Grain elevator with multilevel treatment function

A grain suction machine and fan technology, which is applied to conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of environmental pollution, inconvenient control methods, and reduce the service life of grain suction machines. space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

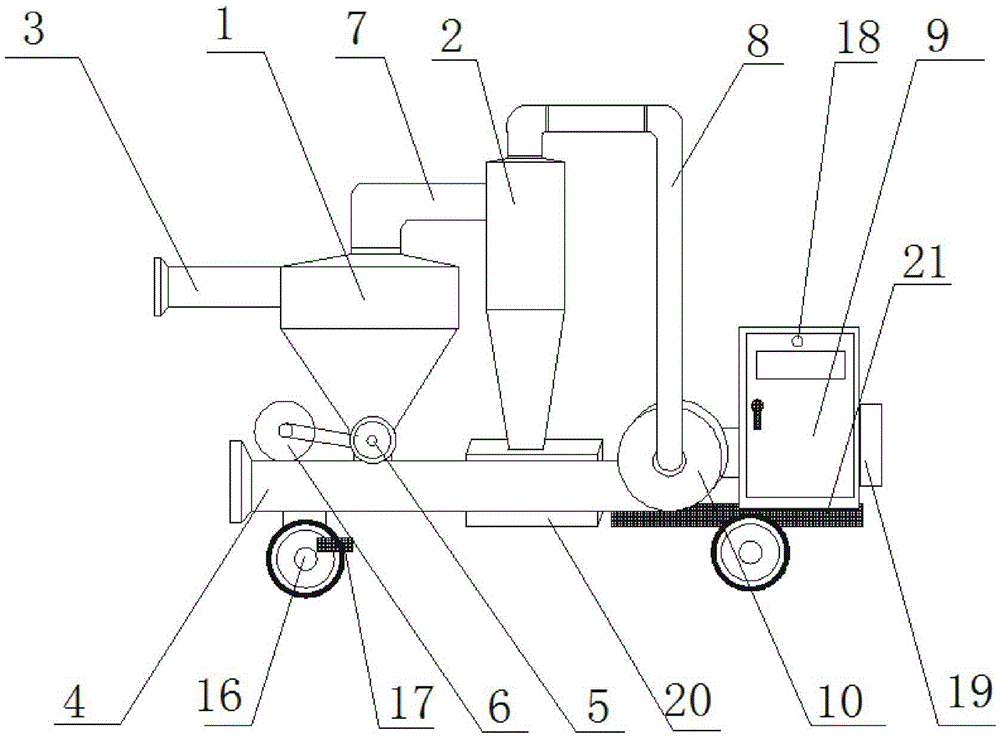

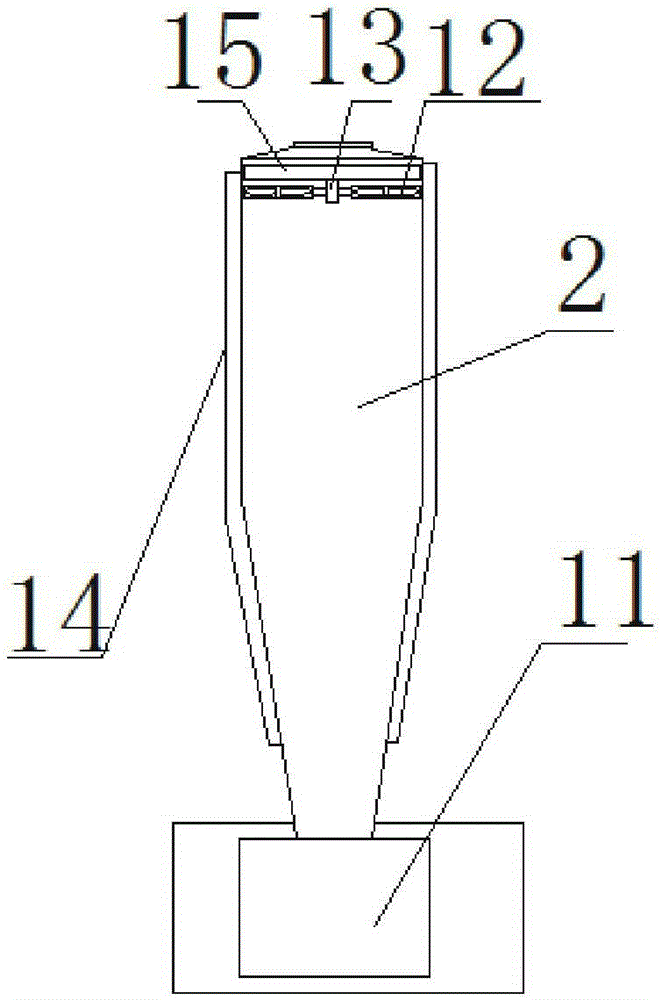

[0022] Such as figure 1 and figure 2 As shown, the bottom of the dust removal chamber 2 is provided with a dust collection box 20 , and the bottom of the dust collection box 20 is provided with a briquetting machine 11 .

[0023] In the present invention, the dust from the dust removal chamber 2 can be collected through the dust collection box 20 to facilitate subsequent processing, and the dust in the dust collection box 20 can be briquetted through the briquetting machine 11, thereby saving collection The space of the dust box 20 is large and convenient to handle the dust.

Embodiment 2

[0025] Such as figure 1 and figure 2 As shown, the inside of the dust removal chamber 2 is provided with a fan 12, the fan 12 is fixedly mounted on the rotating shaft 13, one side of the rotating shaft 13 is fixedly connected to the turntable 15, and the dust removal chamber 2 is provided with a separation layer 14, The bottom of the separation layer 14 is fixedly connected with the discharge pipe 4 .

[0026] In the present invention, the spiral wind can be generated in the dust removal chamber 2 through the work of the fan 12, the rotating shaft 13 and the rotating disk 15, so as to realize the dust removal function of the dust removal chamber 2, and through the separation layer 14, it can be aligned in the dust removal chamber 2. The grain thrown out is collected to prevent it from entering the dust box 20 and causing waste.

Embodiment 3

[0028] Such as figure 1 As shown, the bottom of the discharge channel 4 and the bearing plate 21 are provided with rollers 16, and roller holders 17 are fixedly installed on the rollers 16.

[0029] In the present invention, the roller 16 can be fixed by the roller fixer 17, so as to prevent the grain suction machine from moving during use and affecting the use of the grain suction machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com