Direct-driven permanent-magnet motor

A technology for permanent magnet motors and machine bases, applied in magnetic circuits, electric components, electrical components, etc., can solve the problems of uneven loss of the upper and lower layers of the winding and the left and right layers, increase the burden of rotor heat dissipation, and unfavorable rotor heat dissipation, etc., to reduce the stator Reduce copper consumption and heat generation, improve product market competitiveness, and fix simple and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

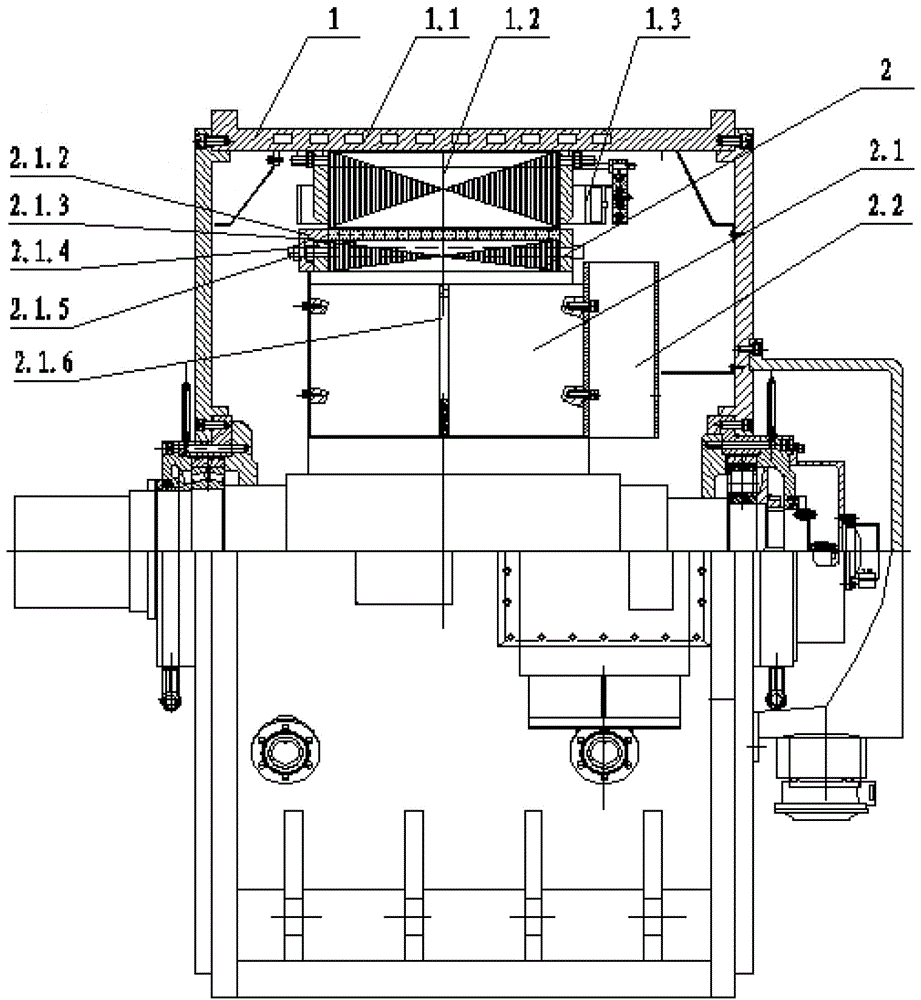

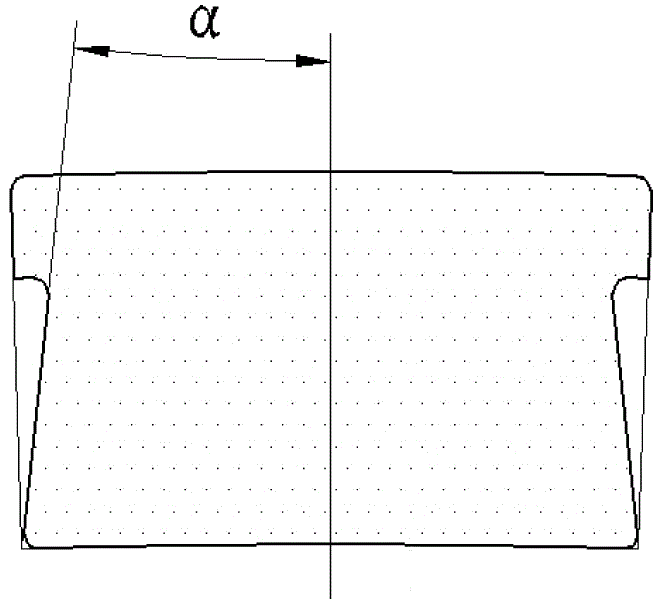

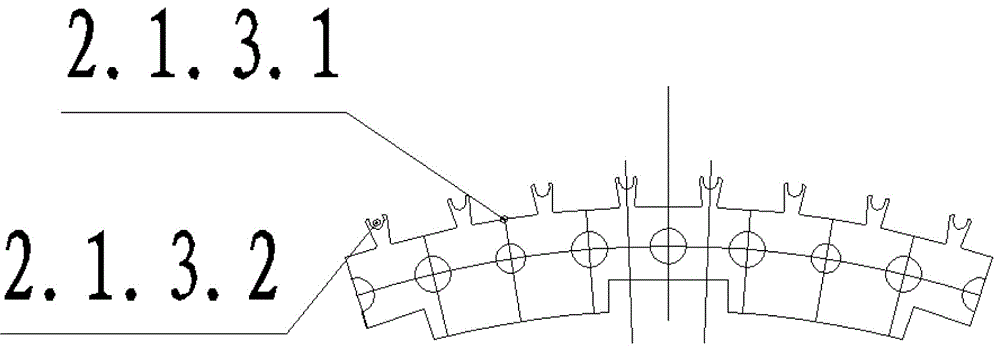

[0028] refer to figure 1 As shown, the present invention discloses a low-speed high-torque direct-drive permanent magnet motor, including a stator 1 and a rotor 2, and the stator 1 includes a water jacket base 1.1 and a stator core fixed on the water jacket base 1.1 1.2, the surface of the stator core 1.2 is regularly provided with a plurality of annular opening slots, and the stator winding 1.3 is arranged in the opening slots; the rotor 2 includes a rotor body 2.1 with a bracket and a rotor fan 2.2 ; The rotor body 2.1 includes a rotating shaft 2.1.6 and a rotor core 2.1.3 arranged on the rotating shaft 2.1.6, and the rotor core 2.1.3 is formed by interleaving and laminating a plurality of fan-shaped rotor punches, A plurality of tapered grooves 2.1.3.1 with tapered cross-sections are arranged on the outer circumference of the fan-shaped rotor punch according to the law, and the tapered grooves 2.1.3.1 are provided with matching cross-sections that are tapered T-shaped The ...

Embodiment 2

[0031] The difference from Example 1 is that a plurality of U-shaped through-holes 2.1.3.2 are regularly arranged on the outer circumference of the fan-shaped rotor punching piece, and the U-shaped through-holes 2.1.3.2 are arranged on adjacent Between two tapered grooves 2.1.3.1.

[0032] The tapered groove 2.1.3.1 and the U-shaped through hole 2.1.3.2 are punched directly from fan-shaped silicon steel sheets, and the rotor magnetic circuit and the yoke are formed after staggered lamination. The tapered groove 2.1.3.1 is used for magnetic steel installation. 2.1.3.2 The U-shaped through hole 2.1.3.2 The width and depth of the U-shaped hole depend on the one hand on the loss of the allowable magnetic flux leakage to the torque under the action of magnetic isolation, and on the other hand depend on the design requirements of the rotor 2 ventilation path, "U The unique design of the "shaped through hole simultaneously plays the double effect of magnetic isolation and ventilation...

Embodiment 3

[0034] The difference from Example 1 is that the fan-shaped rotor punch is regularly provided with a plurality of circular through holes, and the two ends of the rotor core 2.1.3 are provided with rotor tooth pressure plates 2.1.4, one of which is The outer side of the rotor tooth pressure plate 2.1.4 is provided with a rotor pressure plate 2.1.2, and the corresponding positions of the rotor tooth pressure plate 2.1.4 and the rotor pressure plate 2.1.2 are provided with through holes, and the circular through hole and the through hole A tension screw 2.1.5 is arranged in the hole. The rotor iron core 2.1.3 is positioned on the outer circle with the tooling when the fan-shaped rotor punches are stacked, and is fixed as a whole by tightening the screw rod 2.1.5, the rotor tooth pressure plate 2.1.4 and the rotor pressure plate 2.1.2.

[0035] The stator winding of the low-speed direct-drive motor of the present invention heats up evenly, and the rotor magnetic steel is fixed sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com