Vapor deposition equipment and wafer heating carrier and heating method thereof

A stage and wafer technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of uneven heating of wafers, achieve simple methods, improve heat transfer efficiency, and speed up the formation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present application solve the technical problem of uneven heating of wafers on the heating stage in the prior art by providing a wafer heating stage.

[0029] The technical solutions of the embodiments of the present application are to solve the above-mentioned technical problems, and the general idea is as follows:

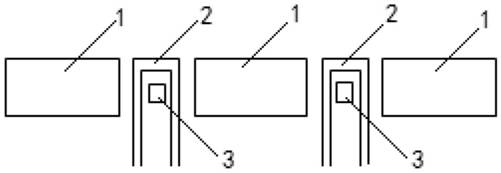

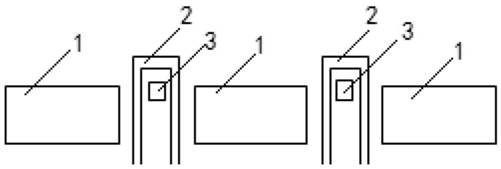

[0030] A wafer heating stage, comprising: a stage body 1, an ejector pin body 2 and a heating device 3; the heating device 3 is arranged in the ejector pin body 2; the stage body 1 is provided with a through hole, and the ejector pin body 2 passes through the through hole; The ejector pin body 2 is used to receive the wafer and place the wafer on the upper surface of the carrier body 1 , wherein the heating device 3 heats the ejector pin body 2 , and the ejector pin body 2 and the carrier body 1 jointly transfer heat to the wafer.

[0031] In this application, a heating device 3 is added to the ejector pin body 2, so that the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com