Patents

Literature

314 results about "Factice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Factice is vulcanized unsaturated vegetable or animal oil, used as a processing aid and property modifier in rubber. Longer chain fatty-acid containing oils such as rapeseed or meadowfoam produce a harder, more desirable factice. Soybean oil produces lower quality factice, though it can be mixed with longer-chain oils to yield factice nearly as good as that made from long chain oils alone. Oil-resistant factice is made with castor oil.

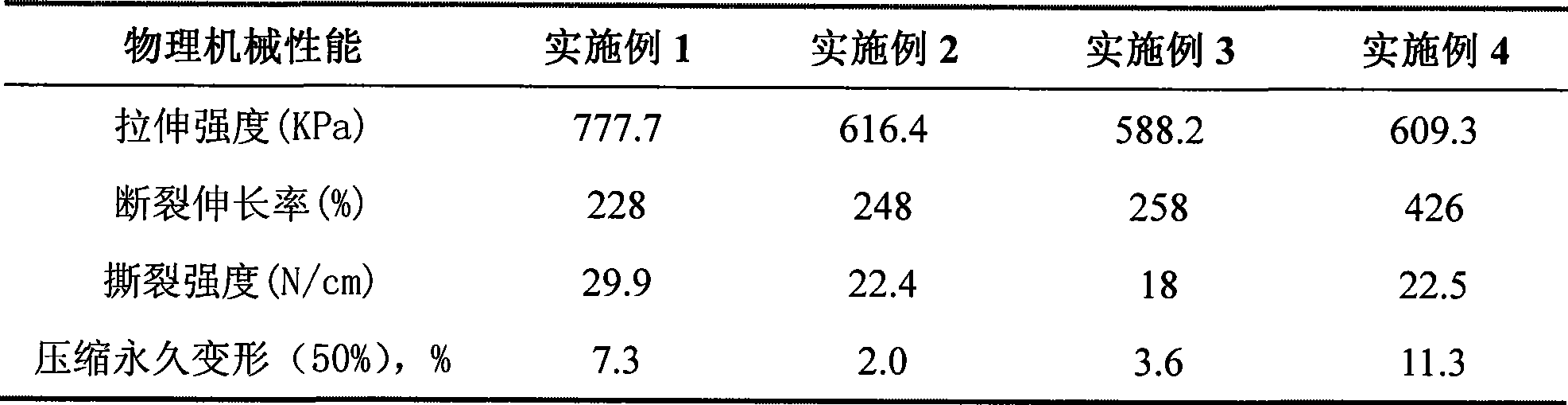

Butadiene styrene rubber foaming plate and preparation thereof

The invention relates to a butadien styene rubber foamed sheet and preparation method. The butadien styene rubber foamed sheet comprises(by weight parts): the total sum of butadien styene rubber, natural rubber and polybutadiene being 100 parts, filler 70-180 parts, black factice or white factice 10-20 parts, naphthenic oil 20-60 parts, black carbon or carbon white 0-25 parts, olefin 1-4 parts, foaming agent 10-20 parts, blowing promoter2-8 parts, sulfur 0.5-3 parts, promoter 0.2-3 parts, antiager 1-4 parts, dispersant 1-4 parts, white titanium pigment 0-15 parts. The method comprises: raw roll milling, pressure type milling by preliminary refiner, milling by roll mixer, extruding by extruder, once foaming and sulphurizing, second foaming and sulphurizing, cooling. The butadien styene rubbr foamed sheet has good elasticity, high extension percentage, high intension, small compression permanent set, antifriction and limited slip, good damping effect, innocuity and vapidness, low price.

Owner:常州美利晟高分子科技有限公司

Rubber mixture and tire

ActiveUS7411018B2Improve featuresGreat tractionSpecial tyresTyre tread bands/patternsSulfurPolybutadiene

The invention relates to a sulfur-vulcanizable rubber compound, in particular for treads of tires, which contains at least one diene rubber, liquid polybutadiene with a molecular weight of 1500-10000 g / mol and a vinyl content of 15-50%, at least one polar filler, at least one high-structure black with an iodine adsorption number of 115-200 g / kg and a DBP number of 125-160 mL / 100 g and at least one glyceride and / or one factice for good abrasion characteristics, good wet traction and good traction on ice and snow with good dry braking at the same time.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

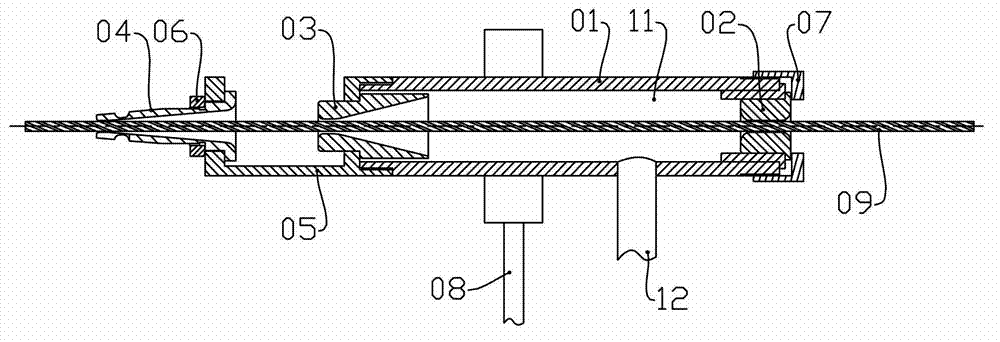

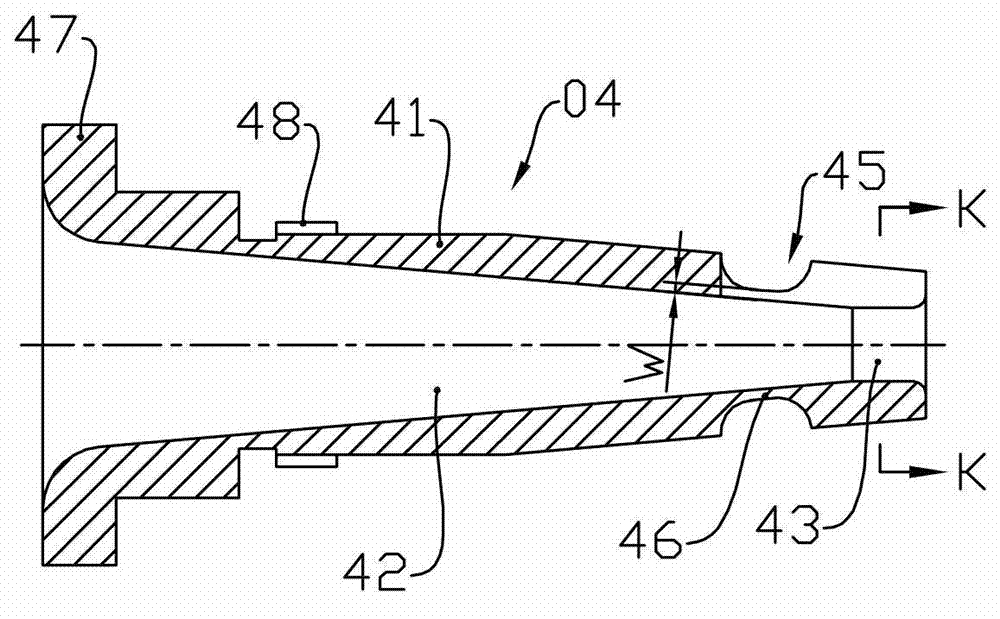

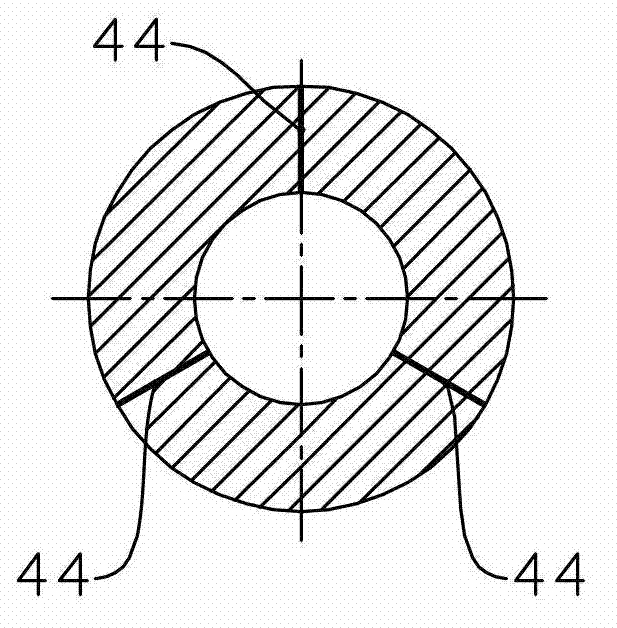

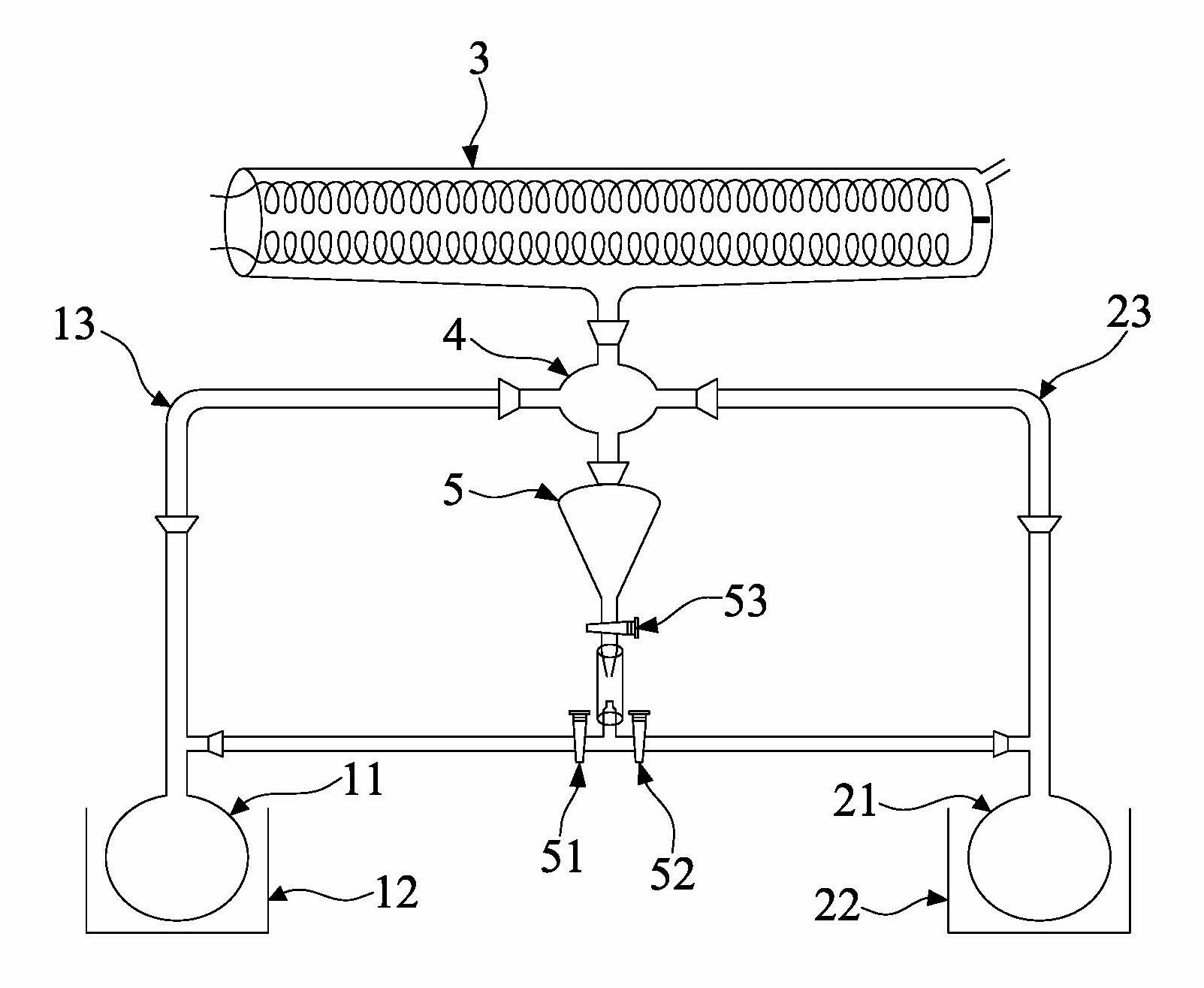

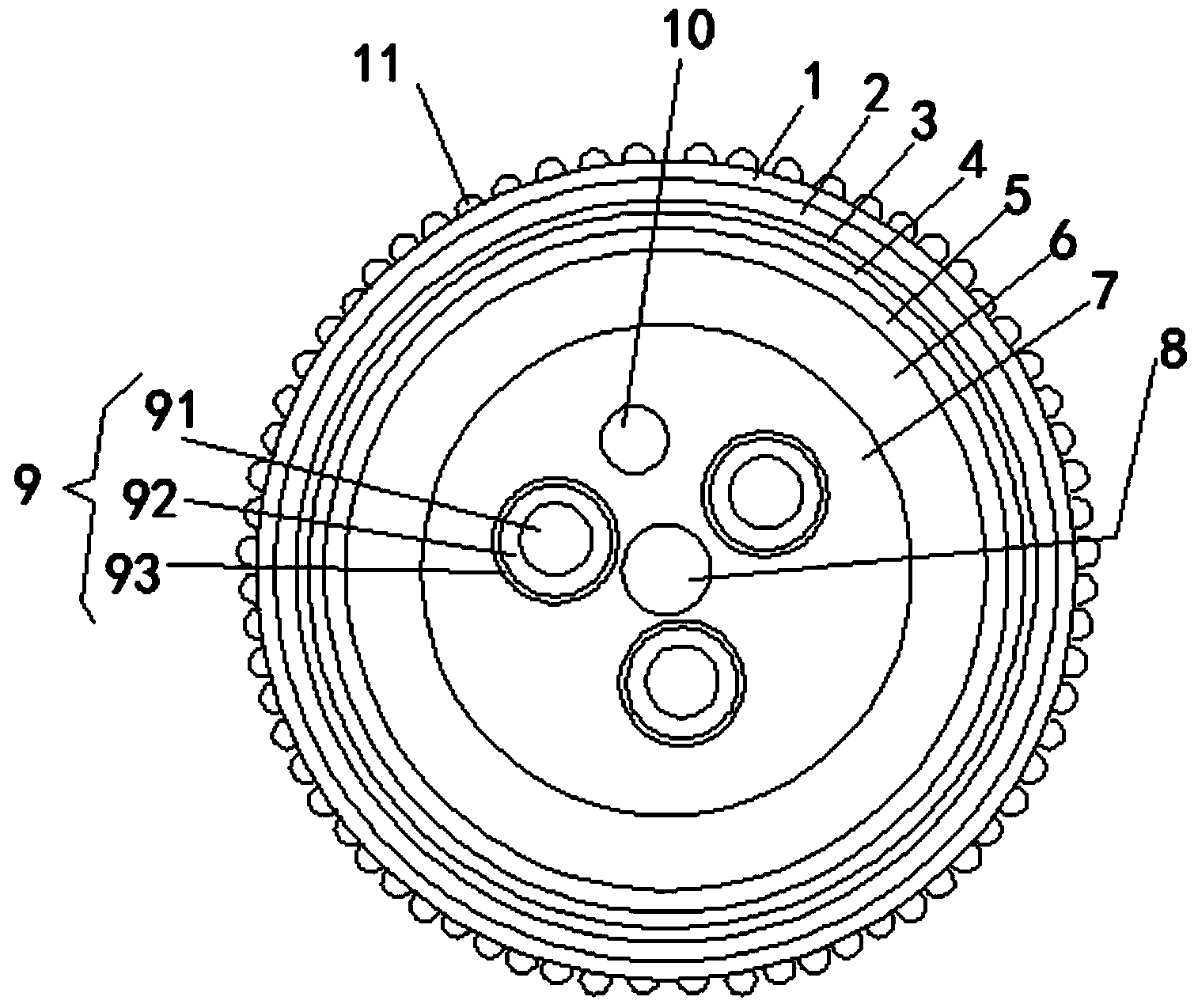

Optical cable factice forming mould and factice extruding device

The invention discloses a factice extruding device which belongs to a cable manufacturing technology. By utilizing a conventional water-resistant factice 'filling' mode, optical fibers in a sleeve can be extruded, the transmission performance is reduced and cable cores are even scrapped in a production process when the cable core diameter is slightly large or when fasten yarns are loose. The factice extruding device comprises a factice cavity, a cable core inlet mould, a factice filling mould and an optical cable factice forming mould, wherein the optical cable factice forming mould is formed by forming taper hole on a mould body with an integral taper tubular structure along an axial direction, the internal diameter of a taper hole inlet end is more than the internal diameter of a taper hole outlet end, and the small diameter end of the taper hole is used as a forming hole; and the mould body is made by spring steel, at least two slits are formed on the mould body along the axial direction and correspond to the forming hole, so that the forming hole has variability, the damage to the cable core is reduced when the cable core is slightly changed in diameter, and the cable core is well protected, so that the loss and production cost are lowered.

Owner:SHENZHEN XINAOKE CABLE +1

Duprene rubber foamed sheet and preparation method thereof

ActiveCN101392076AImprove flame retardant performanceHigh tensile strengthPolymer sciencePropanoic acid

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant, 5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Owner:常州美利晟高分子科技有限公司

High-temperature-resistant modified polyethylene sheath material for special cables

InactiveCN104086716AImprove performanceImprove high temperature resistanceLow-density polyethyleneAluminum silicate

The invention relates to a cable material, particularly a high-temperature-resistant modified polyethylene sheath material for special cables, which is prepared from the following raw materials in parts by weight: 13-16 parts of PEEK (polyetheretherketone), 32-35 parts of metallocene linear low density polyethylene, 15-18 parts of polystyrene, 12-14 parts of silicon dioxide, 6-9 parts of calcium carbonate, 2-3 parts of zinc oxide, 6-8 parts of smectite powder, 12-15 parts of ceramic hollow microsphere, 12-15 parts of aluminum silicate, 3-5 parts of 1,2-propylene glycol adipate, 2-3 parts of n-butyl methylacrylate, 12-13 parts of antimony trioxide, 11-12 parts of white factice, 14-17 parts of tributyl citrate, 1.8-2.2 parts of accelerator M and 14-16 parts of assistant. The insulating material combines the advantages of the metallocene linear low density polyethylene, polystyrene, PEEK and other raw materials, and has effectively improved mechanical properties. On the basis of high flexibility, wear resistance, impact resistance, tear resistance and other characteristics, the material has the advantages of excellent high-temperature resistance, excellent radiation resistance and the like, and is especially suitable to be used as a sheath material for special cables in aerospace and the like.

Owner:LVBAO CABLE GROUP

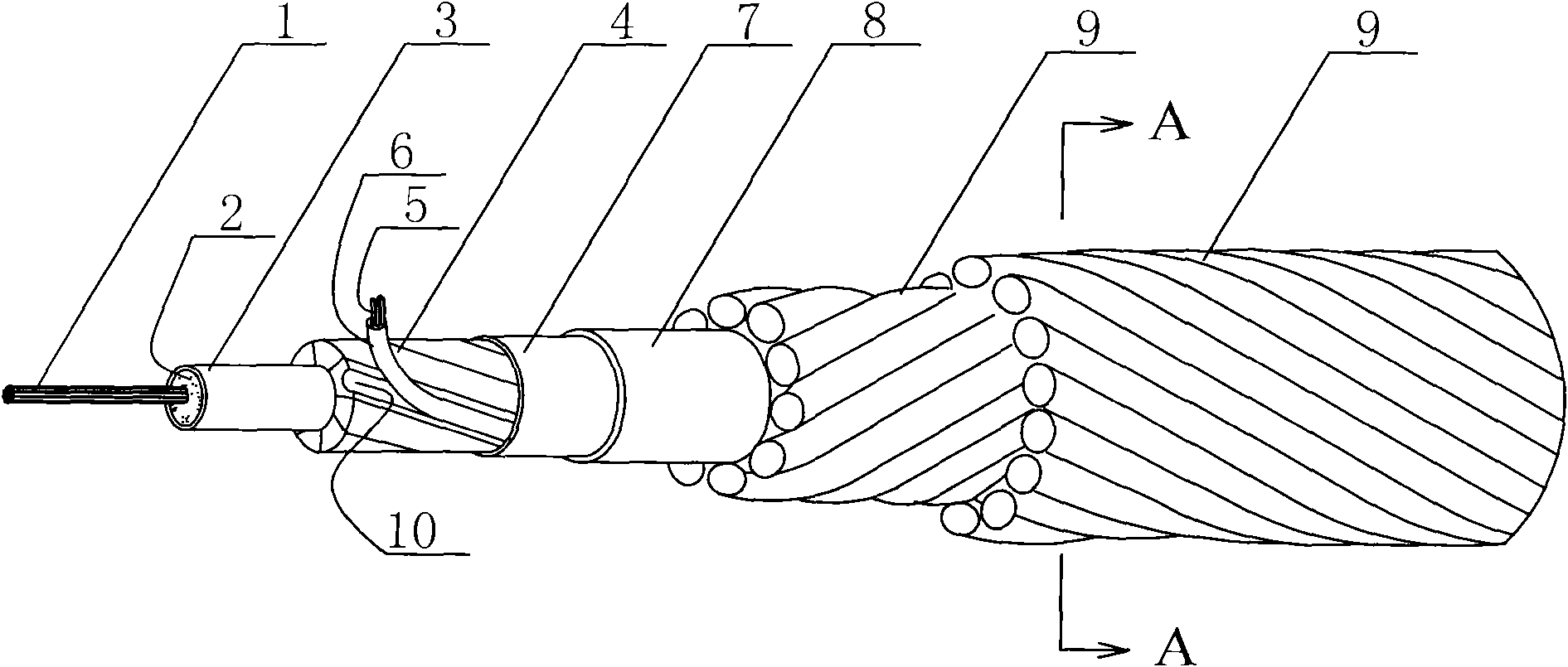

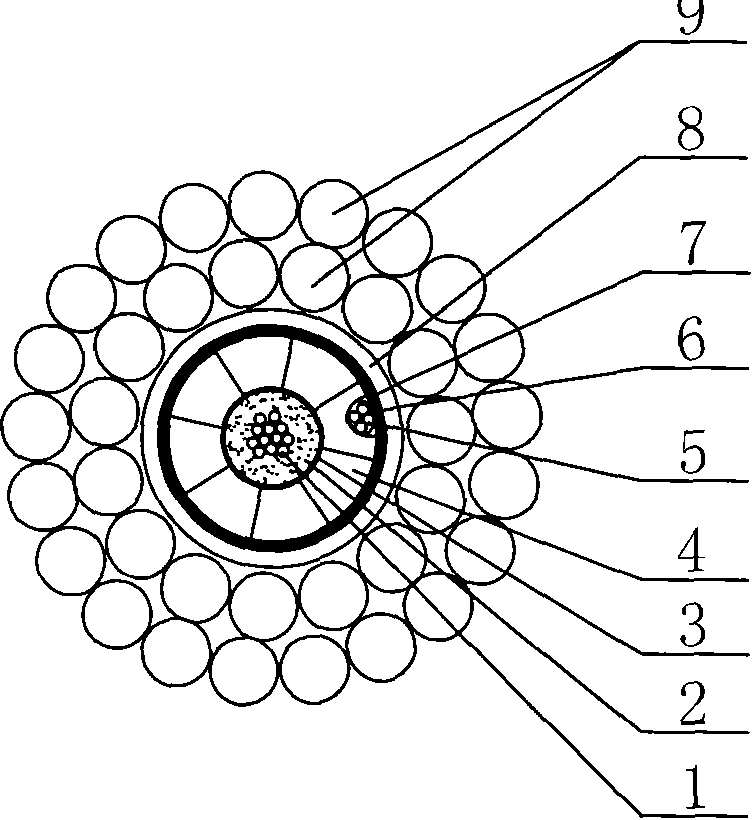

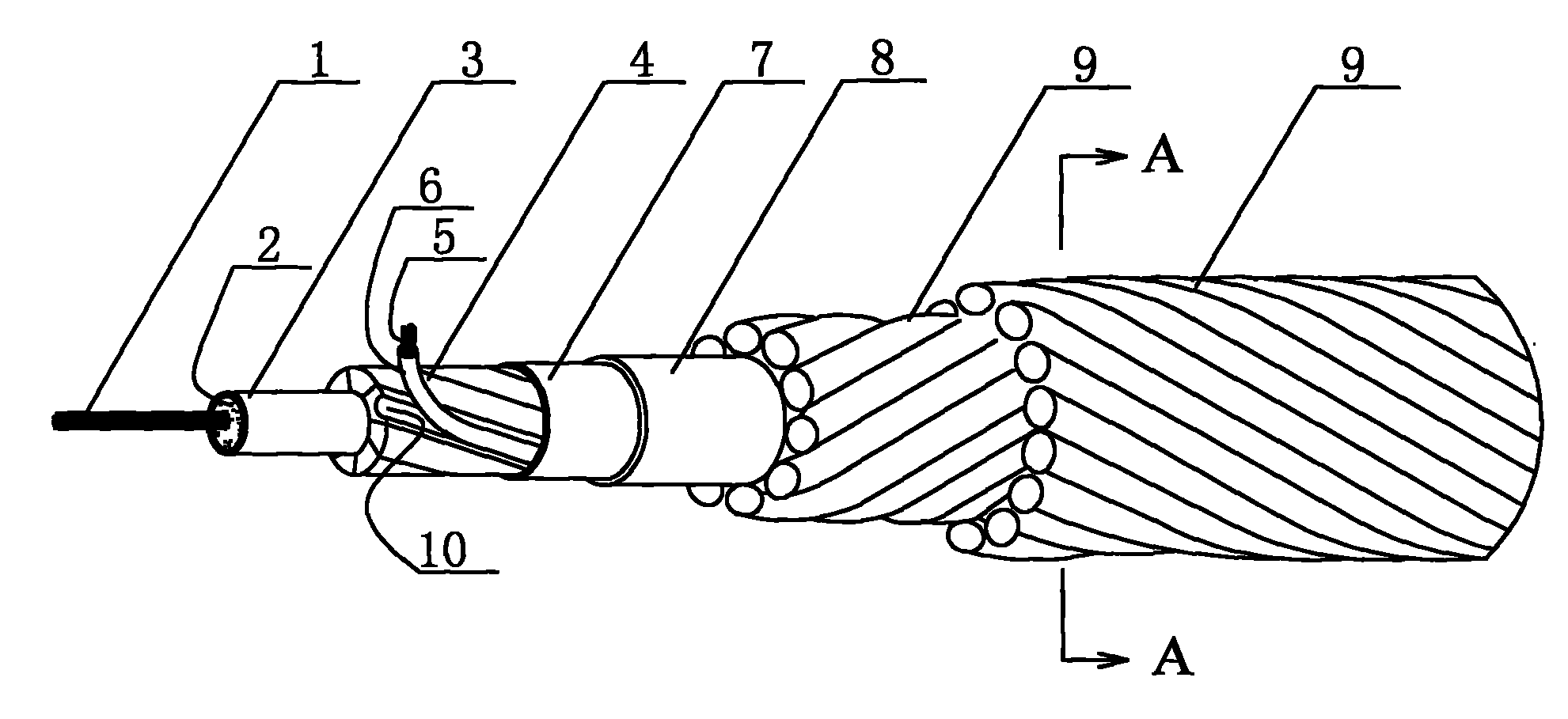

Photoelectric integrated and intelligent transfer wire

ActiveCN101783209AReduce weightHigh strengthNon-insulated conductorsCommunication cablesElectric power transmissionElectrical conductor

The invention discloses an intelligent transfer wire integrating electric power transmission, electric power communication and intelligent temperature sensing together, which comprises transmission fiber, a factice filling layer, a protection sleeve, a stiffening member, a temperature sensing fiber protective casing, an insulation layer, a protective layer and a conductor twisting layer, wherein,the factice filling layer is coated outside the transmission fiber, the protection sleeve is coated outside the factice filling layer, the stiffening member is coated outside the protection sleeve, the outer wall of the stiffening member is provided with a spiral groove, the temperature sensing fiber protective casing is embedded in the spiral groove, temperature sensing fiber is arranged in the temperature sensing fiber protective casing, the insulation layer is packed outside the stiffening member, the protective layer is packed outside the insulation layer, and one or a plurality of conductor twisting layers are packed on the outer wall of the protective layer. The wire of the invention integrates electric power transmission, electric power communication and intelligent temperature sensing together, thus having the advantages of light weight, good high strength, good corrosion resistance, good tenacity and the like.

Owner:WUXI HUANENG ELECTRIC CABLE

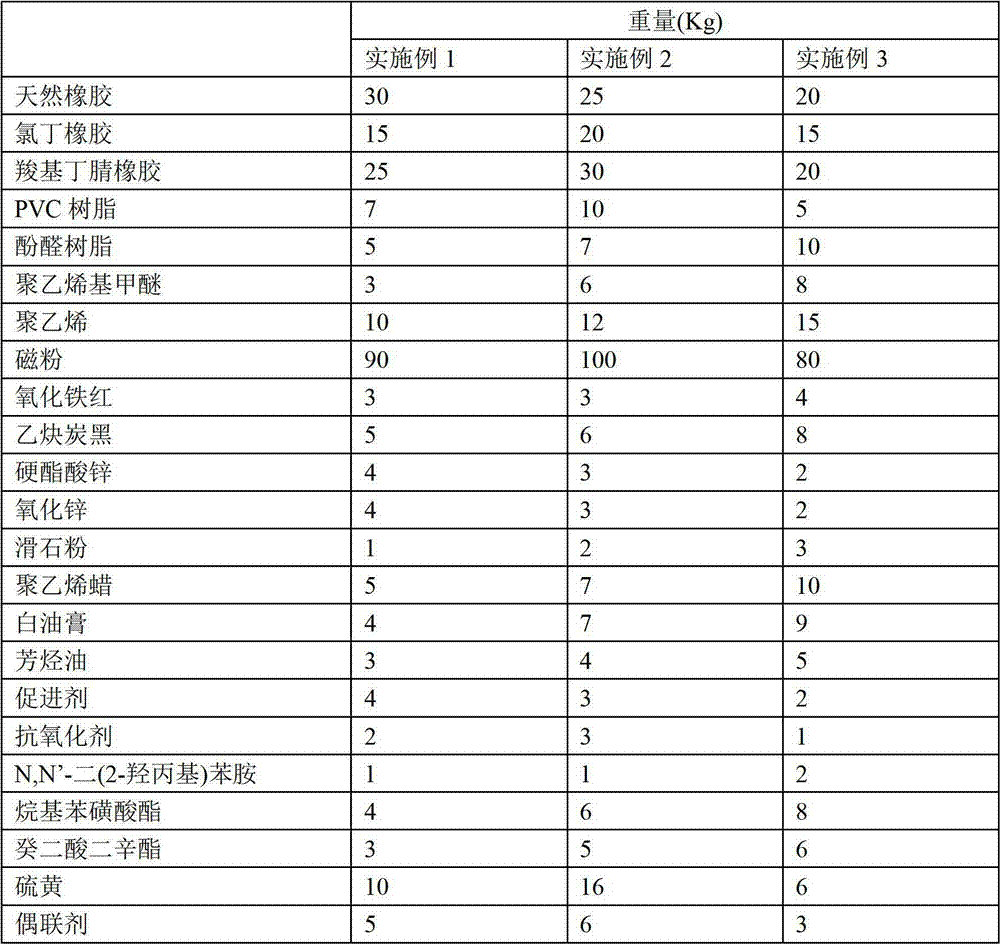

High-intensity magnetic rubber

InactiveCN102875854AImprove mechanical propertiesImprove magnetic propertiesPolymer sciencePolyvinyl chloride

The invention discloses a high-intensity magnetic rubber, belonging to the technical field of macromolecular materials. The magnetic rubber is made from the following raw materials by weight: 20-30 parts of natural rubber, 10-20 parts of chloroprene rubber, 20-30 parts of carboxylated nitrile rubber, 5-10 parts of PVC (Polyvinyl Chloride) resin, 5-10 parts of phenolic resin, 3-8 parts of polyvinyl methyl ether, 10-15 parts of polyethylene, 80-100 parts of magnetic powder, 3-4 parts of iron oxide red, 5-8 parts of acetylene black, 2-4 parts of zinc stearate, 2-4 parts of zinc oxide, 1-3 parts of French chalk, 5-10 parts of polyethylene wax, 4-9 parts of white factice, 3-5 parts of aromatic hydrocarbon oil, 2-4 parts of accelerant, 1-3 parts of antioxidant, 1-2 parts of N,N'-di(2-hydroxypropyl)aniline, 4-8 parts of alkyl besilate, 3-6 parts of dioctyl sebacate, 6-16 parts of sulphur and 3-6 parts of coupling agent. The tensile strength of the magnetic rubber can reach more than 5.5MPa, the elongation at break of the magnetic rubber can reach more than 400%, the Shore hardness of the magnetic rubber can reach more than 60%, and the magnetic induction intensity of the magnetic rubber can reach more than 720Gs.

Owner:昆明云垦橡胶有限公司

Nontoxic rubber color daub and preparation method thereof

The invention discloses a nontoxic rubber color daub and a preparation method thereof. The preparation method is characterized by comprising the following steps: mixing 5 to 30 portions of rubber elastomer, 5 to 25 portions of white factice, 20 to 80 portions of mineral filler, 1 to 10 portions of bonding agent, 5 to 20 portions of plasticizing agent, 0.1 to 10 portions of pigment, and 0.5 to 3 portions of anti-aging agent with or without proper amount of auxiliary materials on a mixing machine at a temperature of 50 to 250 DEG C; and mixing the rubber elastomer and the white factice evenly first, then adding other components, and mixing the components evenly. The nontoxic rubber color daub is nontoxic and pollution-free, has strong temperature difference adaptability, good hand feeling and bright color, and can not only be used as a toy for children and a tool for artists to make models, but also can be used as a building joint filling material.

Owner:NINGBO SONGHE STATIONERY

Eraser

An eraser composition comprising 22-41 wt % styrene-ethylene / butylene-styrene block copolymer, 5-15 wt % ethylene / propylene copolymer, 30-50 wt % calcium carbonate, 10-25 wt % factice; and 0.1-7 wt % pumice is provided. The eraser composition optionally contains up to 1 wt % titanium dioxide. The eraser composition preferably has a hardness of from 70 to 85 Shore A.

Owner:CRAYOLA

Insole of rubber foamed shoe and preparation method thereof

InactiveCN104817732AEasy to reboundEco-friendly formulaSolesDomestic footwearParaffin waxPolymer science

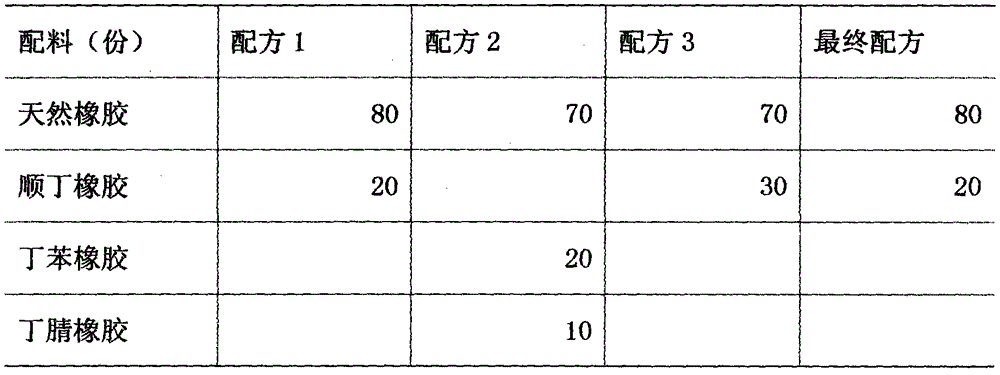

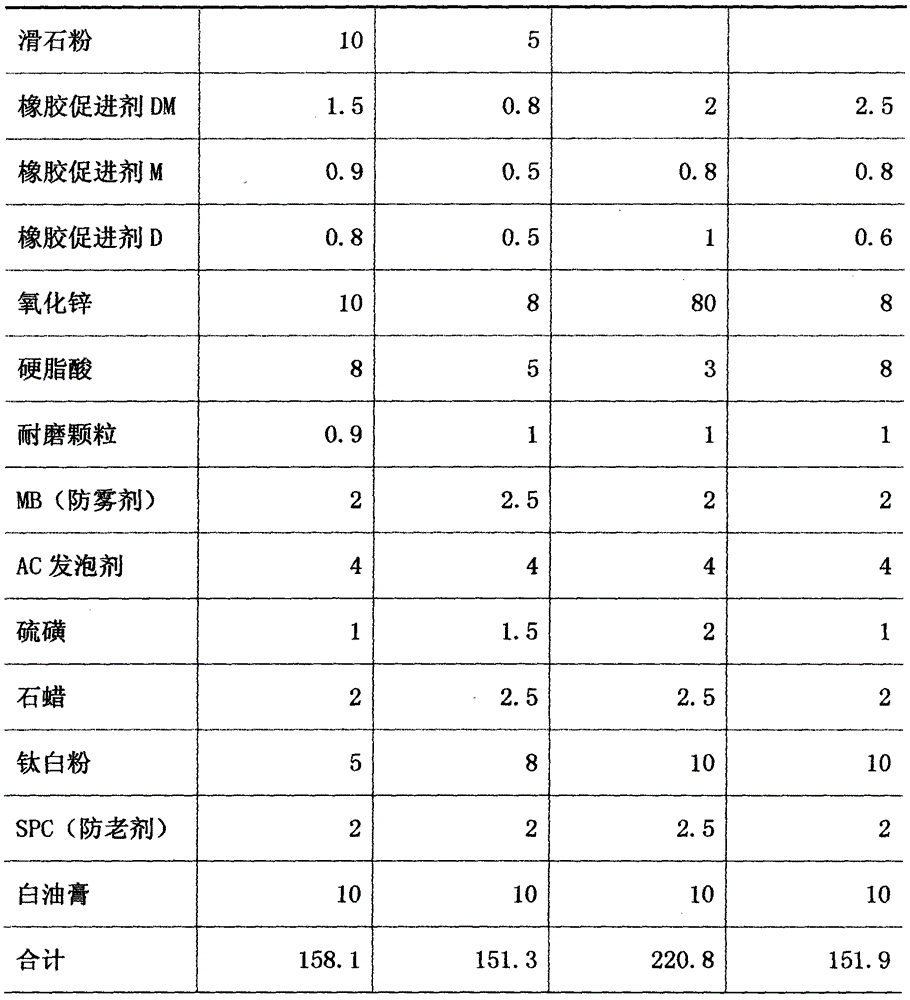

The invention discloses an insole of a rubber foamed shoe and a preparation method thereof. The insole comprises the following raw materials in parts by weight: 70-80 parts of natural rubber, 0-30 parts of cis-polybutadiene, 0.8-2.5 parts of rubber accelerator DM, 0.5-0.9 part of rubber accelerator M, 0.5-1 part of rubber accelerator D, 8-80 parts of zinc oxide, 3-8 parts of stearic acid, 0.9-1 part of wearproof particles, 2-2.5 parts of antifogging agent MB, 4-5 parts of foaming agent AC, 1-2 parts of sulfur, 2-2.5 parts of paraffin, 5-10 parts of titanium dioxide, 2-2.5 parts of anti-aging agent SPC and 10-15 parts of white factice. The preparation method comprises the following steps: putting the raw materials in the formula in a rubber mixing mill to be mixed for 30-35 minutes, thus obtaining a rubber foamed sheet; putting the prepared rubber foamed sheet in a bottom die, fixing a shoe last in a corresponding position on an upper die, sleeving the shoe last with an upper and carrying out foaming molding at a certain temperature for a certain time; removing the shoe last and the die, thus preparing the integrally formed rubber foamed shoe. The insole and the preparation method have the beneficial effects that the formula is environment-friendly; the process is simple; the shoe sole has good resilience; glue is not needed during one-time forming; the insole is free from debonding at high temperature and free from slipping at low temperature, is not broken, has light whole weight and is comfortable to wear.

Owner:郭萧

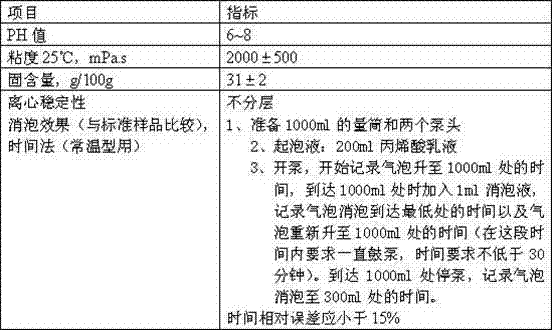

Preparation method of non-silicon defoaming agent

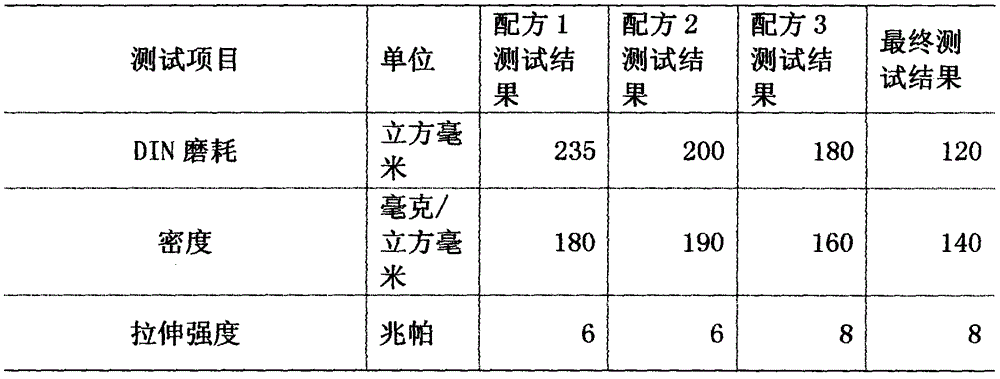

The invention discloses a preparation method of a non-silicon defoaming agent. The method is characterized in that the method comprises the steps that: first, a factice is prepared, wherein materials are blended according to a weight ratio that white mineral oil to white carbon black to polyether to polyether polyol to castor oil is 10-25:2-5:15-25:10-20:10-25; the materials are added into a reaction vessel provided with stirring blades, a motor and a heating system, and are well mixed under a room temperature; discharging can be carried out after 1h of stirring; 80 parts of the prepared factice, 20 parts of self-emulsifying silicone oil, 20 parts of tributyl phosphate, and 10 parts of a mixed emulsifier are well mixed by stirring; 280 parts of water is added such that the mixture is subjected to phase inversion; after phase inversion is completed, 16 parts of a thickening agent is added for regulating the viscosity to 1500-2000CS; and discharging and packaging are carried out. The preparation method is simple, production cost is low, and produced product is environment-friendly and has no pollution. Various performance indicators of the product are good. The non-silicon defoaming agent is suitable to be used in defoaming and foaming-inhibiting of water-based acrylic paints.

Owner:佛山市华联有机硅有限公司

Microwave vulcanized ethylene propylene diene monomer (EPDM) sponge sheath and processing method thereof

InactiveCN102336971AEasy to porosityEnsure completenessFlexible pipesPipe protection against damage/wearPolymer sciencePolyethylene glycol

The invention relates to a microwave vulcanized EPDM sponge sheath and a processing method thereof. Rubber components for the sponge sheath comprise EPDM rubber, fast extruding carbon black, light calcium carbonate, paraffin oil, white factice, a dehumidifying and antifoaming agent, zinc oxide, stearic acid, polyethylene glycol, azodicarbonamide, N-cyclohexyl-2-benzothiazolesulfenamide, dibenzothiazyl disulfide, tetramethyl-thiuram disulfide and sulphur. According to the invention, mixed stock is extruded by an extruder which works under the condition that temperatures of a head, a screw section, a plasticizing section and a feeding section are set; microwave vulcanization is carried out by allowing a semi-finished product extruded by the extruder to directly enter into microwave vulcanizing equipment for vulcanization, with microwave total power maintained to be in range of 6000 to 8000 W, temperature of a microwave section set to be 200 DEG C, and temperature of a heating section set to be 200 to 220 DEG C from beginning to end. The invention enables a uniformly distributed closed pore bubble structure to be formed easily and dimension of a product to be controlled easily. Rapid heat generation of microwave enables vulcanization time to be reduced to some extend, thereby improving production efficiency.

Owner:TIANJIN PENGYI GRP CO LTD

Water-resistant corrosion-resistant paint or water-resistant factice produced by using industrial organic waste as raw material

InactiveCN1434089ALow costSimple processRosin coatingsAnti-corrosive paintsPolyvinyl chlorideSemi solid

The present invention relates to a water-proofing anticorrosion coating material or building oil-containing semi-solid composition produced by using industrial organic wastes and its preparation method. The water-proofing anticorrosion coating material is a monocomponent or double-component resin modified imitation asphalt paint made up by compounding industrial organic wastes, modifying resin, SBS sizing material, mixing solvent, adjuvant, filler and solidifying agent, and the building oil-containing semi-solid composition is made up by mainly using industrial organic wastes, polyvinyl chloride resin and SBS sizing material as modifying agent. Said products are water-proof, and have strong anticorrosion performance, and their production process is simple.

Owner:JIANGNAN UNIV

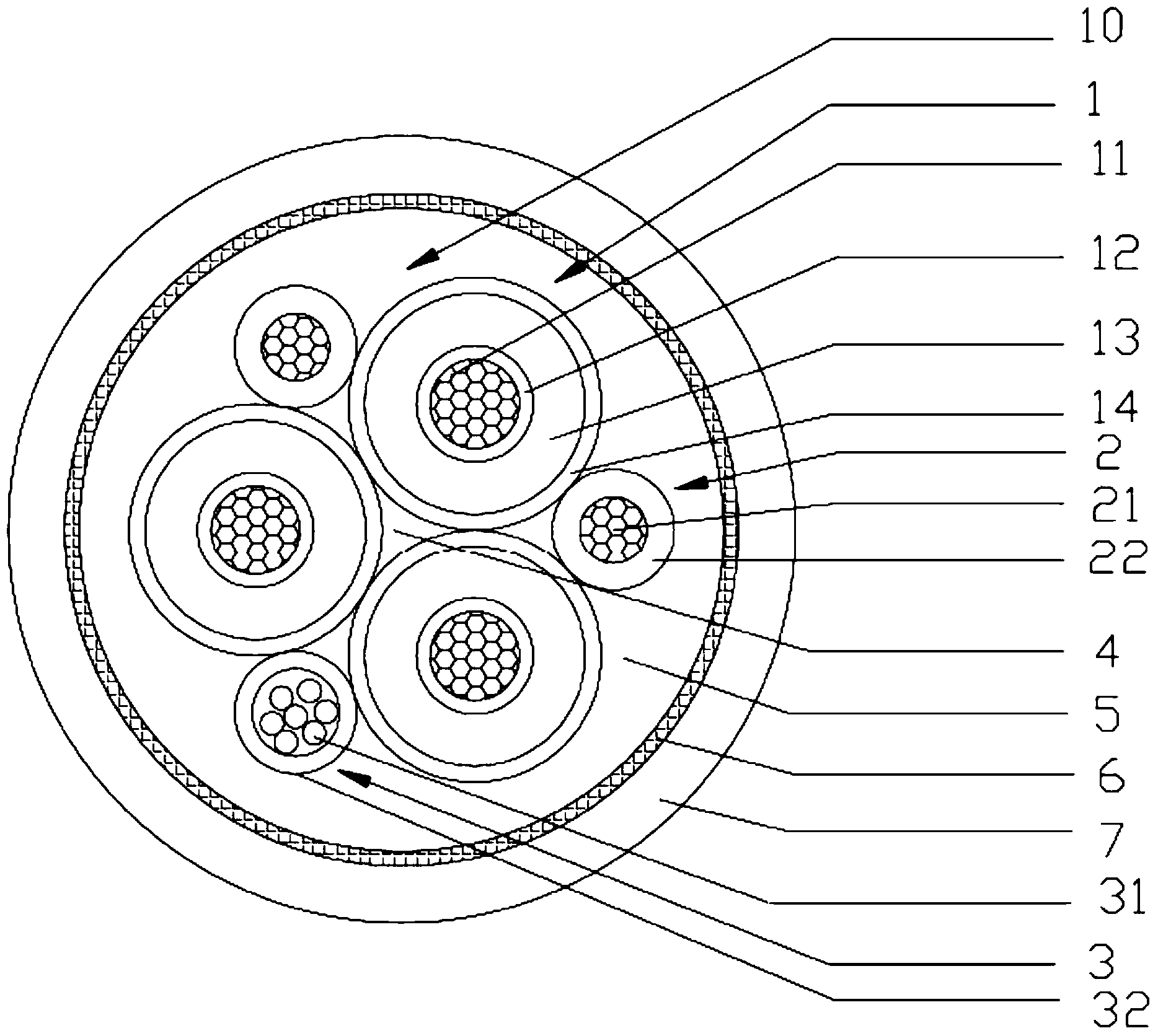

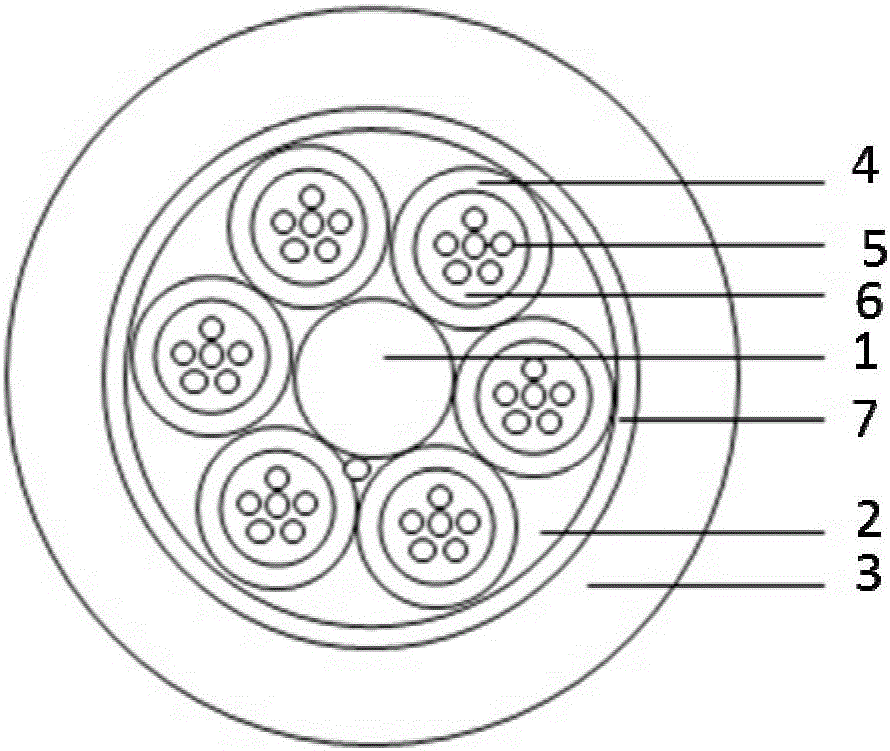

Torsion resistant photoelectric composite medium-voltage drum cable

ActiveCN104036859AExtended service lifeExtend your lifePower cables with screens/conductive layersInsulated cablesYarnPolytetramethylene terephthalate

The invention discloses a torsion resistant photoelectric composite medium-voltage drum cable. The torsion resistant photoelectric composite medium-voltage drum cable comprises a plurality of power line cores and a plurality of ground line cores which are twisted together to form a cable core, as well as at least one optical unit, a special chloroprene rubber inner sheath wrapping the cable core, a reinforcing layer which is woven at the exterior of the special chloroprene rubber inner sheath and is embedded in the special chloroprene rubber inner sheath, and a special chloroprene rubber outer sheath wrapping the reinforcing layer; in power line core conductors and ground line core conductors, the stranding directions of two adjacent layers are opposite, and the stranding direction of each layer is opposite to the stranding direction of strand lines in a corresponding layer; the reinforcing layer is a terylene wire-woven reinforcing layer; insulating layers in the power line cores are ethylene propylene rubber layers; loose bushings are made of polybutylene terephthalate plastics; water-resisting yarns are made of water-resisting aramid fibers; thixotropic composites are made of factice; and nonmetallic reinforcing members are made of aramid fibers. With the torsion resistant photoelectric composite medium-voltage drum cable of the invention adopted, the special chloroprene rubber sheaths are adopted as the inner sheath and the outer sheath of the cable, and therefore, the torsion resistant photoelectric composite medium-voltage drum cable has excellent low temperature resistance, wear resistance, oil resistance and other properties, and the service life of the cable can be prolonged.

Owner:JIANGSU HENGTONG POWER CABLE

Painted smooth mirror surface color-holding lip glaze and preparation method thereof

ActiveCN110638691AHigh glossImprove durabilityCosmetic preparationsMake-upEngineeringFilm-forming agent

The invention provides painted smooth mirror surface color-holding lip glaze and a preparation method thereof. The painted smooth mirror surface color-holding lip glaze comprises the following components in percentage by weight of 20-80% of grease, 0.1-15% of oil-in-water emulsifying agents, 0.05-15% of coloring agents, 0.5-10% of oil-phase film forming agents, 0.5-20% of water-phase film formingagents and the balance water. The painted smooth mirror surface color-holding lip glaze is an oil-in-water type lip product, oil is an inner phase, and the water is a continuous outer phase, so that the problem of greasy feeling of ointment type products can be well solved. Besides, the oil-phase film forming agents and the grease mutually cooperate to generate synergistic effects, so that the glossiness, the persistence and the nourishing degree can be greatly increased.

Owner:广州那比昂生物科技有限公司

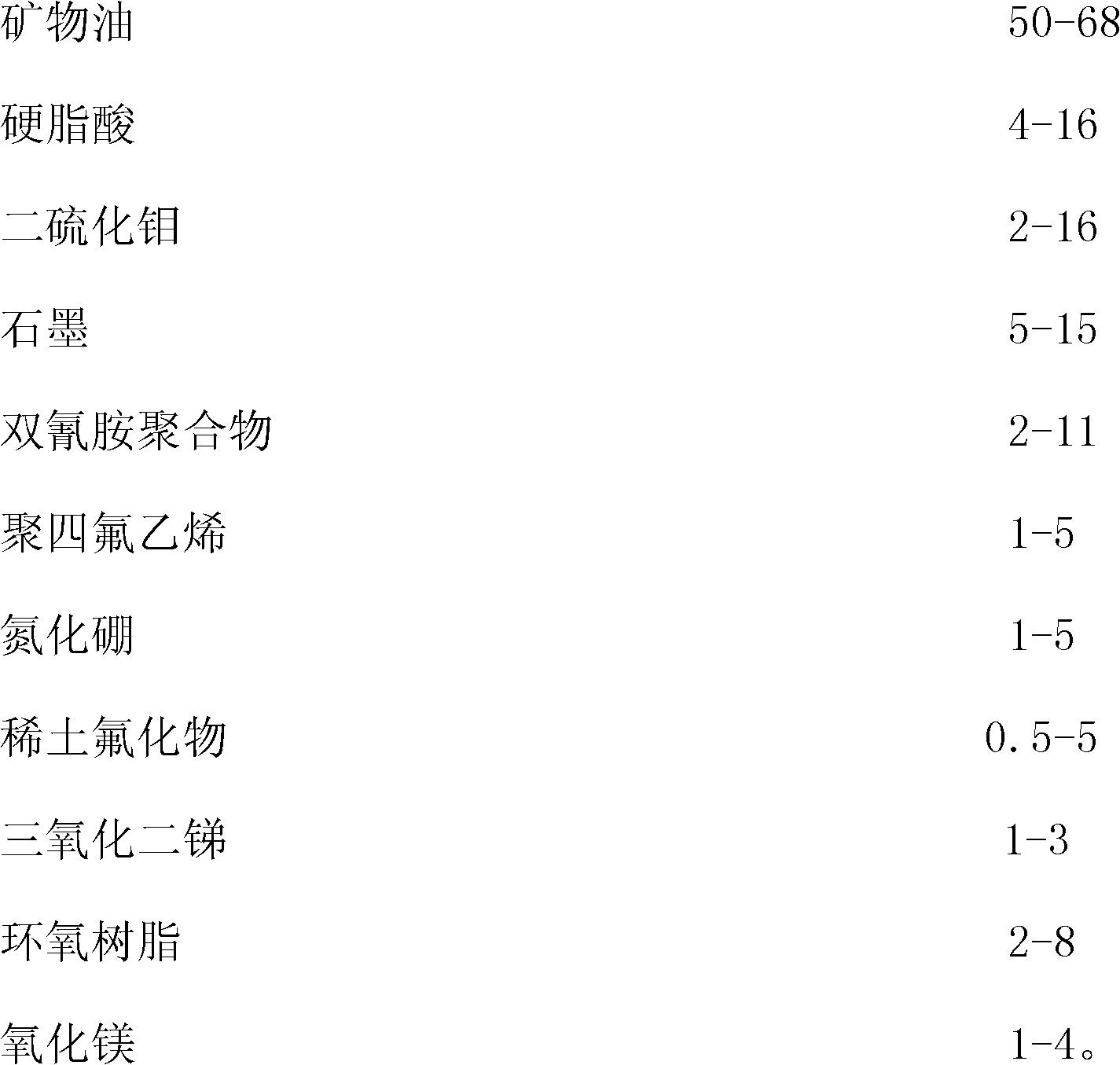

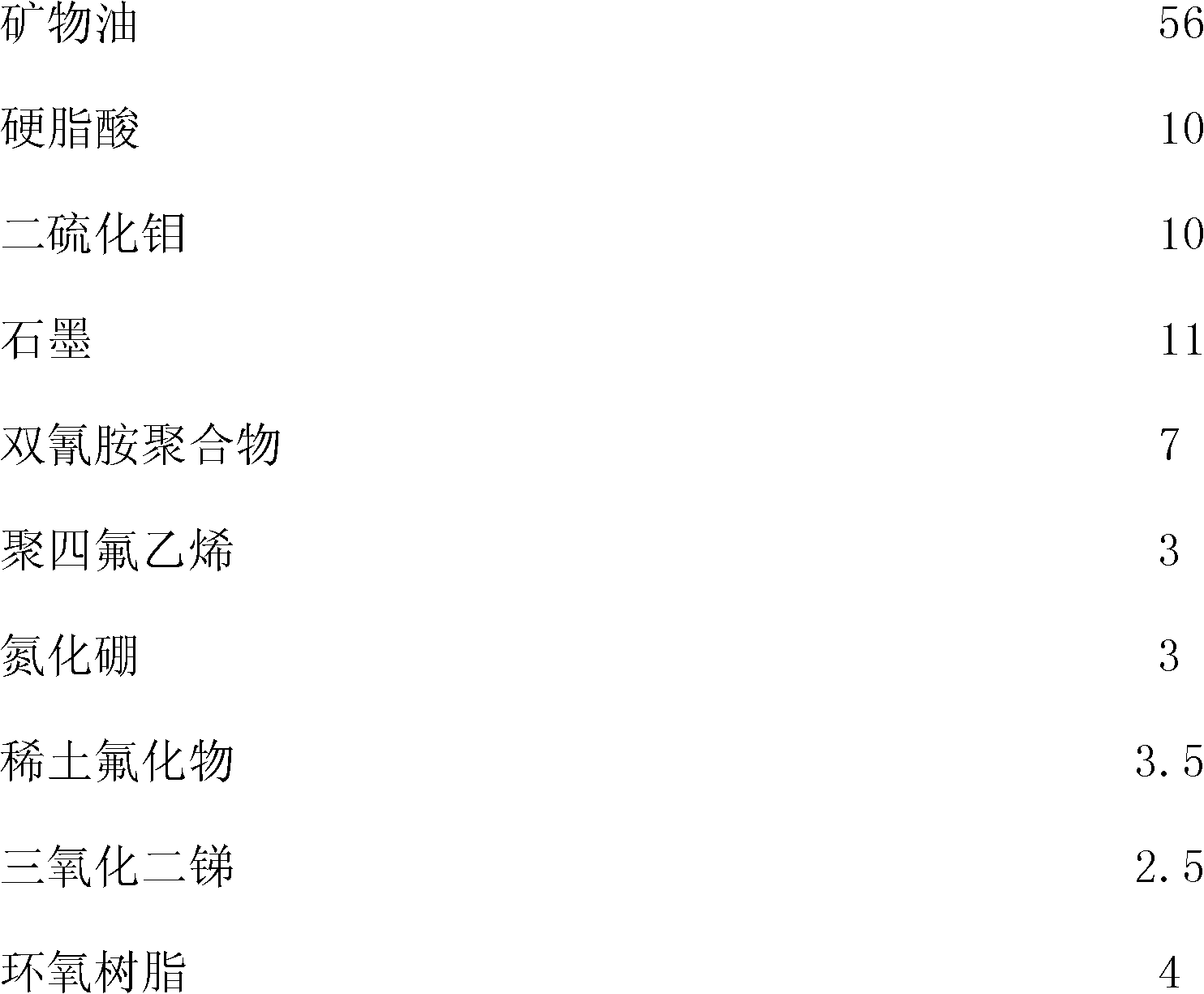

Wear-resisting protective factice for rail wheeltrack

The invention provides wear-resisting protective factice for a rail wheeltrack, comprising the following raw materials in parts by weight: 50-68 parts of mineral oil, 4-16 parts of stearic acid, 2-16 parts of molybdenum disulfide, 5-15 parts of graphite, 2-11 parts of dicyandiamide polymer, 1-5 parts of polytetrafluoroethylene, 1-5 parts of boron nitride, 0.5-5 parts of rare earth fluoride, 1-3 parts of antimony trioxide, 2-8 parts of epoxy resin and 1-4 parts of magnesium oxide. In the invention, due to the addition of the magnesium oxide, the wear resistance of the factice is improved by 700min, and the wear-resisting protective factice has a remarkable practical value.

Owner:XI'AN KAIFENG RAILWAY MECHANICAL AND ELECTRICAL EQUIPMENT CO LTD

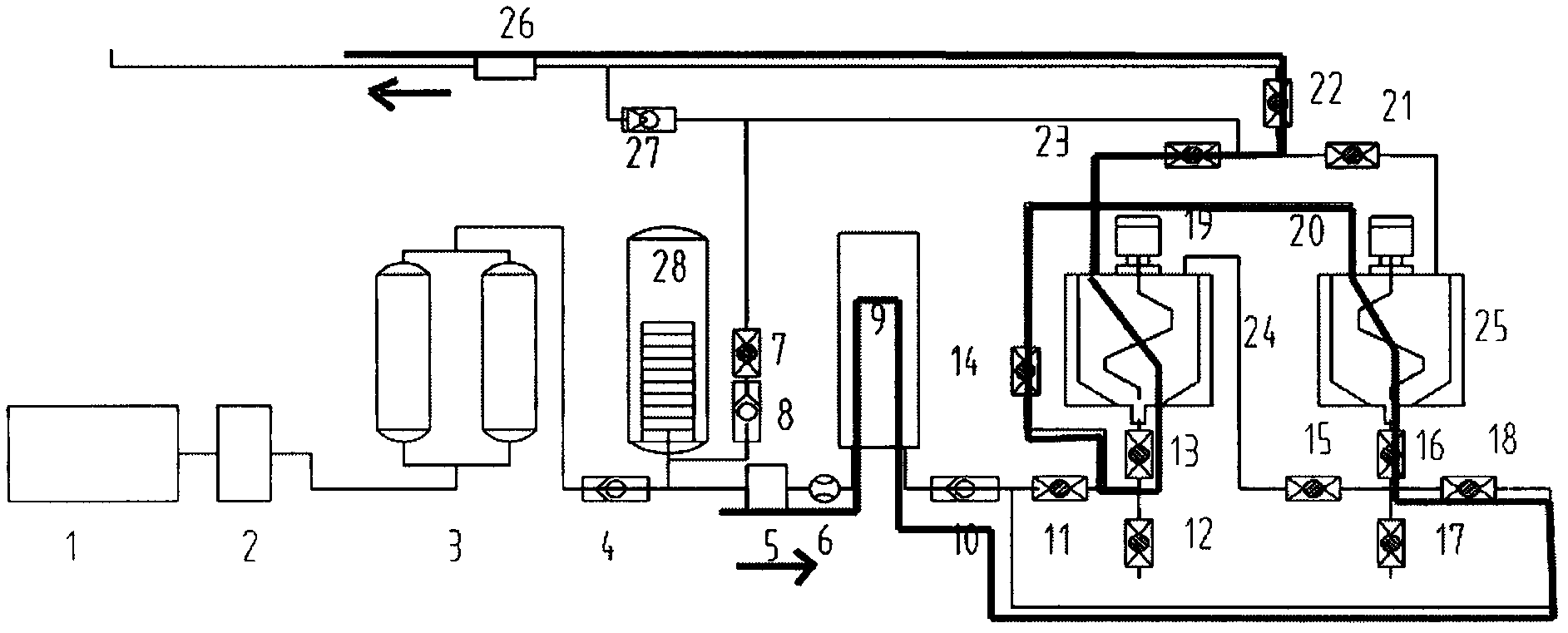

Device and method for efficiently producing stable ozone (O3) ointment

InactiveCN102406549AImprove stabilityImprove efficiencyPharmaceutical product form changeVegetable oilCoconut oil

The invention relates to a production process for efficiently transforming vegetable oil (such as olive oil, coconut oil, sunflower seed oil and the like) into stable ointment containing ozone (O3). In the production process, two-stage reaction kettles in series connection and a residual gas recovery technology are adopted and the temperature of the reaction kettles can be controlled so that efficiency and O3 utilization ratio are improved and stability of O3 oil is strengthened. The production process can be used for producing the stable O3 ointment in large quantity; and the obtained O3 ointment can be applied to treatment of skin diseases and skin beauty and has good sterilizing effect.

Owner:李明利

Military camouflage ointment and preparation thereof

The invention relates to a military camouflage ointment and a preparation method thereof, comprising 70 to 92 parts of matrix raw material; 1 to 8 parts of lake; 1 to 6 parts of titanium oxide; 1 to 6 parts of nano-zinc oxide; and 5 to 10 parts of DEET. Mineral oil and dimethyl silicone oil are firstly mixed and stirred, hydrogenated castor oil, ceresin and lanolin are added till the dissolution; talcum powder, the titanium oxide and the nano-zinc oxide are further added and stirred for even mixing; the lake and the DEET are added, and then the homogenization, the filling, the sealing and the preservation are carried out. The ointment of the invention can solve the technical problems that the existing military camouflage ointment can not simultaneously meet the purposes of meeting camouflage, preventing UV burns, infrared ray, visible light and mosquito bites, the ointment of the invention can prevent the UV burns, the mosquito bites and the infrared ray, thus having the advantages of safety, no allergy, no toxicity or side effects, mild aroma, good air permeability, insolubility in water, easy cleaning, high performance-price ratio, convenient carrying and good stability.

Owner:XIAN HANGJIE CHEM TECH

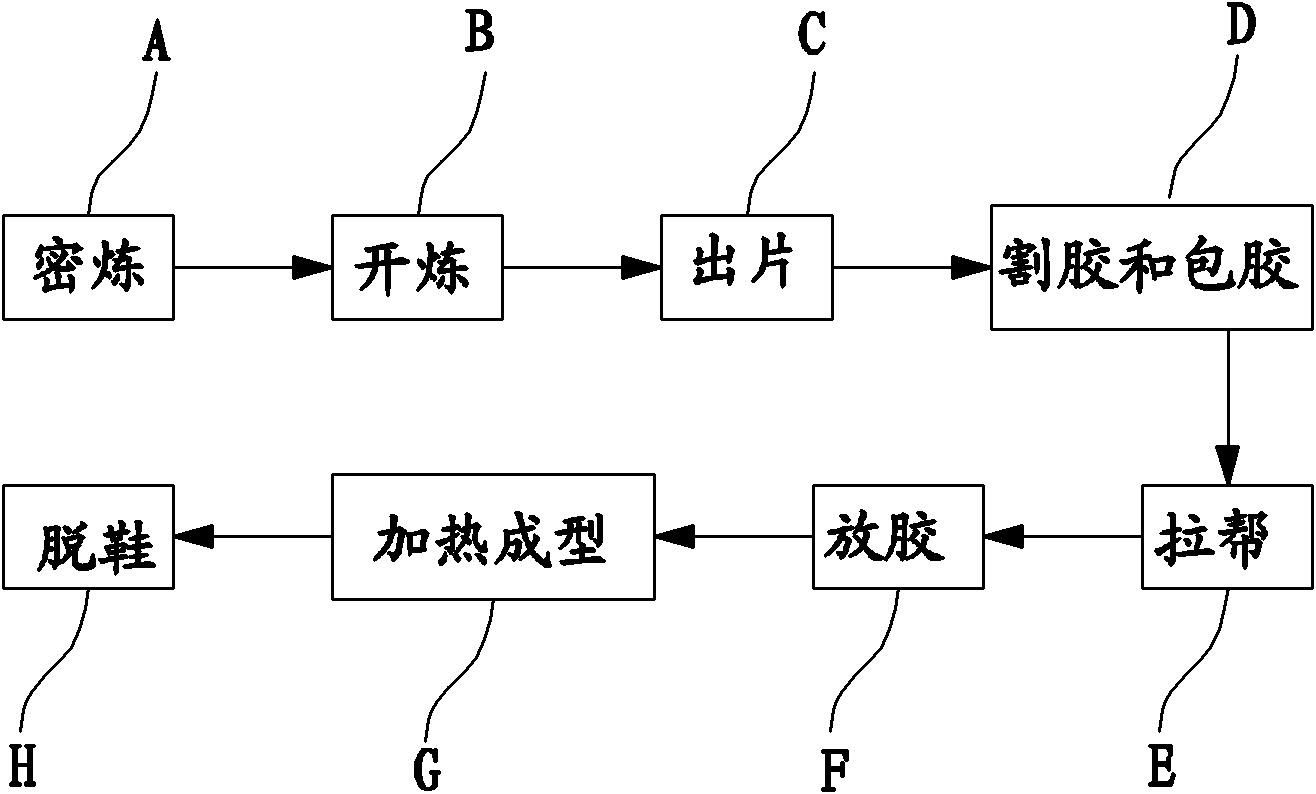

Sole formula and production process thereof

The invention discloses a sole formula and a production process thereof. The formula comprises the following components: 3-5 parts of natural rubber, 10-13.8 parts of isoprene rubber, 5-7 parts of talc powder, 10-14.5 parts of nano ointment, 3-5.6 parts of white carbon black, 0.94-1.2 parts of zinc carbonate, 0.1-0.3 part of flow promoter, 0.01-0.03 part of DCP (Dicumyl Peroxide), 0.188-0.276 part of anti-aging agent, 0.125-0.25 part of protective wax, 0.05-0.08 part of p-toluenesulfonyl, 0.1-0.2 part of sulfur and 0.025-0.05 part of foaming agent. The production process comprises the procedures of banburying, open milling, sheet discharging, rubber tapping, rubber coating, bringing up, sizing, heating, molding, taking off shoes and the like. The sole produced by adopting the production process has the characteristics of high binding property, high elasticity, high stretching strength, high tear resistance, high electrical insulating property, high wear resistance, high drought resistance, low temperature resistance, noise resistance, high processability and the like.

Owner:福建晋江市越峰鞋塑有限公司

Method for extracting tea essential oil from oolong tea stalks

ActiveCN102504956ALow impurity contentImprove efficiencyEssential-oils/perfumesDistilled waterProcess engineering

The invention discloses a method for extracting tea essential oil from oolong tea stalks. The method comprises the following steps of: putting the oolong tea stalks serving as raw materials into a tea stalk distillation device, adding distilled water, and distilling; measuring petroleum ether, adding into a petroleum ether distillation device, and distilling; connecting the tea stalk distillation device and the petroleum ether distillation device through a glass guide pipe, fully mixing volatile gas distilled from the tea stalks and petroleum ether steam in a gas storage bag, introducing mixed steam into a condensation pipe, condensing to form oil-water mixed liquid, and refluxing the mixed liquid to a separating funnel; refluxing a water phase and an oil phase in the separating funnel to a first flask and a second flask respectively, so that the circular extraction process is finished once; repeating the process to fully extract the essential oil from the tea stalks; and taking the second flask with the petroleum ether out, concentrating a solution in the second flask, and collecting to obtain tea essential oil paste. By the method, the extraction cost of the tea essential oil can be reduced, and the economic benefit of tea processing is improved.

Owner:HUAXIANG YUAN TEA IND

Water resistant leather cup material

The invention discloses a water resistant leather cup material, which is composed of the following raw materials in parts by weight: 90 to 95 parts of butyronitrile rubber, 2 to 4 parts of epoxy linseed oil, 30 to 40 parts of filling material, 8 to 12 parts of zinc stearate, 1 to 2 parts of aluminum nitride, 1 to 2 parts of white factice, 0.3 to 0.6 part of antioxidant 168, 0.1 to 0.5 part of anti-aging agent RD, 2 to 3 parts of dimethyl decanedioate, 1 to 2 parts of bamboo charcoal powder, and 1 to 3 parts of fast extruding carbon black N550. The material has a high environmental fire resistant and water resistant performance and a long service life, can be used under severe and damp circumstance, and maintains excellent and stable properties at the same time.

Owner:WUHU JIACHENG ELECTRONICS TECH

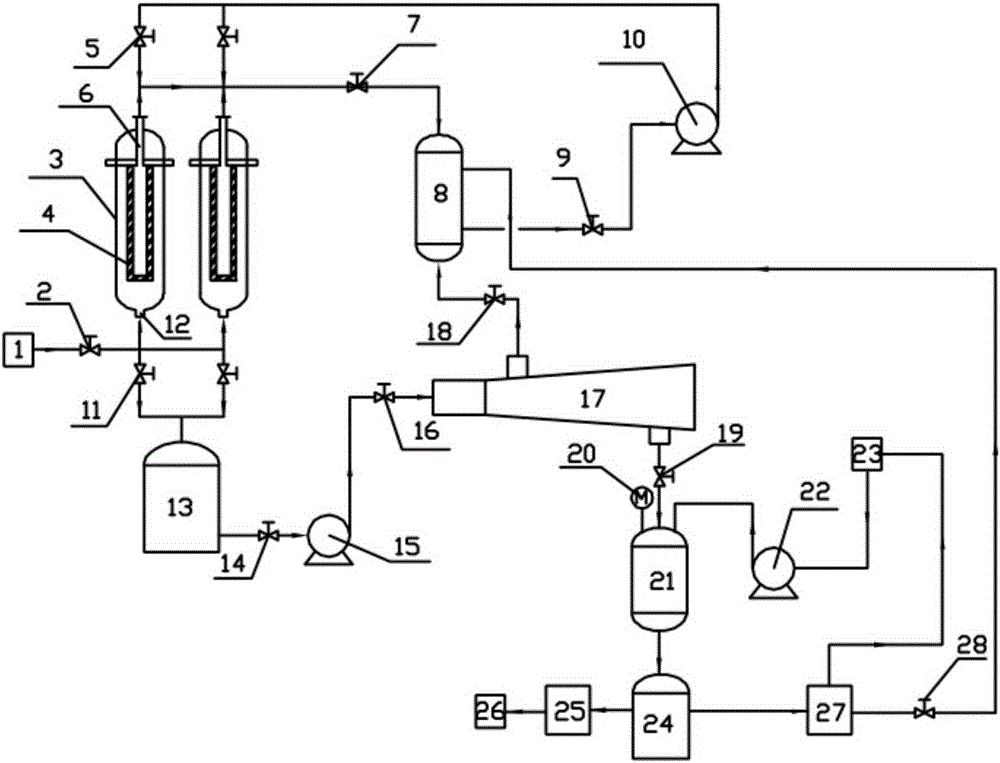

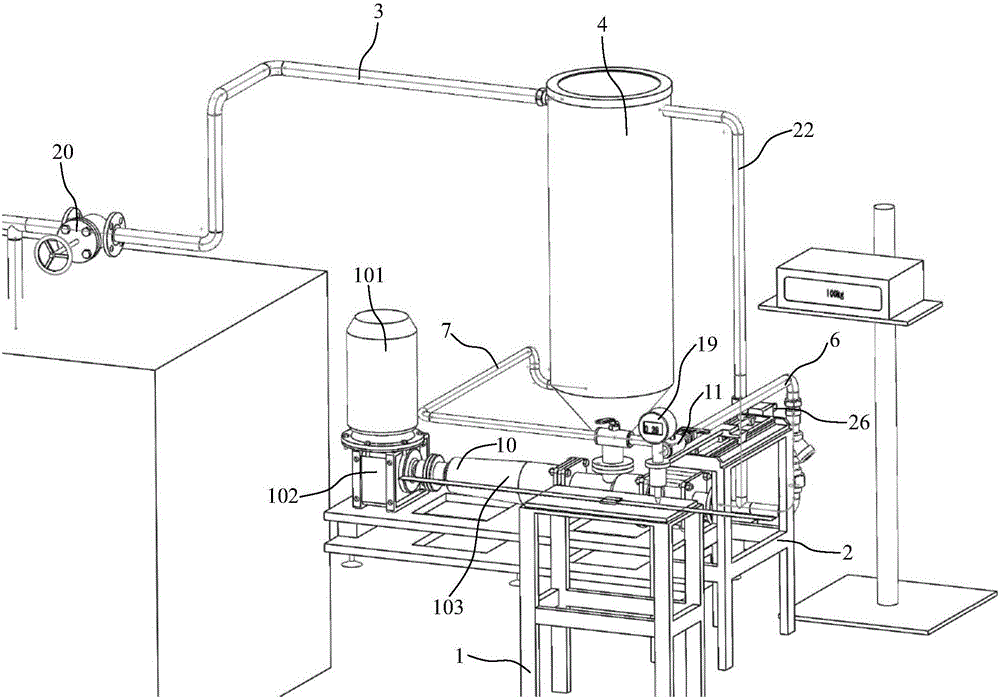

Dust removal purification device and method for crude coal tar

InactiveCN105327550AGuaranteed uptimeEasy to handleFiltration circuitsTar working-up by solvent extractionDistillationTar

The invention discloses a dust removal purification device and method for crude coal tar. The dust removal purification device comprises a backwashing filter, a horizontal decanter centrifuge, a residual oil buffer tank, a purified tar tank, a factice tank, a vacuum filter, a dryer and a distillation apparatus, wherein a filter element is arranged in a cavity of the backwashing filter, and dust-containing coal tar is purified continuously through filtering and backwashing of the filter element; residual oil after backwashing enters the horizontal decanter centrifuge for liquid-solid separation, and purified tar and factice are obtained. In order to increase the recovery rate of the purified tar sufficiently, the factice is extracted with a recycling solvent, and final products of a system comprise purified coal tar and dry cinders. The backwashing filter and the horizontal decanter centrifuge are adopted to cooperate with the solvent extraction system for dust removal purification of the crude coal tar, through graded and stepped treatment, the treating capacity of the system is improved sufficiently while the coal tar is recovered to the greatest extent, besides, the solvent is recycled, and energy saving and environmental protection are realized.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Wear-resistant drilling pump valve sealing gasket and its preparation method

The invention discloses a wear-resistant drilling pump valve sealing gasket and a preparation method thereof. The sealing gasket consists of the following raw materials by weight: 50-60 parts of isoprene rubber (SKI-3), 15-25 parts of styrene butadiene rubber (SBR1712), 10-15 parts of PTFE, 10-15 parts of modified nano diamond, 5-10 parts of nano silicon nitride, 4-7 parts of white factice, 2-3 parts of zinc dibutyl dithiocarbamate, 16-22 parts of high abrasion furnace black N330, 3-4 parts of insoluble sulfur powder M-80, 2-3 parts of zinc oxide, 1-2 parts of manganese dioxide, 1-2 parts of stearic acid, 2-3 parts of 2-(2, 4-dinitrophenyl thio) benzothiazole, and 1-2 parts of N-cyclohexylthiophthalimide. Compared to a traditional sealing gasket, the sealing gasket provided by the present invention has the advantages of low friction wear, good resilience and high compressive strength, and can prolong the service life of the product in the use process in the same conditions.

Owner:TONGLING SIDE TECH

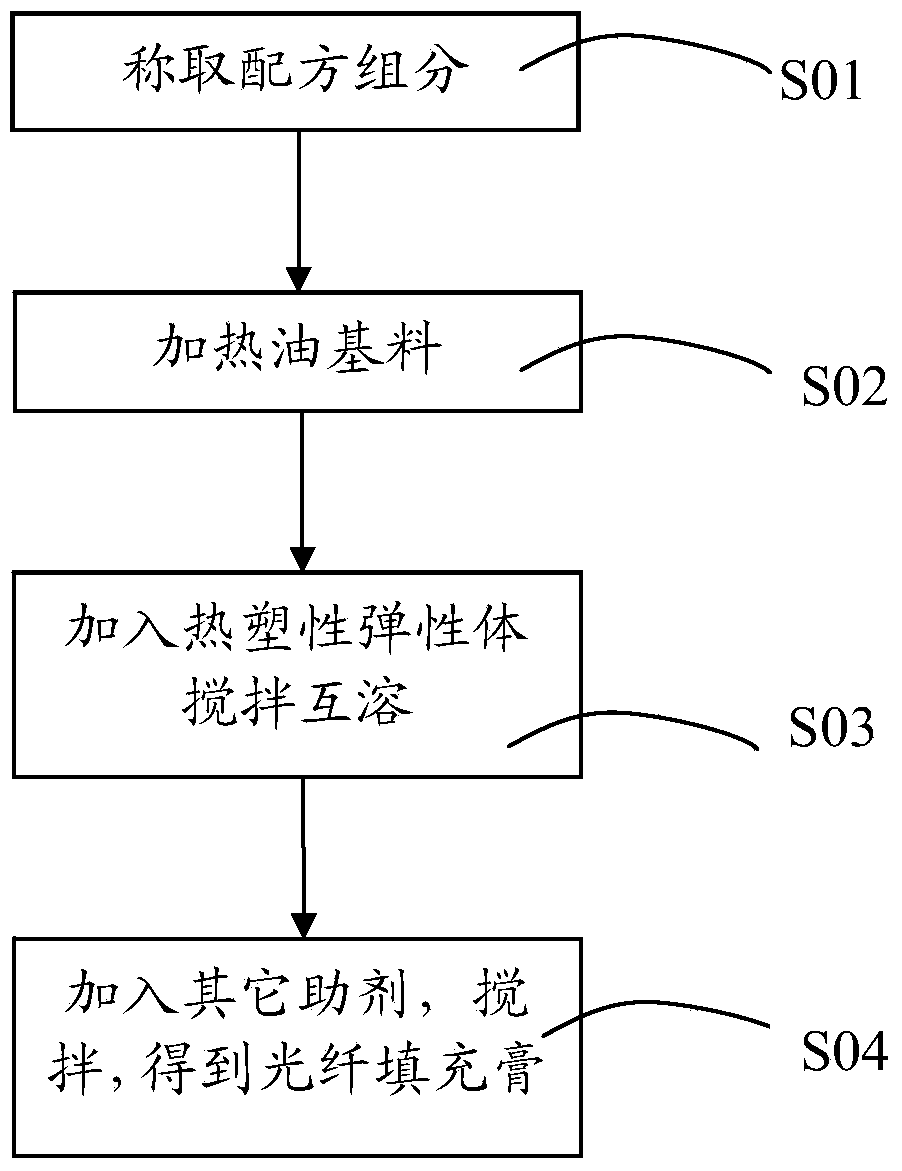

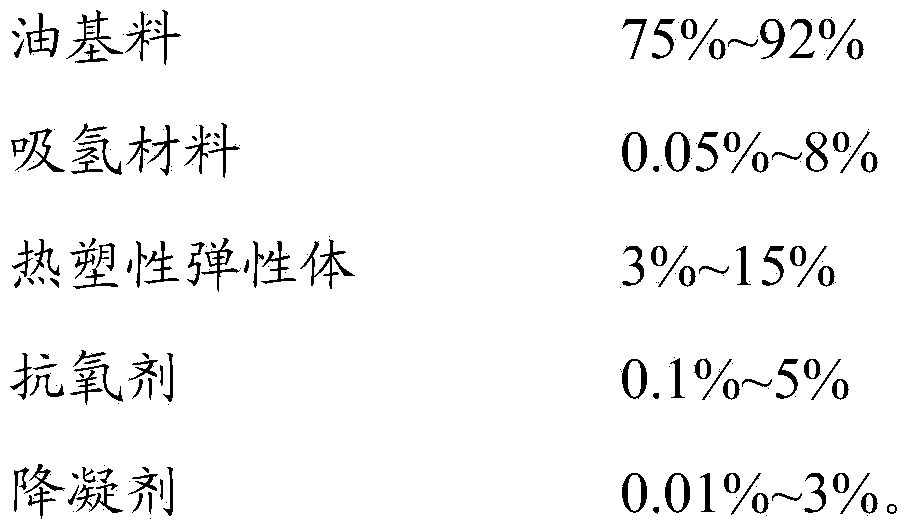

Fiber filling paste and preparation method thereof

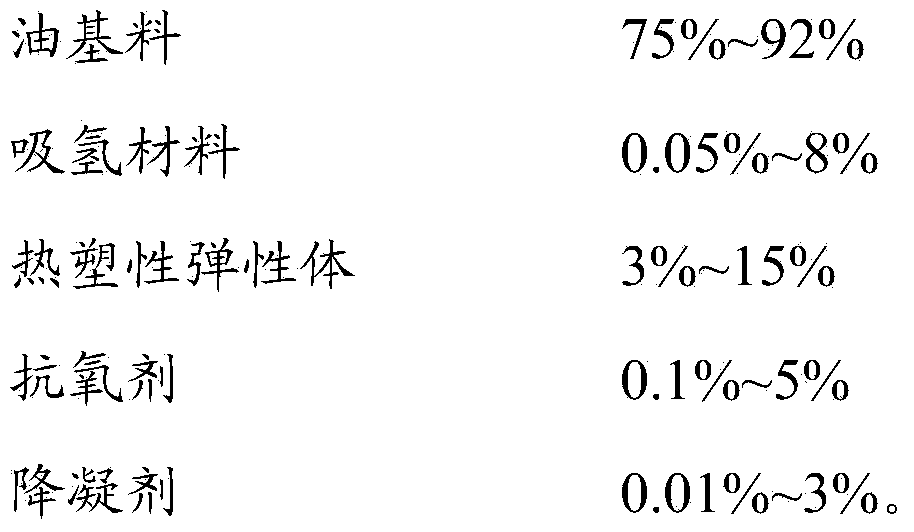

InactiveCN104181655AWith hydrogen absorption functionLow viscosityFibre mechanical structuresFiberHydrogen

The invention discloses a fiber filling paste and a preparation method thereof. The fiber filling paste comprises the following formula ingredients with the following weight percentage: 75%-92% of oil base material, 0.05%-8% of hydrogen absorbing material, 3%-15% of thermoplastic elastomer, 0.1%- 5% of antioxidant, and 0.01%-3% of pour point depressant. The fiber filling paste has the hydrogen-absorption function through the use of the hydrogen absorbing material, and meanwhile adopts the thermoplastic elastomer as a constitution body of a paste net structure. The fiber filling paste has good compatibility with a plurality of oil base materials and adopts the antioxidant and the pour point depressant compositely to have a synergies effect, thereby preventing the risks of high viscosity of the filling paste, hard cone penetration, high hydrogen evolution value and oil paste leakage due to the use of silicon dioxide inorganic thickening agent, calcined silicon dioxide or bentonite. The preparation process is simple; the requirement on the manufacture device is low; and each performance index of products is convenient to control.

Owner:SHENZHEN XIN CHANG LONG NEW MATERIALS TECH CO LTD

Deep sea cable

ActiveCN104318991AHigh strengthImprove adhesionSubmarine cablesInsulated conductorsPower cableElectromagnetic interference

The invention discloses a deep sea cable. A filling layer is covered with a wrapping tape layer, the center of the filling layer is filled with a reinforcing inner core, three power cables are evenly distributed on the outer ring of the reinforcing inner core, the wrapping tape layer is covered with a metal shielding layer in an adhesion mode, the metal shielding layer is covered with an inner coating, the inner coating is covered with an armor layer, the gap between the inner coating and the armor layer is filled with a water-resisting factice layer, the armor layer is sleeved with an outer coating, and an external fixing concave groove is formed in the outer coating. According to the deep sea cable, the water-resisting factice layer and the filling layer achieve the effects of two water-resisting tapes from outside to inside, the metal shielding layer achieves the electromagnetic interference preventing effect, the filling layer and the reinforcing inner core both achieve the effect of reinforcing the strength of the cable, a balance weight can be installed in the external fixing convex groove in the outer coating, the adhesive force of the cable to the sea bed can be enhanced, and the influences of sea bed ocean currents on fixation of the cable are well avoided.

Owner:江西吉恩海缆有限公司

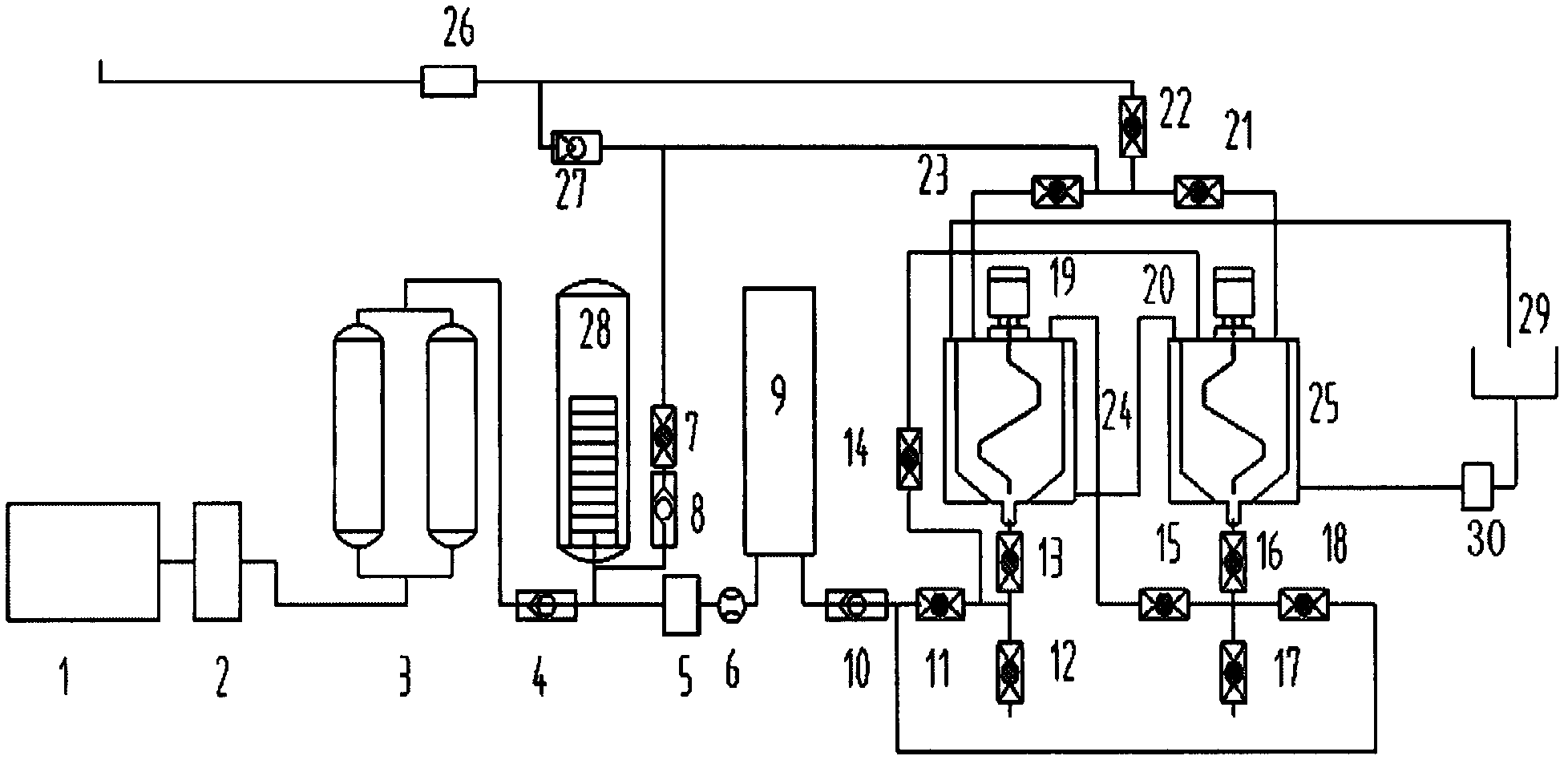

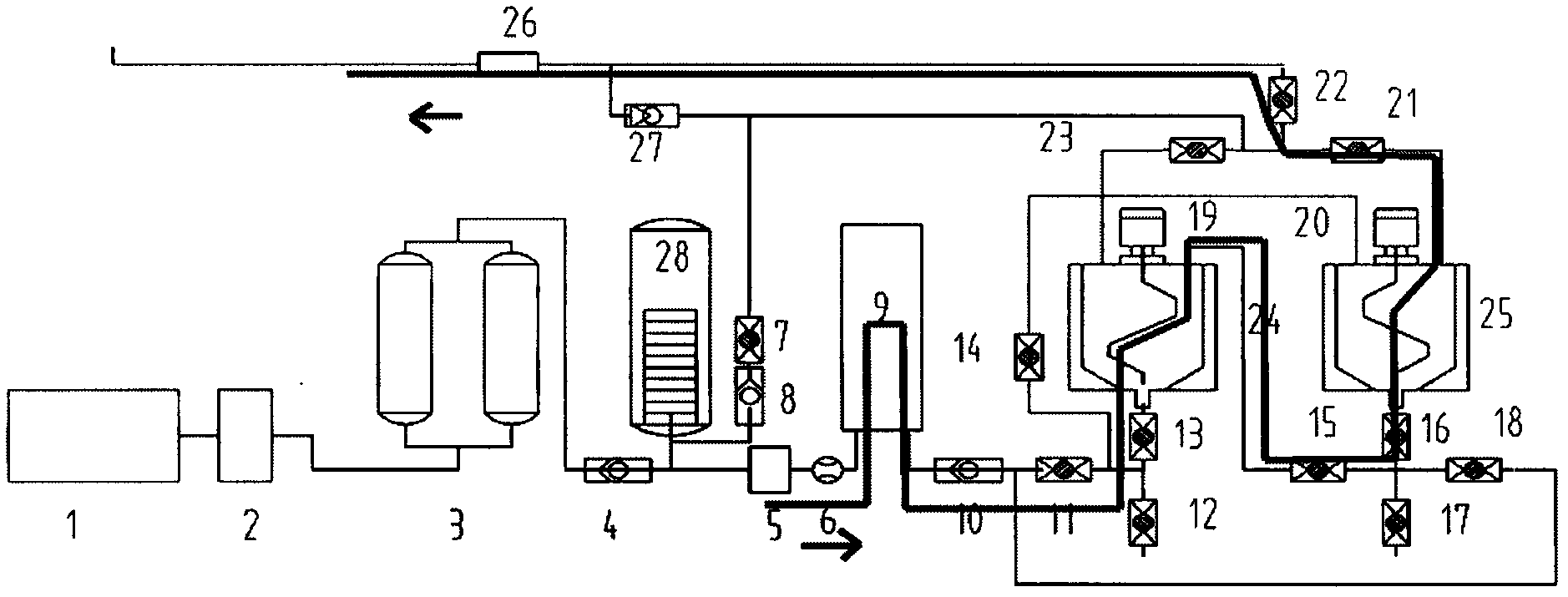

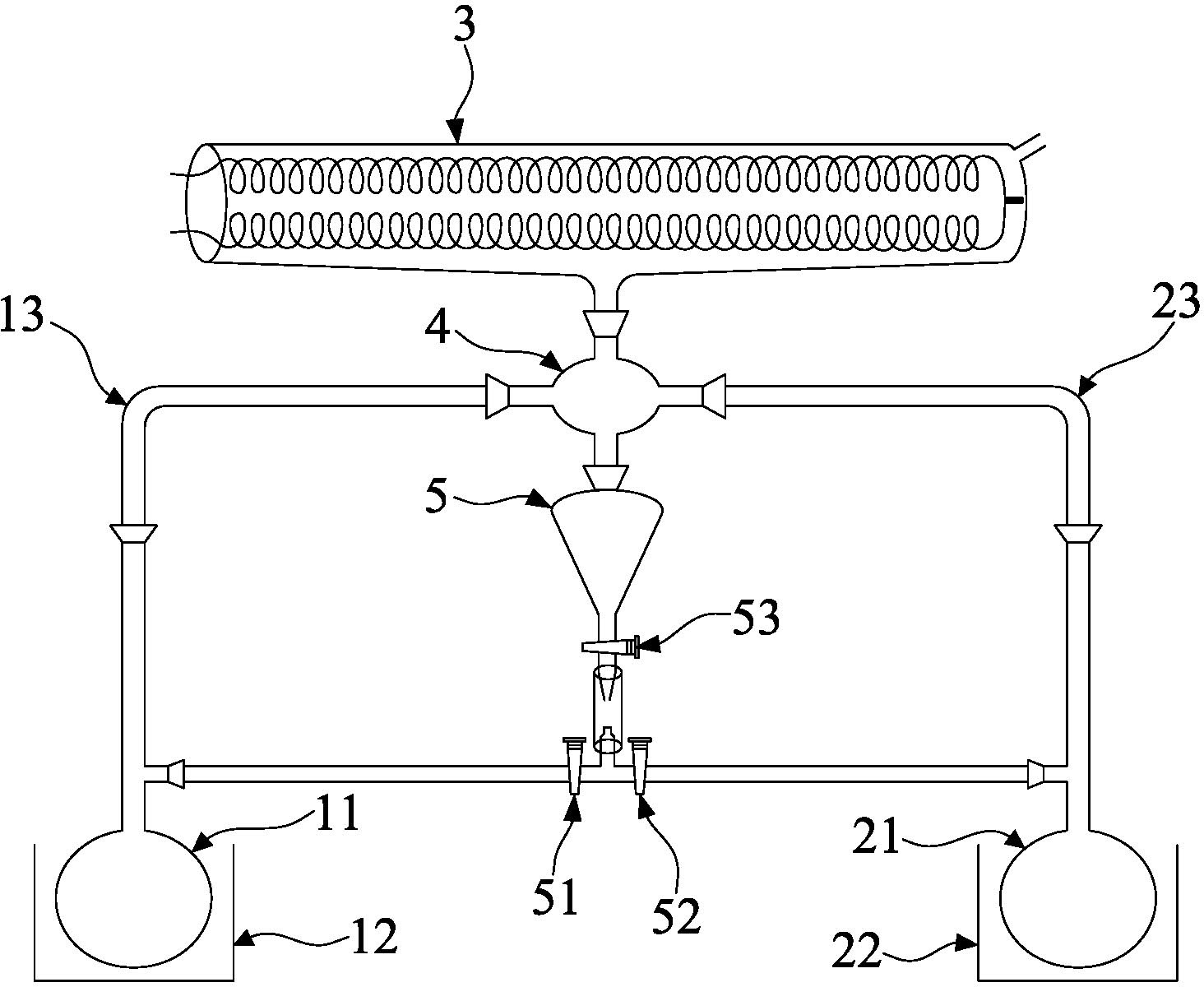

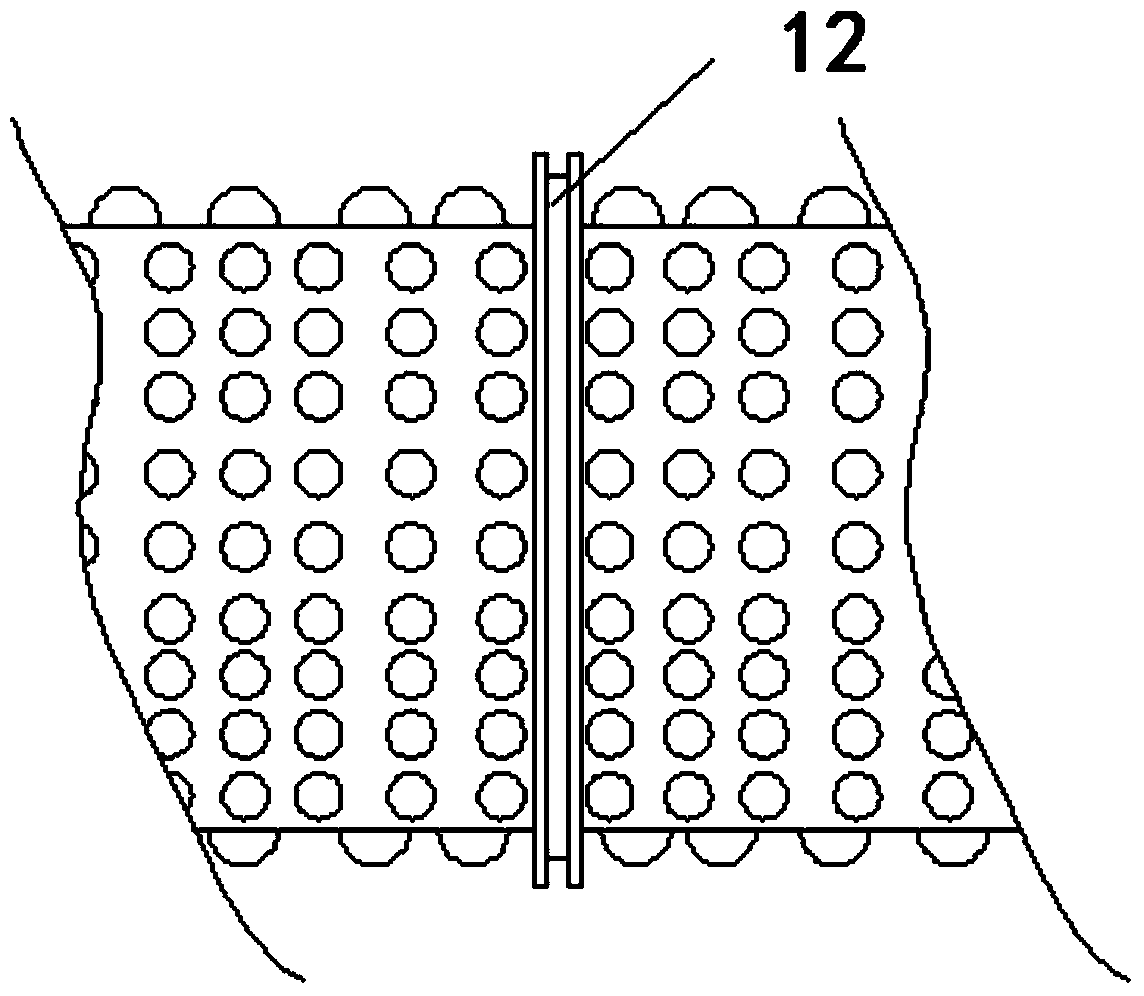

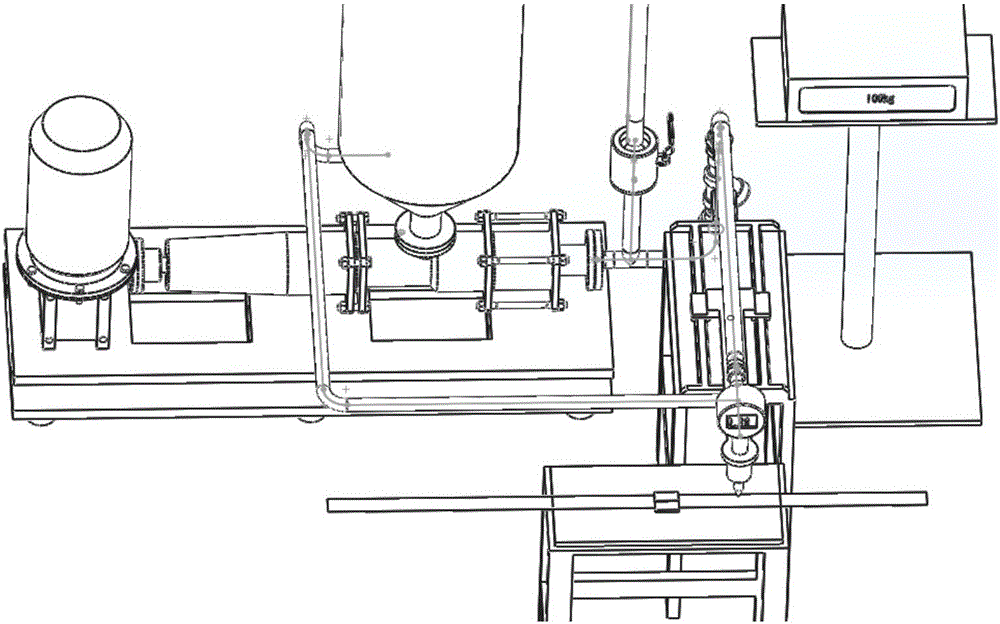

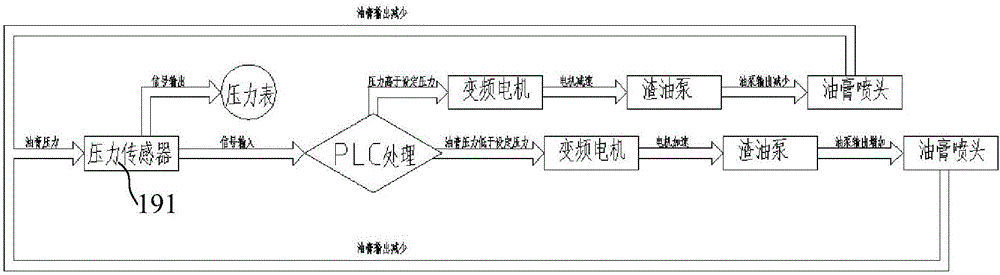

Optical fiber and cable factice spraying system adjusting spraying amount intelligently

ActiveCN106019513AGuaranteed uniformityImprove reliabilitySpraying apparatusFibre mechanical structuresFrequency changerSpray nozzle

The invention discloses an optical fiber and cable factice spraying system adjusting spraying amount intelligently. The optical fiber and cable factice spraying system comprises an oil conveying pipe, a first oil return pipe, an oil inlet pipe, a PLC control module, an factice pushing mechanism and an image recognition module, wherein an oil supply pipeline is provided with an electromagnetic valve, and the PLC control module is connected with a variable frequency motor, the electromagnetic valve, the image recognition module and a servo motor; the PLC control module receives a spray nozzle factice real-time pressure value signal from a pressure sensor of a digital display intelligent pressure gauge; when a factice trajectory in an actual factice trajectory image is too narrow, the PLC control module controls the variable frequency motor to accelerate through a frequency converter, a screw pump accelerates the rotation speed to increase output until the trajectory tends to a set pattern; and when a factice trajectory in the factice trajectory image is too wide, the PLC control module controls the variable frequency motor to decelerate through the frequency converter. The optical fiber and cable factice spraying system realizes the automatic judgment of factice outlet amount and maintains the factice outlet amount at a stable numerical value, realizes the automatic increase and decrease of the factice, and ensures the uniformity of the coated factice.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

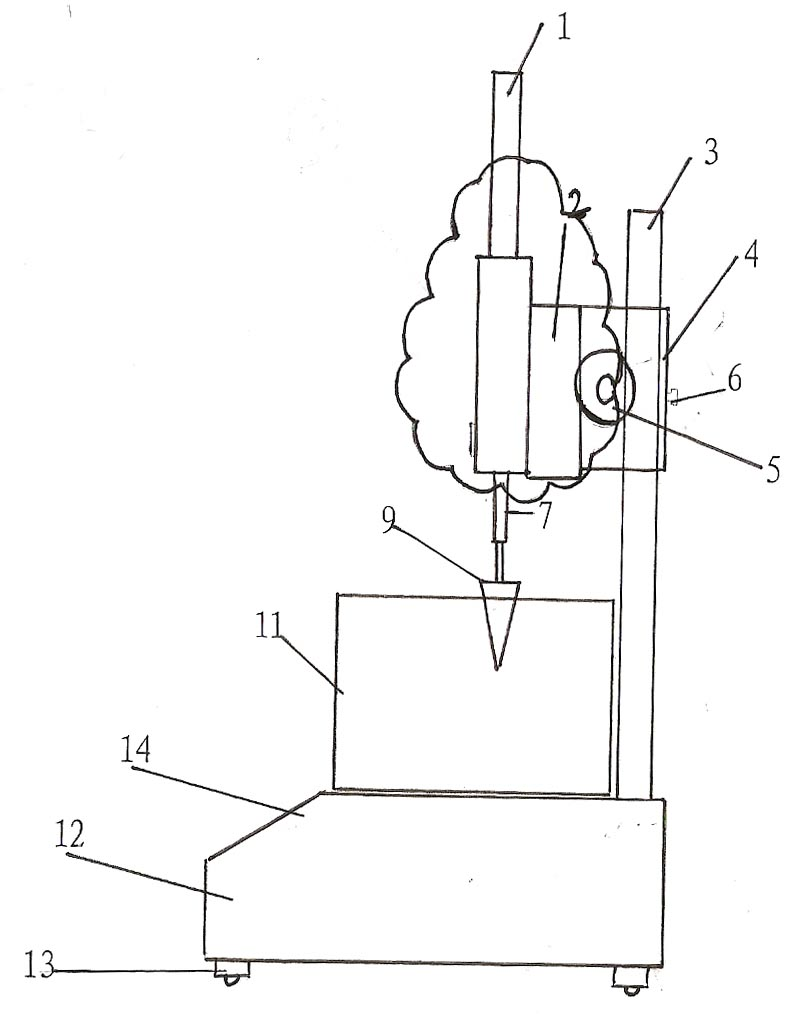

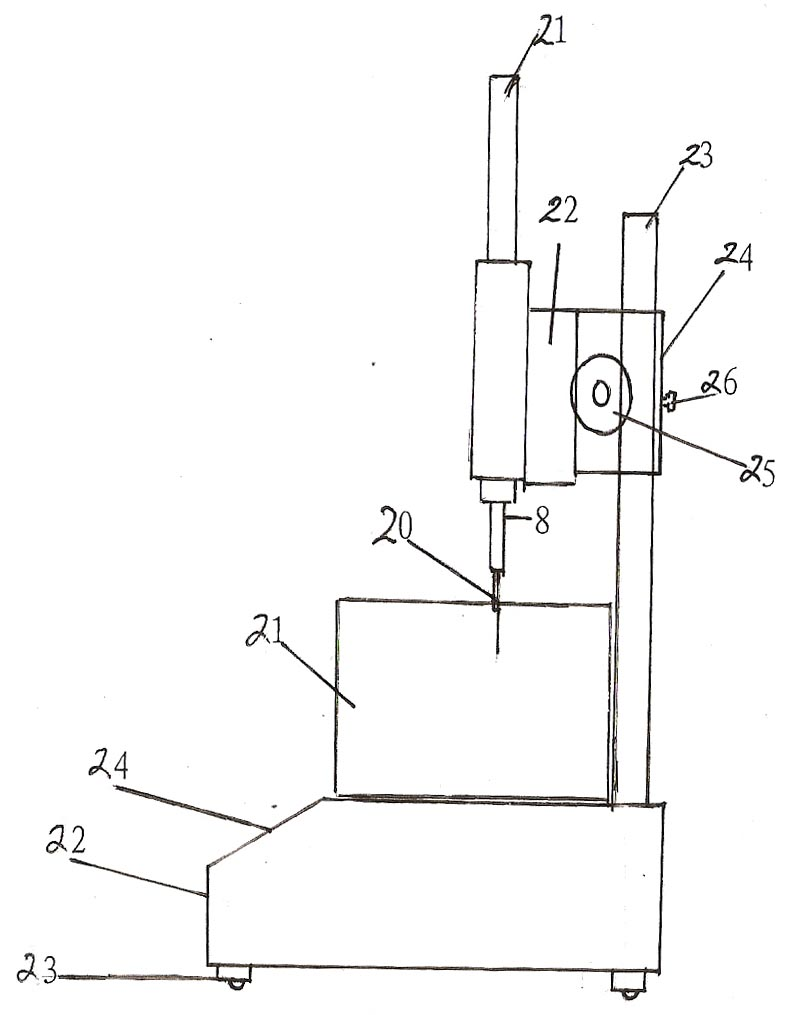

Factice construction degree and asphalt needle penetration computer comprehensive determinator

InactiveCN102607998AReasonable structureImprove detection accuracyFlow propertiesNumerical controlNeedle penetration

The invention discloses a factice construction degree and asphalt needle penetration computer comprehensive determinator, which is characterized by comprising a base, wherein a vertical rod is arranged on the base, a liftable measuring head device is arranged on the vertical rod, a release control device controlled by an electromagnet is arranged on the measuring head device, the release control device controlled by the electromagnet can be combined with a chuck in a releasable manner, and the chuck is connected with a falling member which falls into an object to be measured in the measuring process in a releasable manner, and a displacement measuring device which is connected with a computer numerical control device is arranged above the release control device. The factice construction degree and asphalt needle penetration computer comprehensive determinator is reasonable in structure, not only can be used for determining the construction degree of factice for caulking of building waterproof asphalt, simultaneously can be used for measuring the needle penetration of petroleum asphalt, liquid petroleum asphalt and residues obtained after evaporation for paving highroads, changes the current simulation that the construction degree of factice is measured by manual control, greatly improves the detection precision and has advancement and practicability, thereby improving the engineering quality.

Owner:NANTONG ACADEMY OF BUILDING RES

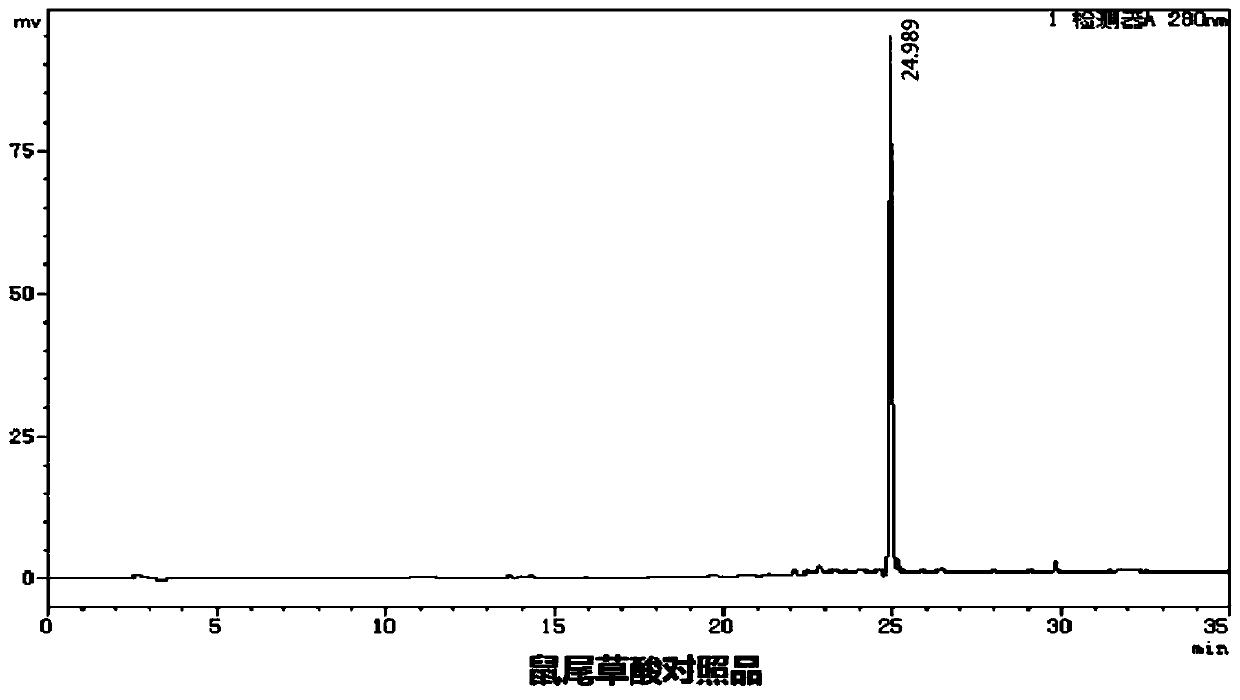

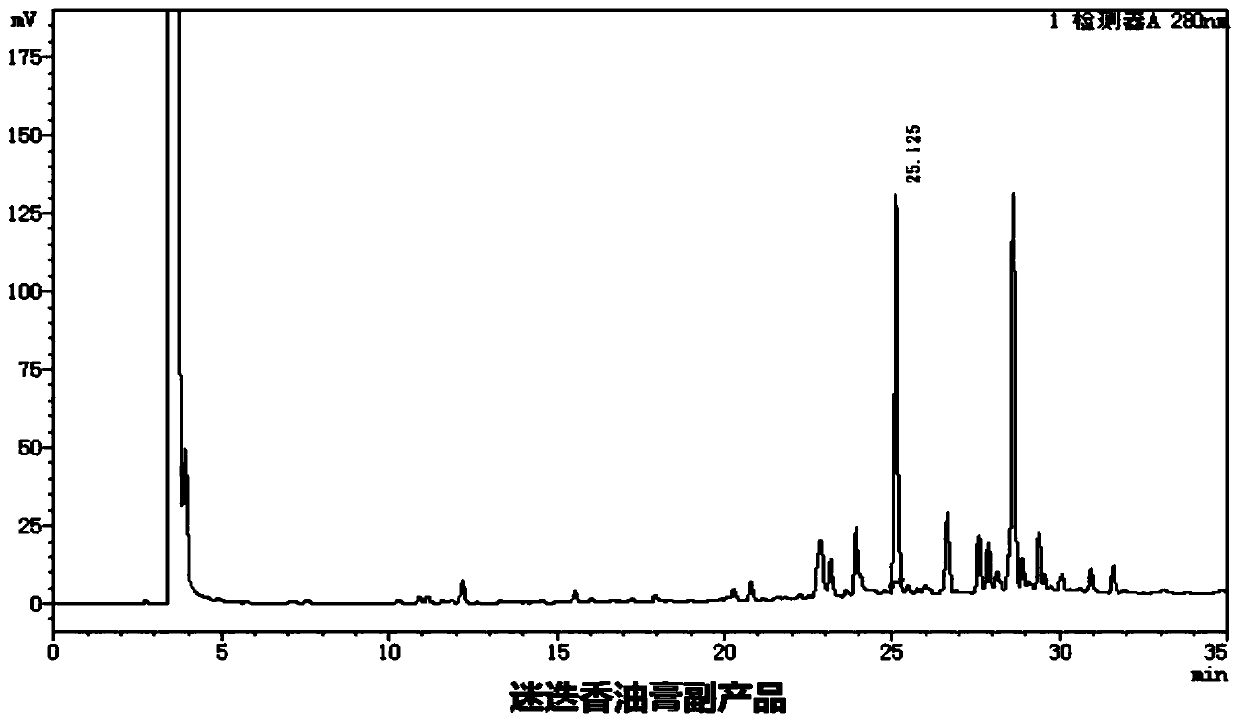

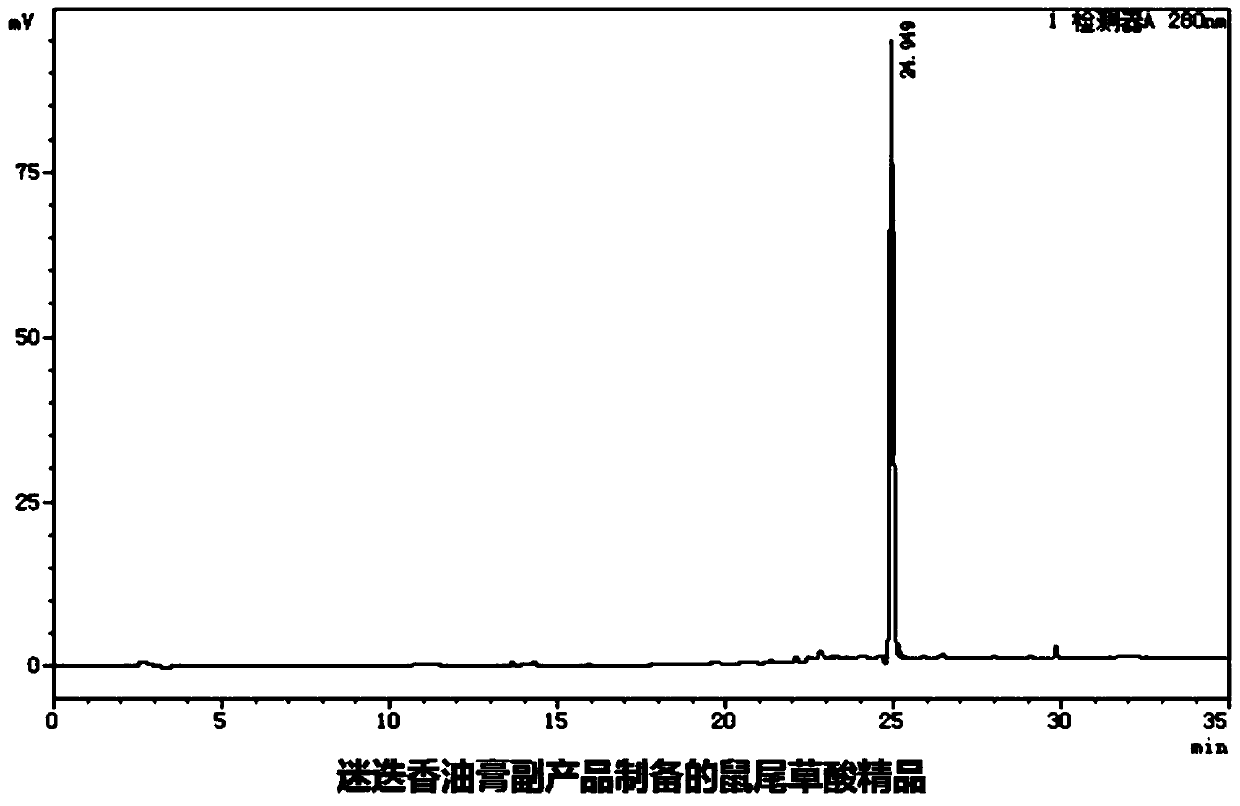

Method for preparing high-purity carnosic acid from rosemary oil paste byproduct

ActiveCN110845328AEasy to operateHigh yieldCarboxylic compound separation/purificationAgainst vector-borne diseasesActivated carbonProcess engineering

The invention discloses a method for preparing carnosic acid from a rosemary oil paste byproduct, and the method comprises the following steps: preparing an R67 extract, preparing the rosemary oil paste byproduct, preparing rosemary oil paste particle powder, carrying out solid-liquid extraction on the rosemary oil paste powder, concentrating the extract, and crystallizing to prepare crude carnosic acid dry powder, remove impurities from the crude carnosic acid product by activated carbon adsorbing, and refining carnosic acid to prepare a carnosic acid product with carnosic acid content of 95-98%. The method has the characteristics of simplicity in operation, high efficiency, recyclability of the extract, environmental friendliness, high product yield and the like.

Owner:湖南德诺贝莱健康产业有限公司

Hard high-damping foamed rubber sole and preparation method thereof

The present invention discloses a hard high-damping foamed rubber sole and a preparation method thereof. The hard high-damping foamed rubber sole is prepared from the following raw materials in partsby weight: 60-90 parts of natural rubber, 10-40 parts of chloroprene rubber, 3-7 parts of active zinc oxide, 1-3 parts of magnesium oxide, 1-3 parts of stearic acid, 0.5-1 part of anti-aging agent I,1-2 parts of anti-aging agent II, 5-8 parts of terpene resin, 6-15 parts of black factice, 15-25 parts of naphthenic oil, 20-40 parts of carbon black, 1-3 parts of urea, 1-3 parts of foaming agent I,1-3 parts of foaming agent II, 3-5 parts of physical foaming agent, 1-2 parts of accelerant I, 0.1-0.5 part of accelerant II, and 1-3 parts of sulfur. Compared with the prior art, the hard high-damping foamed rubber sole is characterized in that two closed-pore foaming agents, namely a foaming agent AC and a foaming agent OBSH, are synergized with the physical foaming agent, allowing the foamed rubber sole to have the advantages of light weight, low density, high comfort degree, and obvious damping effect; and meanwhile, the advantages of corrosion resistance and good anti-aging performance ofthe rubber are also maintained.

Owner:JIHUA 3515 LEATHER & SHOES

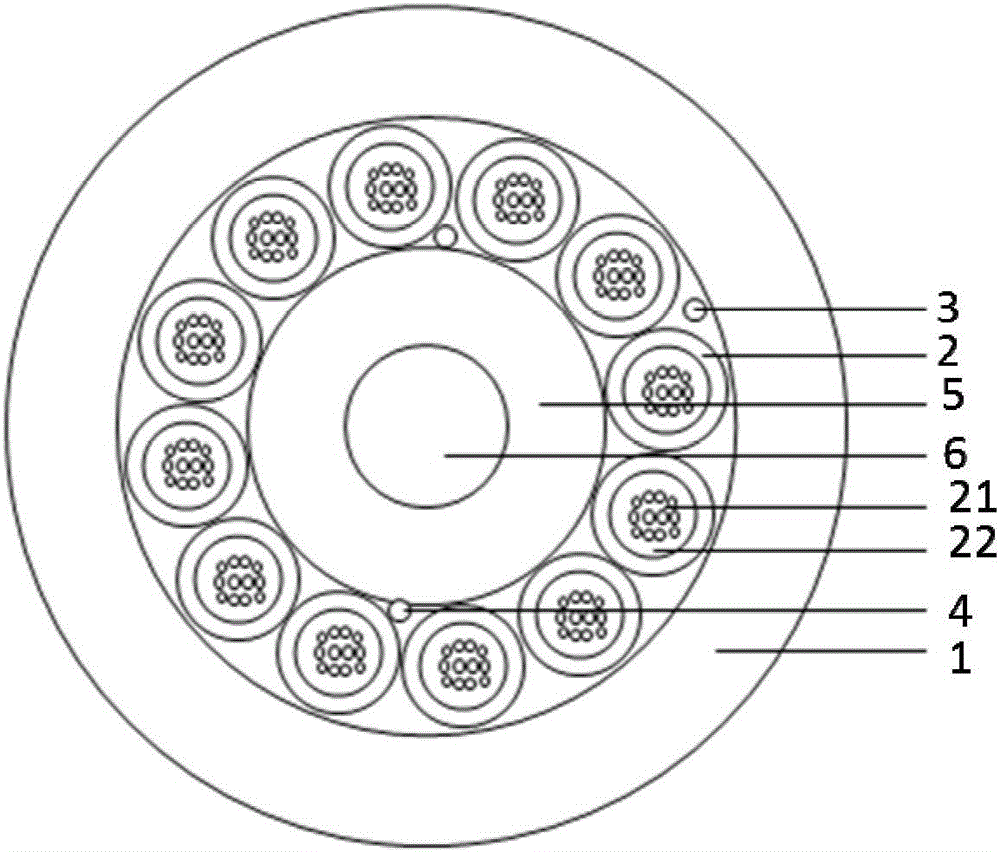

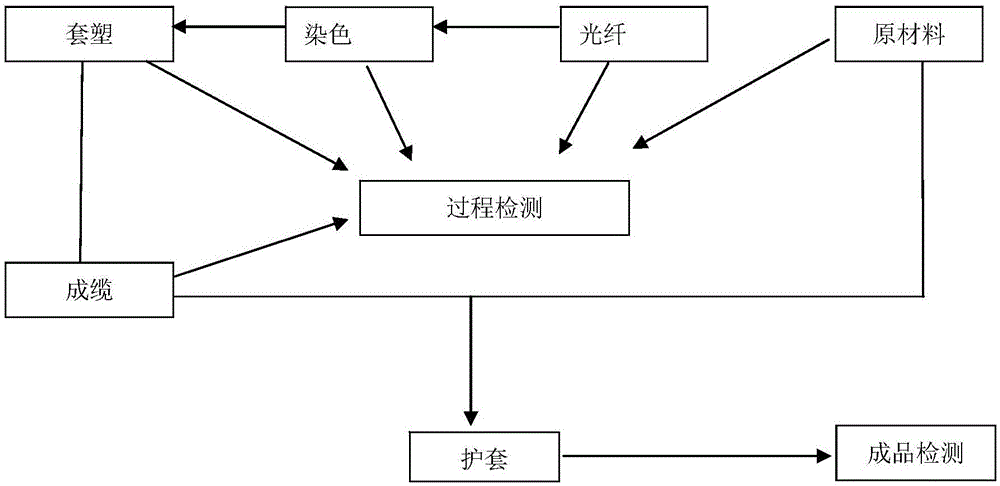

Center beam tube type optical cable, manufacturing method and fixing method of center beam tube type optical cable and plastic fixture

PendingCN106443918ASmall sizeAvoid destructionOptical fibre/cable installationFibre mechanical structuresFiberYarn

The invention provides a center beam tube type optical cable, a manufacturing method and a fixing method of the center beam tube type optical cable and a plastic fixture. The center beam tube type optical cable comprises an outer sheath, a plurality of loose tube sleeves located in the outer sheath and arranged in a circle, cable cores wrapped by the loose tube sleeves, a tear rope and water blocking yarn, wherein the tear rope and the water blocking yarn are located among the loose tube sleeves, and the cable cores comprise reinforcing part cushion layers wrapped by the loose tube sleeves and non-metallic reinforcing parts located in the reinforcing part cushion layers. By the adoption of the novel small-diameter optical cable, the optical cable size is effectively reduced; all materials of the optical cable are non-metallic materials, so that damage caused by thunderstorms to the optical cable is effectively avoided; besides, grounding for lightning protection in the construction process is omitted, so that construction efficiency is improved. A semi-dry structure is adopted for the cable cores, so that pollution caused by factice to the environment is reduced. The large number of the optical fiber cores meets the requirement of the access network layer for the number of optical fiber cores; in cooperation with the special non-metallic fixture, effective fixing is achieved in a connector box and a light splitting and fiber distribution box.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com