Deep sea cable

A deep-sea cable and power cable technology, applied in the direction of submarine cables, insulated cables, cables, etc., can solve the problems of electromagnetic interference, cable line displacement and damage, interference, etc., to enhance adhesion, strengthen strength, and prevent electromagnetic interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

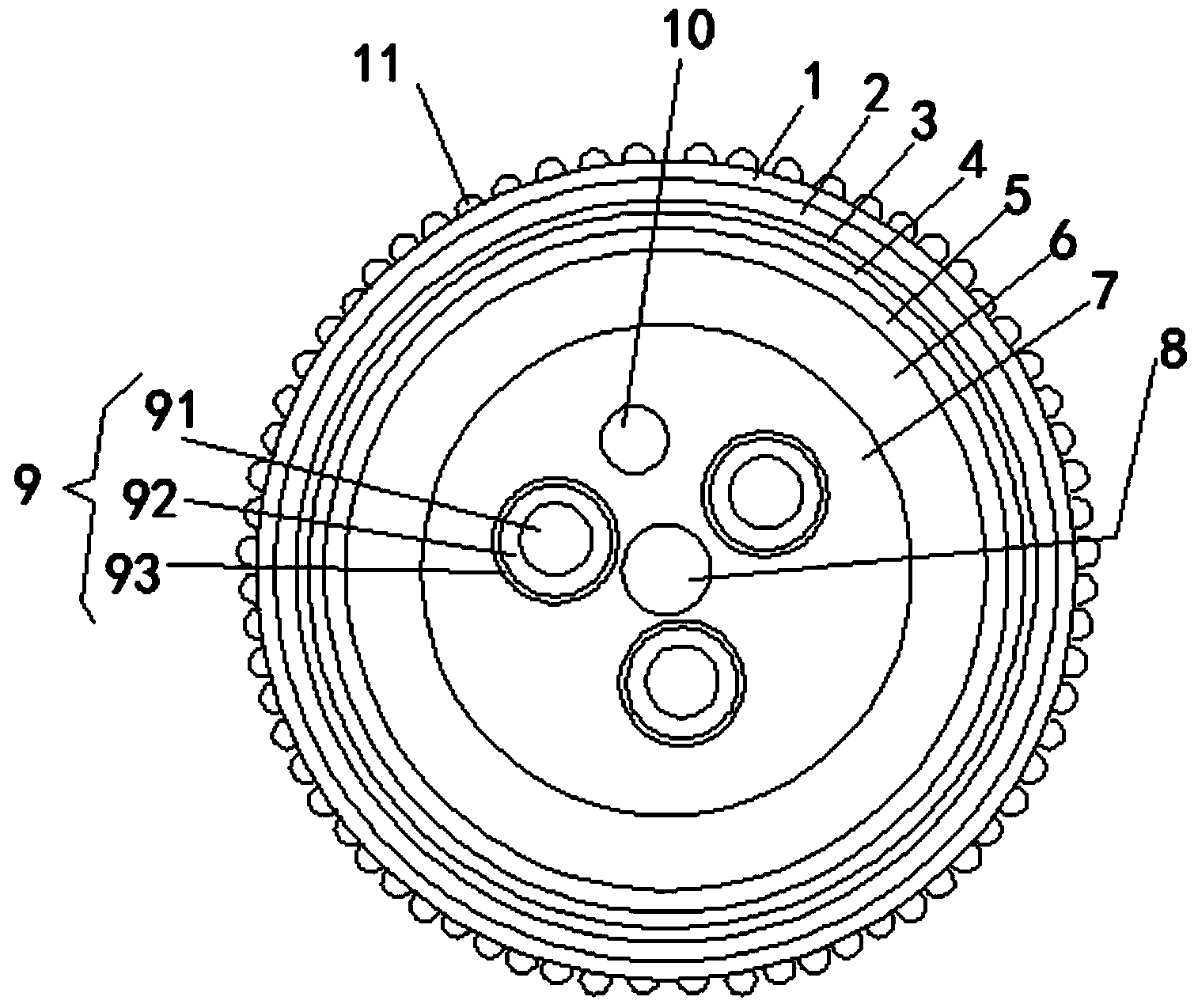

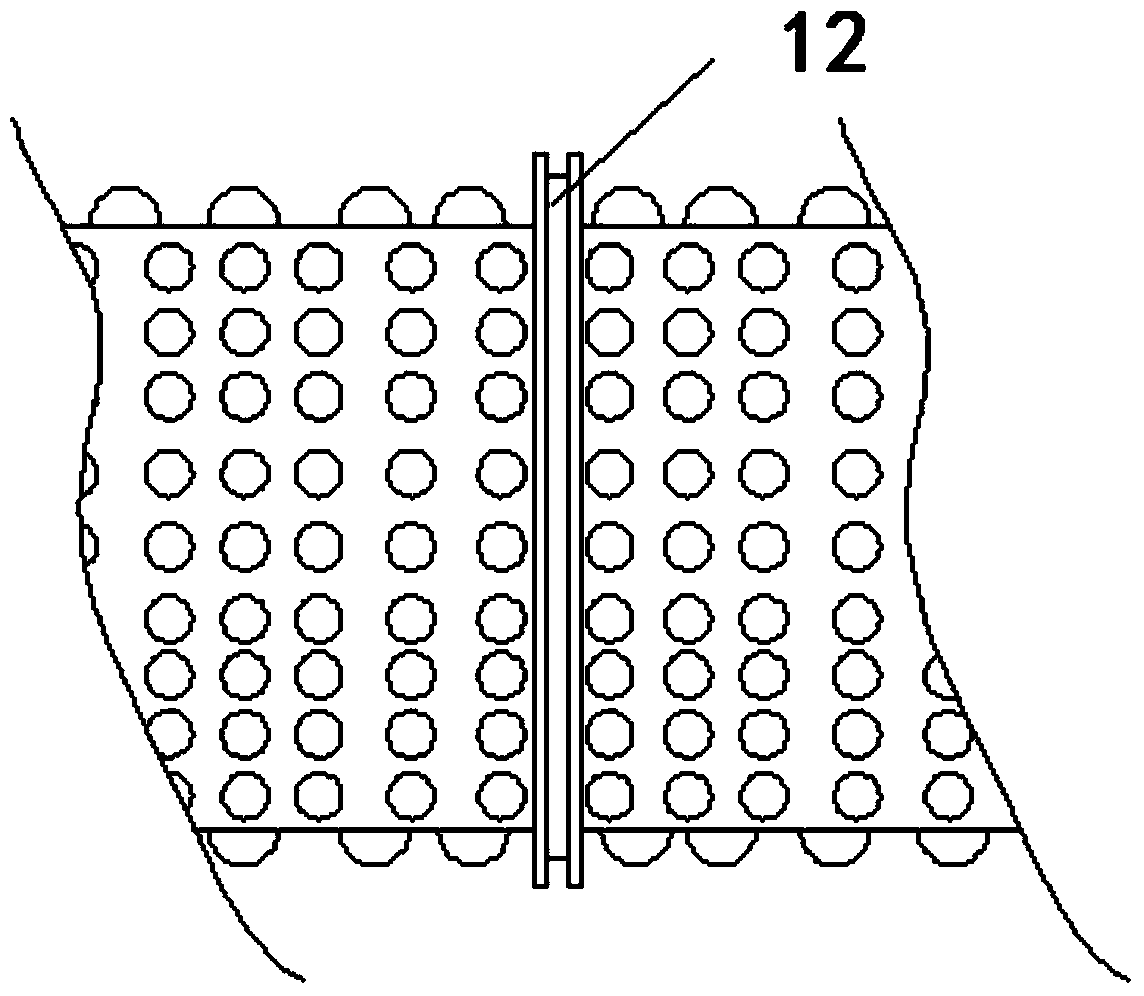

[0017] see Figure 1-2 The invention provides a technical solution: a deep-sea cable, including an outer coating layer 1, an armor layer 2, a water-blocking grease layer 3, an inner coating layer 4, a metal shielding layer 5, a wrapping tape layer 6, a filling layer 7, Reinforce the inner core 8, the power cable 9, the communication cable 10 and the external fixed convex groove 12, and the outside of the filling layer 7 is wrapped with the wrapping tape layer 6, which is woven by hemp rope, and the hemp rope here The rope is a twist-like rope structure made of raw hemp. The center of the filling layer 7 is filled with a reinforced inner core 8. The filling layer 7 is composed of water-blocking ointment injected into the filling rope. The filling layer is woven together by cotton and hemp The filling rope structure of the twist-shaped rope, the filling rope is injected with water-blocking ointment, and the water-blocking ointment is infiltrated into the filling rope, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com