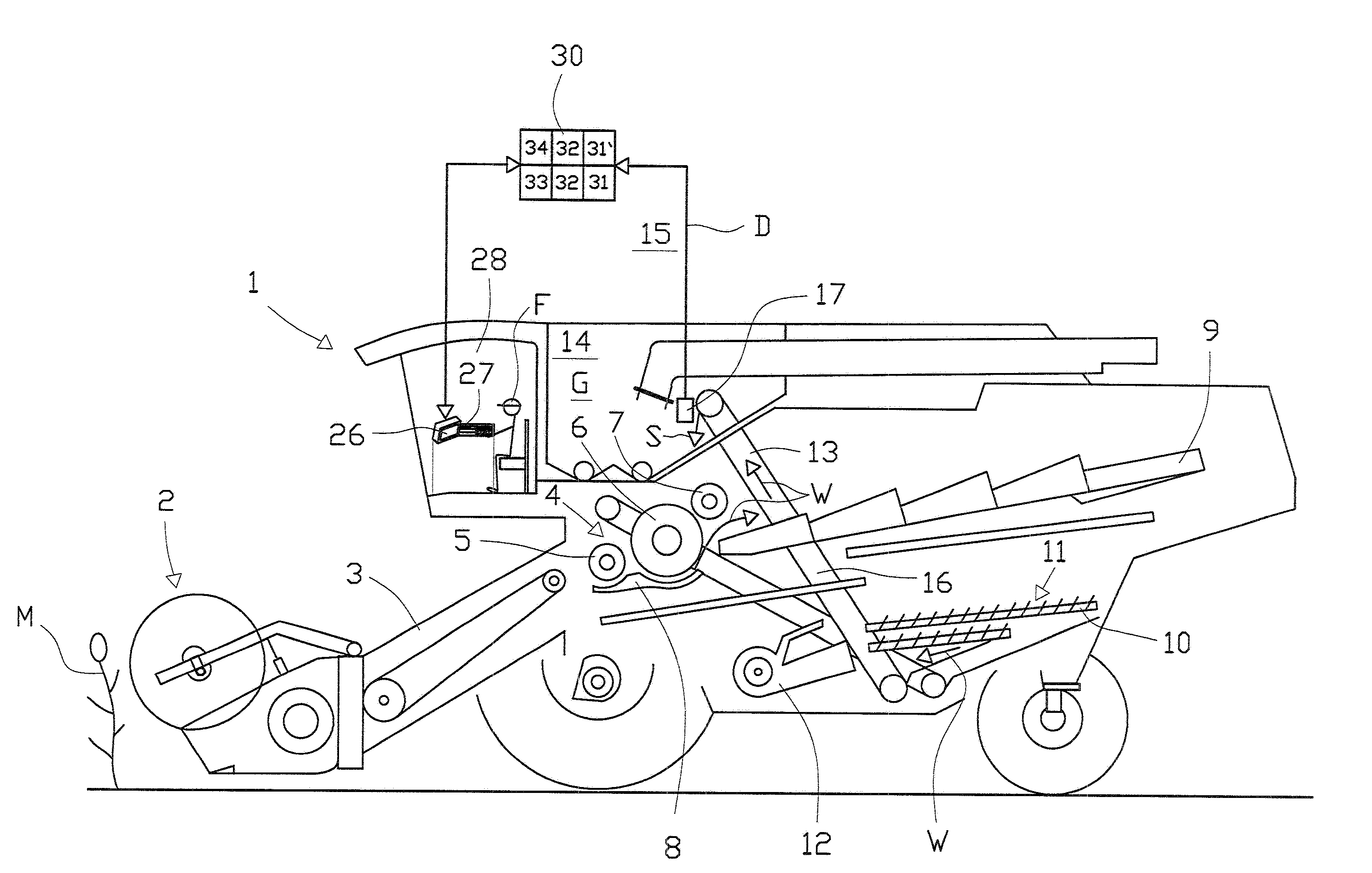

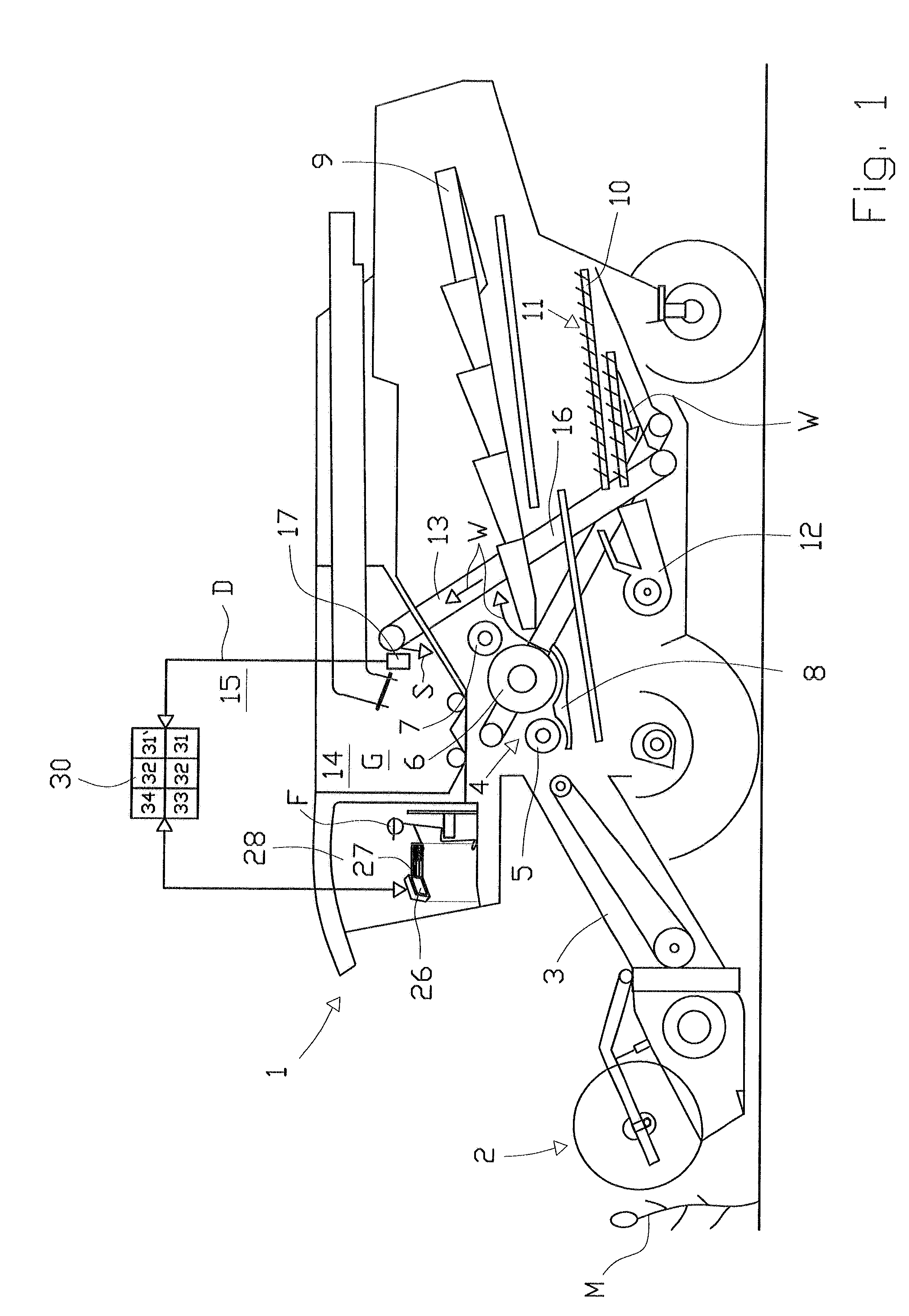

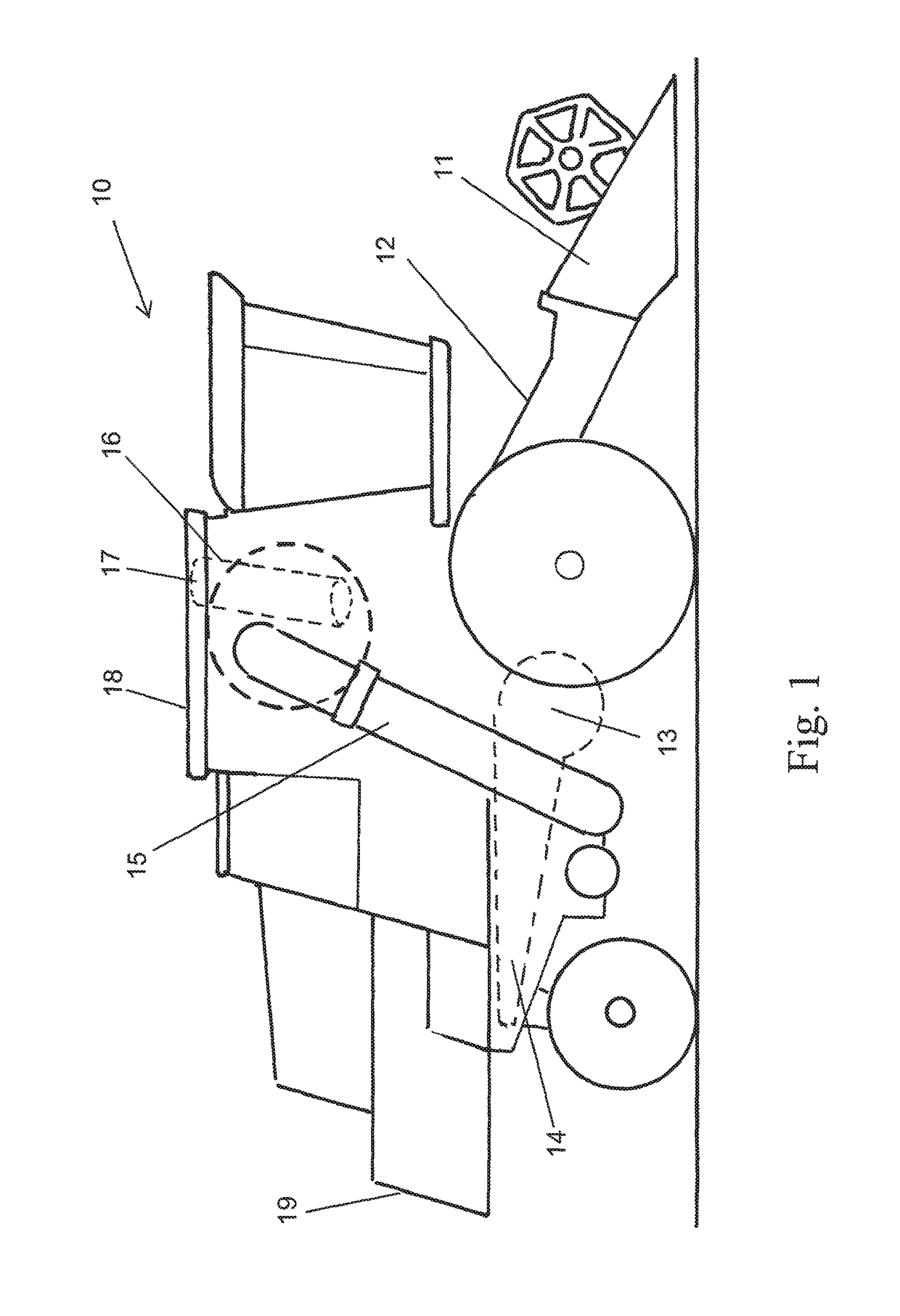

A device for detection and determination of a composition of a bulk material, has an image recording unit, at least one control unit, at least one memory unit, and a selection unit to enable a qualified determination to be made, during a transfer of a crop material flow into a container of an agricultural harvesting machine, of a composition of a crop during processing of the crop material, so that adjustment parameters of working assemblies of the agricultural harvesting machine are changeable during the processing of the crop material, wherein the image recording unit has at least two image detectors for recording images or image series of the crop material flow at equidistant intervals or permanently, wherein one of the image detectors is disposed substantially perpendicularly to a top side of a surface of the crop material flow emerging from a grain elevator head or a discharge chute, and another one of the two image detectors is disposed substantially perpendicularly to an underside of a surface of the crop material flow.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

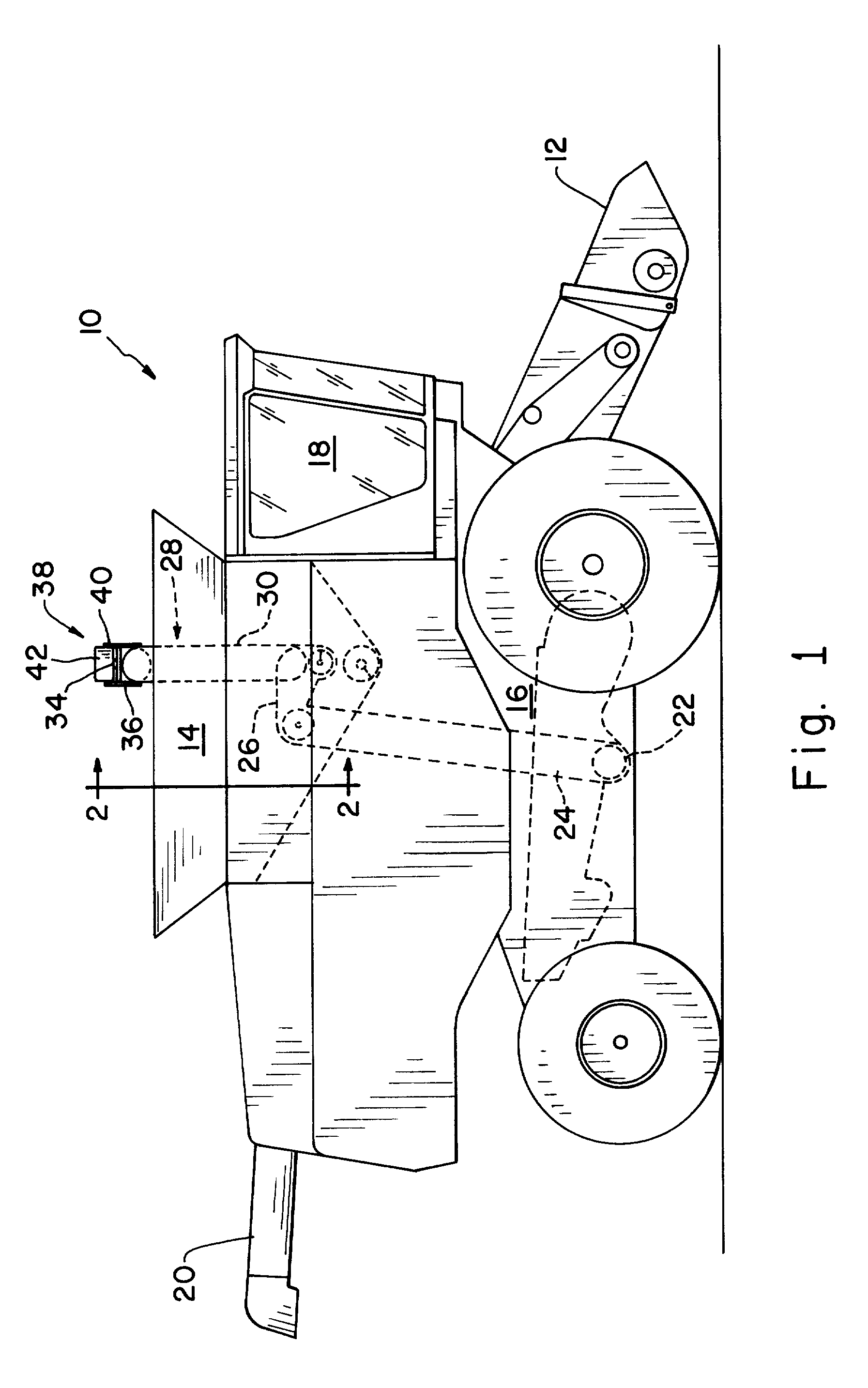

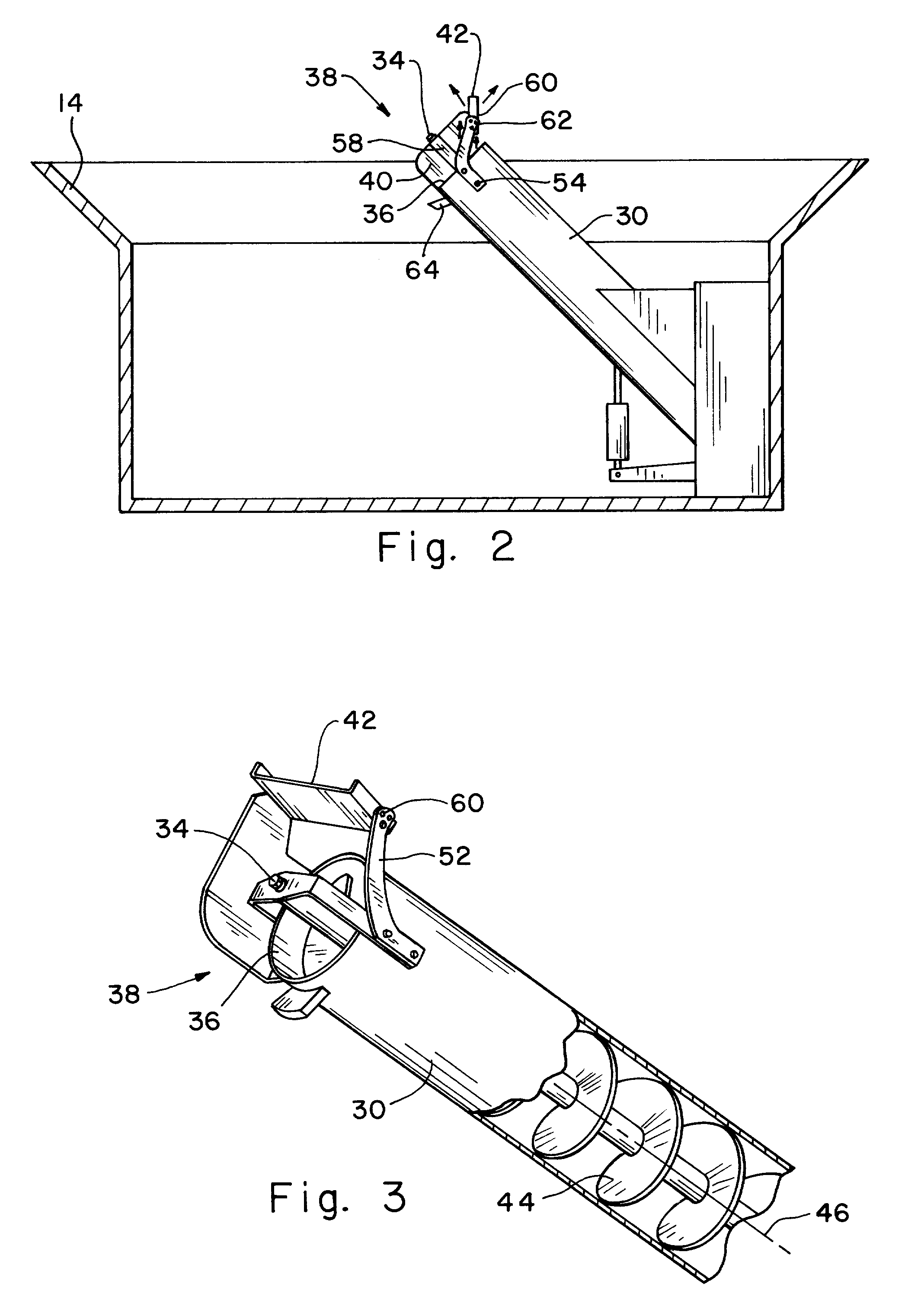

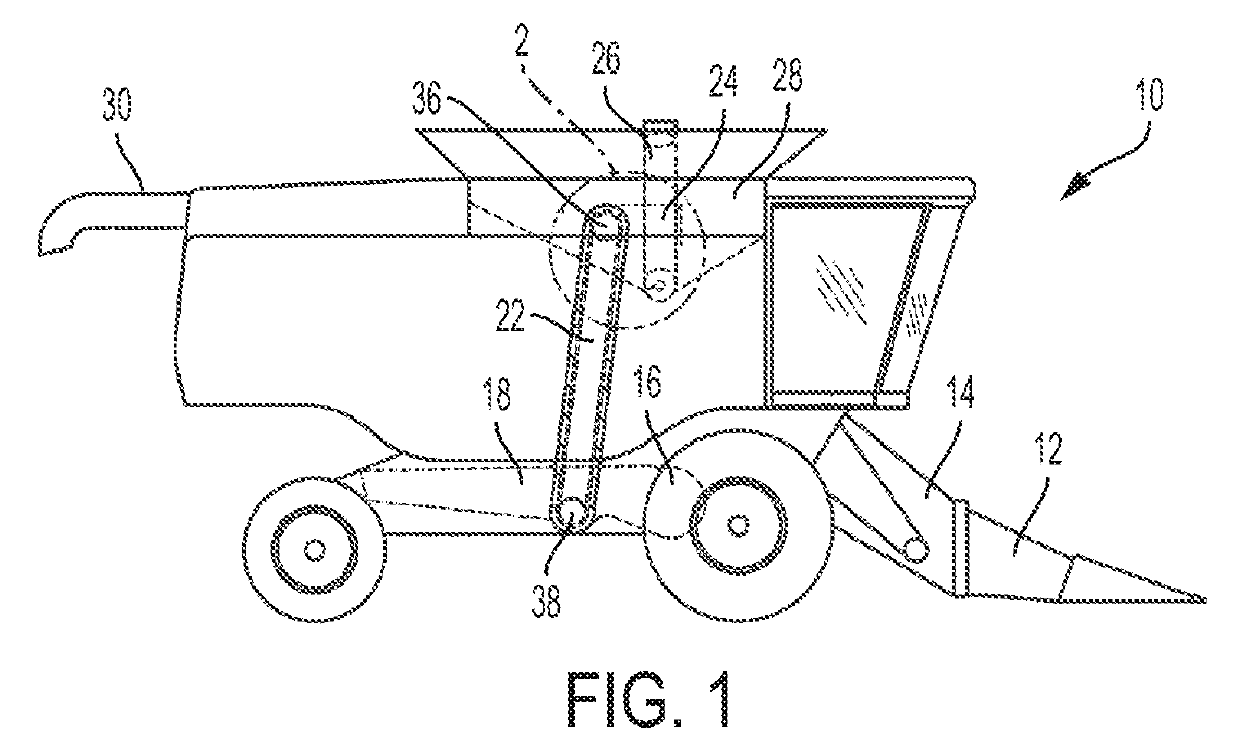

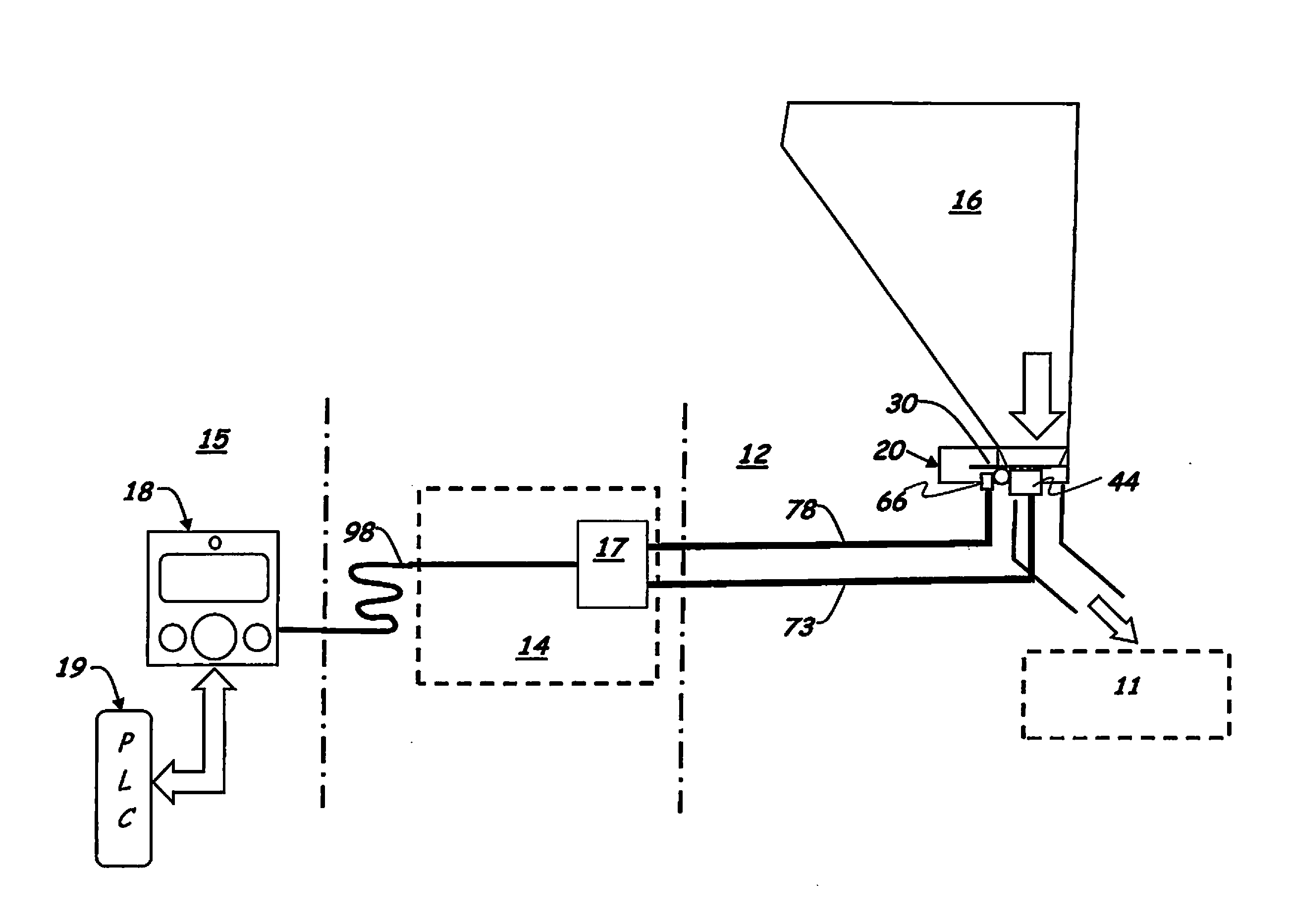

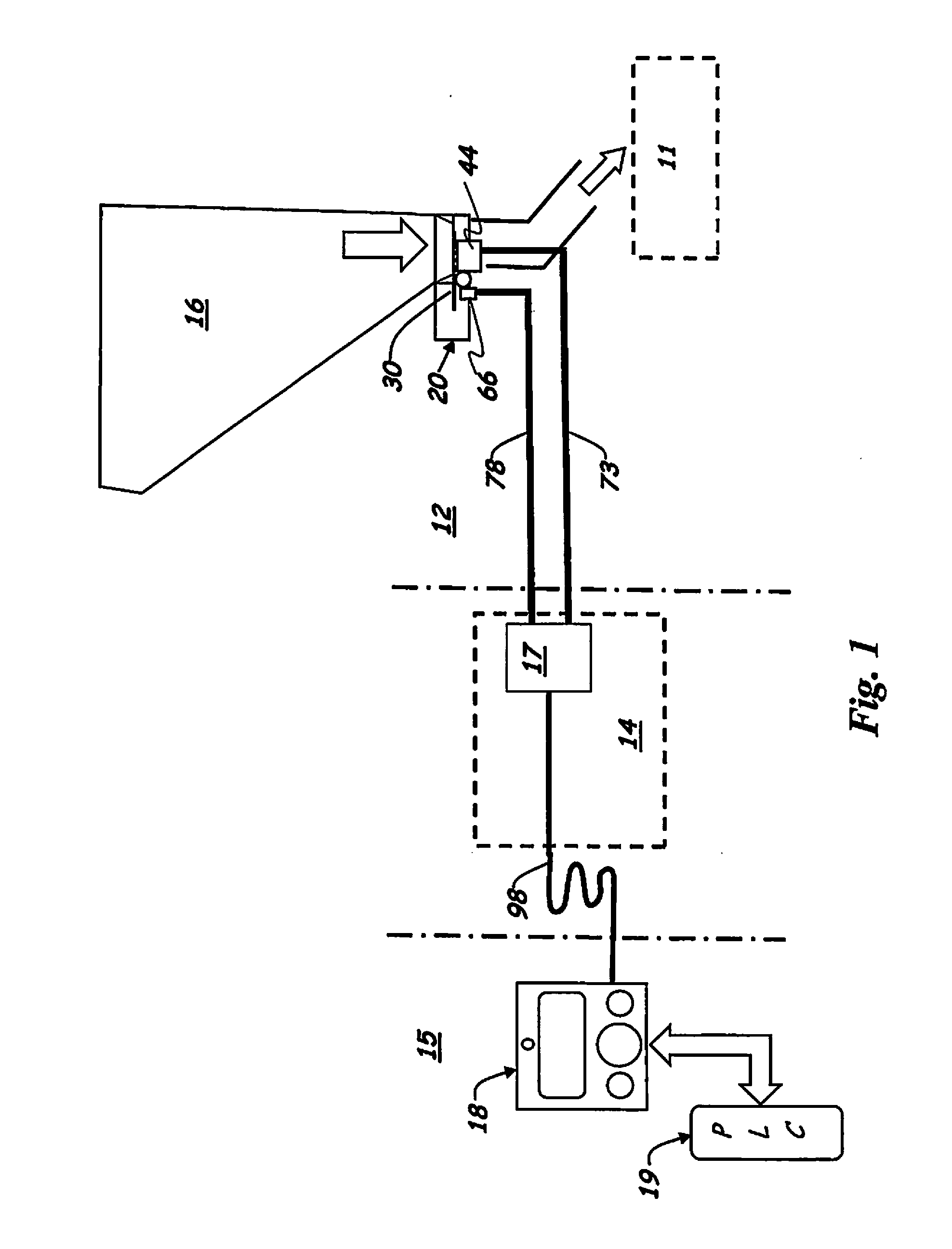

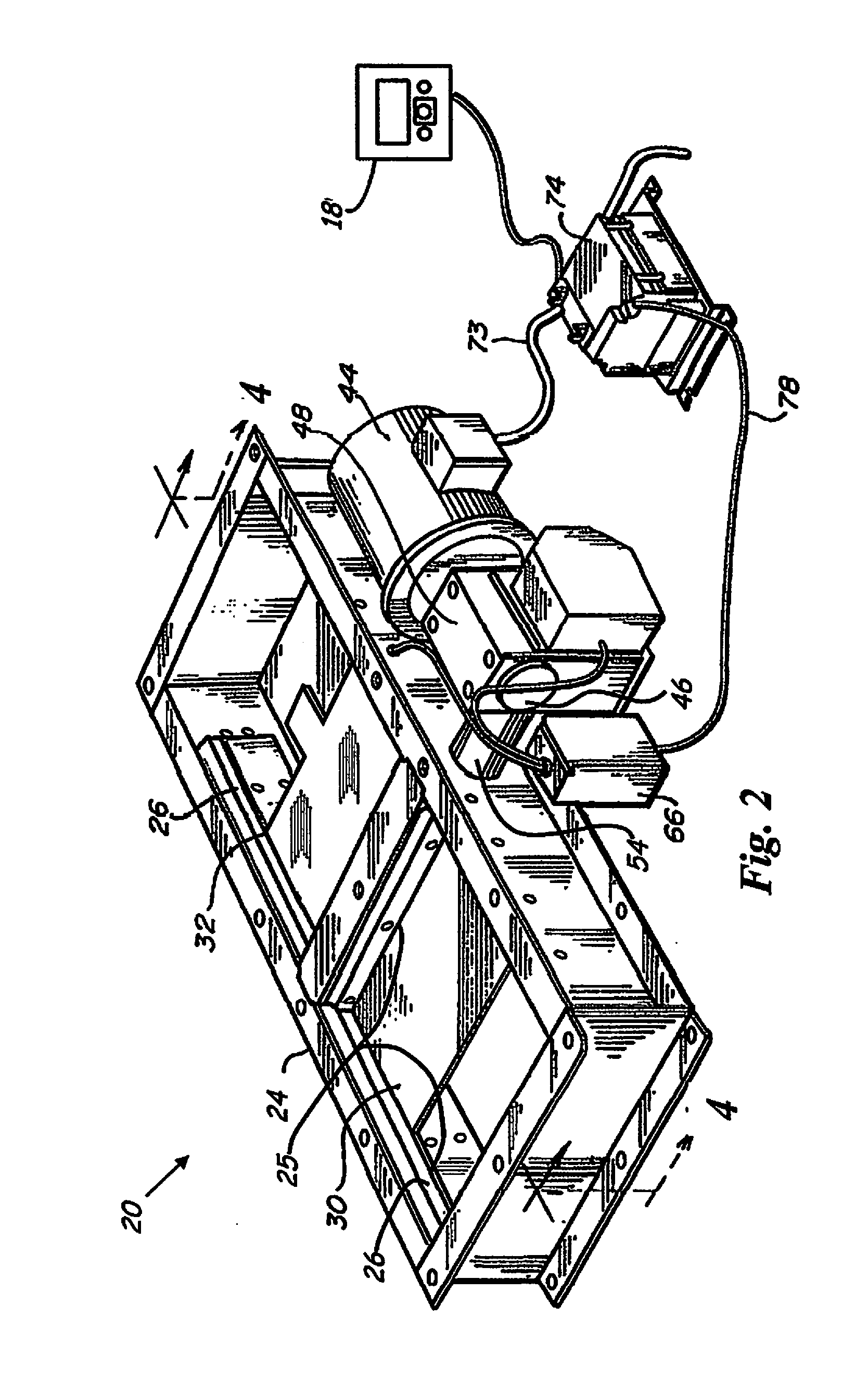

Mass flow grain monitor and method

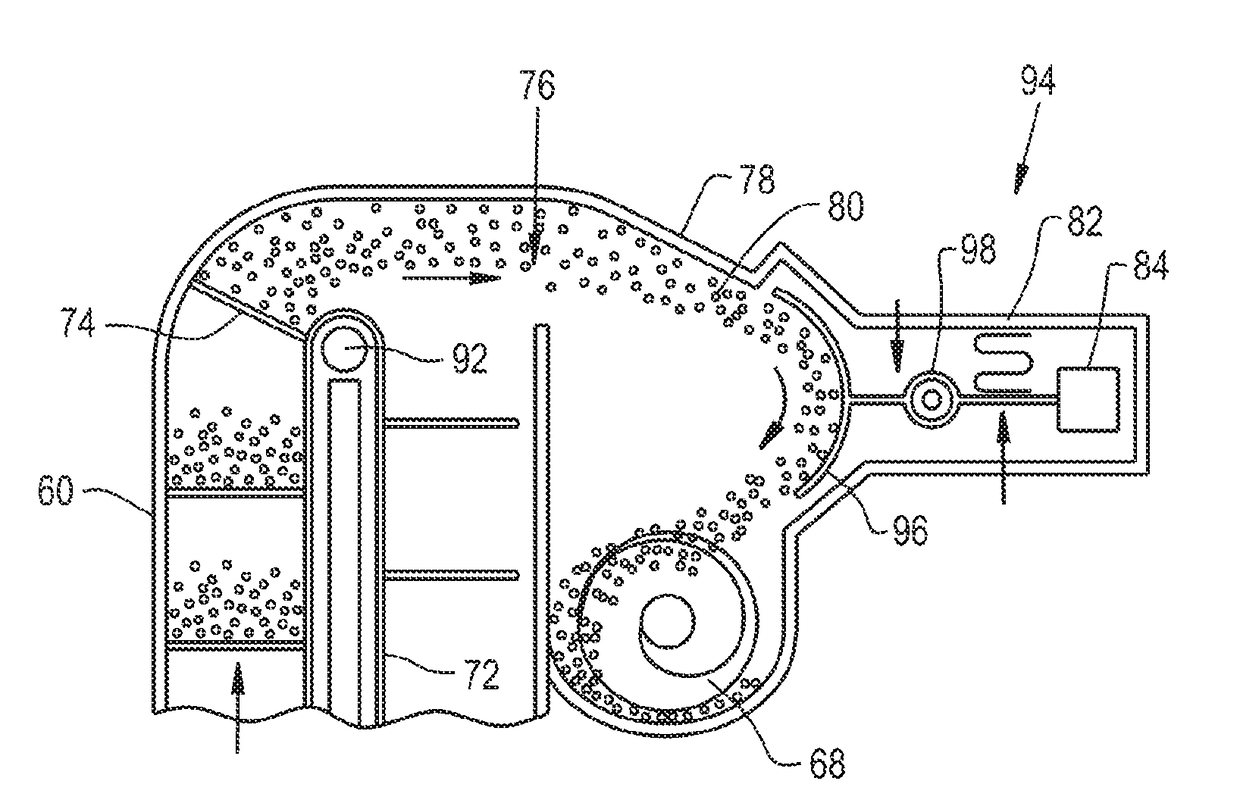

A mass flow grain monitor is located adjacent the upper end of the clean grain elevator assembly of a harvester and includes a load cell having a member that is subject to slight deformation under loads for use in generating an output signal that is proportional to the load. As the grain flow reaches the top of the elevator assembly, its direction is changed such that a centrifugal force is exerted by the moving flow that is proportional to the mass of the grain flow at that instant. Such centrifugal force is directed vertically against the deformable member of the load cell which is itself generally horizontally disposed when the harvester is on level ground so that the entire weight of the deformable member can be treated as tare and zeroed out of the system when it is calibrated with the harvester on level ground. Having the member generally horizontally disposed and measuring the force of the grain vertically causes a significant reduction in the amount of error introduced into the output from the monitor when the harvester encounters upsloping or downsloping hillside conditions.

Owner:AGCO CORP

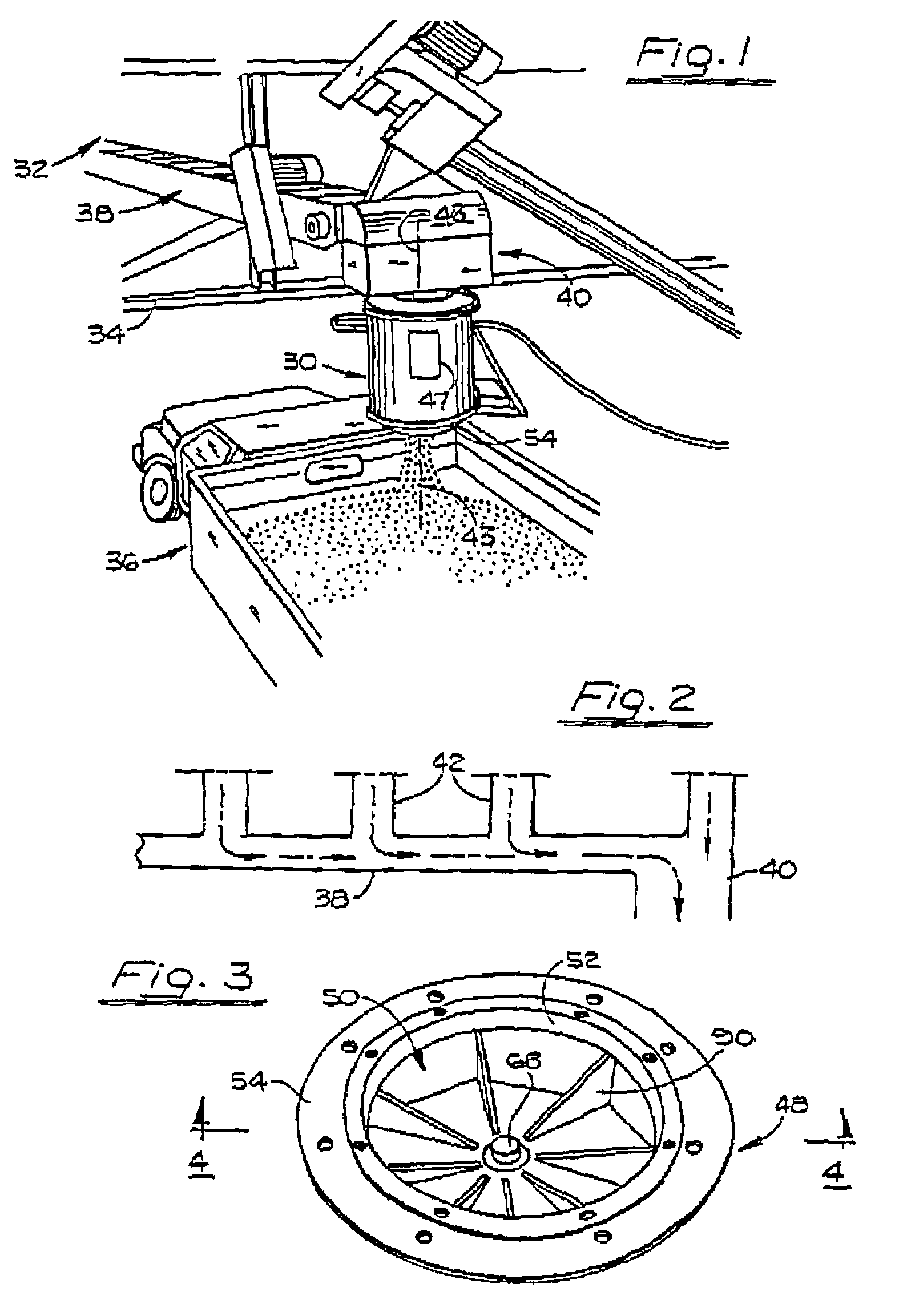

Seed treater

InactiveUS7273314B1Small sizeReduce manufacturing costLiquid surface applicatorsFlow mixersGrain elevatorEngineering

A drum for hanging from the ceiling constituting the floor of the second story of a grain elevator. The device is self-contained, and has top closure elements with a central feedhole, and a bottom closure element with a central discharge hole. It includes a rotary spreader and coaters, and an applicator, for spreading grains and mixing them, and for mixing fluid chemicals with the grains. Repeated mixing steps are performed. The grains are introduced into it from the second floor. It can receive the grains and chemicals from various sources including chutes from hopper bins, belts, and screws.

Owner:WHITED JERREL L

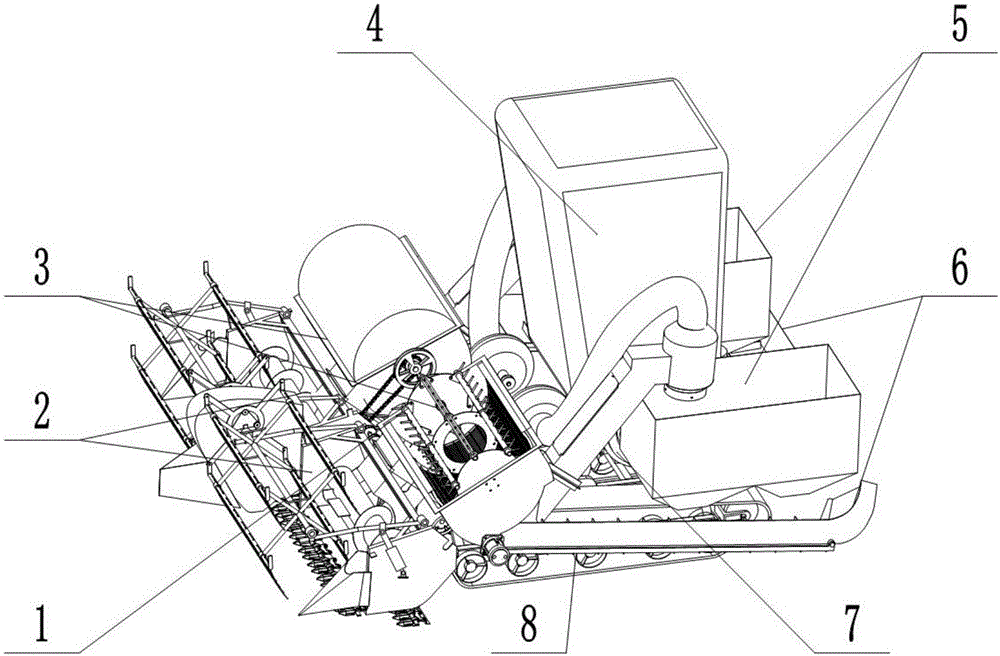

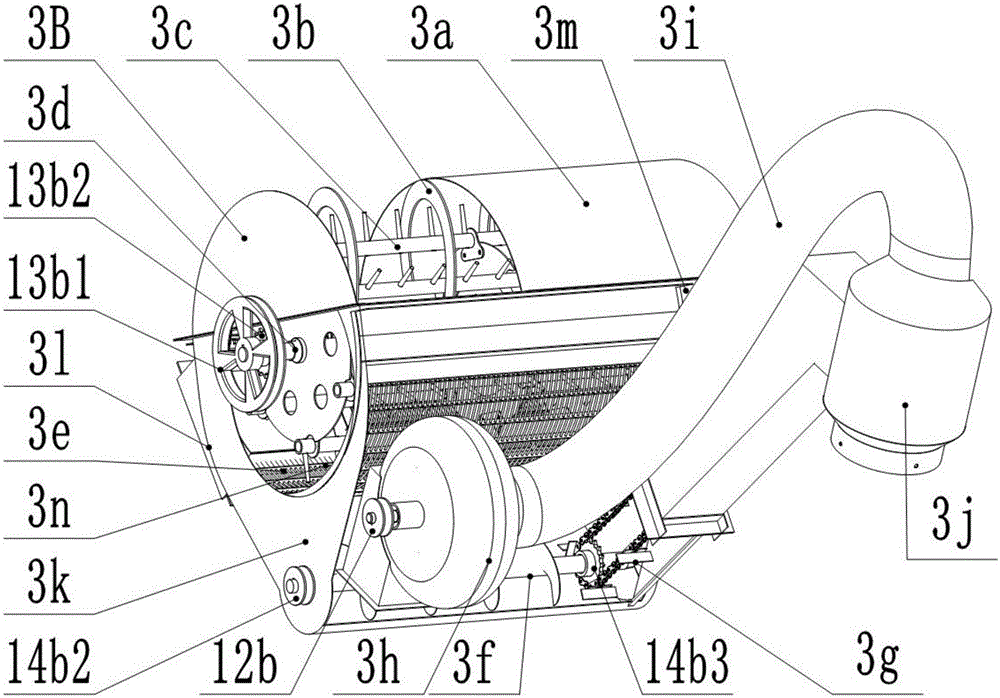

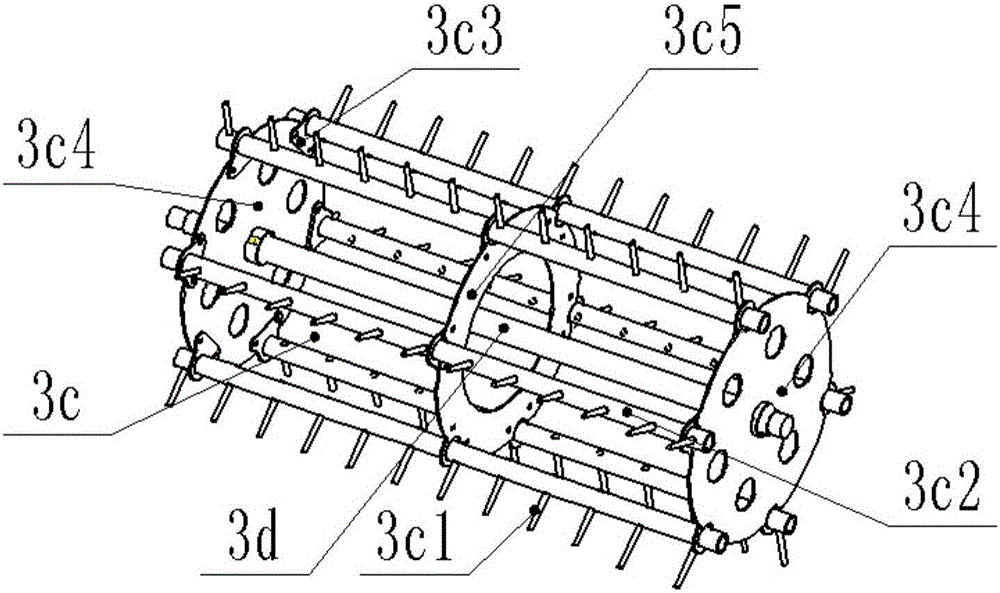

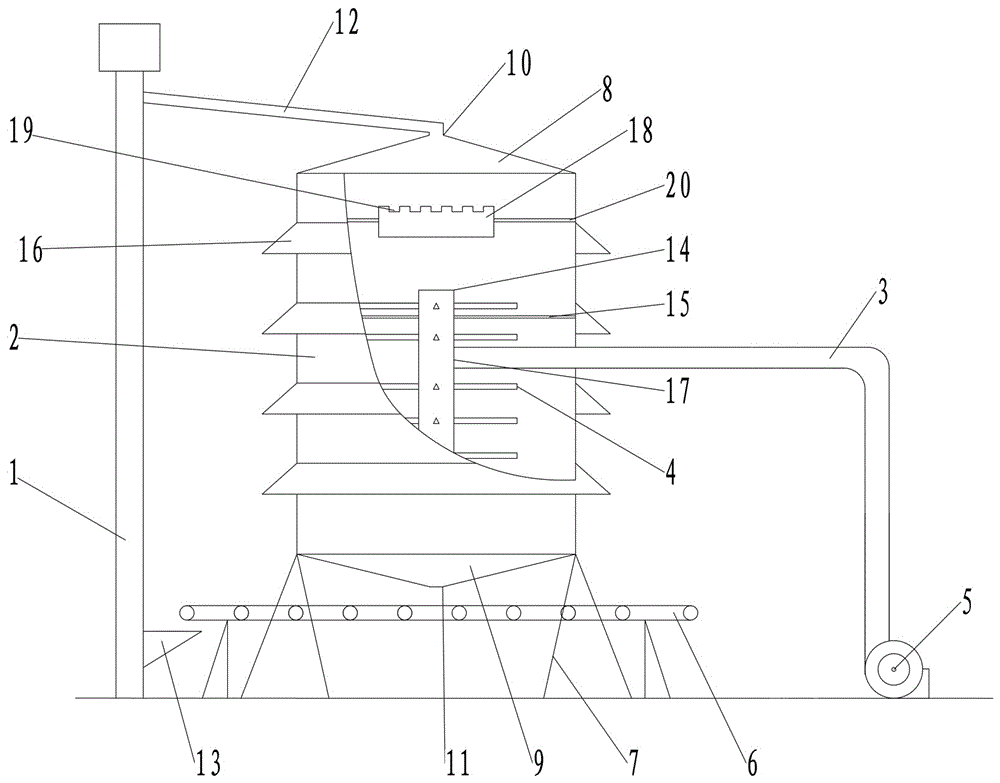

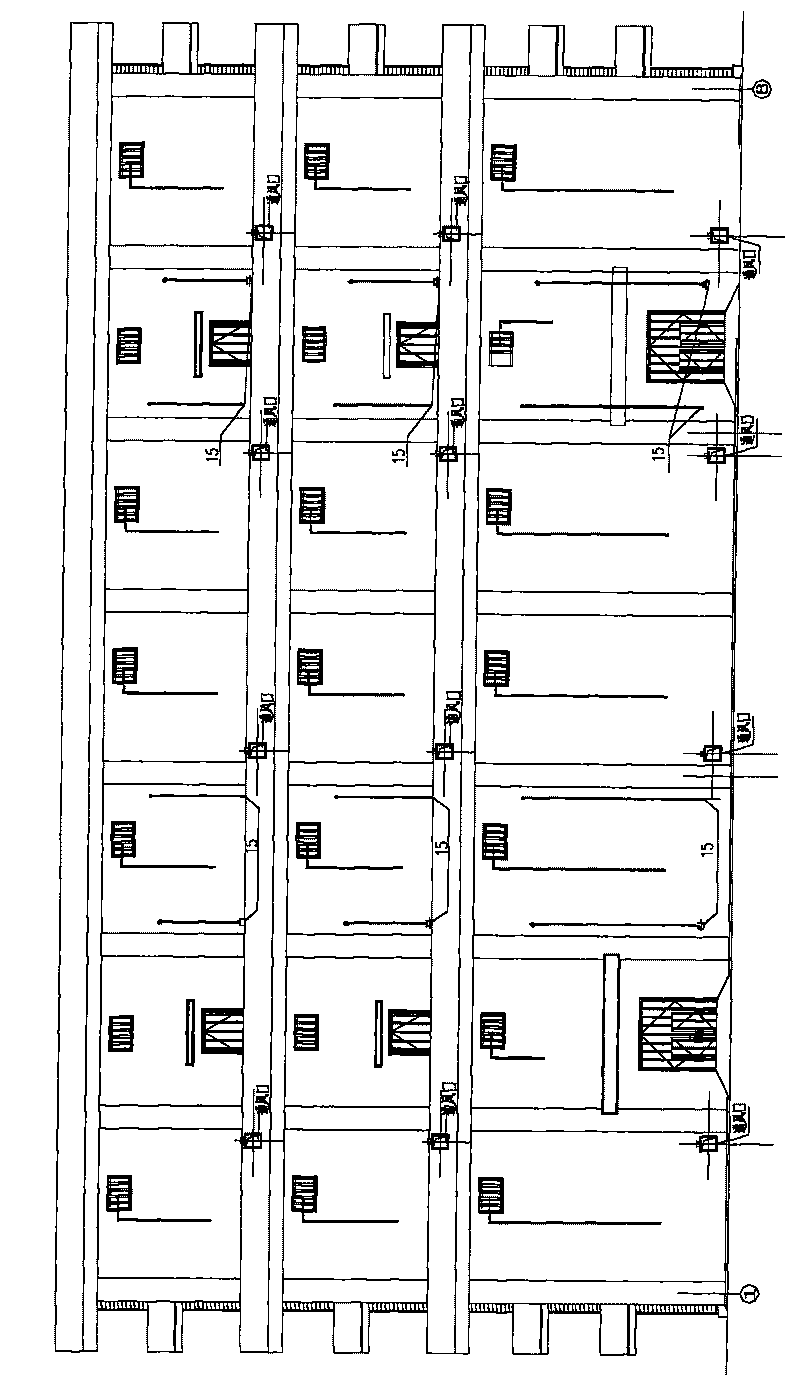

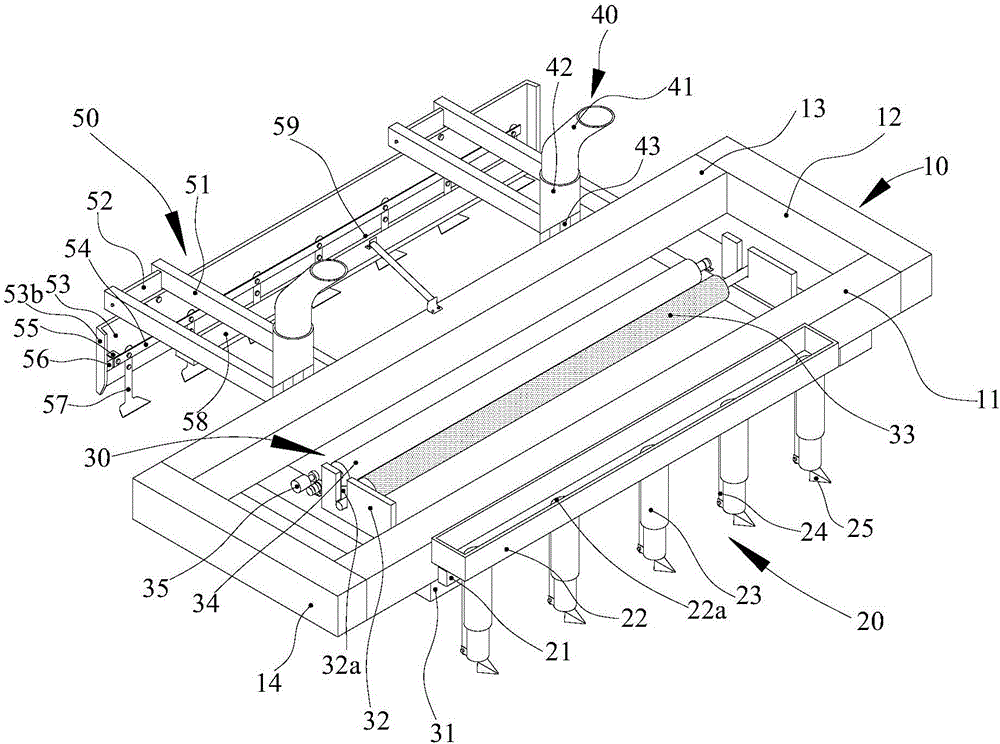

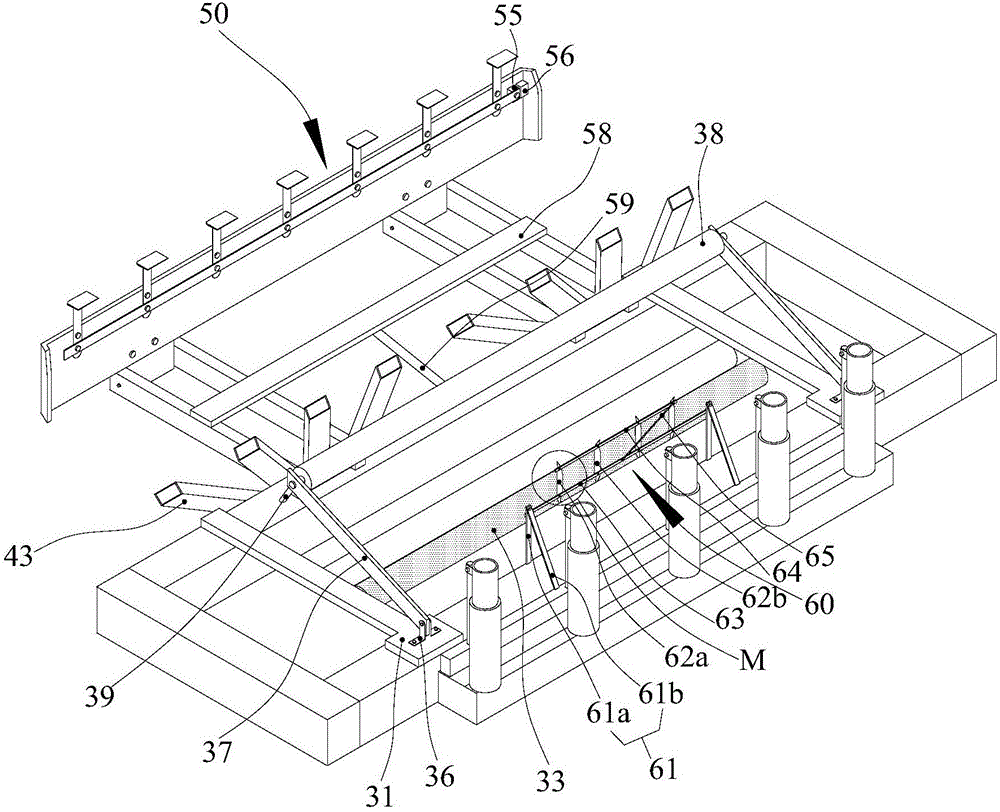

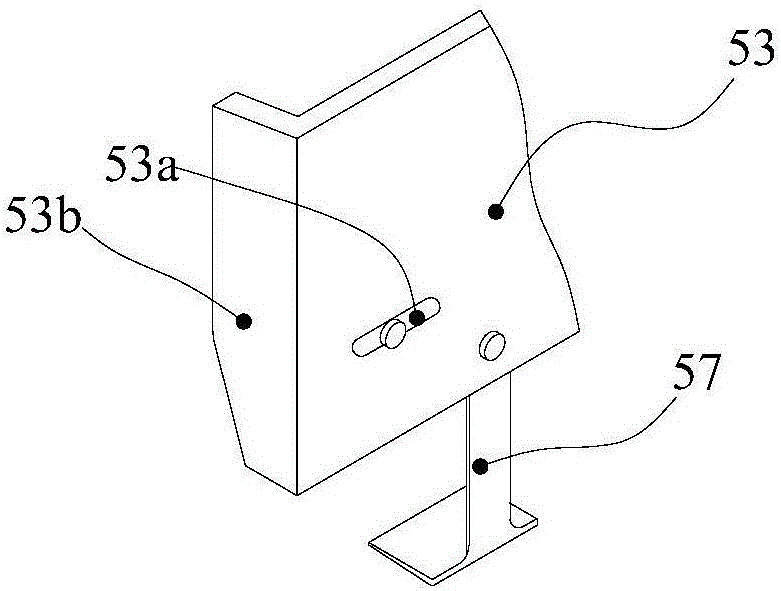

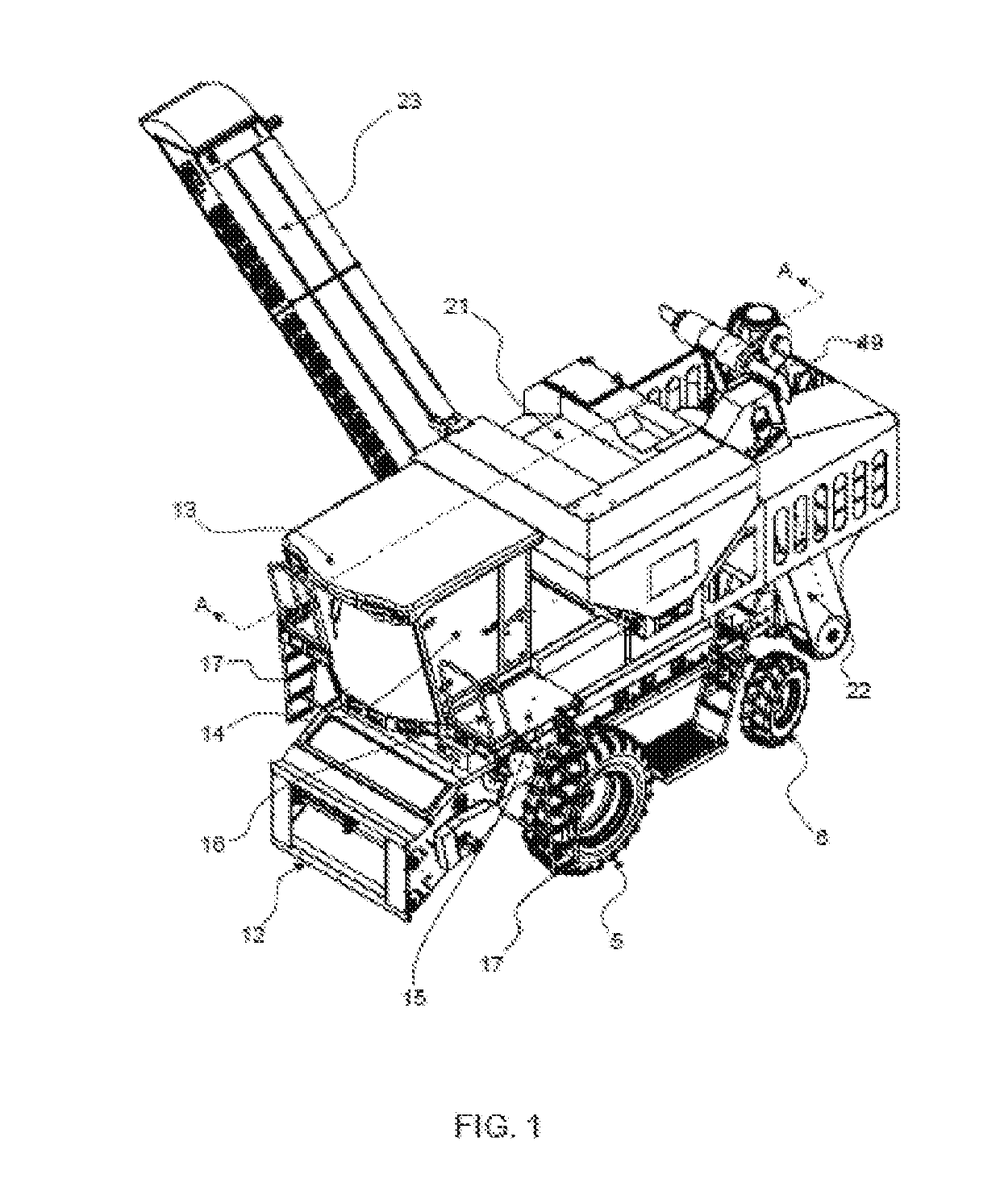

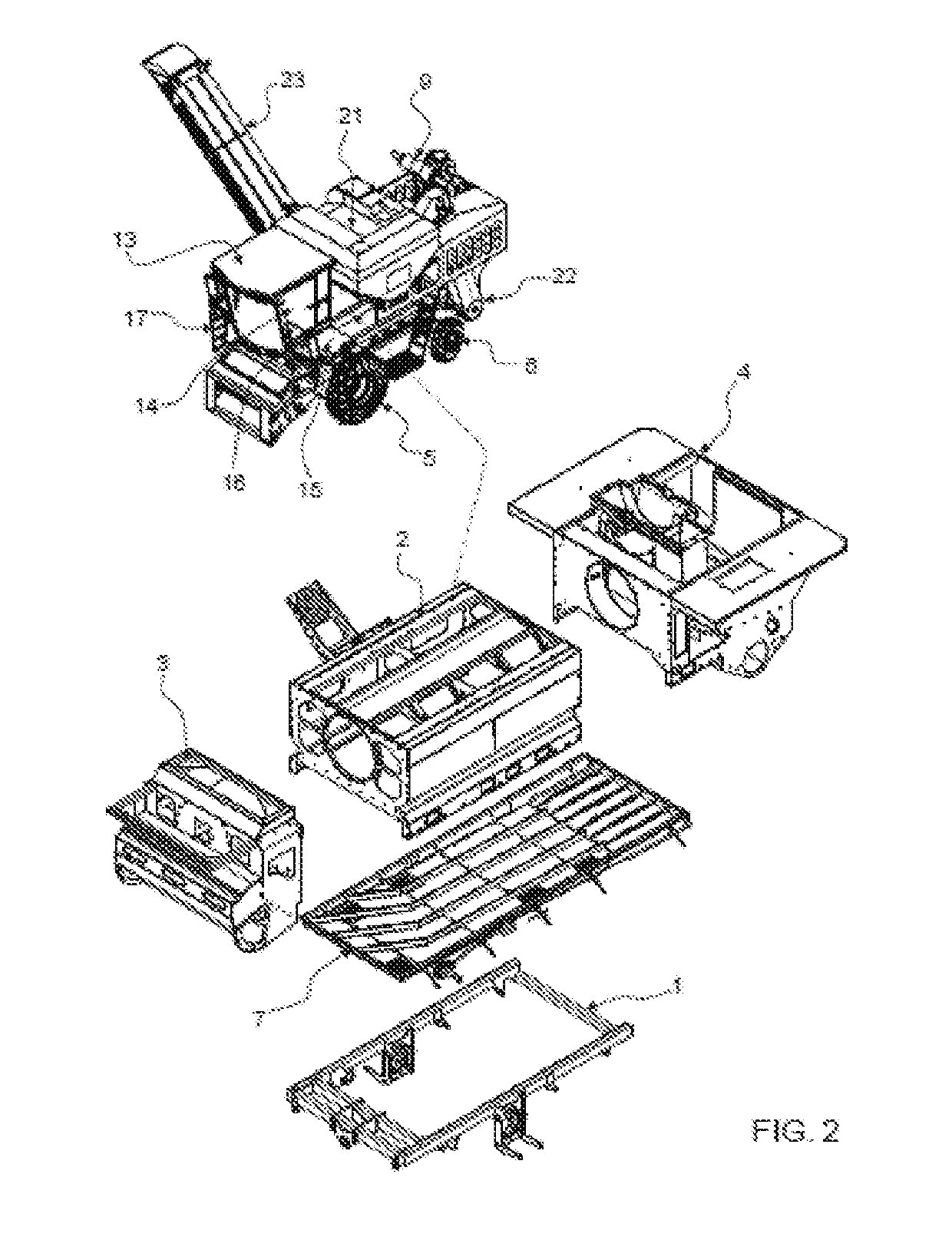

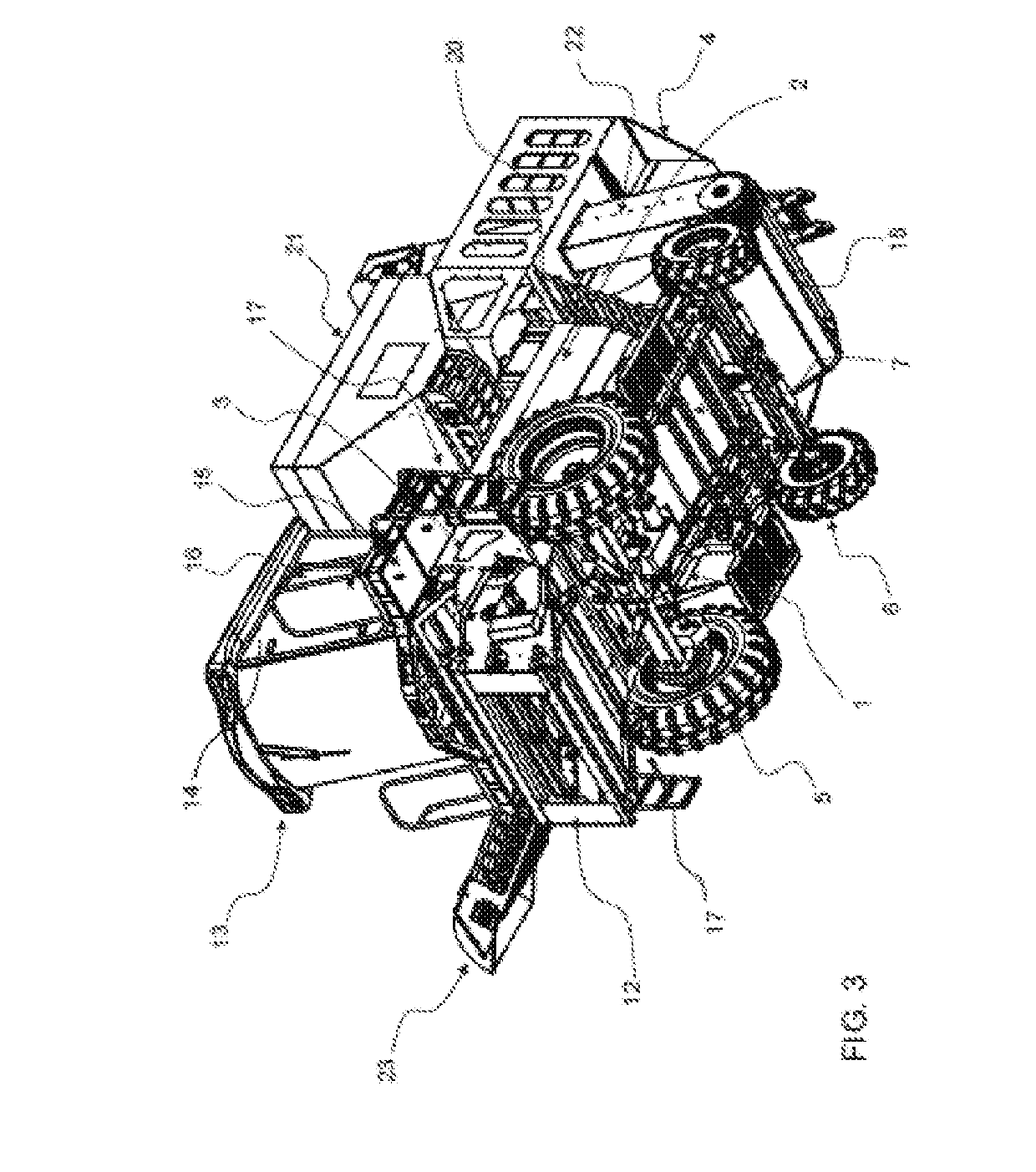

Dual-header dual-roller high-clearance rice harvesting machine

InactiveCN105940858AReduce lossesReduce the degree of rollingMowersThreshersGrain elevatorEngineering

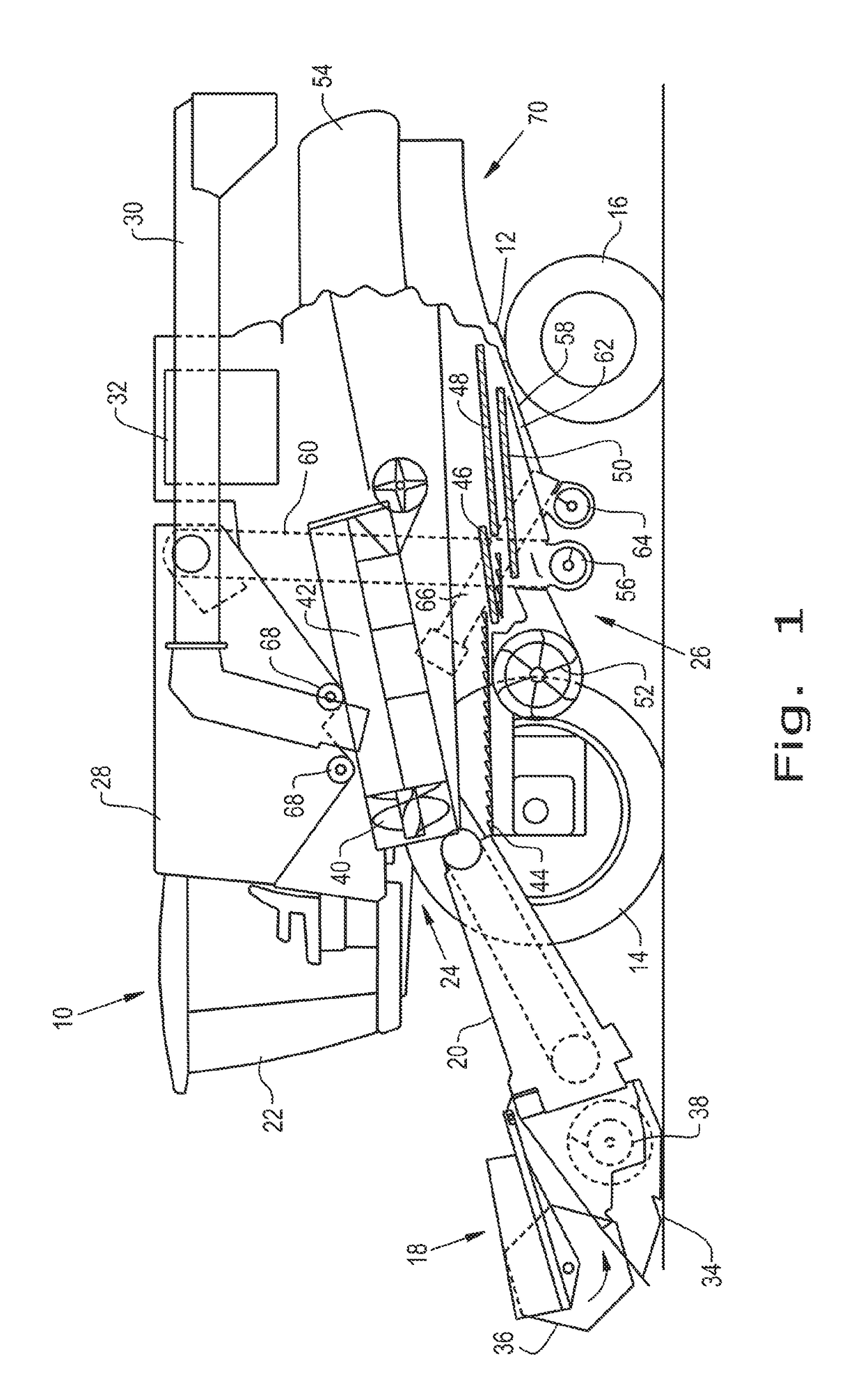

The invention discloses a dual-header dual-roller high-clearance rice harvesting machine which comprises a walking power system provided with a hydraulic continuously variable transmission and an engine, a high-clearance base disc provided with a walking device, a dual-roller cleaning assembly arranged on the high-clearance base disc, a dual ear collecting header located at the front end of the dual-roller cleaning assembly, two scraper-type straw conveying devices located at left and right straw outlets and installed on a high-clearance base disc rack, a driving cab and a control console located at the upper end of the engine, a pair of grain elevators arranged on the two sides of the driving cab and the control console, and a dual-layer lower cutting tool arranged below a shell of the dual ear collecting header. According to the dual-header dual-roller high-clearance rice harvesting machine, the operation height of the dual-layer lower cutting tool can be adjusted, the harvesting machine is applicable to the crop harvesting operation with the requirement for the stubble height, only ear heads are cut down, the working efficiency can be effectively improved, the threshing and cleaning power consumption are lowered, discharged crushed straw is laid on a caterpillar band to be ground, the phenomenon that straw covers stubble is avoided, and the harvesting machine is applicable to common rice harvesting operation.

Owner:HUAZHONG AGRI UNIV

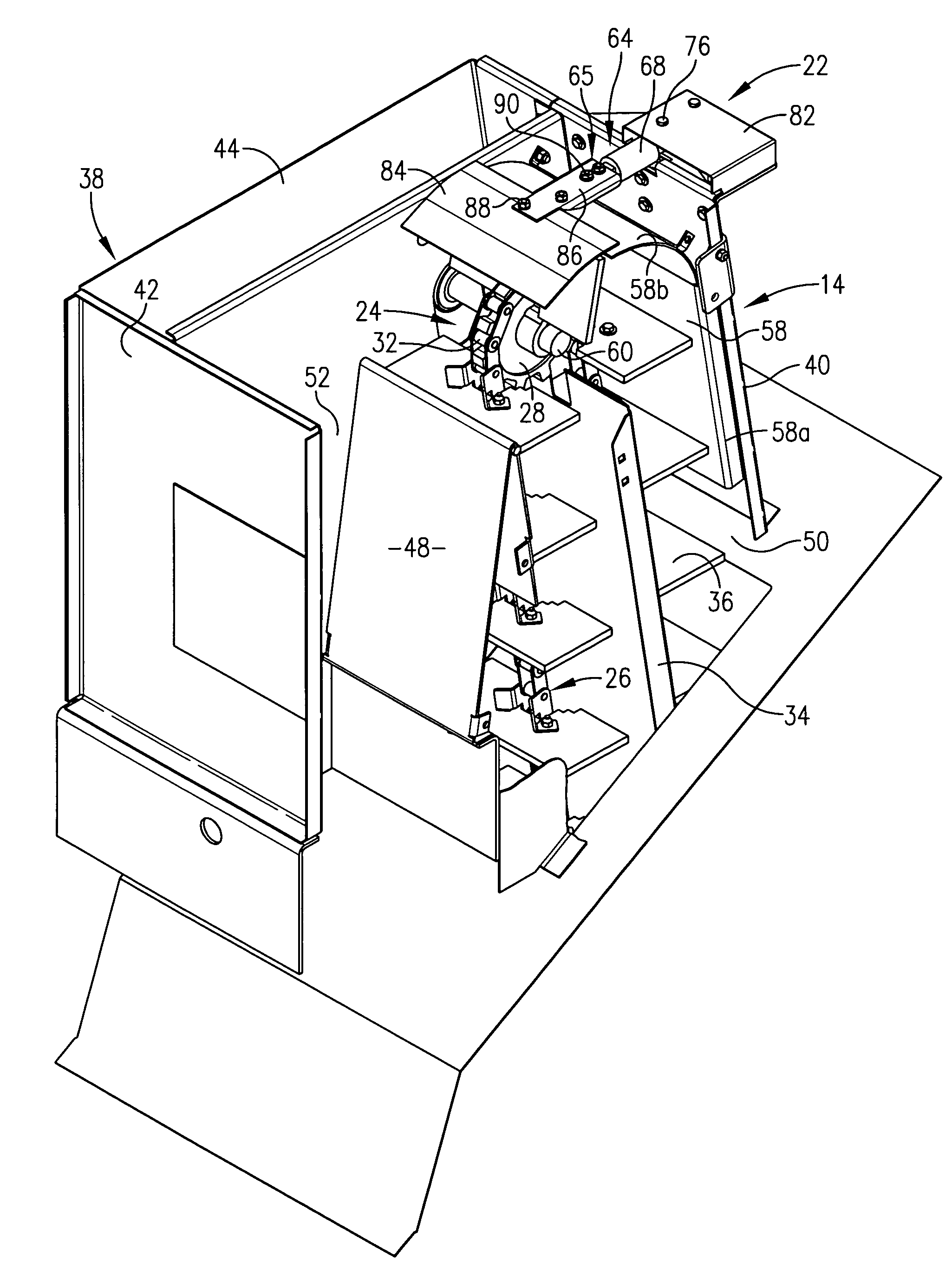

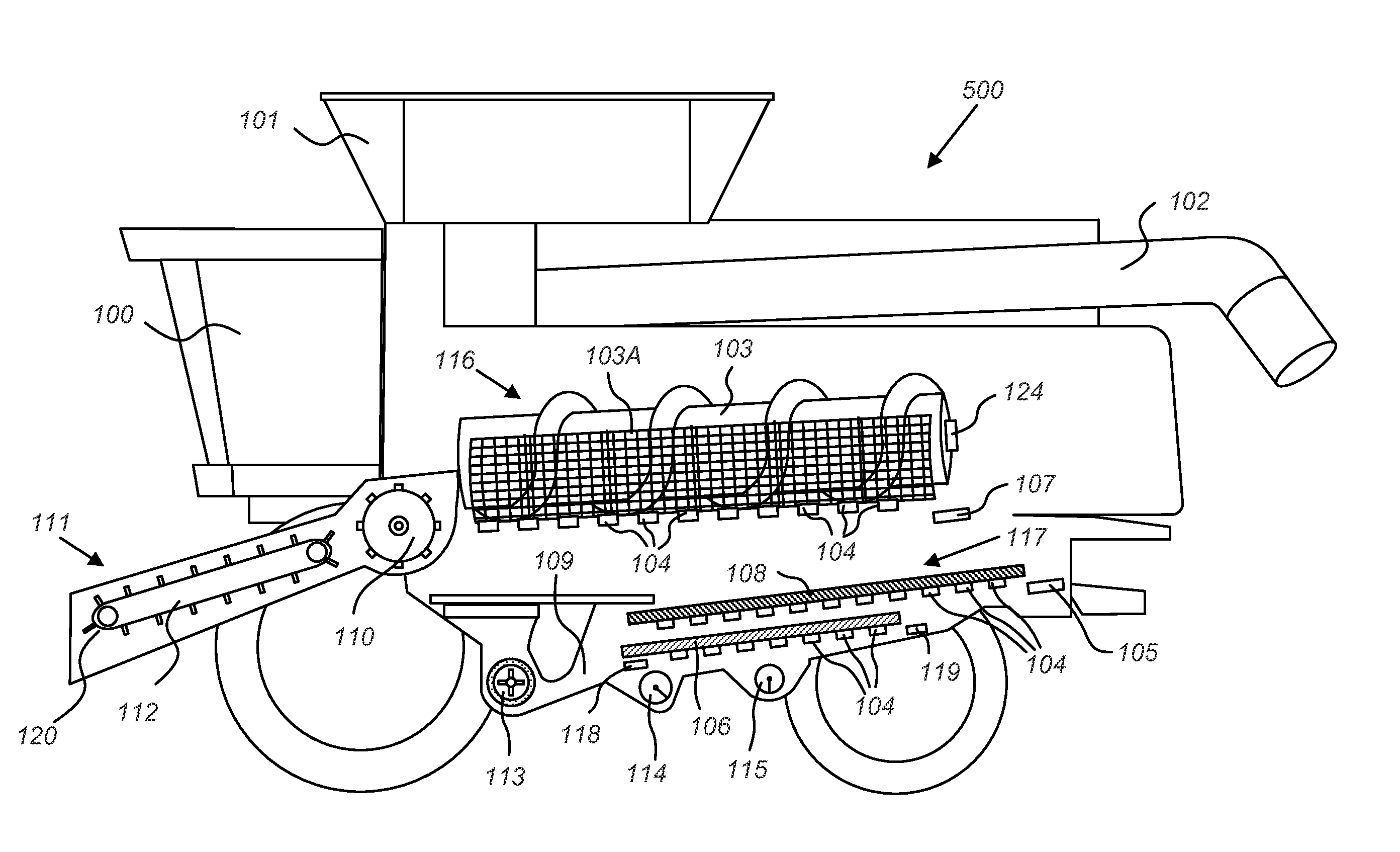

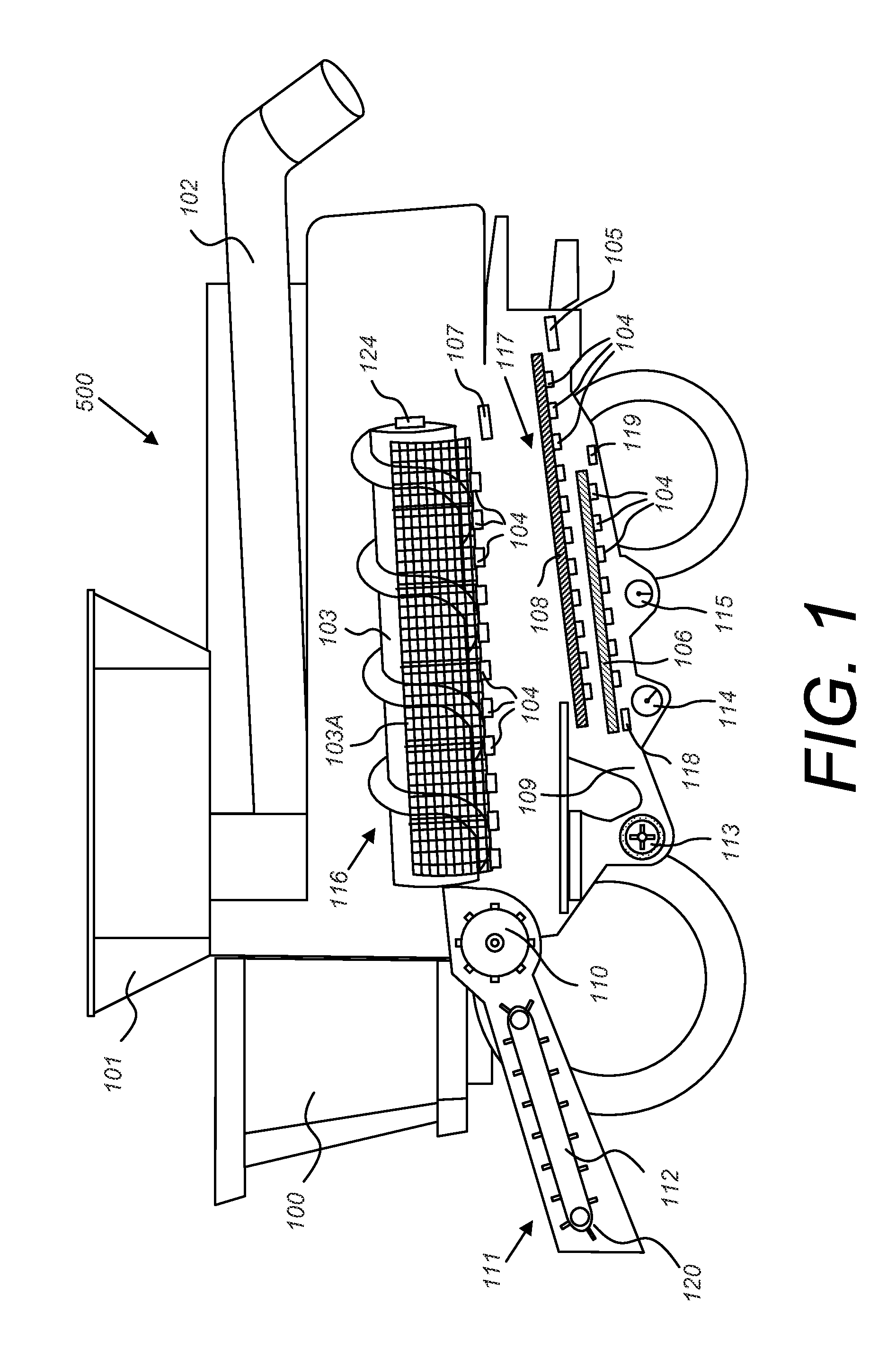

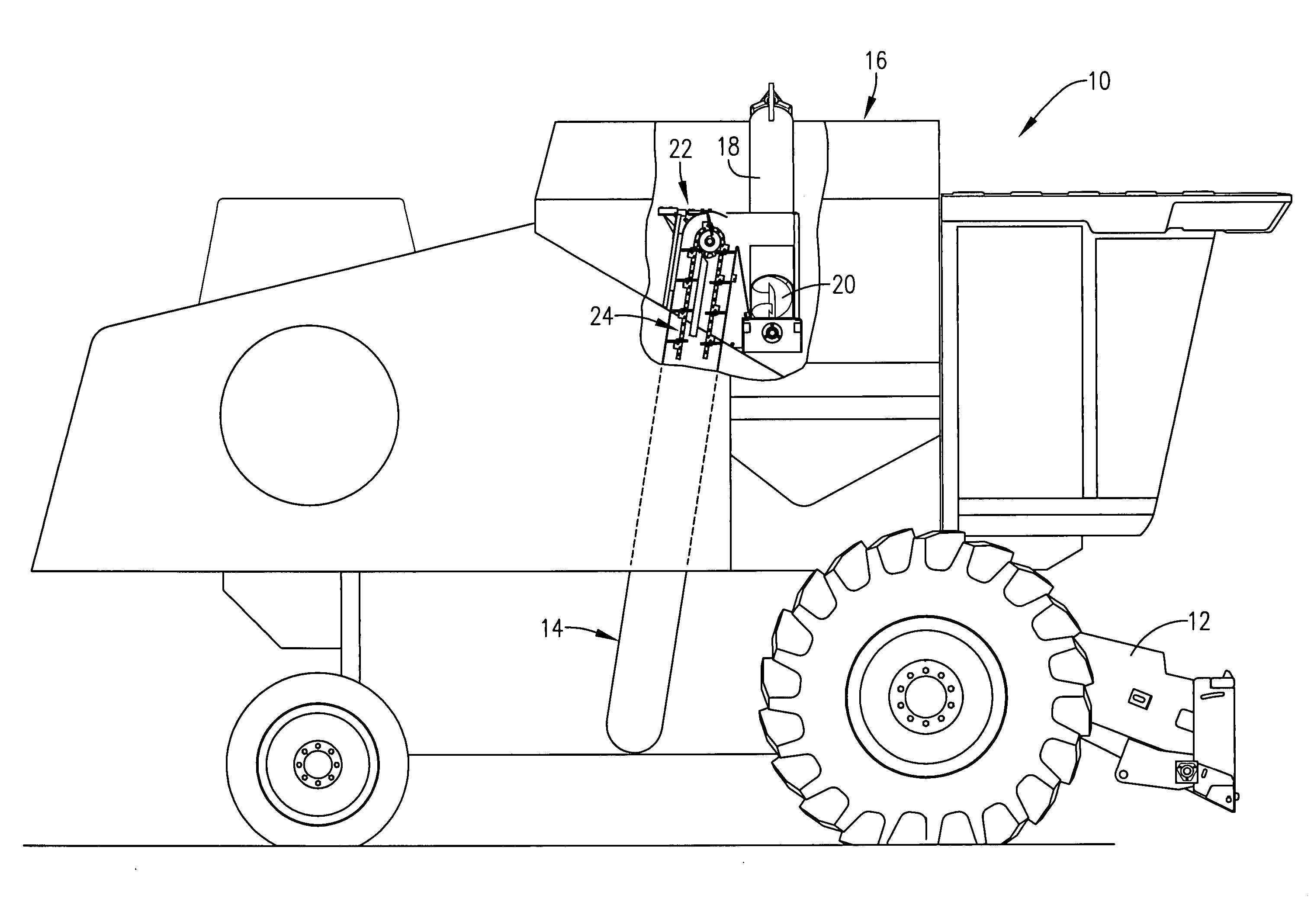

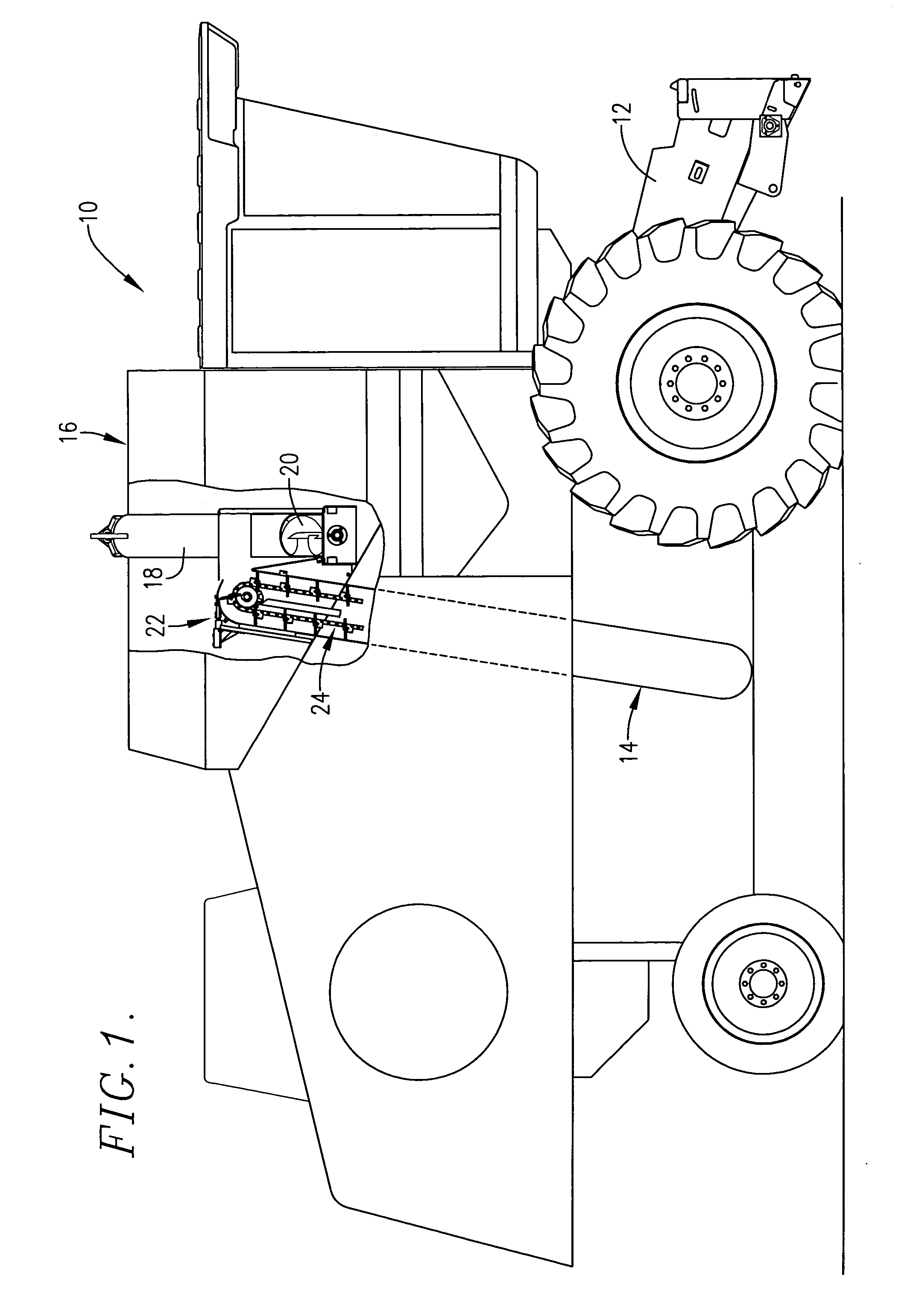

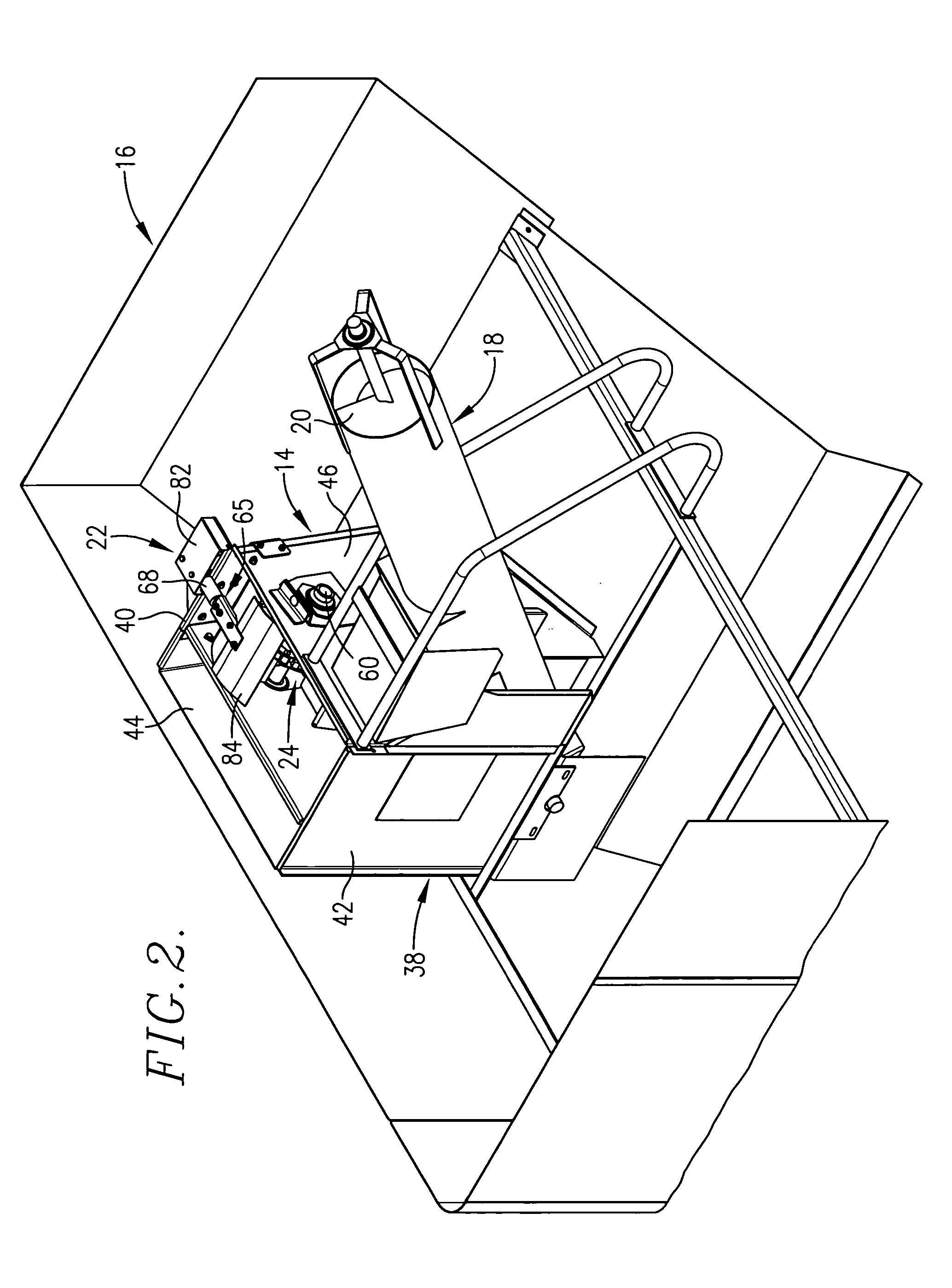

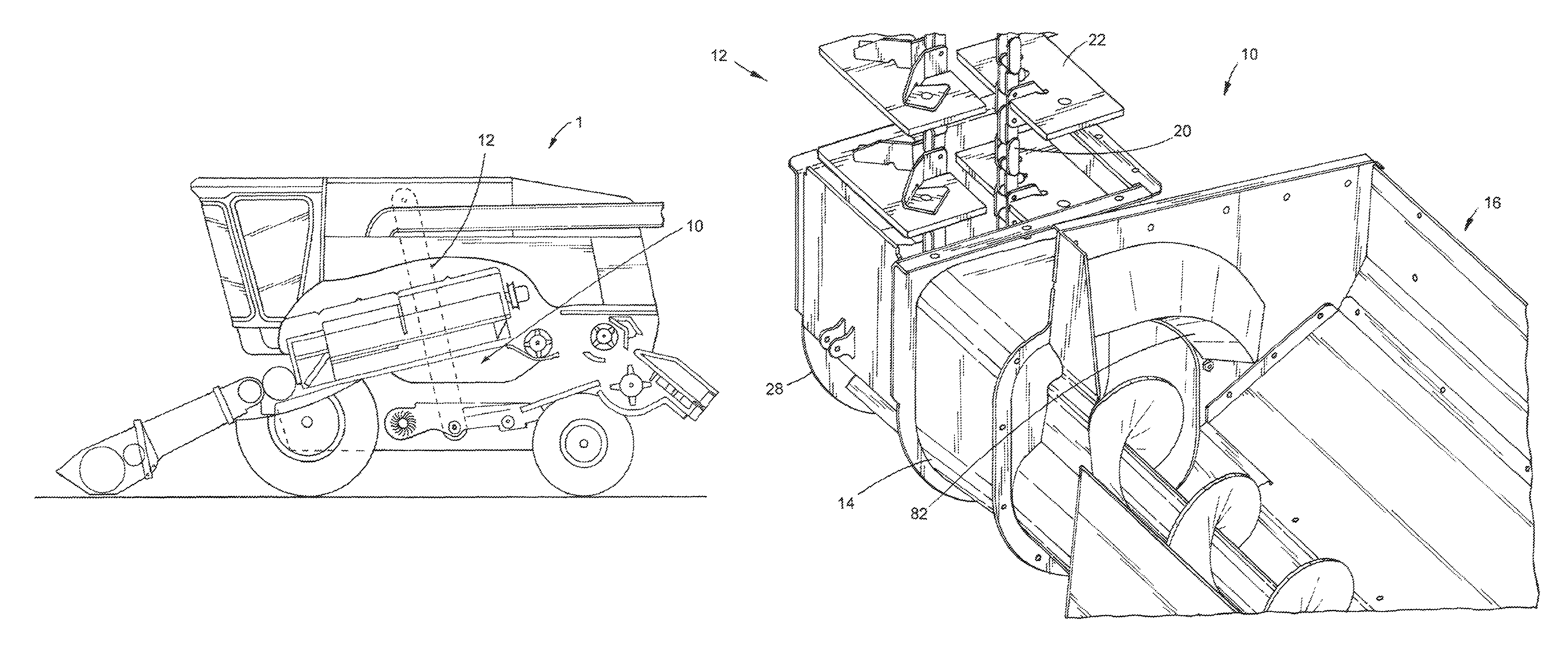

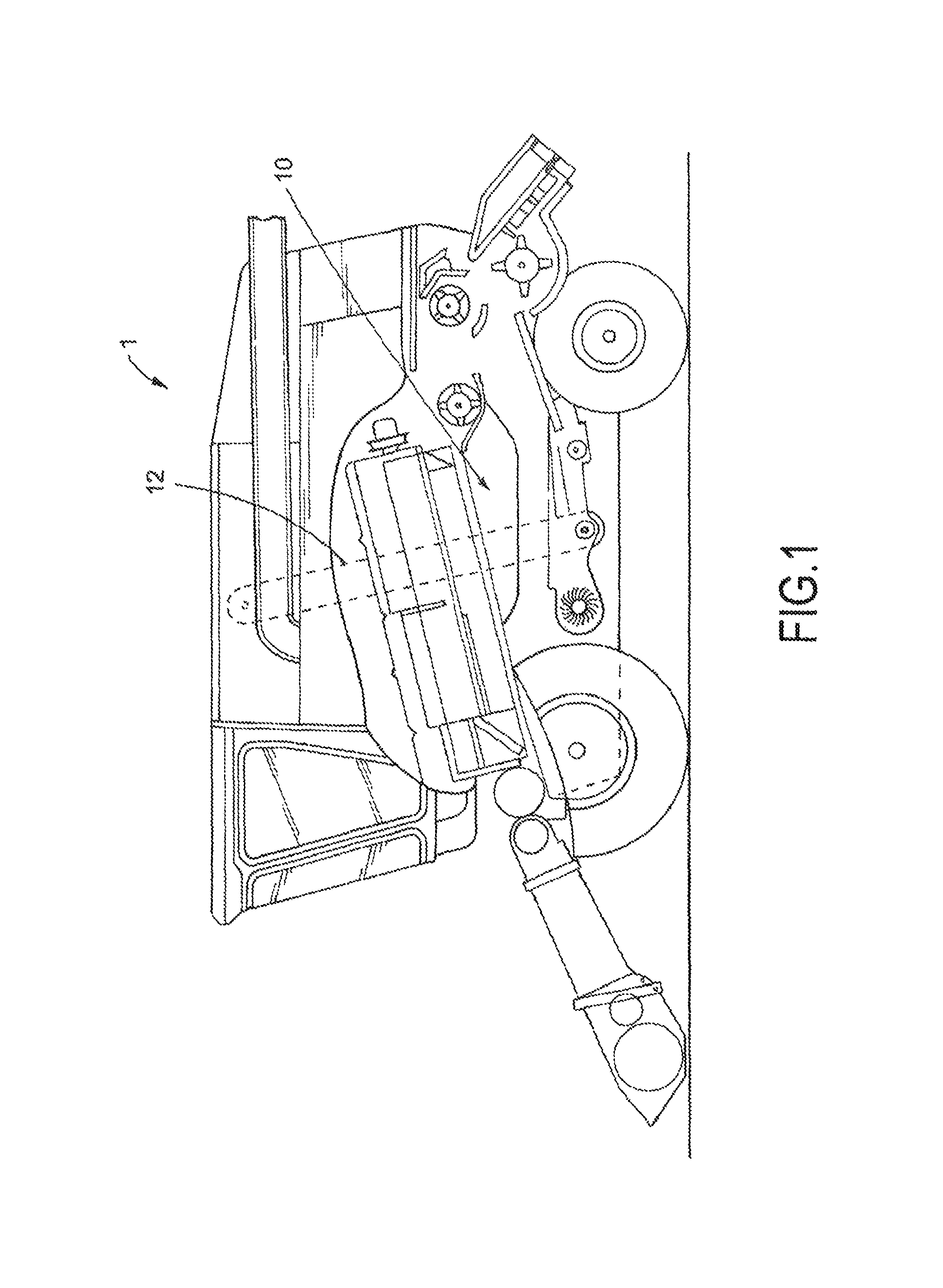

Combine Harvester Improvement

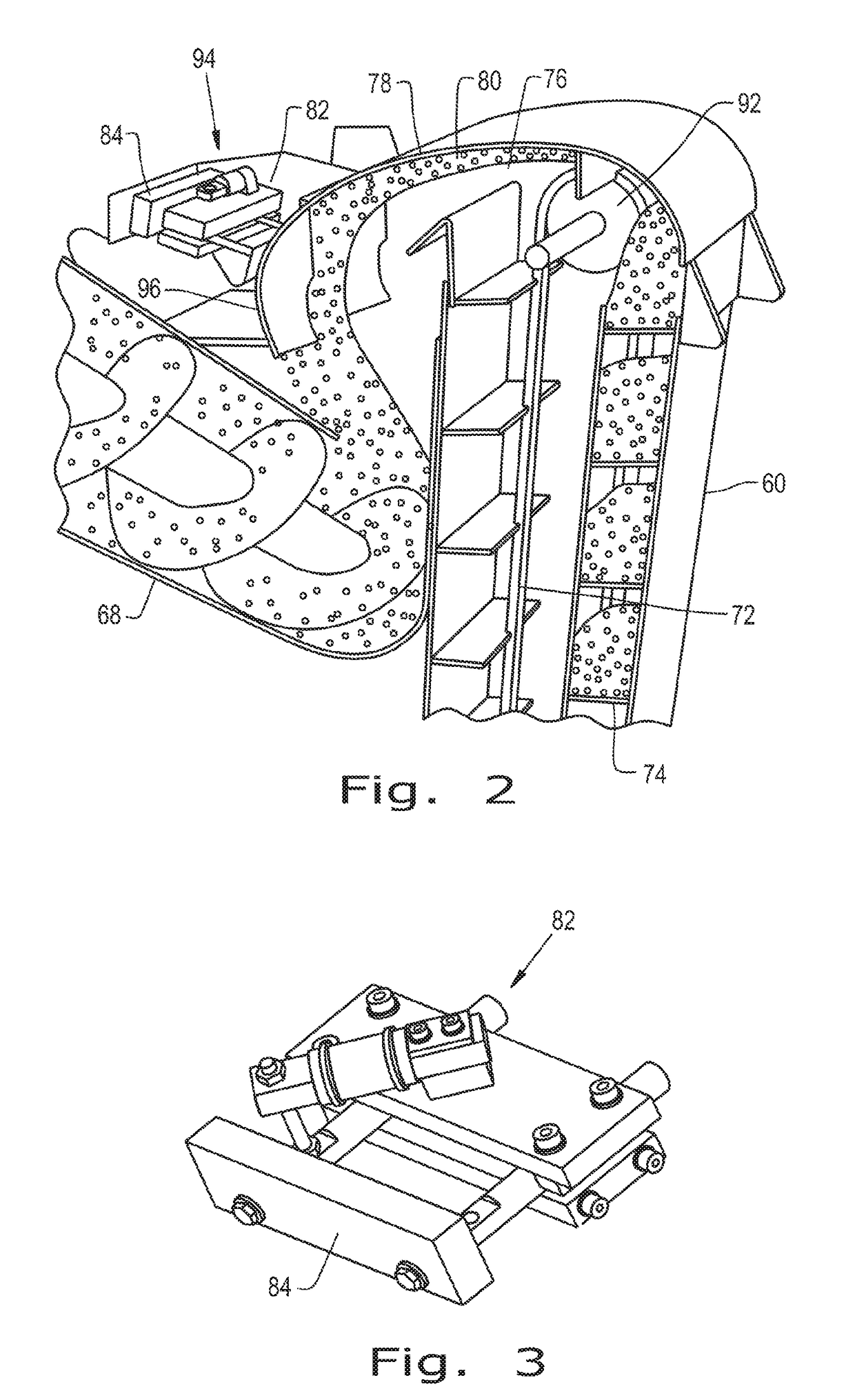

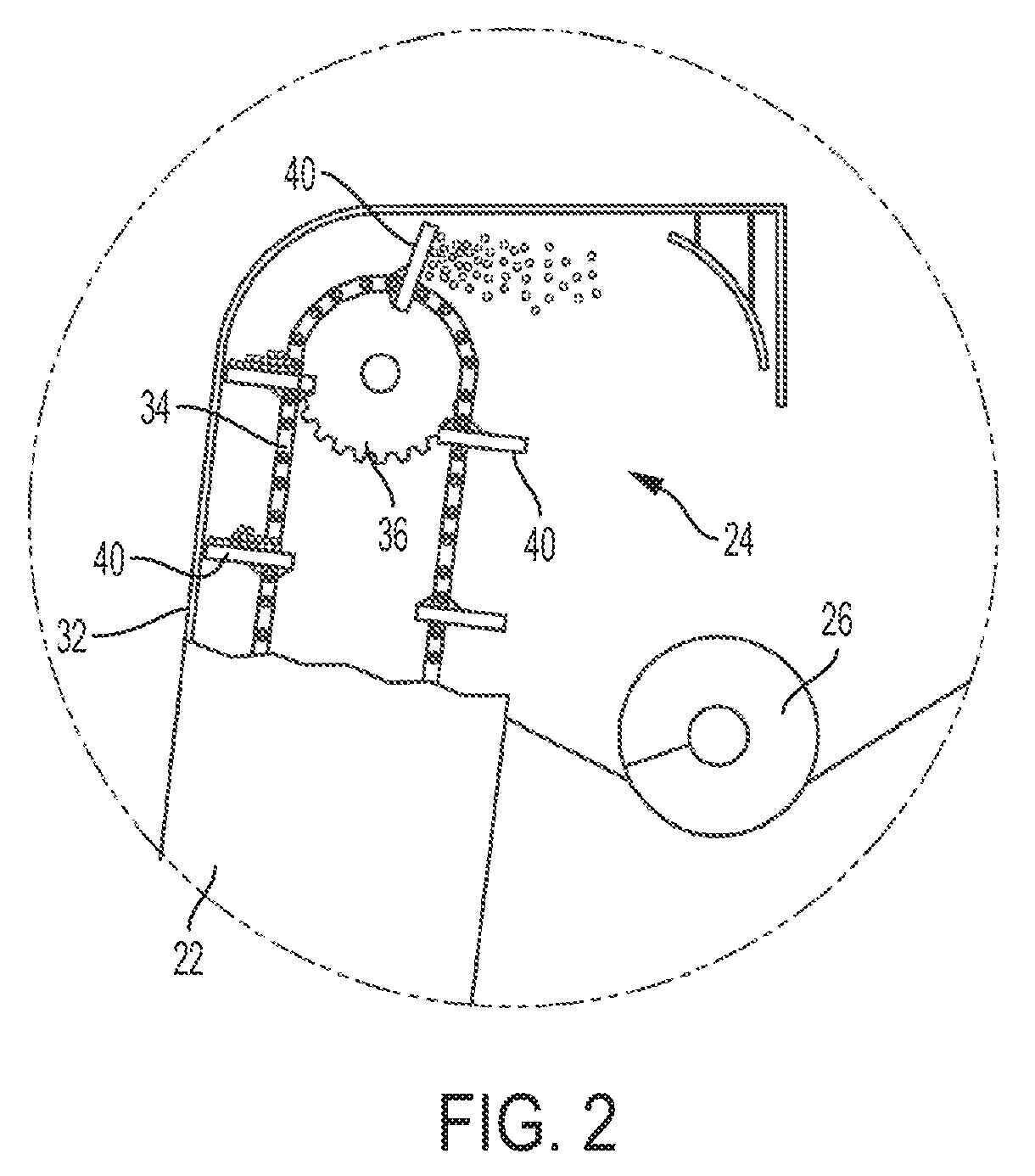

A grain mass flow sensor assembly of an agricultural harvester has a continuously curved sensor plate positioned to receive a grain flow from an exit of the grain elevator. The continuously curved sensor plate is configured to change the direction of the grain flow in order to generate a reaction force for measuring the grain mass flow rate of the grain flow. The continuously curved sensor plate is attached to a sensor plate to load cell mounting bracket. The sensor plate to load cell mounting bracket is attached to a single point load cell torque or moment compensated force transducer at a single mounting point. The single point load cell torque or moment compensated force transducer produces a mass flow sensor signal that is proportionate to the grain mass flow rate.

Owner:BLUE LEAF I P INC

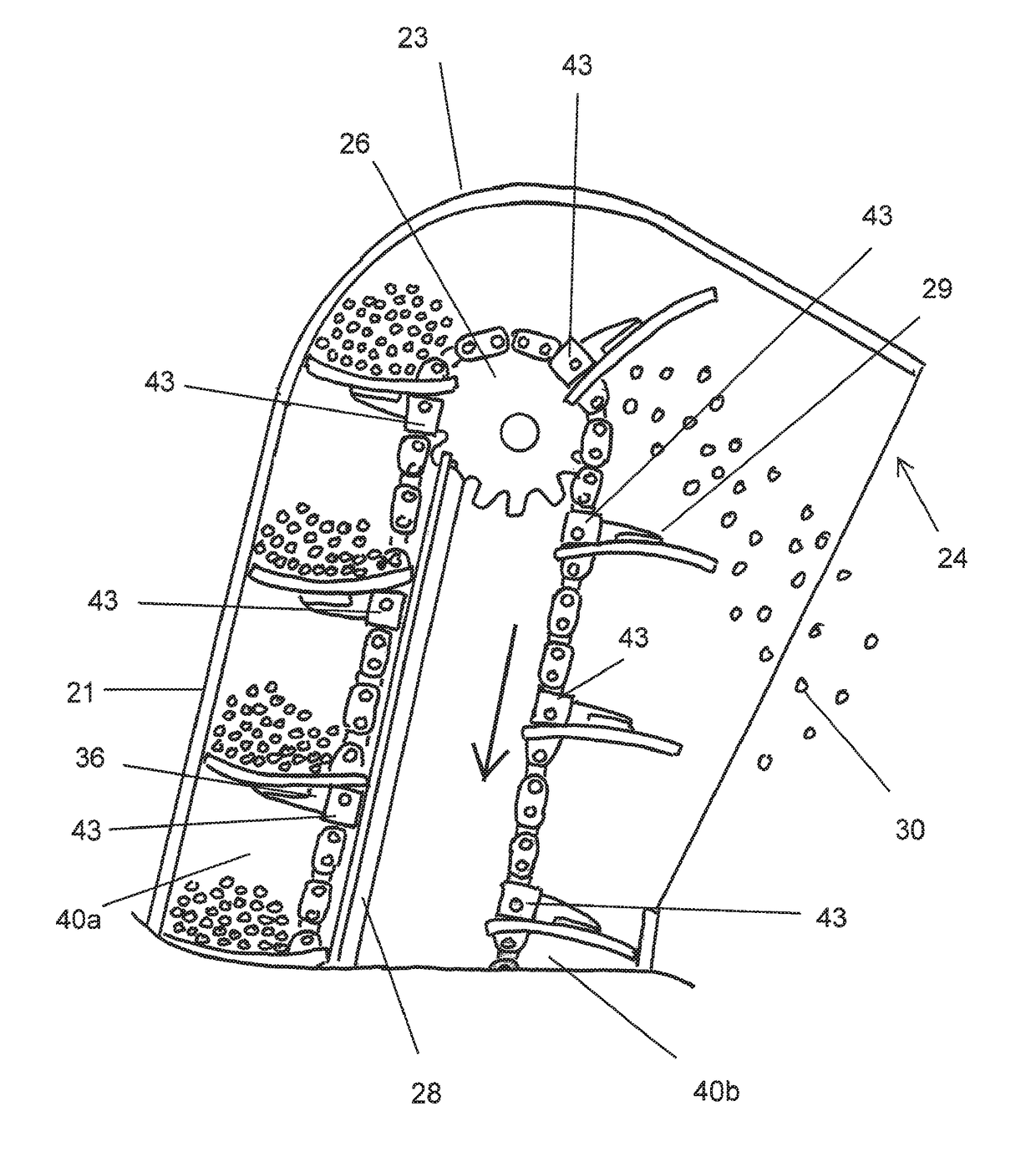

Chain guide for paddle-type conveyor

A guide that fits over a paddle link in a paddle-type elevator in a harvester combine grain elevator. The plastic guide provides a wide, low-friction surface that rides on the intermediate wall of a grain elevator, thereby keeping the paddle links from rubbing against and causing wear to the intermediate wall. The guide also serves to inhibit the paddle from tipping back, thereby preventing the concentration of force by one corner of a paddle link against the intermediate wall. The guide al so helps maintain the correct orientation of flexible paddle against the inside of the elevator housing, thereby inhibiting the paddle from tipping back and leaking grain back into the upward path of the conveyor. The plastic guide also reduces noise caused by the metal parts of a paddle-type elevator from coming into contact.

Owner:KOPF KEITH

Load-based yield sensor

A method of estimating the mass of crop entering into a grain tank on a harvesting machine, comprising the steps of mounting a load sensor on the upper bearing of a conveyor belt moving crop through the clean grain elevator into the grain tank, connecting the load sensor to a processor, using the load sensor to measure a load on the conveyor belt when no crop is present in the clean grain elevator, and also when crop is moving through the clean grain elevator, and comparing the load with no crop present to the load when crop is present to estimate the mass of crop moving through the clean grain elevator.

Owner:INTELLIGENT AGRI SOLUTIONS

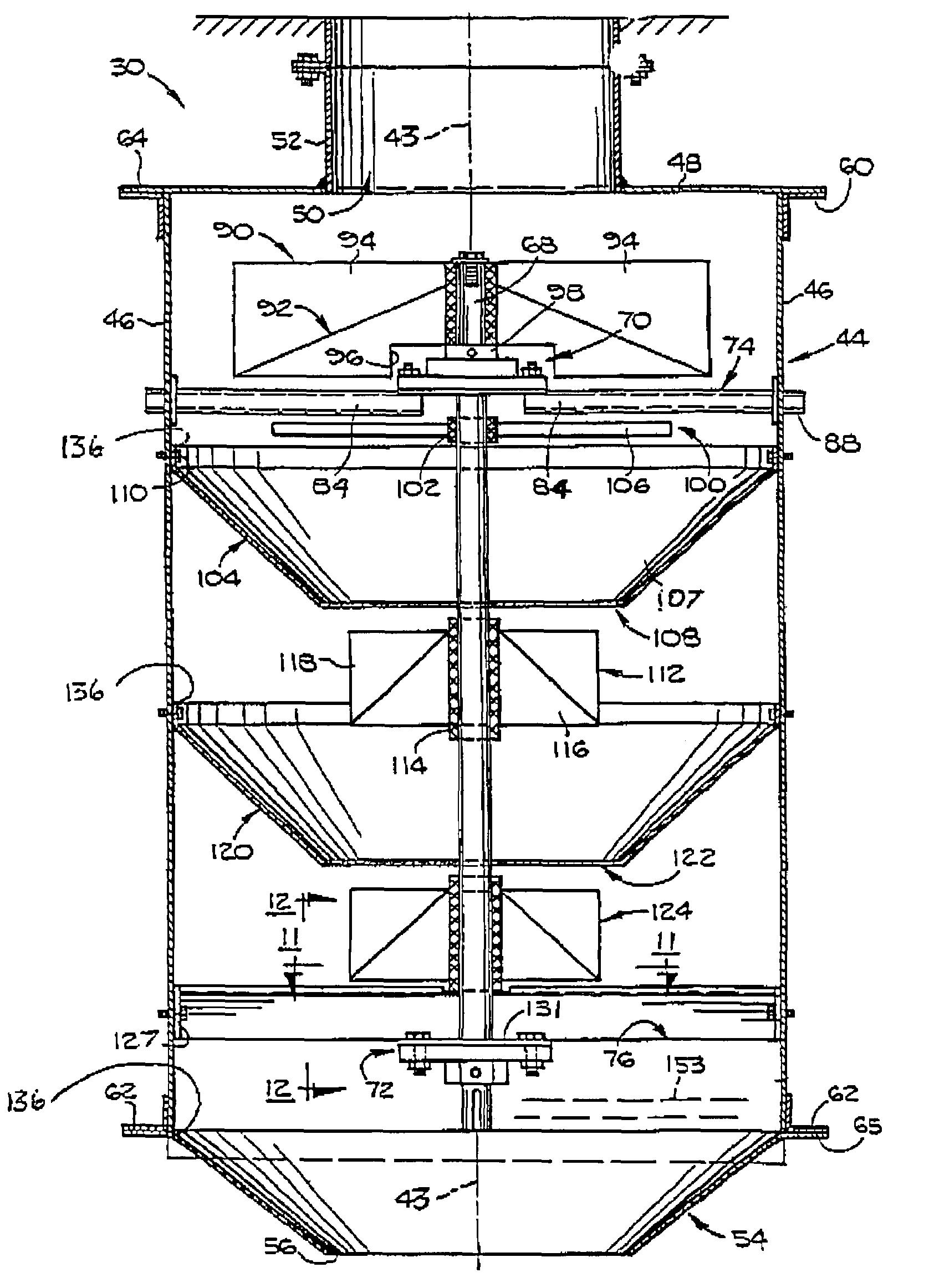

Mass flow grain monitor and method

A mass flow grain monitor is located adjacent the upper end of the clean grain elevator assembly of a harvester and includes a load cell having a member that is subject to slight deformation under loads for use in generating an output signal that is proportional to the load. As the grain flow reaches the top of the elevator assembly, its direction is changed such that a centrifugal force is exerted by the moving flow that is proportional to the mass of the grain flow at that instant. Such centrifugal force is directed vertically against the deformable member of the load cell which is itself generally horizontally disposed when the harvester is on level ground so that the entire weight of the deformable member can be treated as tare and zeroed out of the system when it is calibrated with the harvester on level ground. Having the member generally horizontally disposed and measuring the force of the grain vertically causes a significant reduction in the amount of error introduced into the output from the monitor when the harvester encounters upsloping or downsloping hillside conditions.

Owner:AGCO CORP

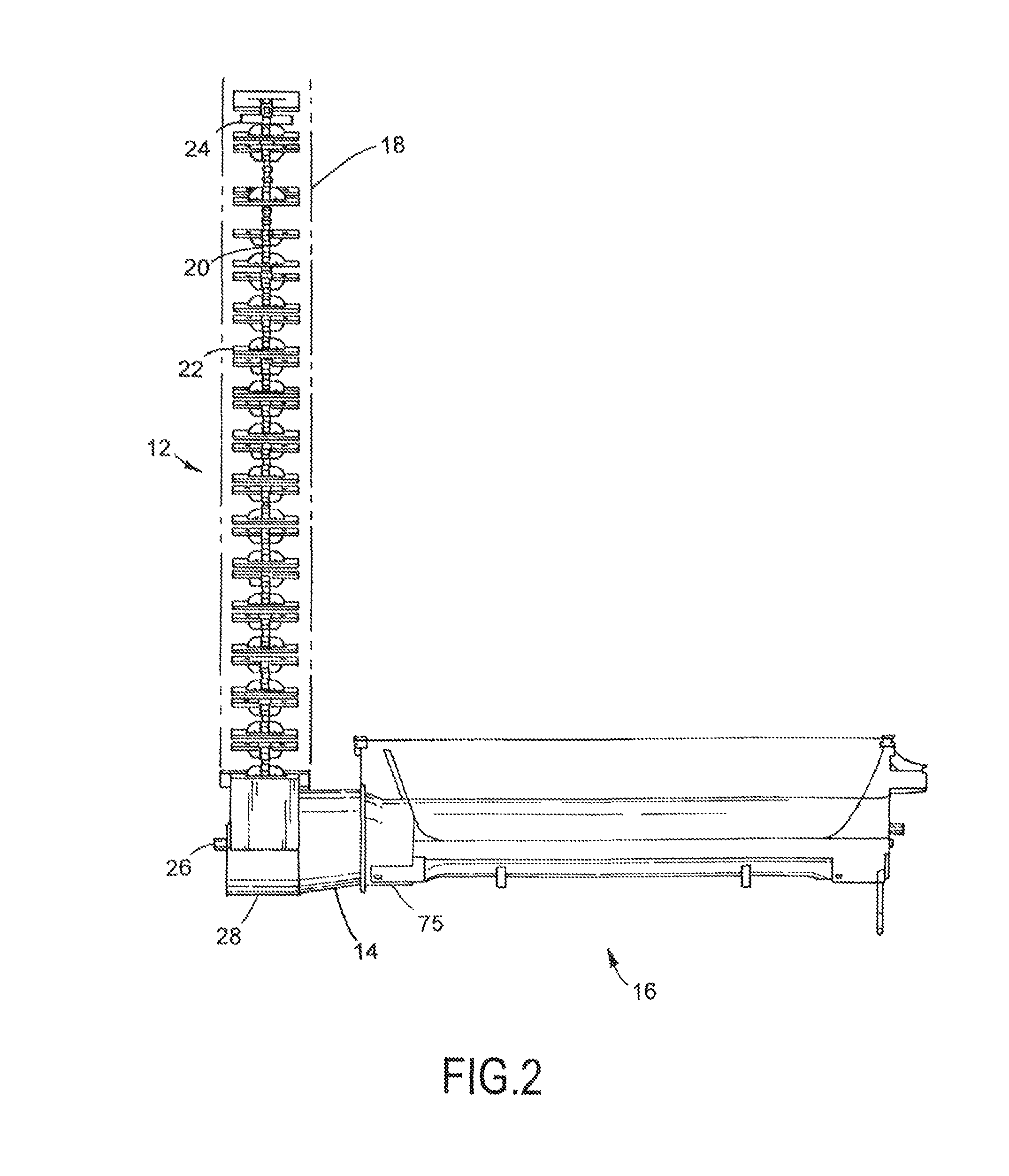

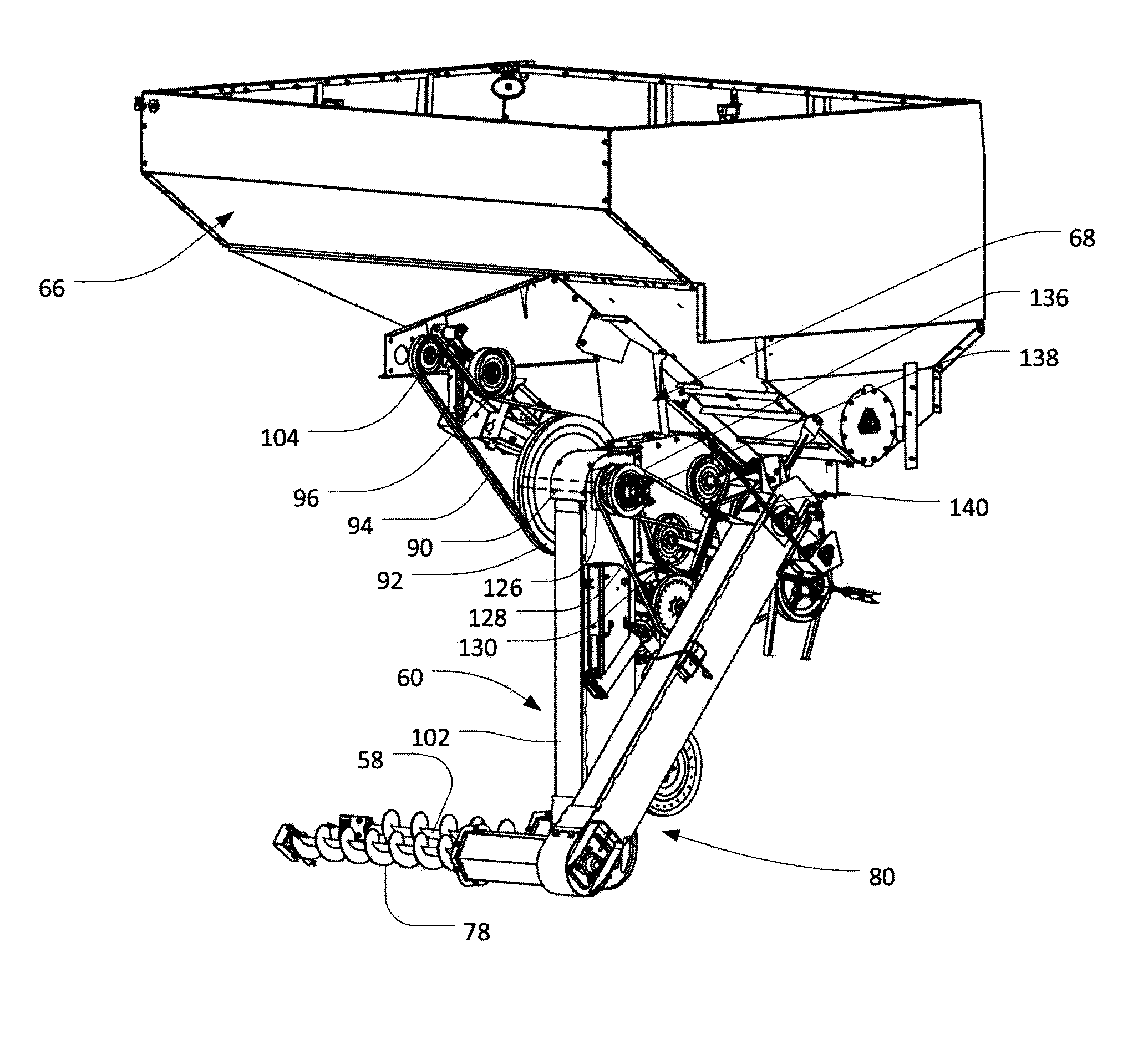

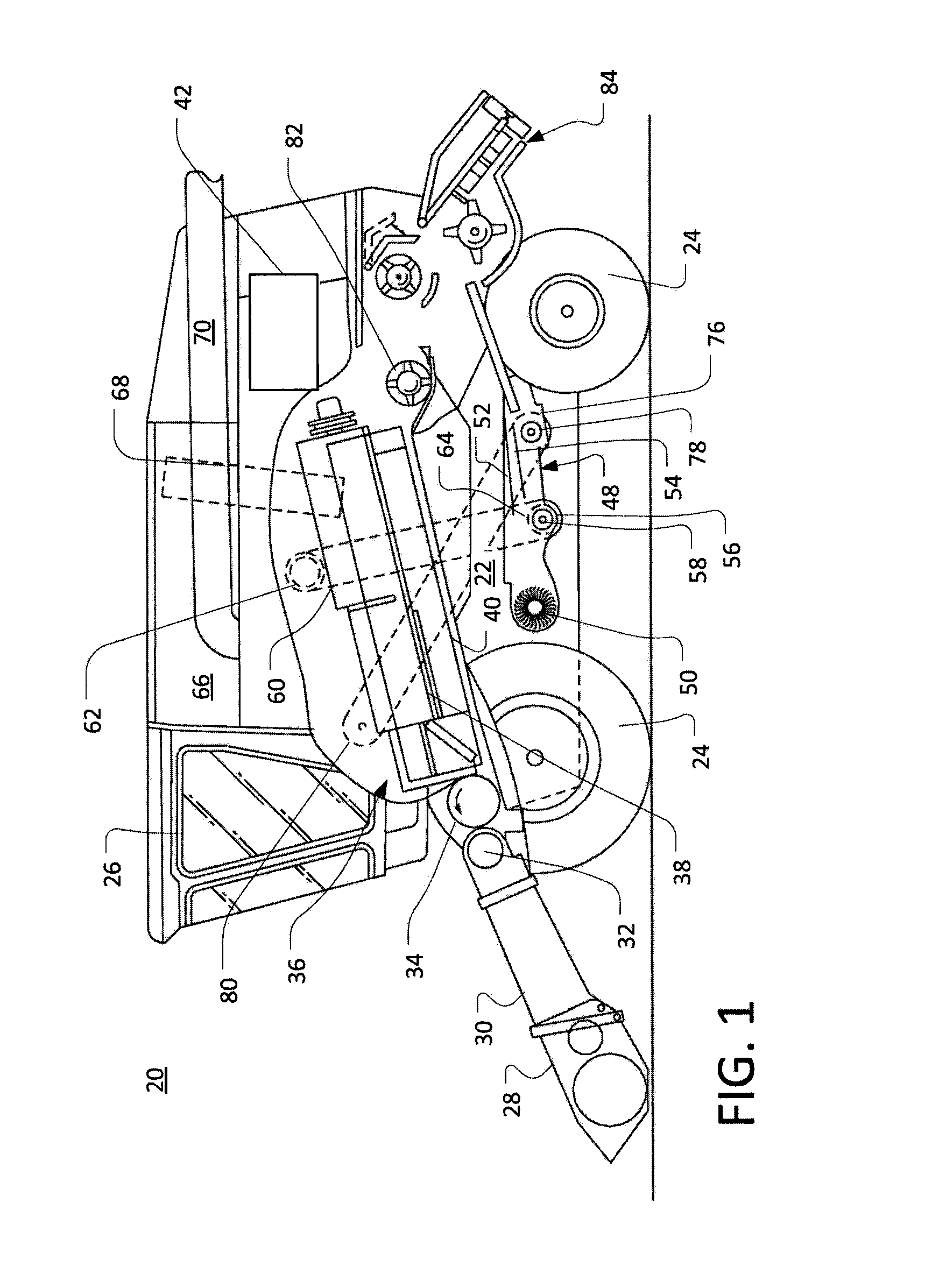

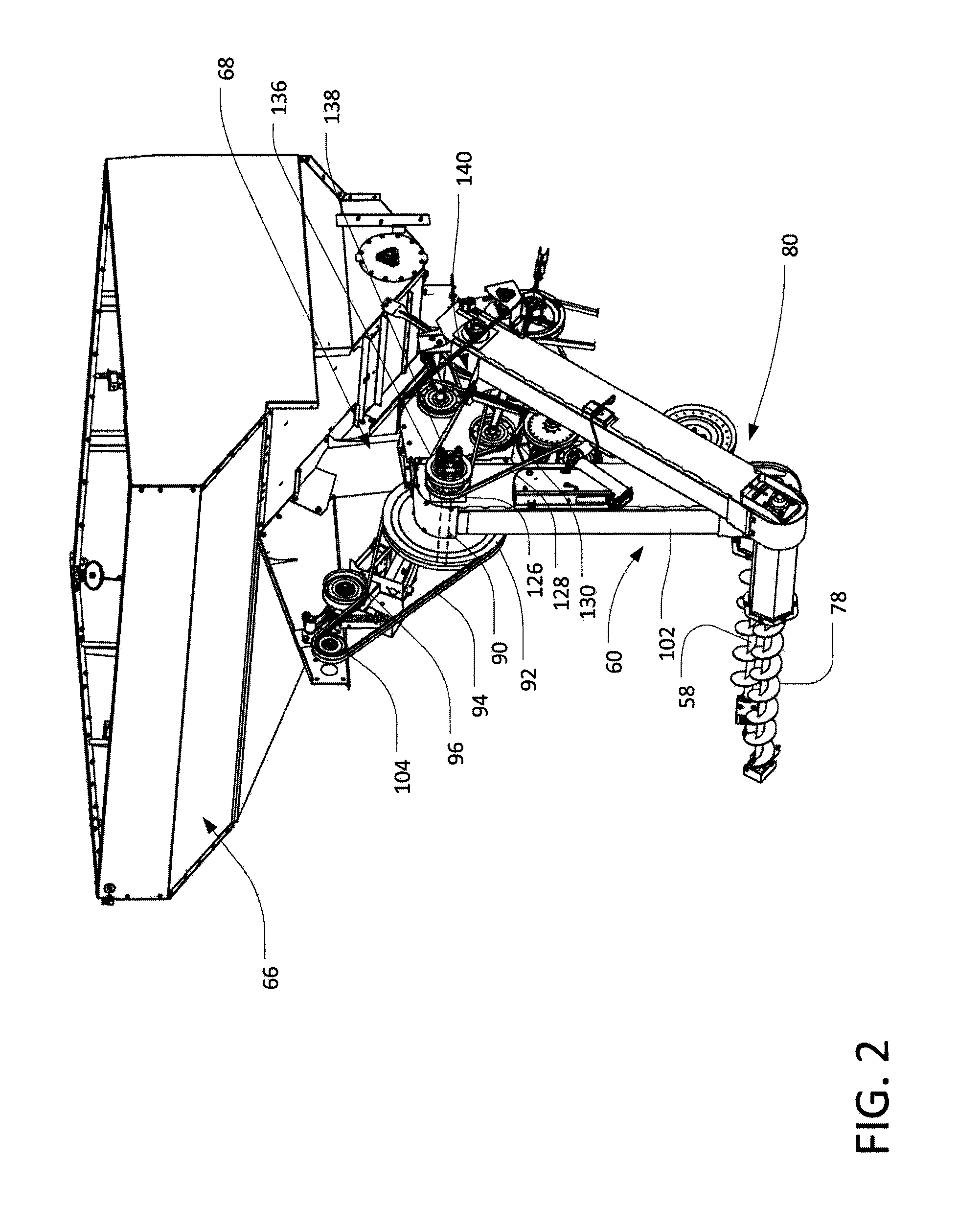

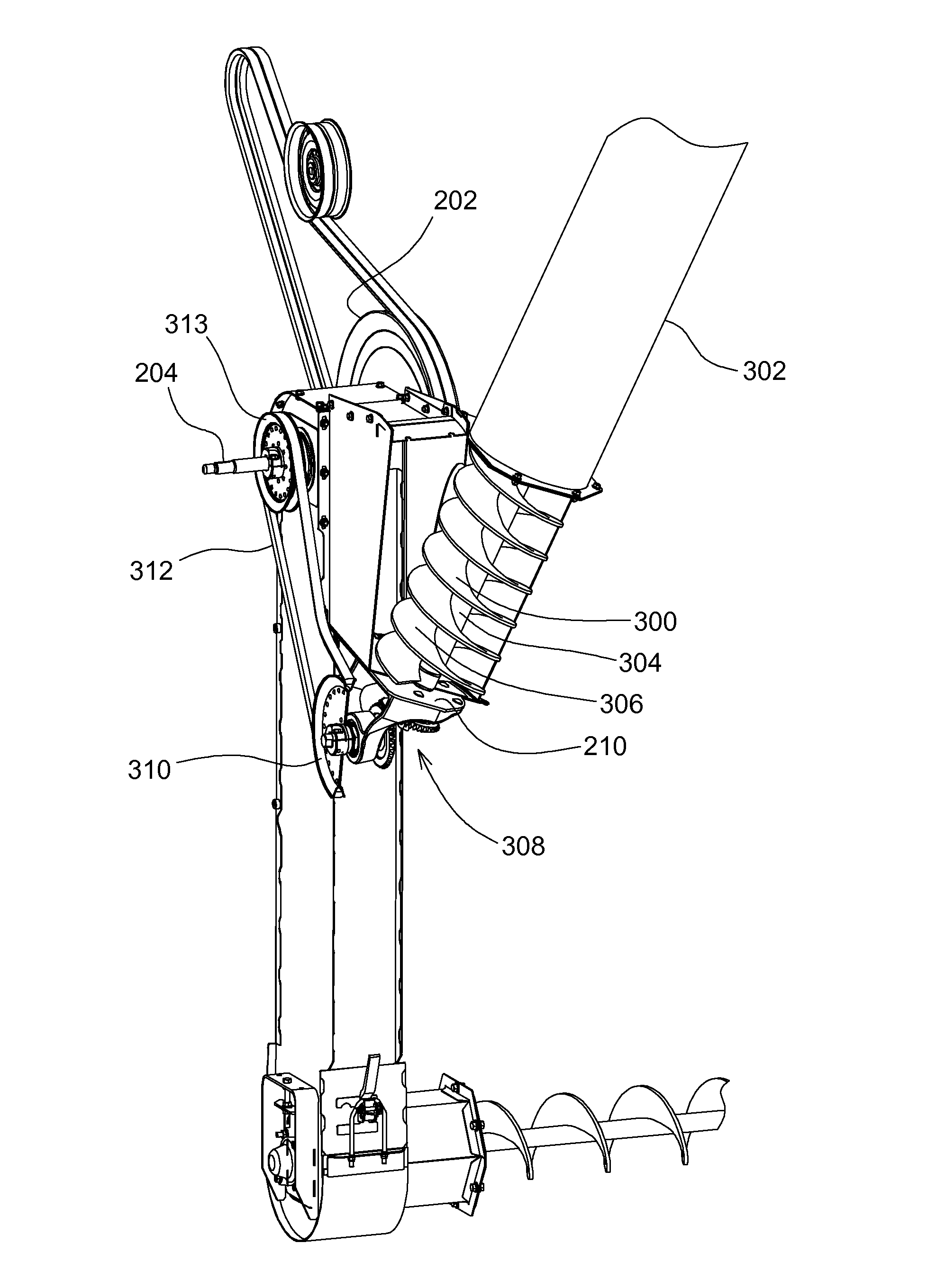

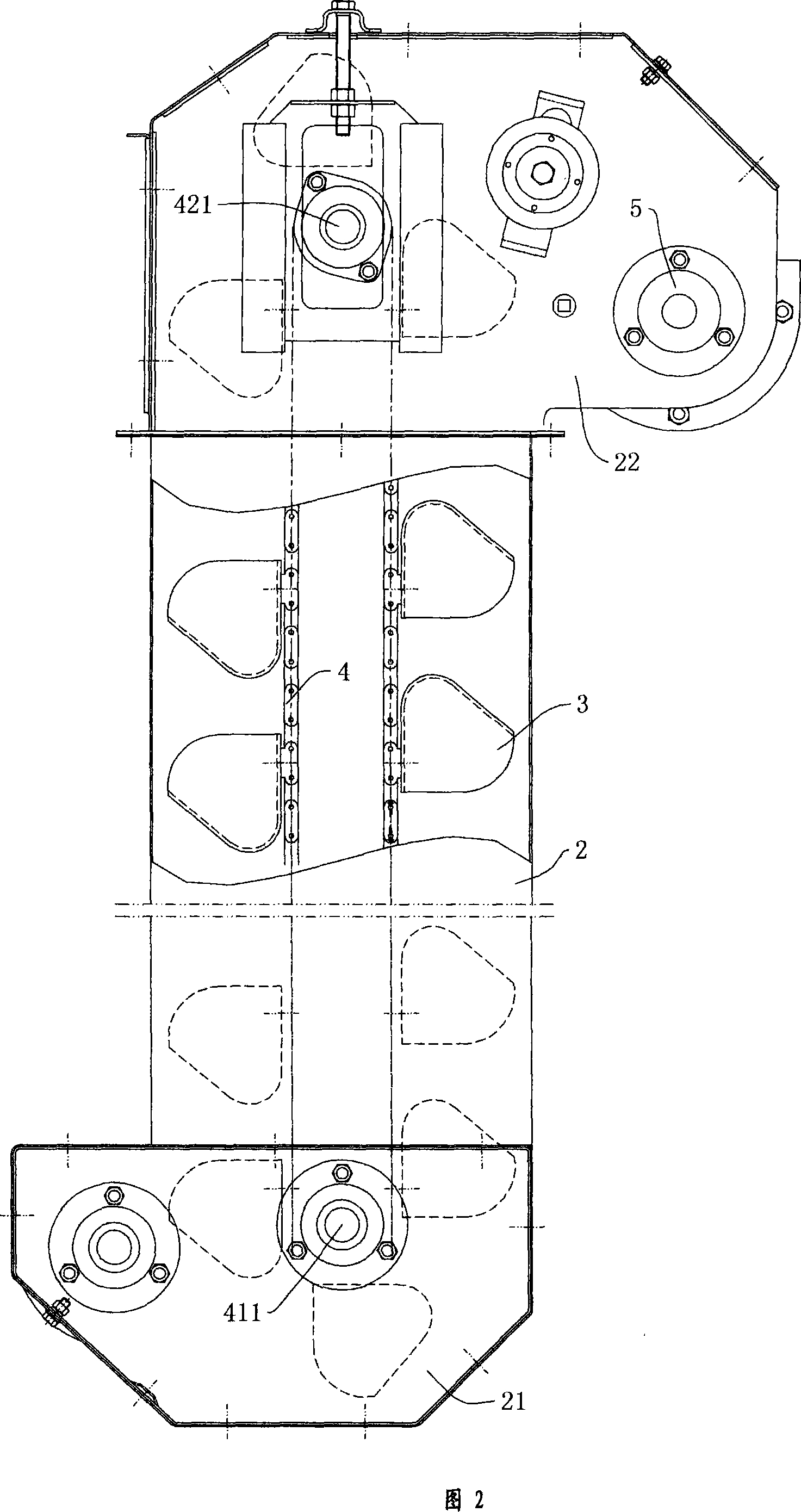

Grain conveyor for a combine harvester

A grain conveyor for a combine harvester capable of increasing capacity and reducing component wear is disclosed. The grain conveyor includes a grain elevator, a transition chamber and an auger assembly. The grain elevator has an inlet for receiving a flow of grain. The transition chamber includes an inlet and an outlet in fluid communication with the transition chamber inlet and the grain elevator inlet. The transition chamber outlet has an asymmetric non-circular opening larger than the non-cylindrical opening of the transition chamber inlet. The auger assembly is operatively connected to the transition chamber and includes an inlet for receiving a flow of grain and an outlet in fluid communication with the transition chamber inlet.

Owner:BLUE LEAF I P INC

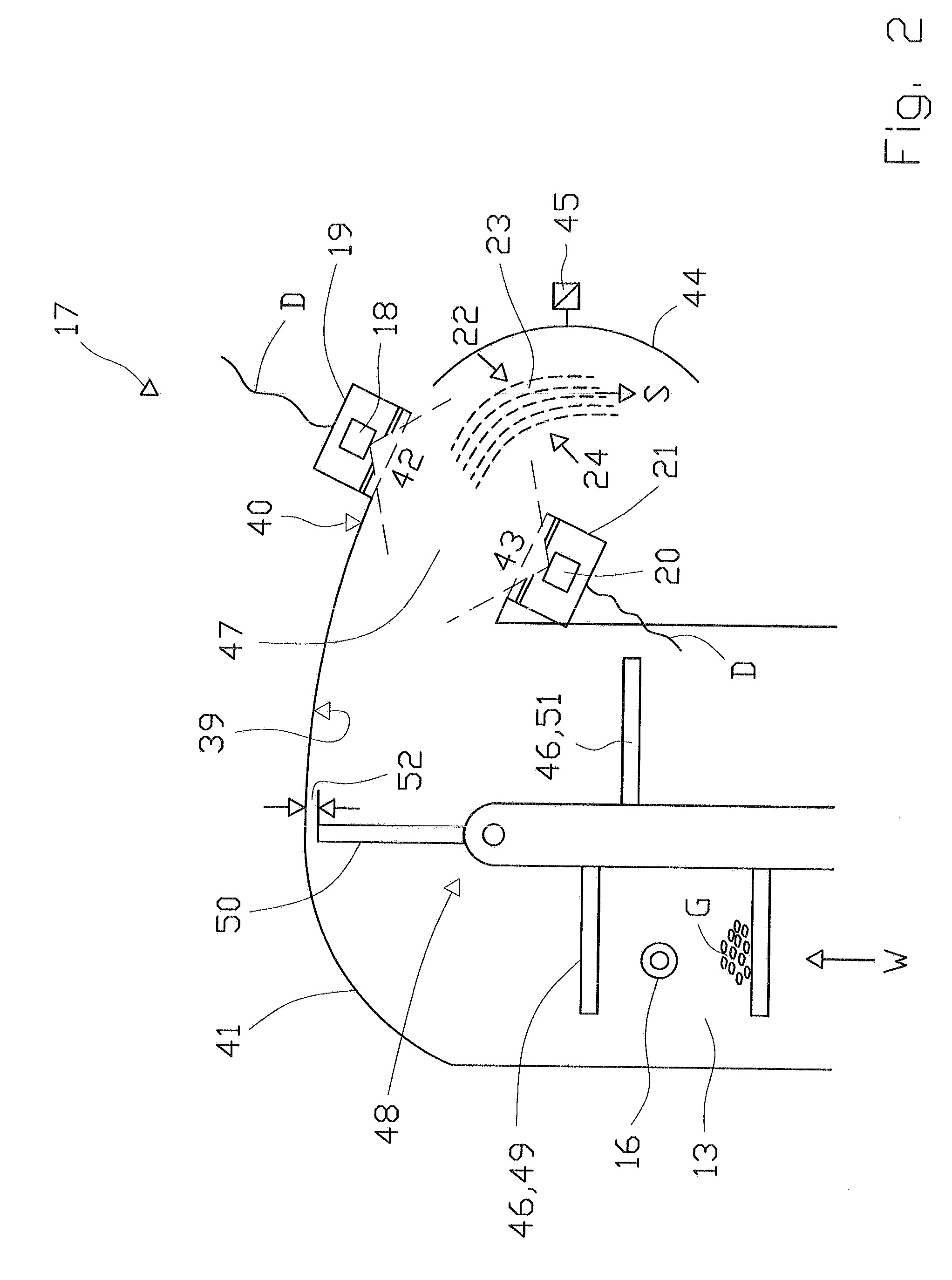

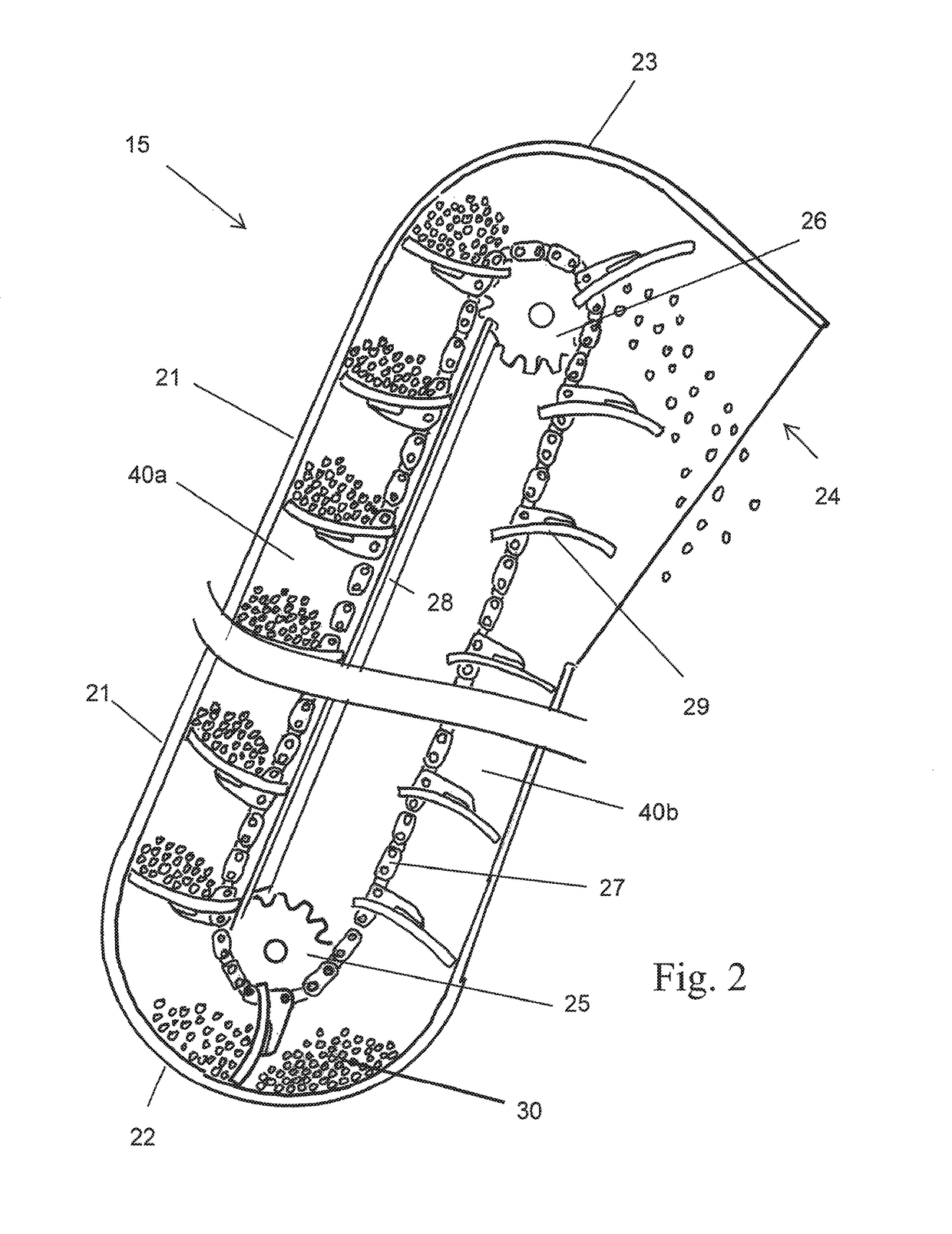

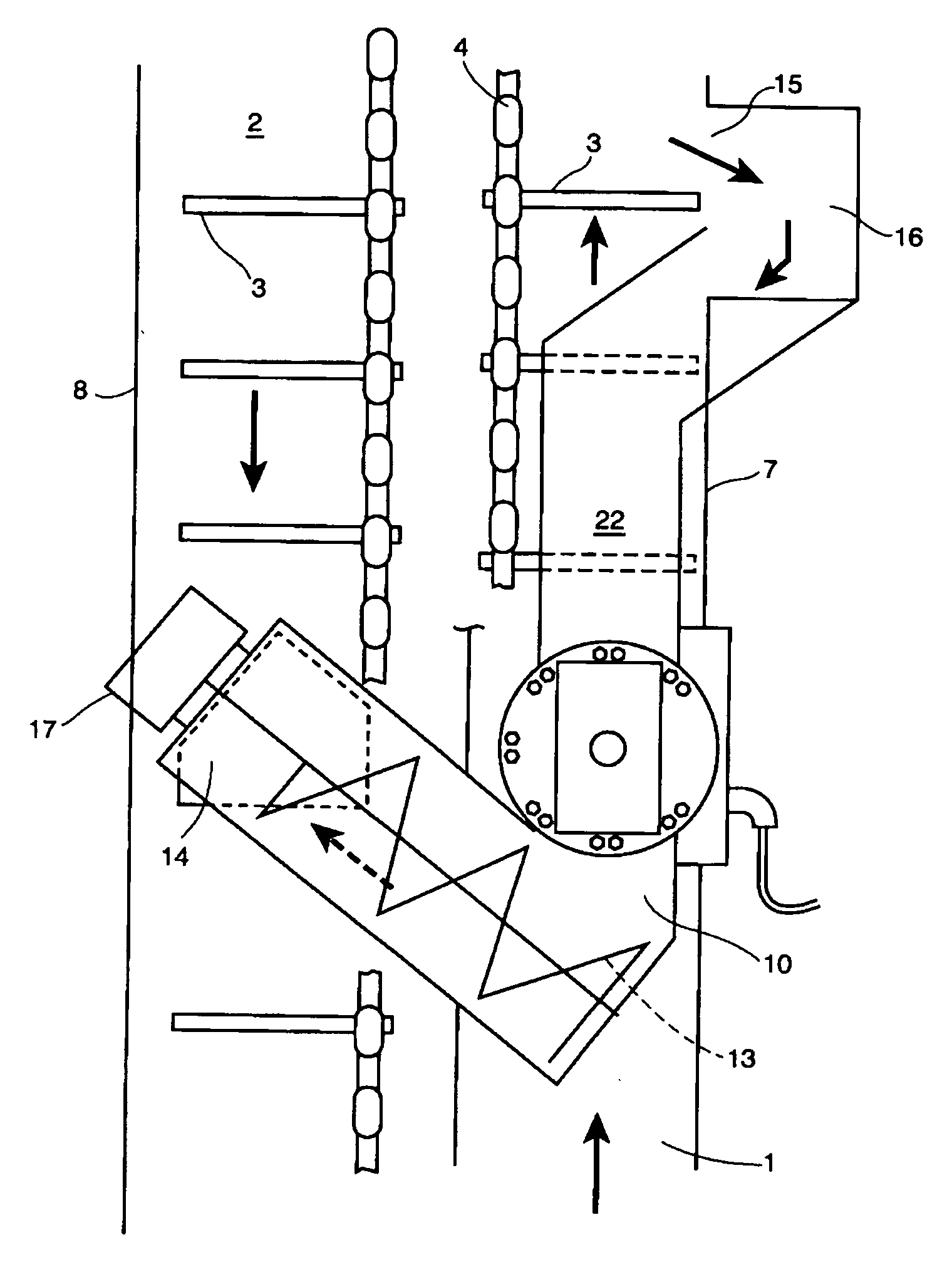

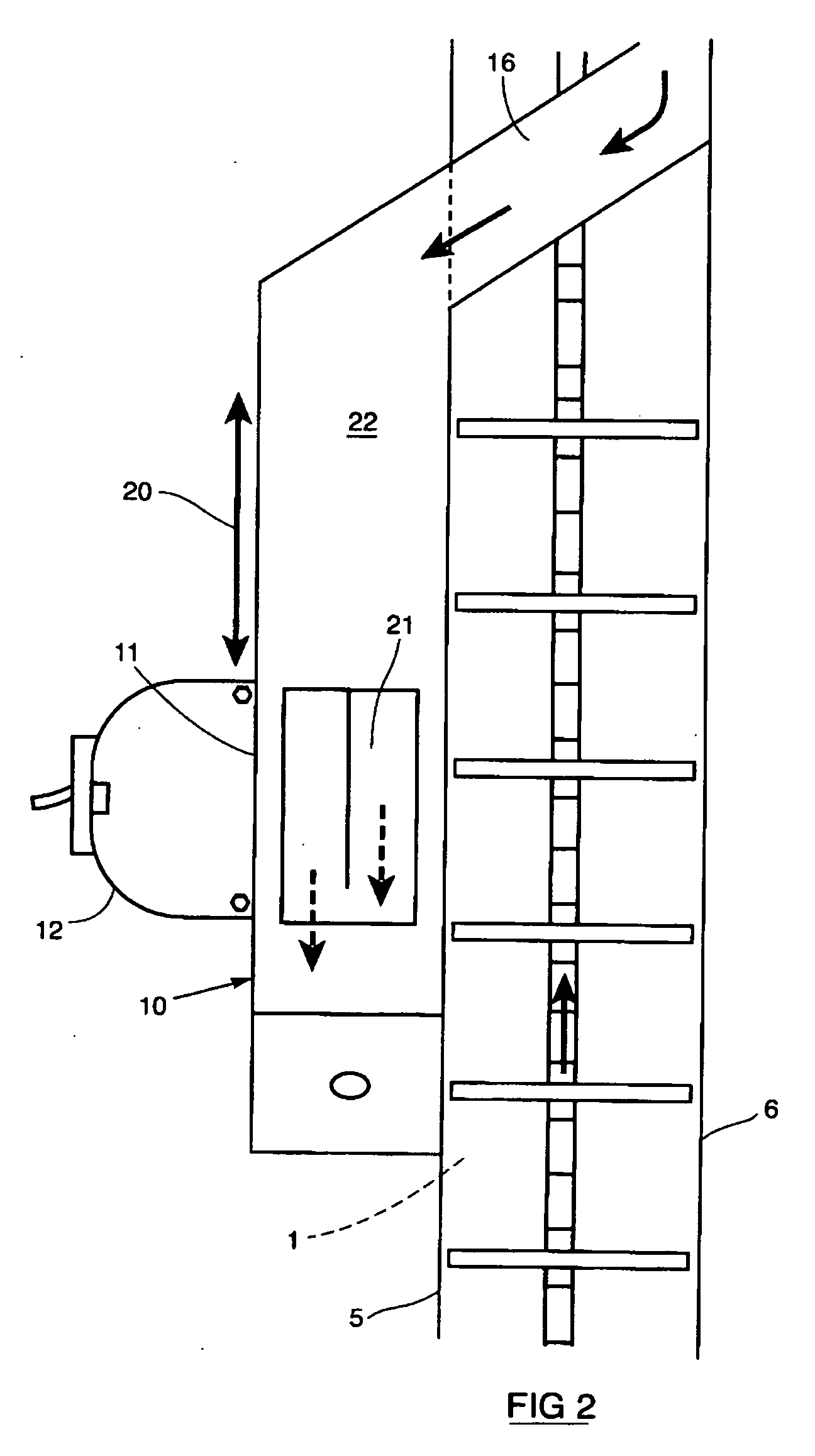

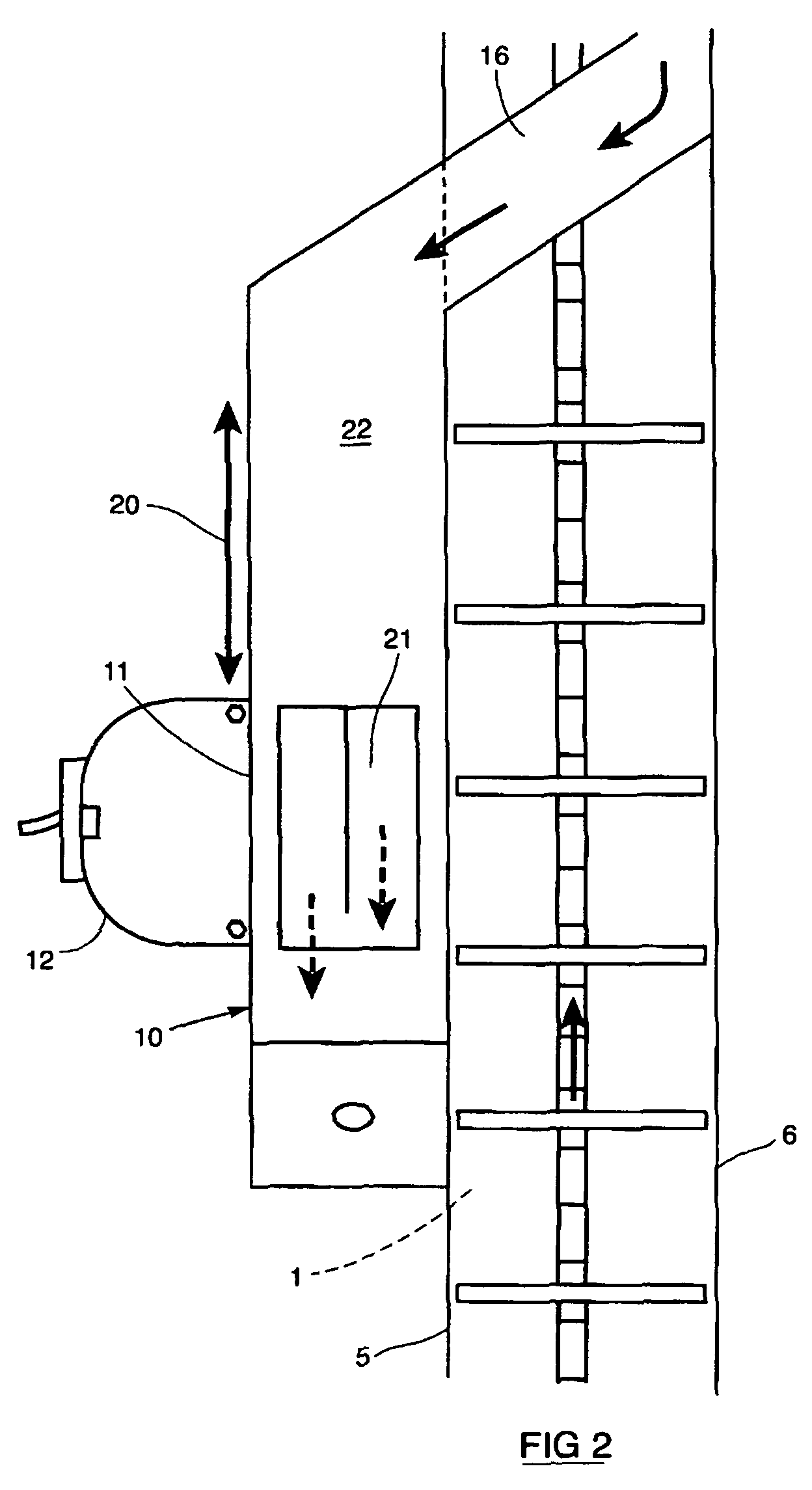

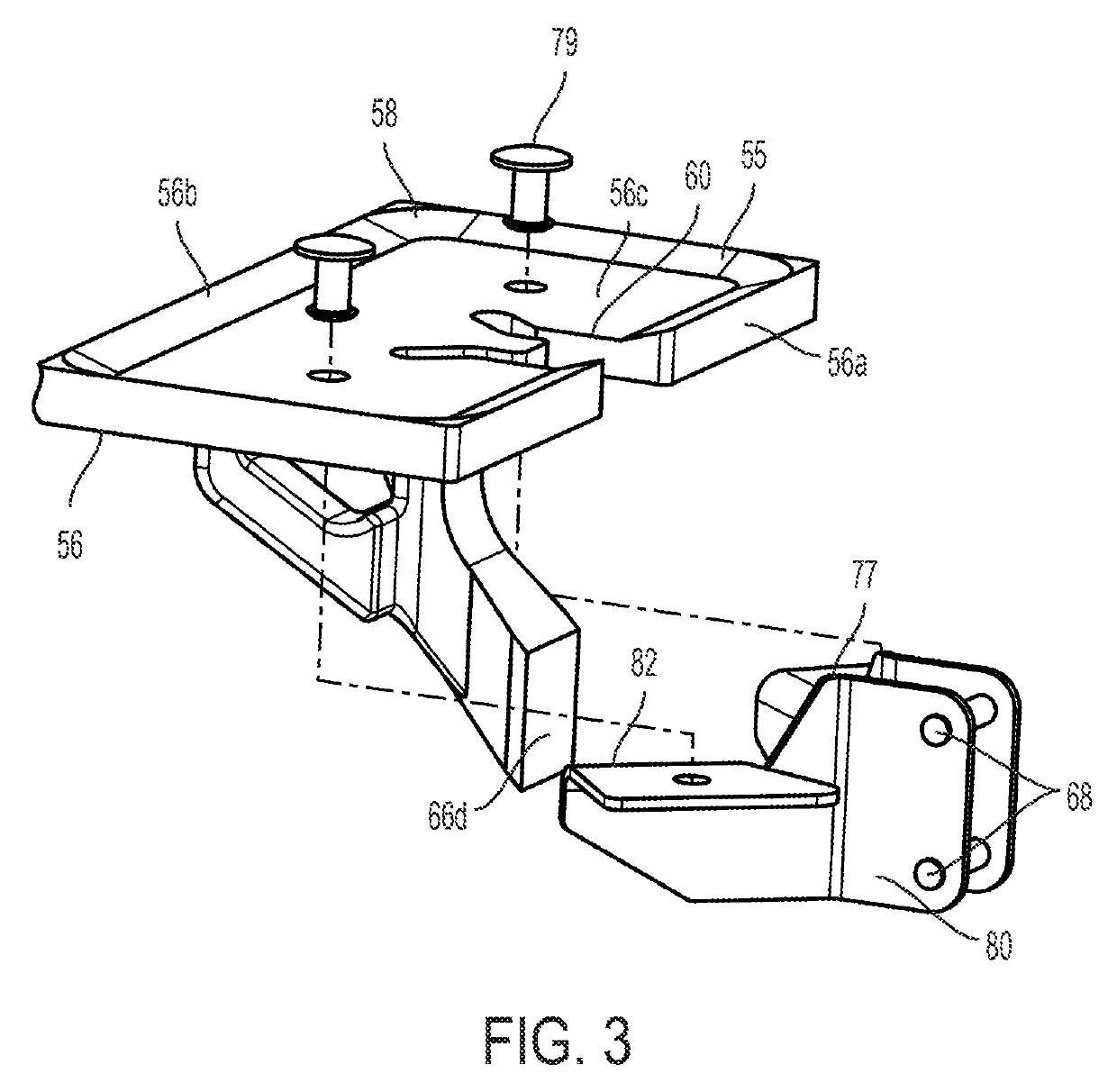

Apparatus for analysing composition of crops in a crop elevator

ActiveUS20090291723A1Constant supply of cropsMowersInvestigating moving fluids/granular solidsGrain elevatorEngineering

An apparatus for analysing crop composition of crops moving in a grain elevator, the elevator including paddles moving up on an up-going side of the elevator and down on a down-going side of the elevator, the apparatus including a crop entrance for entry of crops from the up-going paddles to the analysing apparatus and a housing for containing a portion of crops to be analysed. The crop entrance is located in a plane parallel to the elevator's outer wall at the up-going side of the elevator. The apparatus further includes a sloped gutter portion for bringing crops from the crop entrance towards the housing.

Owner:BLUE LEAF I P

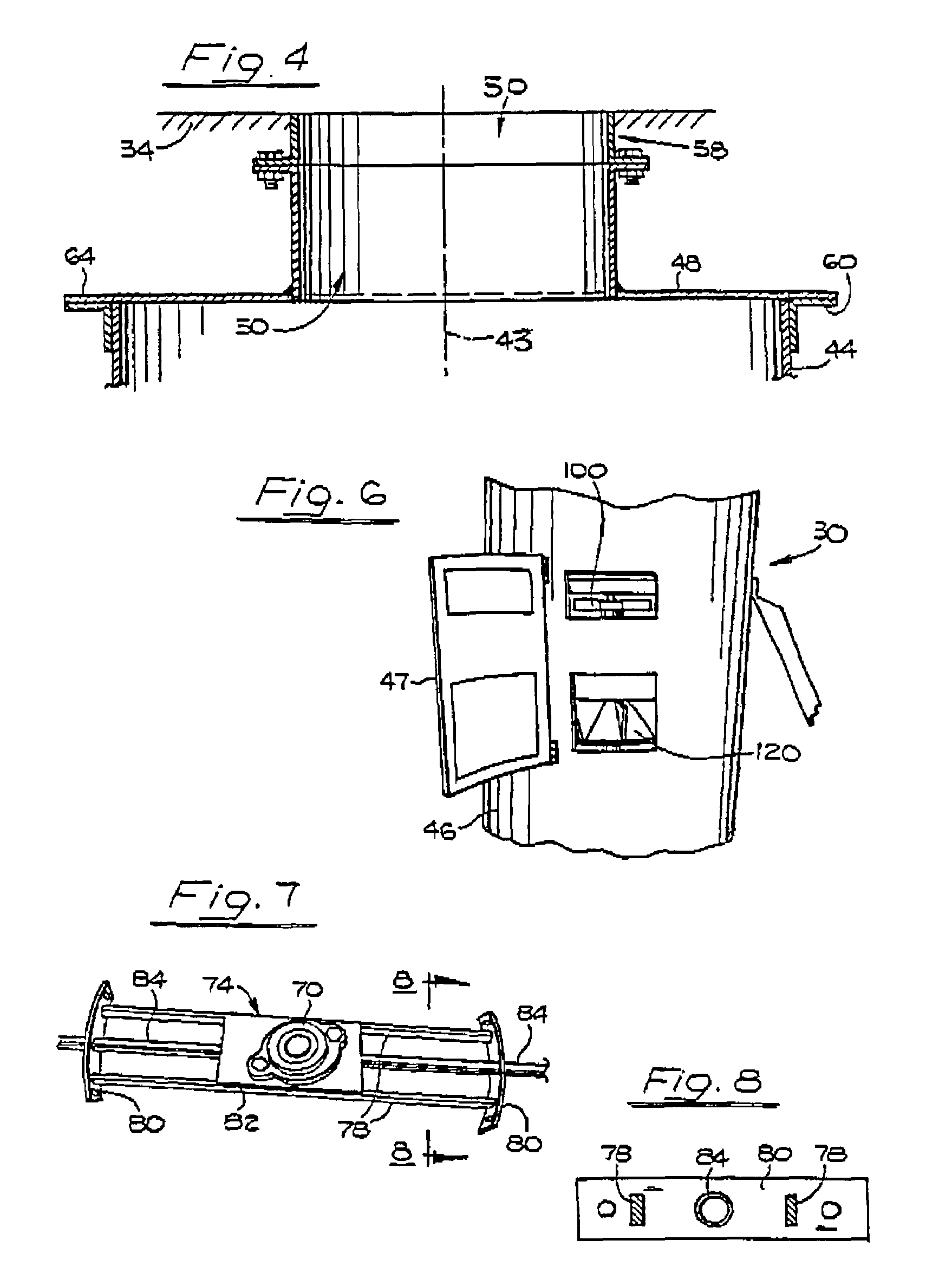

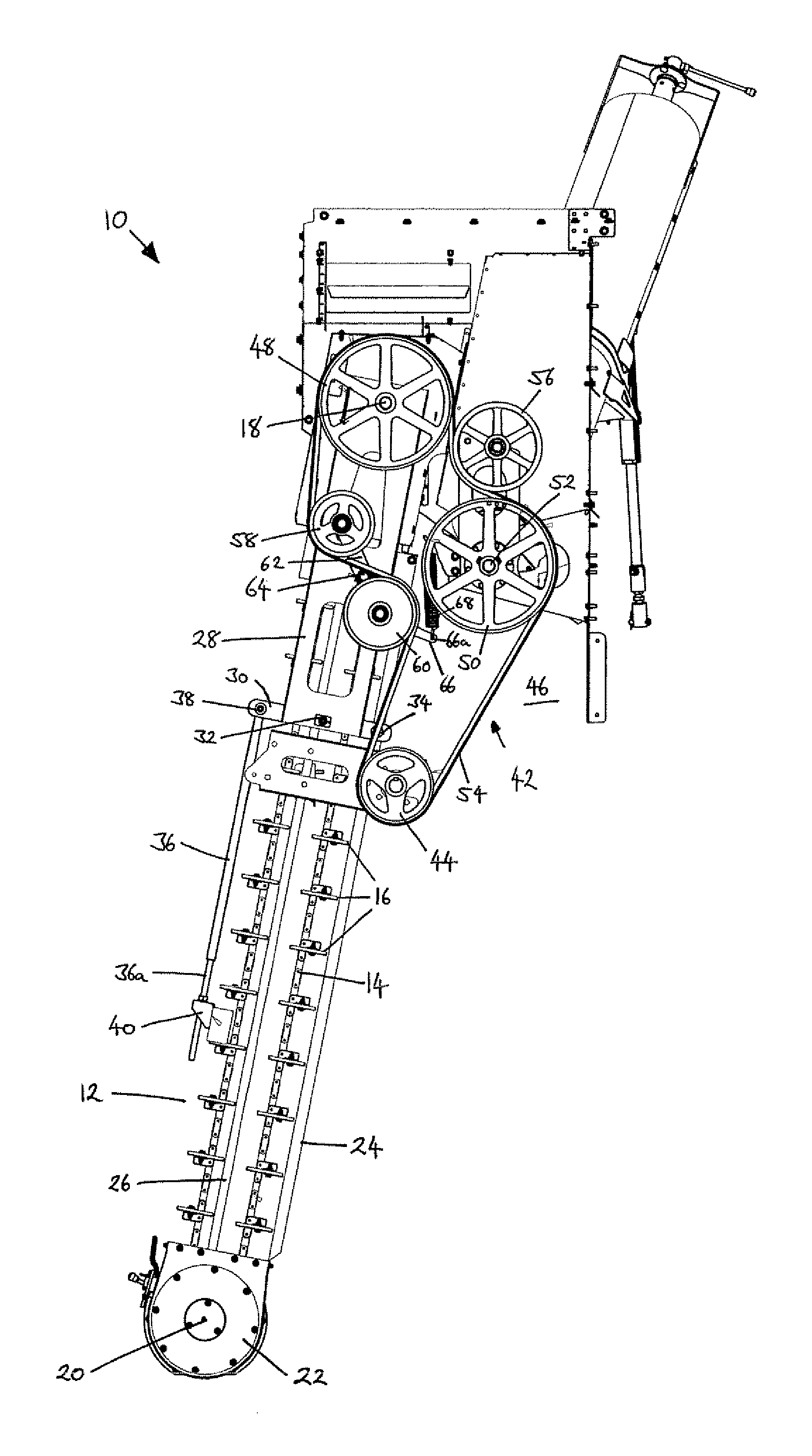

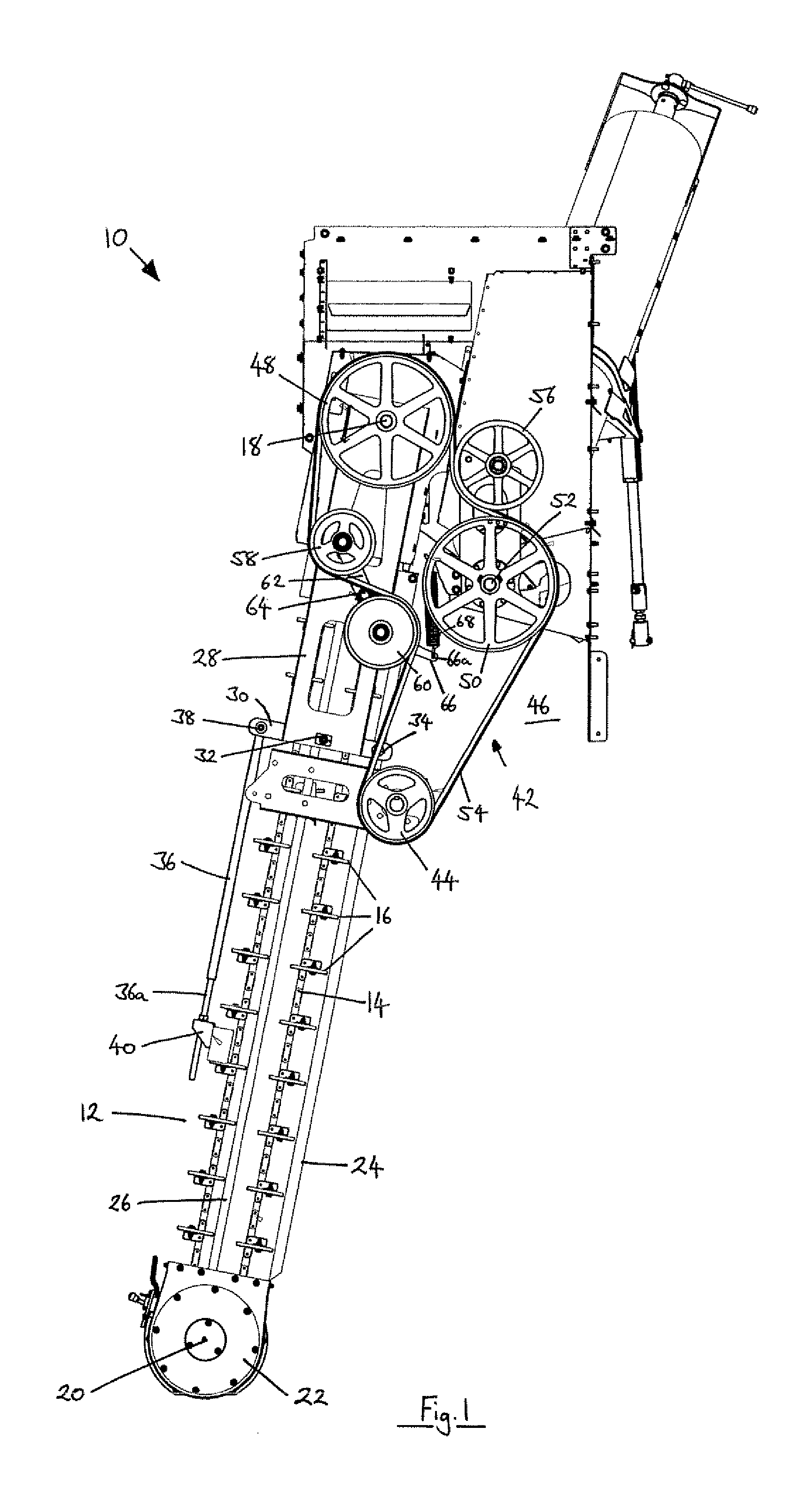

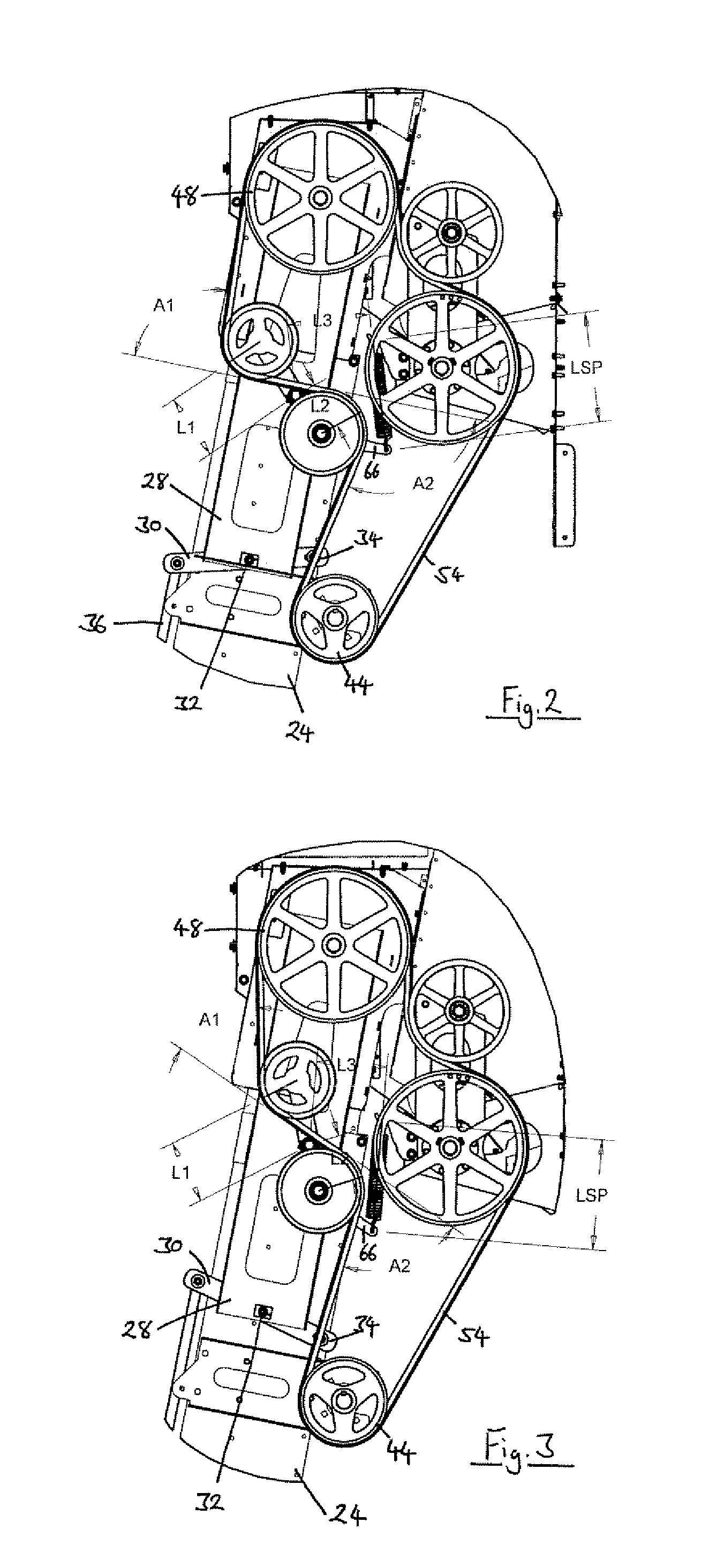

Constant tensioning means for rotary motion transfer apparatus

A rotary motion transfer apparatus, such as a combine grain elevator, which includes first and second endless flexible members which may include belts and / or chains. Each flexible member is trained around a respective set of rotary members which may be pulleys, sheaves or sprockets. One rotary member from each set shares a common shaft and may, or may not, be in driving engagement with one another. The common shaft is mounted on an adjustment frame member that is linearly displaceable with respect to a main frame to adjust the tension in the first endless flexible member. A pair of idler rotary members are provided for tensioning the second endless flexible member and are mounted on a pivot arm which is mounted to the adjustment frame member for pivoting movement around a pivot axis intermediate the pair of idler rotary members. A lever is secured to the pivot arm, and spring means are attached between the lever and the main frame to bias the idler rotary members into engagement with opposite sides of the second endless flexible member with a substantially constant force over an adjustment range of the common shaft.

Owner:LAVERDA

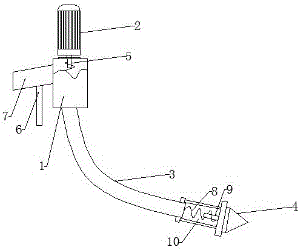

Grain elevator

InactiveCN105668241ASimple structureEasy to assemble and disassembleBulk conveyorsLoading/unloadingGrain elevatorAgricultural engineering

The invention discloses a grain elevator. The grain elevator comprises a grain suction box, a motor, a grain suction hose and a drill bit. The motor is located over the grain suction box. An output shaft of the motor penetrates the top wall of the grain suction box. A grain outlet is formed in the side portion of the grain suction box. The grain outlet communicates with one end of the grain suction hose. A grain discharging barrel inclining downwards is arranged at the position of the grain outlet. A fixing column vertically extending downwards is arranged on the discharging barrel. A spring penetrates into the grain suction hose. One end of the spring is connected with the output shaft, and the other end of the spring is arranged on a connecting column on the back of the drill bit in a sleeving manner. The drill bit is connected to the tail end of the grain suction hose through a connecting rod. A grain suction through cavity for sucking grain is reserved between the grain suction hose and the drill bit. Compared with the prior art, the grain elevator has the beneficial effects that the structure is simple, assembling and disassembling are convenient, universality is high, and application and popularization are facilitated.

Owner:蚌埠市丰源粮油食品贸易有限公司

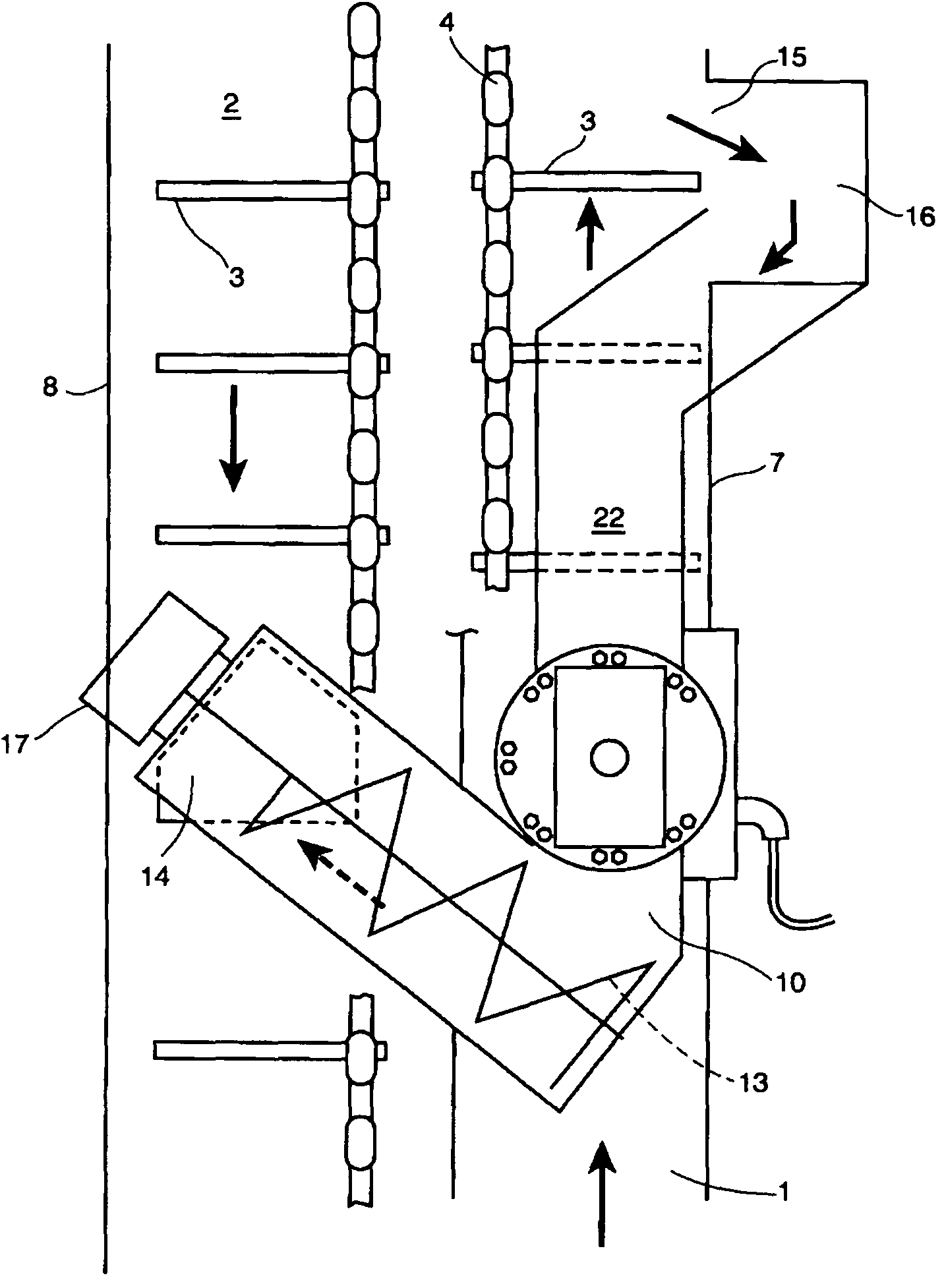

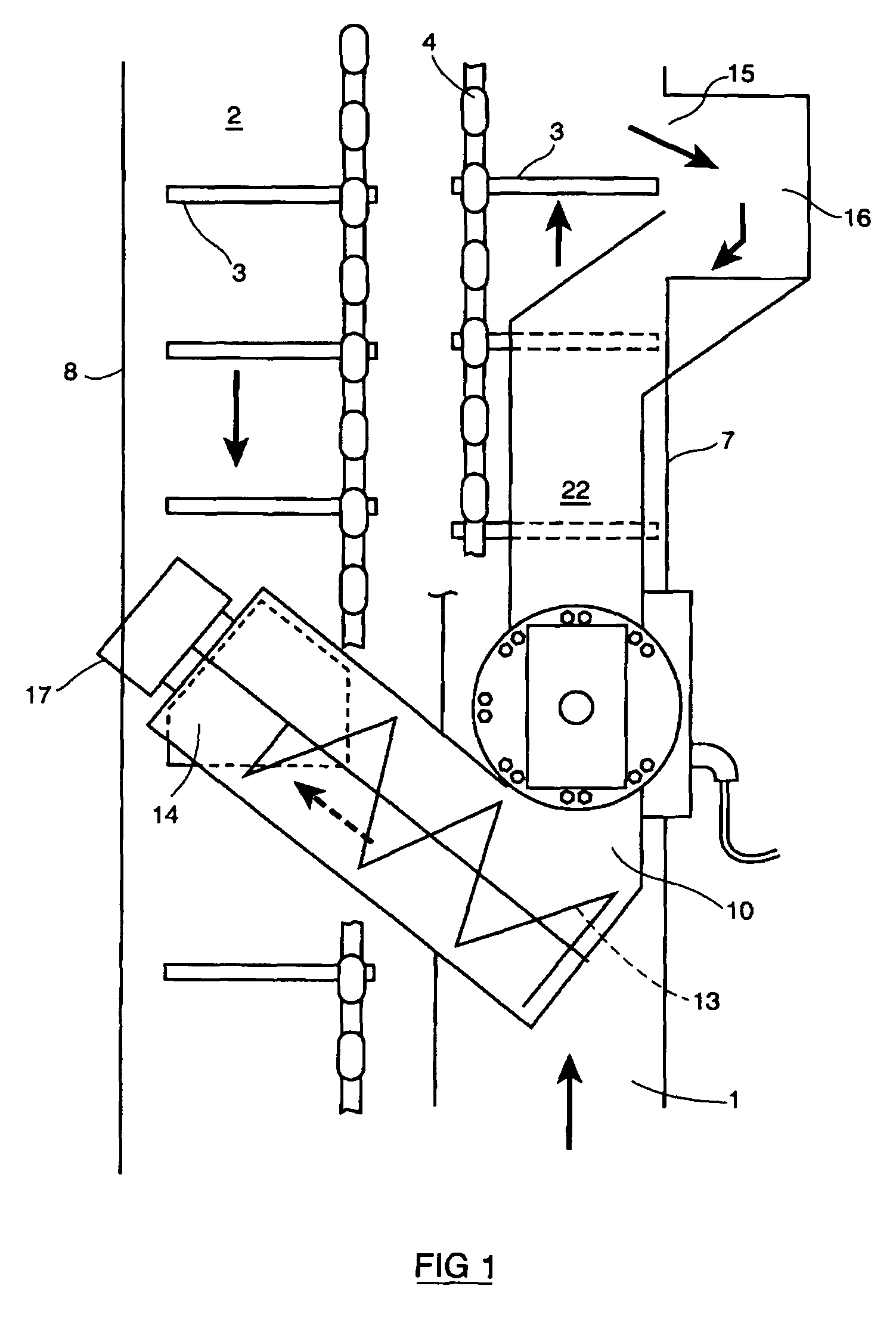

Apparatus for analysing composition of crops in a crop elevator

ActiveUS7771262B2Constant supply of cropsMowersInvestigating moving fluids/granular solidsGrain elevatorEngineering

An apparatus for analyzing crop composition of crops moving in a grain elevator, the elevator including paddles moving up on an up-going side of the elevator and down on a down-going side of the elevator, the apparatus including a crop entrance for entry of crops from the up-going paddles to the analyzing apparatus and a housing for containing a portion of crops to be analyzed. The crop entrance is located in a plane parallel to the elevator's outer wall at the up-going side of the elevator. The apparatus further includes a sloped gutter portion for bringing crops from the crop entrance towards the housing.

Owner:BLUE LEAF I P INC

Novel technology for high-yield cultivation of drought resistance maize in yellow river delta region

InactiveCN106258335AImprove the effect of increasing productionReduce outputPlant cultivationCultivating equipmentsSlurryBiology

The invention discloses a novel technology for high-yield cultivation of drought resistance maize in the yellow river delta region. The production capacity of salination soil in the yellow river delta region is improved, the grain yield is improved, implementation of science and technology demonstration engineering of a grain elevator in the Bohai Sea is promoted, and the food security in China is ensured. On the basis of characteristics of salination soil in the yellow river delta region, hydrological climate and other national conditions, scientific irrigation, straw salt restraining, biological organic fertilizer salt modification and alkali restraining, deep ploughing seeding, nitrogen fertilizer postponing, the stress resistance and yield increasing technology through alga active substances, microelement scientific matching technology are integrated, and the systematized yellow river delta high-quality maize yield increasing cultivation technology system capable of achieving rolling reproduction is constructed, biogas slurry is creatively used for maize grain yield increasing irrigation, straw coverage is adopted for salt restraining and alkali modification, water for irrigation is saved, and the water saving effect is remarkable.

Owner:山东省滨州市秋田种业有限责任公司

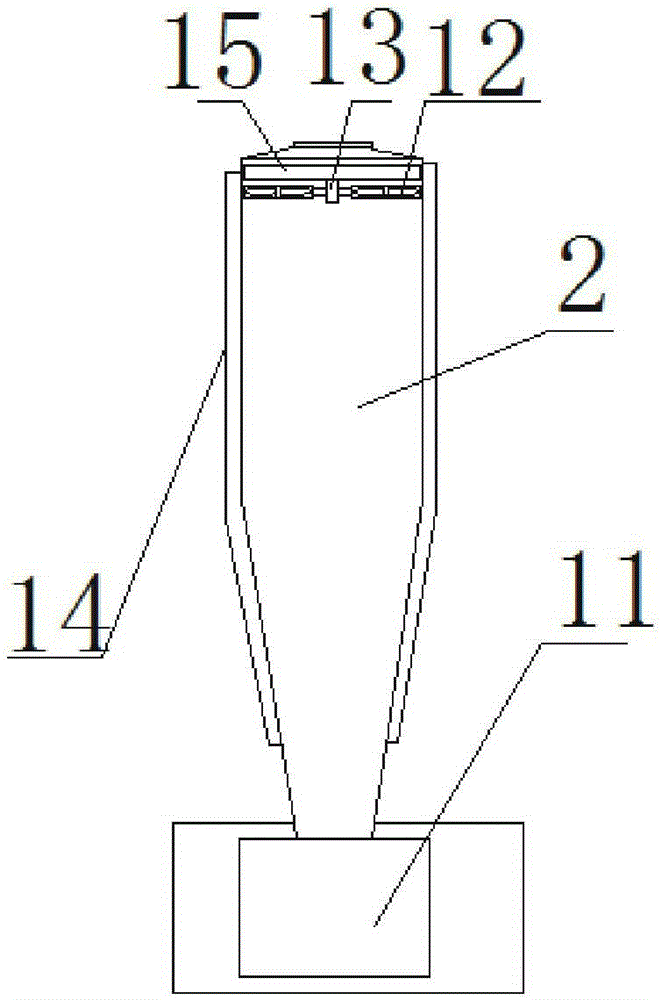

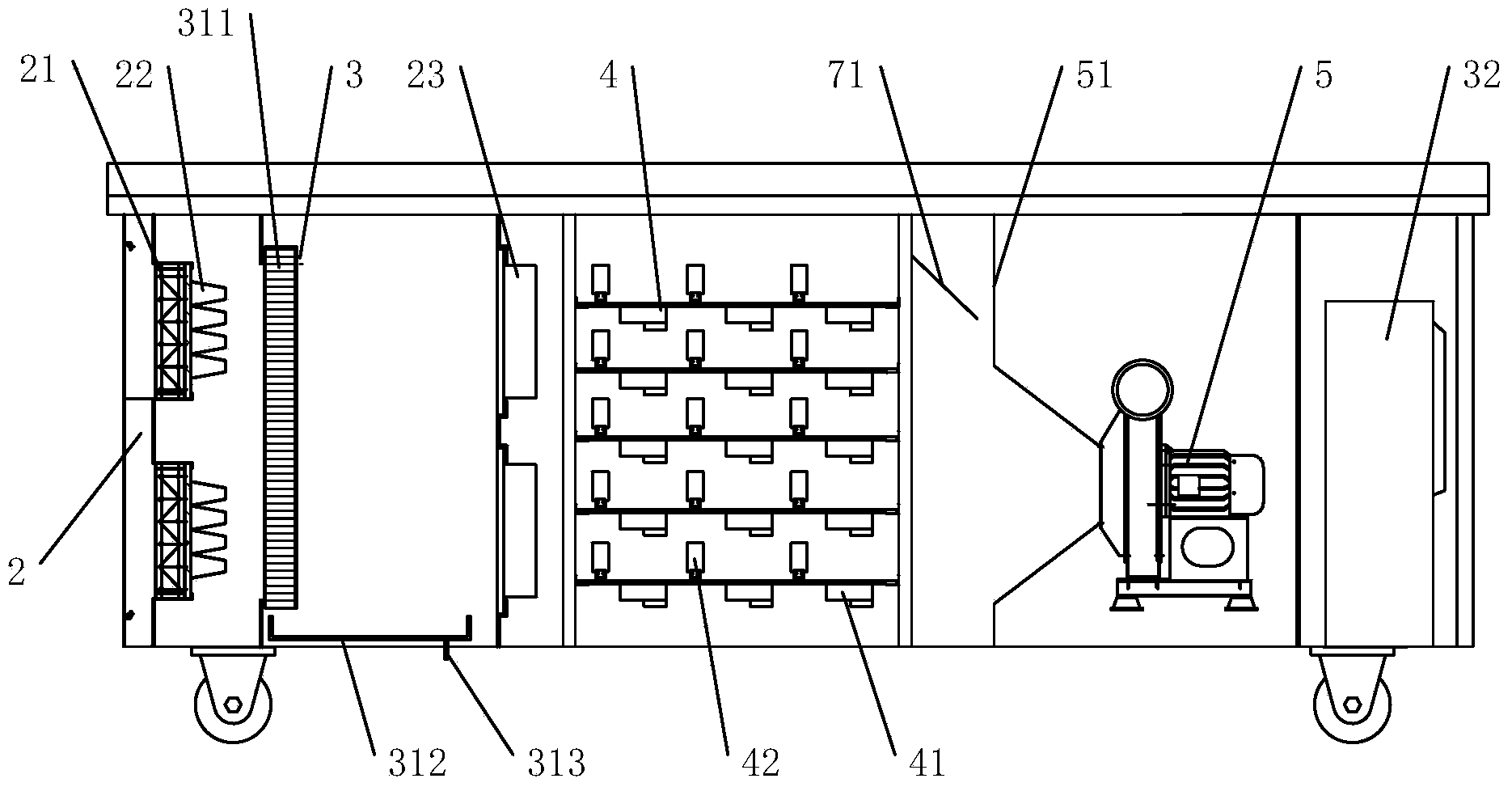

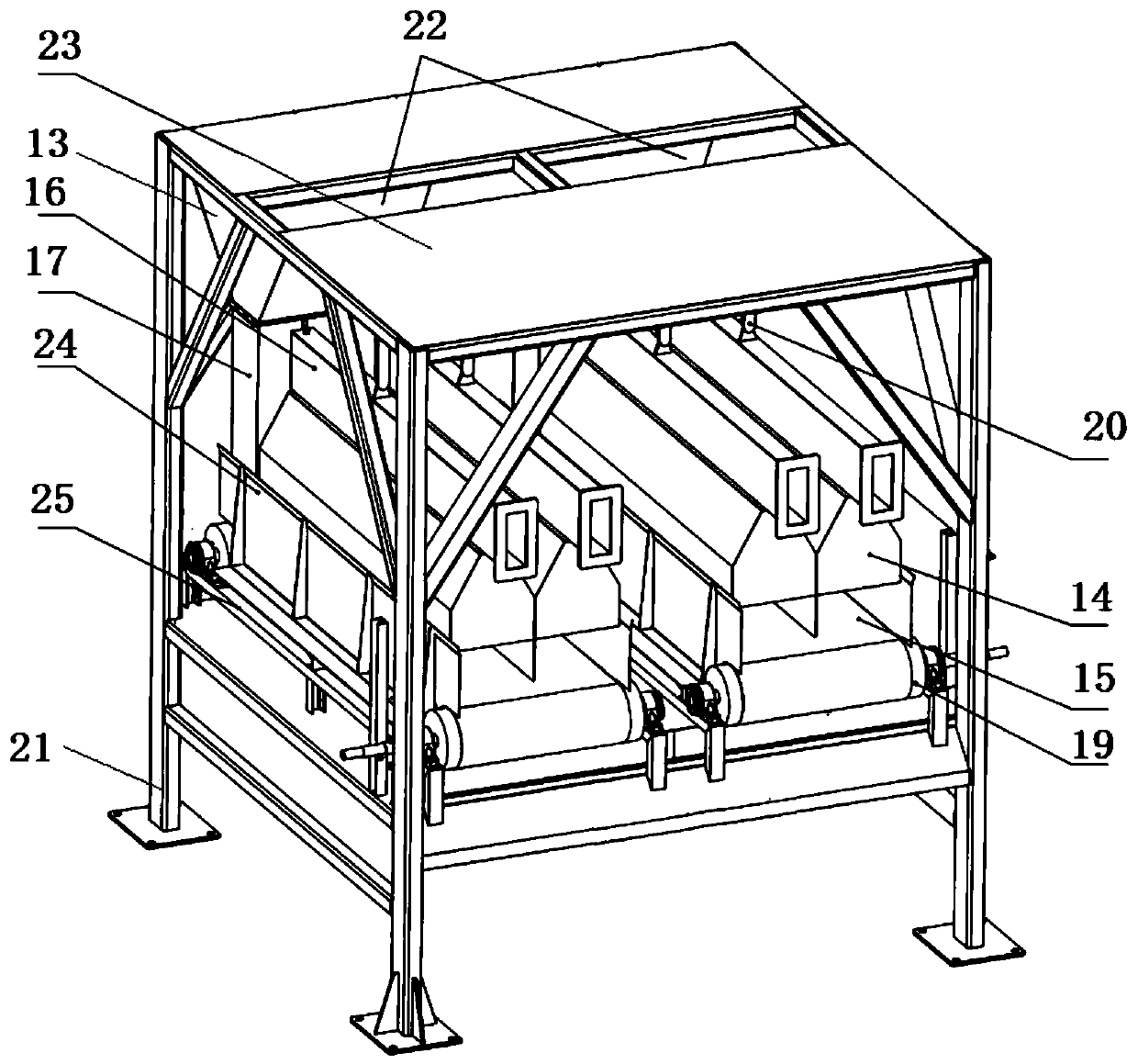

Circulation type grain air drying device

PendingCN106705619AEfficient dryingSolve pollutionDrying gas arrangementsDrying solid materialsGrain elevatorAgricultural engineering

The invention discloses a circulation type grain air drying device. The circulation type grain air drying device comprises a grain elevator and an air drying device body. The air drying device body comprises a cylindrical air drying bin, a ventilation pipe, an air distributing column, a draught fan, a belt conveyor and a supporting frame. The cylindrical air drying bin is provided with a conical upper cover and an inverted-cone-shaped lower cover. A discharging port of the grain elevator is connected with a grain feeding port through a connecting pipeline. The belt conveyor is arranged at the bottom of the grain discharging port. A vertical air pipe is arranged in the cylindrical air drying bin. One end of the air distributing column is fixed to the vertical air pipe. One end of the ventilation pipe communicates with the vertical air pipe, and the other end of the ventilation pipe stretches out of the cylindrical air drying bin. The tail end of the part, stretching out of the cylindrical air drying bin, of the ventilation pipe is provided with the draught fan. The circulation type grain air drying device is reasonable in structure, convenient to use, easy to operate and capable of conducting efficient air drying on grain, and meanwhile the problem that when a traditional coal burning drying machine is used, the environment is polluted is solved.

Owner:封丘县宏鑫农业设备制造有限公司

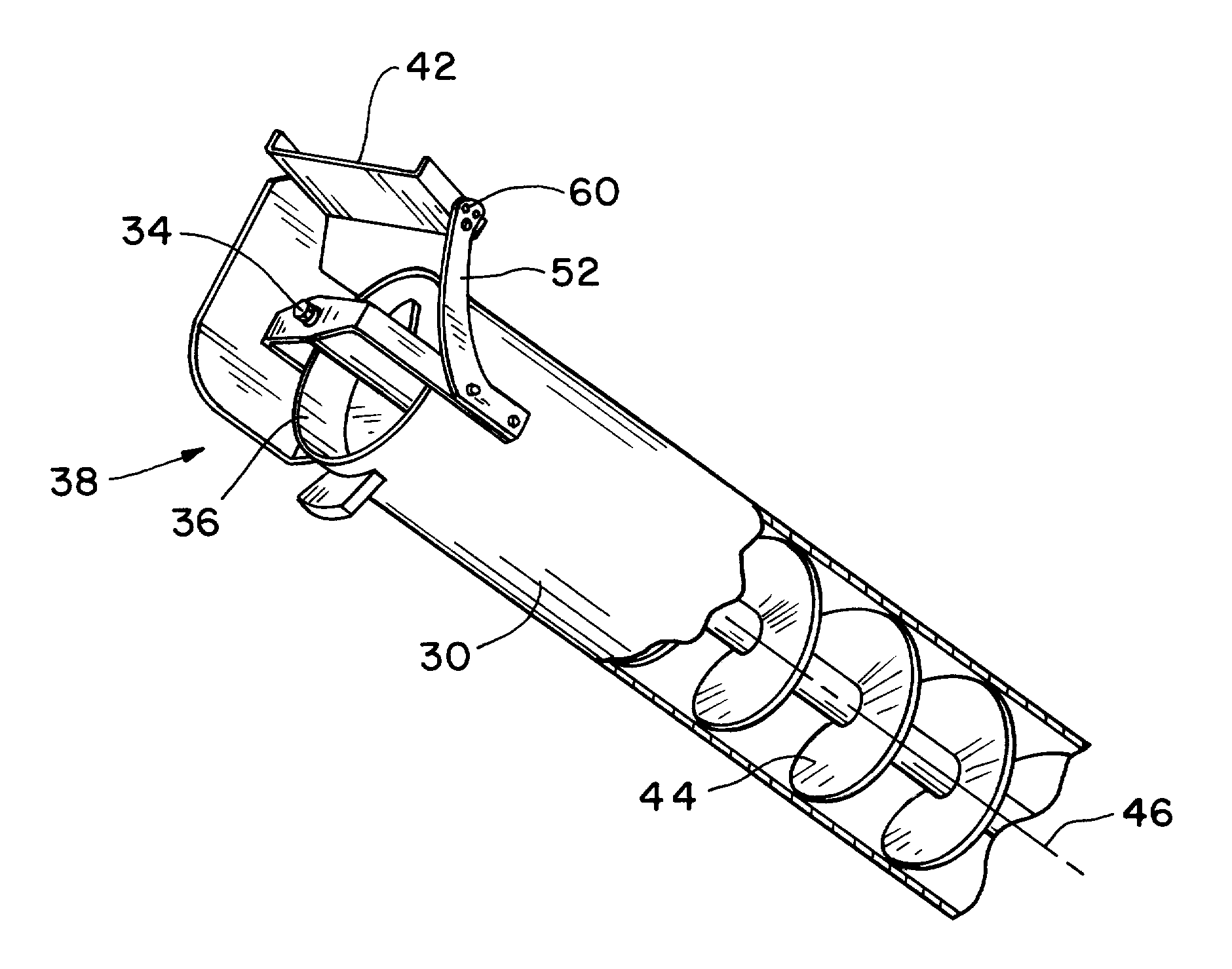

Loading auger deflector

A clean grain conveyor system for a harvesting machine having grain gathering, cleaning and temporary storage capabilities includes a clean grain elevator mechanism, a grain storage tank and a loading auger conveyor for moving grain from the elevator mechanism to a discharge end at the storage tank. The conveyor includes a hollow generally cylindrical tube extending obliquely upwardly from the elevator to the grain storage tank and a coaxially disposed auger journalled for rotation within the hollow tube. A grain flow deflector is fixed to the tube discharge end for minimizing grain scattering outside the tank and for selectively directing the flow of grain from the tube discharge end to compensate for different crops and crop conditions, and to generally center the pile of accumulated grain within the tank.

Owner:DEERE & CO

Grain elevator with multilevel treatment function

The invention provides a grain elevator with the multilevel treatment function and relates to the technical field of agricultural equipment. The grain elevator comprises a separation barrel, a dust removal chamber and a control chamber. A feed port is formed in one side of the separation barrel, and an air-lock valve is fixedly connected with the bottom of the separation barrel. An electromotor is arranged on one side of the air-lock valve, and a discharging channel is fixedly connected with the bottom of the air-lock valve. The separation barrel and the dust removal chamber are fixedly connected through a conveying pipe. A draught fan is arranged on one side of the dust removal chamber. An air guide pipe is fixedly connected between the dust removal chamber and the draught fan. The control chamber is arranged on one side of the draught fan. A bearing plate is arranged at the bottom of the control chamber. According to the grain elevator with the multilevel treatment function, grains can be separated through the separation barrel, and the grains are optimized accordingly; dust from the separation barrel can be treated through the dust removal chamber, and it is guaranteed that outflow air is clean while the grains can not run off; and wind power can be provided for the whole grain elevator through the draught fan, and therefore normal operation of the grain elevator is guaranteed.

Owner:HUNAN LEIGENG LIGHT TILLAGE MACHINE MFG CO LTD

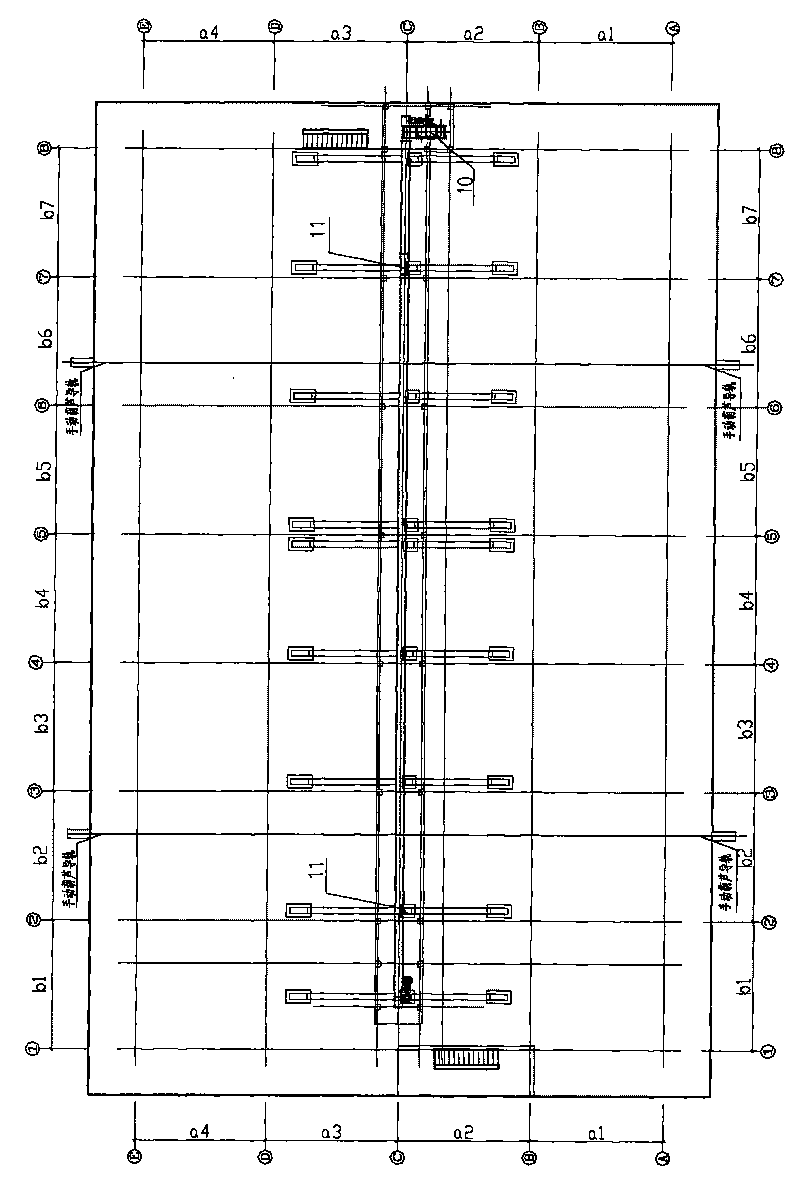

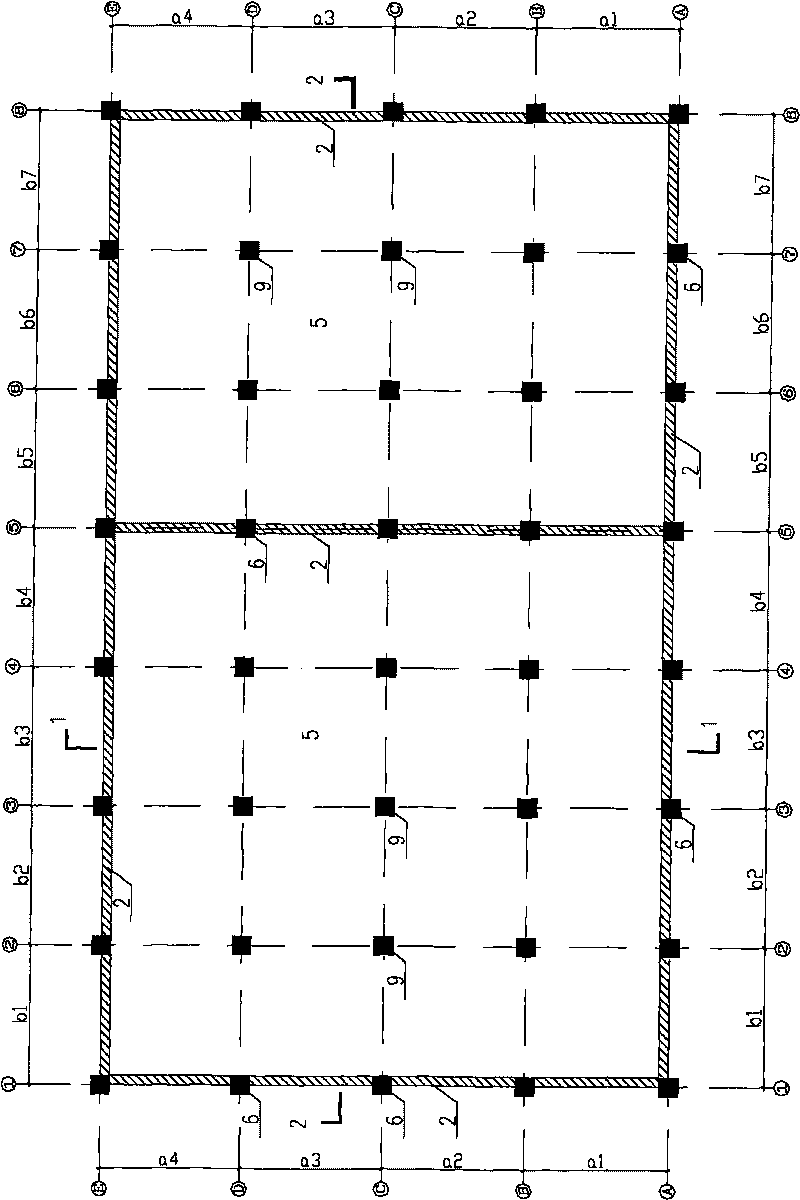

Storied bulk grain warehouse

InactiveCN101748920AGood safe grain storage effectClimate change adaptationBulk storage containerFloor slabGrain elevator

The invention relates to a storied bulk grain warehouse for storing bulk grain, which comprises a warehouse bottom, a warehouse wall, interlayer warehouse floor slabs, a warehouse roof slab, beams, columns, a vertical conveyer, a multi-point discharging conveyer, warehousing distribution chutes and discharging chutes; wherein the vertical conveyer is arranged at the end of the warehouse, and is used to vertically lift and convey grain to the top of the warehouse, the multi-point discharging conveyer is fixed on the top of the warehouse, and is connected with the warehousing distribution chutes, grain is warehoused via the warehousing distribution chutes of each interlayer warehouse floor slabs, the discharging chutes are arranged on the interlayer warehouse floor slabs and pass through the warehouse wall, most of the grain can automatically flow out of the warehouse, and the rest can be discharged out of the warehouse by pneumatic grain elevators combined with free-flow conduits. When the storied bulk grain warehouse is used to store bulk grain, the prior spaces (such as passageways between freight lifts and grain stacks and passageways between grain stacks and walls) reserved for the storage of packed grain can be used to store bulk grain, and thereby the utilization rate of warehouse capacity can be greatly increased; when the storied bulk grain warehouse is used to store bulk grain, because bulk grain can absorb energy under earthquake load, and therefore the storied bulk grain warehouse has high shock resistance; when the storied bulk grain warehouse is used to store bulk grain, grain can be loaded, transported, unloaded and stored in bulk, consequently, the processes of manually packing and unpacking grain in the process of circulation are dispensed with, so that the labor cost is reduced, meanwhile, packs are saved, resources are saved, and the efficiency of grain transportation can be increased.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

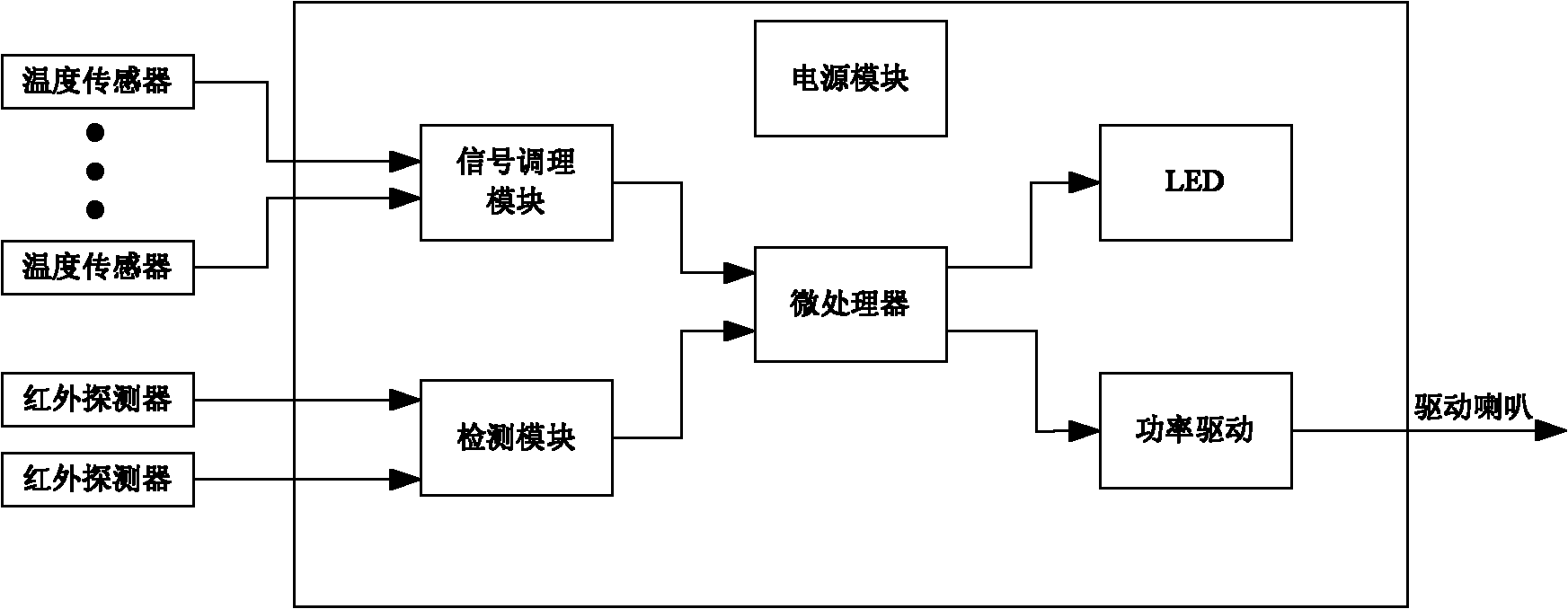

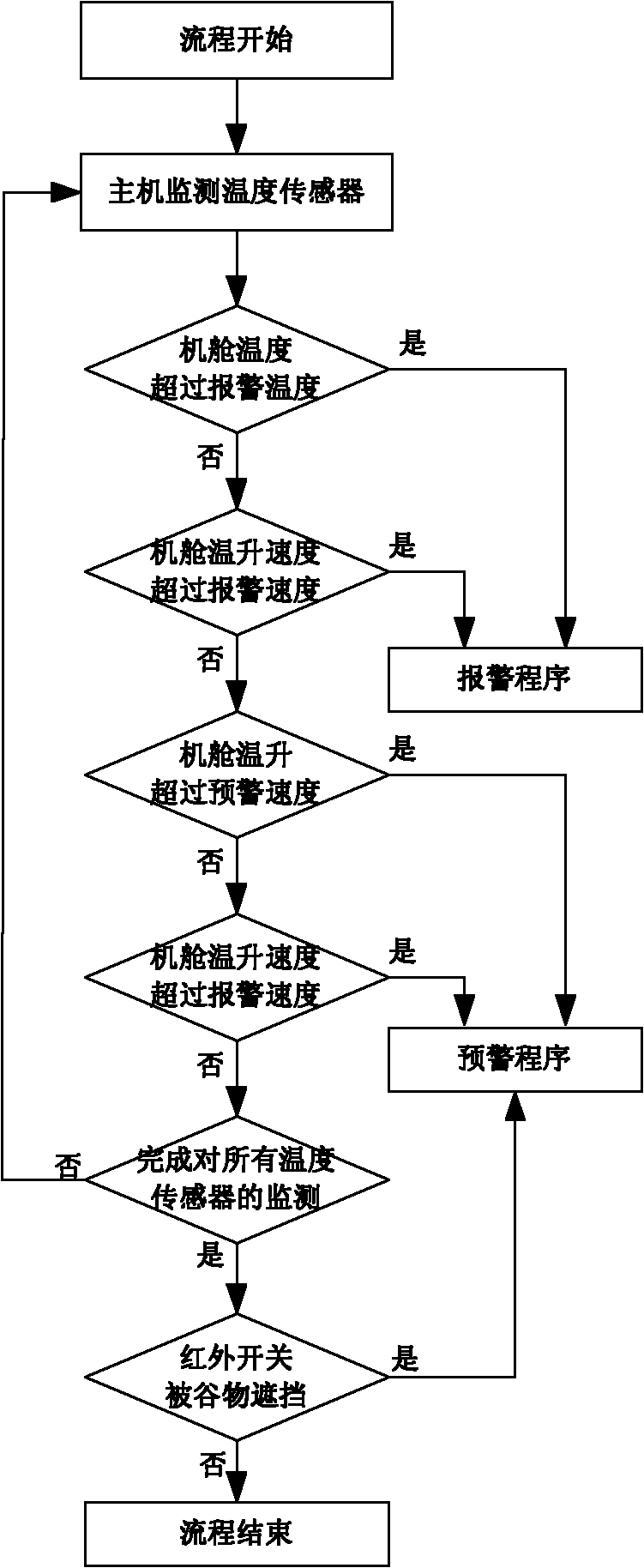

Fire alarm device and fire alarm method for harvester

The invention relates to a fire alarm device and a fire alarm method for a harvester. The fire alarm device comprises temperature sensors and an alarm host device, wherein the alarm host device comprises a microprocessor and a pre-alarm device; the temperature sensors are connected with the microprocessor in the alarm host device through leads; and the microprocessor is connected with the pre-alarm device. The fire alarm device has the characteristics that a plurality of sets of temperature sensors are respectively arranged in an engine room of an engine of the harvester; each temperature sensor comprises a plurality of temperature probes; each temperature probe is connected with the microprocessor; and two sets of infrared detectors are also arranged on a grain elevator in the engine room of the engine of the harvester. The fire alarm device is used for monitoring the temperature and the sundry piling height in the engine room of the engine of the harvester through the temperature sensors, the infrared detectors and the microprocessor and informing a harvester operator of the early warning and alarm information through an LED (Light Emitting Diode) and a buzzer so as to immediately adopt the treatment measures and effectively prevent the occurrence or the expansion of fire.

Owner:万信超

Multifunctional integrated agricultural machine

InactiveCN106718409AShorten the timeLabor savingSowingDrying solid materialsGrain elevatorAgricultural engineering

A multifunctional integrated agricultural machine comprises a machine frame, and the machine frame is fixedly provided with a seeding device, a film laying device, a grain conveying device, a grain spreading device and a film collection device. The machine integrates no-tillage seeding, film laying, grain airing and film collection, the devices can use independently, when one device is used independently, a corresponding hydraulic rod extends out and other hydraulic rods retract, that is, the devices with other functions can be folded. The devices can be used independently and can also be used in a matched mode or combined with a harvester in use. When the machine is combined with the harvester, harvesting, seeding and grain airing can be conducted at the same time, preceding crop grain crops are harvested by the harvester while no-tillage seeding of aftercrop crops is conducted, film laying and grain airing are conducted on the land where seeding is conducted, after grains are aired, the grains are collected into a warehouse through a pneumatic grain elevator, film collection is conducted through the film collection device of the machine, time is saved, a foundation is laid for early harvesting and early seeding, and labor is saved.

Owner:于光成

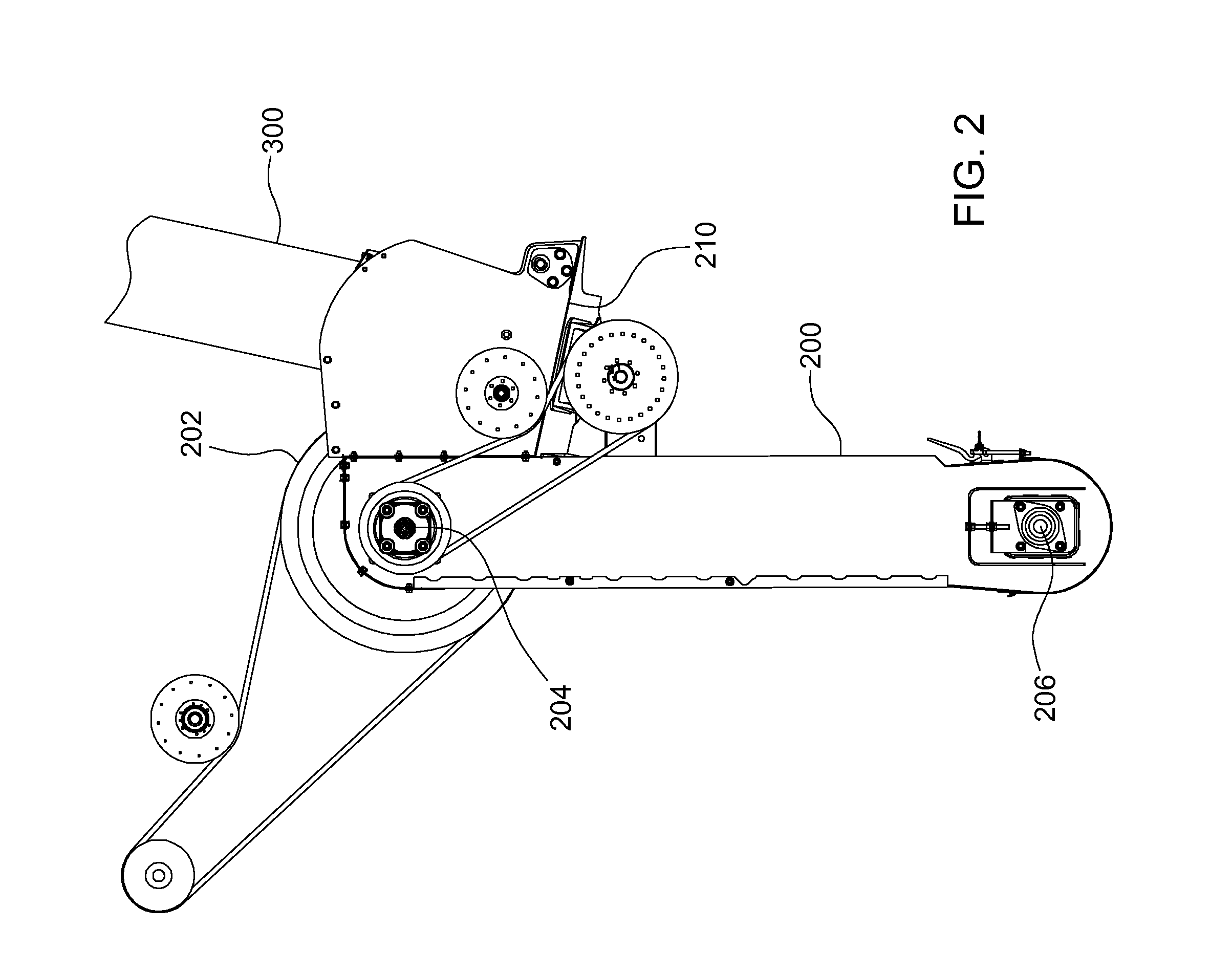

Integrated jackshaft for grain elevators of agricultural combines

A jackshaft and grain elevator arrangement is disclosed for agricultural combines. A grain elevator has a housing, a drive sprocket within the housing, a driven sprocket within the housing, and a chain within the housing. The chain is wrapped around the drive sprocket and the driven sprocket, and a plurality of paddles are attached to the chain. A shaft is fixed to and extends through the drive sprocket to drive rotation of the drive sprocket. A first pulley outside the housing is fixed to the shaft to receive power from an engine of the combine and is configured to transmit that power to the shaft. A second pulley outside the housing is fixed to the shaft to receive power from the shaft and is configured to transmit that power to a first crop processing device.

Owner:DEERE & CO

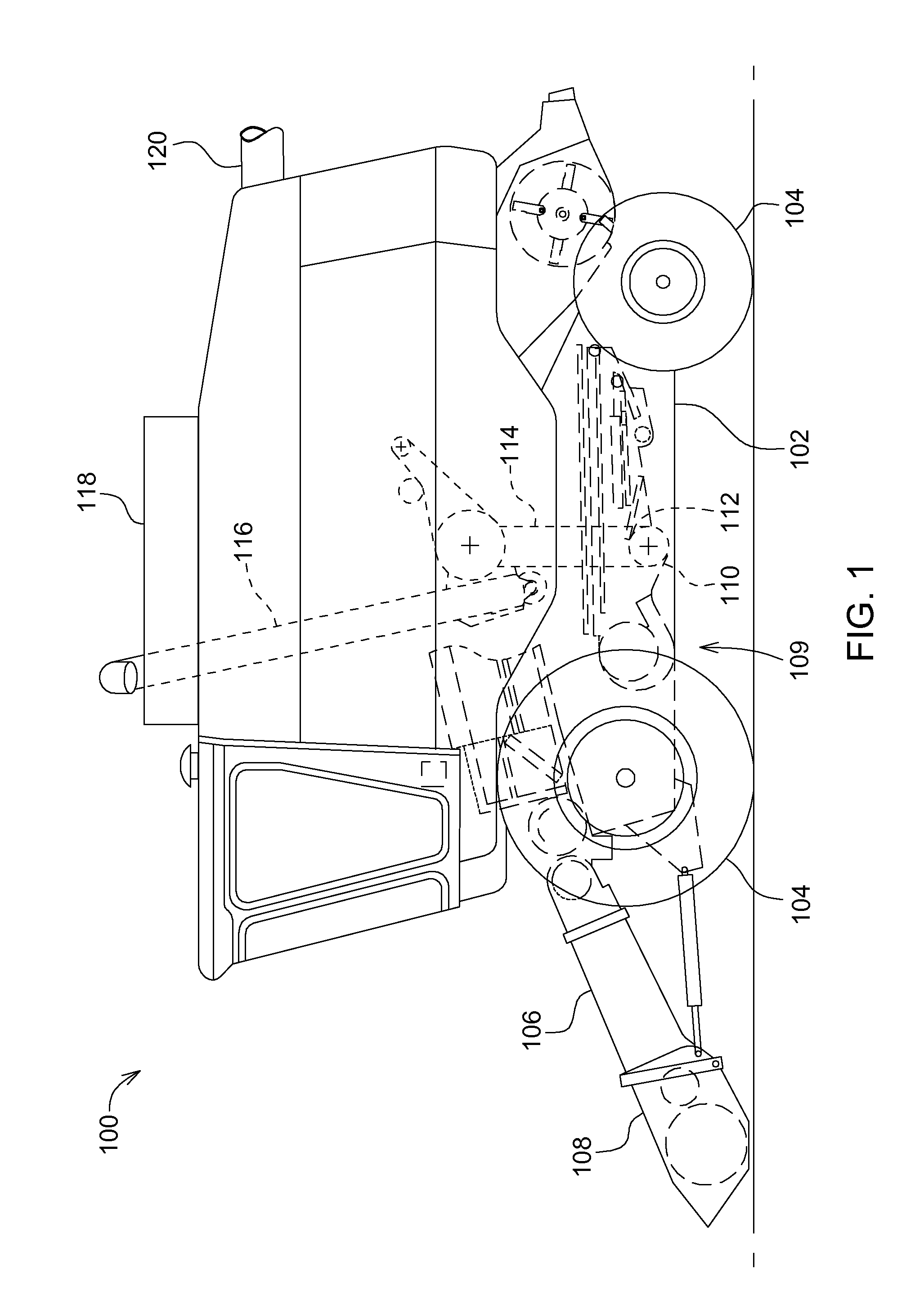

Agricultural harvester with bevel gear drive

A bevel gear drive arrangement for a grain conveyor of an agricultural harvester (100), wherein the agricultural harvester (100) comprises a chassis (102), wheels (104), a grain tank (118), and a grain elevator (114, 116), the bevel gear drive arrangement comprising a frame (408); a first shaft (406) supported on a first bearing (532); a first bevel gear (404) fixed to the first shaft (406); a second shaft (400); a second bevel gear (402) fixed to the second shaft (400), wherein the second shaft (400) is translatable along its axis (510) to a plurality of operating positions with respect to the frame (408).

Owner:DEERE & CO

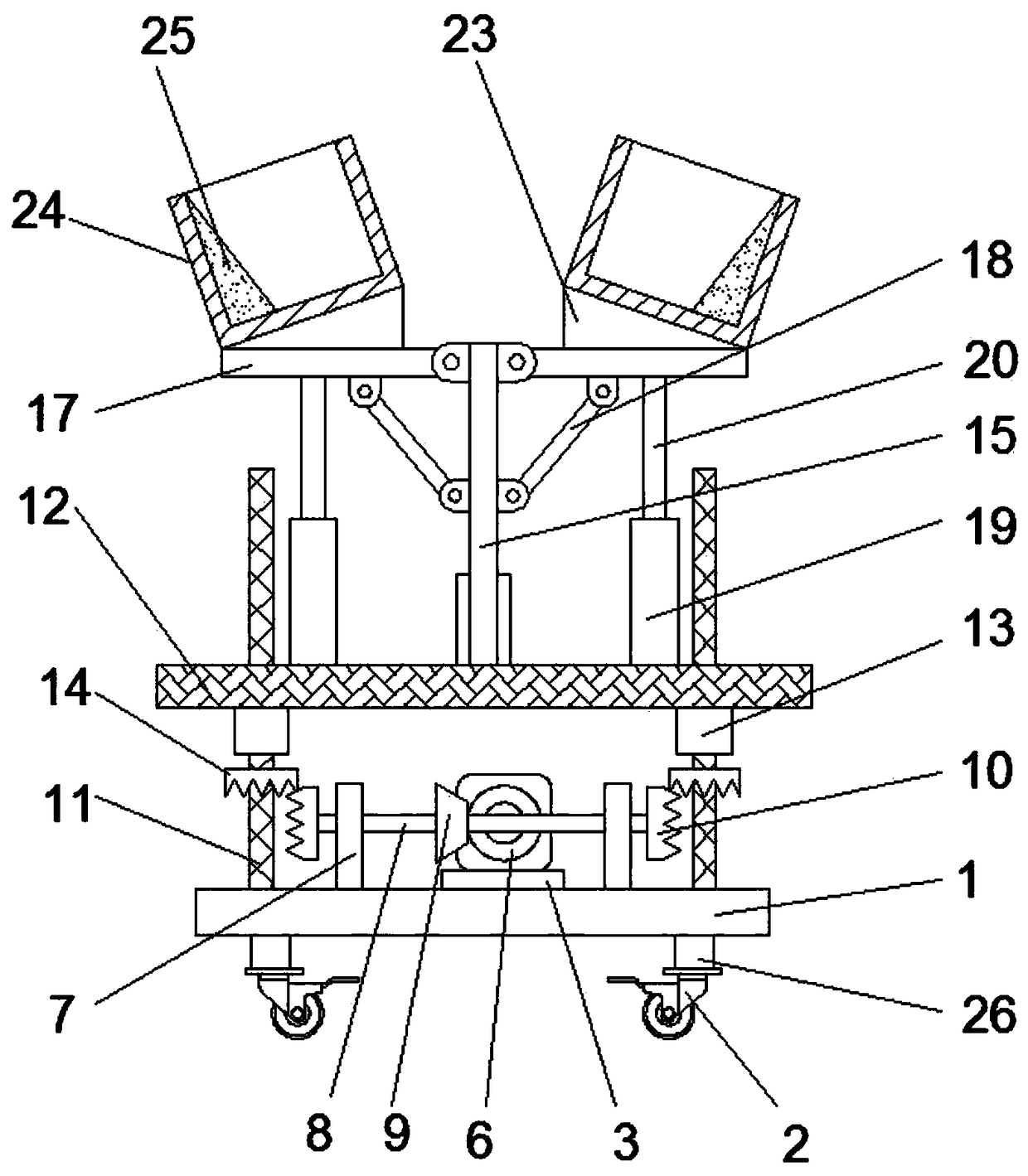

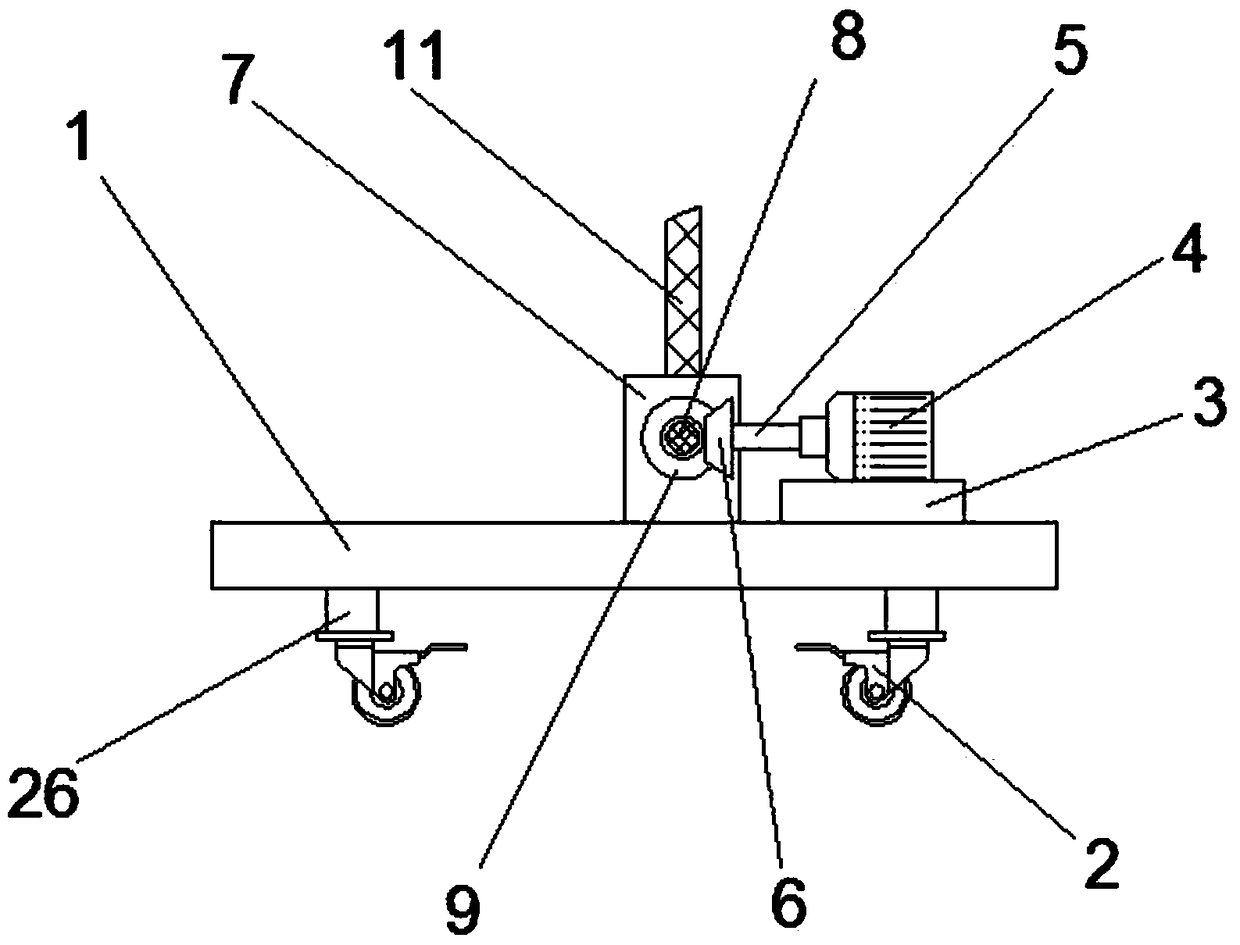

Grain elevator capable of automatically pouring grains

The invention discloses a grain elevator capable of automatically pouring grains. The grain elevator capable of automatically pouring grains comprises a chassis, a motor frame is arranged in the middle of the upper end of the chassis, an electromotor is arranged at the upper end of the motor frame, a motor shaft is arranged at the front end of the electromotor, the front end of the motor shaft isprovided with a first bevel gear, supporting plates are arranged on the left side and the right side of the upper end of the chassis correspondingly, a rotating rod is arranged on the supporting plates, a second bevel gear is arranged in the middle of the rotating rod, and third bevel gears are arranged at the left end and the right end of the rotating rod. According to the grain elevator capableof automatically pouring the grains, during working, a hydraulic cylinder is used for moving supporting rod downwards, loading boxes are inclined, and the grains can be poured on the designated position in slopes; the two loading boxes can be lifted at one time, and the loading and transportation rate is greatly improved; fine columns can move in sleeve columns, so that the supporting plates can be kept stable, then the loading boxes are prevented from tilting, and the grains are prevented from spilling out; and movement in any direction of the grain elevator can be facilitated through universal wheels at the bottom, manual carrying is omitted, the working efficiency is improved, and potential safety hazards are avoided.

Owner:安徽粮友机械科技有限公司

Grain elevator paddle for combine harvester

A paddle for a grain elevator of a combine harvester includes a plate and a leg. The plate is configured to be coupled to a chain at a first location on the chain. The plate has a top side for carrying grain, a bottom side opposite the top side, and a lip that extends along a perimeter of the top side of the plate for retaining the grain on the top side. The leg extends from a bottom side of the plate for releasably contacting the chain at a second location that is spaced from the first location.

Owner:BLUE LEAF I P INC

Gate with variable gate control for handling agricultural granular materials

ActiveUS20140190084A1Minimal numberAchieve modularityDoors/windowsLarge containersProximity sensorGrain elevator

Owner:SCHLAGEL

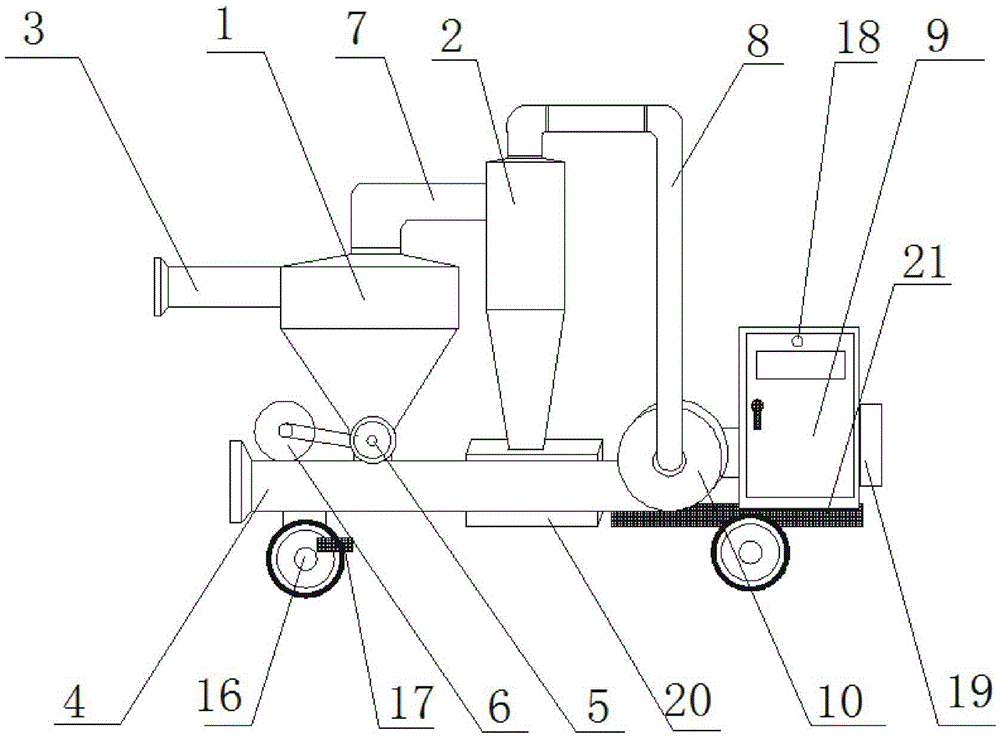

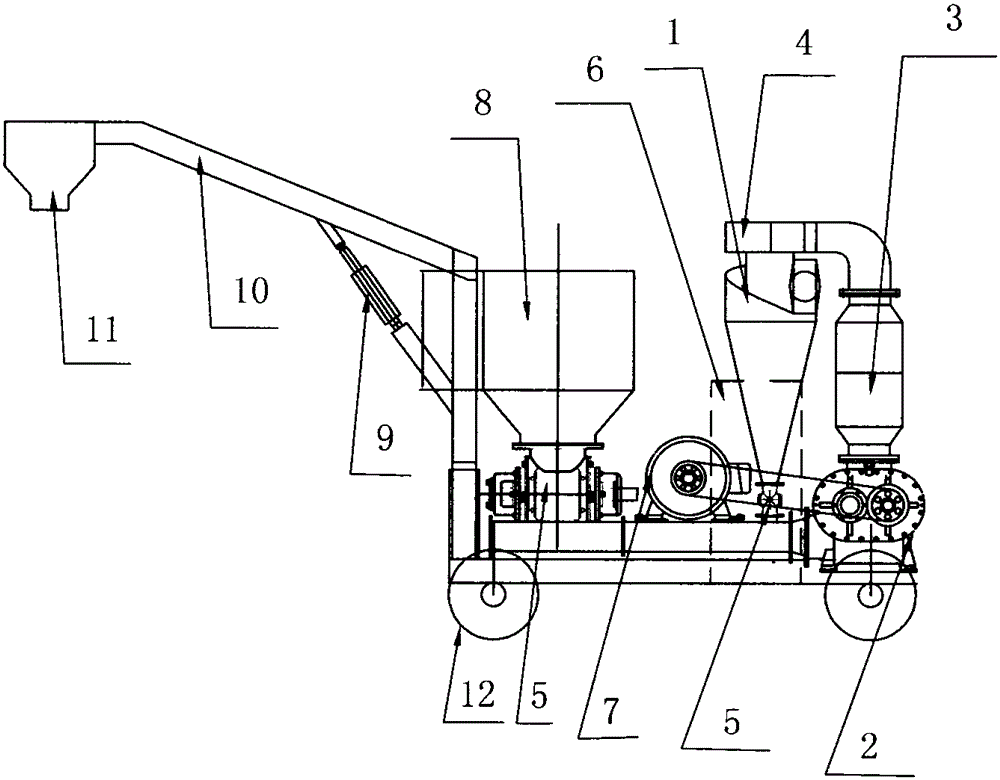

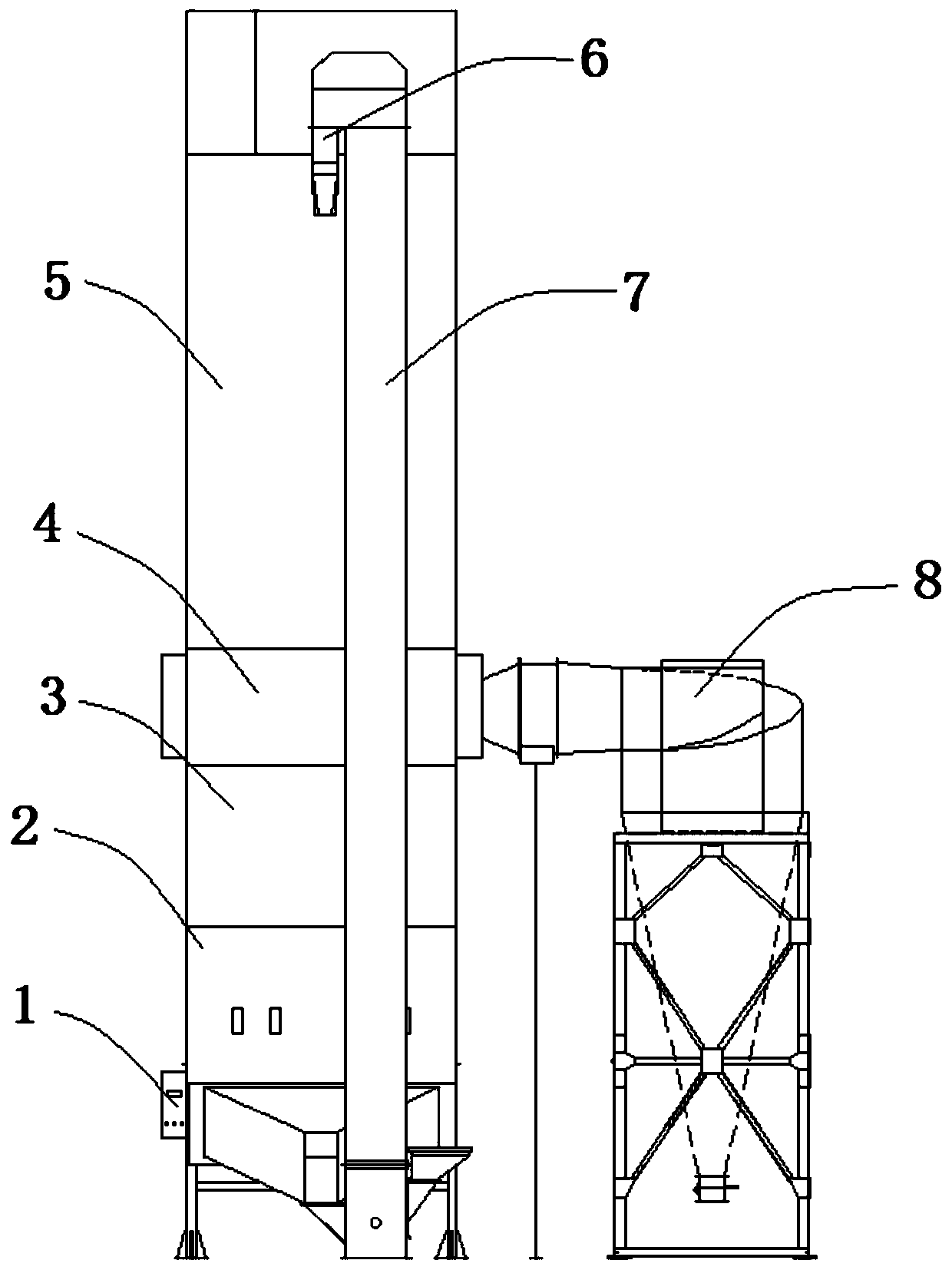

Large grain elevator

InactiveCN105151800AImprove work efficiencyImprove environmental indicatorsBulk conveyorsCycloneGrain elevator

The invention discloses a large grain elevator, and relates to the field of material transferring and transporting. The large grain elevator comprises a grain sucking device, a Roots blower, a silencer, a cyclone dust collector, an air seal device, an electric control cabinet, a motor, a buffering bin, an oil cylinder, an outlet pipeline, an outlet cyclone and walking wheels. The cyclone dust collector is arranged at the upper end of the grain sucking device and connected with the silencer through a pipeline. The Roots blower is arranged below the silencer. The air seal device is connected with the bottom of the grain sucking device. The electric control cabinet is arranged outside the air seal device. The Roots blower is connected with the motor through a crawler belt. The grain sucking device is communicated with the buffering bin through a bottom channel. The air seal device is connected between the buffering bin and the channel. The upper portion of the buffering bin is communicated with the outlet pipeline, and the other end of the outlet pipeline is connected with the outlet cyclone. The lower portion of the outlet pipeline is connected with the oil cylinder. The walking wheels are arranged at the bottom of the whole grain elevator. The large grain elevator has the beneficial effects of being high in working efficiency, large in yield, high in environment protection index and convenient, safe and reliable to operate.

Owner:常州润雍机械厂

Agricultural motor vehicle

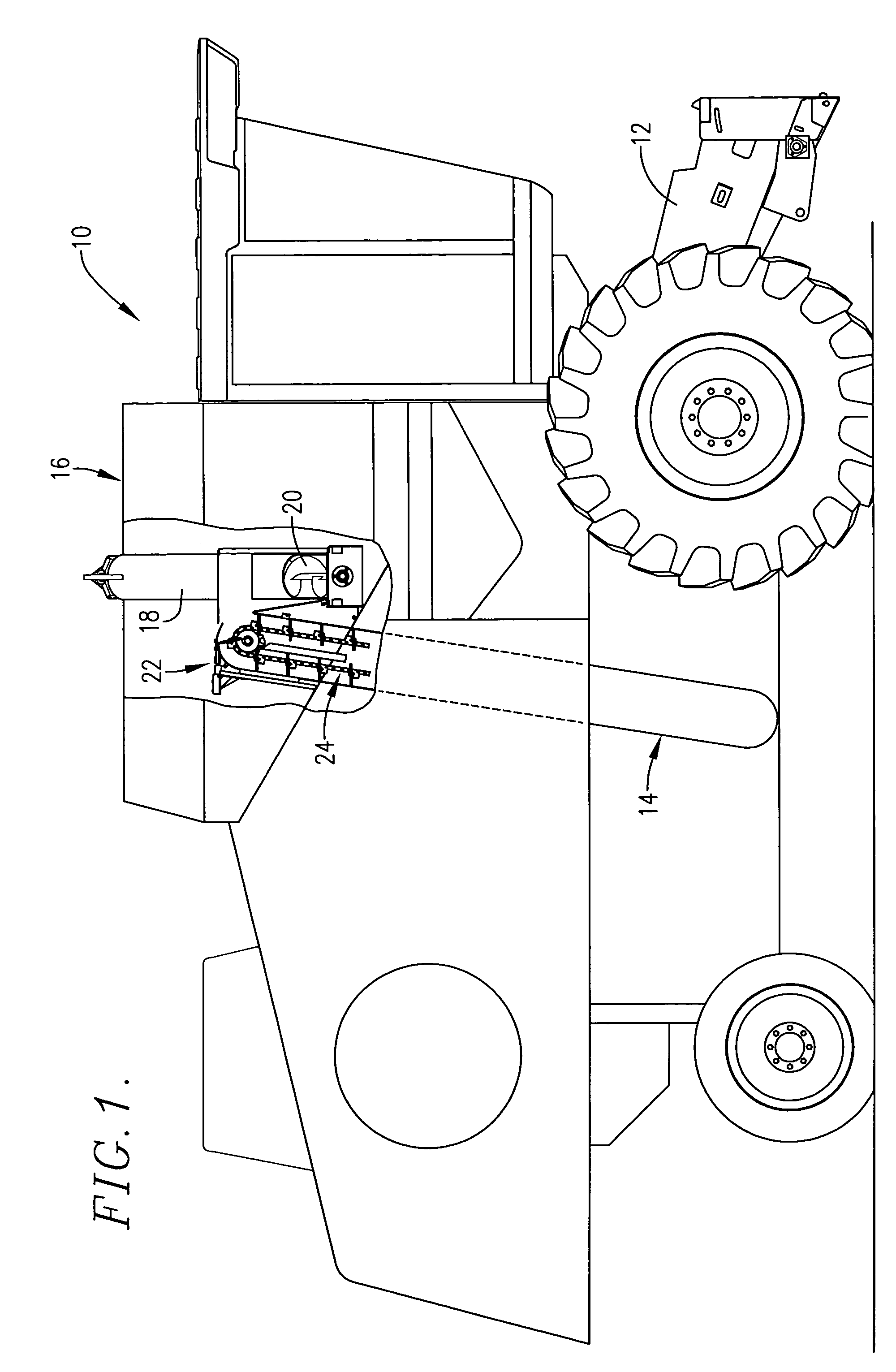

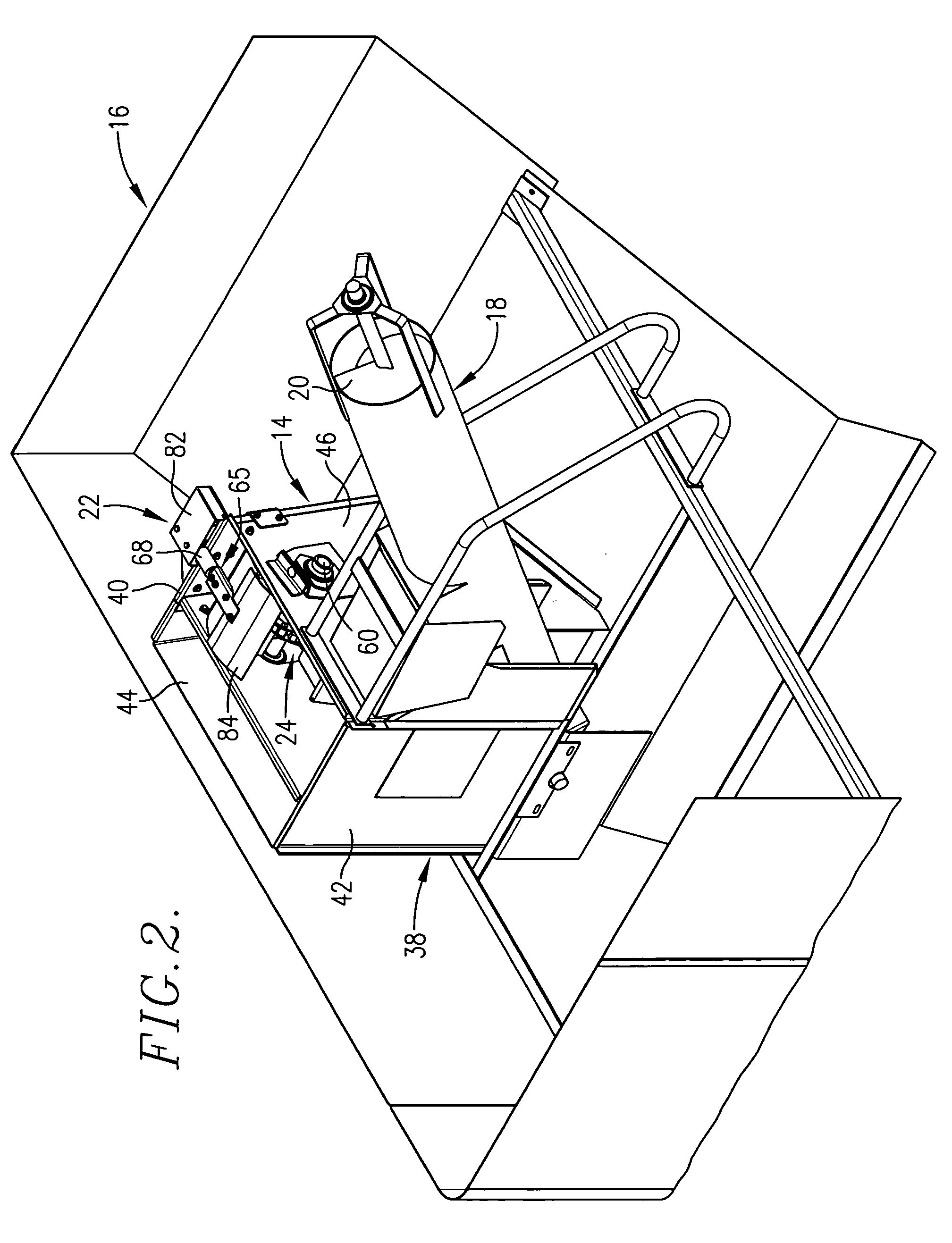

ActiveUS20190254220A1Fast transferCompact structureAgricultural vehiclesSievingGrain elevatorAgricultural engineering

An agricultural motor vehicle able to connect to a variety of agricultural implements, and comprising a structural set having four parts: a lower chassis, an intermediate structure, a front complementary structure, and a rear complementary structure. The set is supported over a set of front traction wheels and a set of smaller rear wheels and also houses a vibrating sieve, above which is located a beating cylinder, the front edge of which connects to a concentrating guiding roller and a hinged inlet nozzle, as well as a cockpit and a grain dumper located over the set. Preceding the grain dumper is a clean grain collection gutter, a motor power set, a suction cleaning set, a clean grain elevator and lastly, a retractable side belt, whose lower edge is hinged at its midpoint and located on the upper edge of the intermediate structure.

Owner:IND REUNIDAS COLOMBO LTD

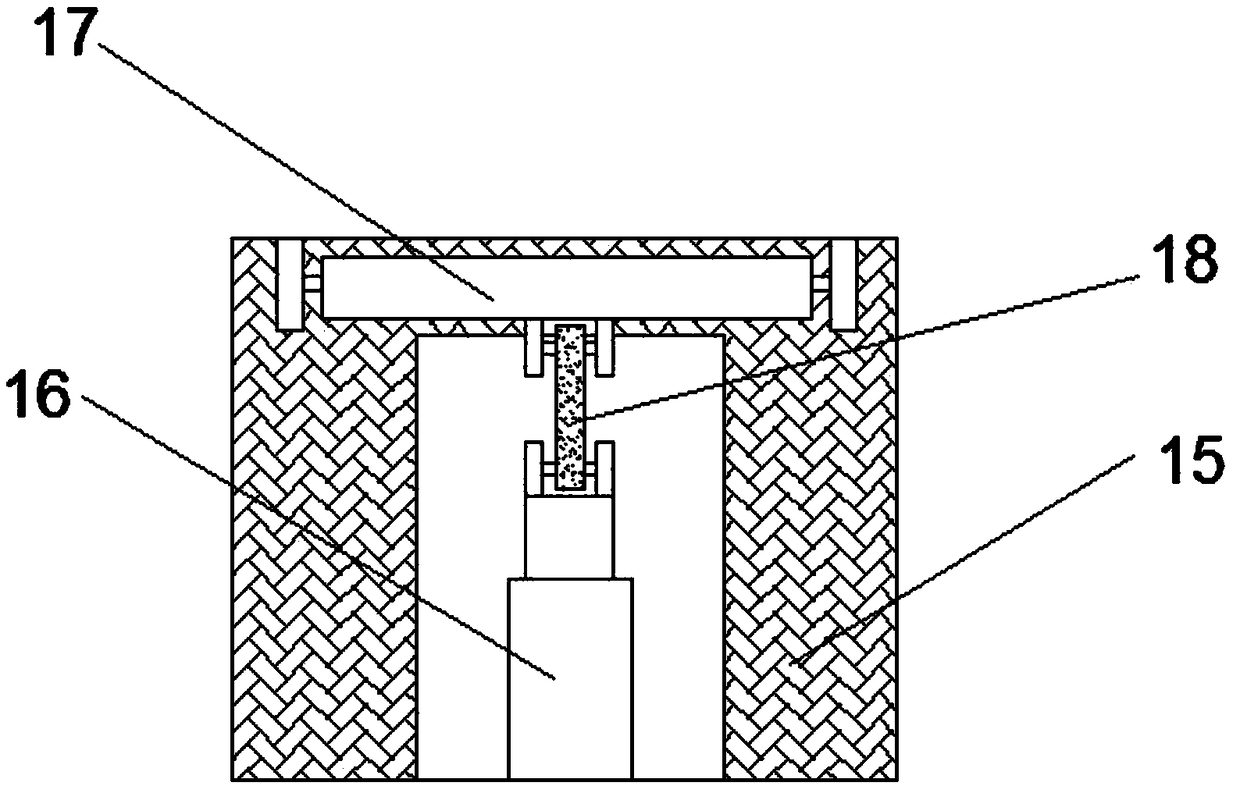

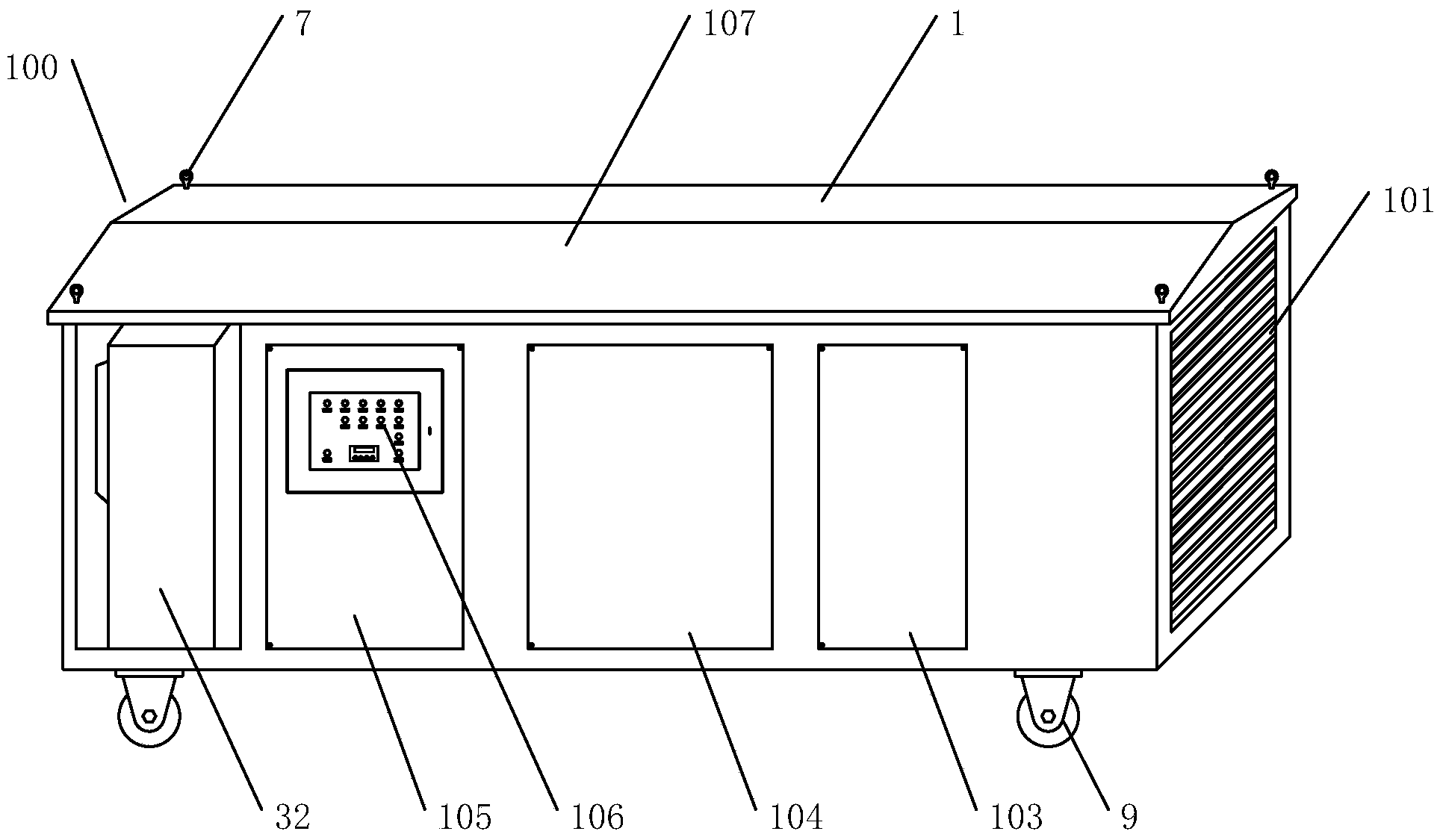

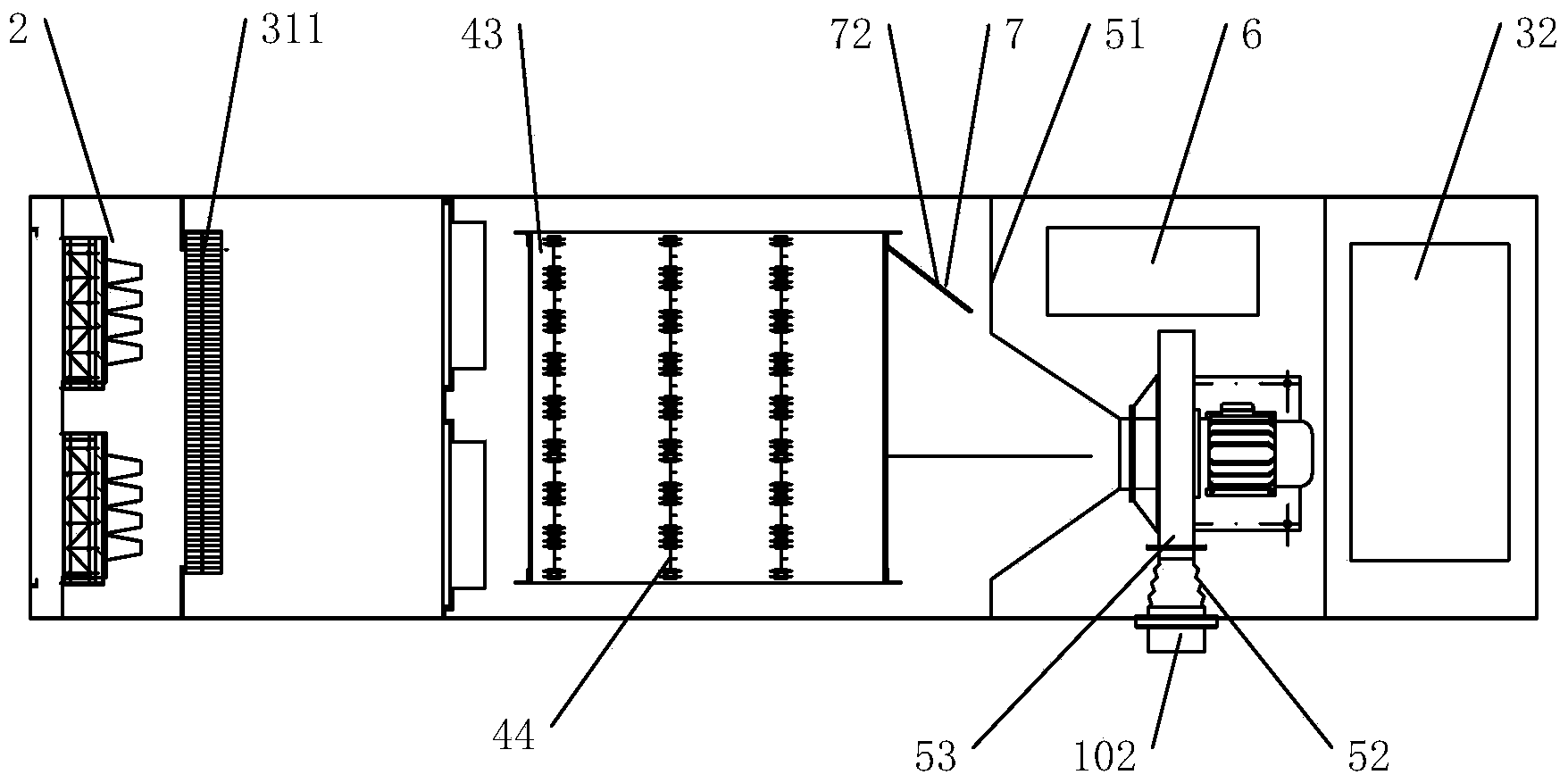

Ozone sterilization and dezymotizing treatment machine for grain elevators

The invention relates to an ozone sterilization and dezymotizing treatment machine for grain elevators, which comprises a shell and a control unit, wherein an air inlet and an air outlet are formed in the shell. The machine is characterized by comprising a filter unit, a refrigeration conditioning unit and an ozone generation unit, wherein the filter unit, the refrigeration conditioning unit and the ozone generation unit are arranged between the air inlet and the air outlet; the control unit is used for controlling the starting and stopping of the refrigeration conditioning unit and the ozone generation unit; the refrigeration conditioning unit and the filter unit are arranged in a crossing manner; the ozone generation unit is arranged at the downstream areas of the filter unit and the refrigeration conditioning unit. According to the ozone sterilization and dezymotizing treatment machine, filtered air can be cooled while the filter air is dried; the ozone generation unit can be effectively cooled while ozone is formed due to the ozone generation unit arranged at the downstream areas of the filter unit and the refrigeration conditioning unit.

Owner:中机天安(北京)粮储安全技术研究院

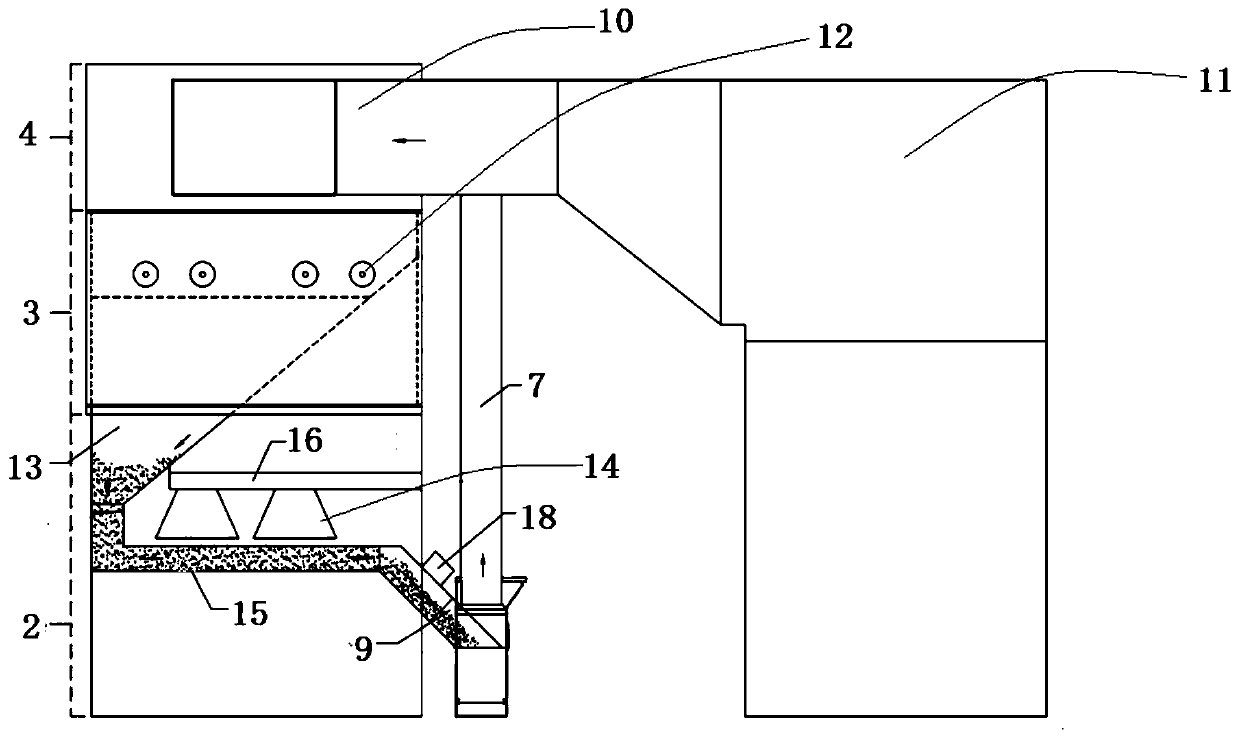

Batch type microwave grain dryer and drying method

PendingCN110094944AReduce waist burst rateReduce moisture gradientDrying solid materials with heatDrying gas arrangementsMicrowaveGrain elevator

The invention relates to a batch type microwave grain dryer and a drying method. The batch type microwave grain dryer is provided with a grain elevator, and a tempering bin, a drying chamber, a collecting chamber and a microwave heating device which are connected with each other are sequentially arranged from top to bottom, wherein the drying chamber is used for drying and dehumidifying grains, and the microwave heating device is used for microwave heating of grains; a discharging port at the upper end of the grain elevator is connected with the tempering bin, and a discharging port of the microwave heating device is connected with a feeding port at the lower end of the grain elevator. According to the batch type microwave grain dryer, the grain discharging speed, the microwave heating radiation frequency and the temperature and humidity of the drying chamber hot air are controlled according to grain temperature and grain moisture, so that variable temperature and variable frequency drying are realized, and the drying efficiency of the grain is effectively improved.

Owner:ZOOMLION HEAVY MASCH CO LTD

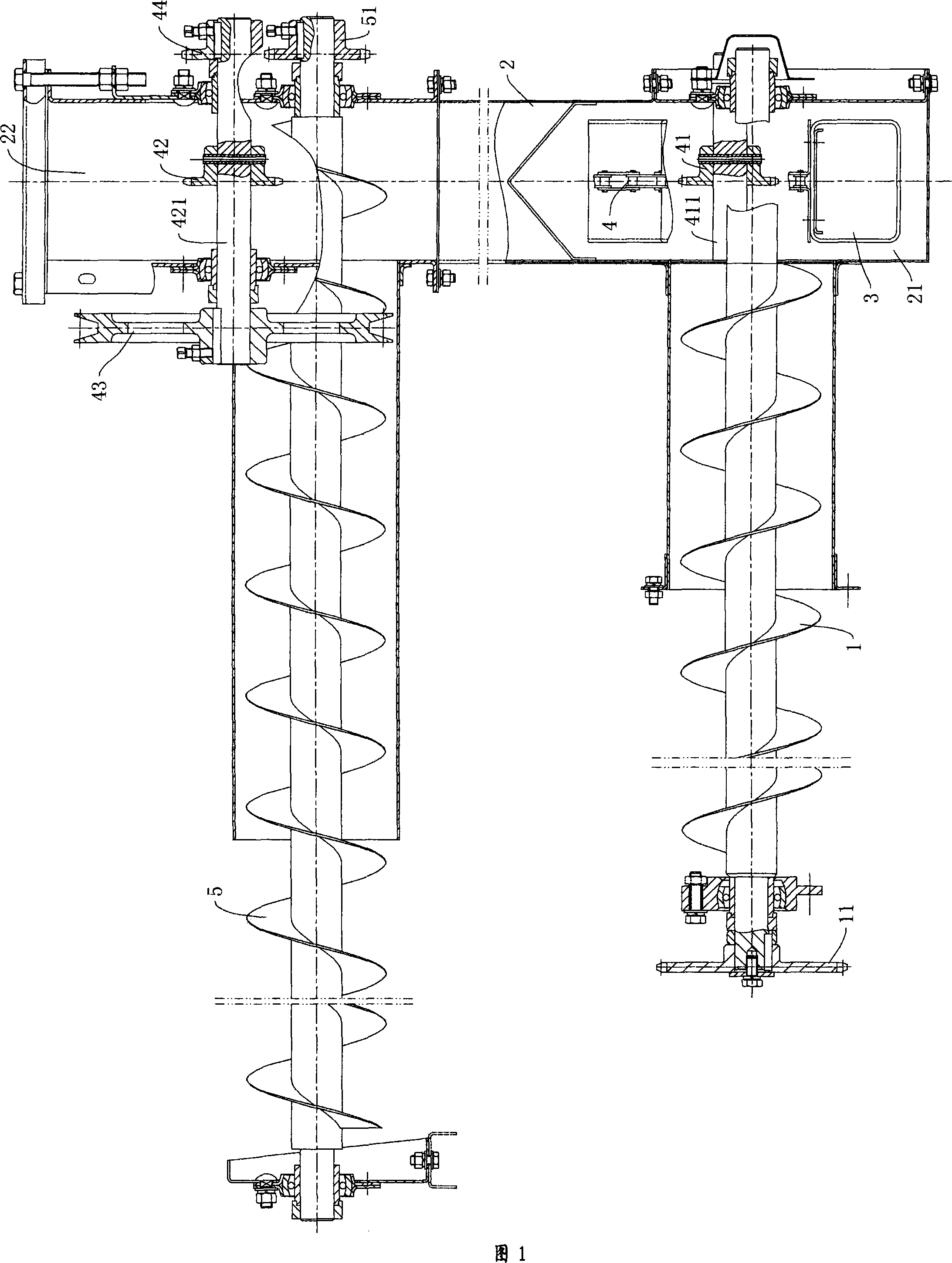

Novel seed lift conveyer of harvester

InactiveCN101228824AFacilitate transmissionSimple and reliable transmissionThreshersGrain elevatorGrain storage

The invention discloses a novel grain elevator of a harvester, which comprises that a cylinder shell is arranged on a machine body; the bottom end of the cylinder shell is provided with a bottom grain storage cavity, while the top end is provided with a top grain storage cavity; a lifting chain that can run with the driving force of a power plant, is arranged inside the cylinder shell via lifting sprockets and lowering sprockets; on the lifting chain, a plurality of grain storage buckets are successively arranged; the bottom grain storage cavity is connected with a bottom screw conveyer for transferring grains, while the top grain storage cavity is connected with a top screw conveyer. In the process of grain lifting, the invention is low in grain breaking rate, strong in lifting force, novel and antiwear in grain storage media, while the whole lifting device is convenient to maintain, of low power consumption and wide range of applicable crops.

Owner:LOVOL HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com