Center beam tube type optical cable, manufacturing method and fixing method of center beam tube type optical cable and plastic fixture

A bundled tube and optical cable technology, applied in the direction of light guide, optics, optical components, etc., can solve the problem of difficult to achieve the size of oil-filled casing, and achieve the effect of improving construction efficiency, avoiding damage and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

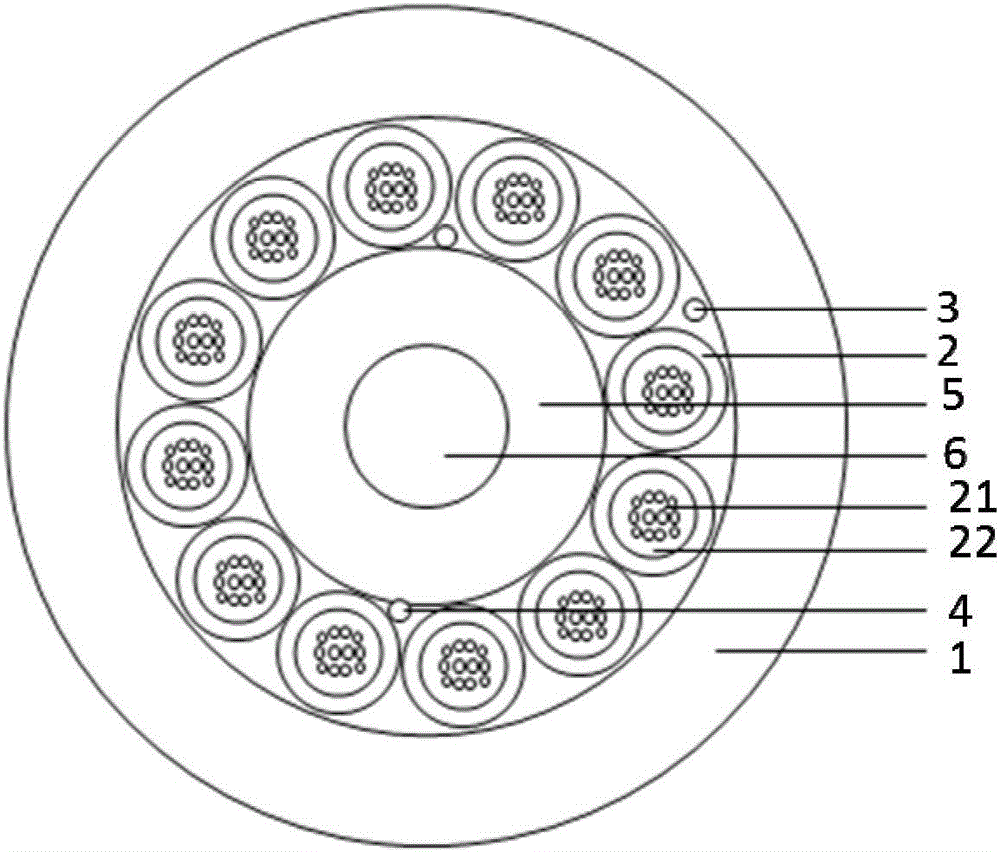

[0032] The central bundle tube optical cable of the present invention is specifically a light non-metallic filled micro-bundle tube optical cable for access networks, such as figure 2 As shown, the central beam tube type optical cable includes: an outer sheath 1, a plurality of loose tube sleeves 2 arranged in a circular arrangement inside the outer sheath 1, a cable core wrapped by the plurality of loose tube sleeves 2, and The tear rope 3 and the water-blocking yarn 4 located between the loose tube sleeves 2. Wherein, the tear rope 3 is arranged close to the outer sheath 1, and the water-blocking yarn 4 is arranged close to the cable core.

[0033] The cable core includes a reinforcement mat 5 covered by a plurality of loose tube sleeves 2 and a non-metallic reinforcement 6 inside the reinforcement mat 5 .

[0034] In this embodiment, there are 12 loose tube sleeves 2 . Each loose tube sleeve 2 includes a plurality of small-diameter optical fibers 21 and ointment 22 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com