Double-sided radiation spiral pipe heating furnace

A technology of spiral coil and heating furnace, which is applied in lighting and heating equipment, furnace, furnace type and other directions, can solve the problems of wear and unsafety of the outer arch of sharp bends, and achieves long service life, uniform heating, and avoidance of furnaces. The effect of tube coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

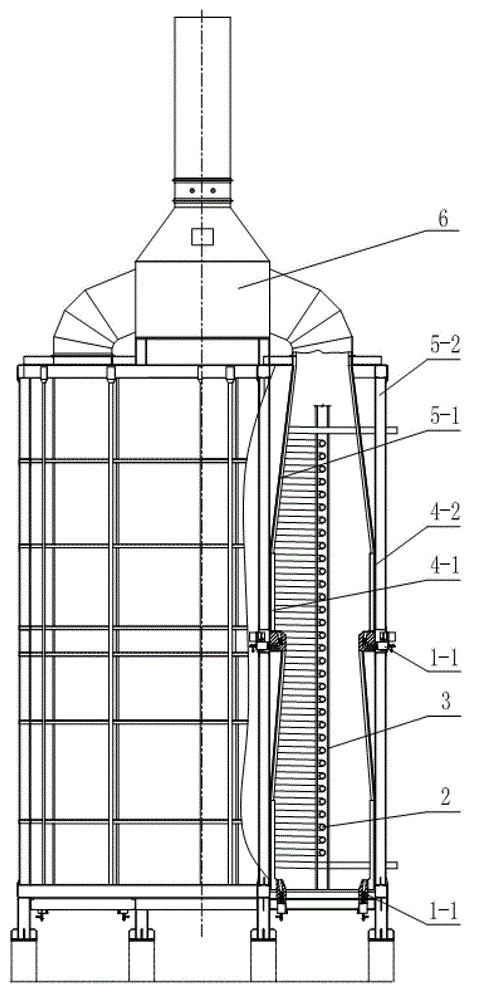

[0023] Such as figure 1 As shown, this embodiment provides a flat wall-attached flame burner heating two-step furnace type double-sided radial spiral coil heating furnace. It is a combined section with a rectangular lower part of a positive trapezoid, including steel structure, flat wall-attached flame burner 1-1, spiral coil 2, pipe frame 3, inner ring radiation wall 4-1, outer ring radiation wall 4-2, Inner ring furnace wall panel 5-1, outer ring furnace wall panel 5-2, flue exhaust duct 6.

[0024] The outer ring furnace wall plate 5-2 is arranged inside the steel structure of the heating furnace. The inner ring radiation wall 4-1 is attached to the outer side of the inner ring furnace wall panel 5-1, the outer ring radiation wall 4-2 is attached to the inner side of the outer ring furnace wall panel 5-2, and the spiral coil tube 2 is formed by the tube The frame 3 is fixedly arranged between the inner ring radiation wall 4-1 and the outer ring radiation wall 4-2; 1 heat...

Embodiment 2

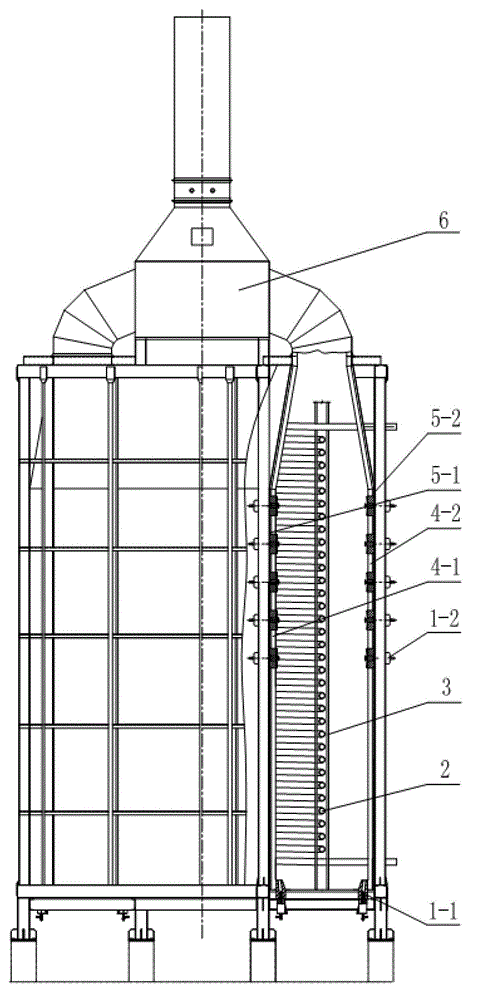

[0028] Such as figure 2 As shown, this embodiment also provides a combination of a flat wall-attached flame burner and a radiant wall-type flameless burner for heating with a double-sided furnace wall spiral coil heating furnace. The cross-section is rectangular, including flat wall-attached flame burner 1-1, radiant wall-type flameless burner 1-2, spiral coil 2, pipe frame 3, inner ring radiant wall 4-1, outer ring radiant wall 4 -2. Inner ring furnace wall panel 5-1, outer ring furnace wall panel 5-2, flue exhaust duct 6.

[0029] The inner ring radiation wall 4-1 is attached to the outer side of the inner ring furnace wall panel 5-1, the outer ring radiation wall 4-2 is attached to the inner side of the outer ring furnace wall panel 5-2, and the spiral coil 2. The pipe frame 3 is fixed between the inner ring radiation wall 4-1 and the outer ring radiation wall 4-2; when the height of the spiral coil furnace tube is above 5-6m, except for the flat wall-attached flame burne...

Embodiment 3

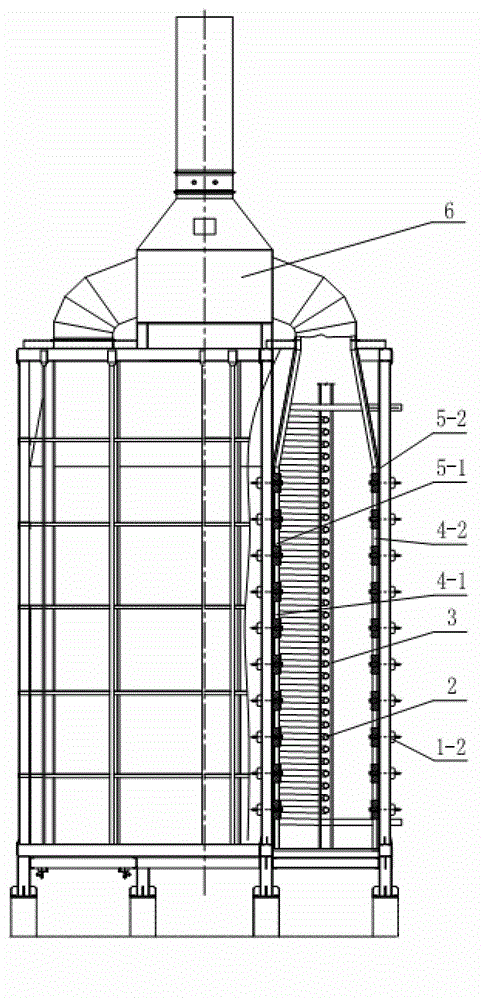

[0033] Such as image 3 As shown, this embodiment also provides a radiant wall-type flameless burner heating double-sided radiant spiral coil heating furnace. Type flameless burner 1-2, spiral coil 2, pipe frame 3, outer ring radiation wall 4-1, inner ring radiation wall 4-2, inner ring furnace wall 5-1, outer ring furnace wall 5- 2. Exhaust flue 6.

[0034] The inner ring radiation wall 4-1 is attached to the outer side of the inner ring furnace wall panel 5-1, the outer ring radiation wall 4-2 is attached to the inner side of the outer ring furnace wall panel 5-2, and the spiral coil 2 is fixed by the pipe frame 3 and placed between the inner ring radiation wall 4-1 and the outer ring radiation wall 4-2; the inner ring radiation wall 4-1 and the outer ring radiation wall 4-2 are flameless The burner 1-2 heats up the radiation wall of the inner and outer rings to a high temperature, and heats the medium to be heated by the heating furnace through the spiral coil 2 that is rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com