Agricultural drying mechanism and automatic control method thereof

A drying and mechanical technology, applied in the field of agricultural drying machinery and its automatic control, agricultural machinery for grain drying and its automatic control, can solve the problems of poor drying effect, high air moisture content, increased operating cost and energy consumption, etc. Achieve the effect of improving product quality, improving air flow, and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

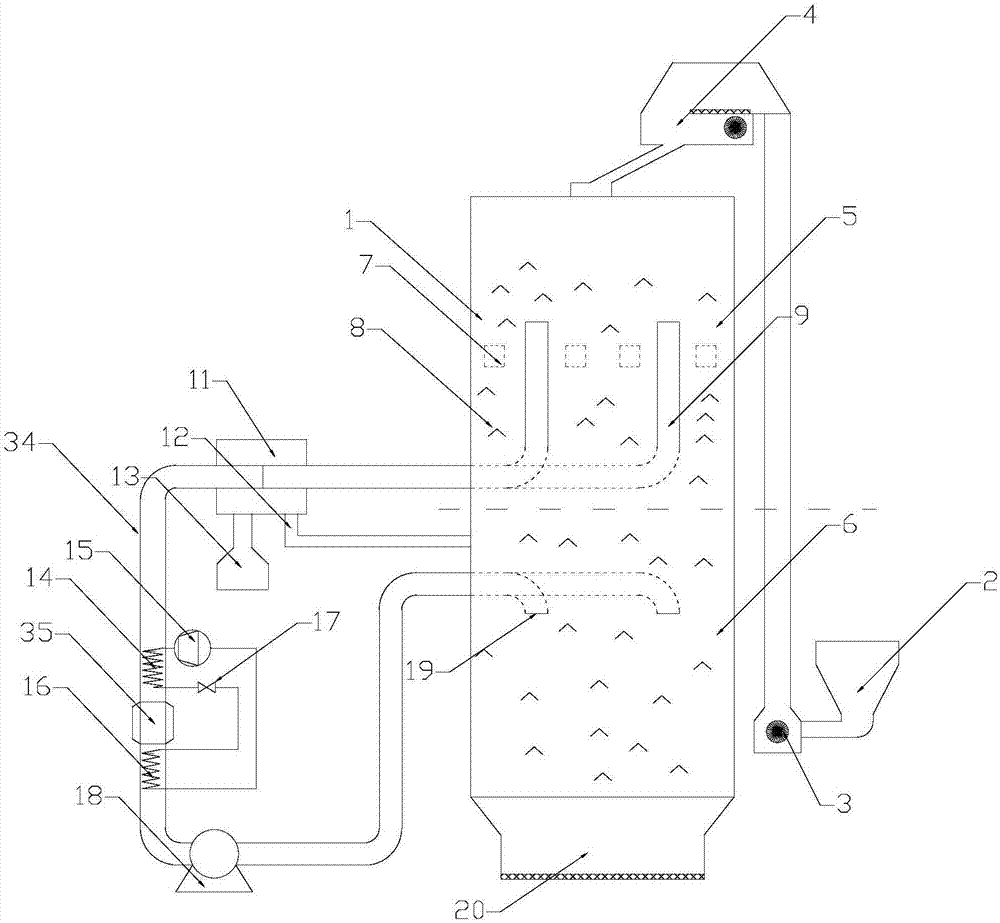

[0056] The structure of the drying machine provided by the invention is as figure 1 shown, including:

[0057] The main body 1 of the drying chamber is composed of the drying chamber 5 on the upper layer and the slowing chamber 6 on the lower floor, and the drying chamber 5 and the slowing chamber 6 are connected;

[0058] Feeding device 2 is used for adding grain therein, which can be equipment such as adding funnels;

[0059] The lifting device 3 connects the feeding device 2 with the feeding device 4, and is used to lift the grain from the feeding device 2 to the feeding device 4 located on the upper part of the drying bin main body 1, and the lifting device 3 can adopt devices such as conveyor belts;

[0060] The feeding device 4 is used to put the grain into the drying bin 5, and equipment such as a vibrating screen can be used;

[0061] Blocking grille 8, distributed in the drying bin 5 and slow Su bin 6, is used to block the grain and prevent it from falling too fast...

Embodiment 2

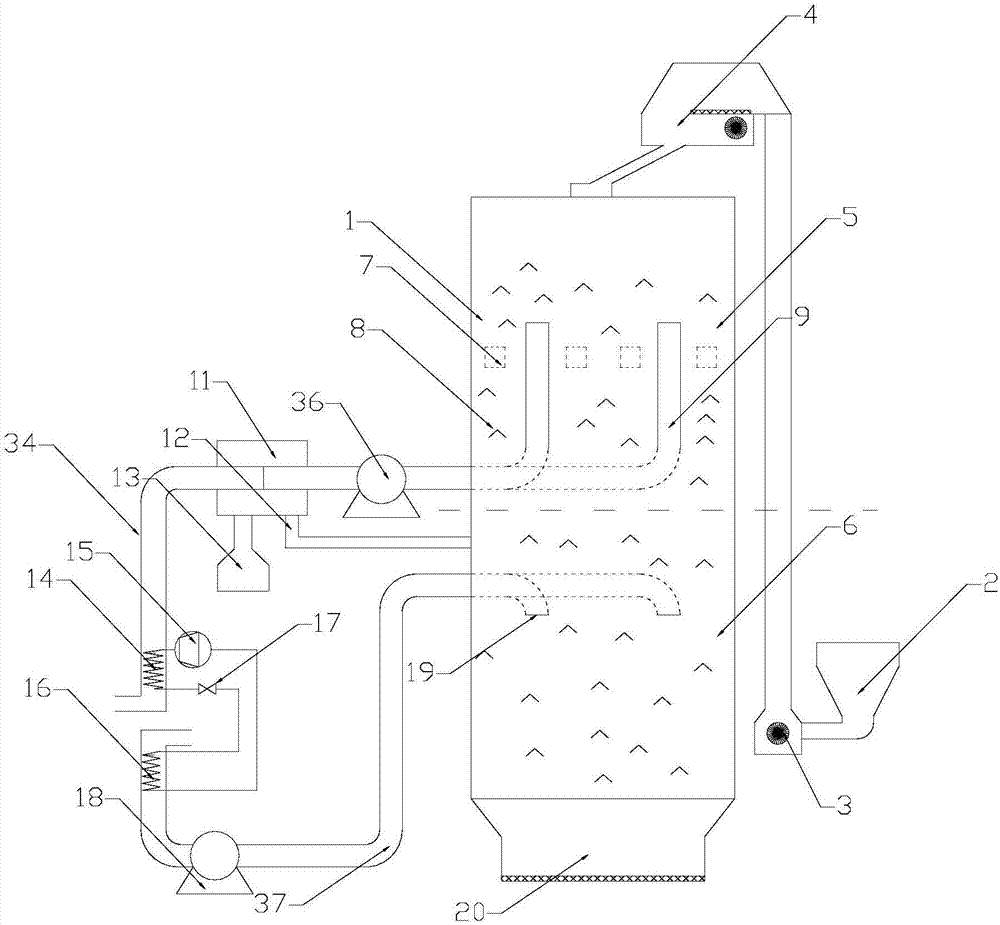

[0079] Another drying machine provided by the invention, such as image 3 shown, with figure 1 The main difference of the shown device is: the outlet of the powder separator 11 is provided with an exhaust pipeline 34, and the evaporator 14 and the suction pump 36 are arranged in the exhaust pipeline 34; A suction pump 18 is arranged in the air pipeline 37, and is used to send the outside air into the slow recovery chamber 6; a condenser 16 is also arranged in the air supply pipeline 37; one end of the evaporator 14 passes through the compressor 15 and the condenser 16 successively , The expansion valve 17 is connected back to the other end of the evaporator 14, forming a closed cycle.

[0080] In the exhaust pipe 34 is the air that has been removed from grains and skin fragments. After the heat energy is utilized by the evaporator 14, the heat energy is directly transferred to the directly collected air in the atmosphere, and this part of heat energy is supplied to the colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com