Screed and paver with same

A technology for screeds and pavers, applied in the directions of roads, road repairs, roads, etc., can solve the problems of uneven heating, deformation of the box bottom plate of the screed, affecting the quality of road paving, etc., so as to reduce thermal stress. Deformation, improving paving quality, reducing the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

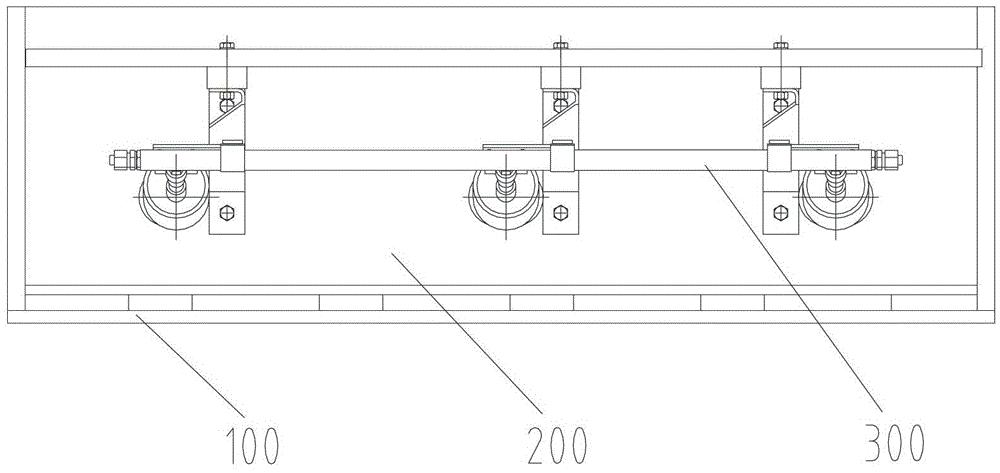

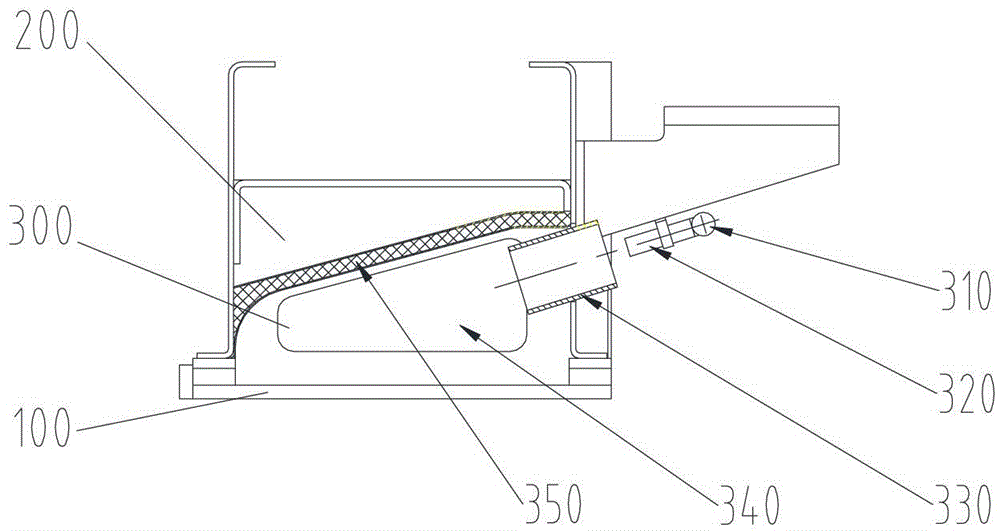

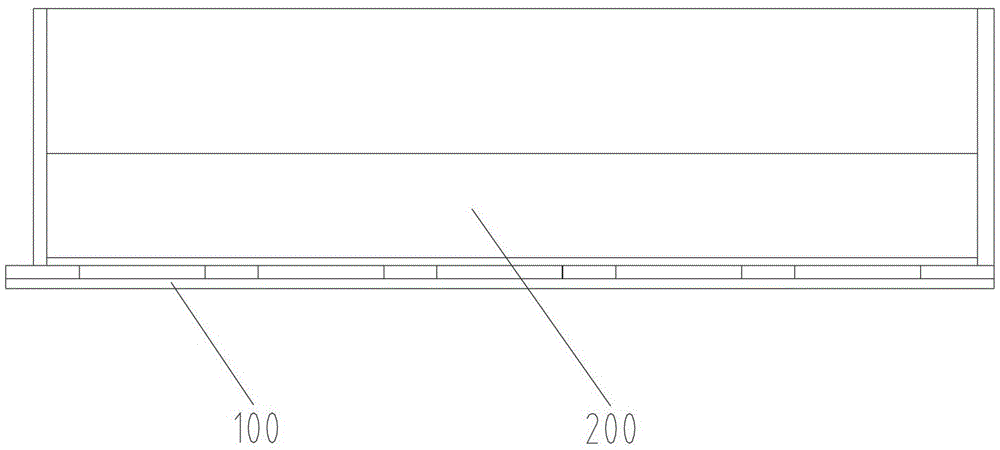

[0042] Such as Figure 6 and Figure 7 As shown, the screed of the first embodiment shows the two middle sections of the screed and the screed heating system 600 . Each of the two intermediate panels includes a box body 200 , and the box body 200 includes a box bottom plate 100 . The screed heating system 600 includes a receiving cavity 610 and a heating device disposed in the box body 200 of each intermediate section.

[0043] In this embodiment, each plate section includes an accommodation cavity surrounded by a separate shell, in order to better heat the bottom plate 100 of the box body, as Figure 7 As shown, the bottom wall of the housing forming the accommodation cavity 610 abuts and fits with the upper surface of the box bottom plate 100 of the plate section where it is located. In an embodiment not shown, the bottom wall of the accommodation chamber may also be formed by the upper surface of the box bottom plate 100 of the plate section where the accommodation chamb...

no. 2 example

[0055] Such as Figure 8 and Figure 9 As shown, the screed of the second embodiment shows the two middle sections of the screed and the screed heating system 700 . Each of the two intermediate panels includes a box body 200 , and the box body 200 includes a box bottom plate 100 .

[0056] The screed heating system 700 includes an accommodating chamber 710 disposed in the box body 200 of each section, and includes a heating device, a circulation device, and a convection pipe 740 as a connecting pipeline.

[0057] In the second embodiment, each containing chamber 710 contains heat transfer oil as a heat transfer fluid.

[0058] The heating device of the second embodiment includes a heating box 720 and a box heater located outside each containing cavity and arranged on the circulation path of the heat transfer fluid. The setting method of this heating device enables the heat transfer fluid to be heated intensively, which can reduce the layout of cables in the electric heater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com