Processing production system for long-storage enriched rice

A production system and nutritional rice technology, applied in application, grain processing, agriculture, etc., can solve the problems of lightly milled nutritional rice, which is easy to oxidize and deteriorate, and is not resistant to storage, so as to achieve improved stability, less loss of nutrients, and inhibition of lipids The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

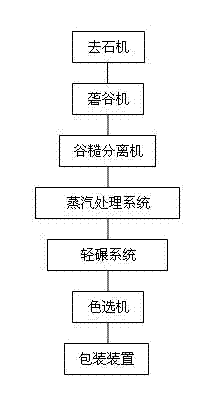

[0020] Such as figure 1 The illustrated storage-stable nutritious rice processing and production system sequentially includes a stone removing machine, a rice hulling machine, a rice grain separator, a steam treatment system, a light milling system, a color sorting machine and a packaging device.

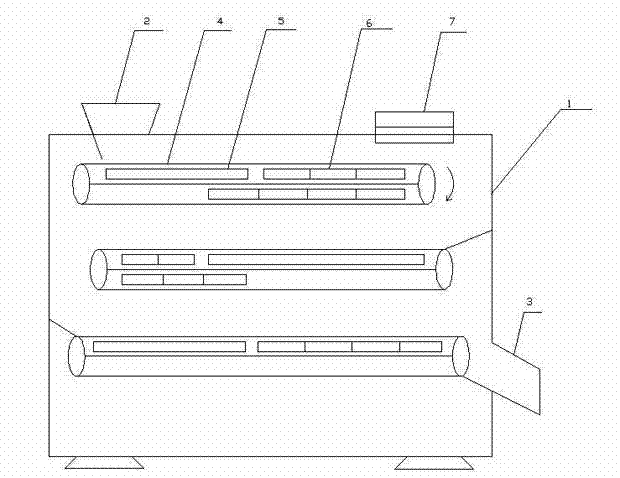

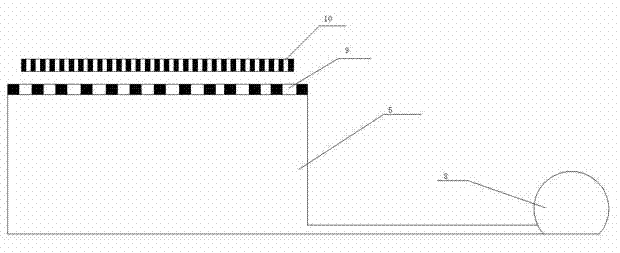

[0021] The steam treatment system (such as figure 2 Shown) include: quenching and tempering box (1), blanking opening (2) and discharge port (3) on the quenching and tempering box, conveyor belt (4) placed in the quenching and tempering box, and hot air side under the conveyor belt The tube (5) and the cold air square tube (6), the pressure relief port (7) on the quenching and tempering box; the brown rice falls from the blanking port (2) to the conveyor belt (4), and is transferred to the discharge port (3) for delivery. Its characteristics are:

[0022] The tempering box (1) is equipped with three layers of conveyor belts, each layer of conveyor belts are arranged in a staggered arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com