Patents

Literature

79results about How to "Reduce uneven heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating cooking device

InactiveUS20050109760A1Easy to shapeLow costDomestic stoves or rangesBaking ovenEngineeringMaterial Perforation

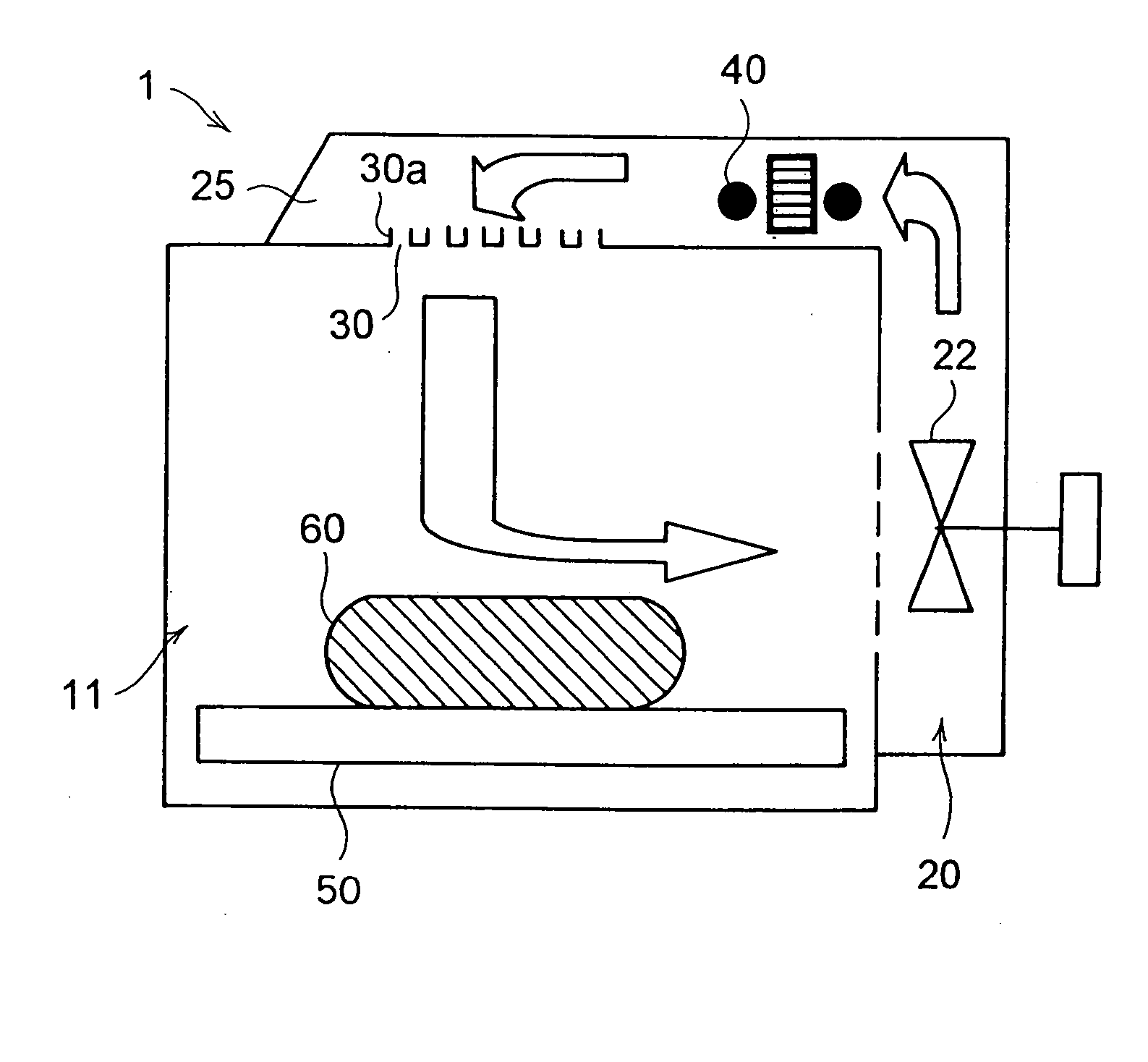

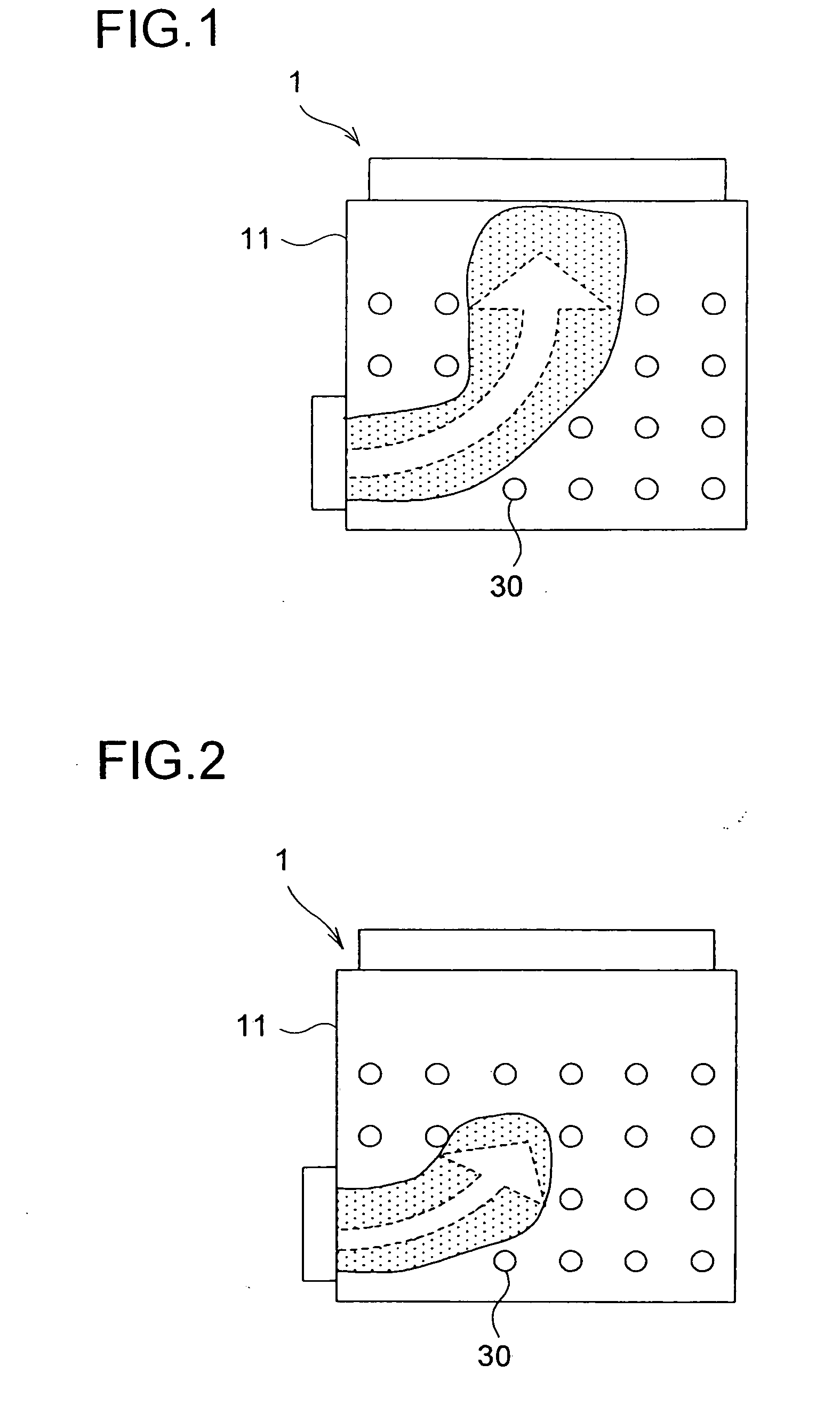

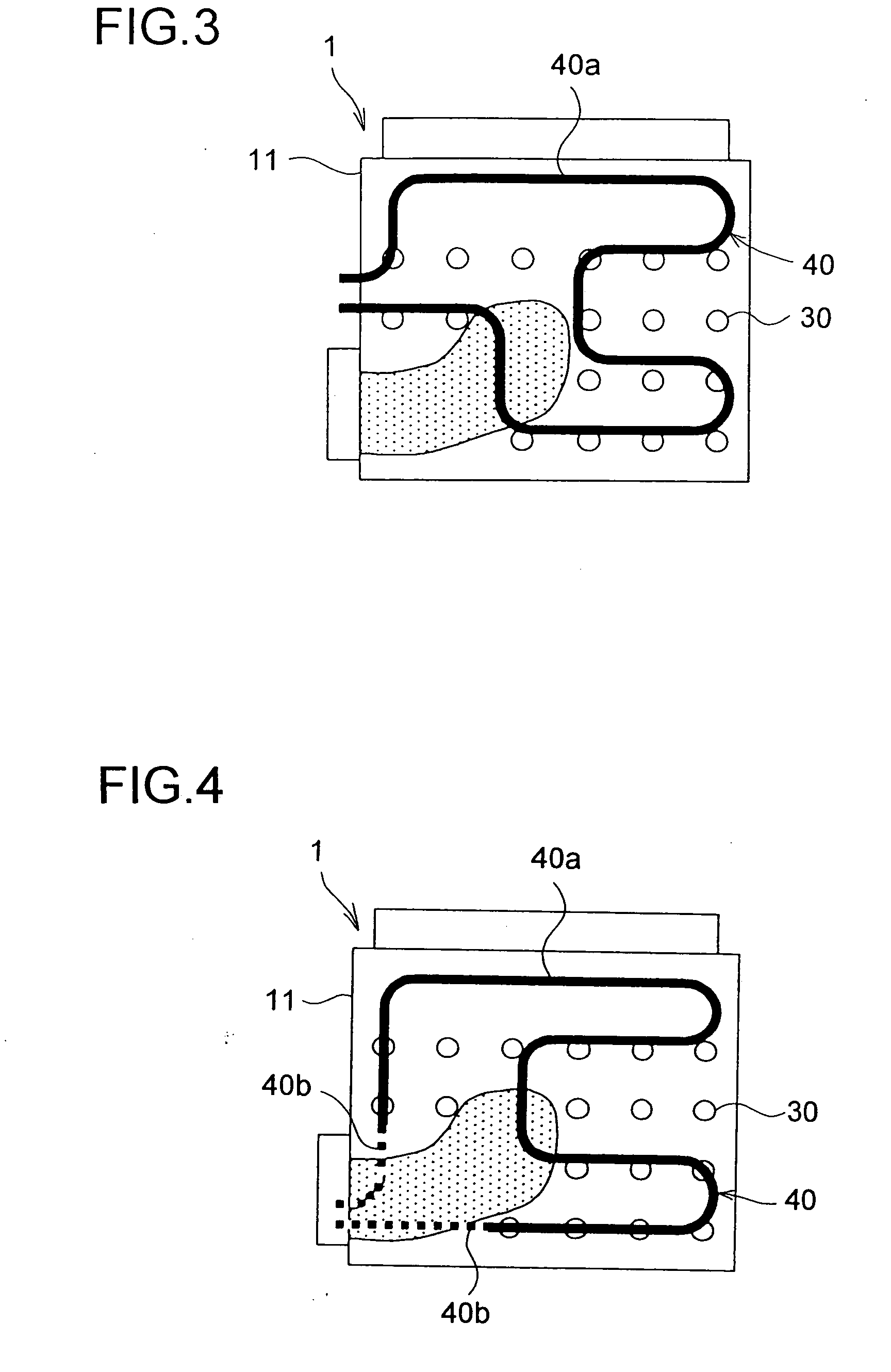

A cooking oven, wherein an upper blowing port blowing hot air in vertical direction and a lateral blowing port for blowing hot air in horizontal direction are provided in a cooking chamber, the upper blowing port is provided in the ceiling wall of the cooking chamber, the lateral blowing port is provided in one of the right and left inside walls thereof, and a suction port is provided in the bottom inside wall thereof in the form of collected perforations, air in the cooking chamber sucked from the suction port is fed to an upper duct and a lateral duct, heated by an upper heater and a lateral heater, respectively, and blown from the upper blowing port and the lateral blowing port, and the distribution of the perforations of the upper blowing port is made such that the distribution of the perforations at a position where the air blows toward air current from the lateral blowing port to a cooked object is made coarser than that at the other positions so that the air current in horizontal direction cannot be obstructed.

Owner:SHARP KK

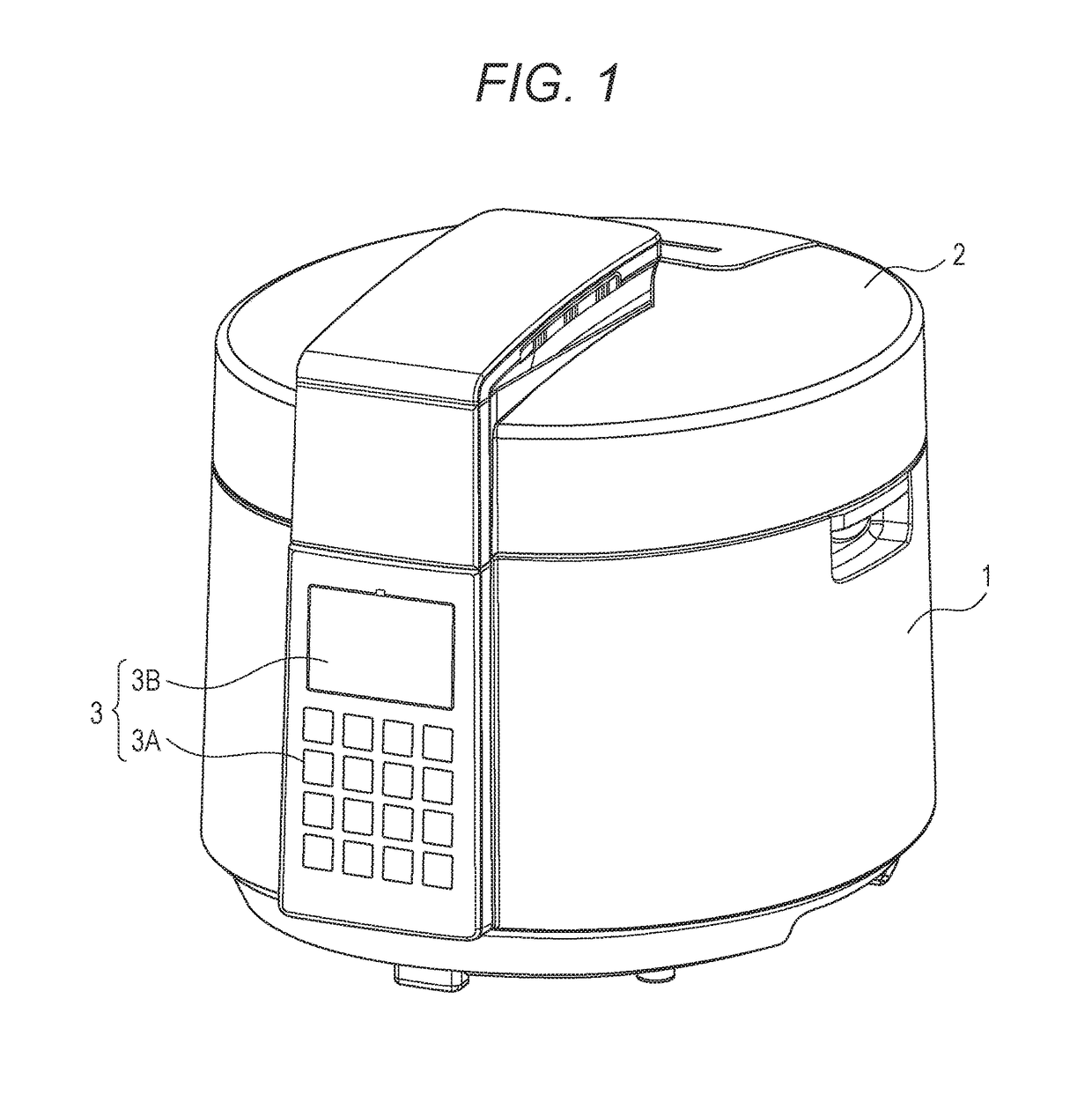

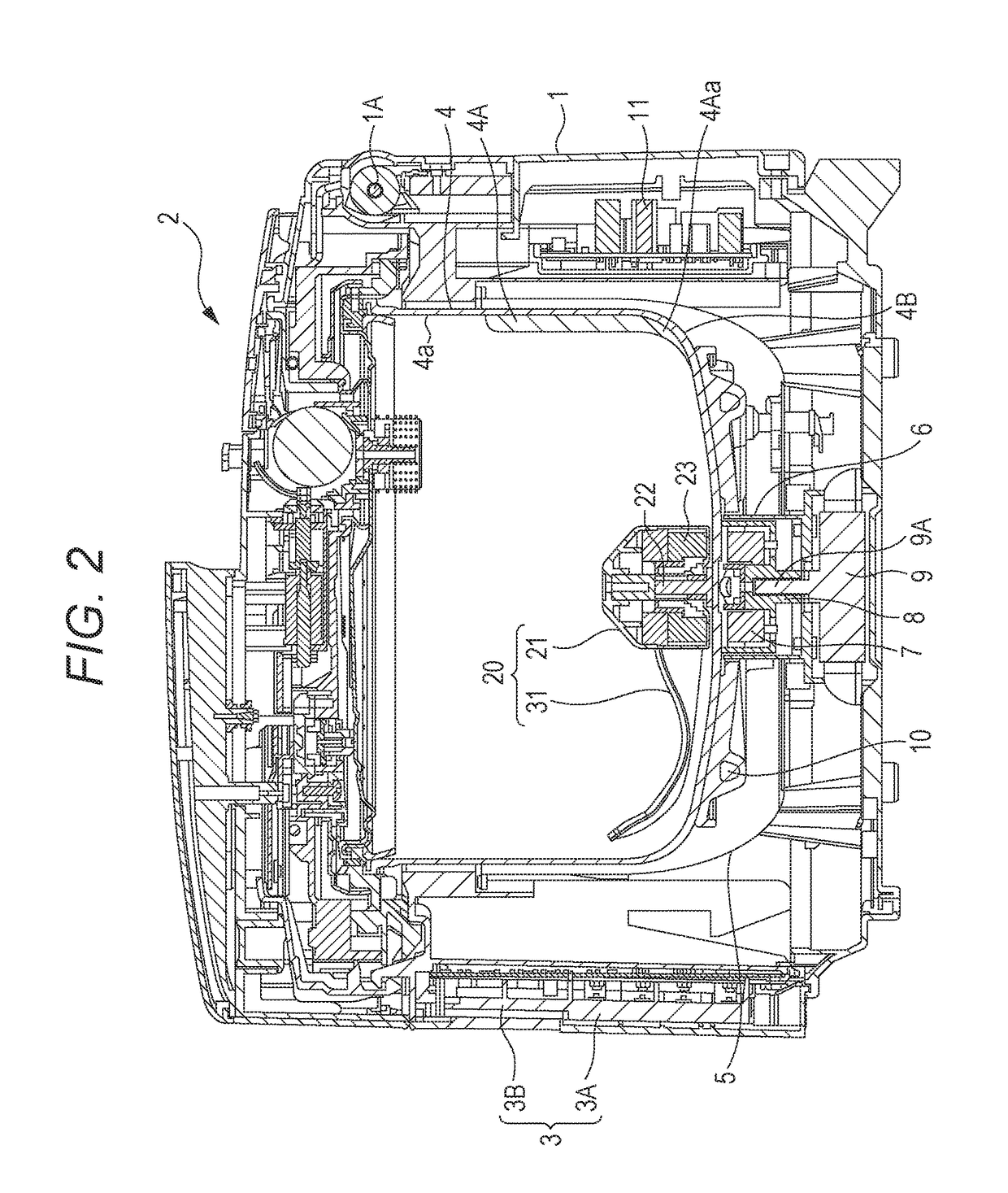

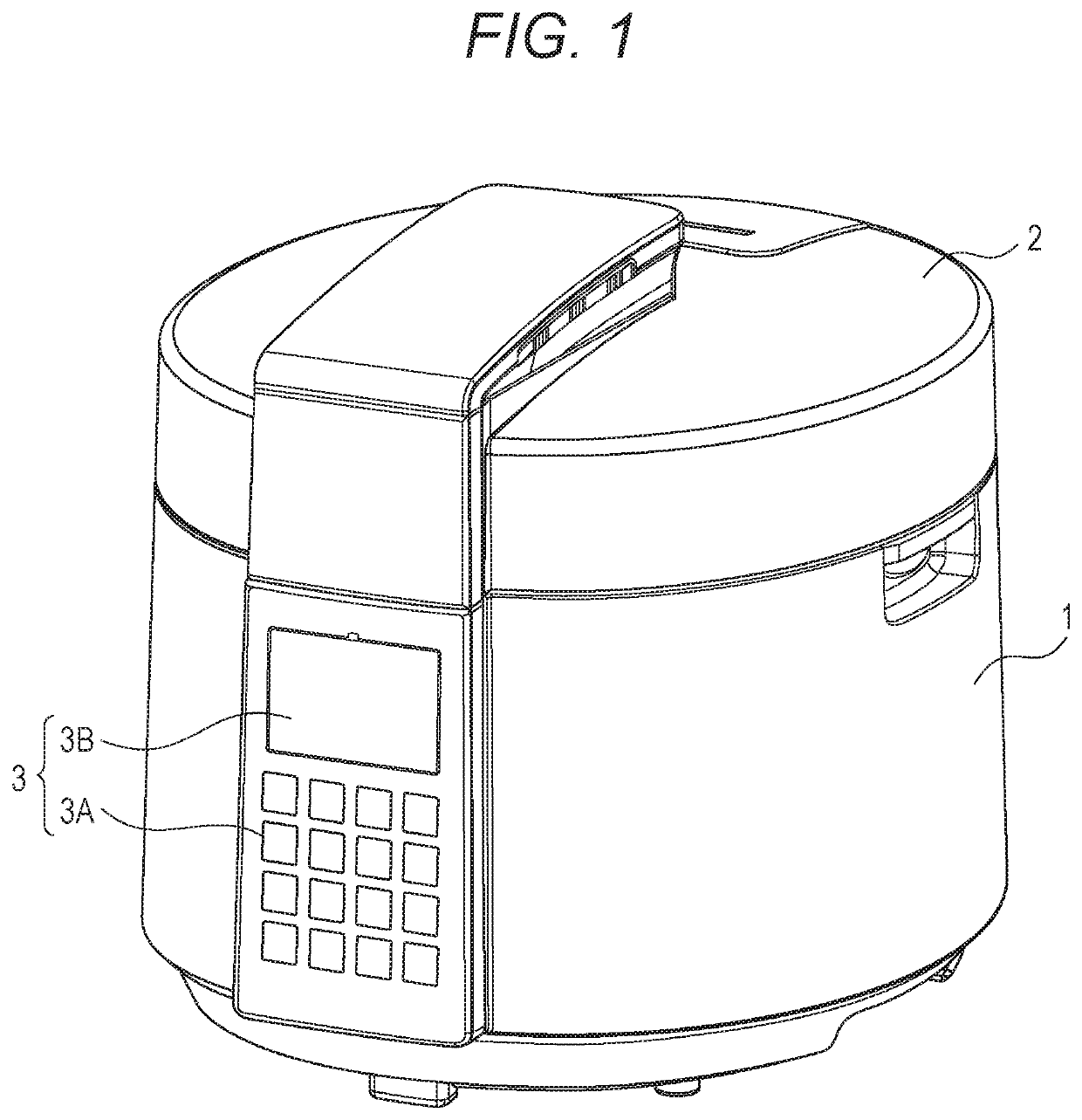

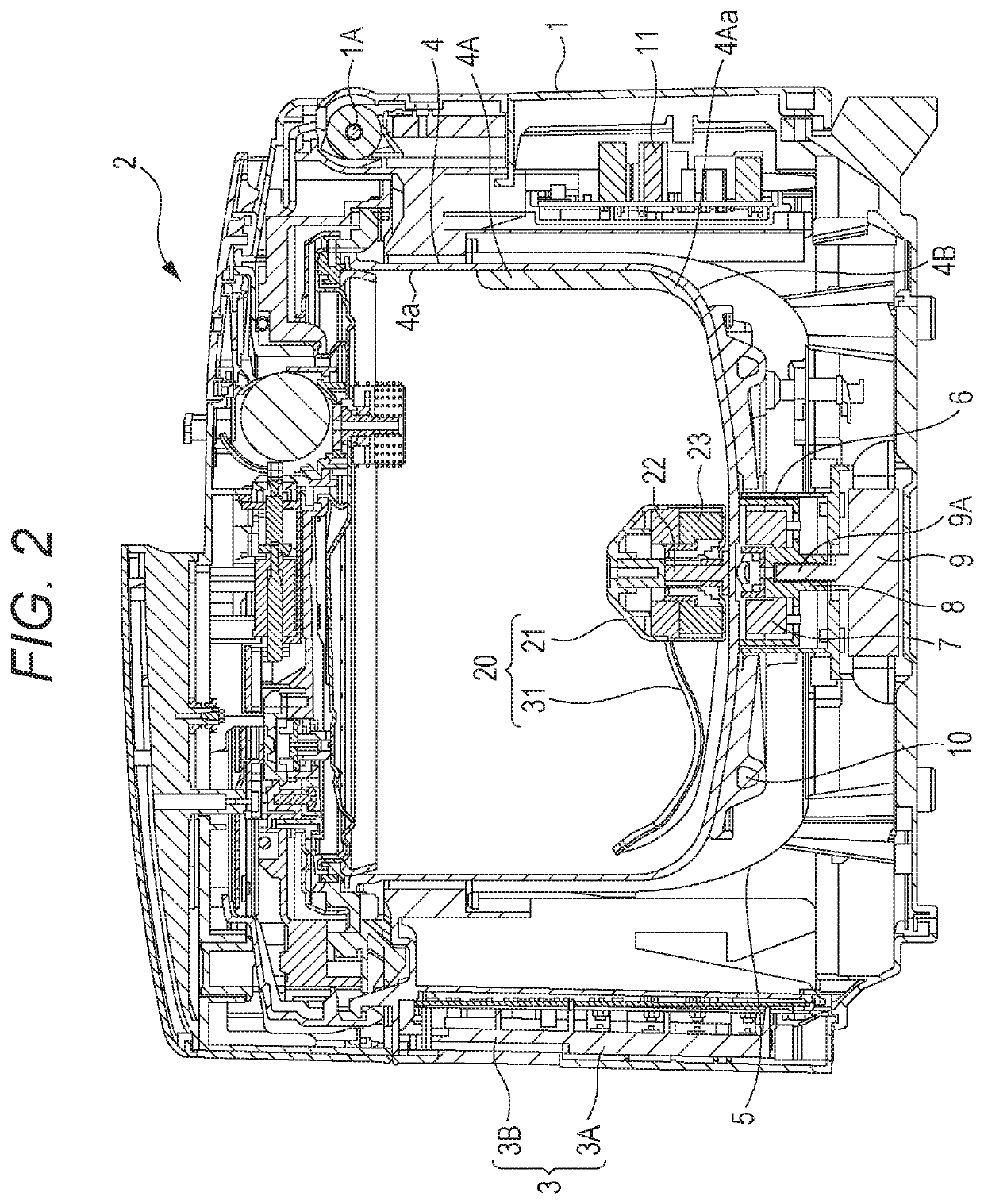

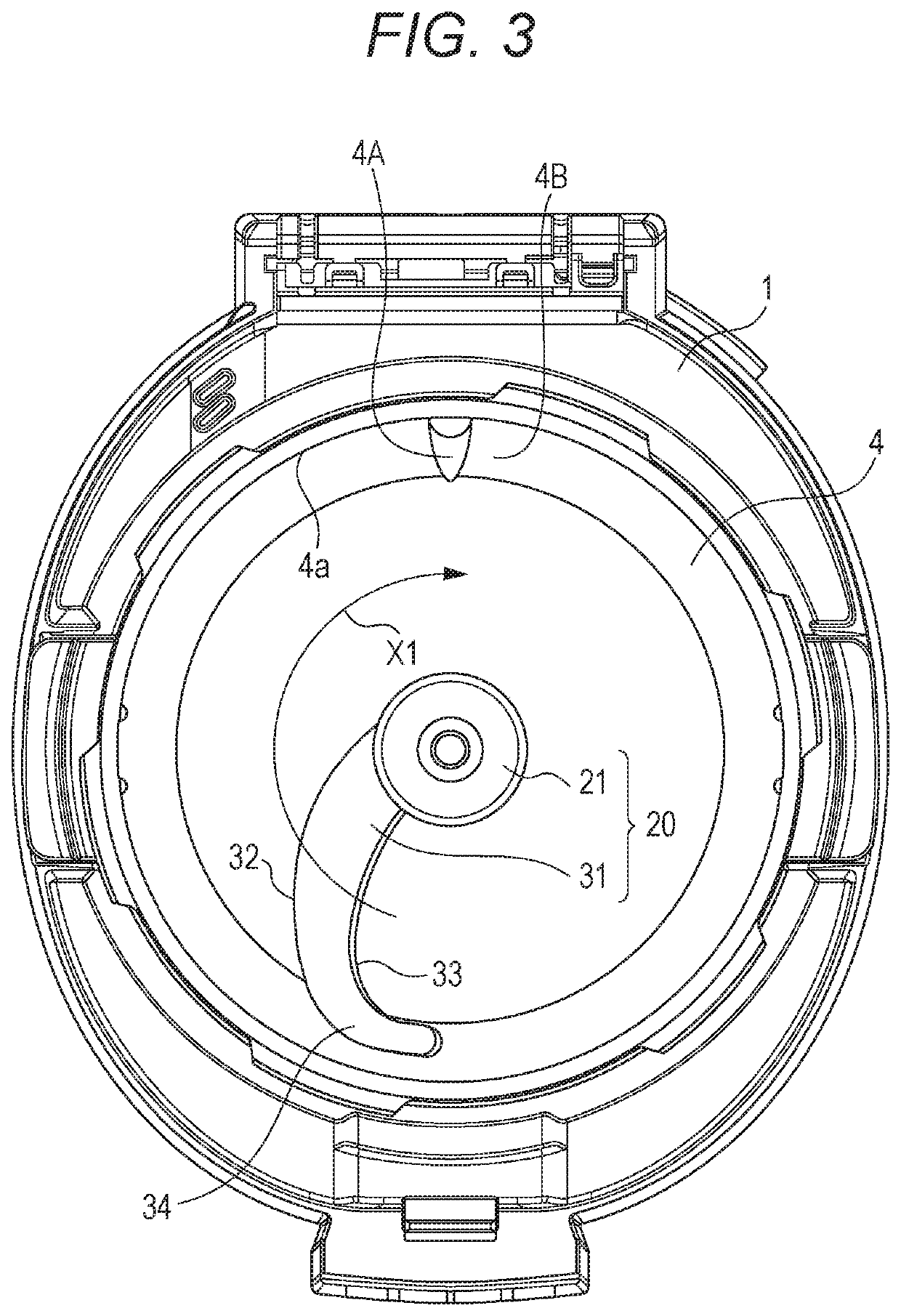

Heating cooker

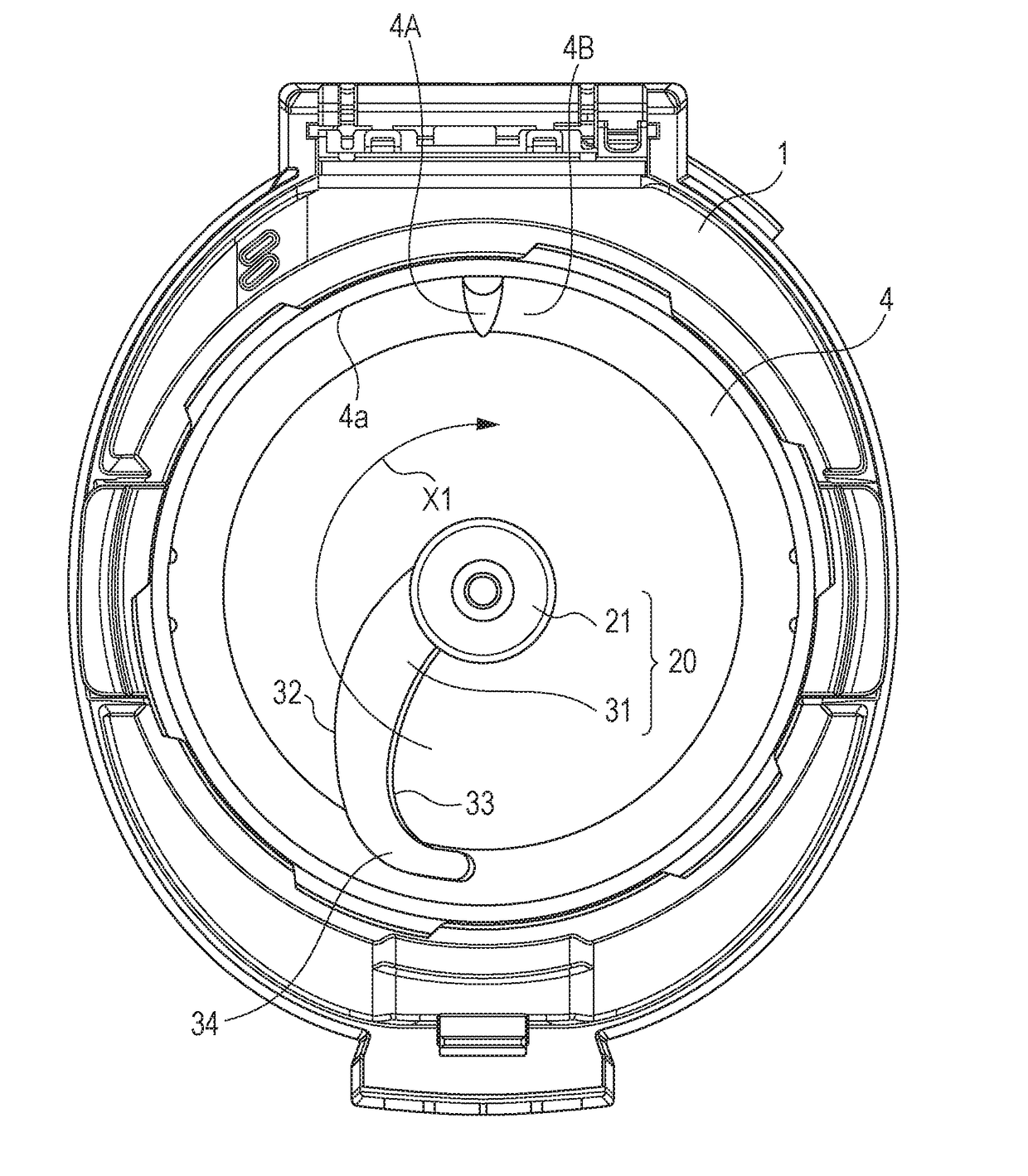

ActiveUS20170360237A1Reduce uneven heatingResistance from a bottom surface of the cooking container reducesCooking insertsVessels with intergral heatingCooker

A stirring body of the present invention includes housing rotatably mounted to a center of a bottom surface of a cooking container, and blade that extends from an outer peripheral surface of housing toward an inner peripheral surface of the cooking container and curves convexly toward a downstream side of a rotating direction in a plan view. Blade has front edge positioned on the downstream side in the rotating direction, and rear edge positioned on an upstream side in the rotating direction relative to front edge. A leading end portion of blade curves along the inner peripheral surface of the cooking container in the plan view and slopes upward toward the upstream side in the rotating direction. Front edge is positioned below rear edge near housing and is positioned above rear edge near leading end portion.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

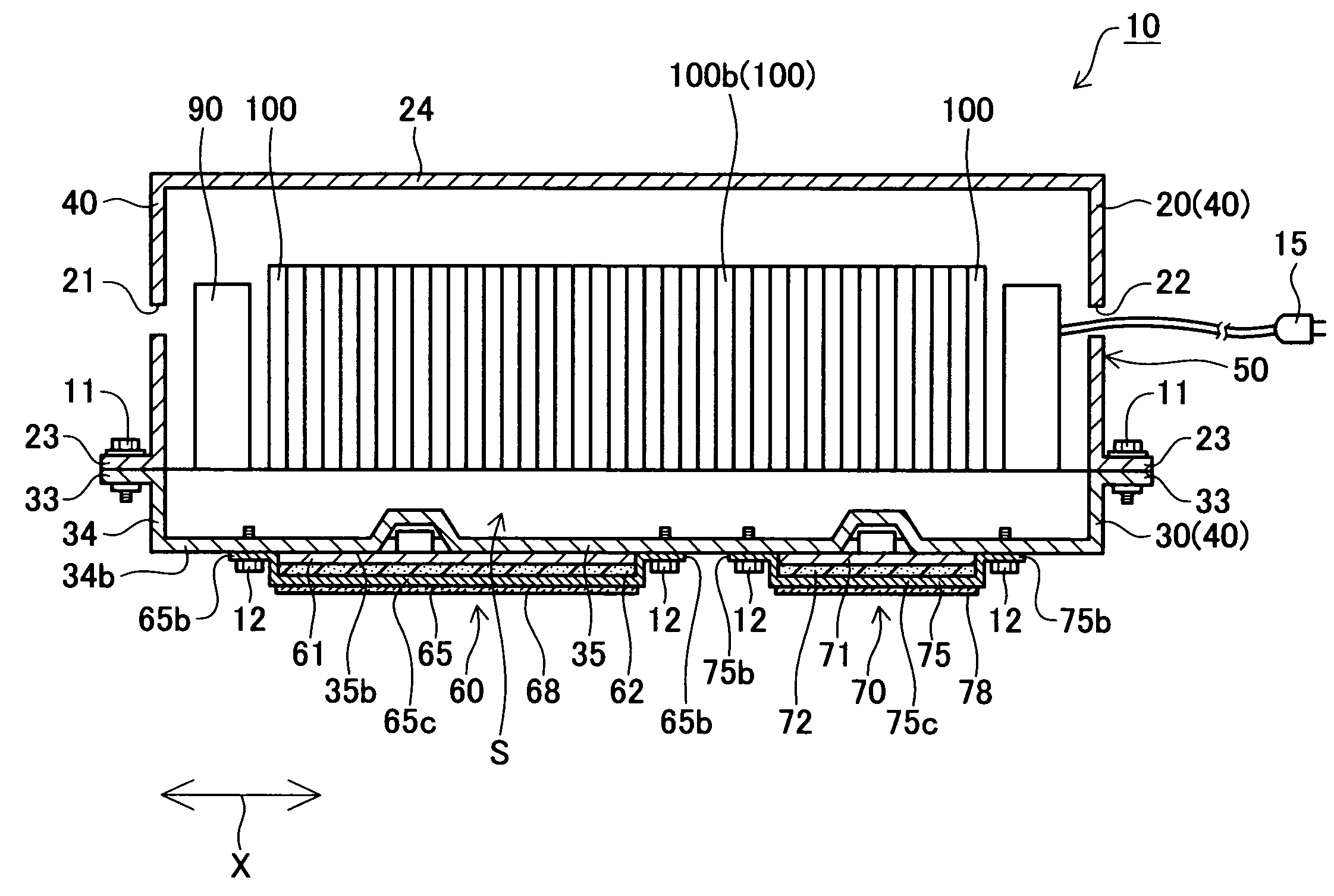

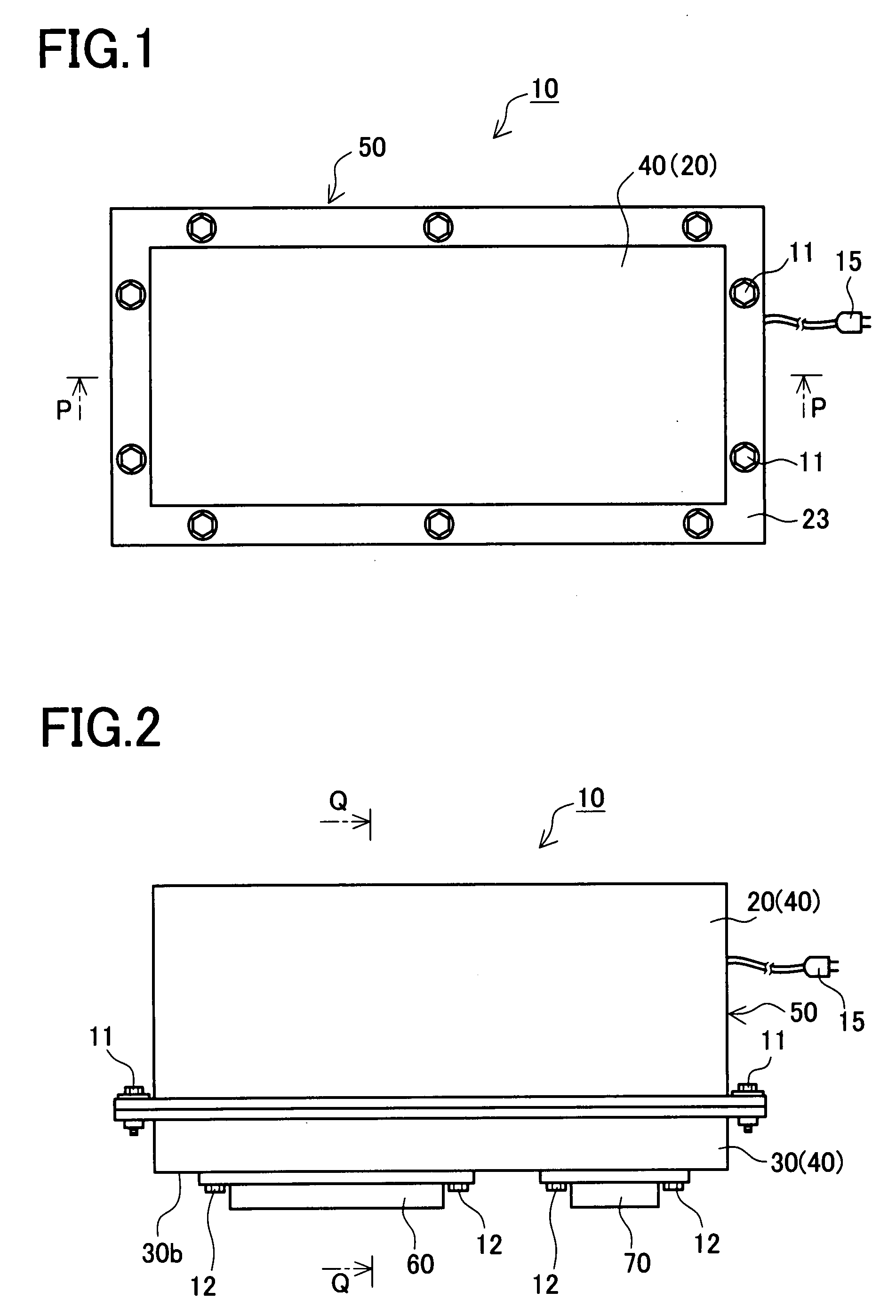

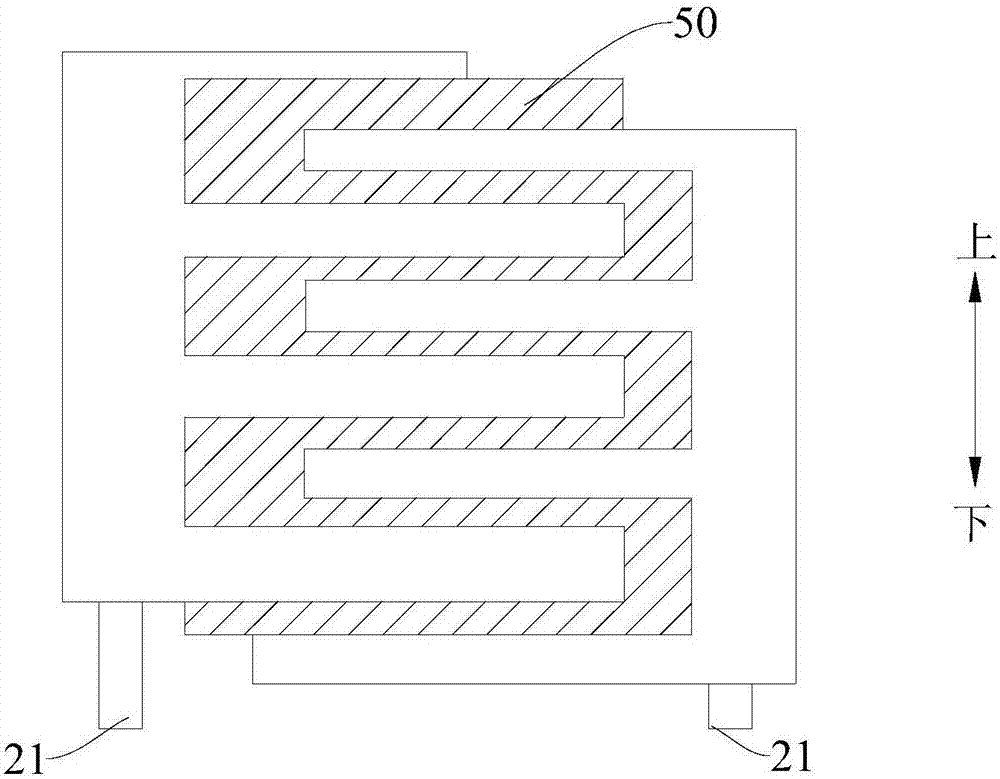

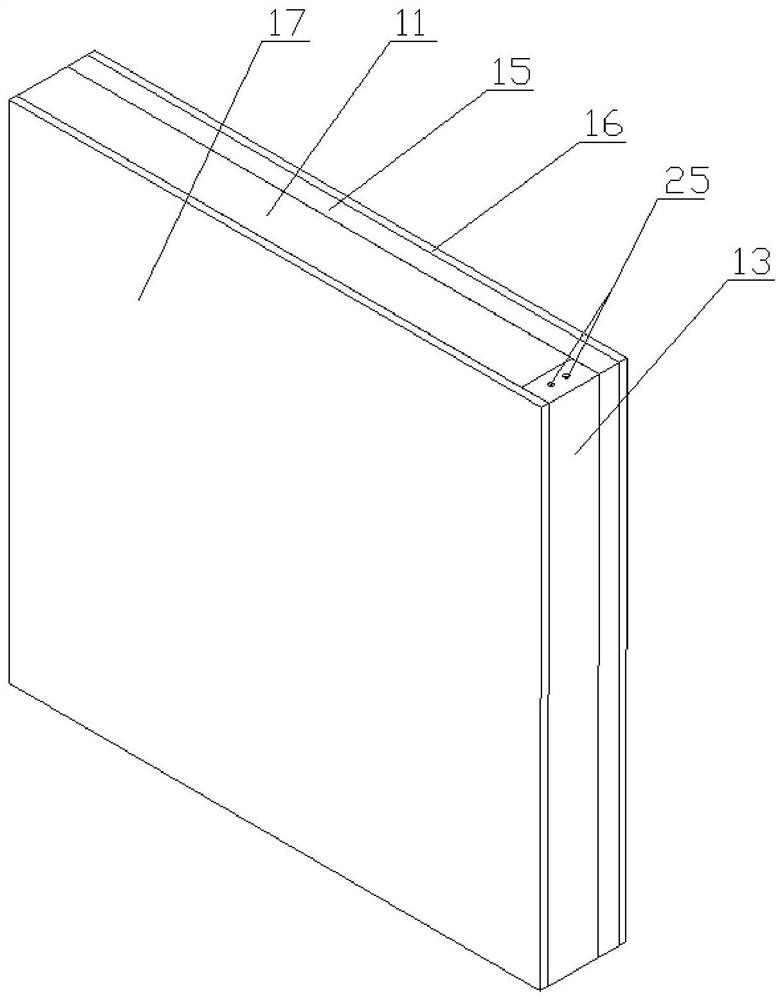

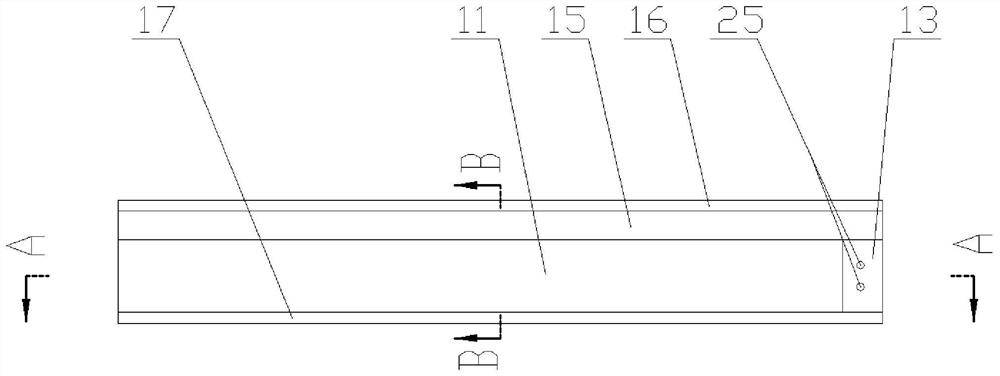

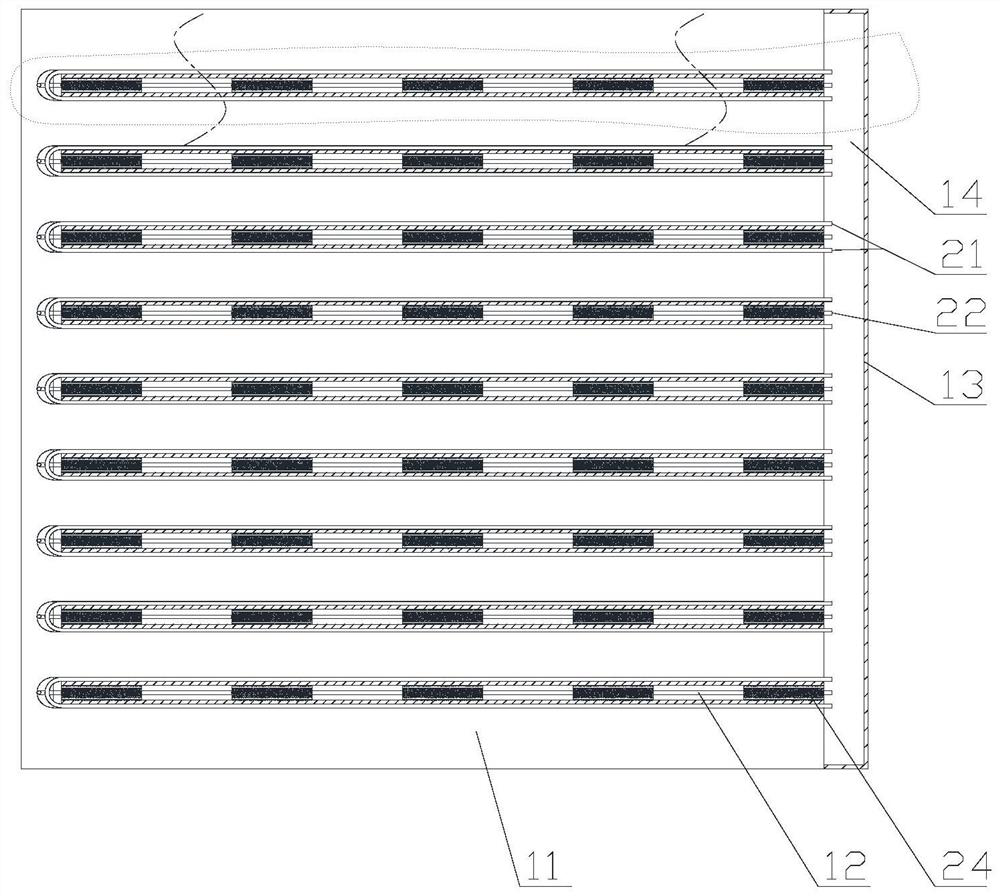

Heater with temperature detecting device and battery structure with the heater

ActiveUS20080093353A1Little changeMinimize uneven heatingCell temperature controlHeater elementsEngineeringMetal sheet

An object of the present invention is to provide a heater with temperature detecting device, arranged to accurately detect the temperature of a laminated sheet heater by use of a temperature detecting device over long periods, and a battery structure including the heater with temperature detecting device. A first heater with temperature detecting device includes a first laminated sheet heater and a temperature sensor having a temperature measuring portion. The first laminated heater is constituted of first and second insulating resin films, a heater element, a first metal sheet, and a second metal sheet and includes a heater metallic section in which, of the first insulating resin film, the second insulating resin film, the heater element, the first metal sheet, and the second metal sheet, any one of only the first metal sheet and only a combination of the first metal sheet and the second metal sheet is arranged in a lamination direction of the laminated heater. The temperature sensor is fastened to the heater metallic section of the first laminated heater with a flat rivet and fixed to an outer surface of the first metal sheet with the temperature measuring portion is in contact with the first metal sheet.

Owner:PANASONIC EV ENERGY CO LTD

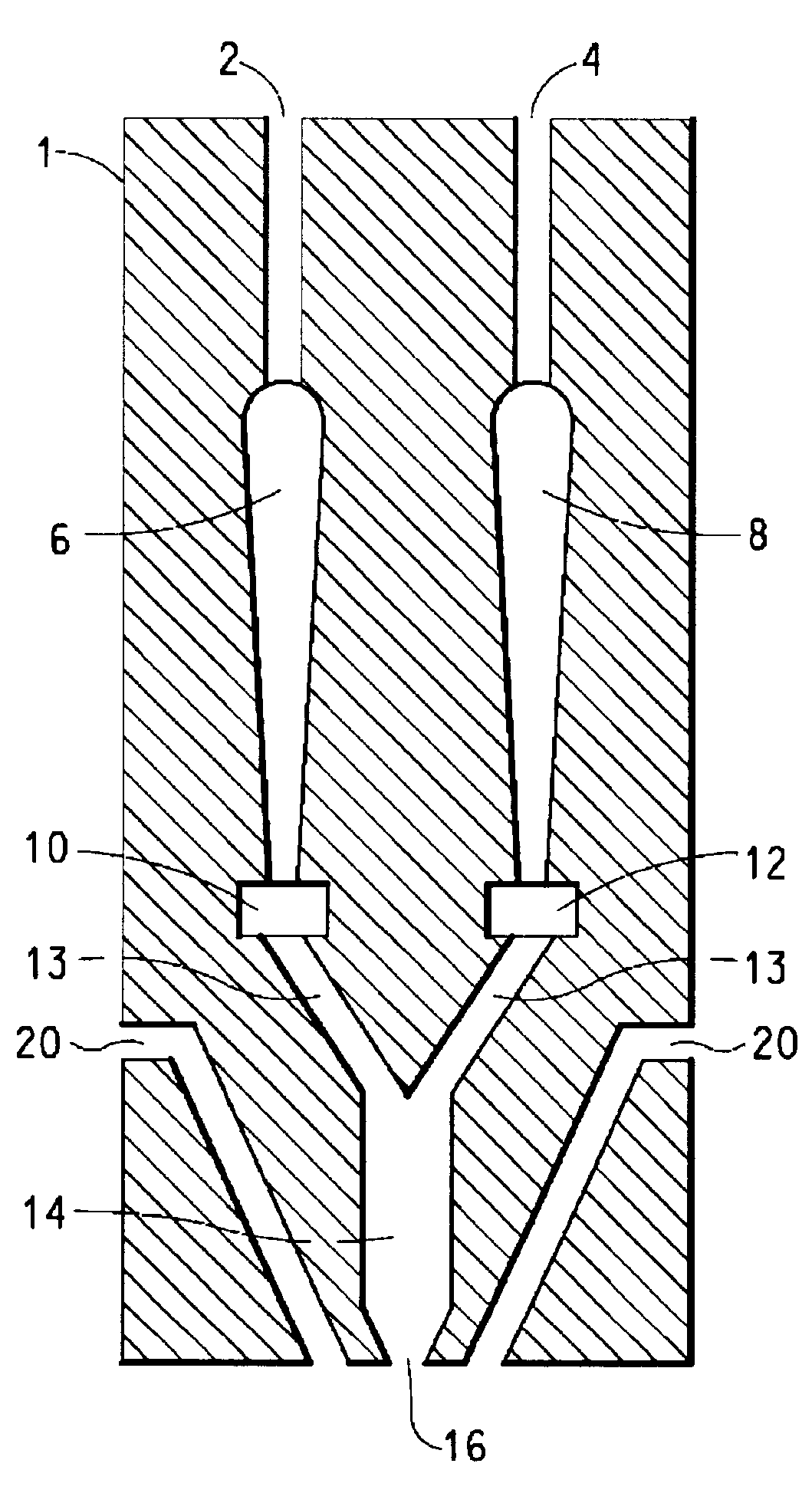

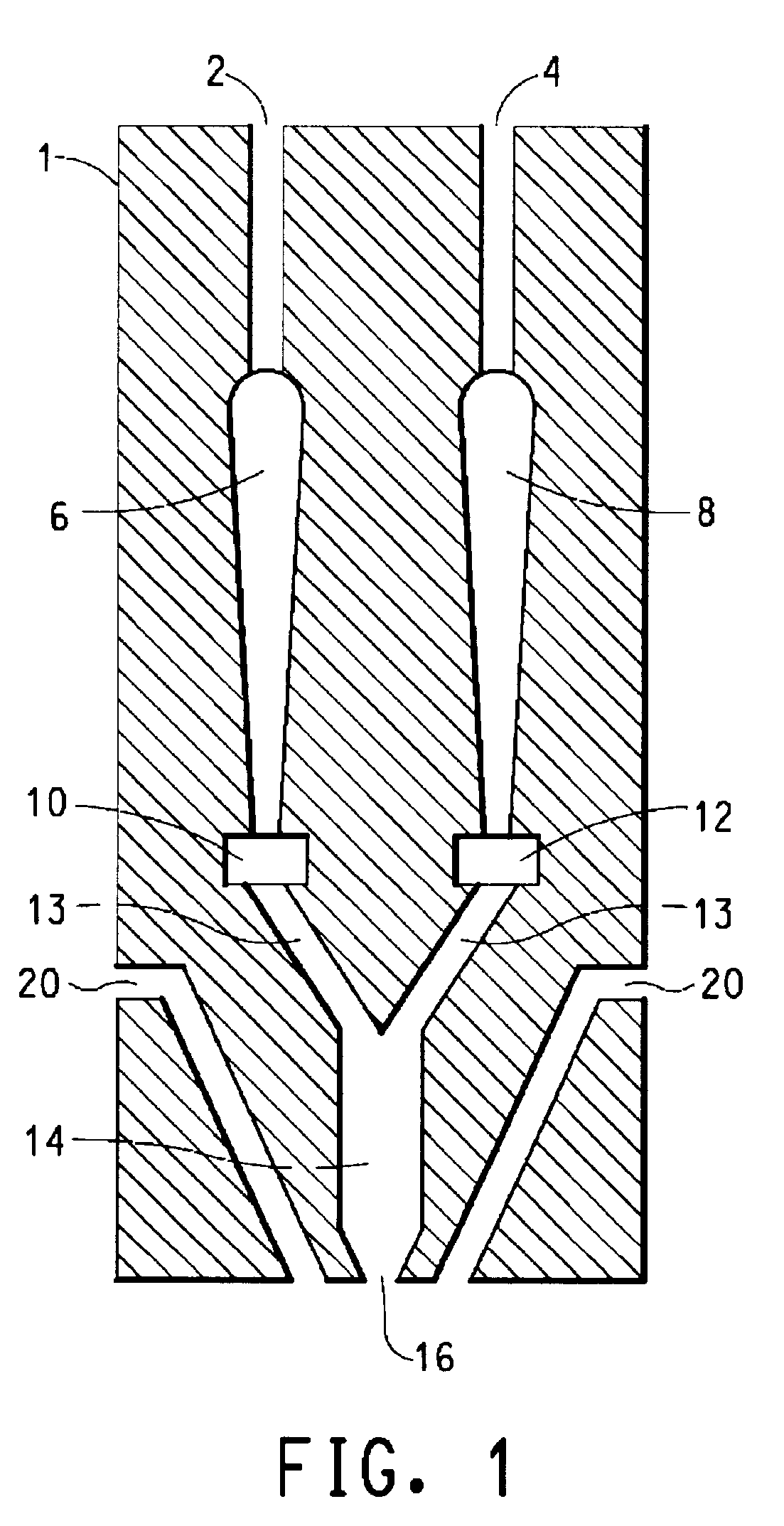

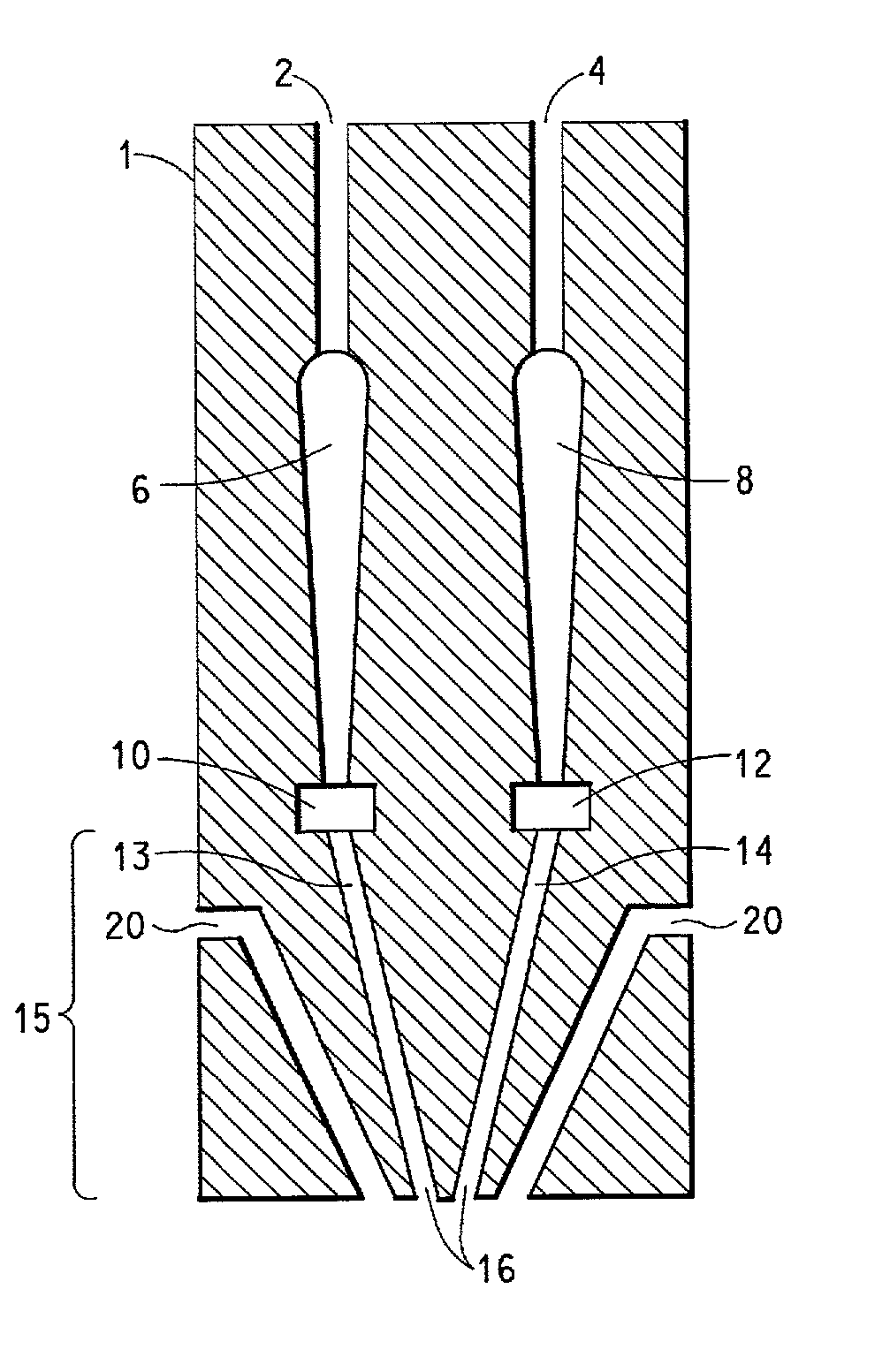

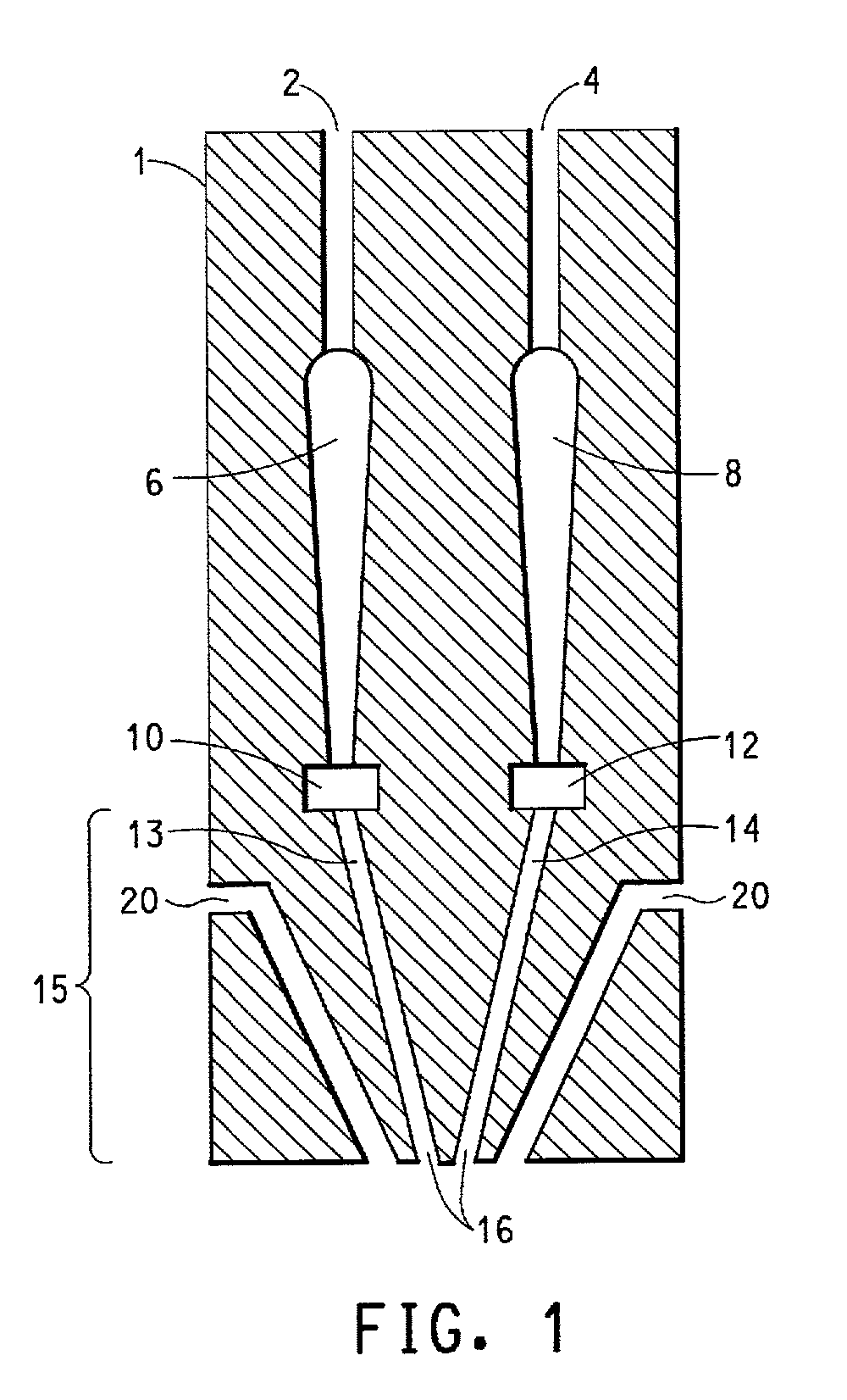

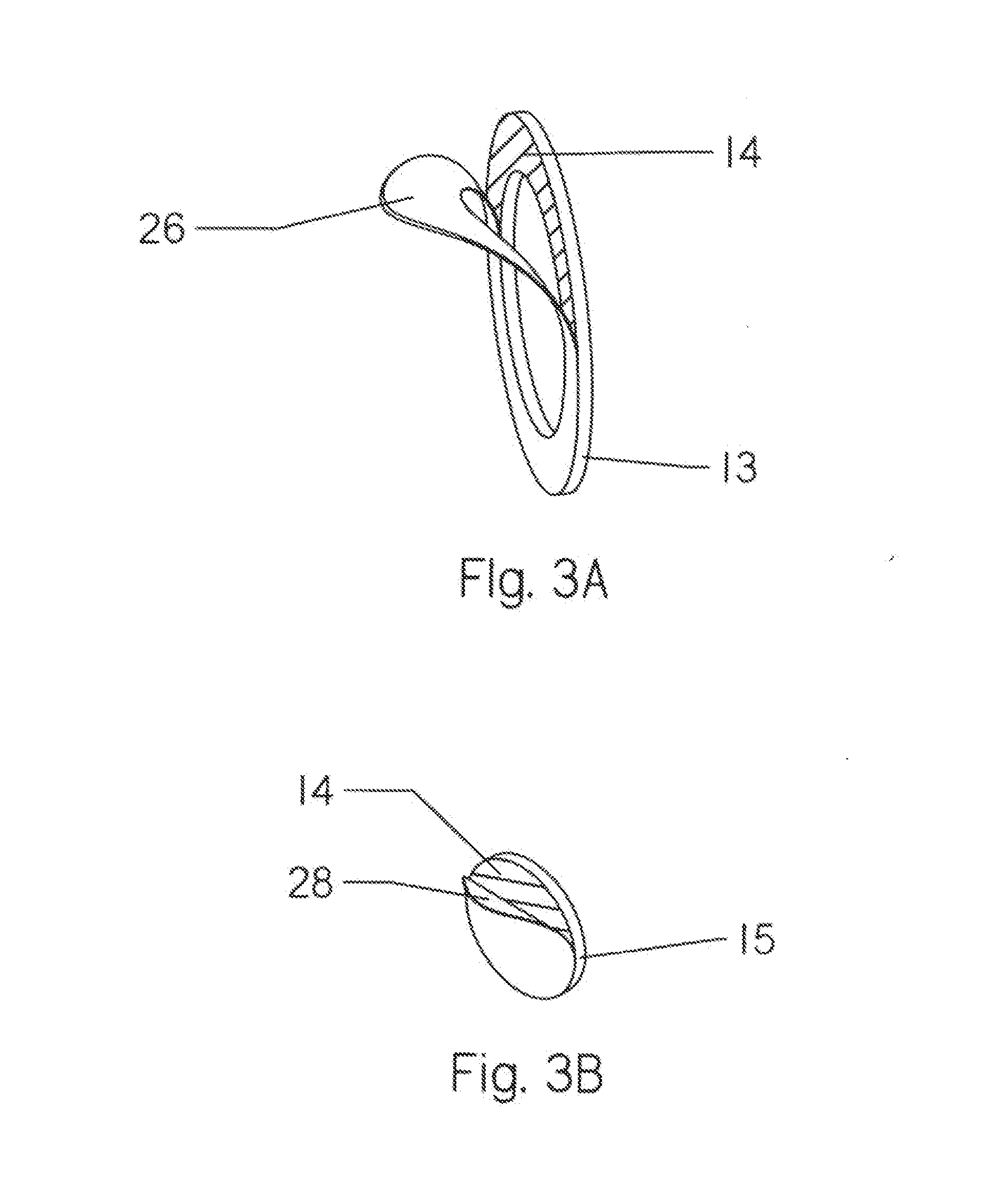

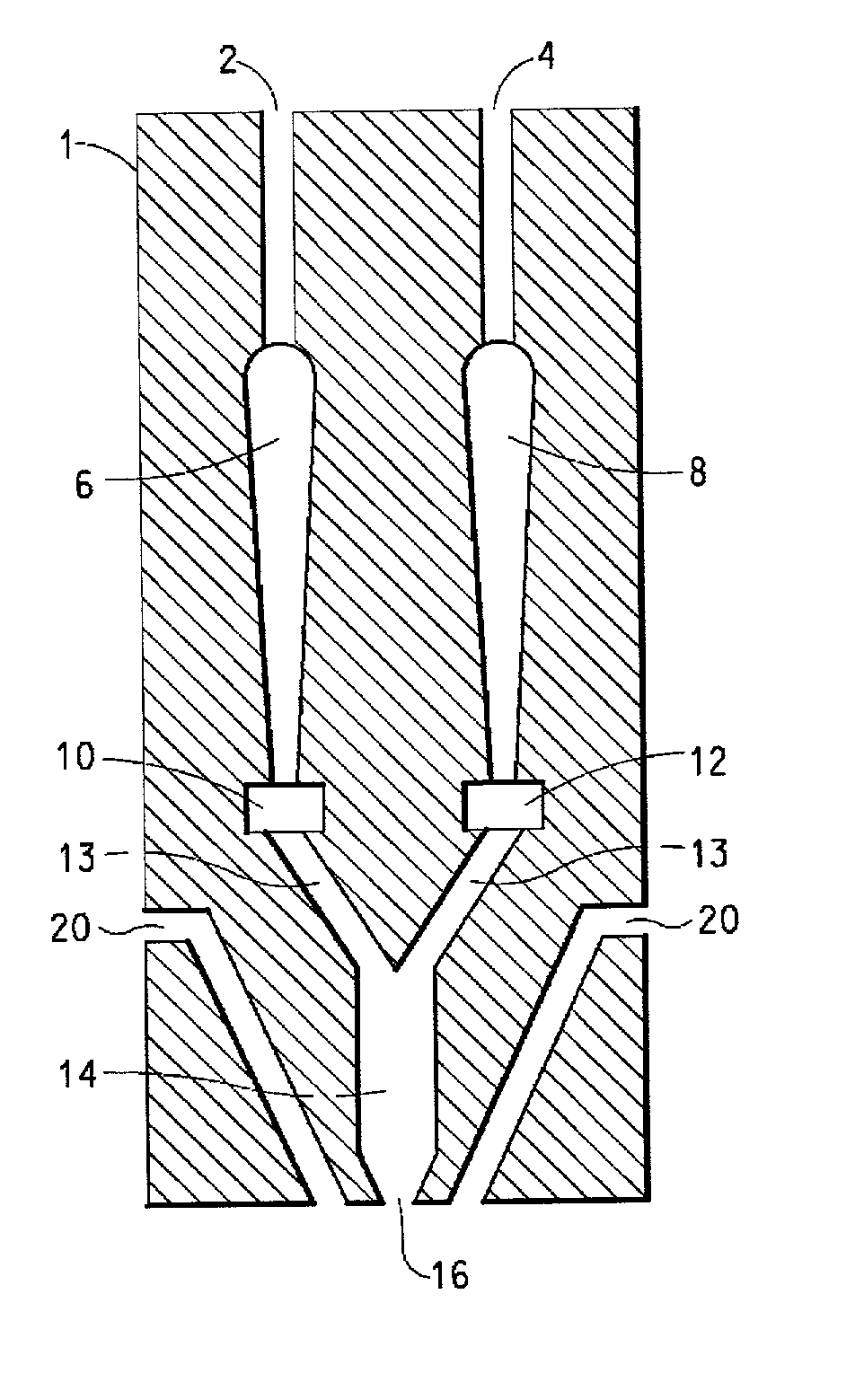

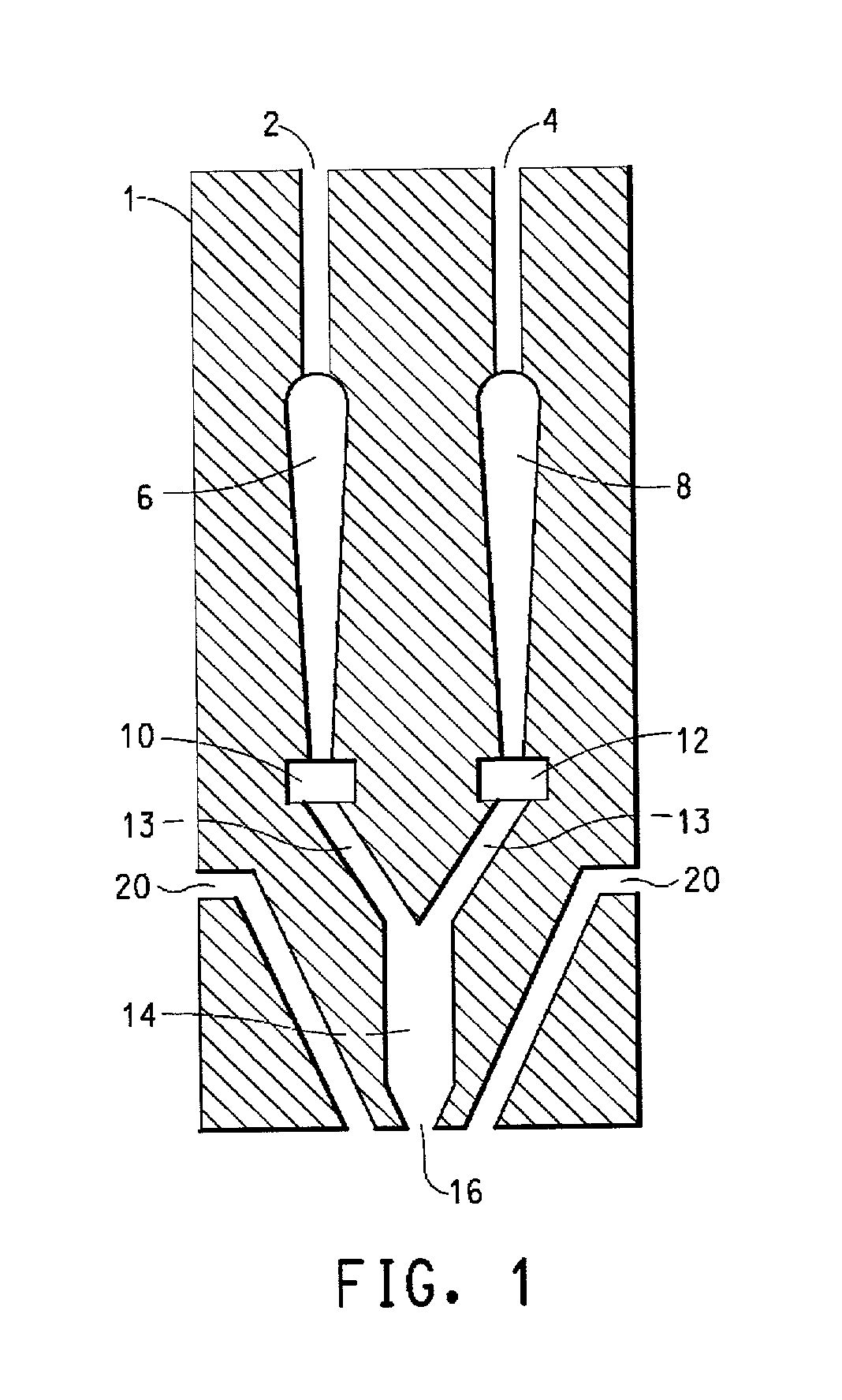

Process and apparatus for making multi-layered, multi-component filaments

InactiveUS6605248B2Minimizing polymer degradationMinimizes gradientConfectioneryLaminationEngineeringMechanical engineering

The present invention is directed to a process for forming a plurality of multi-layered filaments from multiple thermoplastic synthetic polymers and an apparatus containing a melt spinning beam which comprises multiple polymer inlet passages each communicating with separate multiple coat hanger distribution manifolds, separate filters connected downstream of each coat hanger distribution manifold, a combining manifold connected downstream of said filters and spinneret orifices connected downstream of said combining manifold for spinning of said multi-layered filaments.

Owner:3M INNOVATIVE PROPERTIES CO

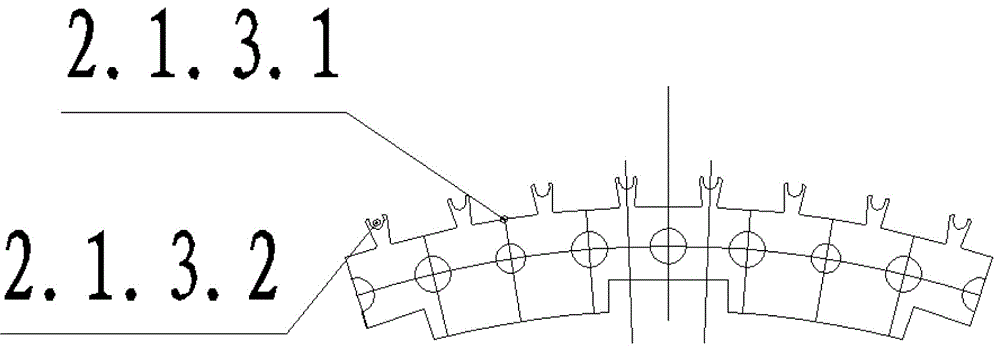

Direct-driven permanent-magnet motor

InactiveCN106208436AEvenly heatedReduce feverMagnetic circuit rotating partsMagnetic circuit stationary partsGlass fiberPunching

The invention discloses a direct-driven permanent-magnet motor. The direct-driven permanent-magnet motor comprises a stator and a rotor, wherein the stator comprises a water jacket engine base and a stator iron core, the stator iron core is fixed on the water jacket engine base, a plurality of annular opening grooves are formed in a surface of the stator iron core according to a rule, stator windings are arranged in the opening grooves, the rotor comprises a rotor body with a support and a rotor fan, the rotor body comprises a rotation shaft and a rotor iron core, the rotor iron core is arranged on the rotation shaft and is formed by laminating a plurality of fan-shaped rotor punching sheets in a staggered way, a plurality tapered grooves are formed in the outer circumference of each fan-shaped rotor punching sheet, and T-shaped magnetic steel with a tapered cross section is arranged in each tapered groove. In the direct-driven permanent-magnet motor, the stator windings uniformly generate heat, the magnetic steel is simple and reliable in fixing, a glass fiber or a jacket sleeve is not needed to be bonded, the rotor body and the magnetic steel are low in heat generation, and the reliability and the safety of the magnetic steel are improved; and meanwhile, the motor process is further simplified, the motor cost is reduced, and the market competiveness of a product is improved.

Owner:中国船舶重工集团公司第七一二研究所

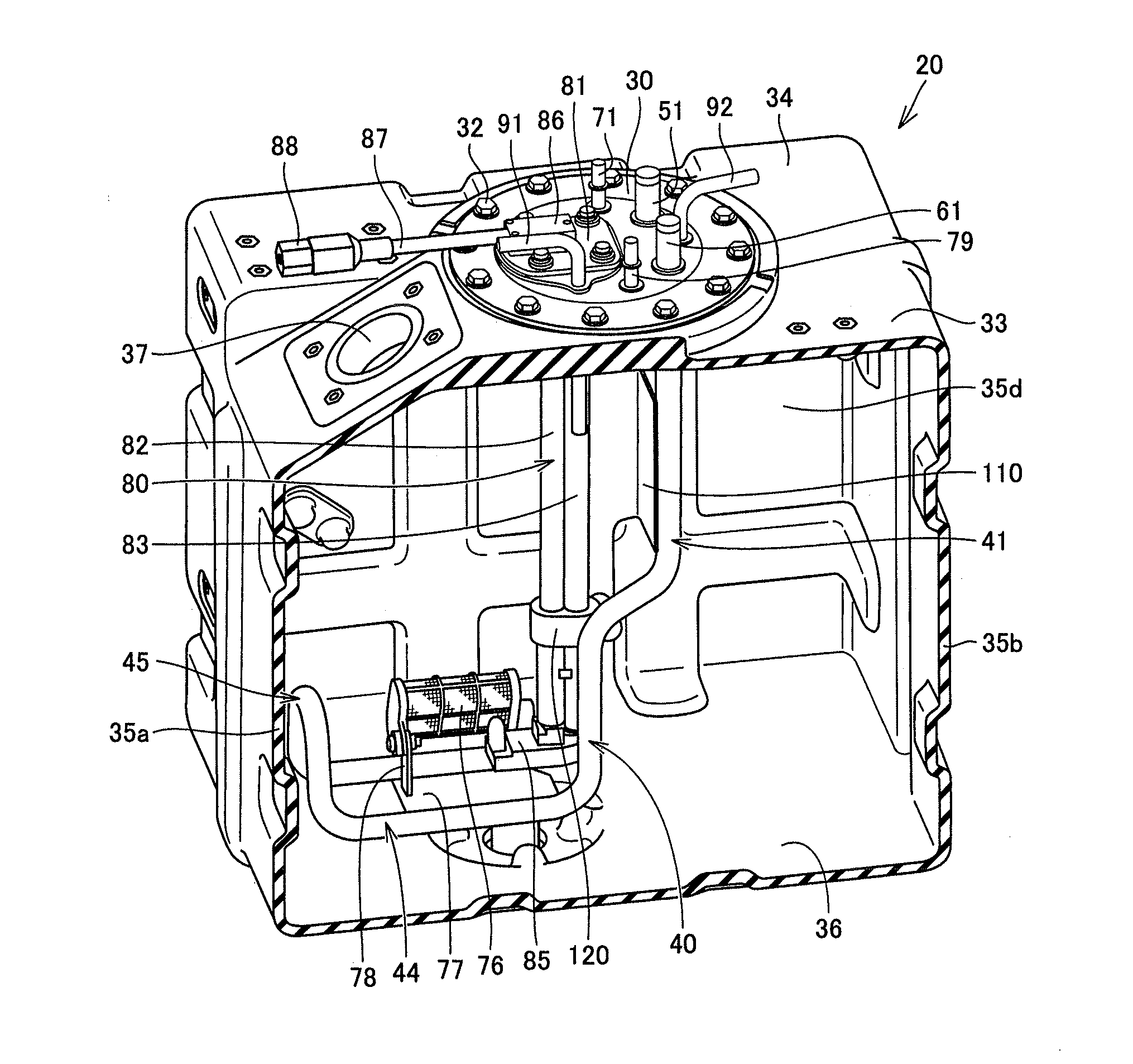

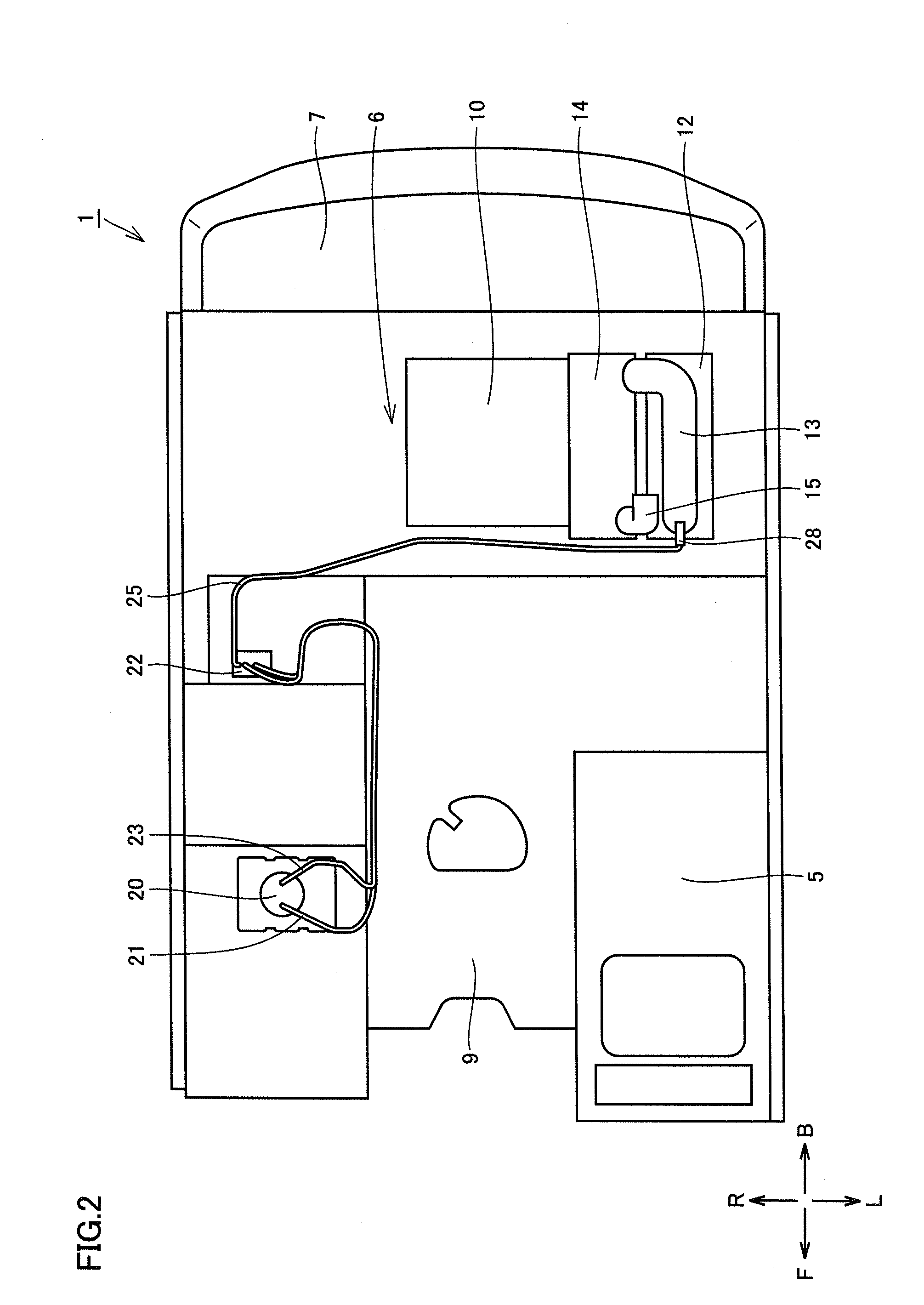

Reducing agent tank and work vehicle

ActiveUS20150192052A1Reduce heat transferReduce uneven heatingInternal combustion piston enginesExhaust apparatusHeat transfer efficiencyMechanical engineering

A reducing agent tank is provided which can improve a heat transfer efficiency to a reducing agent and transfer heat to the reducing agent in a height direction of the reducing agent tank without unevenness. The reducing agent tank includes a container main body which has an upper face and a bottom face and constitutes a space for storing the reducing agent between the upper face and the bottom face, and a heat exchanger which performs heat exchange with the reducing agent. The heat exchanger has penetrating portions and inclined portions. The penetrating portions penetrate to the upper face of the container main body and extend into the space. The inclined portions are inclined relative to the penetrating portions at a position different from each other in an extending direction of the penetrating portions and extend toward a side of the bottom face.

Owner:KOMATSU LTD

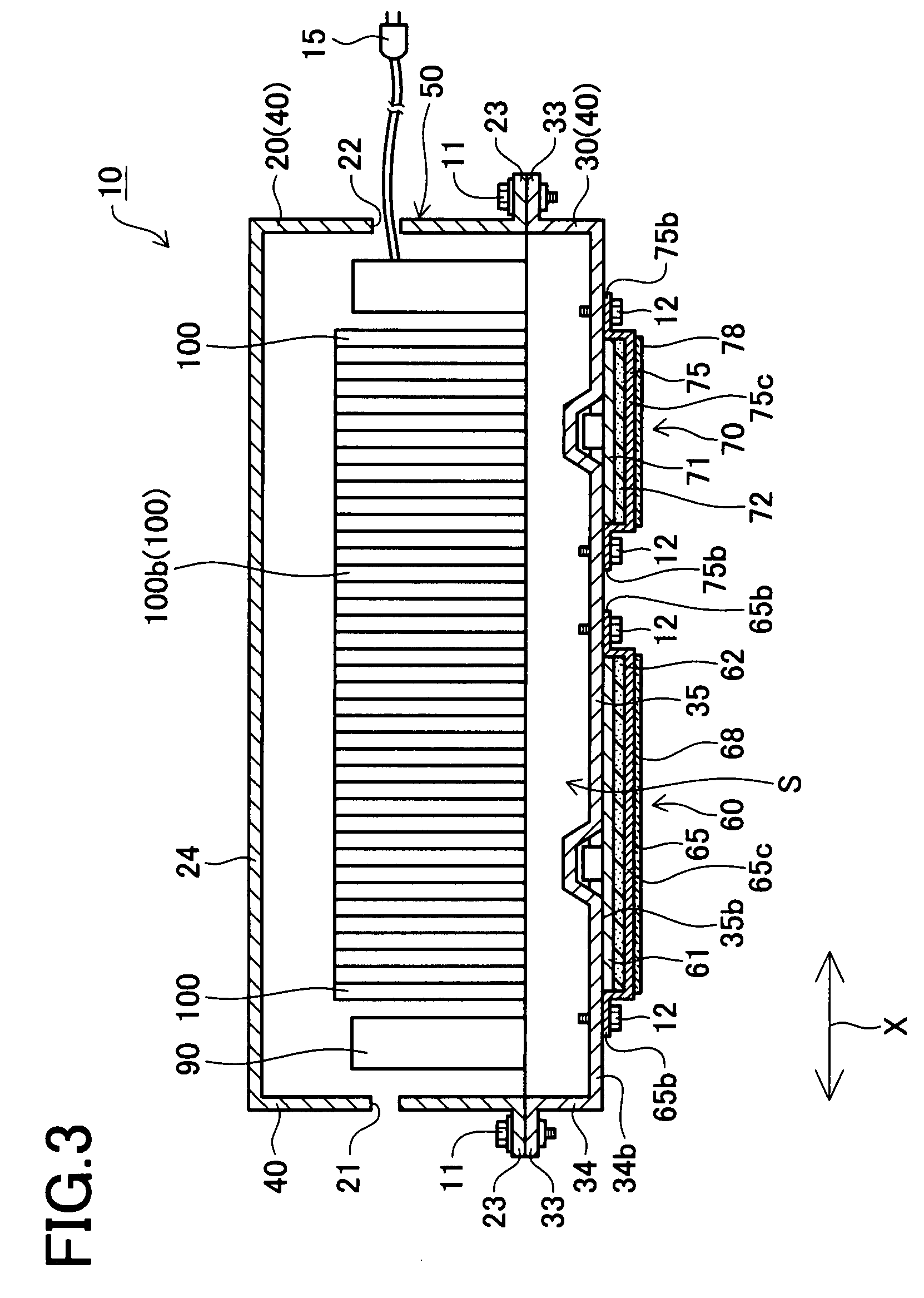

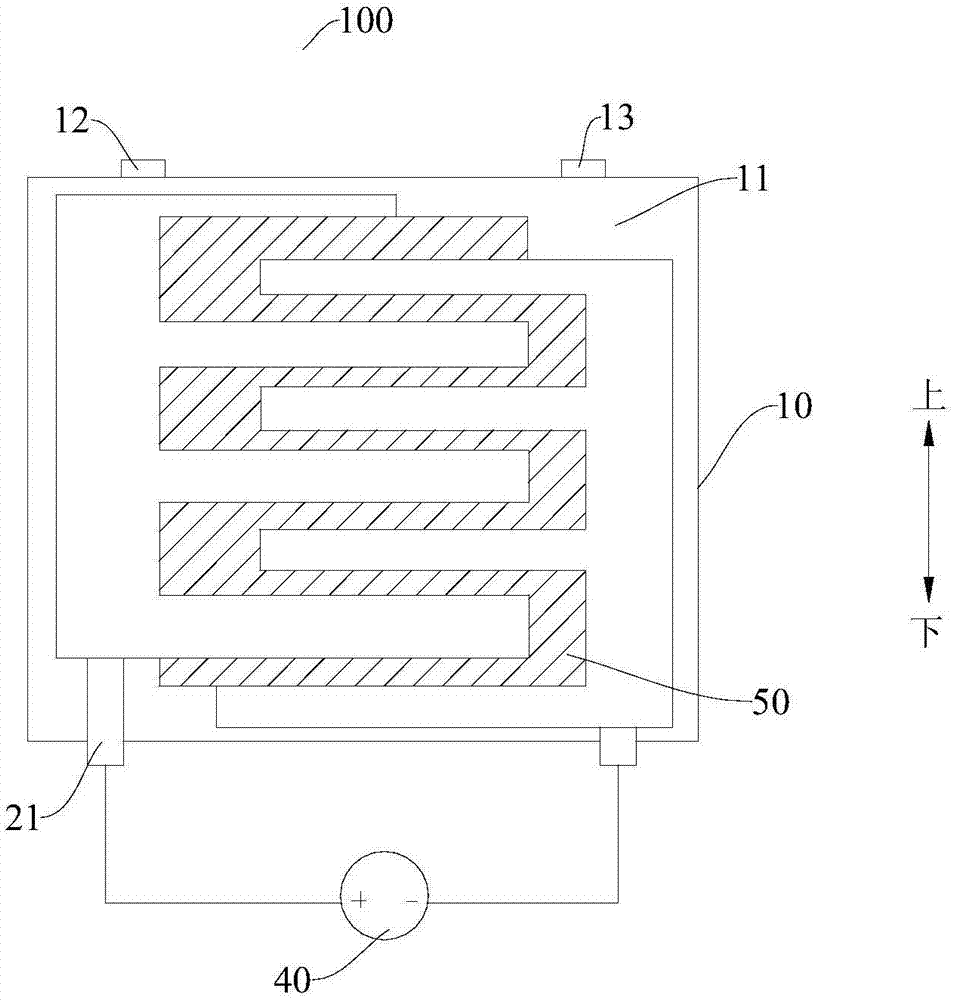

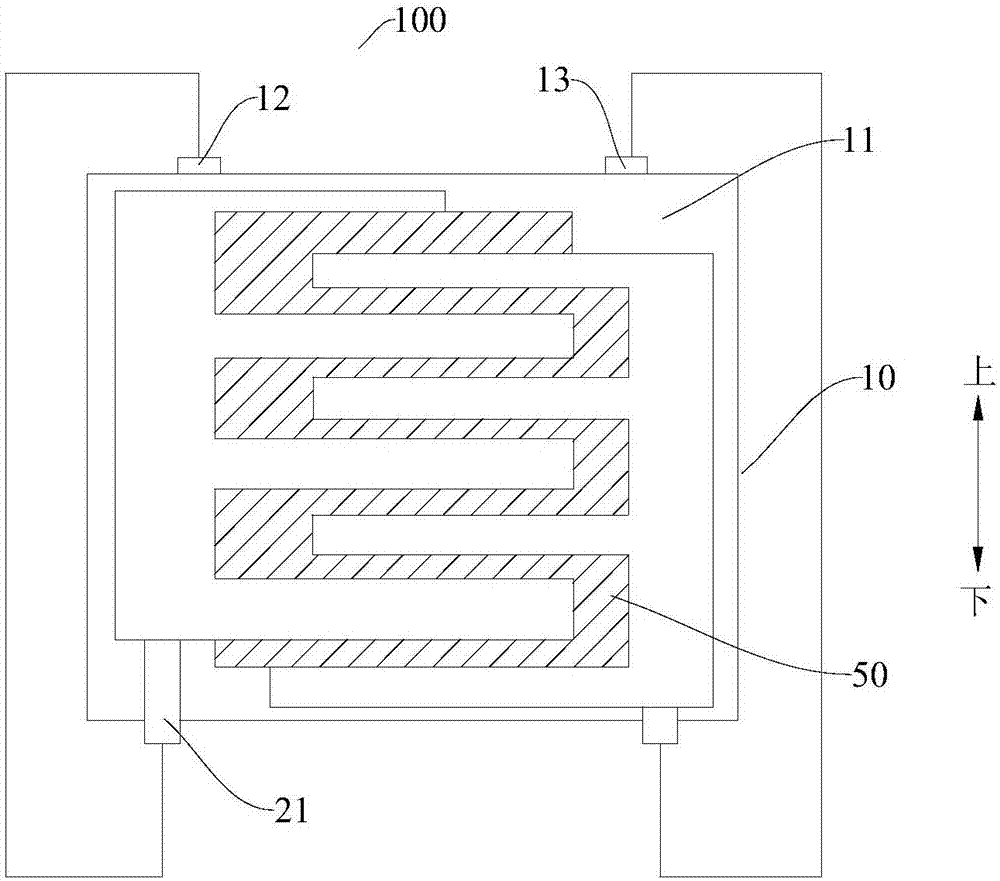

Battery system and electric vehicle equipped with same

ActiveCN106960989AIncrease the rate of chemical reactionsSmall space requirementSecondary cellsBatteriesConnection typeManagement unit

The invention discloses a battery system and an electric vehicle equipped with the same. The battery system comprises one or more automatic temperature-limiting batteries and a battery management unit, wherein each automatic temperature-limiting battery comprises a shell, a roll core, a PTC heating sheet and two heating electrodes; a cavity is limited in the shell; the shell is provided with a positive electrode and a negative electrode; the roll core is arranged in the cavity; the PTC heating sheet is arranged in the cavity and used for heating the roll core; the two heating electrodes are connected with the two ends of the PTC heating sheet respectively to form a part of a heating loop; each PTC heating sheet can be arranged in the roll core or between the roll core and the inner wall surface of the shell, or between adjacent two roll cores; and the battery management unit is used for collecting the temperature of the battery, and controlling the heating loop in charging and discharging of the battery system according to the temperature of the battery. By virtue of the battery system, the original parts and mounting procedures can be simplified, production efficiency can be improved, and cost can be lowered; and in addition, by virtue of the serial-connection type heating circuit, quick temperature rise and uniform temperature distribution in the battery can be ensured, and simple and convenient control on battery heating, and high safety also can be realized.

Owner:成都前锋电子股份有限公司

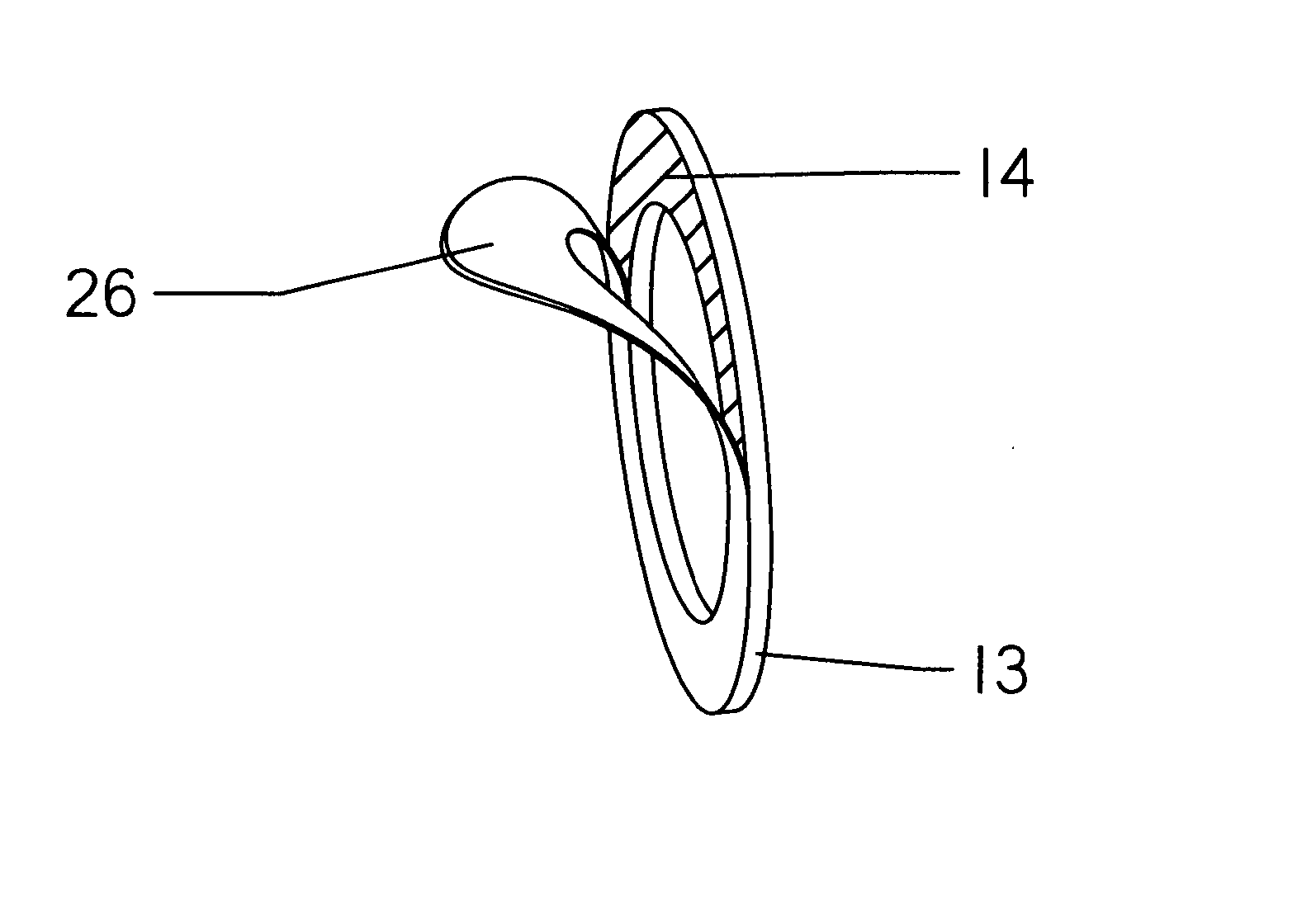

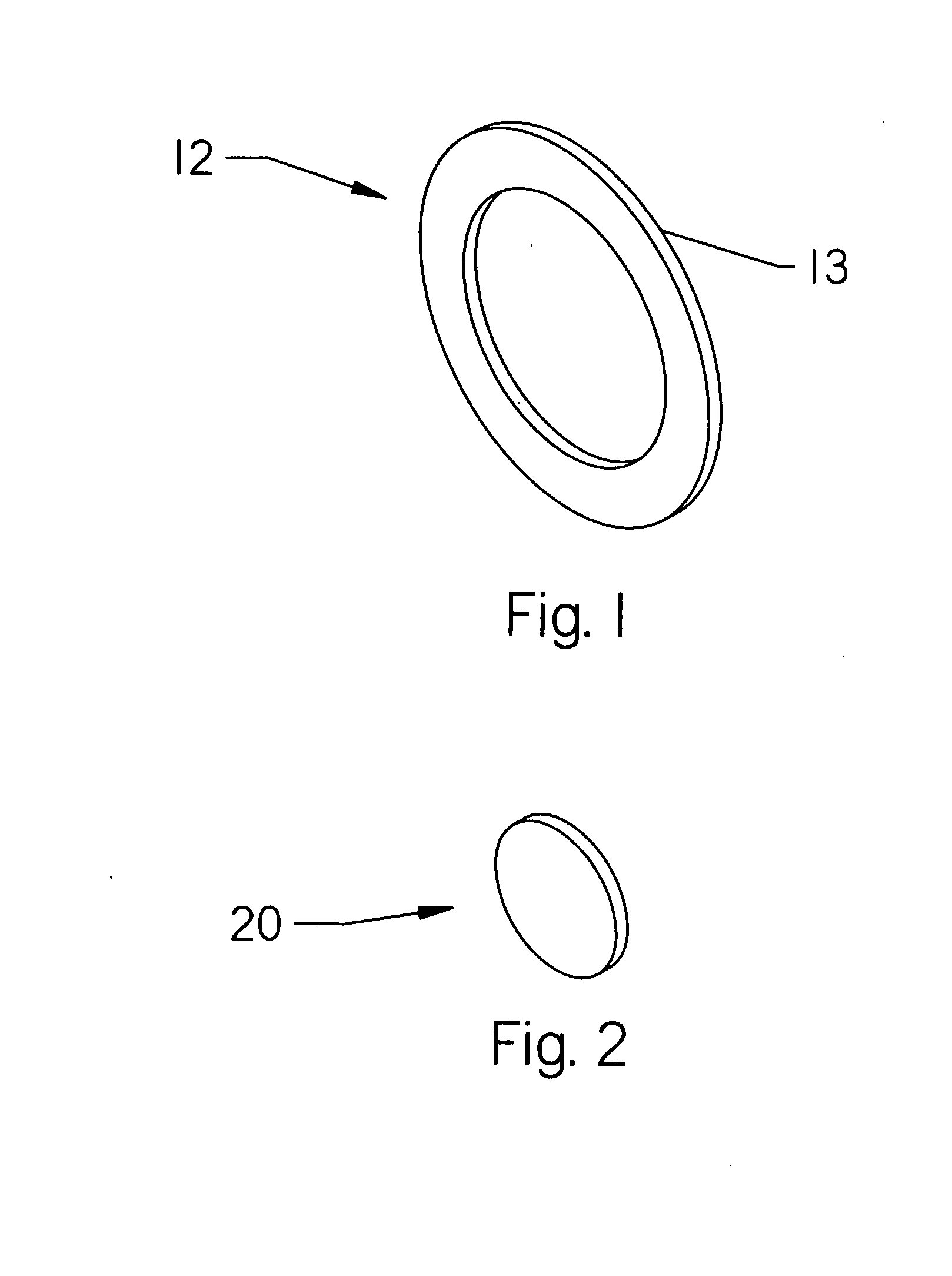

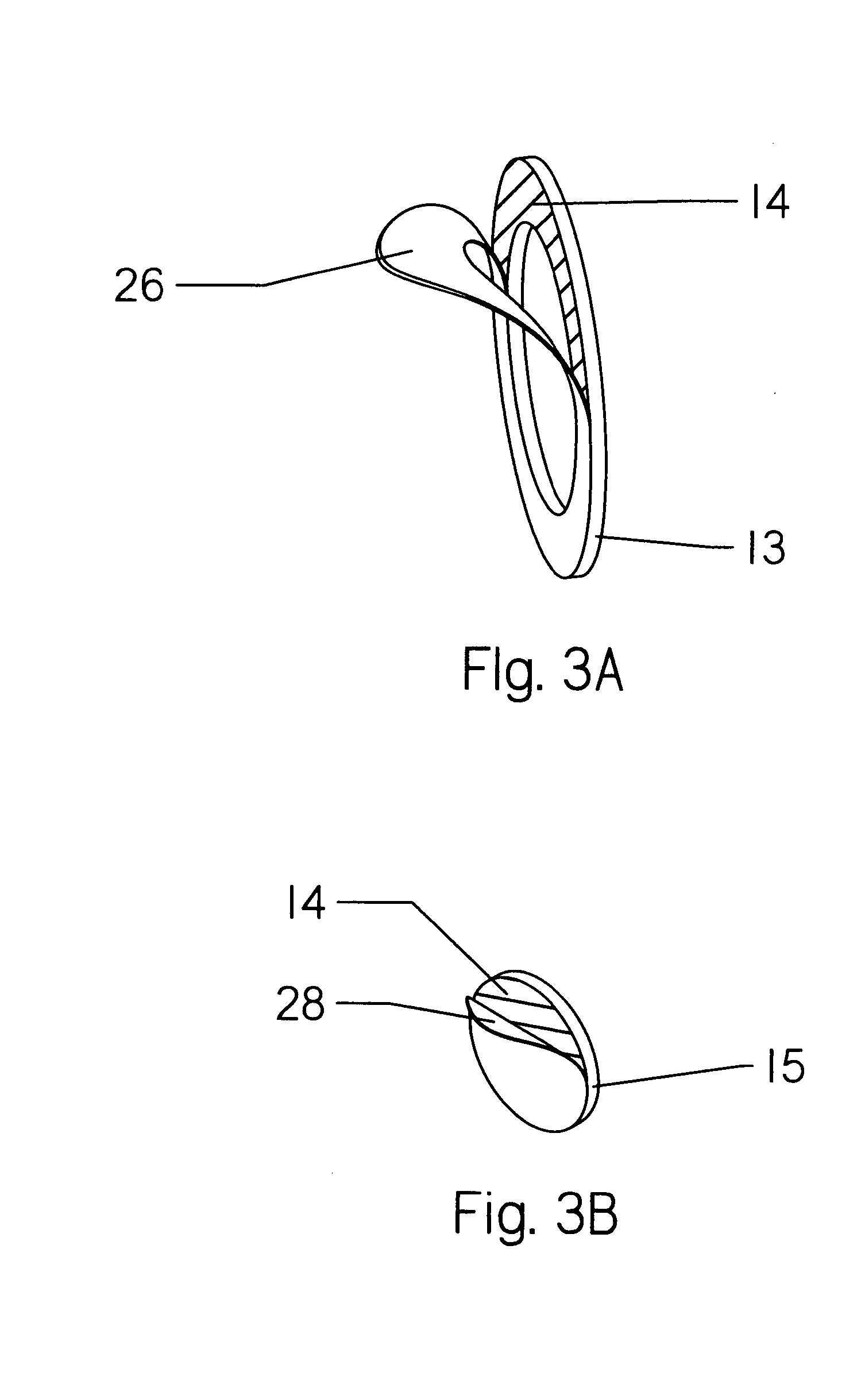

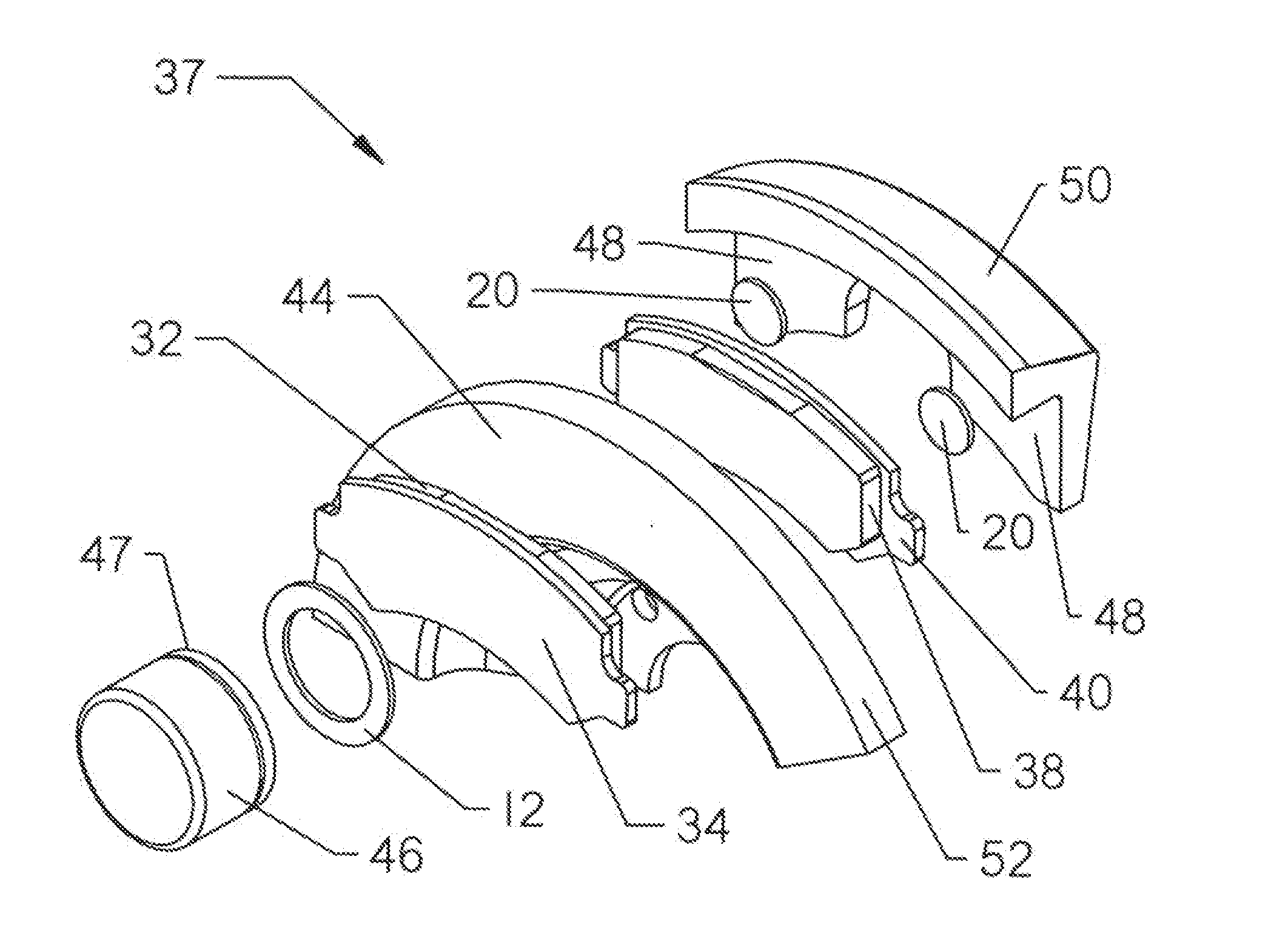

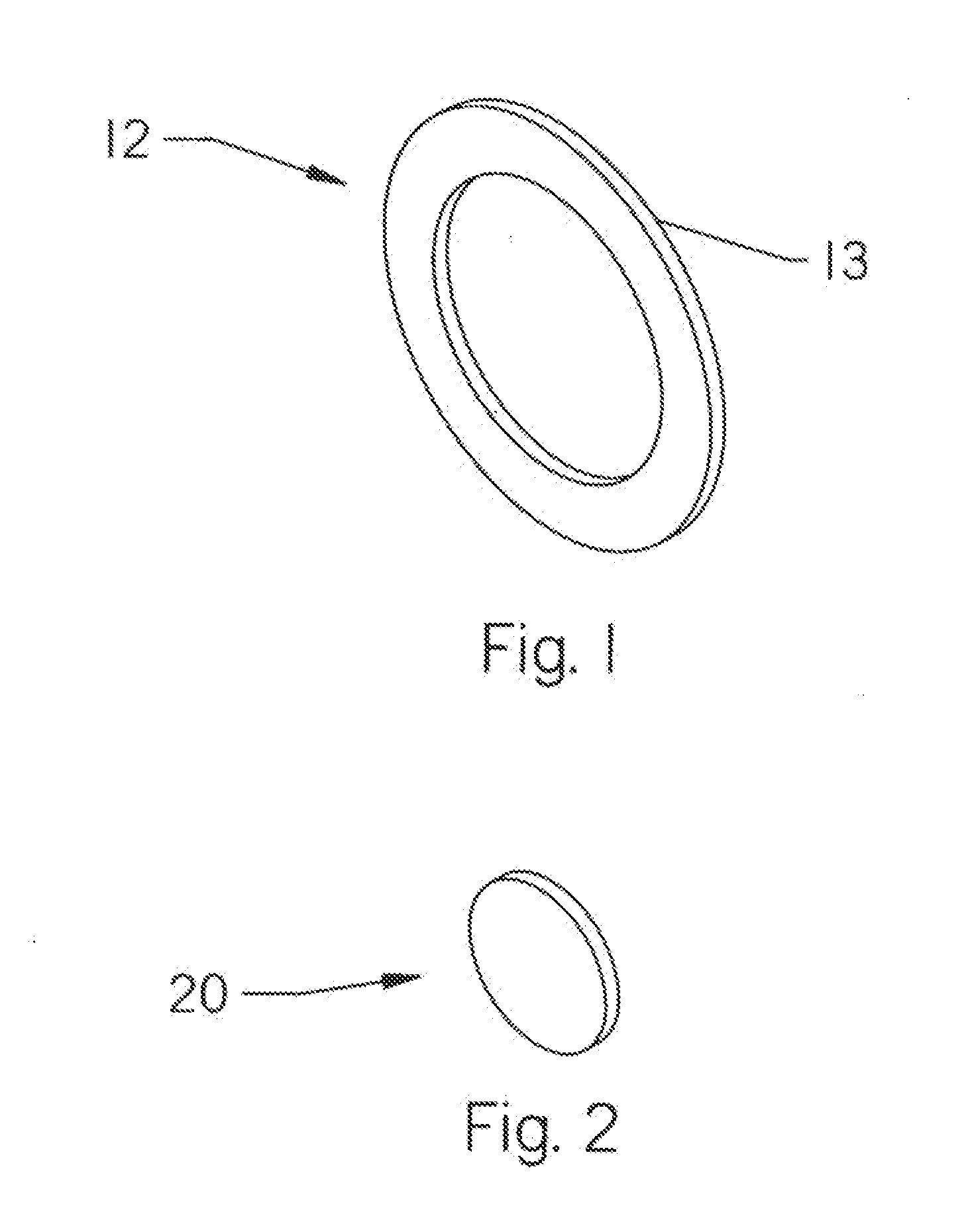

Disc brake pad cushions

InactiveUS20070295567A1Reduce excessive heatReduce uneven heatingAir-treating devicesNoise/vibration controlEngineeringCalipers

Cushions for disc brake pads are disposed between the brake pads and their caliper pistons or caliper fingers. The cushions possess such characteristics of resilience that, during braking action, brake pads follow irregularities and ride over high spots on rotor faces. This action significantly reduces uneven frictional drag, which lowers braking temperature increasing braking efficiency and brake system longevity. Each cushion comprises a resilient body which is further comprised of either a material, such as an elastomeric pad, or a structure such as a compressible spring or other apparatus.

Owner:ADAMS PHILIP HERBERT

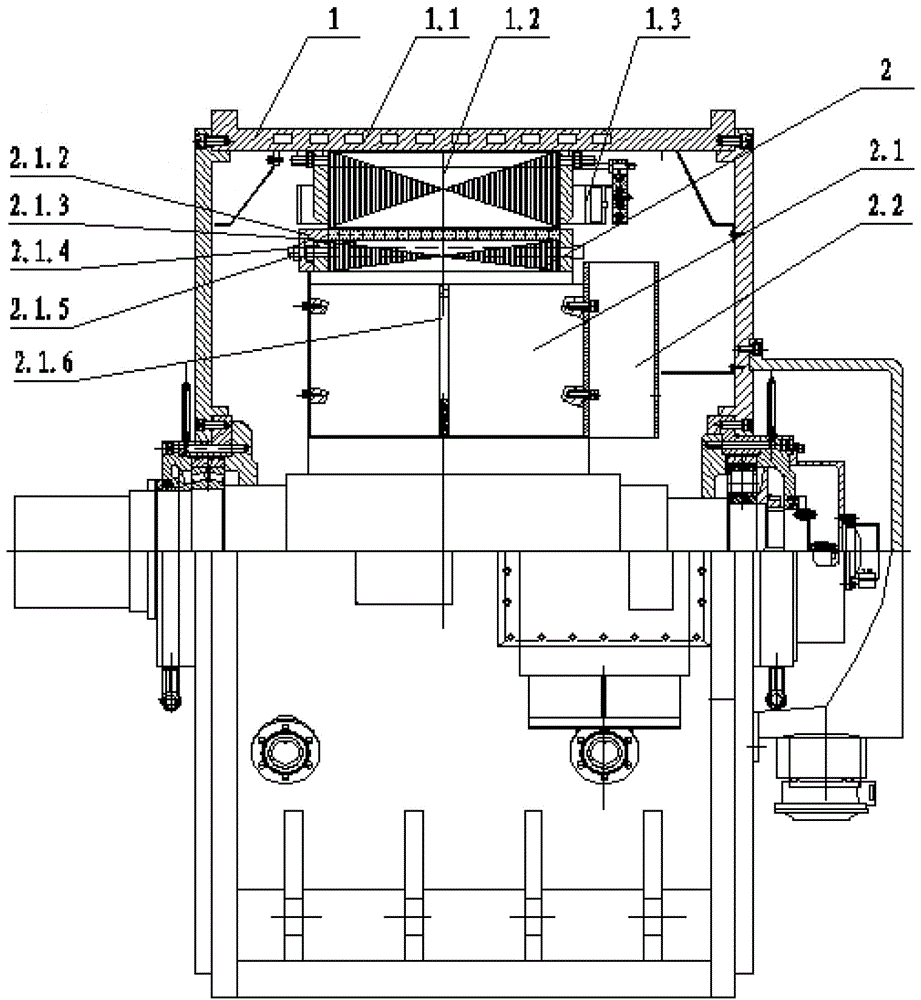

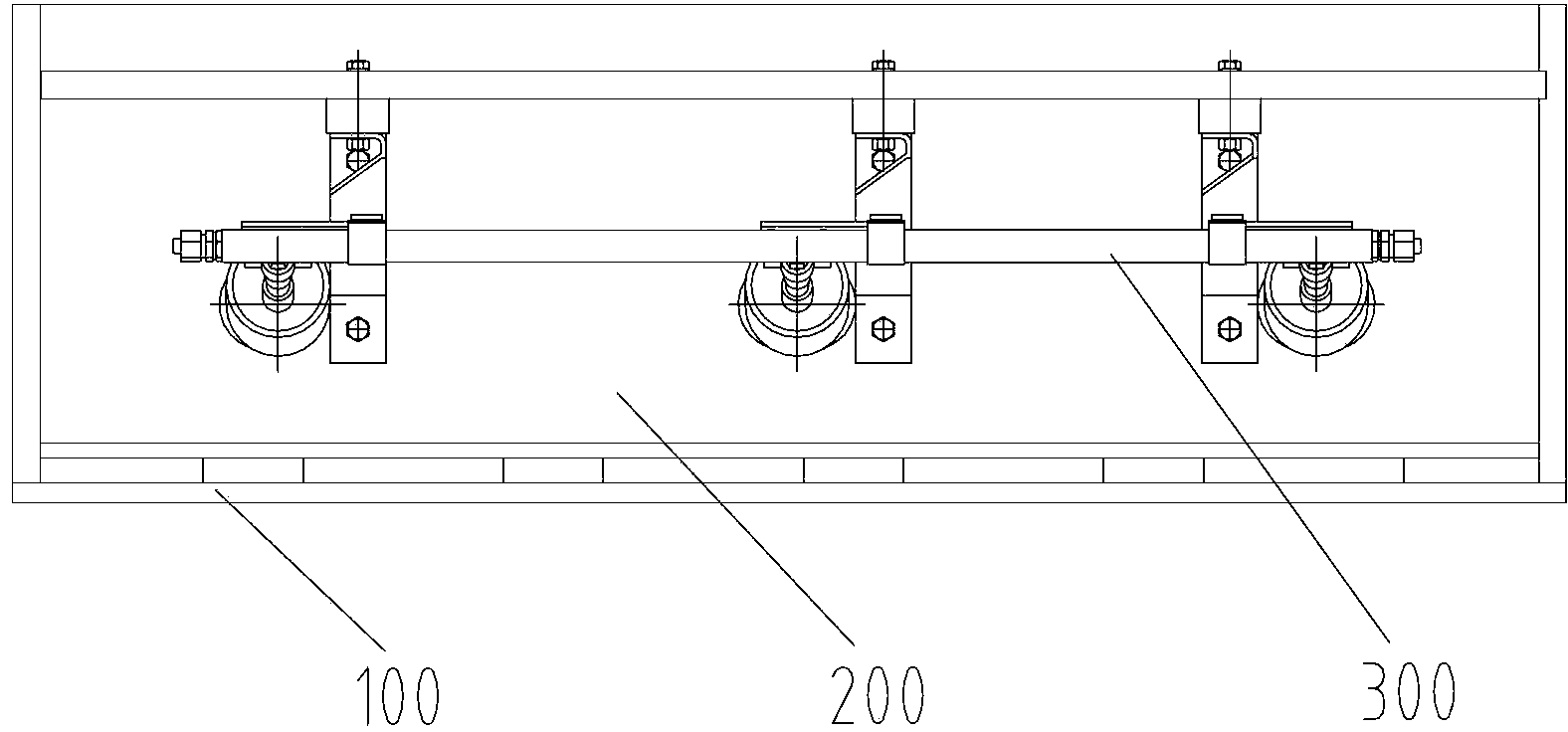

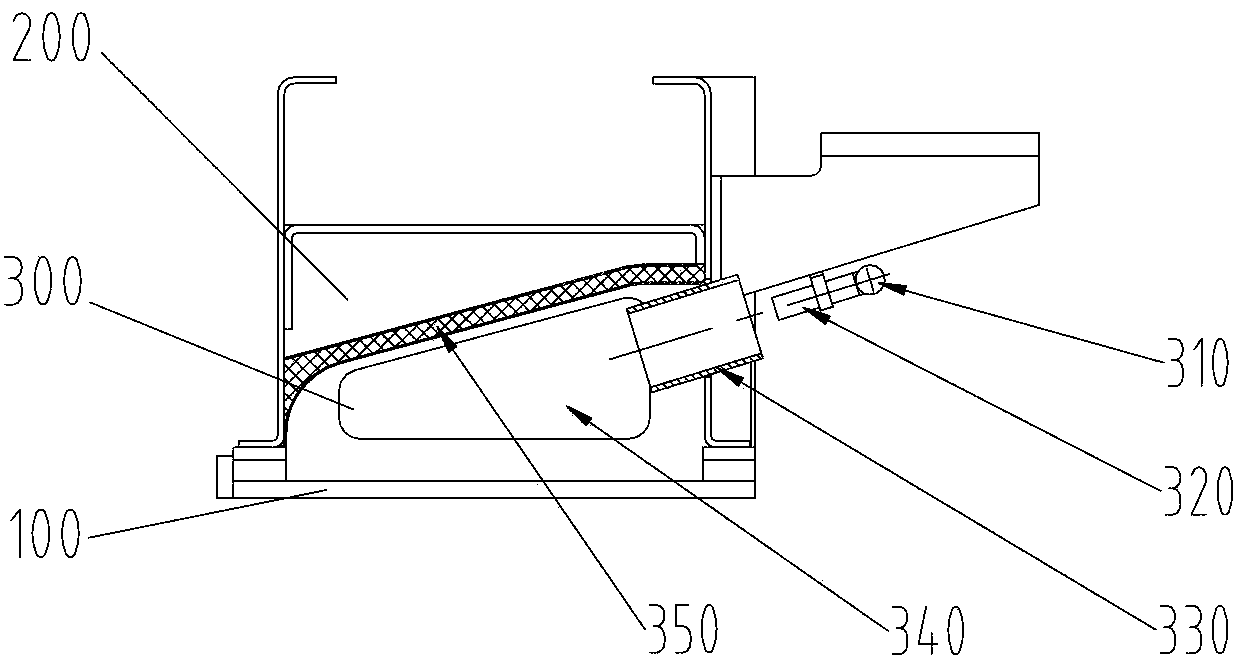

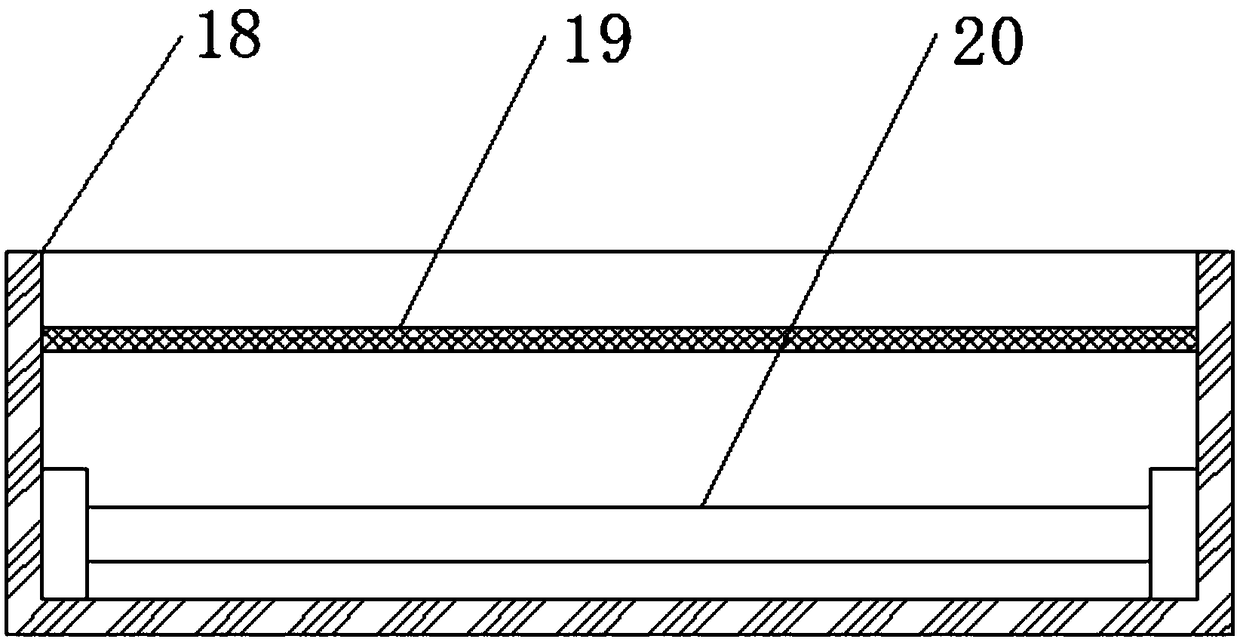

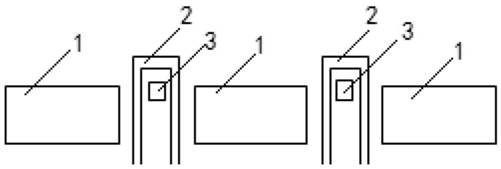

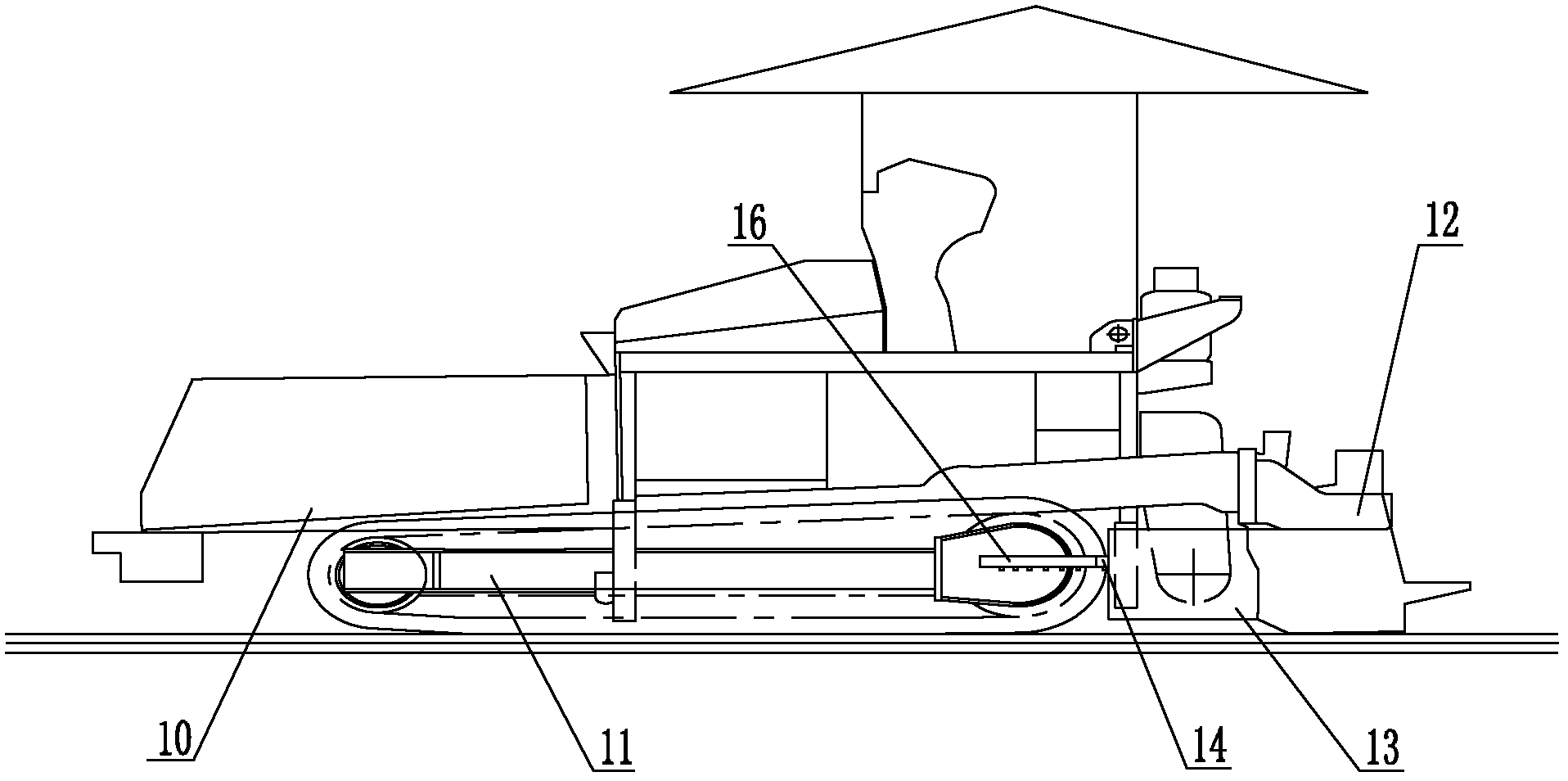

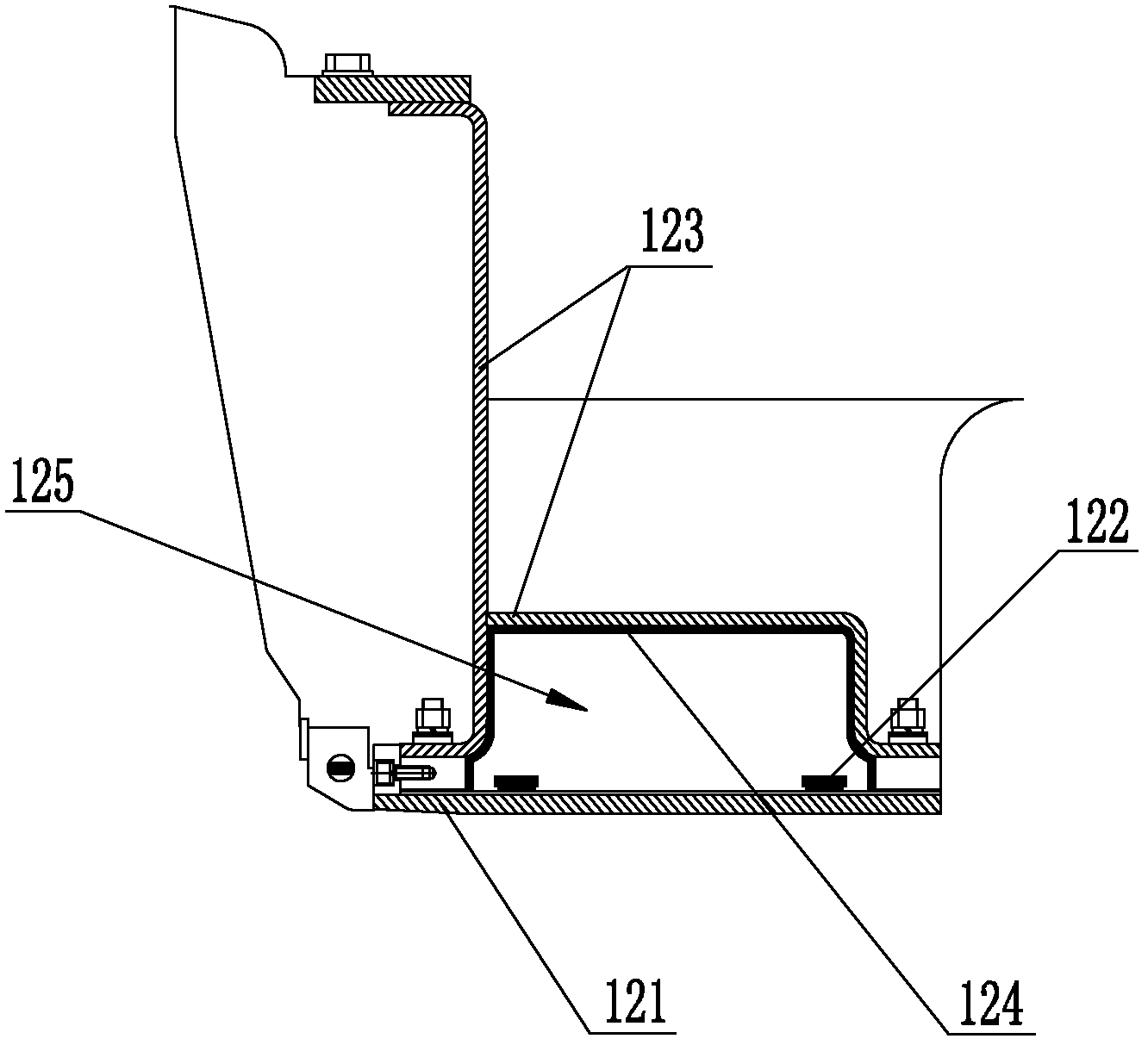

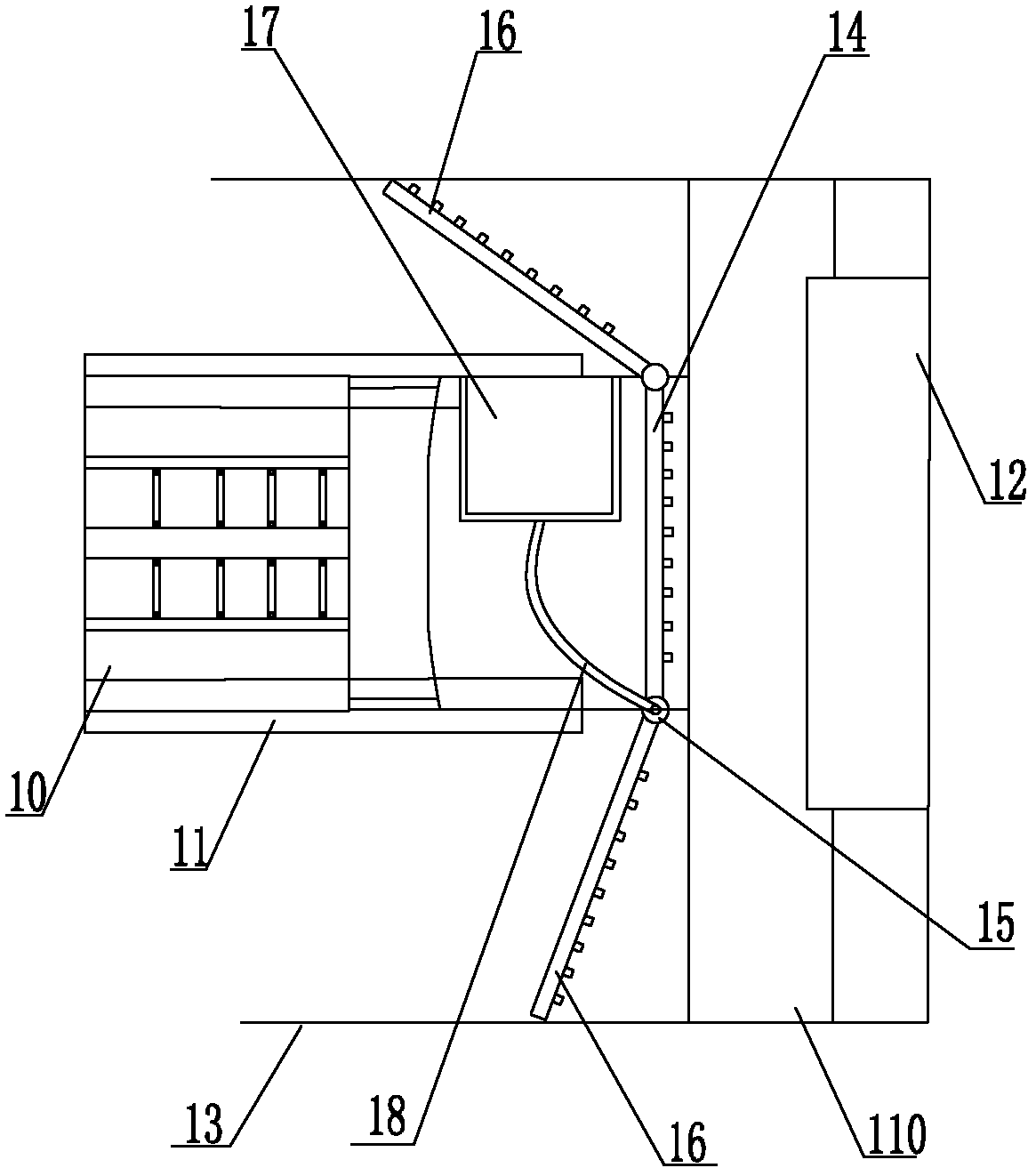

Screed and paver comprising same

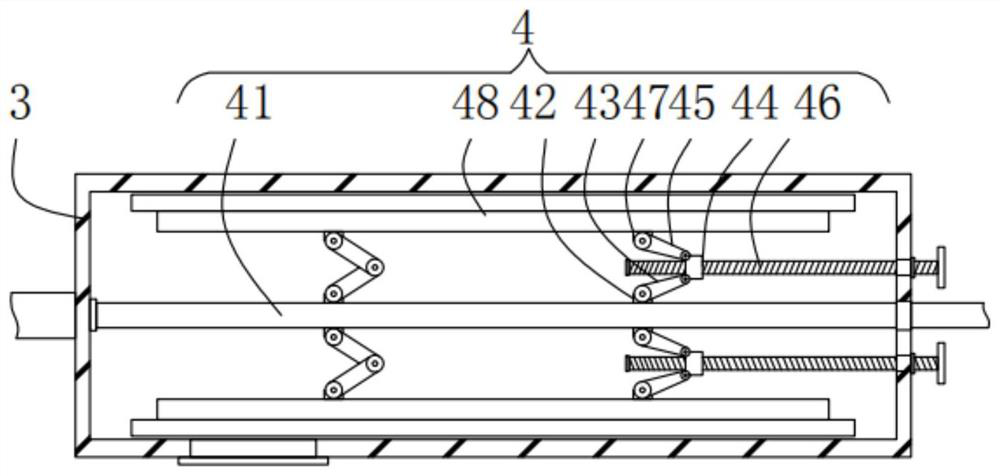

The invention provides a screed and a paver comprising the same. The screed includes at least one plate section and a screed heating system, wherein the plate section comprises a box body and a box body base plate. The screed heating system consists of an accommodating chamber, a heating device and a circulation device, wherein the accommodating chamber is arranged inside the plate section box body and contacted with the box body base plate, and comprises thermal fluids used for heating the box body base plate; the heating device is used to heat the thermal fluids; the circulation device is connected through the accommodating chamber to drive the thermal fluids to cycle between the circulation device and the accommodating chamber. The screed in the invention speeds up the heat-transfer efficiency of the thermal fluids, thus enabling the box body base plate of the screed to be evenly heated, and also enhances the quality of the road paving by reducing the uneven heating degree and deformation induced by thermal stress of the body box base plate.

Owner:ZOOMLION HEAVY IND CO LTD

Pipe preheating device and reheating method thereof

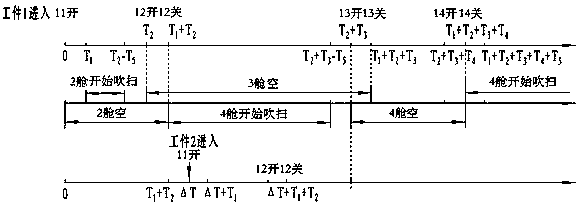

ActiveCN110777246AAchieve recyclingSmooth warm-upFurnace typesHeat treatment furnacesEngineeringNitrogen gas

The invention discloses a pipe preheating device and a preheating method of the pipe preheating device, and belongs to the field of heat treatment. The pipe preheating device comprises a preheating shell and a heat transfer channel. The preheating shell is internally provided with a C-shaped slideway. The heat transfer channel communicates with the C-shaped slideway. The C-shaped slideway comprises a workpiece inlet cabin at the upper end, a workpiece heating cabin at the middle segment and a workpiece preset cabin at the lower end. The workpiece inlet cabin is connected with a workpiece inletchannel. The workpiece preset cabin is connected with a subsequent production line. Inlets and outlets of the workpiece inlet cabin, the workpiece heating cabin and the workpiece preset cabin are provided with doors which can be controlled by a controller to be opened and closed. By means of the pipe preheating device and the preheating method of the pipe preheating device, a workpiece is prevented from being oxidized during preheating, and the utilization rate of preheated nitrogen is further improved.

Owner:山东中安弘安全科技集团有限公司 +1

Producing method of rice and sweet potato composite convenient straight rice noodles

The invention relates to a producing method of rice and sweet potato composite convenient straight rice noodles, and belongs to the technical field of food processing.The producing method is characterized in that milled early long-grain nonglutinous rice and sweet potato starch serve as the raw materials, compound bacteria (lactic acid bacteria and yeast) are used for fermenting mixed rice noodles in a limited mode, nutritional factors of rice noodles are increased, and rehydration performance of the product is improved.Part of rice noodles is degraded in a limited mode in a fermentation process, produced ethyl alcohol makes rice noodles produce a porous structure in the twin-screw extrusion process, and the rehydration performance of the convenient straight rice noodles is further enhanced based on the strong absorption effect of alcohol for water and lipid, the permeation capacity and cavitation effect of infrared rays and the internal and external uniform drying effect during microwave pulse drying.The made convenient straight rice noodles are low in breakage rate, good in rehydration performance and excellent in food taste and quality.

Owner:NANCHANG UNIV

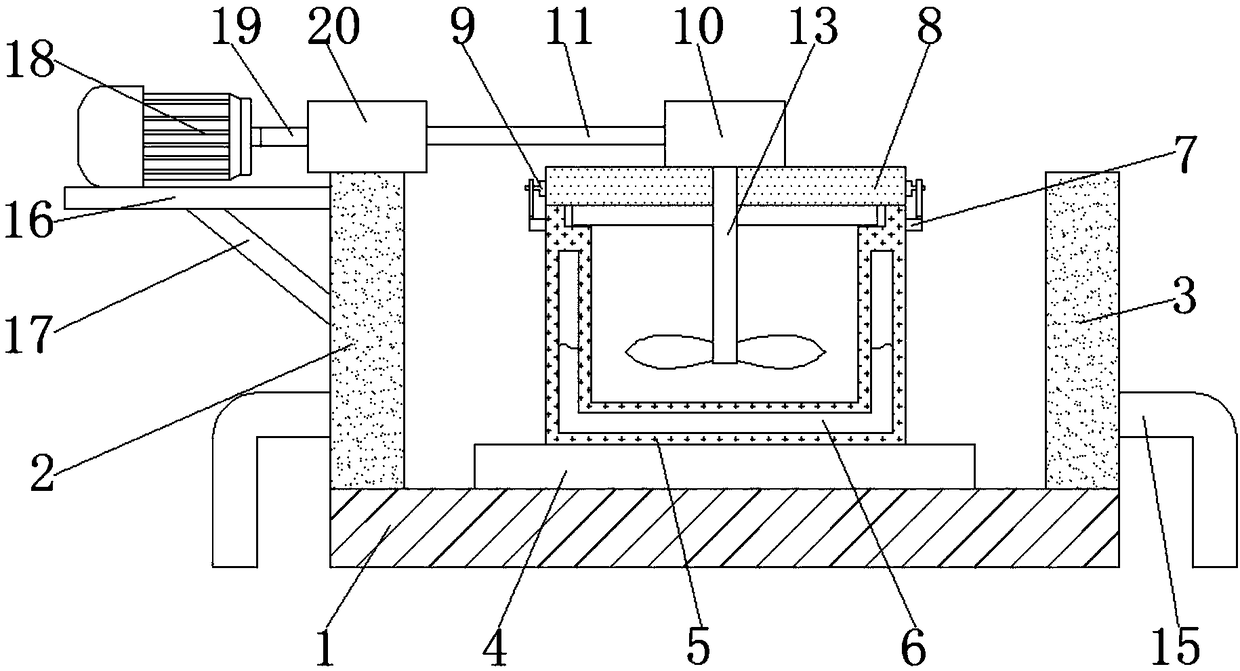

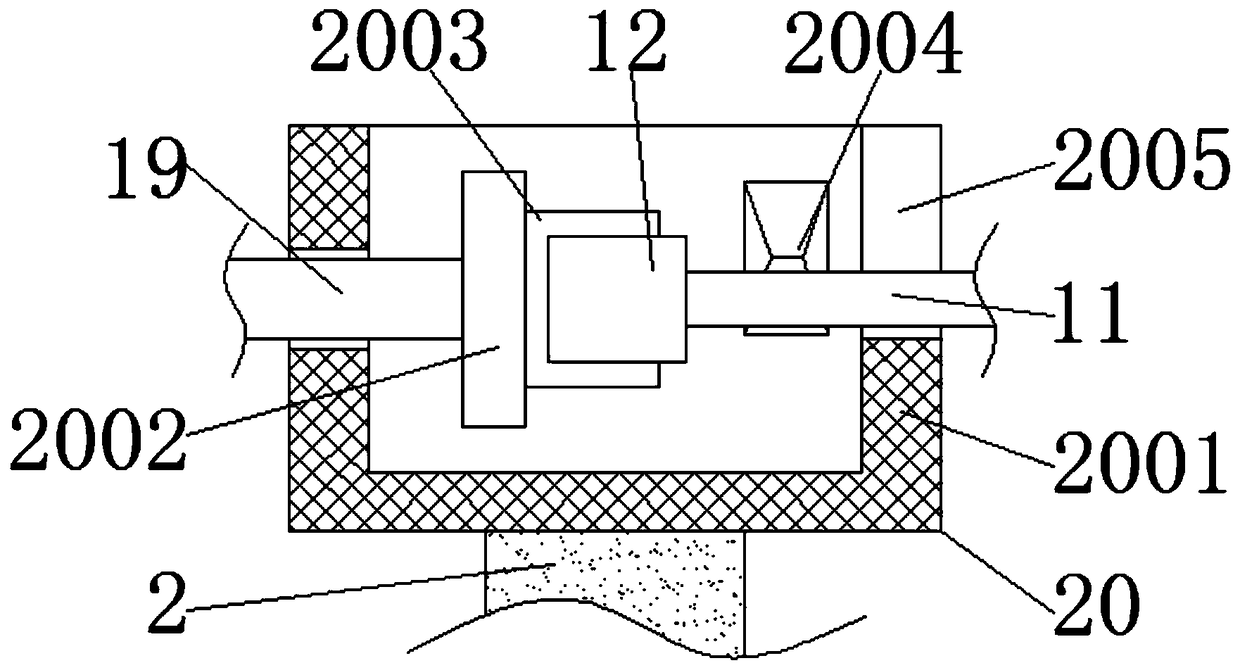

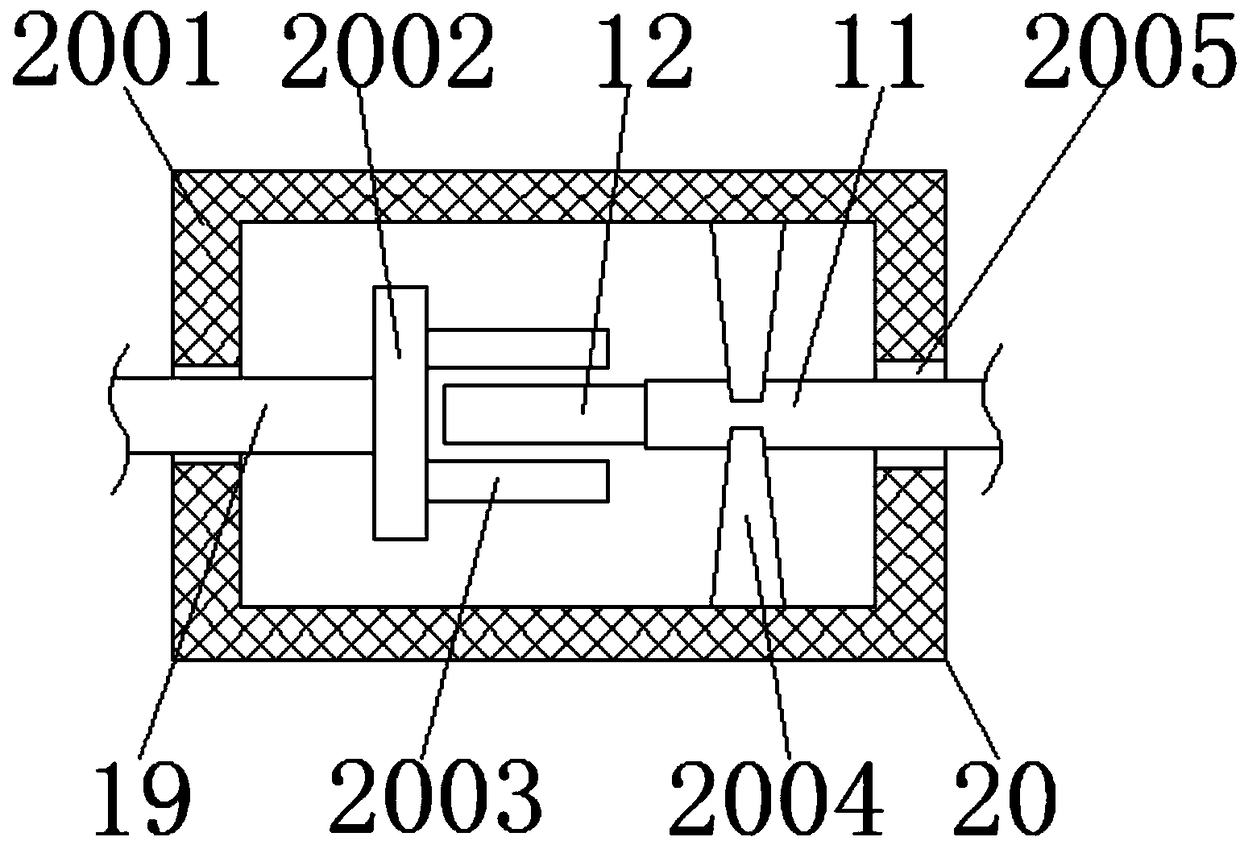

Bone-in pork shank steaming device with uniform heating function

InactiveCN108634765AReduce uneven heatingHeating evenlyWarming devicesVessels with intergral heatingNoseFood processing

The invention relates to the technical field of food processing and discloses a bone-in pork shank steaming device with a uniform heating function. The bone-in pork shank steaming device comprises a base. A first mounting plate, a second mounting plate and a heating plate are fixedly connected to the upper surface of the base, and a steaming box is fixedly connected to the upper surface of the heating plate. A heating groove is formed in the steaming box, and clasp noses are fixedly connected to the top ends of the outer walls of the two sides of the steaming box correspondingly. The upper surface of steaming box is in lap joint with a box cover, and clasps are fixedly connected to the outer walls of the two sides of the box cover. According to the bone-in pork shank steaming device with the uniform heating function, through a steering device, a second rotating rod drives stirring blades to rotate, the stirring effect during pork shank steaming is achieved, the effect that liquid in the steaming box is uniformly heated during heating is achieved, the inner wall of the steaming box is uniformly heated through aluminum wires in the heating groove, the situation of nonuniform heatingin the steaming box is reduced, and the effect of steaming time reducing is achieved.

Owner:ANHUI DONGSHENG FOOD

Process and apparatus for making multi-layered, multi-component filaments

InactiveUS20020170661A1Reducing and eliminating passingMinimizing polymer degradationMelt spinning methodsDomestic articlesEngineeringMelt spinning

The present invention is directed to a process for forming a plurality of multi-layered filaments from multiple thermoplastic synthetic polymers and an apparatus containing a melt spinning beam comprising an orthogonal beam having disposed within said beam multiple polymer inlet passages each communicating with separate multiple coat hanger distribution manifolds, separate filters connected downstream of each coat hanger distribution manifold, a spinneret connected downstream of said filters with separate polymer flow passages communicating with separate exit orifices for spinning of said multi-layered filaments.

Owner:3M INNOVATIVE PROPERTIES CO

Production method of instant straight rice noodles compounded from rice and potatoes

InactiveCN105851837AGood rehydrationImprove qualityYeast food ingredientsFood shapingMicrowaveCavitation

The invention relates to a production method of instant straight rice noodles compounded from rice and potatoes, and belongs to the technical field of food processing. The production method is characterized in that potato starch and milled long grain nonglutinous rice are used as raw materials, and composite microbes (lactic acid bacteria and microzyme) are used for performing restrictive fermentation on the blended rice flour, so that the nutrition factors of the rice noodles are increased; besides, the rehydration performance of the rice noodles is improved. In the fermentation process, part of the rice flour is restrictively degraded, and generated ethanol forces the rice noodles to form hole structures in a dual-screw extruding process. Due to cavitation and internal and external homogeneous drying effects during radio frequency-microwave pulse synergetic drying, the rehydration performance of the instant straight rice noodles is further improved. The instant straight rice noodles prepared by the production method disclosed by the invention are low in noodle breaking rate, good in rehydration performance, and good in eating quality.

Owner:NANCHANG UNIV

Spring-Based Disc Brake Pad Cushions

InactiveUS20160108978A1Reduce excessive heatReduce uneven heatingNoise/vibration controlFriction liningElastomerEngineering

Cushions for disc brake pads are disposed between the brake pads and their caliper pistons or caliper fingers. The cushions possess such characteristics of resilience that, during braking action, brake pads follow irregularities and ride over high spots on rotor faces. This action significantly reduces uneven frictional drag, which lowers braking temperature increasing braking efficiency and brake system longevity. Each cushion comprises a resilient body which is further comprised of either a material, such as an elastomeric pad, or a structure such as a compressible spring or other apparatus.

Owner:ADAMS PHILIP HERBERT

Process and apparatus for making multi-layered, multi-component filaments

InactiveUS20020056940A1Reducing and eliminating passingMinimizing polymer degradationConfectioneryLaminationEngineeringMechanical engineering

The present invention is directed to a process for forming a plurality of multi-layered filaments from multiple thermoplastic synthetic polymers and an apparatus containing a melt spinning beam which comprises multiple polymer inlet passages each communicating with separate multiple coat hanger distribution manifolds, separate filters connected downstream of each coat hanger distribution manifold, a combining manifold connected downstream of said filters and spinneret orifices connected downstream of said combining manifold for spinning of said multi-layered filaments.

Owner:3M INNOVATIVE PROPERTIES CO

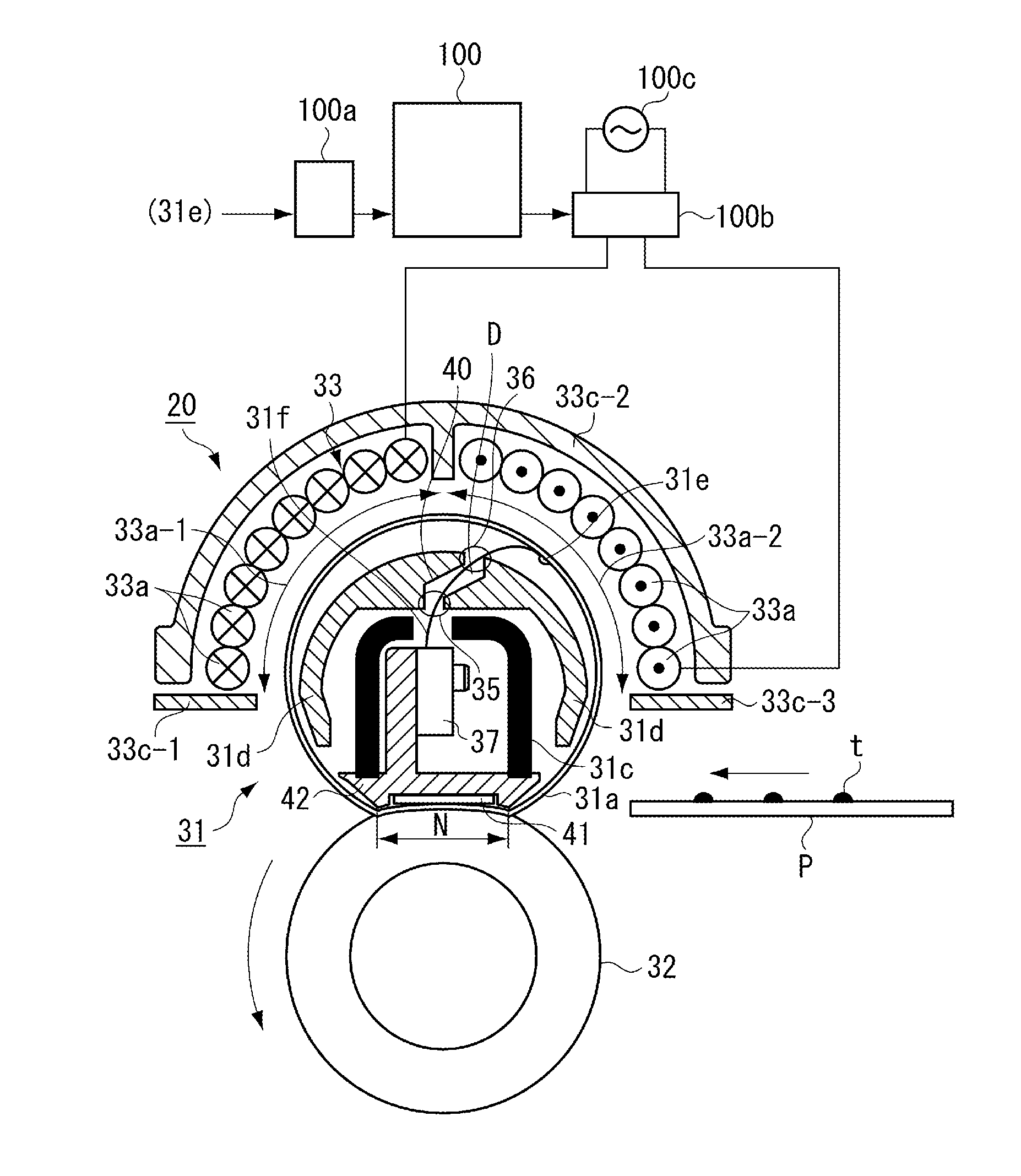

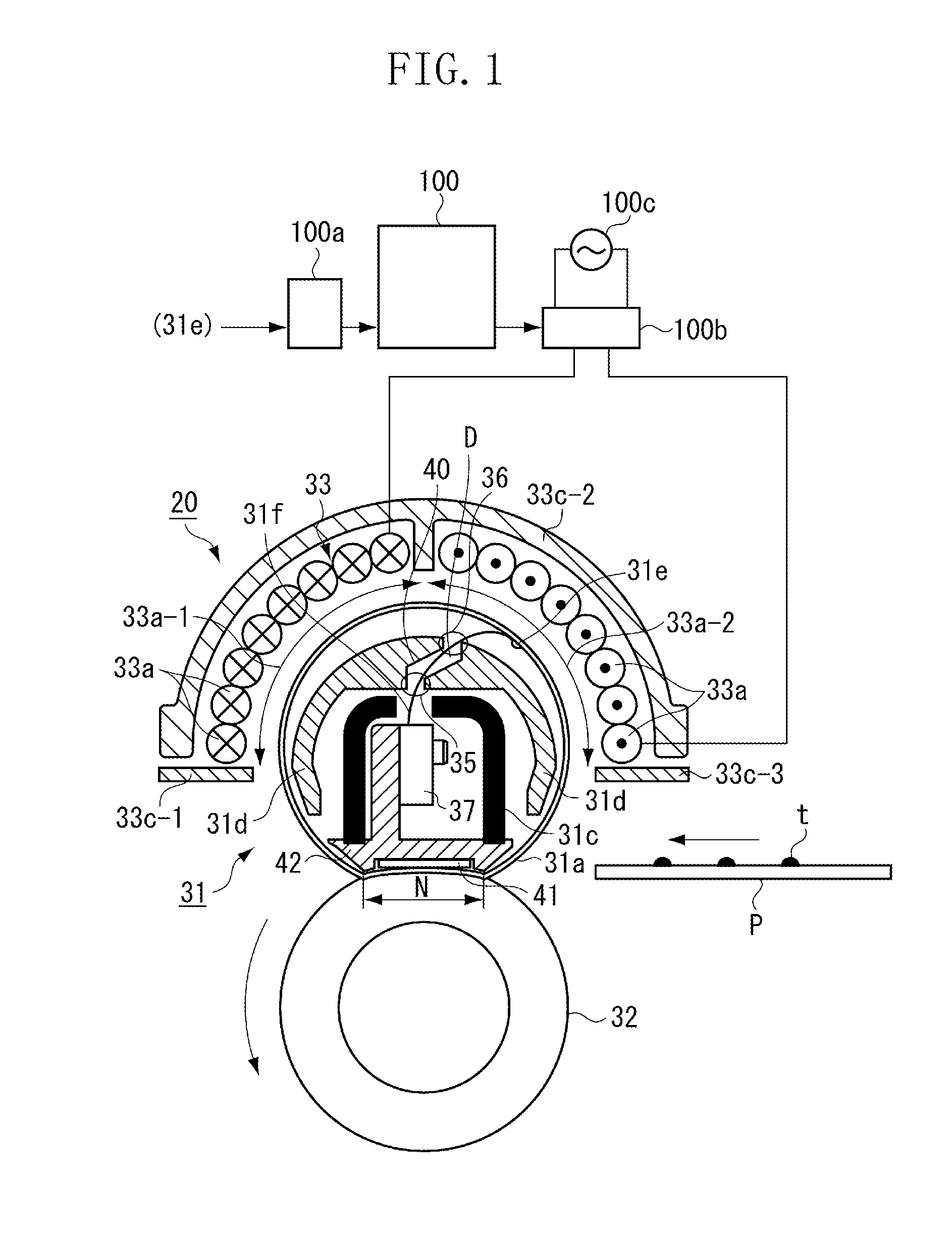

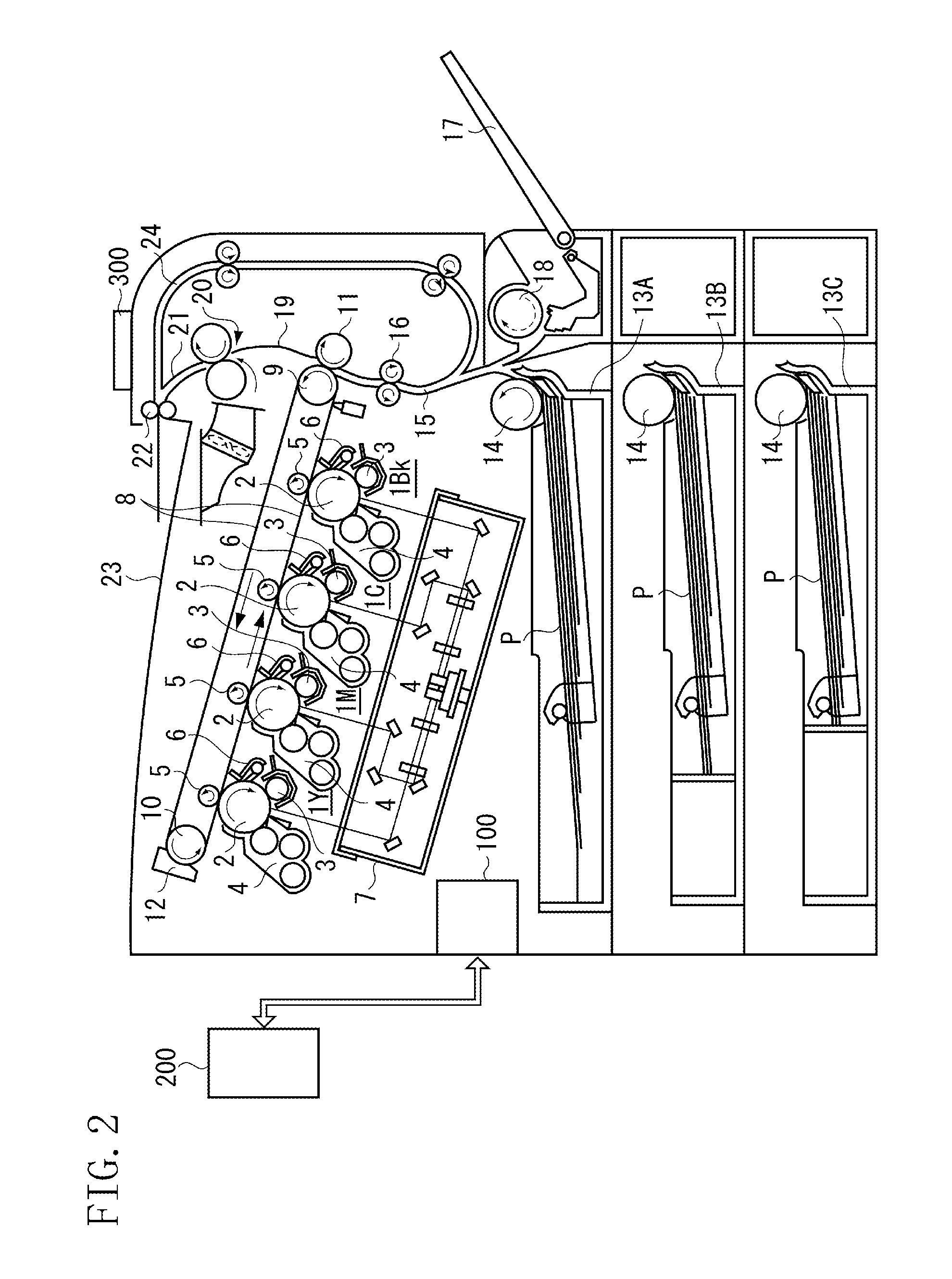

Image heating apparatus

A temperature detection unit is arranged in a position between a magnetic field generation coil and a magnetic core that lies inside a heat generation member. A cut portion for exposing the temperature detection unit through the magnetic core has a thickness when seen in a cross section in the direction of a magnetic flux.

Owner:CANON KK

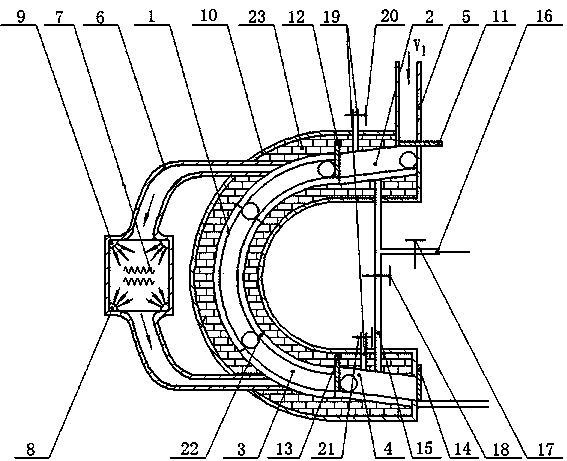

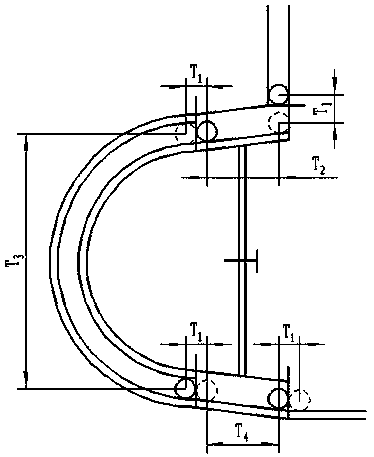

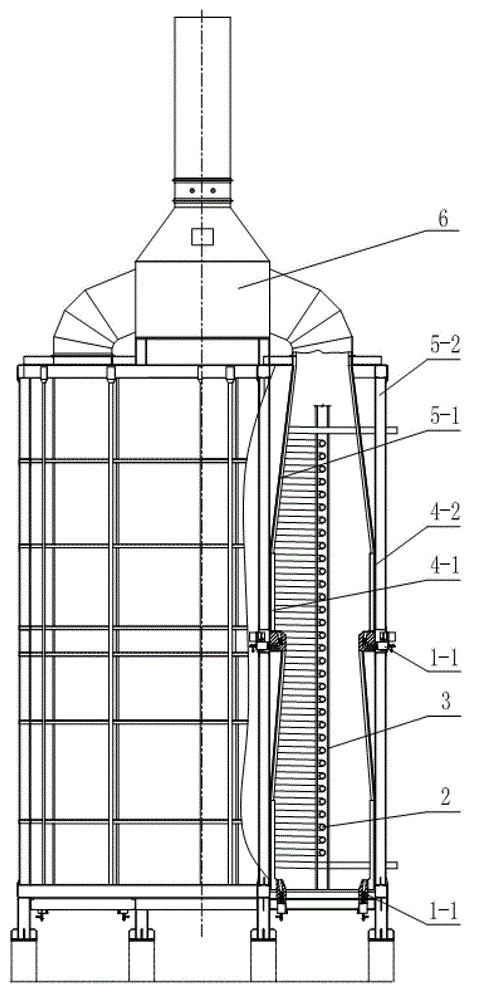

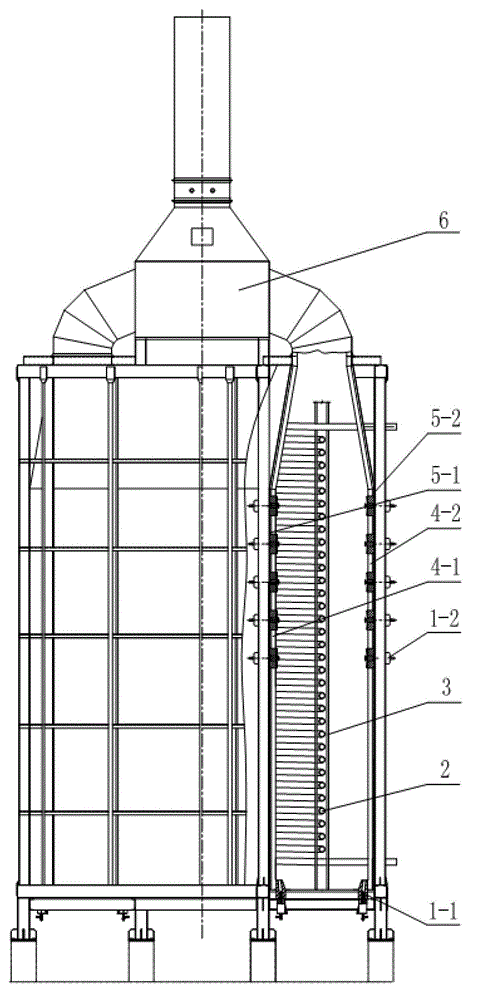

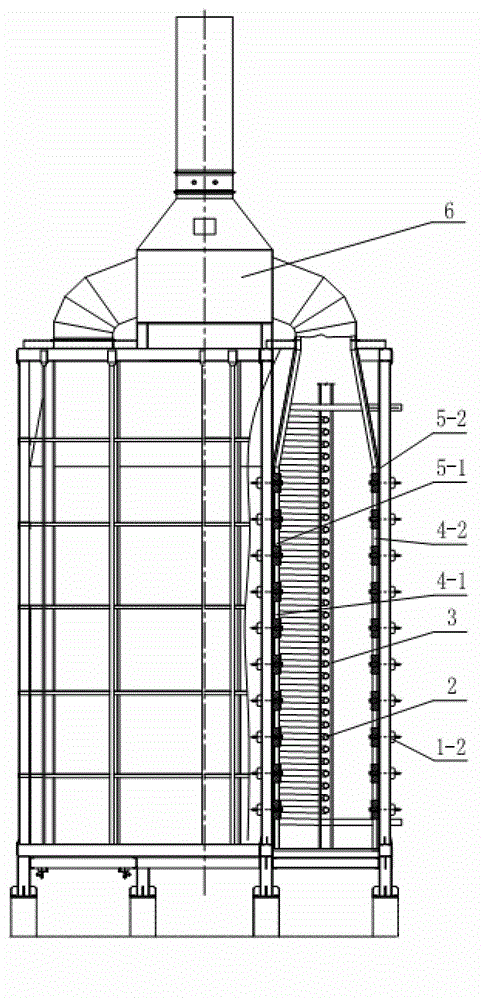

Double-sided radiation spiral pipe heating furnace

The invention relates to the technical field of tube heating furnaces for petroleum refining, petrochemical industry and coal chemical industry, particularly to a double-sided radiation spiral pipe heating furnace which comprises a steel framework, an outer ring radiation wall, a spiral pipe, an inner ring radiation wall and a flame combustor, wherein the outer ring radiation wall is attached inside the steel frame, the spiral pipe is positioned on the inner side of the outer ring radiation wall; the inner ring radiation wall is positioned on the inner side of the spiral pipe; and the flame combustor heats for enabling the inner ring radiation wall and the outer ring radiation wall to reach a high temperature to form radiations, and then the inner ring radiation wall and the outer ring radiation wall supply heat to the spiral pipe in a double-sided radiation mode. The double-sided radiation spiral pipe heating furnace can heat furnace pipes evenly, improve average heat strength of radiations of the furnace pipes, save cost, shorten the hydraulic length of the furnace pipe, increase the flow speed of medium inside the pipes, and avoid cock inside the pipes. Meanwhile, abrasions caused by high solid content medium inside the pipes to the inner walls of bending pipes can be avoided, and potential risks caused by the abrasions can be eliminated.

Owner:BEIJING PETROCHEM ENG

Production method of rice and lotus root compound convenient straight rice noodles

The invention relates to a production method of rice and lotus root compound convenient straight rice noodles, and belongs to the technical field of food processing. The production method is characterized in that early indica rice and lotus root starch are used as raw materials, and the mixed rice flour is subjected to limited fermentation with compound bacteria (lactic acid bacteria and saccharomycetes), so that nutritional factors of the rice noodles are added, and the rehydration performance of a product is improved. In the fermentation process, part of the rice noodles are restrictively degraded, and ethyl alcohol generated forces the rice noodles to produce hole structures in a dual screw extrusion process; meanwhile, based on the strong absorption effect of alcohol on water and fat, the penetrating capacity of infrared rays and the cavatition effect as well as inside and outside uniform drying effect of microwave pulse drying, the rehydration performance of the convenient straight rice noodles is further enhanced. The convenient straight rice noodles prepared by the production method disclosed by the invention are low in breakage rate and high in rehydration performance, and have delicious taste.

Owner:NANCHANG UNIV

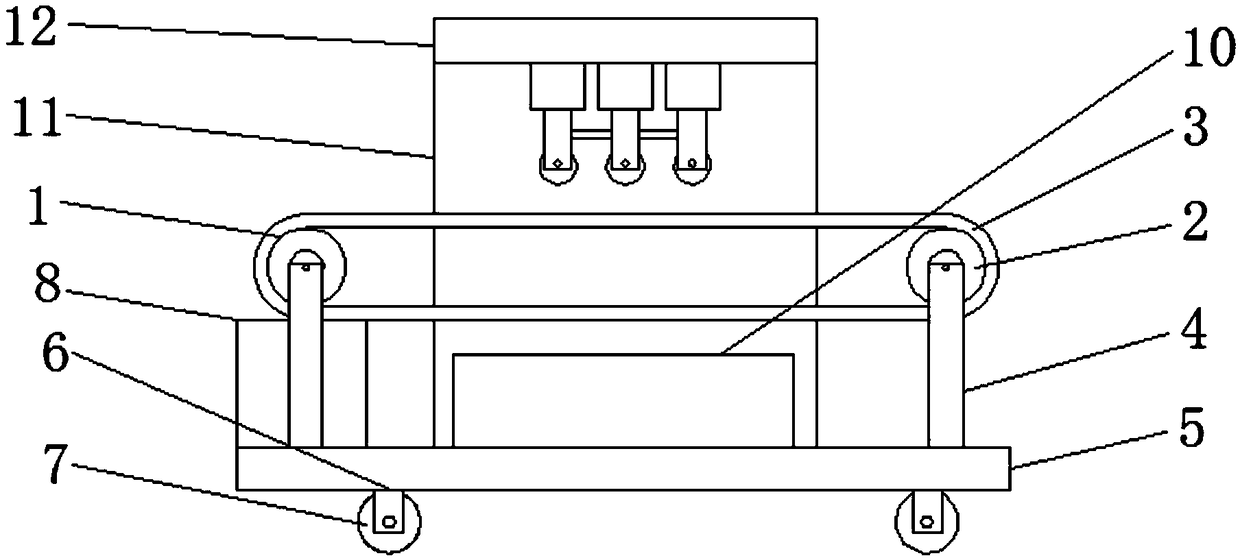

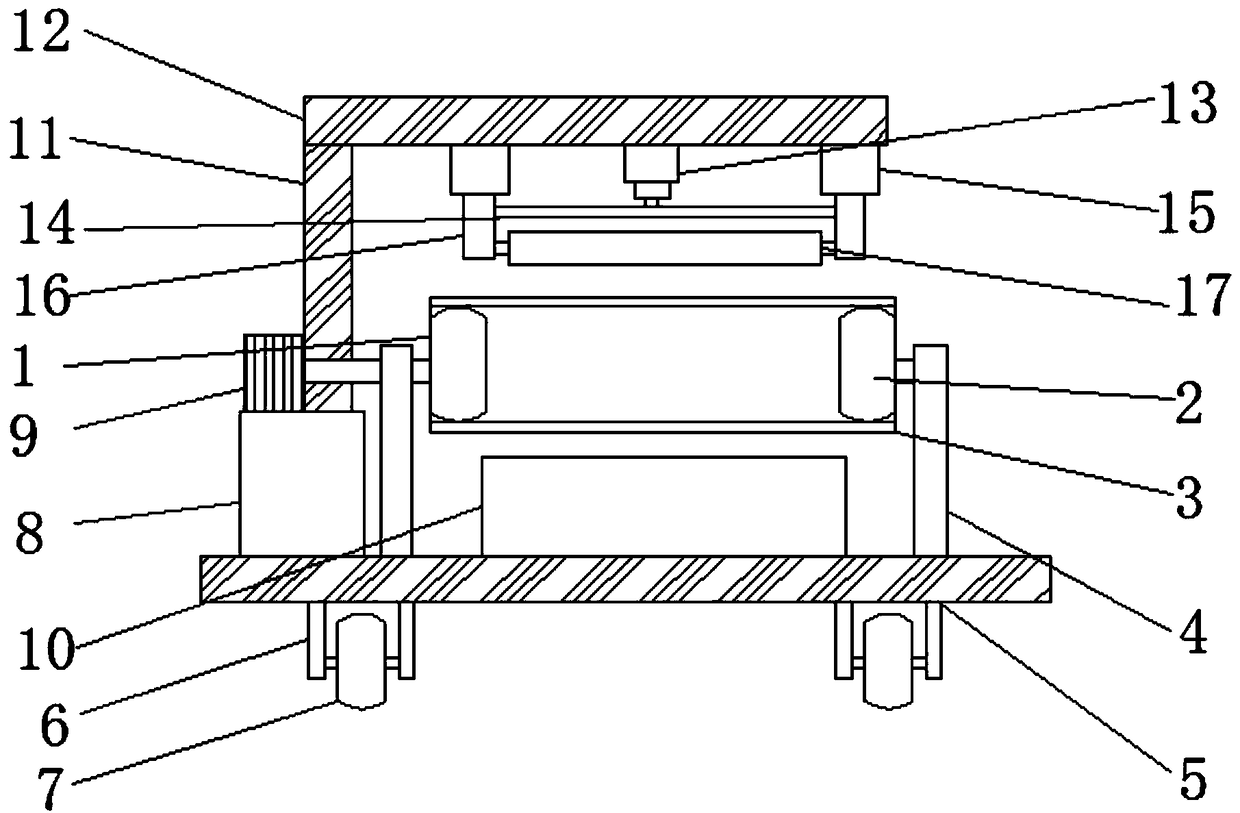

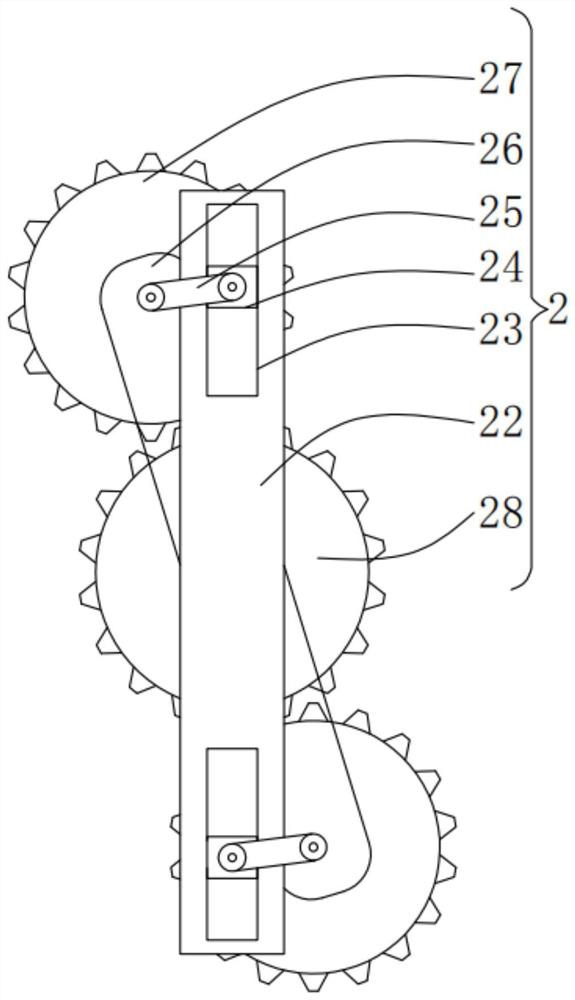

Conveying equipment for tea processing

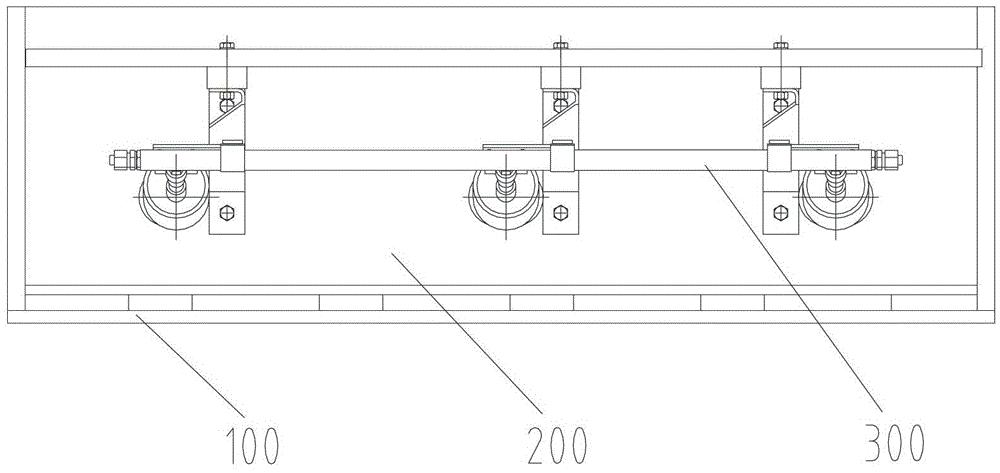

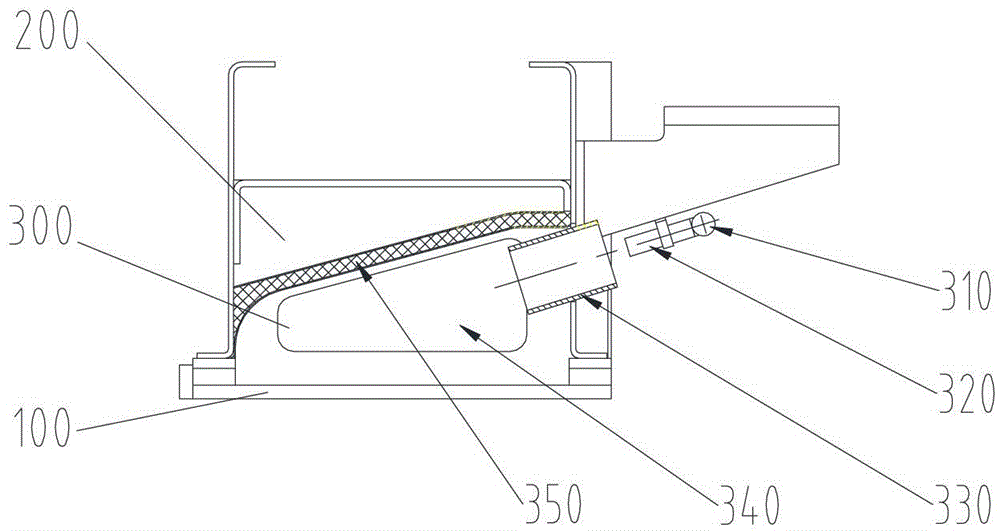

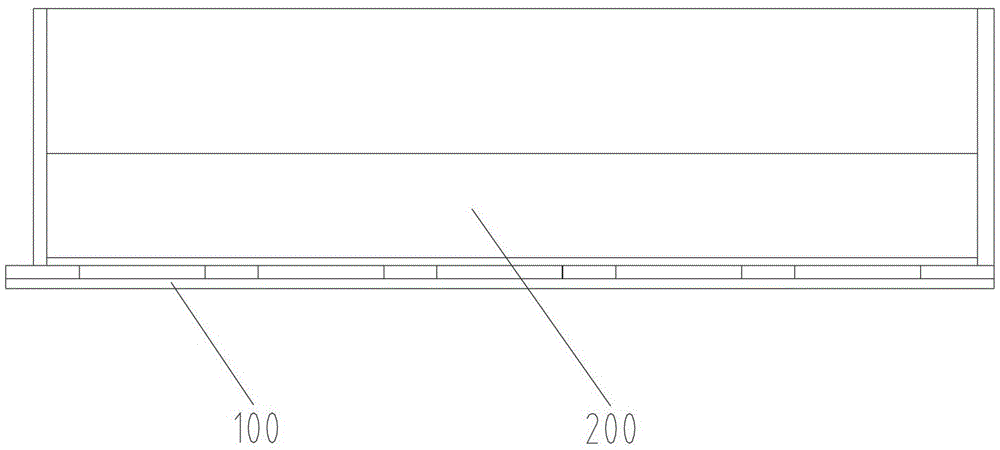

InactiveCN109455477AFast processingReduce uneven heatingConveyorsPre-extraction tea treatmentDrive wheelEngineering

The invention relates to the technical field of tea processing equipment, and discloses conveying equipment for tea processing. The conveying equipment comprises a driving wheel and a driven wheel; aconveying belt sleeves the surfaces of the driving wheel and the driven wheel; the front and rear surfaces of the driving wheel and the driven wheel are separately provided with supporting rods; the bottom parts of the four supporting rods are fixedly connected to a base; the bottom part of the base is fixedly connected to a support; the bottom part of the support is movably connected to walking wheels; a fixed post is fixedly connected to the rear side of the left side of the top of the base; a motor is fixedly connected to the top part of the fixed post; the output end of the motor penetrates to the outer sides of the supporting rods and is fixedly connected to the driving wheel; and a drying mechanism which is matched with the conveyer belt to be used is fixedly connected to the top part of the base. The conveying equipment has the advantages that tea can be dried in the conveying process; processing efficiency is improved; and the problems that the function is single, and time andlabor are wasted are solved.

Owner:安徽五亩生态农业发展有限公司

Heating cooker

ActiveUS10602868B2Reduce uneven heatingResistance from a bottom surface of the cooking container reducesCooking insertsVessels with intergral heatingEngineeringFront edge

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

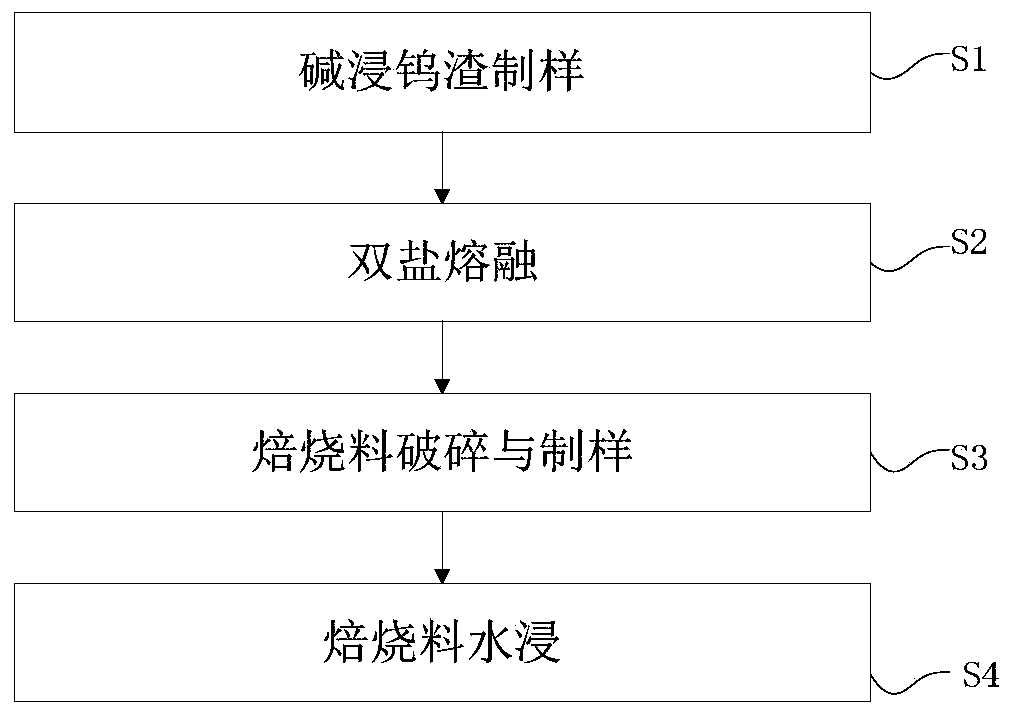

Method for efficiently separating and recovering tungsten from alkaline leaching tungsten slag

The invention discloses a method for efficiently separating and recovering tungsten from alkaline leaching tungsten slag. The method comprises the following steps that after the alkaline leaching tungsten slag, mixed salt and a combustion-supporting medium are uniformly mixed, the mixture is roasted and smelted in a muffle furnace, a roasted material obtained by roasting and smelting is subjectedto crushing, dry grinding, screening and then water leaching, and sodium tungstate in the roasted material is separated and enriched in a water phase so as to be recovered. According to the method, ananhydrous sodium sulfate and sodium carbonate mixed salt system is adopted, a weak oxidation environment is provided in a roasting process, oxidation and recovery of low-valent tungsten are facilitated, the process route of tungsten recovery is shortened, and the productivity is improved; meanwhile, the combustion-supporting medium is added into the materials, the heat conduction performance of amaterial layer is effectively improved, the phenomenon of uneven heating of different parts of the material layer is reduced, and the tungsten recovery rate is improved; and the tungstate in the roasted material is enriched by adopting a water leaching method, the leaching rate is high, the leaching cost is low, environmental pollution is small, and the leaching slag can be subjected to subsequent separation and recovery according to the content of valuable elements such as cobalt and nickel.

Owner:HUBEI GREEN TUNGSTEN CO LTD

Screed and paver with same

Owner:ZOOMLION HEAVY IND CO LTD

Method for reducing splashing of silicon liquid in polycrystalline silicon electron beam smelting process

InactiveCN103570024AReduce uneven heatingAvoid thermal convectionSilicon compoundsMaterials preparationCrucible

The invention belongs to the field of electron beam smelting, and in particular relates to a method for reducing the splashing of silicon liquid in a polycrystalline silicon electron beam smelting process. The method comprises the steps of material preparation, vacuumizing, pretreatment and smelting, wherein after the pretreatment step, the following steps are performed: (1) adjusting electron beam current, and heating and melting a silicon material; (2) adjusting electron beam spots to spirally move towards the circle center of a crucible along the upper edge of the inner wall of the crucible, causing the electron beam spots to reversely spirally move after the electron beam spots move to the circle center of the crucible, and repeating the spiral movement; (3) after the movement of the electron beam spots is completed, performing electron beam smelting. The method has the remarkable effects that silicon material loss caused by the splashing of the silicon liquid can be reduced, ablation in a vacuum cavity can be reduced, the hidden danger of stopping of an electron gun in case of sudden changes in pressure in the vacuum cavity caused by the splashing of the silicon liquid can be avoided, and a process is simple and easy to operate.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

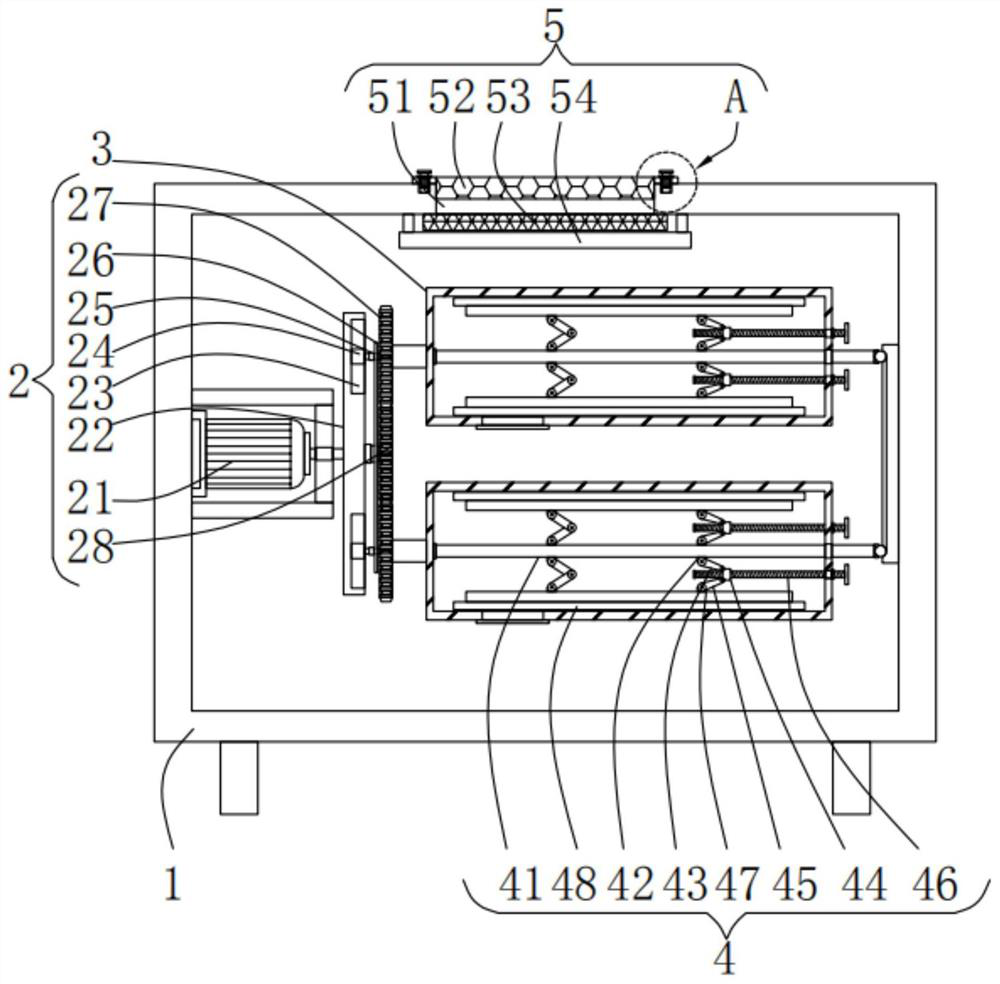

Dark tea baking equipment

InactiveCN112378200AResidue reductionAddressing Changes in TastePre-extraction tea treatmentHollow article cleaningElectric machineryEngineering

The invention provides dark tea baking equipment, comprising: a body; a rotating device fixedly installed on the left side in the main body and comprising a first motor, wherein a rotating rod is fixedly installed at one end of an output shaft of the first motor, two first sliding grooves are formed in each of the two sides of the rotating rod, first sliding blocks are slidably connected into thetwo sliding grooves, first connecting rods are rotatably connected to the right sides of the first sliding blocks, driven rods are rotatably connected to the other ends of the first connecting rods, two first gears are fixedly mounted at each of the two ends of the driven rods, second gears are fixedly mounted in the middles of the right sides of the driven rods, and the bottoms of the two first gears are engaged with the tops and the bottoms of the second gears; and a drying barrel, the left side of which is fixedly mounted on the right sides of the two first teeth through a connecting block.The dark tea baking equipment provided by the invention has the advantages that the problem of taste change caused by uneven heating of dark tea during baking is solved, and the working efficiency ofdark tea making is improved, so that the production yield is increased.

Owner:安化县永泰福茶号

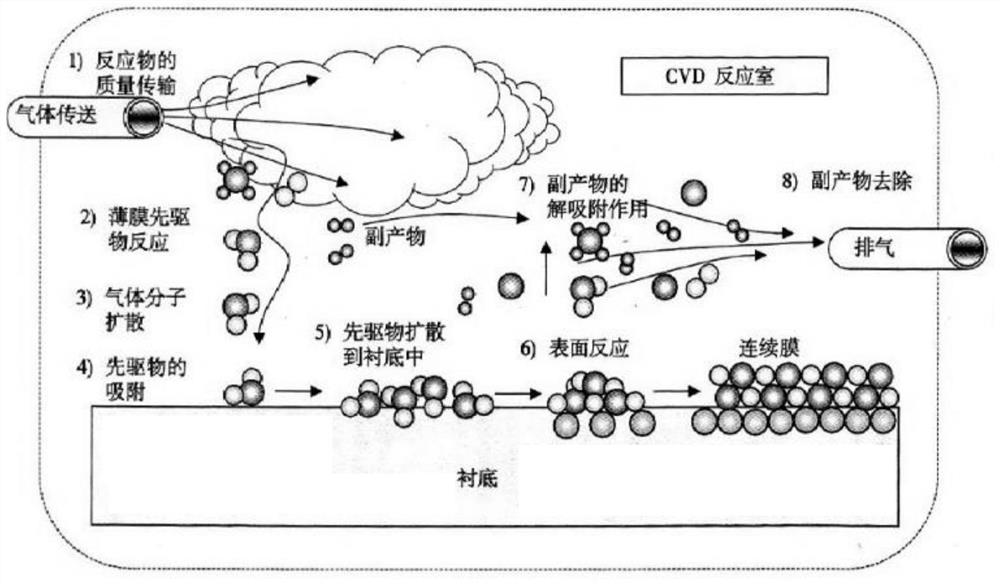

Vapor deposition equipment and wafer heating carrier and heating method thereof

PendingCN114672789ACompensate for uneven heatingReduce uneven heatingChemical vapor deposition coatingWaferEngineering

The invention discloses vapor deposition equipment as well as a wafer heating platform deck and a heating method thereof. The vapor deposition equipment comprises a platform deck body, an ejector pin body and a heating device, the heating device is arranged in the ejector pin body; a through hole is formed in the carrying table body, and the ejector pin body penetrates through the through hole; the ejector pin body is used for bearing a wafer and placing the wafer on the upper surface of the carrying table body, the heating device heats the ejector pin body, and the ejector pin body and the carrying table body jointly transfer heat to the wafer. The heating device is additionally arranged in the ejector pin body, so that the ejector pin body is heated by the heating device, the ejector pin body and the carrying table body jointly transfer heat to the wafer, the ejector pin body can reduce heat lost in the through hole or make up the heat lost in the through hole, and then the non-uniform heating degree of the wafer on the carrying table body is reduced; or the phenomenon that the wafer is heated unevenly on the carrying table body is avoided, the forming speed of a film on the upper surface of the wafer can be increased, the thickness of the film is increased, and the film forming efficiency of the surface of the wafer is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

Ironing plate and paver

The invention provides an ironing plate which comprises a bottom plate, a heating element and a plate frame body, wherein the plate frame body is covered on the bottom plate, and a heating chamber is defined by the plate frame body and the bottom plate; and the heating element is arranged in the heating chamber. The ironing plate also comprises a heat reflection element arranged in the heating chamber. The ironing plate is internally provided with the heat reflection element, and heat emitted to the heating chamber from the heating element can be reflected to the bottom plate so as to improve the heating speed of the bottom plate. Meanwhile, the bottom plate far away from the heating element is heated by heat reflected by the heat reflection element so as to eliminate the phenomenon that the bottom plate is unevenly heated.

Owner:SANY HEAVY IND CO LTD (CN)

Double-U-shaped thermal activation building envelope structure with cross-shaped drill holes and operation control method

PendingCN112797829AHeat Injection Ability AttenuationReduce uneven heatingHeat storage plantsTemperature control using electric meansClassical mechanicsStructural engineering

The invention discloses a double-U-shaped thermal activation building envelope structure with cross-shaped drill holes. The double-U-shaped thermal activation building envelope structure is characterized by comprising a wall base body, a plurality of double-U-shaped heat exchange pipelines and a temperature monitoring system, wherein the plurality of cross-shaped drill holes are formed inside the wall base body, each heat exchange pipeline is composed of a first U-shaped pipe, a second U-shaped pipe and a heat exchange working medium, the first U-shaped pipes are placed inside vertical drill holes of the cross-shaped drill holes, the second U-shaped pipes are placed inside horizontal drill holes of the cross-shaped drill holes, and the first U-shaped pipes and the second U-shaped pipes are fixed to the four end portions of the cross-shaped drill holes through special fixing pieces and U-shaped pipe fixing rubber strips. According to the thermal activation building envelope structure, the heat accumulation phenomenon widely existing in the interior of a traditional thermal activation building envelope structure can be effectively avoided without intermittent control over a thermal activation building system, and therefore the higher natural energy utilization rate can be achieved, and the corresponding initial investment and operation cost of a source end and a pumping system are effectively reduced.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Making method for waterproof asphalt caulking factice of building with fire resistance

InactiveCN107663381AFlame retardantEasy constructionBuilding insulationsChlorinated paraffinsFire resistance

The invention relates to the technical field of a waterproof material and relates to a making method for a waterproof asphalt caulking factice of a building with fire resistance. The method comprisesthe following steps: taking the following raw materials in parts by weight: 40-65 parts of asphalt, 2-15 parts of chlorinated paraffin, 1-11 parts of styrene-butadiene-styrene segmented copolymer, 1-10 parts of styrene-isoprene-styrene segmented copolymer, 5-25 parts of calcium carbonate and 5-20 parts of iron oxide red; putting asphalt into a dosing reaction kettle, heating, rising temperature to110 DEG C and dewatering for 30min; heating to 180-220 DEG C, and then adding styrene-butadiene-styrene segmented copolymer and adding styrene-isoprene-styrene segmented copolymer, keeping high temperature, stirring and then grinding; cooling to 120-160 DEG C and then adding calcium carbonate and iron oxide red; uniformly stirring and then adding chlorinated paraffin; uniformly stirring and thenemptying and packaging, thereby acquiring the waterproof asphalt caulking factice of the building with fire resistance. The waterproof asphalt caulking factice of the building with fire resistance ischaracterized by high temperature flame retardant, low volatility, high construction degree, high caking property and high density.

Owner:北新防水(河南)有限公司

Heavy truck traction seat micro-hole cooling grid plate and EPC ceramic sand core method production method

InactiveCN109028975AReduce uneven heatingClear structureFoundry mouldsHandling discharged materialEngineeringEvanescent mode

The invention discloses a heavy truck traction seat micro-hole cooling grid plate and an EPC ceramic sand core method production method. The heavy truck traction seat micro-hole cooling grid plate comprises a body. Vent holes are formed in the body and distributed in the body in an arrayed manner. The vent holes are obliquely formed, the distances between the adjacent vent holes are 15 mm, and thewidths of the vent holes are 2 mm. The length of the body is 500 mm, and the width of the body is 400 mm. The EPC ceramic sand core method production method of the heavy truck traction seat micro-hole cooling grid plate includes the specific steps that I, firstly, a model of a casting is made through foams; II, a ceramic sand core is fixed to the foam model; III, the foam model is brush-coated with a binder; IV, the foam model is put in an evanescent mode sand box, and forming is carried out through negative pressure air extracting; and V, after molten steel is poured into a riser, the foamsare burnt to be removed. The heavy truck traction seat micro-hole cooling grid plate is produced with an EPC ceramic sand core method, the cooling grid plate for a cement kiln can be cast, the coolinggrid plate has a very clear structure contour, the minimum hole diameter is 2 mm, other small and medium structural parts with complex structures can also be cast, and the cooling grid plate is especially suitable for a heavy truck traction seat.

Owner:南通新兴机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com