Pipe preheating device and reheating method thereof

A technology of preheating device and pipe, which is applied in the field of heat treatment, can solve the problems of increasing the heating energy consumption of the preheating furnace, oxidation of the workpiece surface, and reducing the temperature in the furnace, so as to improve work efficiency, smooth preheating treatment, and ensure continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

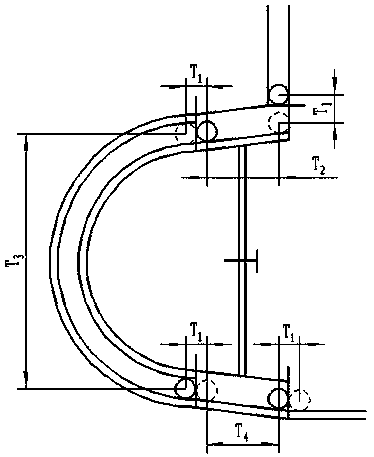

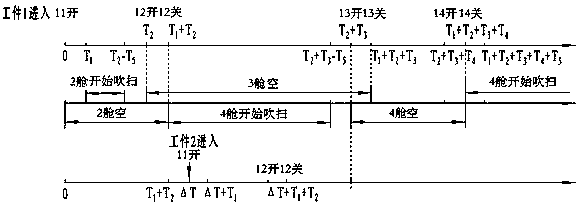

[0068] Determine the workpiece heating time T=38.5s and the interval between two workpieces according to the processing conditions of the production line △T=32s, T1=0.5s, T2=4s, T3=30s, T4=4s, T5=2s, when the workpiece heating cabin 2 is at the same time When the number of heated workpieces n is 1;

[0069] The controller automatically calculates the opening time of the hatch;

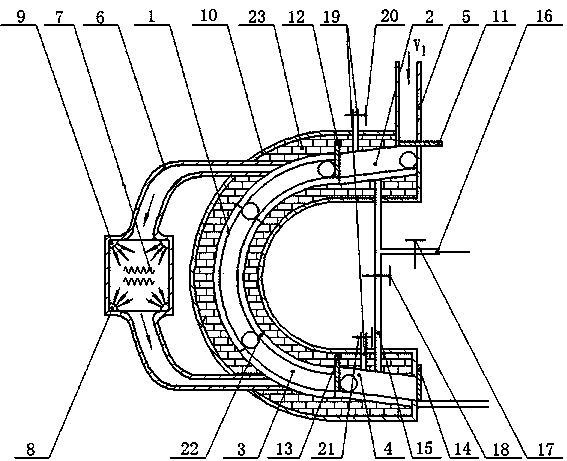

[0070] The resistance wire 7 in the heat transfer channel 6 is heated, the blower 9 and the exhaust fan 8 are started, the hot air flow enters the workpiece heating cabin 3 from the heat transfer channel 6, and the hot air flow between the heat transfer channel 6 and the workpiece heating cabin 3 circulates continuously;

[0071] When the first workpiece is put into the workpiece entering channel 5, the system starts timing, and the No. 1 cabin door 11 remains open. After 0.5s, after the workpiece enters the workpiece entering cabin 2, the No. 1 cabin door 11 closes;

[0072] At 1s, the No. 3 valve 13...

Embodiment 2

[0083] Determine the workpiece heating time T=38.5s and the interval between two workpieces according to the processing conditions of the production line △T=24s, T1=0.5s, T2=4s, T3=30s, T4=4s, T5=2s, when the workpiece heating cabin 3 is at the same time When the number of heated workpieces n is 2;

[0084] The controller automatically calculates the opening time of the hatch;

[0085] The resistance wire 7 in the heat transfer channel 6 is heated, the blower 9 and the exhaust fan 8 are started, the hot air flow enters the workpiece heating cabin 3 from the heat transfer channel 6, and the hot air flow between the heat transfer channel 6 and the workpiece heating cabin 3 circulates continuously;

[0086] When the first workpiece is put into the workpiece and enters the channel 5, the system starts timing, and the No. 1 cabin door 11 remains open. When 0.5s, as soon as the workpiece enters the workpiece entering cabin 2, the No. 1 cabin door 11 is closed; image 3 Shown, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com