Patents

Literature

102results about How to "Reduce waist burst rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method allowing lower broken rice rate

The invention relates to a processing method allowing lower broken rice rate and belongs to the technical field of rice processing. The processing method includes the steps of rice screening, stone removal, magnetic separation, moisture measurement and drying or atomizing, hulling, husked rice separation, thickness classification, moisture measurement and drying or atomizing, rolling, white rice classification, cooling, polishing, color sorting, water content detection, and sterilizing and packaging. The rice processed by the processing method is low in broken rice rate, long in shelf life and good in glossiness, and flavor of the rice is rarely lost.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

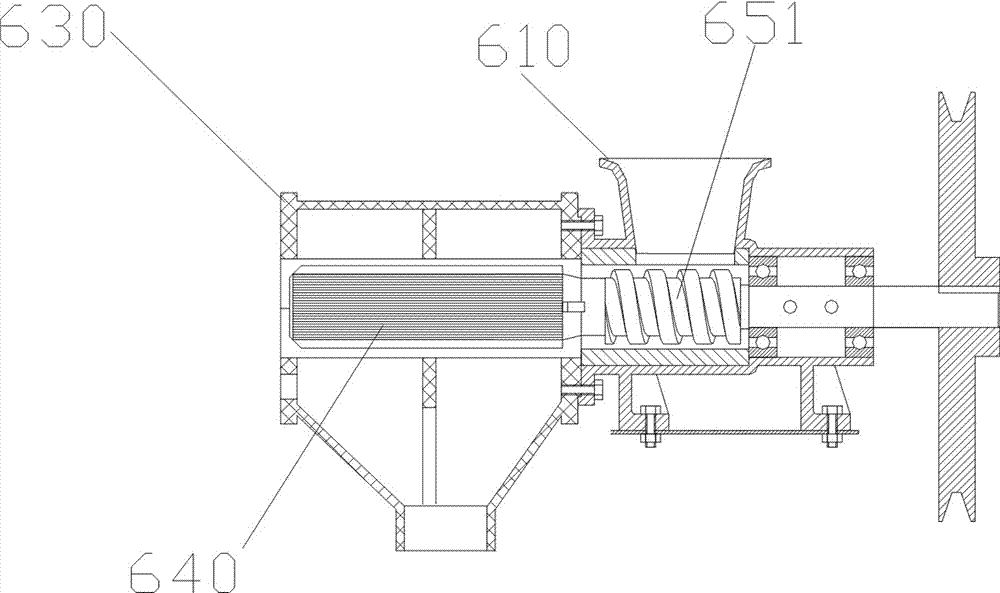

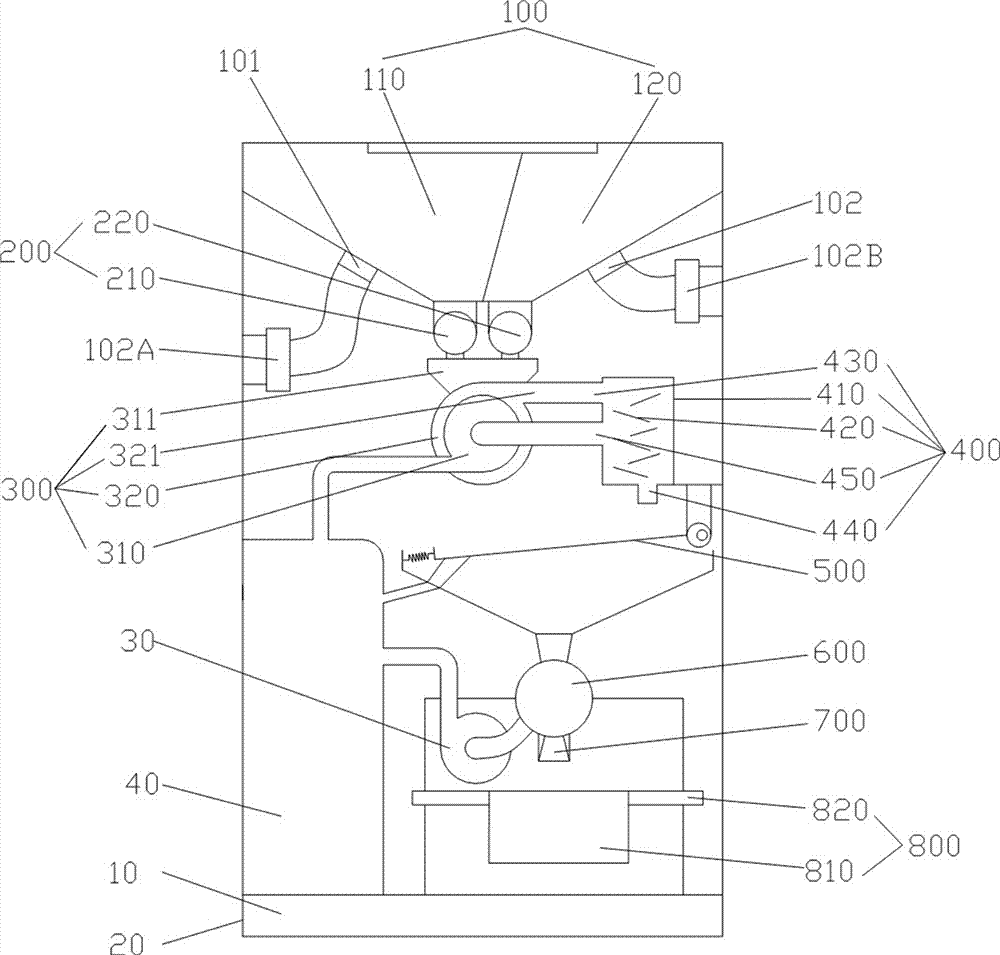

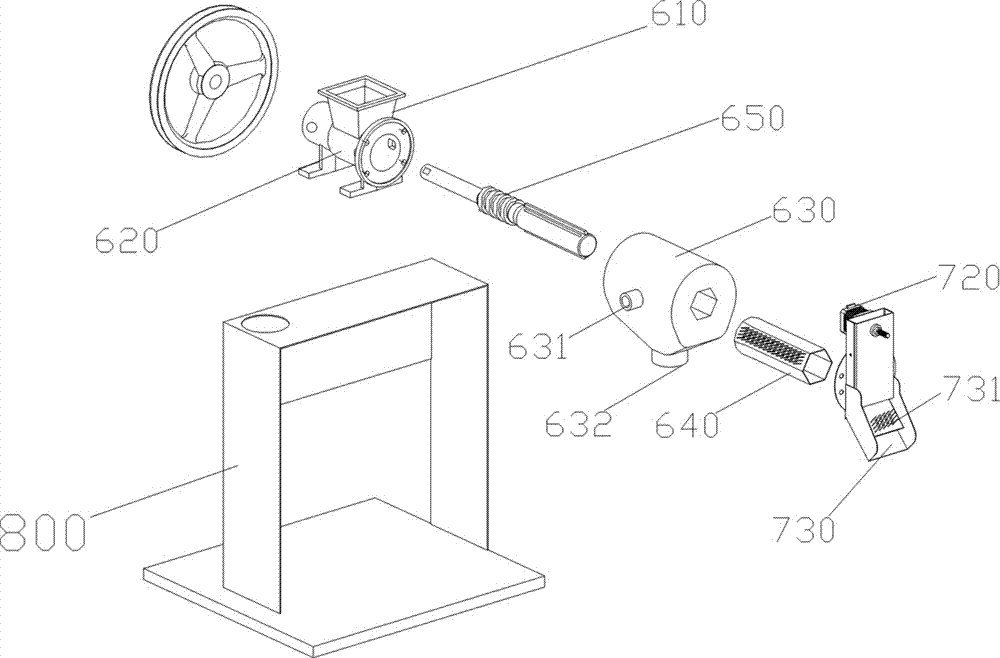

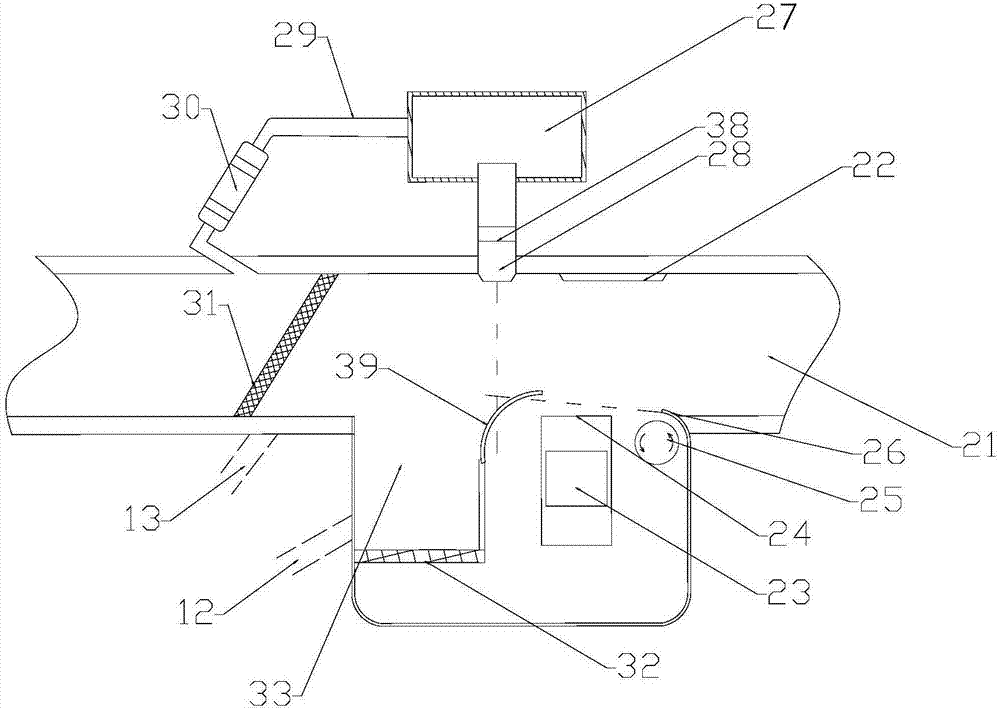

Unattended operation self-service intelligent rice husking machine and rice husking method

PendingCN107497525AGuaranteed freshReduce the broken rice rate and waist burst rateGrain huskingGrain polishingBroken riceManufacturing engineering

Owner:深圳市艾雷特科技有限公司

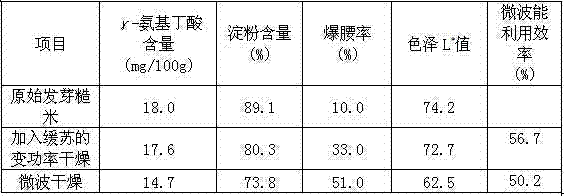

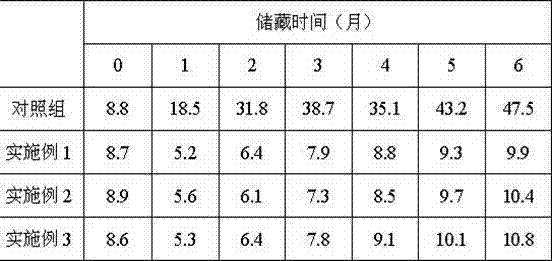

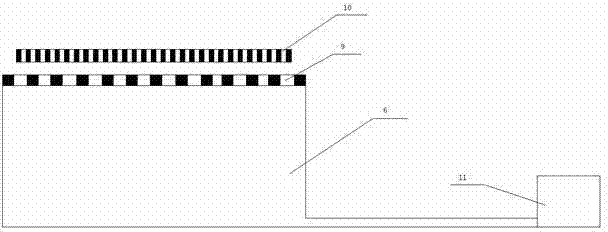

Microwave drying germinated brown rice quality protecting method based on tempering and variable power

InactiveCN104489082ARich in nutrientsReduce waist burst rateSeed preservation by dryingMicrowaveGamma-Aminobutyric acid

The invention discloses a microwave drying germinated brown rice quality protecting method based on tempering and variable power, and relates to a drying method of germinated brown rice. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power solves the problems that an existing microwave drying method of the germinated brown rice destroys nutritional ingredients in the germinated brown rice, and microwave energy is low in utilization efficiency. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power includes: evenly and flatly spreading the germinated brown rice on a continuous microwave drying device conveying belt, introducing a tempering and variable power technology under certain microwave drying power and certain air speed, and drying the germinated brown rice until moisture content of the germinated brown rice ranges from 14% to 15%. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power retains the nutritional ingredients in the germinated brown rice to the utmost. The germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power contains 13.1-18.5mg / 100g of gamma-aminobutyric acid, and starch content in the germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 69.0%-89.3%. Breakdown rate of the germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 30.0%-40.0%. Color L* value of the germinated brown rice after being dried through the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 60.6-70.4. Microwave energy utilization efficiency of the microwave drying germinated brown rice quality protecting method based on the tempering and the variable power is 50.7%-60.5%. The microwave drying germinated brown rice quality protecting method based on the tempering and the variable power obtains good quality products, retains the intrinsic nutritional ingredients and intrinsic colors of the germinated brown rice to the utmost, and achieves good quality.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Production method of germinated brown rice and application thereof

InactiveCN106576498APromotes bud formationShorten the timeEdible seed preservationSeed immunisationGerminationBrown rice

The invention discloses a production method of germinated brown rice, which comprises the following steps of: (1) cleaning and disinfection; (2) soaking and sterilization; (3) heat treatment; (4) germination; (5) pre-gelatinization; (6) tempering; and (7) drying and vacuum packaging. The method disclosed by the invention is simple, can effectively solve the problems of difficulty in cooking, poor taste and poor stability of the germinated brown rice, and promotes nutritional value of the germinated brown rice.

Owner:SICHUAN DANONGHE AGRI DEV CO LTD

Production method of clean rice with excellent pulpability

InactiveCN102960609AEnhance cooking characteristicsPromote degradationFood preparationHigh humidityFar infrared

The invention relates to a production method of clean rice with excellent pulpability. The production method is characterized by comprising the steps of slowly adding acid solution in an atomization way, irradiating by a low-heat source far infrared ray to gradually activate enzymes in rice after tempering for a period of time, and simultaneously evaporating free moisture in the rice to obtain the clean rice with the excellent pulpability. According to the preparation method, the rate of rice crack is effectively reduced through slow humidification by an atomization method and low-temperature high-humidity tempering treatment, and the loss of nutritional ingredients is also reduced.

Owner:NANCHANG UNIV

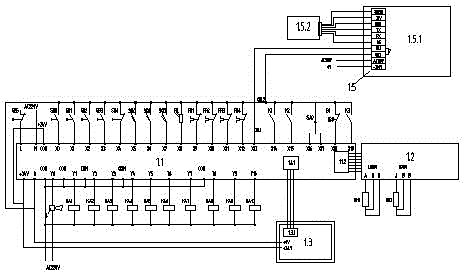

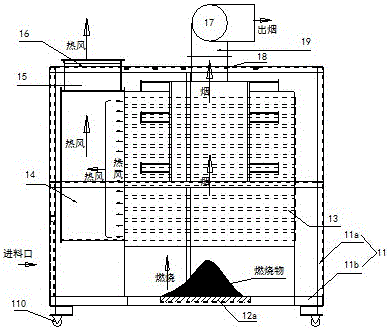

Controller special for two-section fire grain drier with multi-protection function

InactiveCN102749876AImprove reliabilitySolution to short lifeProgramme control in sequence/logic controllersAgricultural engineeringTouchscreen

The invention discloses a controller special for a two-section fire grain drier with a multi-protection function. The controller comprises a programmable controller, a temperature sensor module, a touch screen and a moisture meter, wherein the programmable controller serves as a control host machine; a program control module is arranged in the programmable controller; the programmable controller controls the action of each part of the drier; a two-section fire combustor is adopted to heat; a temperature sensor is adopted to collect the temperature of hot air and the temperature of grains; the moisture meter is adopted to detect the moisture of the grains; the touch screen is adopted to set operation parameters, monitor the temperature and the operation state of the drier and timely display the abnormal information of the drier equipment. Different heating ways can be selected according to different grain drying requirements, so that a grain drying process is scientific and reasonable. The controller also has the functions of detecting overload protection of a motor, oil-lacking protection of an oil tank, slipping of a belt of a lifter and the like. The controller has the characteristics of high reliability, long service life, convenience in operation and maintenance, complete protection function and the like.

Owner:JIANGSU TIANYU AGRI MACHINERY

Production method of germinated rice

InactiveCN102599435ASimple production processEasy to implementFood preparationOzone generatorPesticide residue

The invention relates to the technical field of food processing, one of grain deep processing, in particular to a production method of germinated rice. The production method has the following advantages: more particularly, germination of unhusked rice is directly accelerated to prepare germinated unhusked rice and then the germinated unhusked rice is processed into the finished product, namely germinated rice; in the implementation process, the unhusked rice is soaked and sterilized in ozone water solution prepared by an ozone generator and a gas-liquid mixing pump, so that the pesticides on the surface of the unhusked rice can be effectively oxidized, the pesticide residues can be reduced and the quality of the germinated rice product can be guaranteed; after being soaked in cold water and warm water alternately, the unhusked rice is put in the environment with temperature being 30-33 DEG C and relative humidity being 85-90% to undergo germination acceleration to prepare the germinated unhusked rice; the germinated unhusked rice is processed into the germinated rice after being dried in the low temperature state; the comprehensive nutritive indexes of the germinated rice product produced by the method greatly exceed the comprehensive nutritive indexes of the common rice; the germinated rice product has magical effect on improving sub-health of modern people; and the product has low production cost, good effects and good prospect.

Owner:何寒

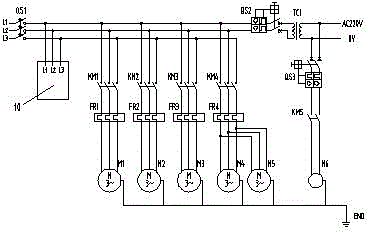

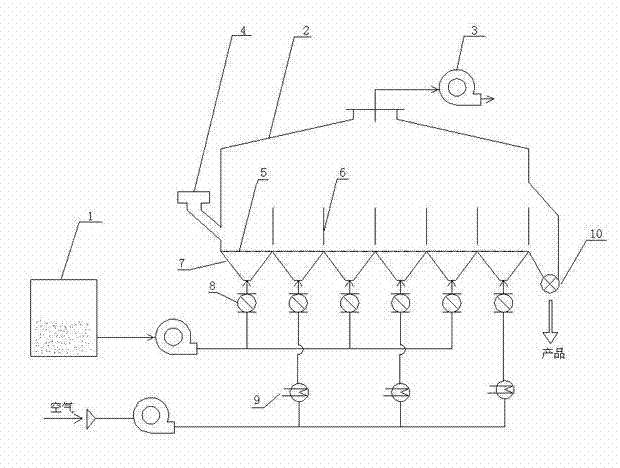

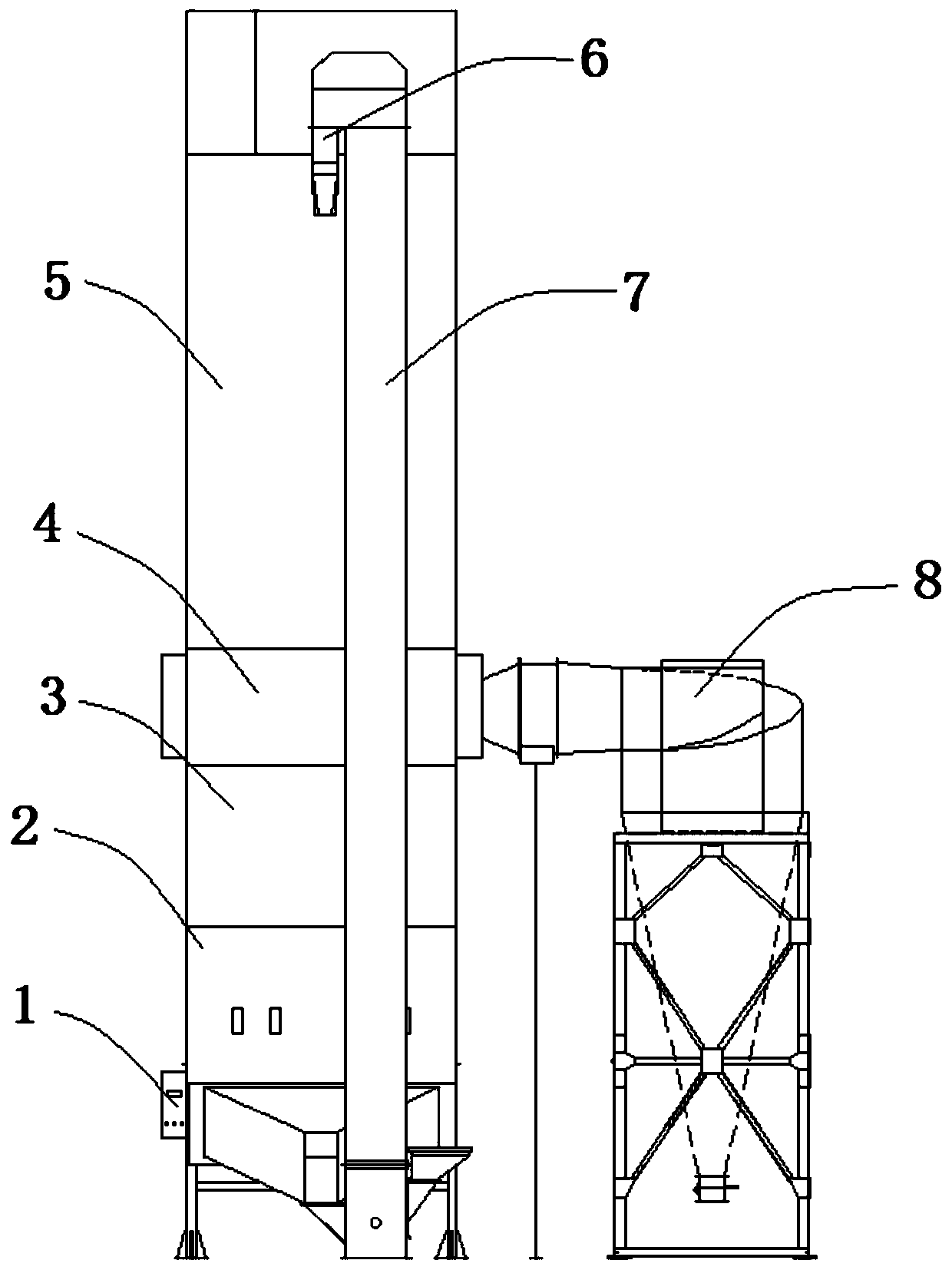

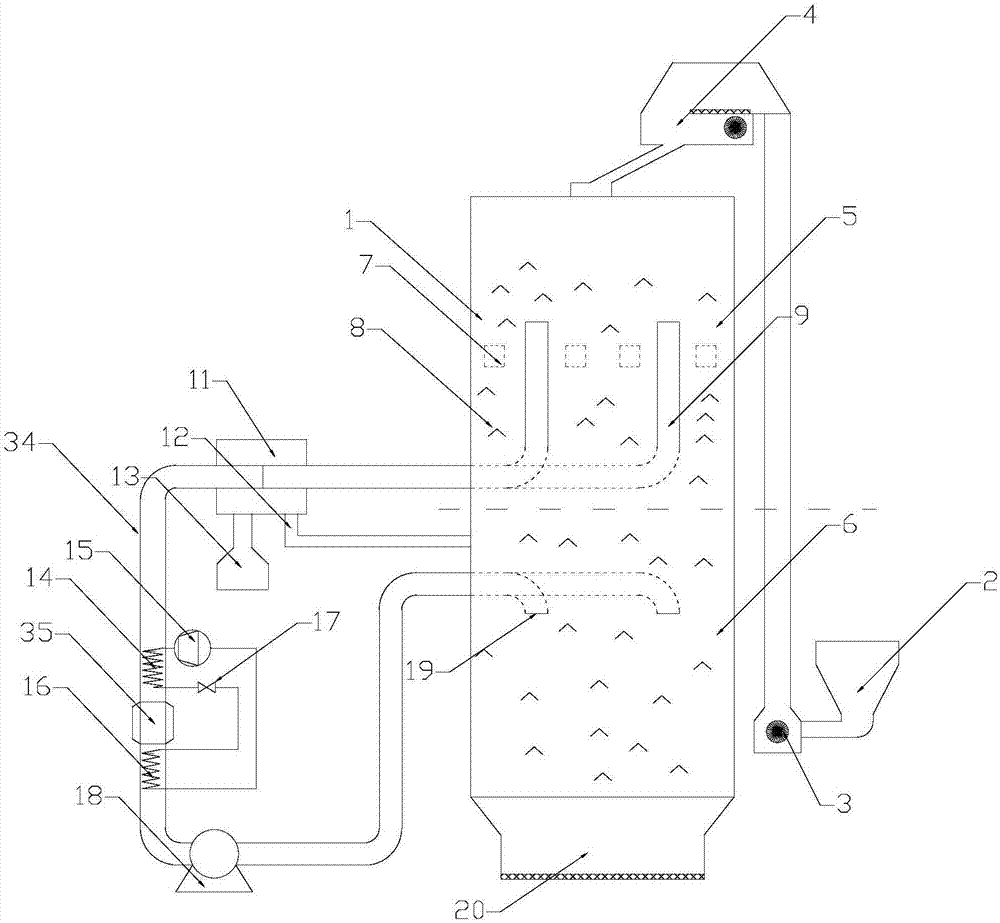

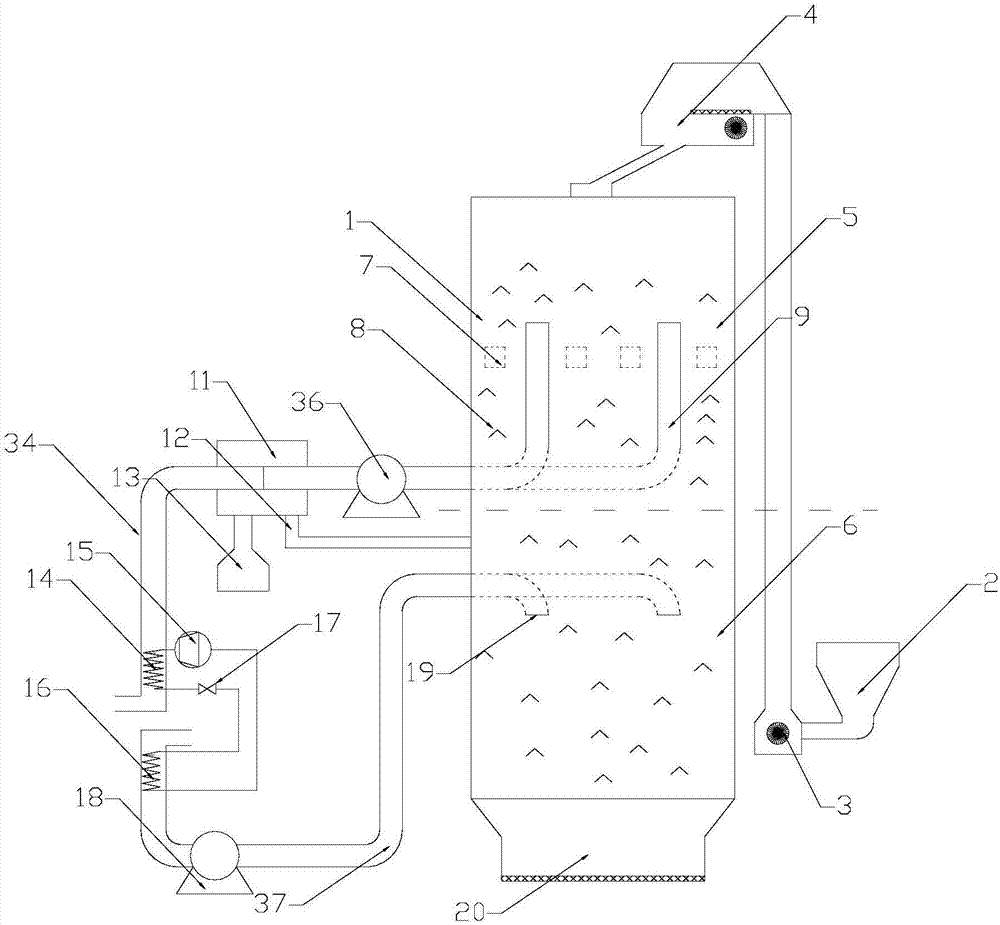

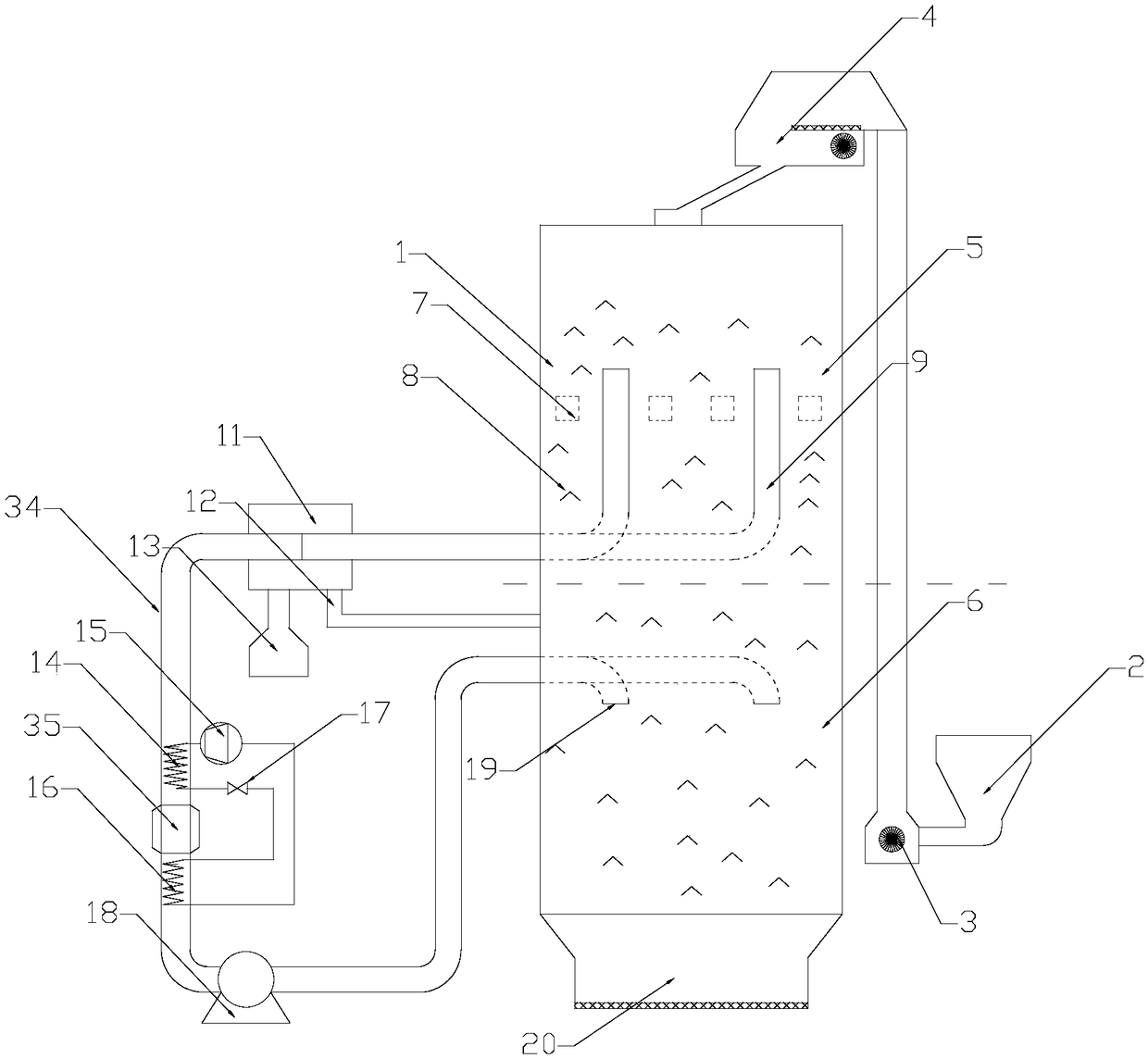

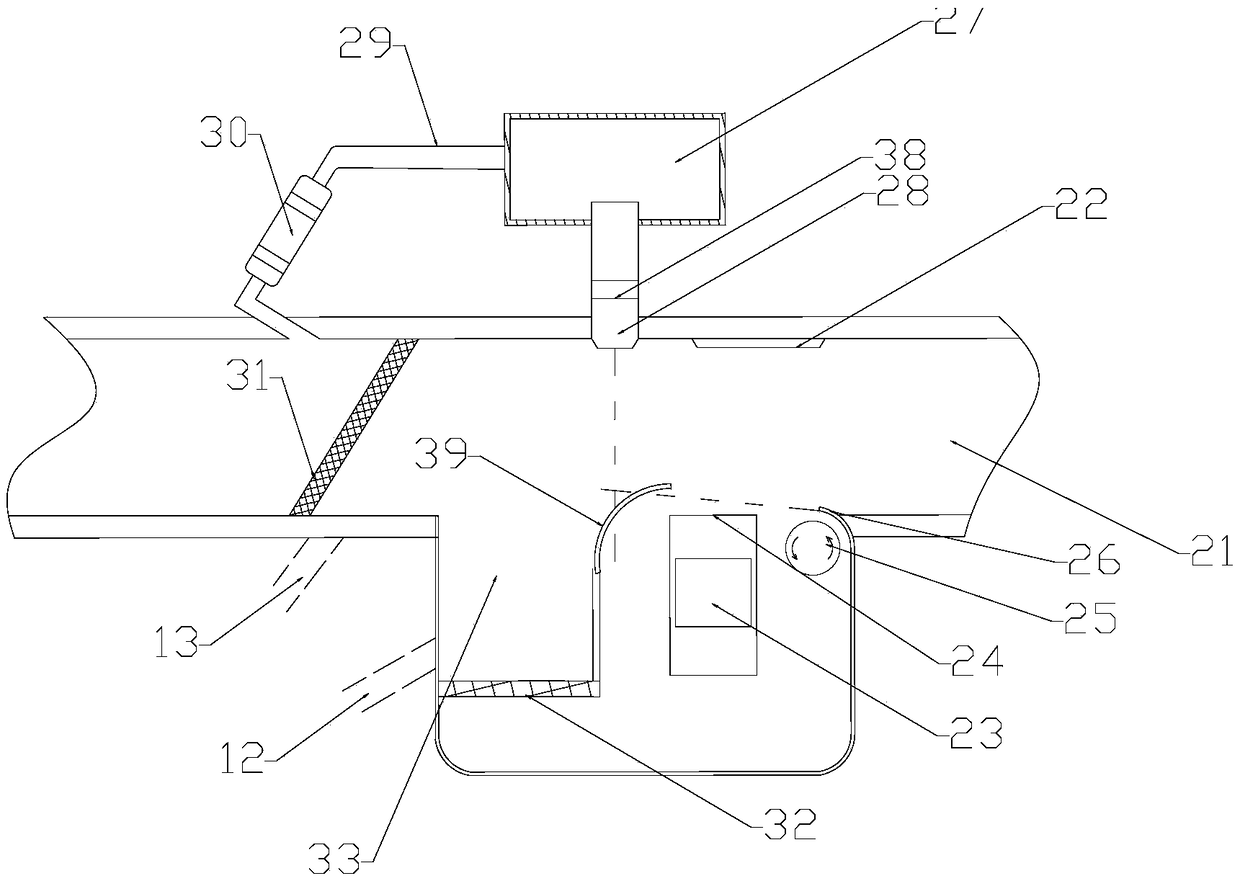

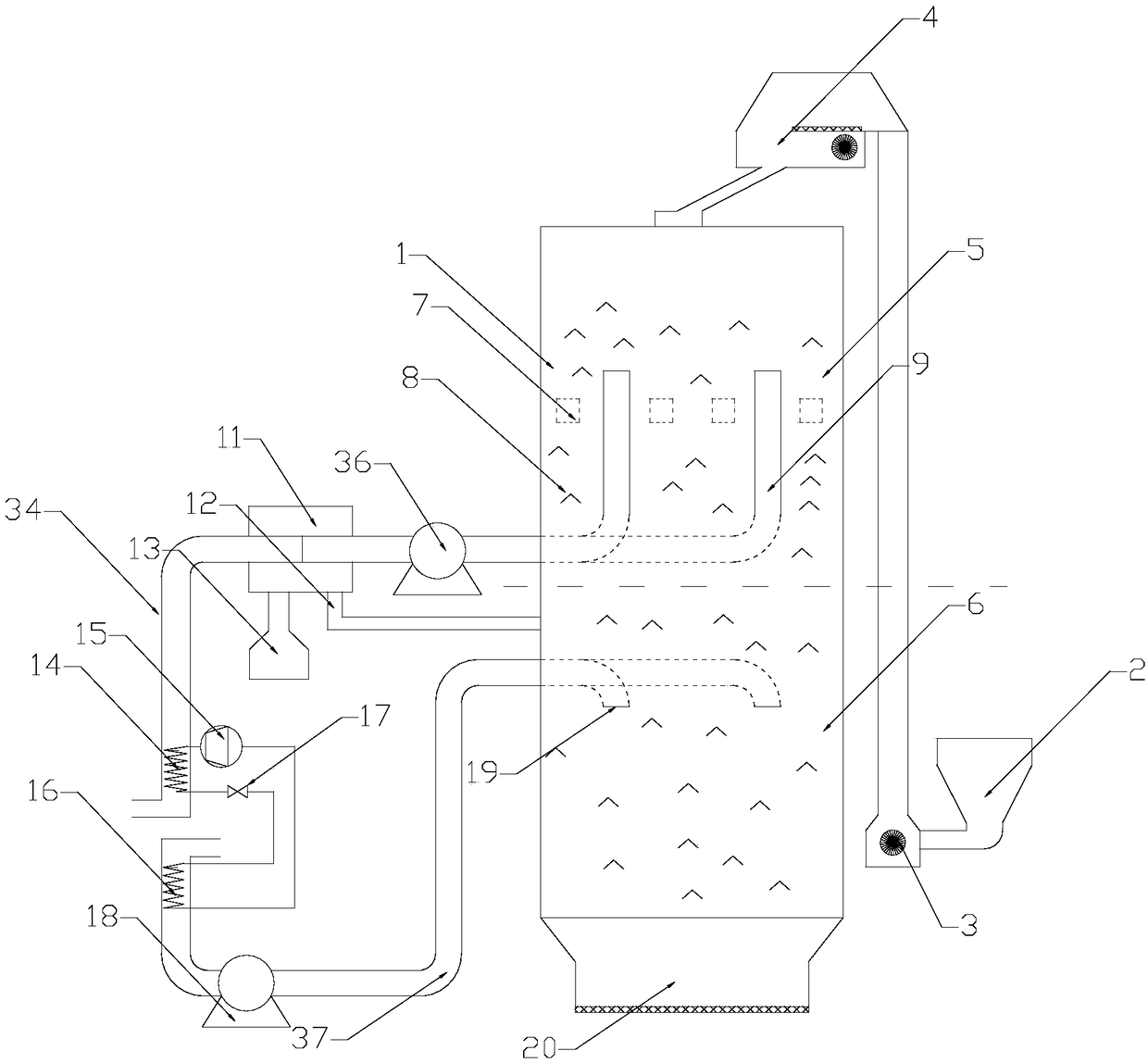

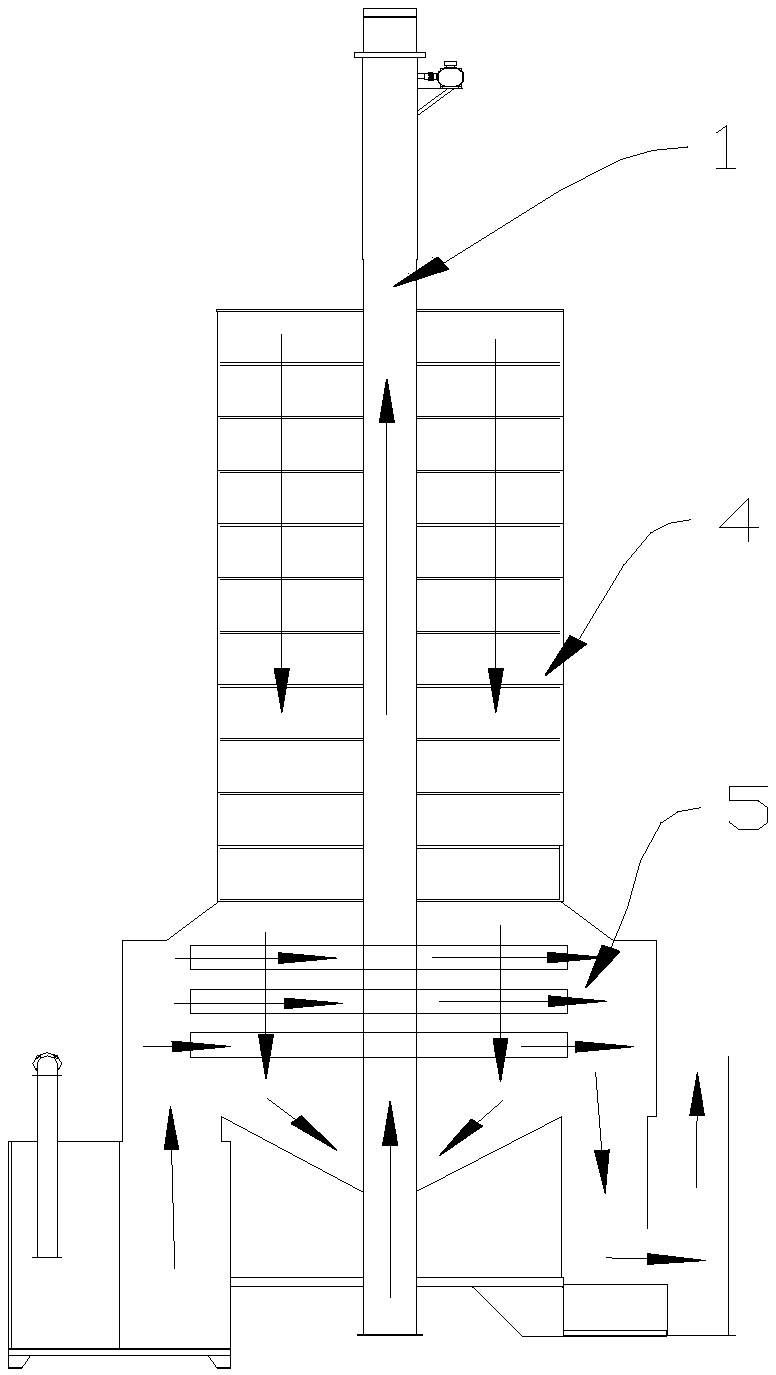

Hot air flow self-regulated type grain drying device

ActiveCN107144119AReduce waist burst rateDrying gas arrangementsDrying solid materialsAgricultural engineeringGrain drying

The invention relates to a hot air flow self-regulated type grain drying device, and belongs to the technical field of grain drying devices. The hot air flow self-regulated type grain drying device has an effect that the air flow of the tempering section can be regulated, gradient control over the hot air flow in the drying process is achieved, and the crack rate in the grain drying process is decreased; and meanwhile, heat in extracted hot air is recycled again, and the synergistic effect of reducing flow without reducing heat is achieved.

Owner:江苏瑞特电子设备有限公司

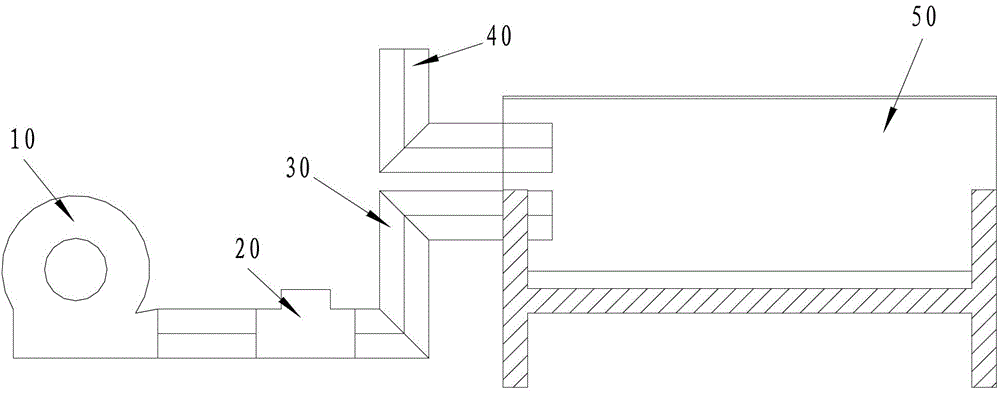

Material drying device and method

ActiveCN104422256AImprove efficiencyIncrease profitDrying gas arrangementsDrying solid materialsPulp and paper industryWind power

The invention discloses a material drying device and method. The material drying device comprises a fan, a heater, an air inlet pipe and a drum, wherein the air inlet pipe comprises an air inlet end and an air outlet end, the heater is connected with the fan and the air inlet end respectively, and the air outlet end extends into the drum from one end of the drum. The material drying device further comprises an adjusting unit and a controller, the adjusting unit comprises an air direction and amount adjusting unit, the controller comprises an air direction control module, and the air direction and amount adjusting unit comprises an adjusting air inlet and a material level sensor. The adjusting air inlet further comprises an air duct, a blade component and a blade control part. The blade control part and the material level sensor are electrically connected with the air direction control module, and the air direction control module adjusts the opening angle of the blade component through the blade control part, so that air from the air duct can cover the surface of the material. By the material drying device and method, utilization of drying air energy is optimized, energy loss is reduced, and efficiency of the drying device is improved.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

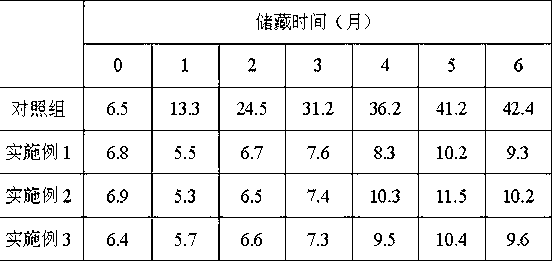

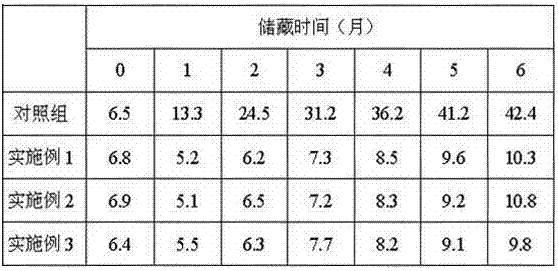

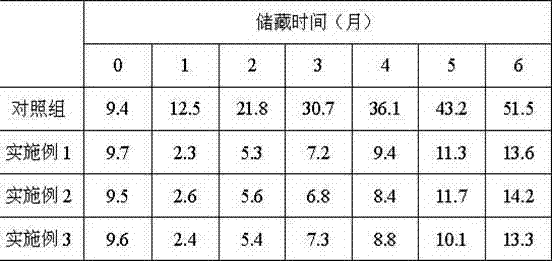

Method for extending storage period of embryo rice

InactiveCN102972518AReduce waist burst rateHigh embryo retention rateSeed preservation by heatingLipid oxidationEmbryo

The present invention relates to a method for extending a storage period of embryo rice, which is characterized by using a method of air preheating, superheated steam treatment, and air step-by-step cooling to achieve the purpose of extending the storage period of the embryo rice. The superheated steam treatment can kill worm eggs hidden in rice grains, passivate the activities of lipoxygenase and lipase in the embryo rice, and inhibit lipid oxidation. The use of air preheating and air step-by-step cooling treatment can prevent the embryo rice from cracking and nutrient losses to some extent. The method can significantly improve the storage period of the embryo rice.

Owner:NANCHANG UNIV

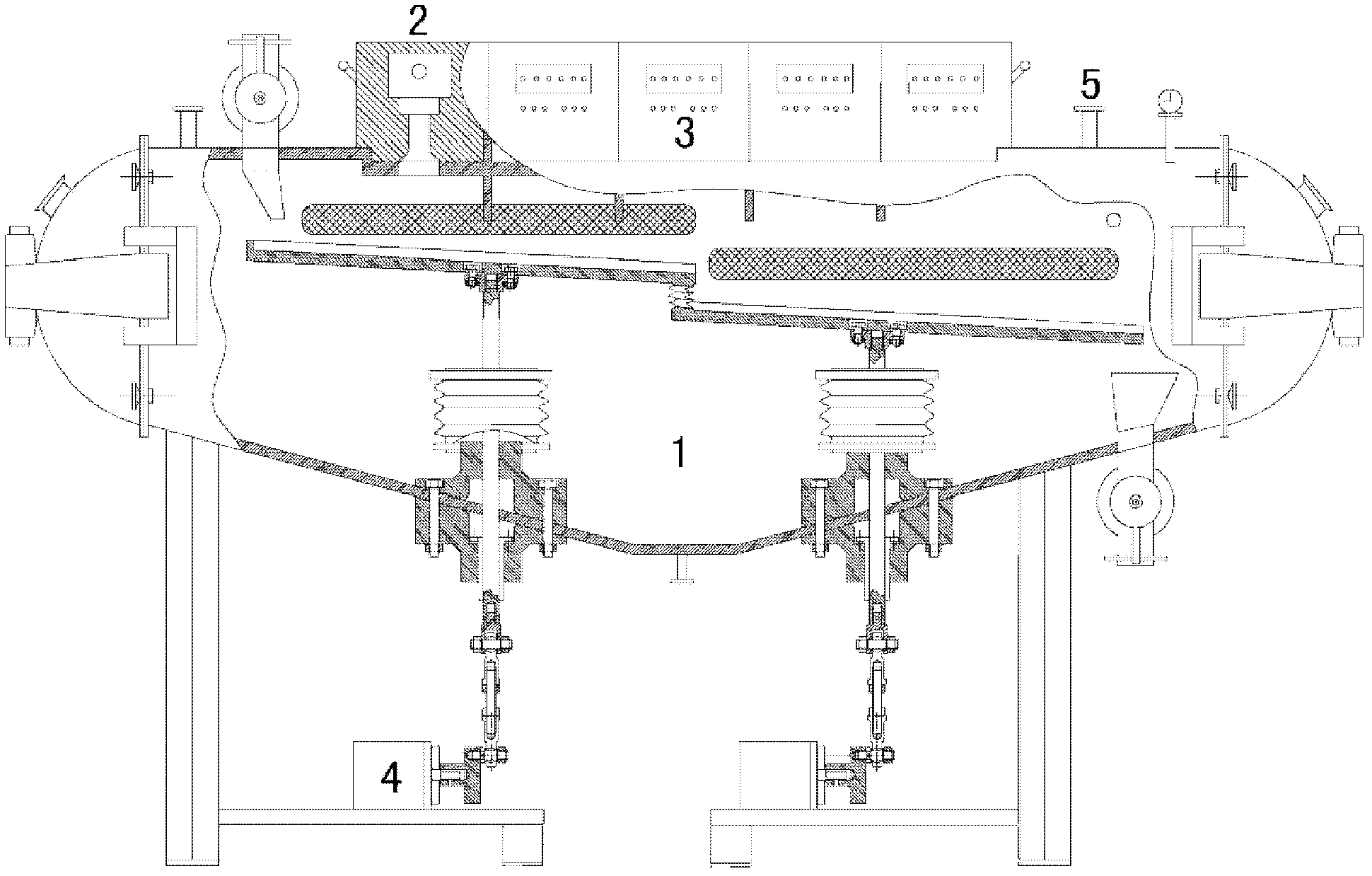

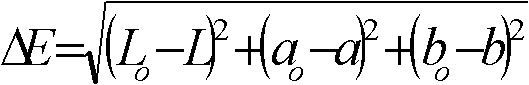

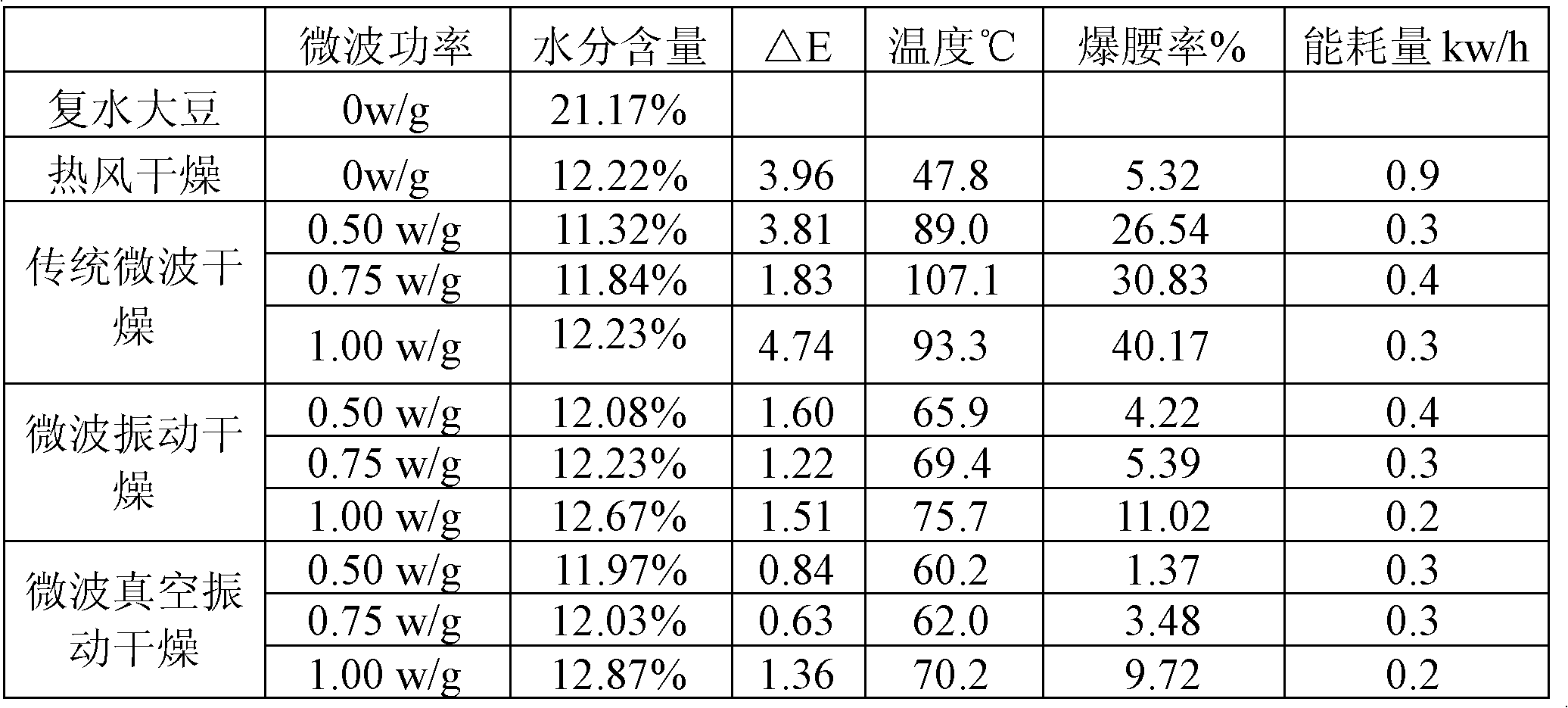

Vacuum microwave vibration drying method with low energy consumption and low percent cracked rice for granular food-borne material

ActiveCN102626135ADry evenlyReduce waist burst rateSeed preservation by dryingVibration amplitudePressure function

The invention relates to a vacuum microwave vibration drying method with low energy consumption and low percent cracked rice for a granular food-borne material. The vacuum microwave vibration drying method comprises the steps of: filling grains subjected to a pre-treatment into a vacuum tank; vacuumizing to below -0.065 Mpa, wherein a microwave output power is 0.5 w / g-1.0 w / g, a vibration frequency is 350 r / min-550 r / min, and a vibration amplitude is -2 cm to 2 cm; and reducing moisture content of the material from 20%-25% to less than 13% after 12 min to 30 min. According to the invention, the vacuum microwave vibration drying method is adopted to fully make use of the advantage of a fast microwave drying speed and a vacuum low-temperature drying superiority to reduce a boiling point of water in the material through a negative pressure function for one aspect, thereby shortening a drying time and reducing drying energy consumption, and change the position of the material in a microwave field in real time through a vibration function for the other aspect, thereby improving uniformity of microwave energy absorption, reducing percent cracked rice and improving drying quality. The vacuum microwave vibration drying method, disclosed by the invention, can reduce the energy consumption by 70% when compared with the traditional hot air drying method, and can reduce the percent cracked rice by 60% when compared with a microwave vibration drying method.

Owner:JIANGNAN UNIV +1

Method for improving rice eating quality and storage period

InactiveCN102972521AGood passivation effectReduce waist burst rateSeed preservation by irradiation/electric treatmentSeed preservation by heatingNutrientHorticulture

The present invention relates to a method for improving rice eating quality and storage period, which is characterized in that: a lactic acid solution is slowly added in a manner of atomization, so that the rice is in a weak-acid and high-humidity environment, low-dose X-ray irradiation is used to activate the enzymes in rice for some time, then hot air and microwave are combined to treat the rice to produce moderate gelatinization, and at the same time the insect enzyme bacteria in the rice are killed. The method can significantly improve the eating quality and the storage period of rice, slow humidification by atomization and low temperature and high humidity retarding treatment can effectively reduce the rice fissuring rate, and the loss of nutrients is reduced.

Owner:NANCHANG UNIV

Method for improving stewing performance and storage performance of unpolished rice

InactiveCN102948671AGood cooking effectReduce waist burst rateSeed preservation by irradiation/electric treatmentSeed preservation by heatingMicrowaveHigh humidity

The invention relates to a method for improving the stewing performance and the storage performance of unpolished rice. The method is characterized in that the microwave and superheated steam combined treatment is adopted, the unpolished rice is properly gelatinized (the gelatinization degree is 20 to 30 percent) through controlling the water addition quantity and the water adding speed, and meanwhile, insect bacterium enzymes inside rice grains are killed or passivated for reaching the goal of improving the stewing quality and the storage performance. Through the microwave and superheated steam synergistic effect, the surface gelatinization of unpolished rice grains is very uniform, meanwhile, ova, bacteria and mycete hidden in the rice grains are effectively killed, lipoxidase and lipase in the unpolished rice are passivated, and the lipid oxidation is inhibited. Through controlling the water adding quantity and the water adding speed and adopting the low-temperature high-humidity treatment after the microwave treatment, the crackling rate of the rice grains can be effectively reduced, and the nutritional ingredient loss is reduced. The method has the advantages that the environment is protected, no pollution exists, and the stewing performance and the storage performance of products are obviously improved.

Owner:NANCHANG UNIV

Microwave-hot air combined compound type rice drying method based on glass transition

ActiveCN109631500ARapid preheatingReduce waist burst rateDrying solid materials with heatDrying gas arrangementsVitrificationMicrowave

The invention provides a microwave-hot air combined compound type rice drying method based on glass transition, and belongs to a grain drying technology. According to the method, a glass transition technology is combined with a microwave-hot air combined drying technology, in the condition that the moisture gradient between the inner and the outer of a rice grain is less than or equal to 6%, microwaves are used for rapidly heating the rice grain, the rice is dried by hot air when reaching the rubber state, and thus the operation is completed; and according to the method, the rate of cracking at a waist of the rice is reduced, the drying time is saved, the drying efficiency is improved, and the drying energy consumption is reduced.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for prolonging storage period of milled rice with embryos through microwave and hot air combined treatment

InactiveCN102948465AReduce waist burst rateAvoid damageSeed preservation by coatingSeed preservation by irradiation/electric treatmentBiotechnologyAnimal science

The invention relates to a method for prolonging the storage period of milled rice with embryos through microwave and hot air combined treatment. The method is characterized in that the microwave and hot air combined treatment is adopted, the synergistic interaction effect is utilized for efficiently killing ova and mycete hidden in rice grains, lipoxidase and lipase in the milled rice with embryos are passivated, the lipid oxidation is inhibited, meanwhile, the ehitosan coating and the low-temperature high-humidity treatment are adopted, the crackling rate of the rice grains is effectively reduced, and the nutritional ingredient loss is reduced. The milled rice with embryos treated by the method is environment-friendly and has no pollution, and the storage period of products is obviously prolonged.

Owner:NANCHANG UNIV

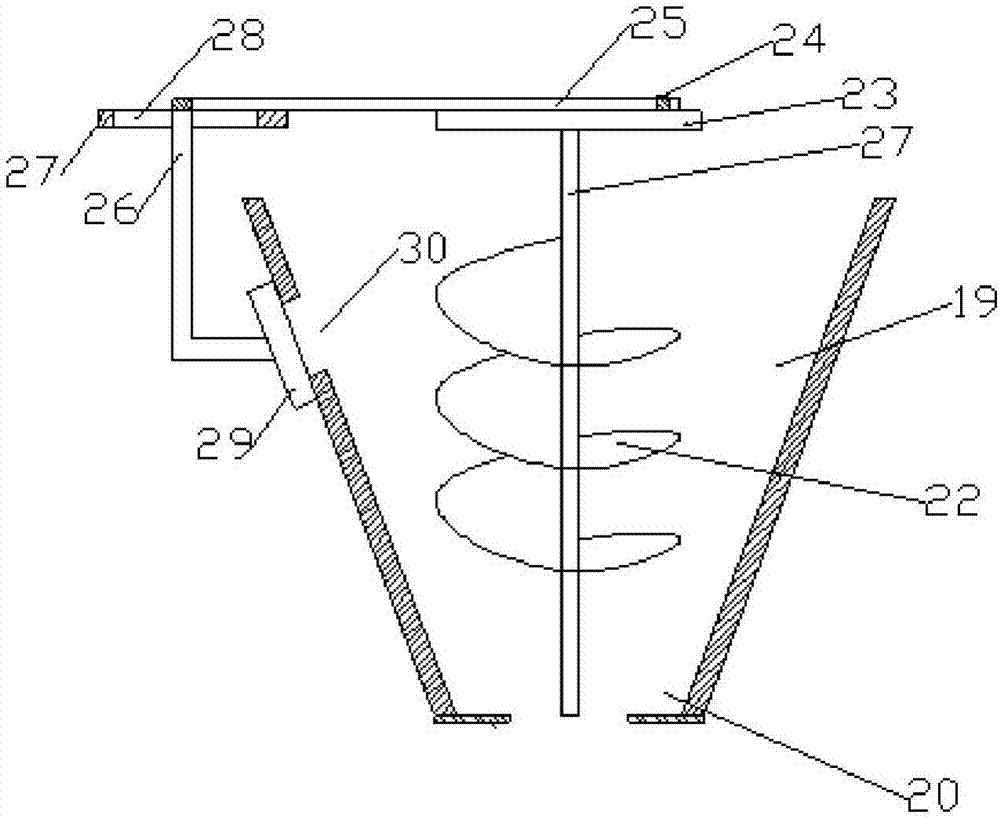

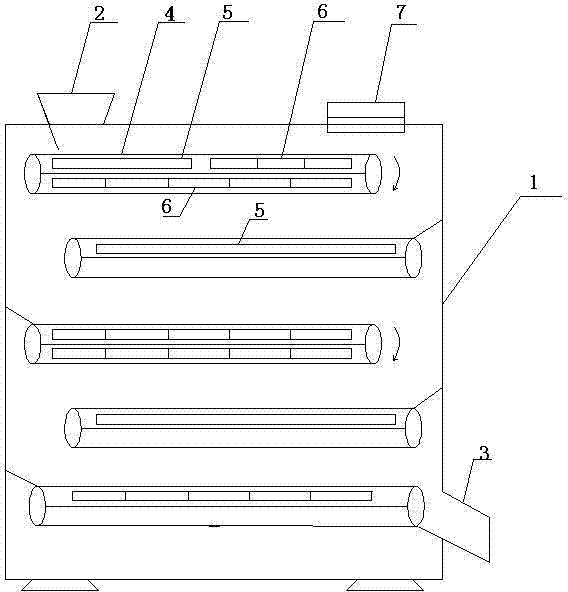

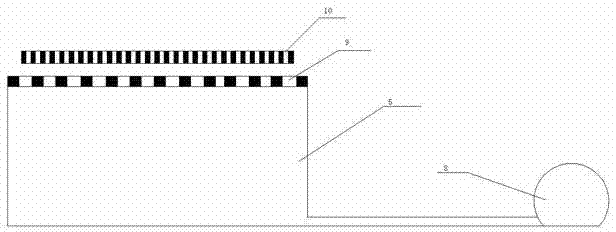

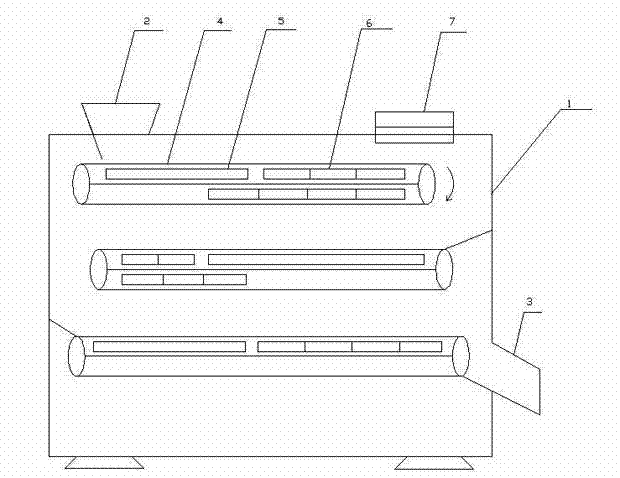

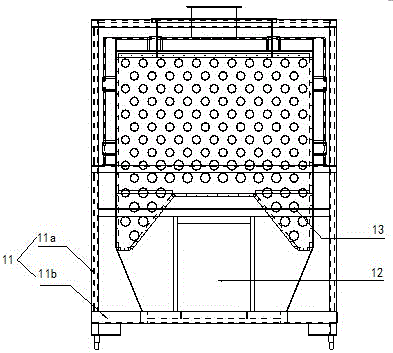

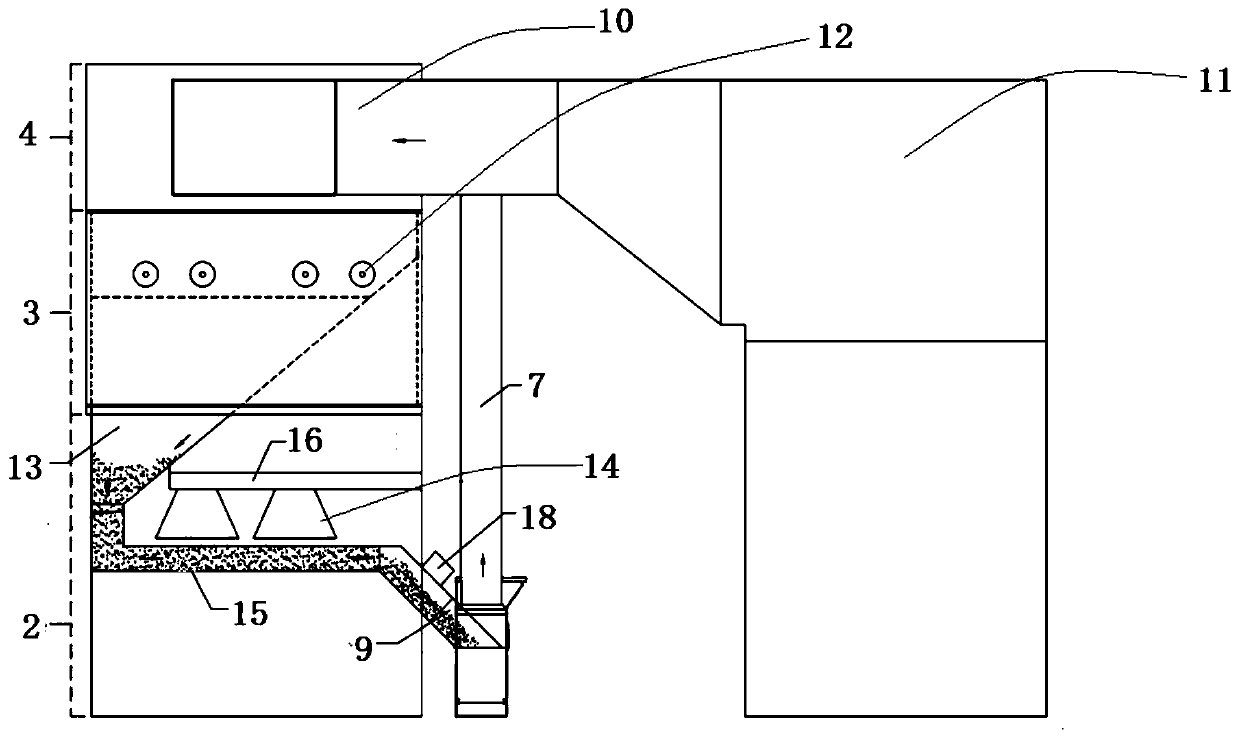

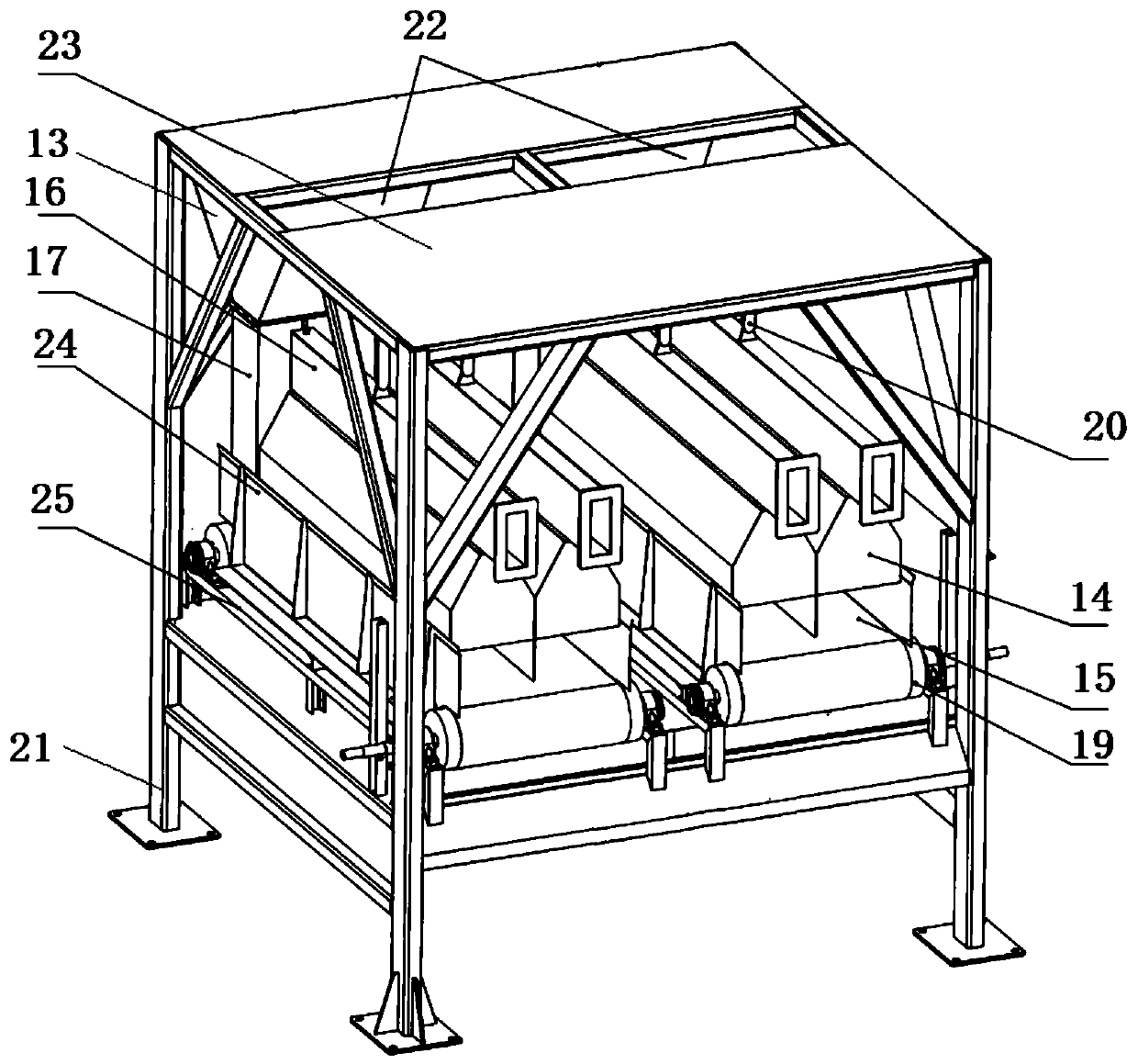

Unpolished rice tempering and enzyme deactivation equipment

The invention relates to unpolished rice tempering and enzyme deactivation equipment, comprising a tempering box, a blanking opening and a discharging opening on the tempering box, conveying belts placed inside the tempering box, hot air square pipes and cold air square pipes below the conveying belts. Unpolished rice falls down to the conveying belts from the blanking opening and is conveyed to the discharging opening to be conveyed out; the tempering box is internally provided with five layers of conveying belts; all the layers of conveying belts are arrayed in a staggered manner; the hot air square pipes and the cold air square pipes are arrayed below each layer of conveying belt; the hot air square pipes are connected with a saturated steam generator through a pipeline and the cold air square pipes are connected with an air cooler through a pipeline; air blowing openings are distributed on the hot air square pipes and the cold air square pipes; the conveying belts are provided with small holes for an air flow to pass through; and the quantities and the lengths of the hot air square pipes and the cold air square pipes on each conveying layer are different. The unpolished rice tempering and enzyme deactivation equipment has good tempering effect and can be used for killing worms, mildews and bacteria hidden in the unpolished rice in a tempering process and passivating lipolytic enzymes such as lipoxidase and lipase.

Owner:NANCHANG UNIV

Production method of quick-cooking rice

InactiveCN102960610AUniform gelatinization inside and outsideImprove performance qualityFood preparationSurface moistureCavitation

The invention relates to a production method of quick-cooking rice. The method is characterized by comprising the following steps of: slowly humidifying and tempering by an atomization method; and evaporating moisture of the rice surface by use of hot air; and processing with ultrasonic wave and microwave, wherein based on the special inside-to-outside heating principle from of microwave and the cavitation effect, resonance effect and warm effect of the ultrasonic wave, the rice grains are moderately gelatinized tiny holes are formed at the same time, and the cooking performance of the rice can be obviously improved. The joint treatment of hot air, microwave and ultrasonic wave also can obviously kill or passivate entomogenous fungi enzyme hidden in the rice grains to improve the storage performance of rice. By humidifying and tempering based on an atomization method, the crackle ratio of rice grains is effectively reduced, and the loss of nutrients is reduced. The method provided by the invention is environment-friendly and pollution-free in rice treatment, and obviously improves the cooking performance and storage performance of the product.

Owner:NANCHANG UNIV

Device for brown rice deinsectization enzyme

InactiveCN102948470AImprove temperature riseReduce crackingSeed preservation using chemicalsSeed preservation by heatingAlternative treatmentProduct gas

The invention relates to a device for brown rice deinsectization enzyme. The device comprises a treating cabin, a feeding hole and a discharging hole, wherein the feeding hole is formed in the treating cabin; the discharging hole is formed on a side which corresponds to the feeding hole in the treating cabin; a transport tape positioned below the feeding hole is arranged in the treating cabin; a material falls off from the feeding hole, and is fed to the discharging hole through the transport tape; vent holes are distributed in the transport tape; a plurality of air inlets which are formed tightly along the conveying direction of the transport tape are formed below the transport tape; overheated steam generated by an overheated steam generator and hot air generated by an air heater are conveyed to each air inlet through an air pump and a pipeline, reach the material through the vent holes, and is discharged from the air outlets; overheated steam and hot air are introduced into adjacent air inlets respectively; and gas discharged from adjacent air inlets is isolated by a clapboard after passing through the vent holes. Due to the adoption of the device disclosed by the invention, worms, molds and bacteria in brown rice can be killed efficiently, and lipolytic enzymes such as lipoxidase and lipase in brown rice are passivated; and alternative treatment is performed through overheated steam and air, so that cracked rice of brown rice can be prevented.

Owner:NANCHANG UNIV

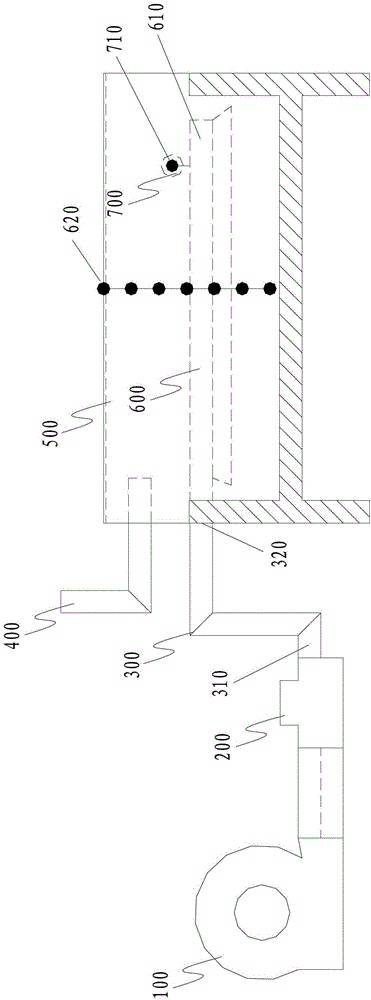

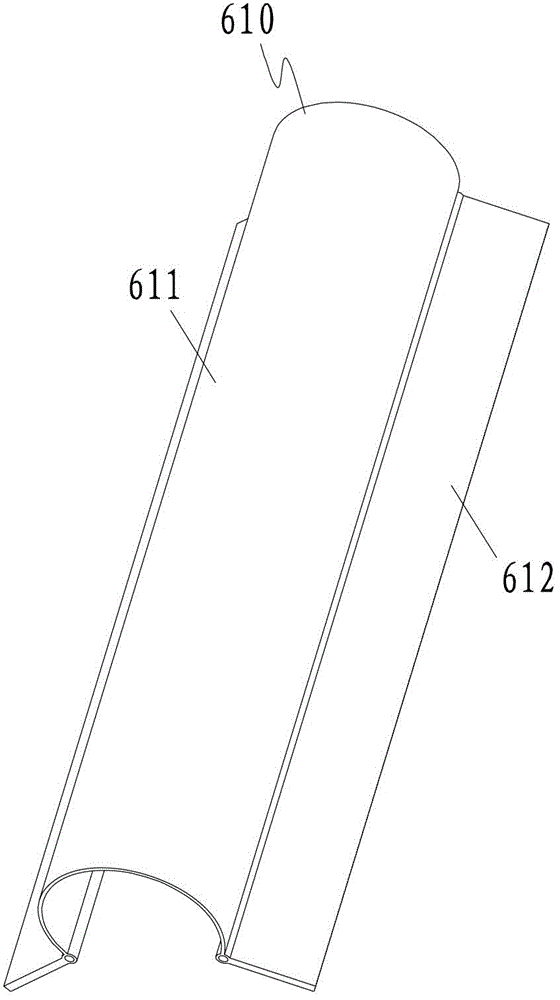

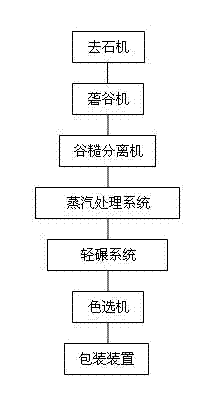

Processing production system for long-storage enriched rice

The invention relates to a processing production system for long-storage rice. The processing production system comprises a stoning machine, a rice huller, a rice-unpolished rice separator, a steam treatment system, a light grinding system, a color selector and a packaging device; the steam treatment system comprises a tempering box, a charging hole, a discharging hole, conveyor belts, a hot air square tube, a cold air square tube and a pressure relief opening, wherein the charging hole and the discharging hole are arranged in the tempering box; the conveyor belts are arranged in the tempering box; the hot air square tube and the cold air square tube are arranged below the conveyor belts; the pressure relief opening is arranged in the tempering box; three layers of conveyor belts are arranged in the tempering box and are arranged in a staggered manner, and the distance of each layer of the conveyor belts is 0.4-0.8 meter; and the unpolished rice is transmitted from the front ends of the first layer of the conveyor belts to the tail ends of the first layer of the conveyor belts, and drops to the front ends of the next layer of the conveyor belts, so as to get through the three layers of the conveyor belts in sequence and be fed out from the discharging hole. The processing system can simultaneously produce long-storage enriched rice and rice bran, and has such advantages as high efficiency, and environment friendliness; and moreover, the amount of produced broken rice is low, and the generality is good.

Owner:NANCHANG UNIV

Method of prolonging the storage period of germinated brown rice by microwave-superheated steam combined treatment

InactiveCN102960439AReduce waist burst rateEfficient killingSeed preservation by heatingSeed preservation by dryingAdditive ingredientCombined treatment

The invention relates to a method of prolonging the storage period of germinated brown rice by microwave-superheated steam combined treatment. The method is characterized in that by adopting the microwave and superheated steam combined treatment, not only can the germinated brown rice with high moisture content be dried, but also the purpose of prolonging the storage period of the germinated brown rice can be achieved. By adopting the method, worm eggs, bacteria, and mold fungus hidden in rice grains can be effectively killed, lipoxygenase and lipase in the germinated brown rice are passivated, and lipid oxidation is inhibited; and at the same time, by adopting low-temperature high-humidity treatment before and after the microwave treatment, the cracking rate of the rice grains is effectively reduced, and the loss of nutritional ingredients is reduced. The method of treating the germinated brown rice has the advantages of being high in efficiency, environment-friendly, and pollution-free, and significantly increasing the product quality guarantee period.

Owner:NANCHANG UNIV

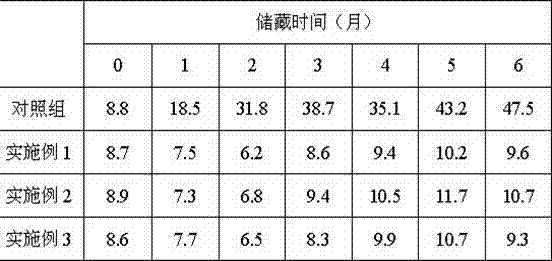

Germinated brown rice low in cracking ratio and rich in gamma-aminobutyric acid and production method of germinated brown rice

The invention discloses germinated brown rice low in a cracking ratio and rich in gamma-aminobutyric acid and a production method of the germinated brown rice. The germinated brown rice belongs to biotechnology field of food. A production method for the germinated brown rice comprises the following steps of: screening and purifying a brown rice material; spraying ethanol to disinfect; humidifying and tempering by acid liquor; forcing the brown rice to germinate at a low-temperature low-oxygen environment; and drying in a moderate manner. The prepared germinated brown rice has a cracking ratio within 3%, and 15-30 mg / 100g of GABA (Gamma-amino Butyric Acid). The germinated brown rice prepared by the method provided by the invention has such characteristics of being low in cracking ratio, high in GABA and capable of whitening and the like, thereby solving a problem that the germinated brown rice produced by a traditional technology is high in cracking ratio, difficult to cook, poor in mouthfeel, and cannot be crushed.

Owner:广西月亮河长寿村生物科技有限公司

Production technology for activated rice enriched with functional components

InactiveCN103960579AEasy to operateEasy to realize industrial productionFood thermal treatmentFood dryingHydrogenPhosphoric acid

The invention discloses a production technology for activated rice enriched with functional components, belonging to the field of food biotechnology. The production technology is characterized by comprising the following steps: after screening unpolished rice, humidifying and atomizing by using citric acid liquid with the pH (Potential of Hydrogen) being 2.0-3.0; then carrying out high-temperature activation, tempering and drying, slightly grinding the rice, polishing and packaging to obtain the semi-rice-skin-removed activated rice. The activated rice prepared by the production technology has the characteristics of capability of being grinded to be white, low rice grinding rate, good cooking performance, good palatability, easiness in digestion and absorption by a human body and the like. The contents of gama-aminobutyric acid (GABA) and inositol phosphate in the activated rice prepared by the production technology are 15-20mg / 100g and 5-18mg / g.

Owner:NANJING AGRICULTURAL UNIVERSITY

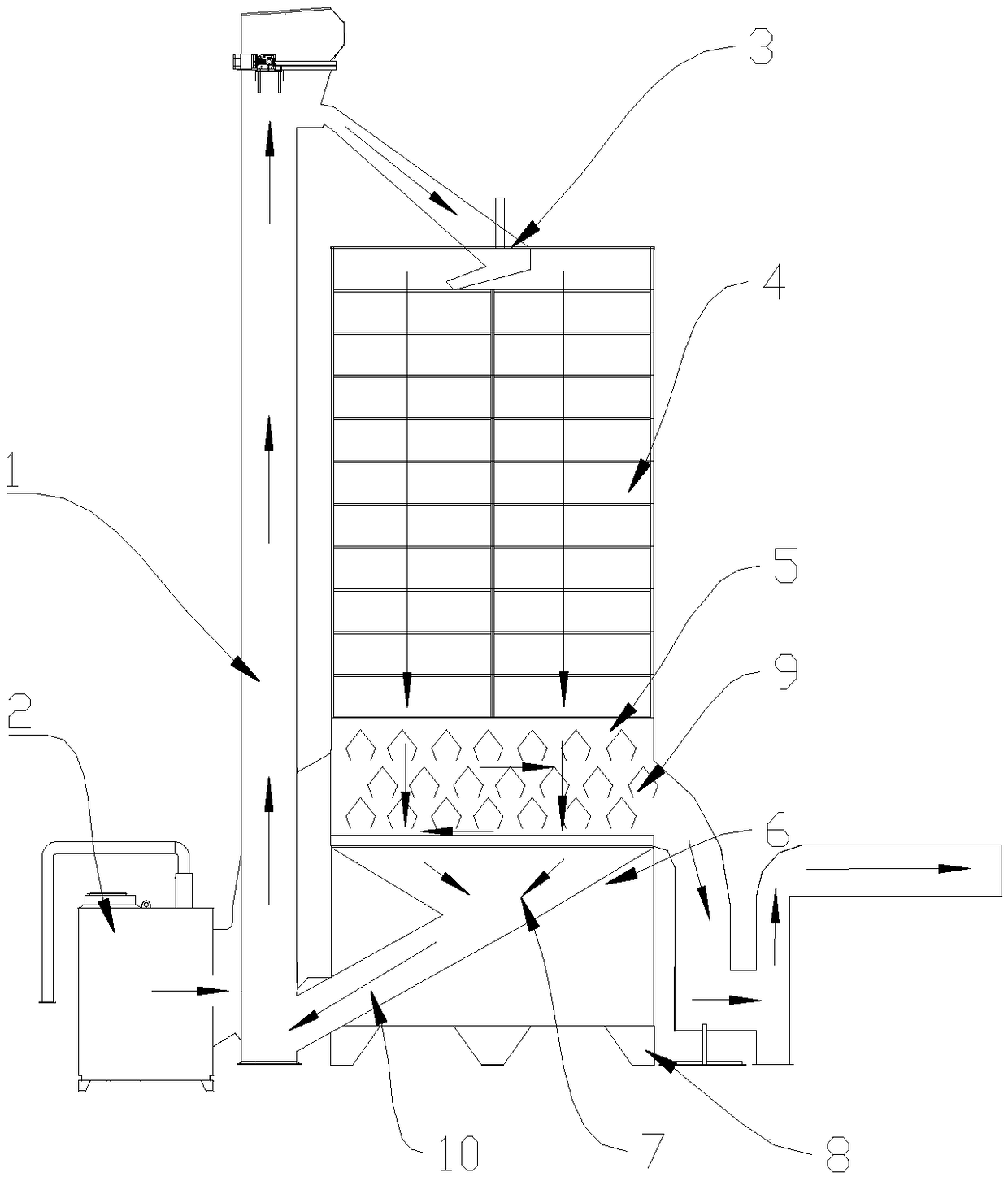

Grain drying unit

InactiveCN105724566ALow costPromote environmental protectionSeed preservation by dryingHigh energyAgricultural engineering

The invention discloses a grain drying unit. The grain drying unit comprises a hot-blast stove, a grain dryer and a connecting pipe for connecting the hot-blast stove with the grain dryer, wherein the hot-blast stove is a biomass hot-blast stove and takes cereal waste as a fuel, the grain dryer which is a batch type recirculating grain dryer is capable of achieving recirculating drying, and one end of the connecting pipeline is connected with a hot-blast outlet while the other end of the connecting pipe is connected with an intake hood. The grain drying unit has the advantages of high automation level, high processing capability, high energy utilization ratio and low cost.

Owner:ANHUI XINSHENGLI BIOLOGY TECH

Batch type microwave grain dryer and drying method

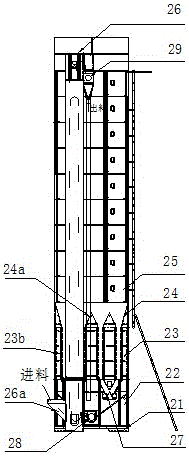

PendingCN110094944AReduce waist burst rateReduce moisture gradientDrying solid materials with heatDrying gas arrangementsMicrowaveGrain elevator

The invention relates to a batch type microwave grain dryer and a drying method. The batch type microwave grain dryer is provided with a grain elevator, and a tempering bin, a drying chamber, a collecting chamber and a microwave heating device which are connected with each other are sequentially arranged from top to bottom, wherein the drying chamber is used for drying and dehumidifying grains, and the microwave heating device is used for microwave heating of grains; a discharging port at the upper end of the grain elevator is connected with the tempering bin, and a discharging port of the microwave heating device is connected with a feeding port at the lower end of the grain elevator. According to the batch type microwave grain dryer, the grain discharging speed, the microwave heating radiation frequency and the temperature and humidity of the drying chamber hot air are controlled according to grain temperature and grain moisture, so that variable temperature and variable frequency drying are realized, and the drying efficiency of the grain is effectively improved.

Owner:ZOOMLION HEAVY MASCH CO LTD

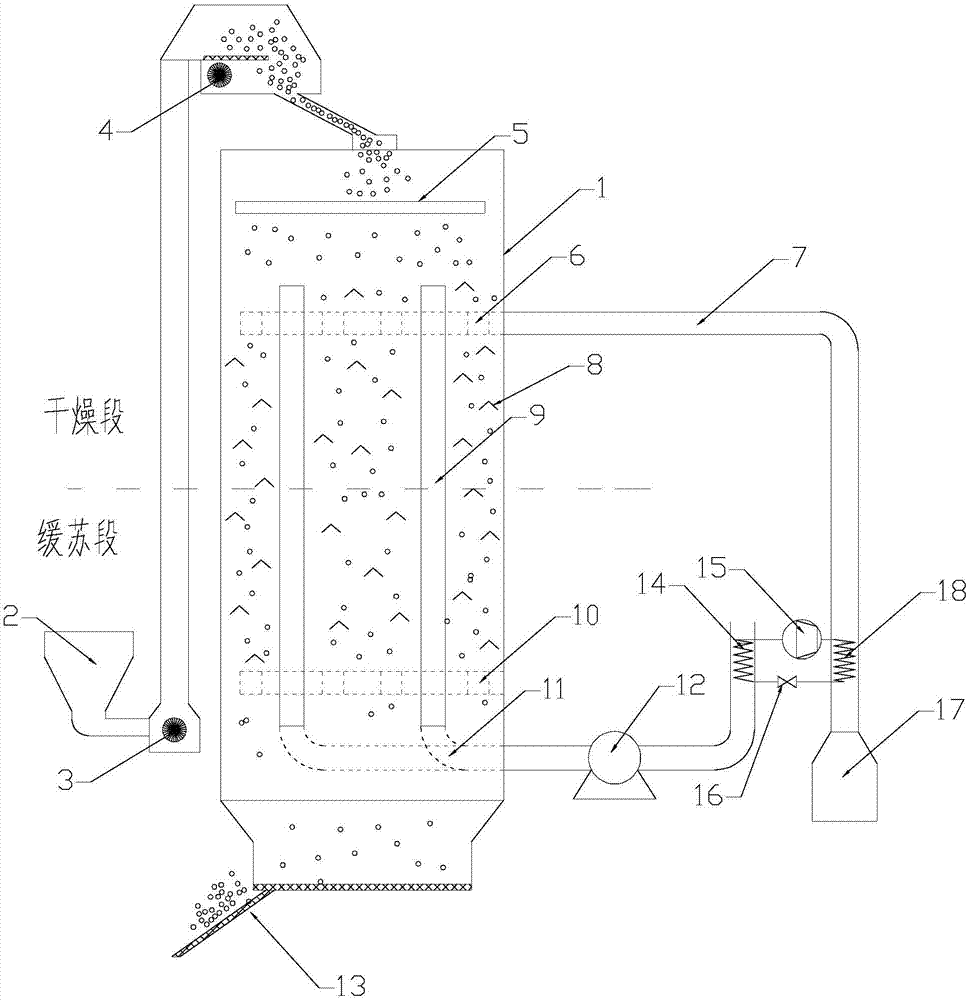

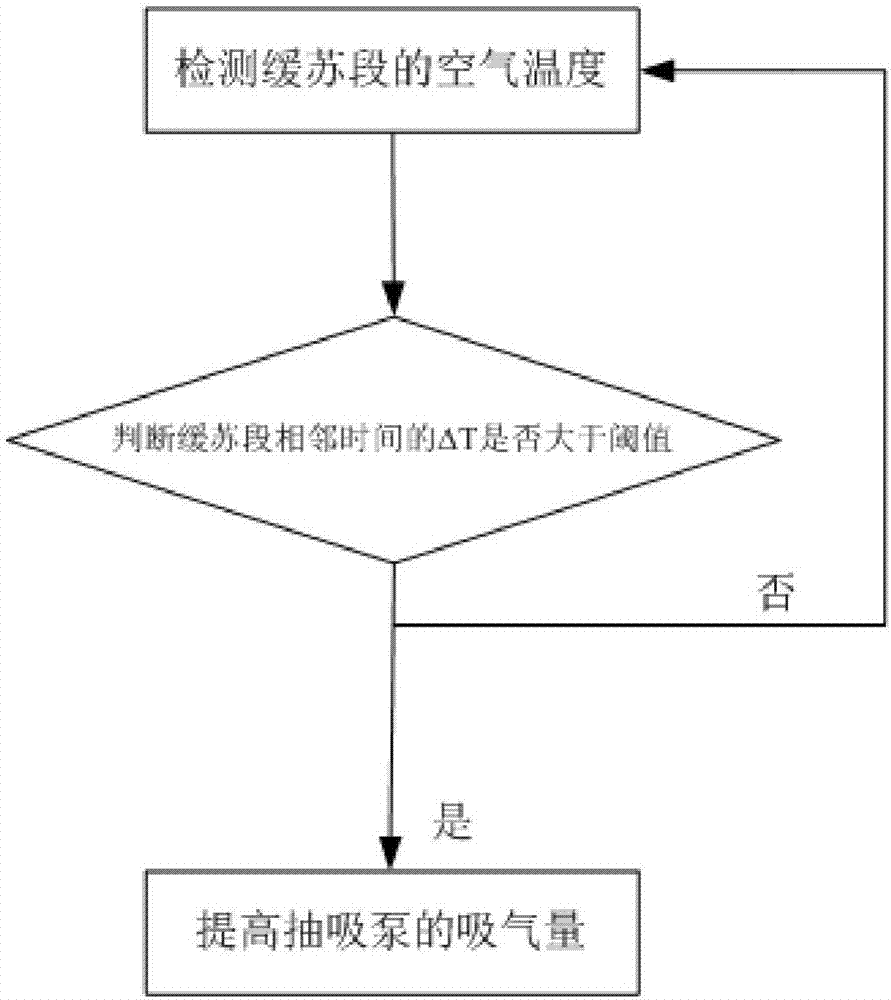

Agricultural drying mechanism and automatic control method thereof

InactiveCN107449265AReduce waist burst rateIncrease profitClimate change adaptationDrying gas arrangementsTraffic volumeAutomatic control

The invention relates to an agricultural drying mechanism and an automatic control method thereof, in particular relates to an agricultural mechanism for drying grain and an automatic control method thereof, and belongs to the technical field of agricultural mechanisms. The drying mechanism is mainly applied to the grain drying; water produced in the grain drying process is drained through the drying mechanism during the drying stage, and meanwhile, the air is returned to a tempering bin after the heat is recovered from the heat, thus the requirement on low-temperature and high-flow-rate drying air in the tempering process is met, and the grain crackle ratio is decreased; meanwhile, the grains carried out during the drying process can be separated out and returned to the tempering bin, so that the grain utilization rate is increased.

Owner:毛强平

Method for prolonging storage period of brown rice

InactiveCN102948474AGuaranteed qualityFast heating in short timeSeed preservation using chemicalsAdditive ingredientLipid oxidation

The invention relates to a method for prolonging the storage period of brown rice. The method is characterized in that the aim of prolonging the storage period of brown rice is fulfilled by adopting a method for alternatively treating through air and overheated steam. According to the method, gradual heating and alternate treatment are adopted, so that the percent cracked rice of brown rice can be lowered specifically, loss of nutritional ingredients is reduced, eggs hidden in rice grains can be killed by hot air and overheated steam in a synthetic way, the activity of lipoxidase and lipase in brown rice is passivated, and lipid oxidation is suppressed. Due to the adoption of the method, the storage period of brown rice can be prolonged remarkably.

Owner:NANCHANG UNIV

Agricultural drying machine and automatic control method thereof

ActiveCN109387063APrevent removalSolve the removal problemClimate change adaptationDrying gas arrangementsAutomatic controlAgricultural engineering

Owner:ANHUI SUNMIRO AGRI TECH

Method for processing rice

ActiveCN108906170AIncreased broken rice rateImprove integrityGrain millingTransfer procedureBroken rice

The invention relates to the technical field of rice processing, in particular to a method for processing rice. Through the control on the rice processing steps and environment parameters of rice, thebroken rice rate of the rice during unhusked rice processing to the rice is greatly improved, the steps needing to detect and control the water content in each process step is reduced, it is achievedthat the temperature and humidity of the transmission link are controlled in the process of transmission, so that cooling and the improvement of the tenacity of rice grains are achieved in the process of transmission, the fissure rate and the broken rice rate are reduced, and the integrality of the rice grains is improved.

Owner:湖南恒华生态农业科技股份有限公司

Cereal dryer

PendingCN108812885AIncrease contact areaReduce uneven heatingSeed preservation by dryingHot blastEngineering

The application discloses a cereal dryer, which comprises a tempering grain tank, a drying ventilation chamber communicated with the tempering grain tank, a draining crop mechanism connected to the drying ventilation chamber, a cereal input mechanism used for inputting cereal into the tempering grain tank, and a hot-blast stove used for providing hot air for the tempering grain tank, wherein a wind guide structure which is used for draining hot air to increase contact area of hot air and cereal is arranged inside the drying ventilation chamber. By the use of the cereal dryer of the invention,the problem that cereal is not uniformly heated can be overcome, and cereal crack rate is reduced. In comparison with the prior art, the cereal dryer has the following advantages: cereal is more uniformly heated and dried, and cereal drying quality is remarkably improved.

Owner:HUNAN NONGYOU MACHINERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com