Patents

Literature

138 results about "Dry structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

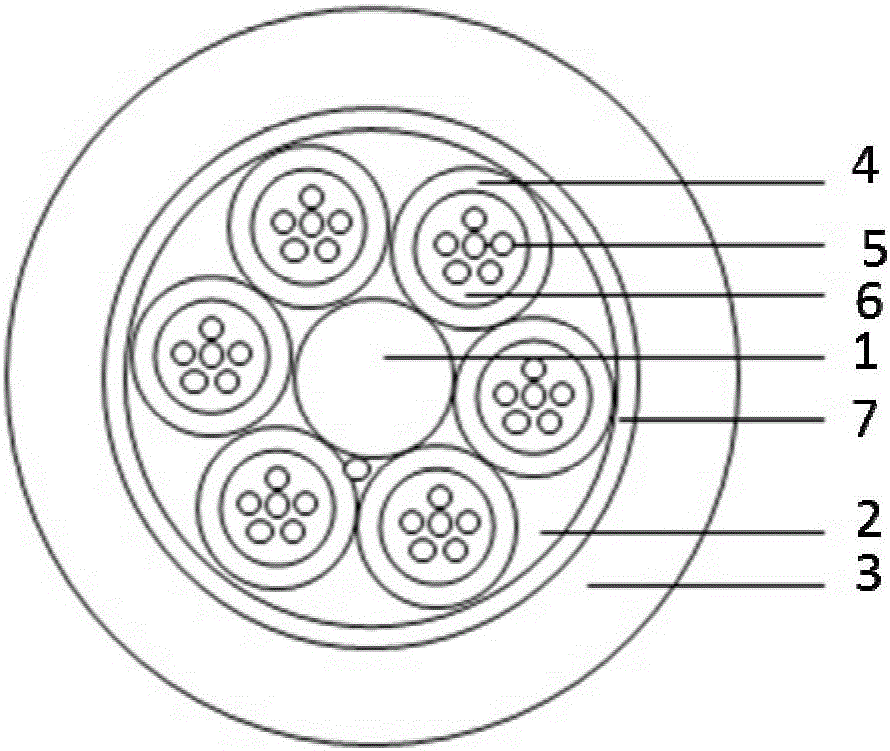

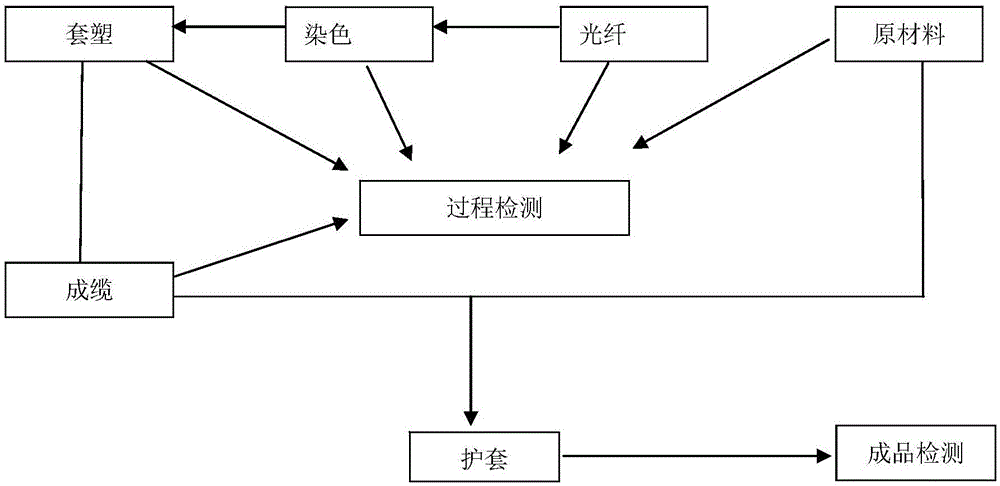

Full-dry high fiber count air-blowing micro-cable and optical fibre bundle processing method

ActiveCN102023357AThe number of fiber cores increasesGood flexibilityFibre mechanical structuresFiberDry structure

The invention provides a full-dry high fiber count air-blowing micro-cable and a preparation method of an optical fibre bundle thereof. The micro-cable contains a central nonmetallic reinforcer, a plurality of optical fibre bundles which are stranded and arranged on the nonmetallic reinforcer, a nonmetallic tension element which is wrapped or longitudinally covered on the periphery of the optical fibre bundles and a polyethylene jacket which is arranged on the periphery of the tension element through extrusion molding. Each optical fibre bundle is prepared by two-step coating and photocuring and has higher flexibility. A plurality of the prepared optical fibre bundles are directly stranded to obtain a cable, thus the fiber count of the cable is greatly increased; and grease is not required to be filled in the whole optical fiber cable and the entire optical fiber cable is in a full-dry structure, thus the environmental pollution in construction can be avoided and the micro-cable provided by the invention has higher promotion value and application value.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

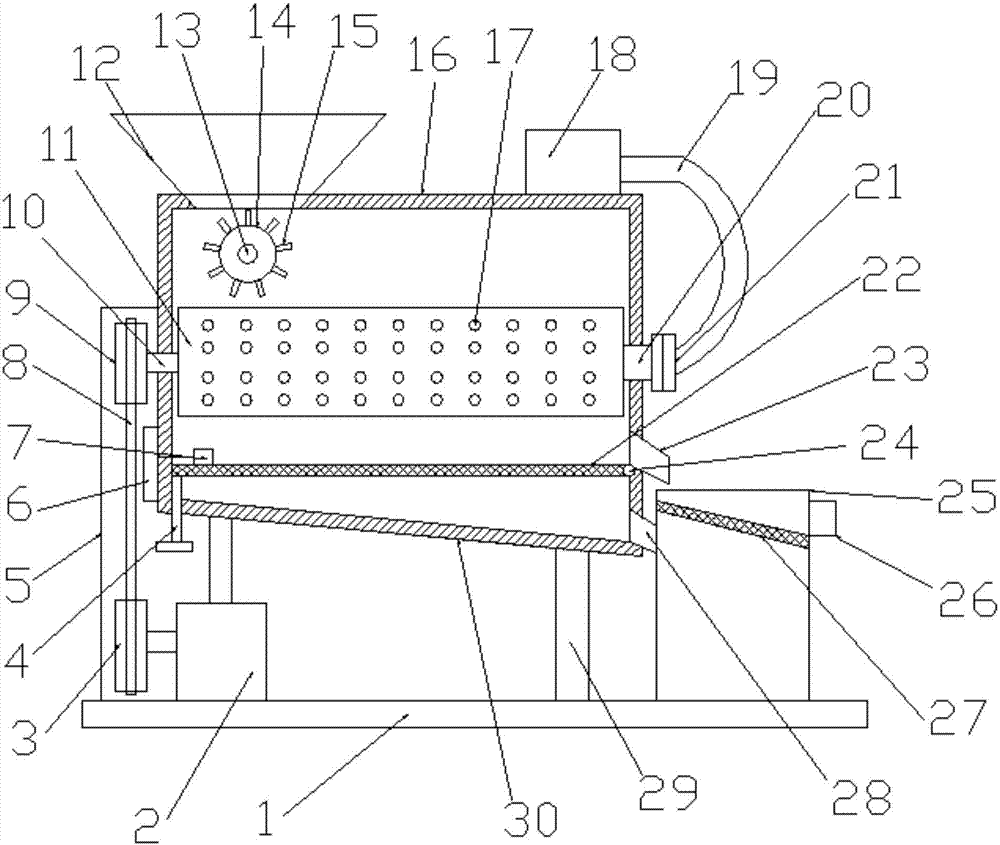

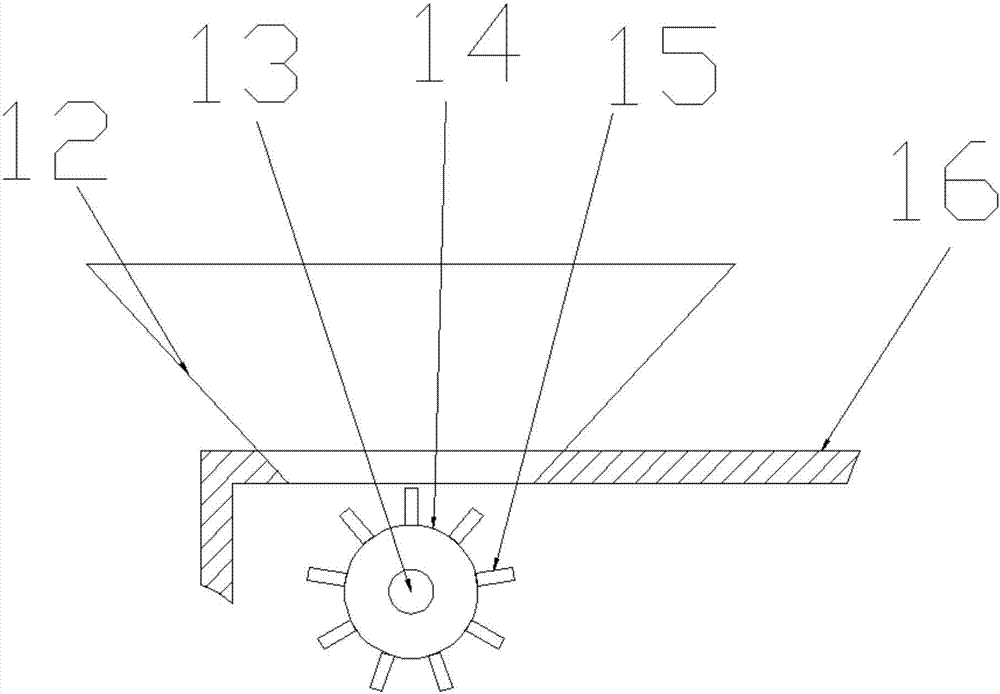

Tea drying, sieving and separating device

InactiveCN107279332AEvenly heatedEasy to dropSievingPre-extraction tea treatmentDry structureTransducer

The invention discloses a tea drying, screening and separating device, which includes a fixed plate, an organic casing is arranged on the fixed plate, and a bracket is arranged at the bottom of the casing. The invention provides a tea drying, screening and separating device, which has a novel structure; The drying structure is ingeniously set, and the material distribution mechanism is set to make the raw materials evenly dispersed. The hot air in the inner chamber of the drying drum dries the tea leaves attached to the surface from the inside to the outside through the vent holes, and the heat is even. The tea leaves are fully heated to ensure the quality and high drying efficiency. In addition, it is convenient to drop the dried tea leaves for screening. The present invention drives the transducer set on the screen through an ultrasonic power supply, and attaches ultrasonic waves to the screen to make the fine powder accept The huge ultrasonic acceleration can suppress the blocking factors such as adhesion, friction, flat drop, wedging, etc., and can greatly improve the efficiency of screening and cleaning. In addition, the invention performs secondary screening to ensure the high quality of finished products.

Owner:银川金帮手信息科技有限公司

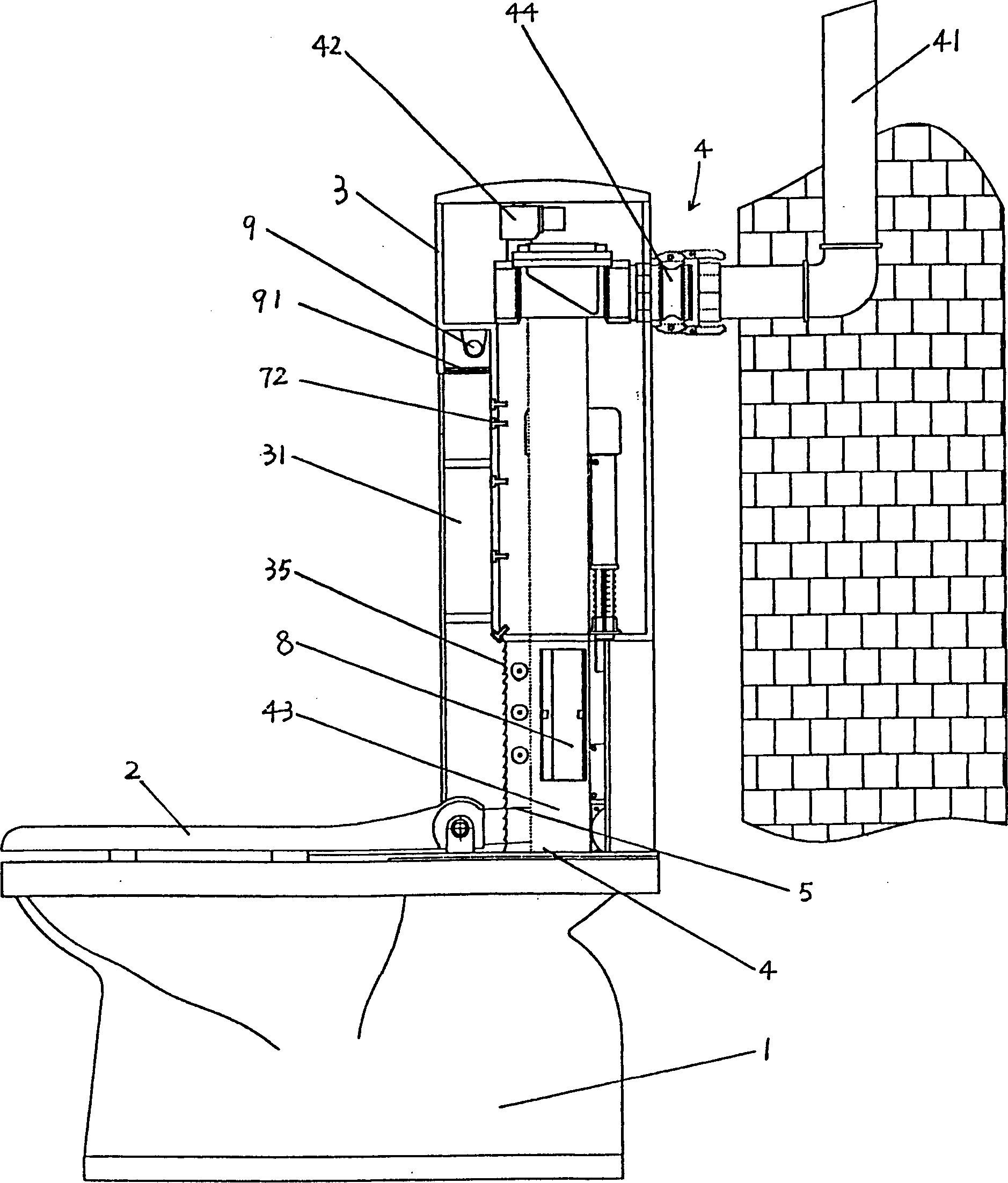

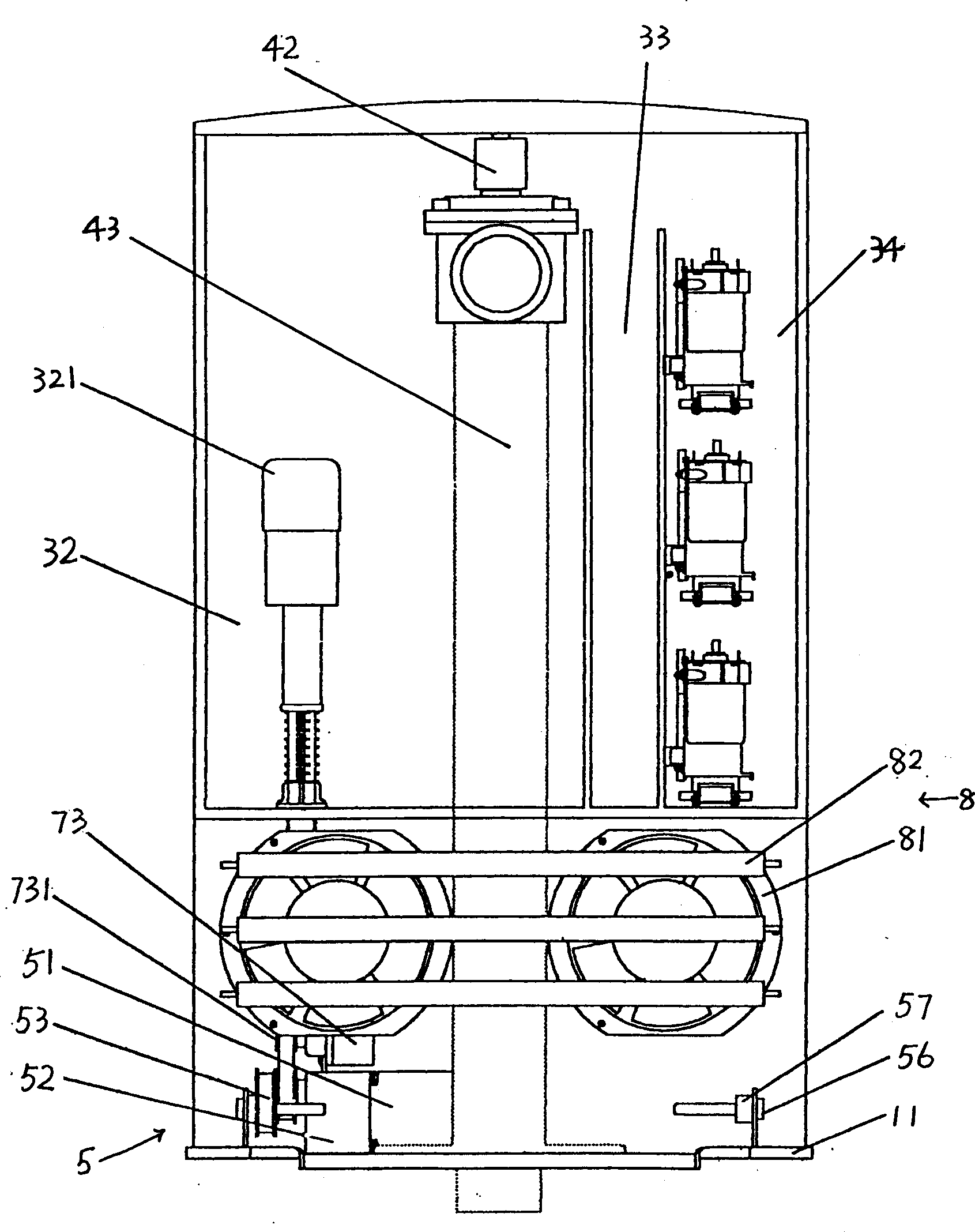

Water closet with seat sterilizing function

InactiveCN1824896AEnsure hygiene and sterilityWater closetsBathroom coversAutomatic controlDry structure

The invention supplies a toilet that has seat antisepsis function. It includes toilet bowl,seat antisepsis box, draft structure,seat rotating structure, liquor washing structure, clean water washing structure, drying structure, ultraviolet light antisepsis structure, and automatic control structure. The invention could take liquor antisepsis, clean water washing, drying, and ultraviolet light antisepsis in time after user using it. It ensures the sanitation of toilet seat.

Owner:潘定国

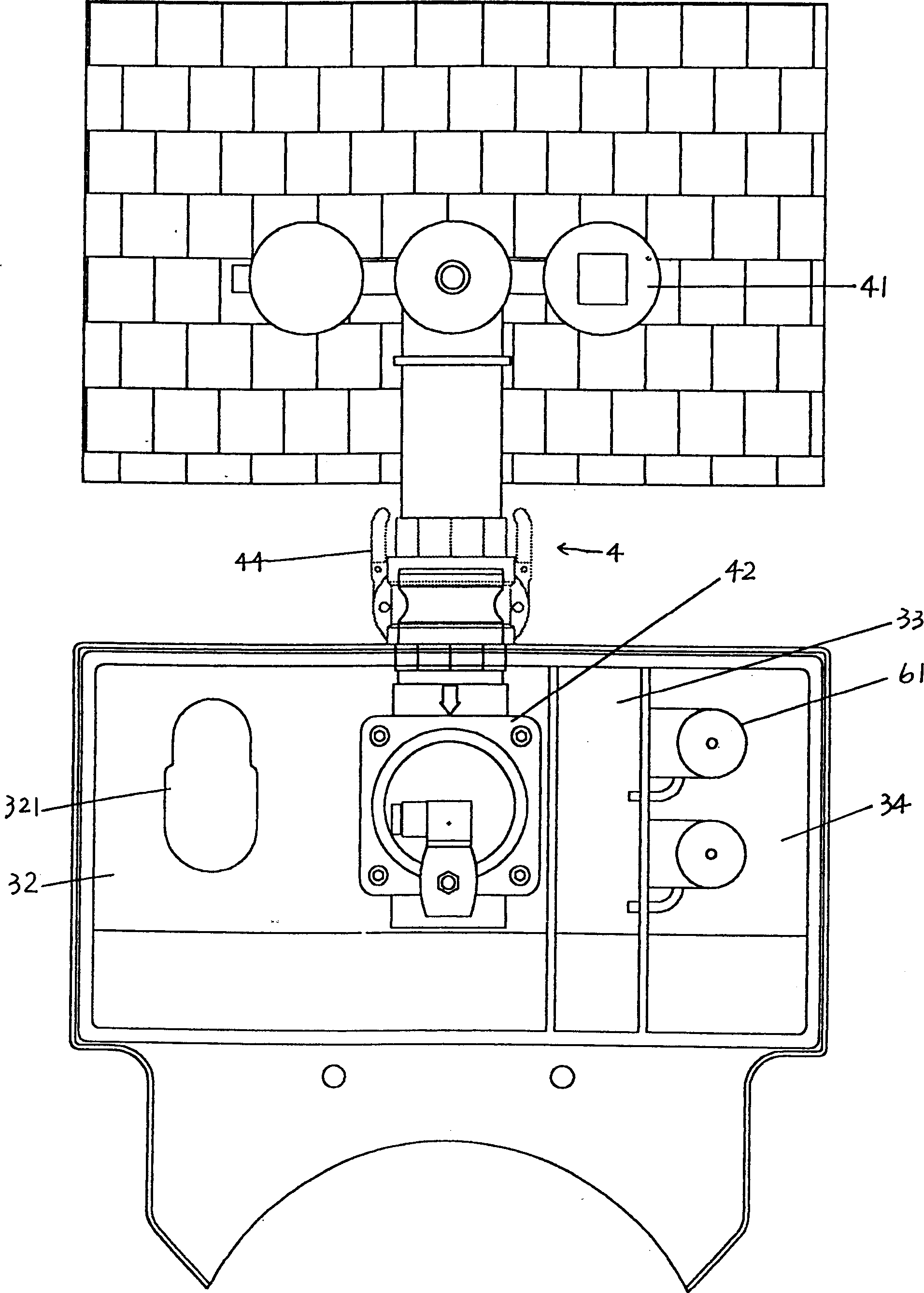

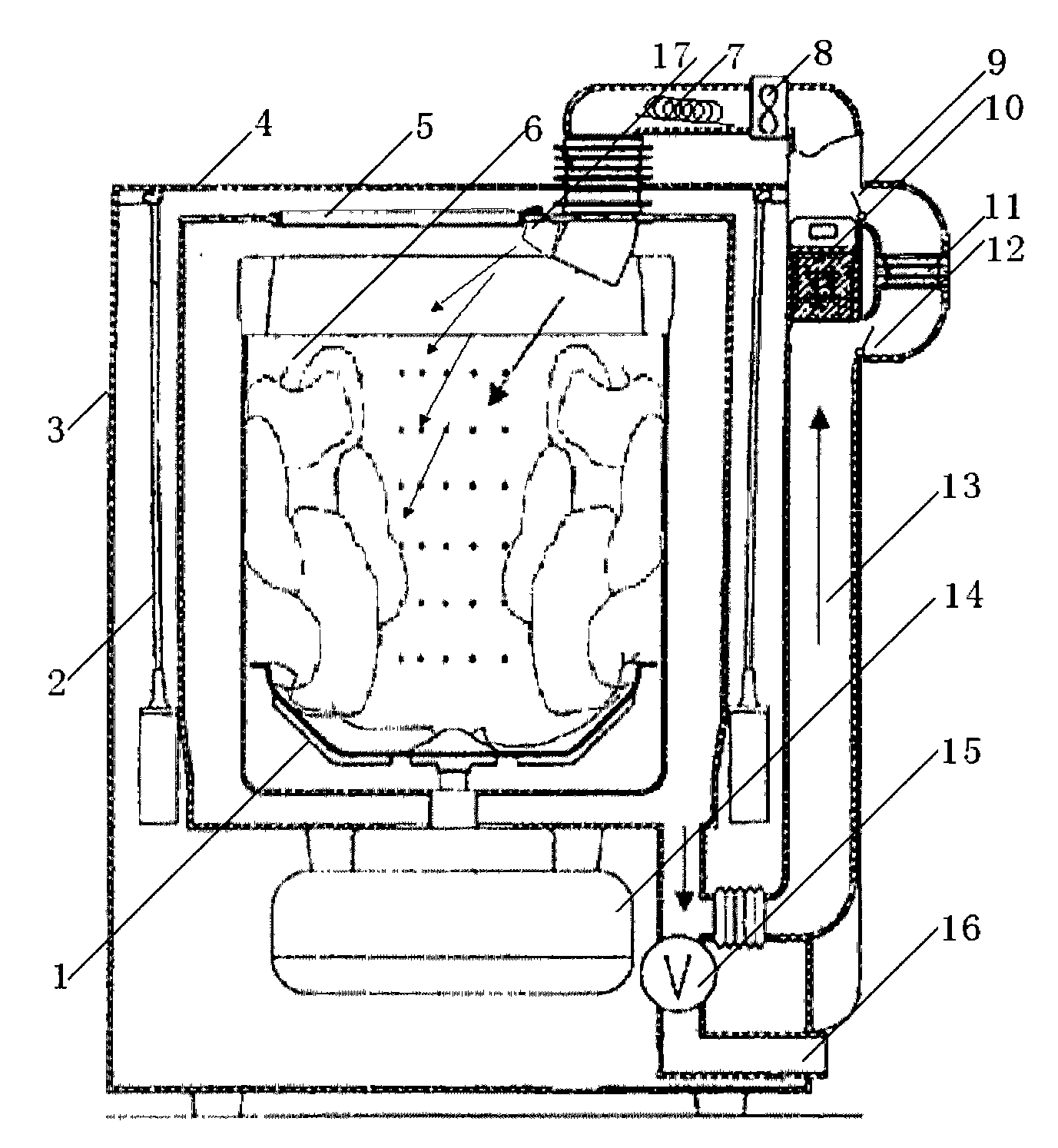

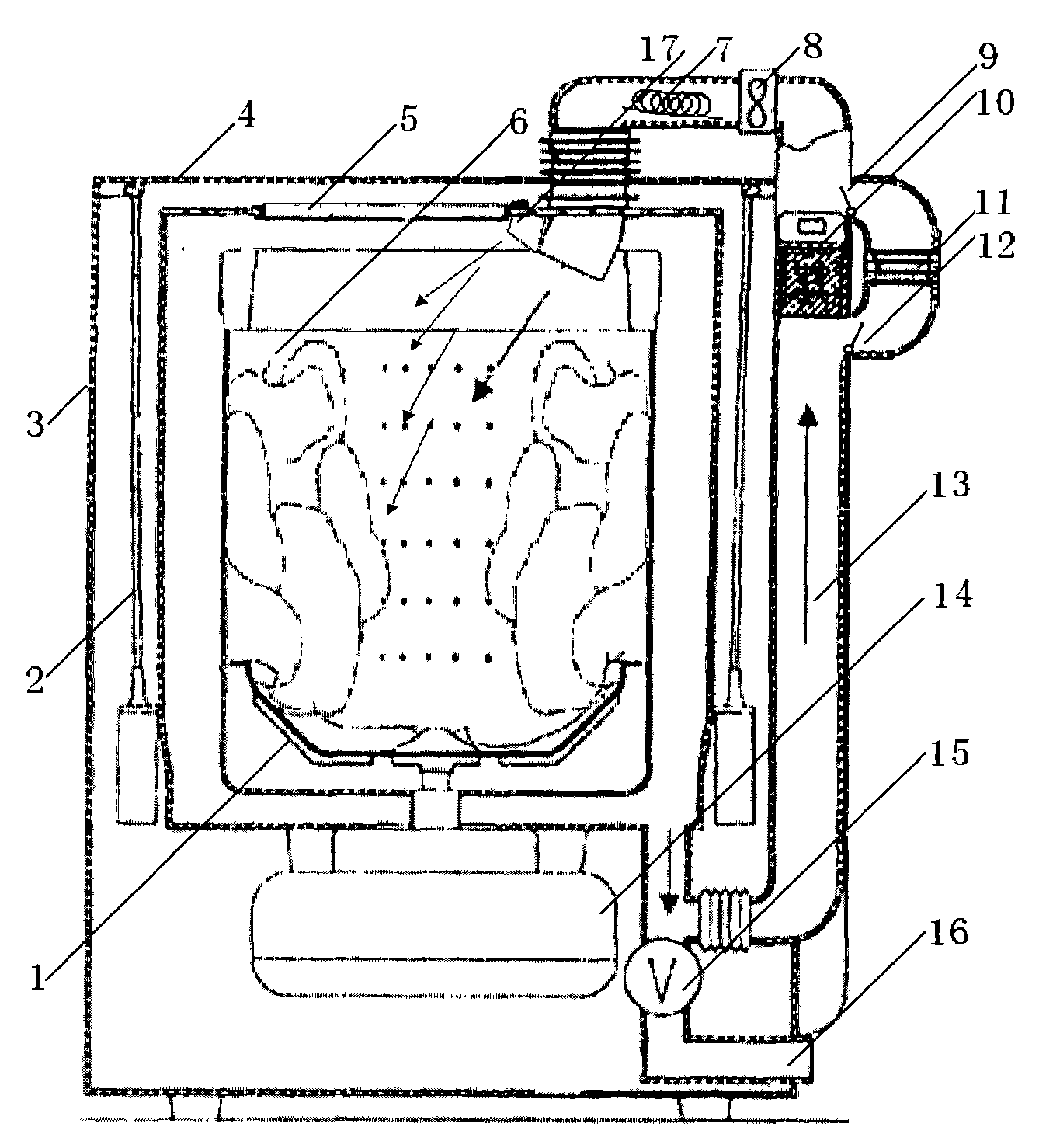

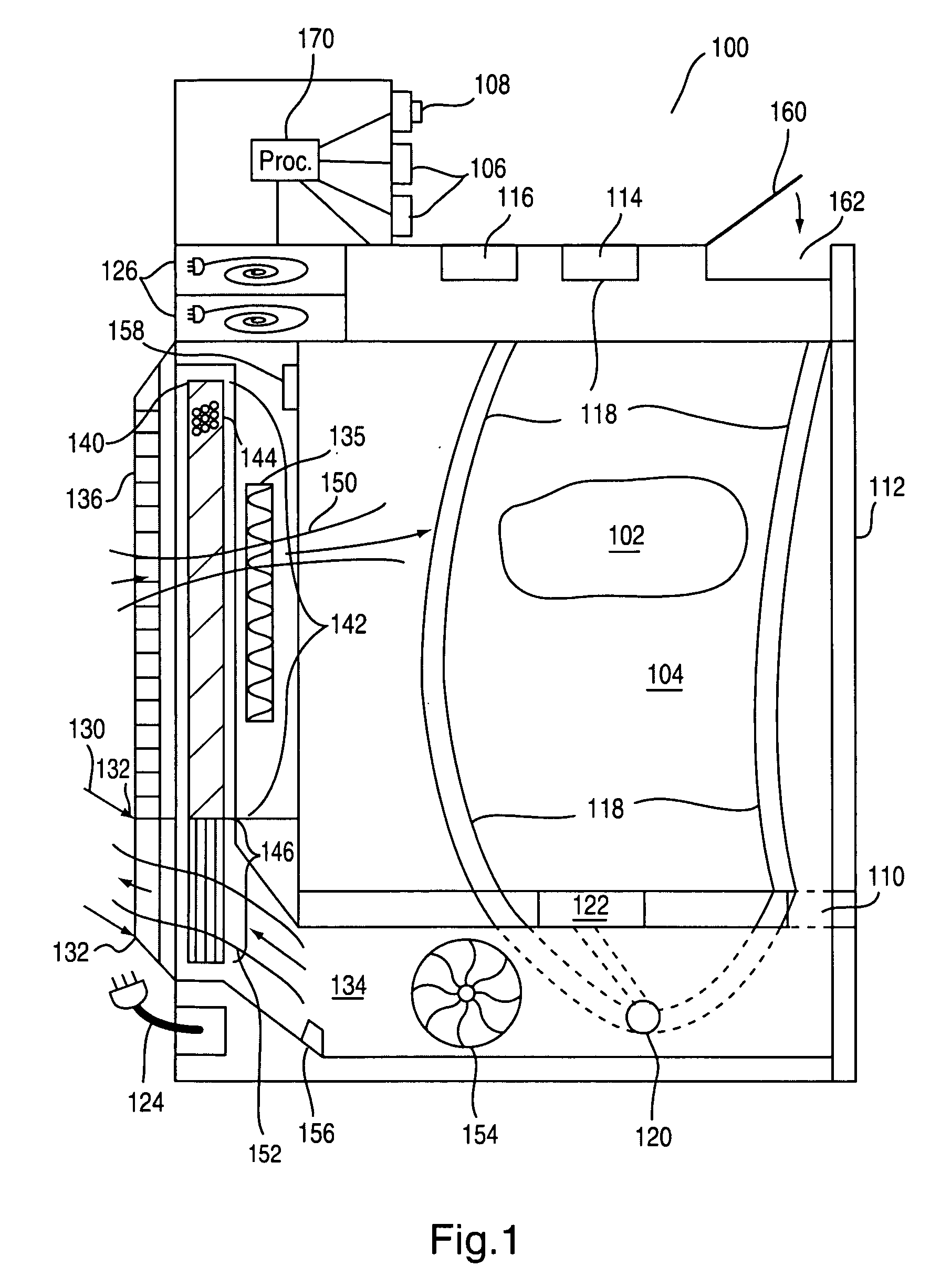

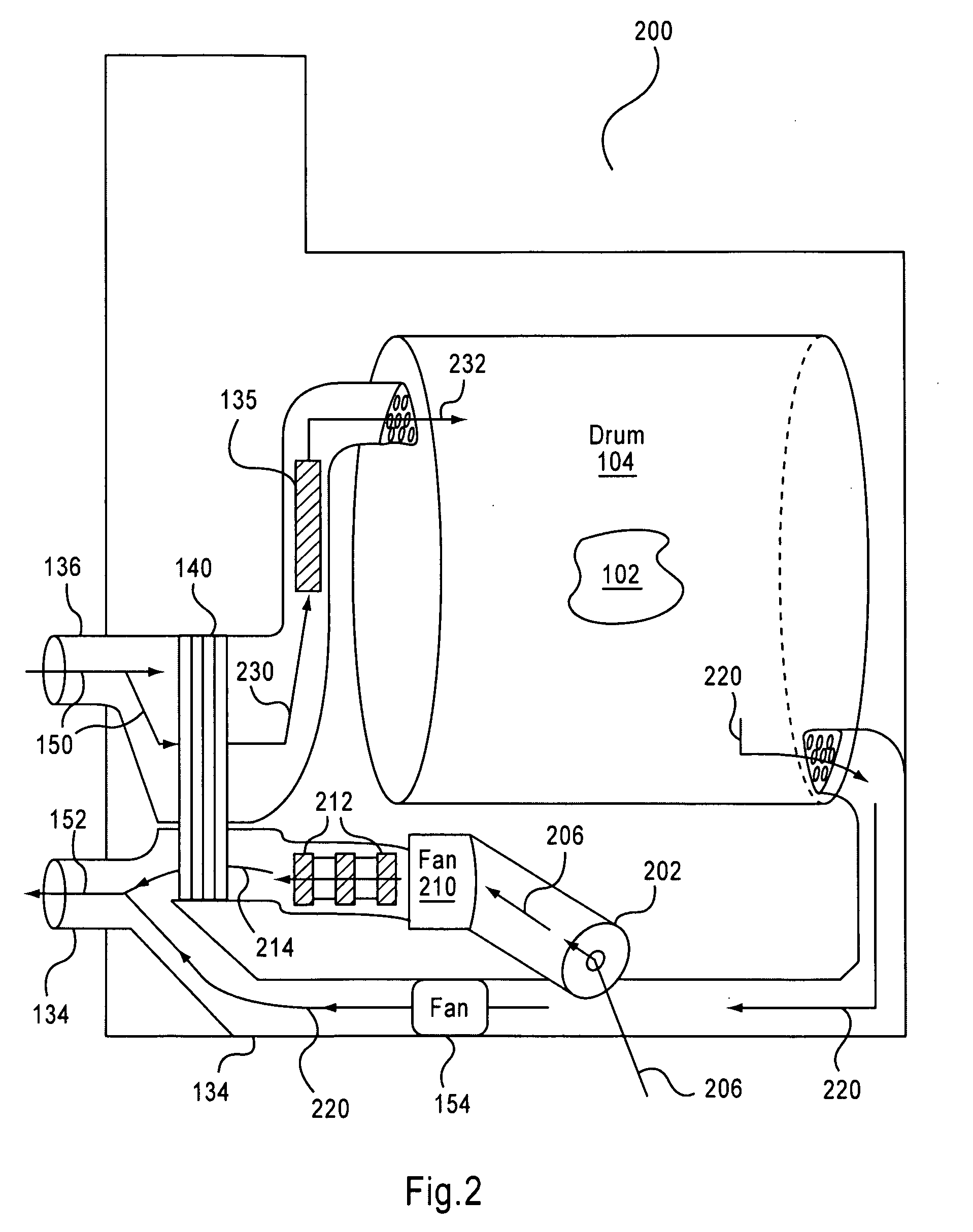

Process for drying by imitating sunlight with drying structure of laundry machine and removing ozone by catalyzed sorption

ActiveCN101285260AEffective dehumidification and dryingEffective disinfectionTextiles and paperChemicalsFiberDry structure

The invention discloses a method for imitating the sun drying and adopting superoxide anion to remove ozone by adopting a drying structure of a washing machine. The drying structure refers to a circulation path of the drying structure of a dryer in the prior art. The inside of the air path for drying clothes is provided with an ozone generator and a catalyzed sorption device. The clothes are irradiated by near infrared rays, far infrared rays and ultraviolet rays. The sunlight is imitated to dry the clothes. After the imitated sun drying is completed, a catalyst is used to absorb the residual ozone in order to remove the ozone which is harmful to human body. The method has the advantages of the function of sterilization, fiber bulking and the ability to be performed all weather and has the effect basically the same as the natural sun drying.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

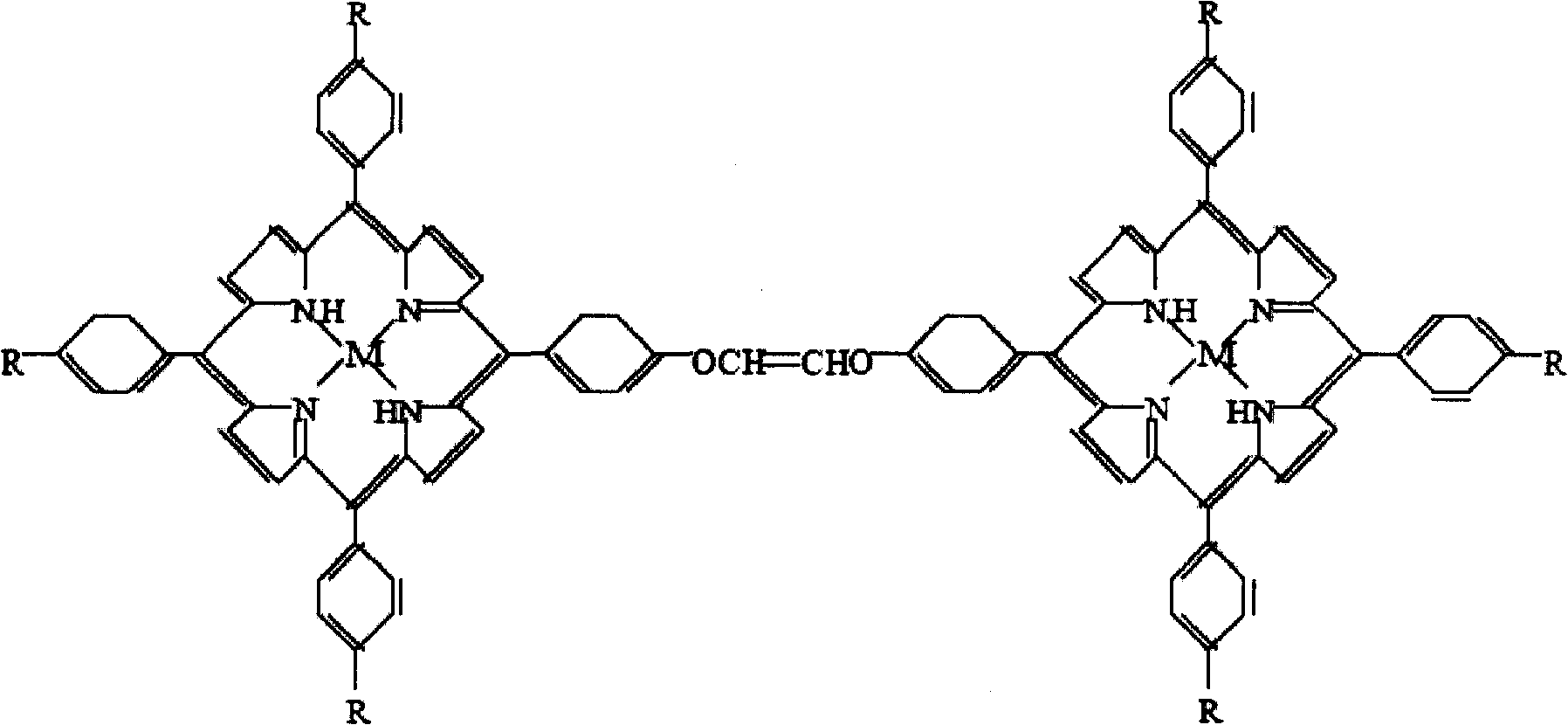

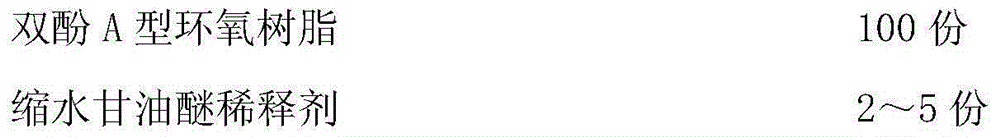

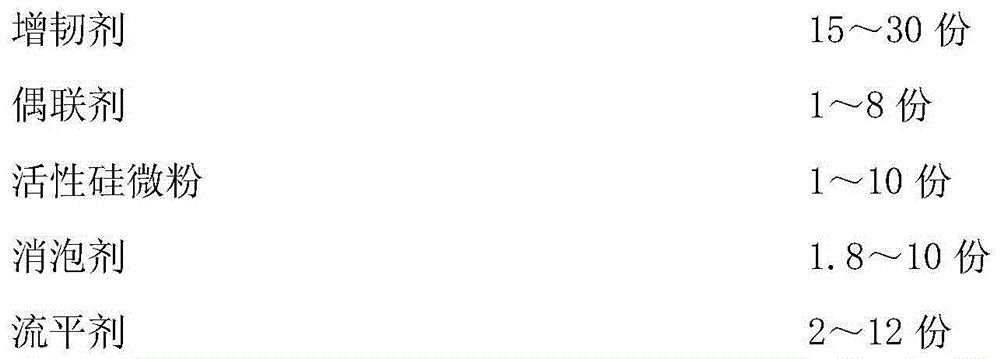

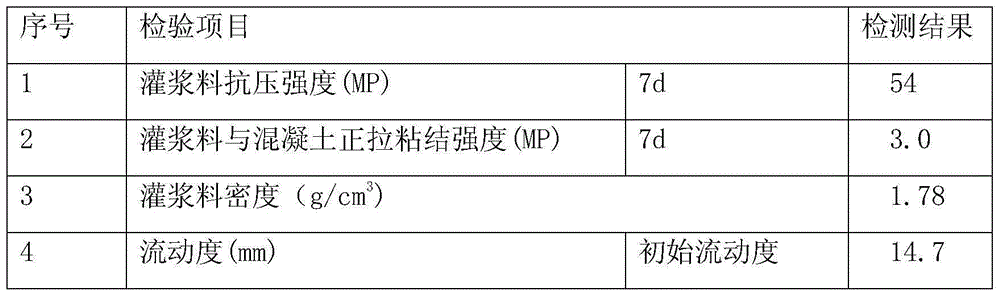

Epoxy grouting material for glass fiber sleeve reinforcing system and preparing method of epoxy grouting material

The invention provides an epoxy grouting material for a glass fiber sleeve reinforcing system. The grouting material is mainly formed by mixing a component A, a component B and a component C according to the mass ratio of 2 to 1 to 2-10. The component A is composed of bisphenol A type epoxy resin, reactive diluents, flexibilizer, silane coupling agents, defoaming agents, flatting agents and active micro silicon powder. The component B is a cashew phenol modified phenolic aldehyde amine curing agent and the component C is composed of quartz sand, coal ash and blanc fixe. The epoxy grouting material can be normally cured in a dry environment, a humid environment and a complete water environment, has extremely good mobility and is capable of being normally grouted in seams with the width of 1.5 cm, and no layering phenomenon is generated after grouting. The physical and mechanical properties of the grouting material meet the requirement of self-leveling mortar, grouting can be conducted at one place, the grouting material can conduct self-leveling, the formula of the grouting material is specially designed, and the grouting material has extremely good adhesivity on the surfaces of both the humid structure and the dry structure and is high in intensity and good in tenacity.

Owner:CARBON TECH CO LTD

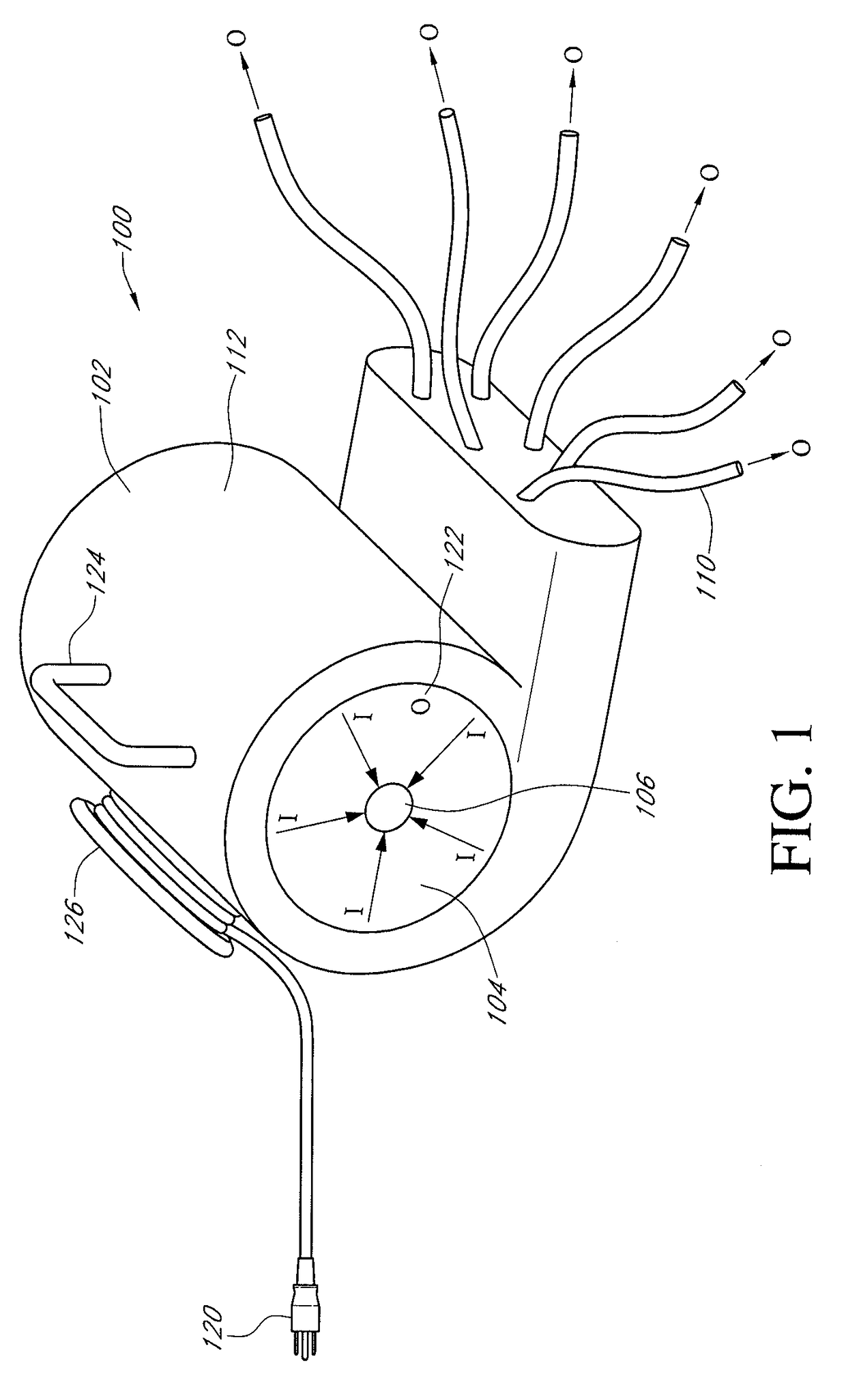

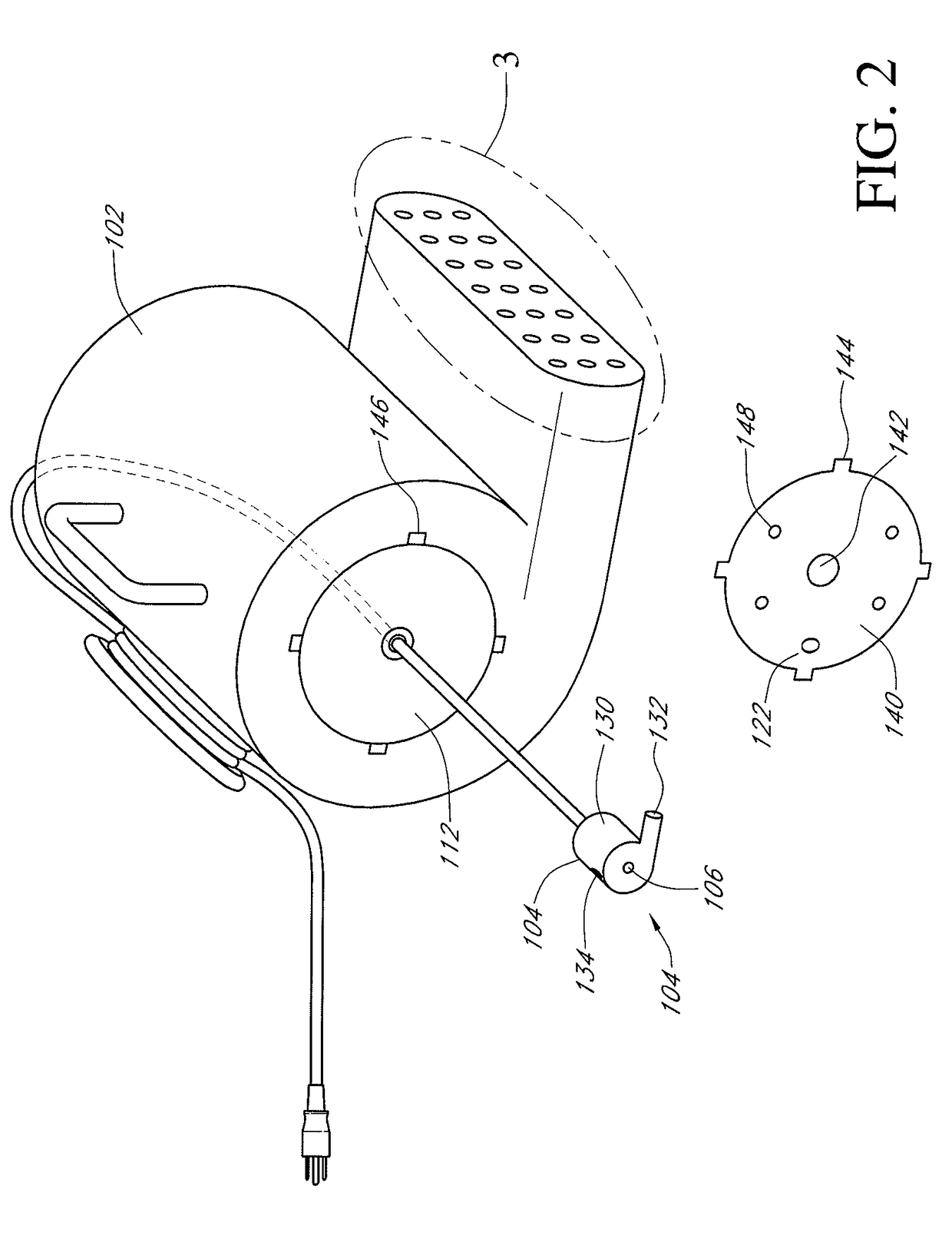

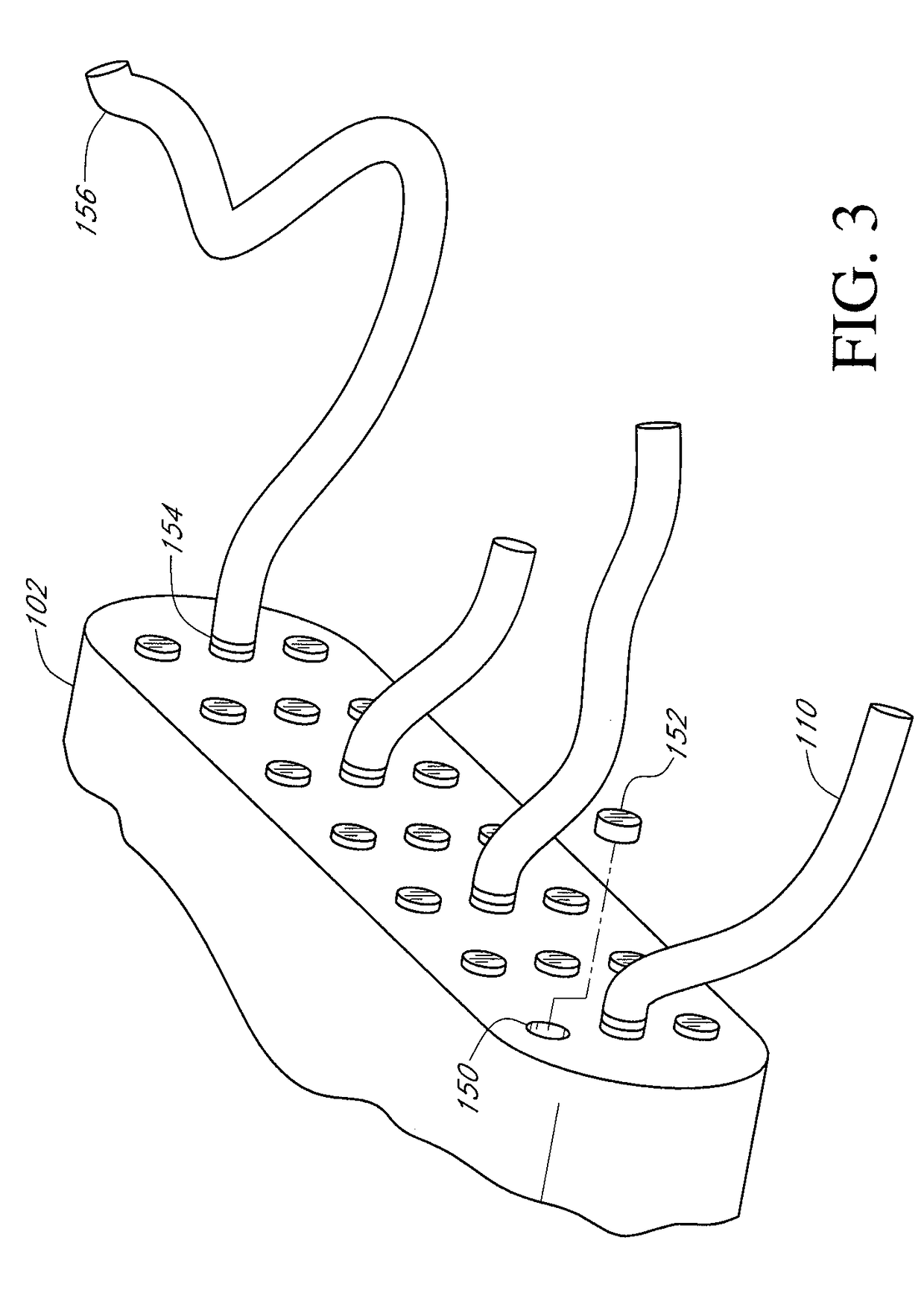

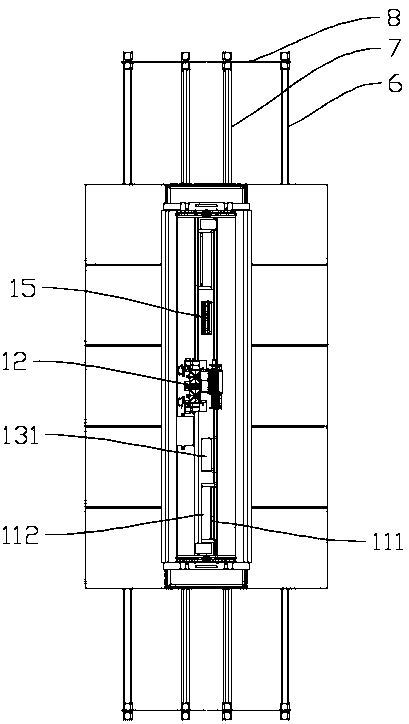

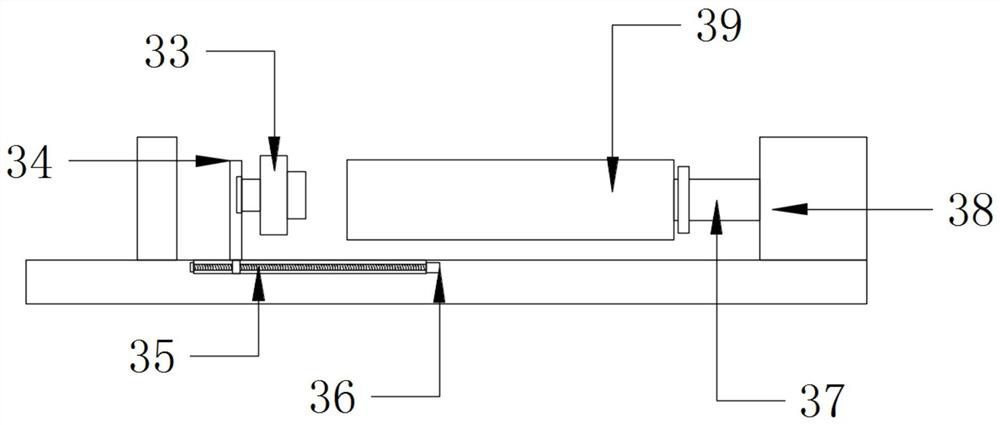

Pressurized drying system

ActiveUS8468716B1Rapidly and thoroughly dryRapidly and inexpensively dryDrying using combination processesSuction cleanersDry structureEngineering

A system for drying structures including an enclosed housing with a plurality of outlet openings, a plurality of flexible outlet hoses each connected to a respective outlet opening, and a vacuum motor engaged with the housing such that an outlet of the vacuum motor is exhausted into an interior of the housing so as to pressurize the interior of the housing such that compressed air is directed through the plurality of outlet hoses. Also a method of drying an interior of a structure, including placing a pressurized drying system adjacent a region of a structure, forming a plurality of openings in surfaces of the structure where the surfaces define enclosed spaces, inserting distal ends of outlet hoses of the pressurized drying system into respective openings of the surfaces of the structure, and engaging the pressurized drying system so as to generate a flow of pressurized air and to direct the pressurized air into the enclosed spaces.

Owner:XPOWER MFG INC

Process for drying by imitating sunlight and removing ozone by using ultra-oxygen negative ion

ActiveCN101285259AEffective dehumidification and dryingEffective disinfectionTextiles and paperChemicalsFiberDry structure

The invention discloses a method for imitating the sun drying and adopting superoxide anion to remove ozone. The method adopts a drying structure of a washing machine. The drying structure refers to a circulation path of the drying structure of a dryer of the washing machine in the prior art. The inside of the air path for drying clothes is provided with an ozone generator and a catalyzed sorption device. The clothes are irradiated by near infrared rays, far infrared rays and ultraviolet rays. The sunlight is imitated to dry the clothes. After the imitated sun drying is completed, a catalyst is used to absorb the residual ozone in order to remove the ozone which is harmful to human body. The method has the advantages of the function of sterilization, fiber bulking and the ability to be performed all weather and has the effect basically the same as the natural sun drying.

Owner:HAIER GRP CORP +1

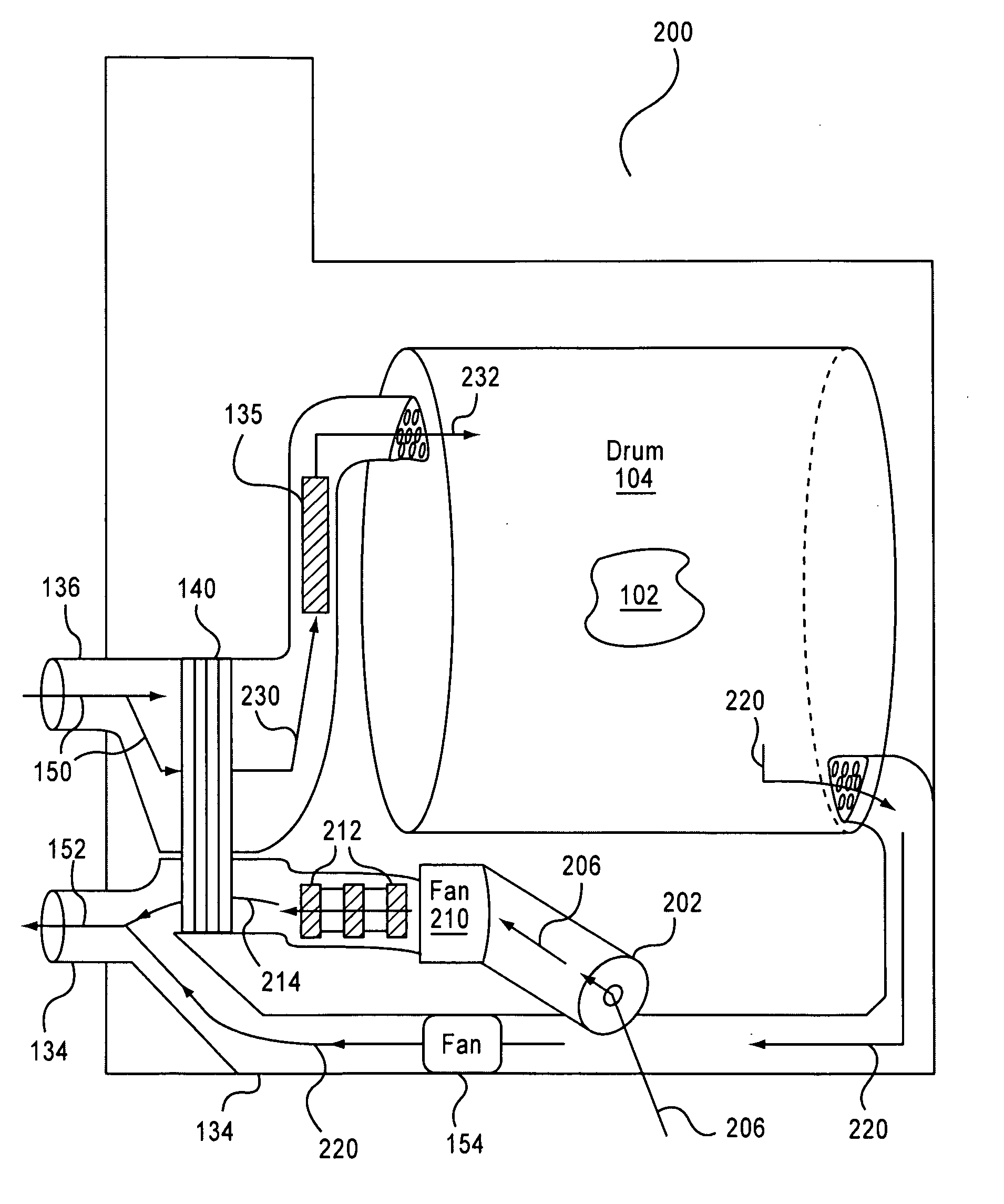

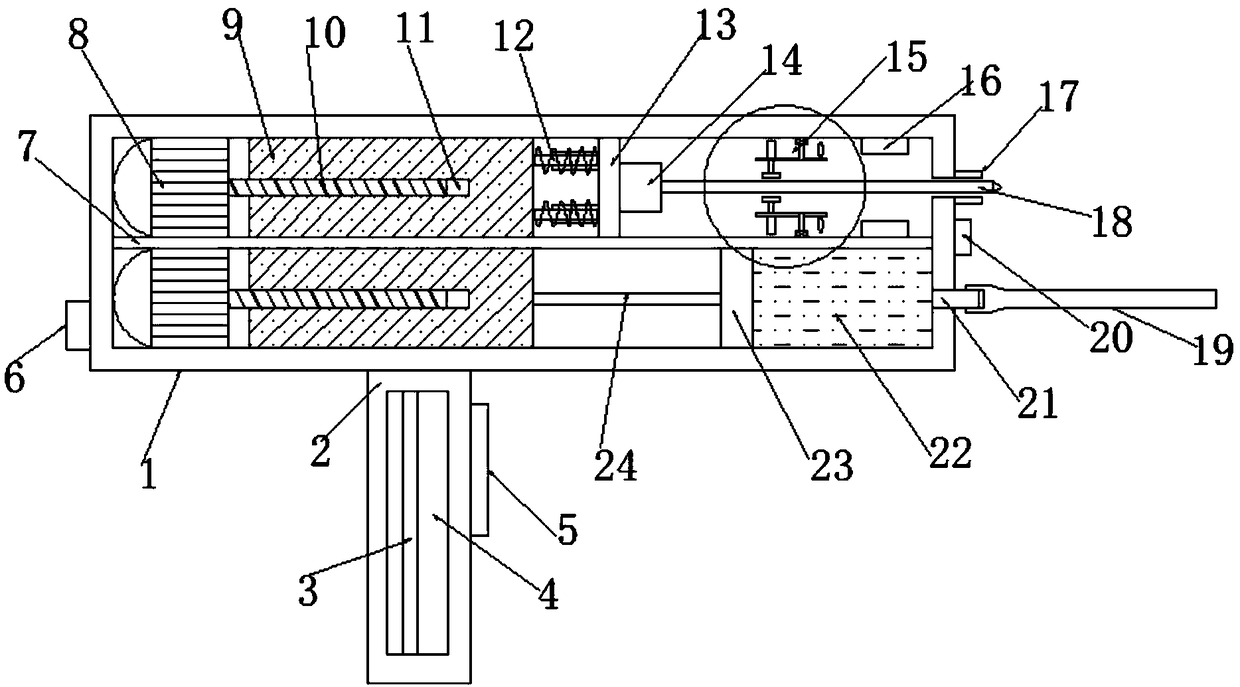

Dryer having structure for enhanced drying and method of use

InactiveUS20080276484A1Improve drying efficiencyShorten the timeDrying solid materials with heatDrying gas arrangementsDesiccantDry structure

A dryer and a drying apparatus attachable to a dryer are disclosed. A wheel having desiccant material is located in line and in close proximity with a heating element. The wheel includes a first portion positioned in an inlet air path and a second portion positioned in an outlet air path. The desiccant material removes water molecules from air within the inlet air path, and lowers the vapor pressure of the incoming air. In the outlet air path, heated air flows through the second portion to transfer energy to the desiccant material. The wheel rotates to change the desiccant material within the portions.

Owner:PROTEGE ENTERPRISES

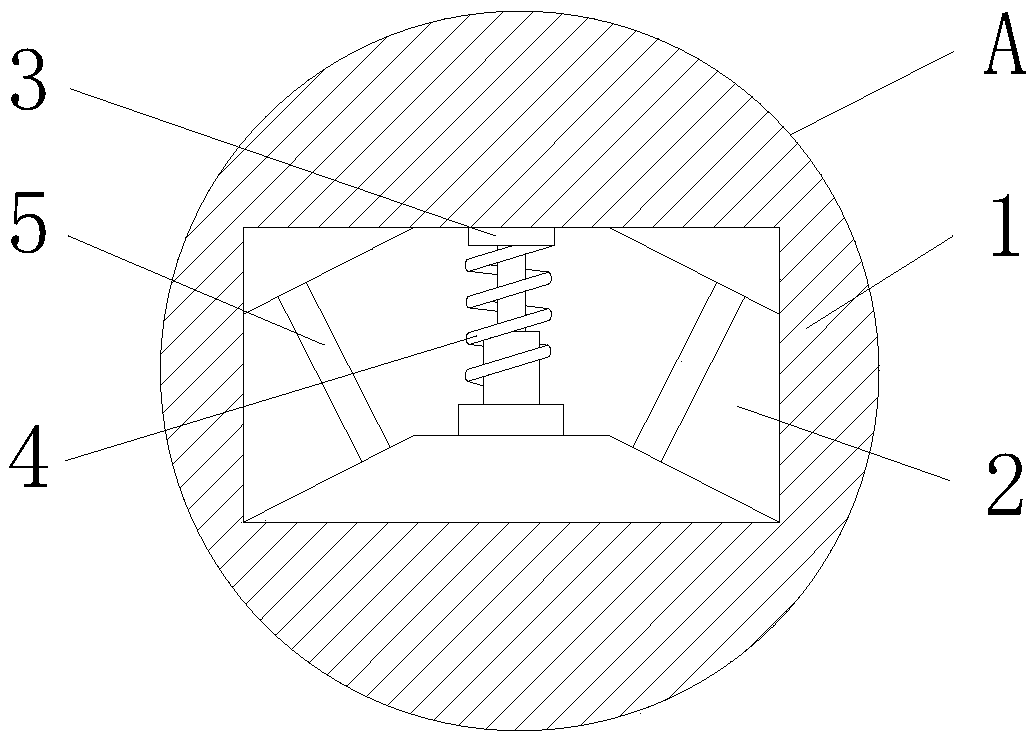

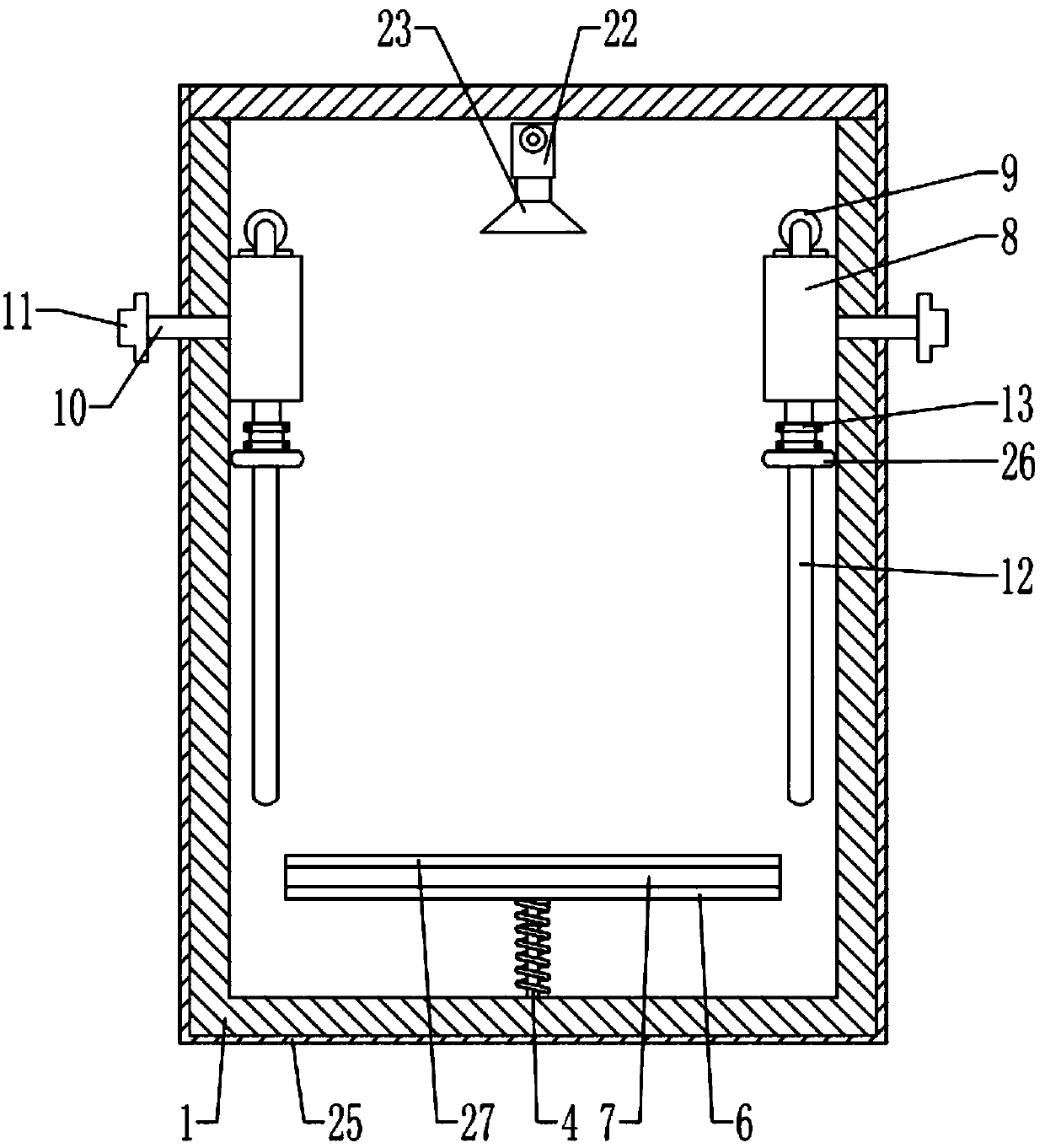

Crack repairing device for building indoor decoration

The invention discloses a crack repairing device for building indoor decoration. The crack repairing device comprises a body, a handle is fixed to the lower side of the body, and a partition plate isarranged in the body. The partition plate divides an inner cavity of the body into a hole drilling cavity and a repairing filling cavity, and pushing mechanisms are arranged on the left side of the hole drilling cavity and the left side of the repairing filling cavity. The output end of the pushing mechanism in the hole drilling cavity is connected with a mounting plate through a buffering mechanism, and a hole drilling motor is fixed at the right end of the mounting plate. A drilling rod is arranged at the output end of the hole drilling motor, and the drilling rod penetrates through a penetrating hole in the right end of the body. A gas blowing and drying structure is arranged in the hole drilling cavity, and comprises a gas blowing module and a heating module. According to the crack repairing device for building indoor decoration, repairing gaps can be trimmed through the drilling rod, so that padding is conducted on the gaps conveniently; meanwhile, hot gas can be generated throughthe gas blowing and drying mechanism by the device, and padding can be quickly solidified and sized; and therefore the working efficiency of workers is improved, and the practicability is high.

Owner:北京高度国际建筑装饰集团有限公司

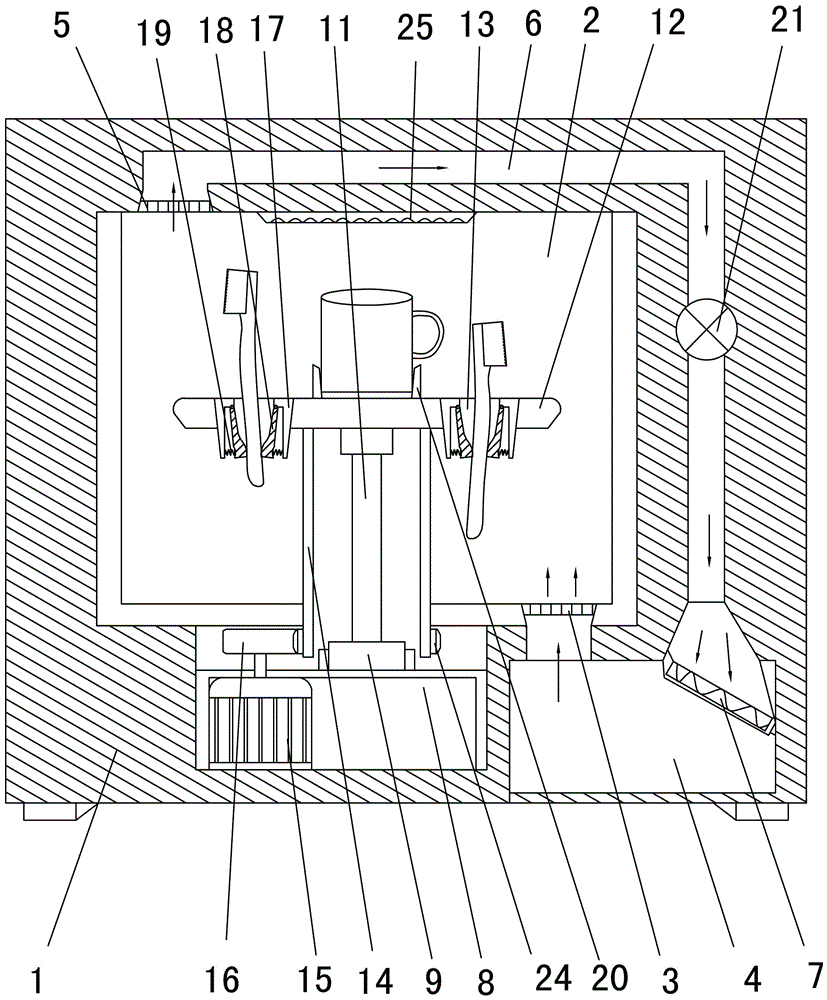

Tooth set disinfector with hot air drying function

The invention discloses a tooth set disinfector with a hot air drying function. The tooth set disinfector comprises a box, wherein the interior of the box is provided with a containing inner cavity, a hot air containing cavity and an air conveying cavity passage; the containing inner cavity is provided with a hot air inlet and a hot air outlet; a support rotary bearing is arranged in an installation inner cavity, and a support shaft core and a rotary placing disc are arranged on the support rotary bearing; a plurality of tooth set clips for placing tooth sets are arranged on a disc body of the rotary placing disc; a driving structure is arranged in the installation inner cavity and is used for driving the rotary placing disc to rotate. The tooth set disinfector has the advantages that a hot air tooth set drying structure with an internal circulation function is arranged, the hot air tooth set drying structure adopts hot air with temperature of 35 to 50 DEG C to blow, dry and disinfect the tooth sets from bottom to top; by combining the hot air internal circulating function and the rotary tooth set placing disc, the tooth sets can be subject to all-bearing uniform heating, drying and disinfection, so as to completely kill germs which are attached to the tooth sets.

Owner:郑明星

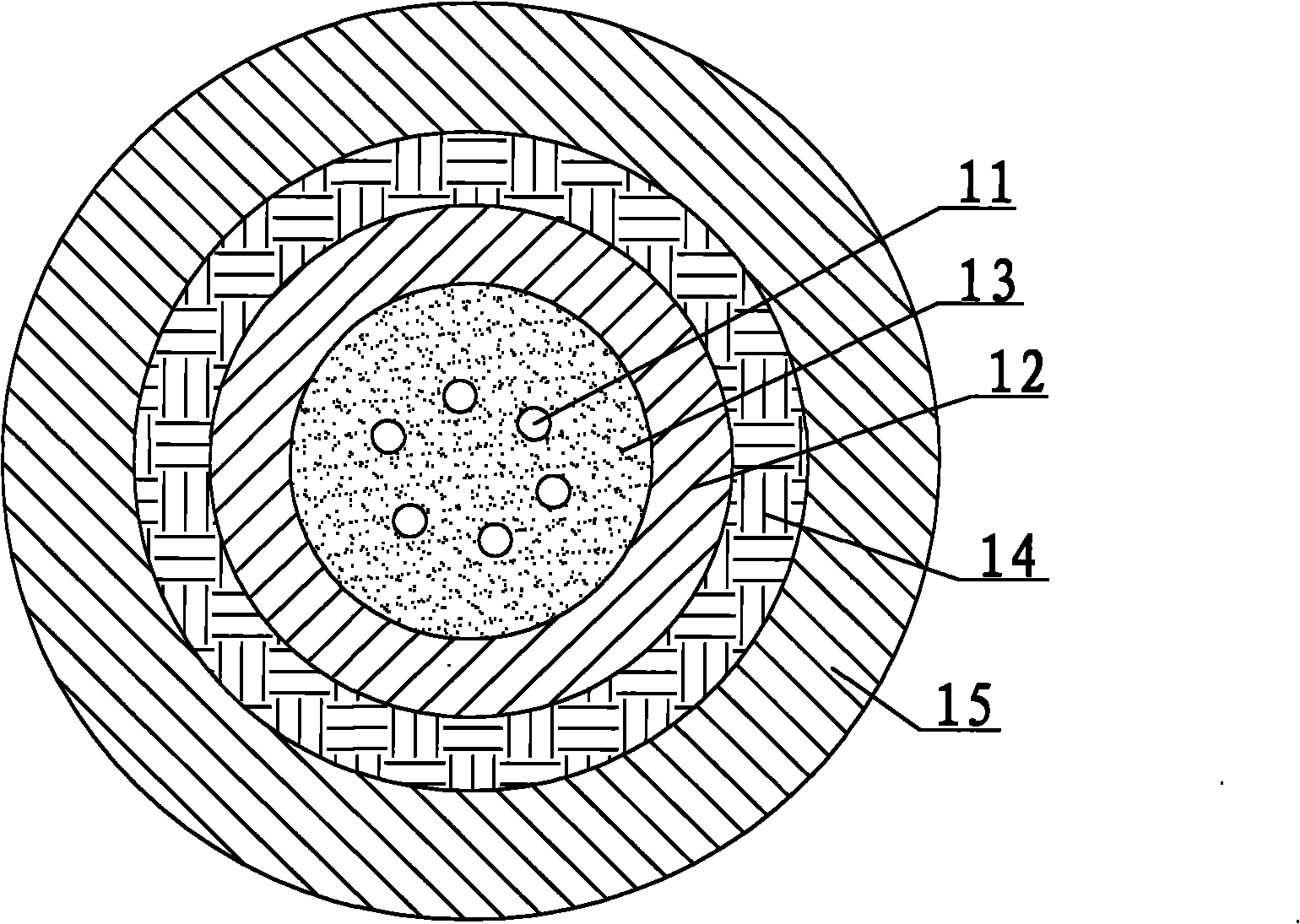

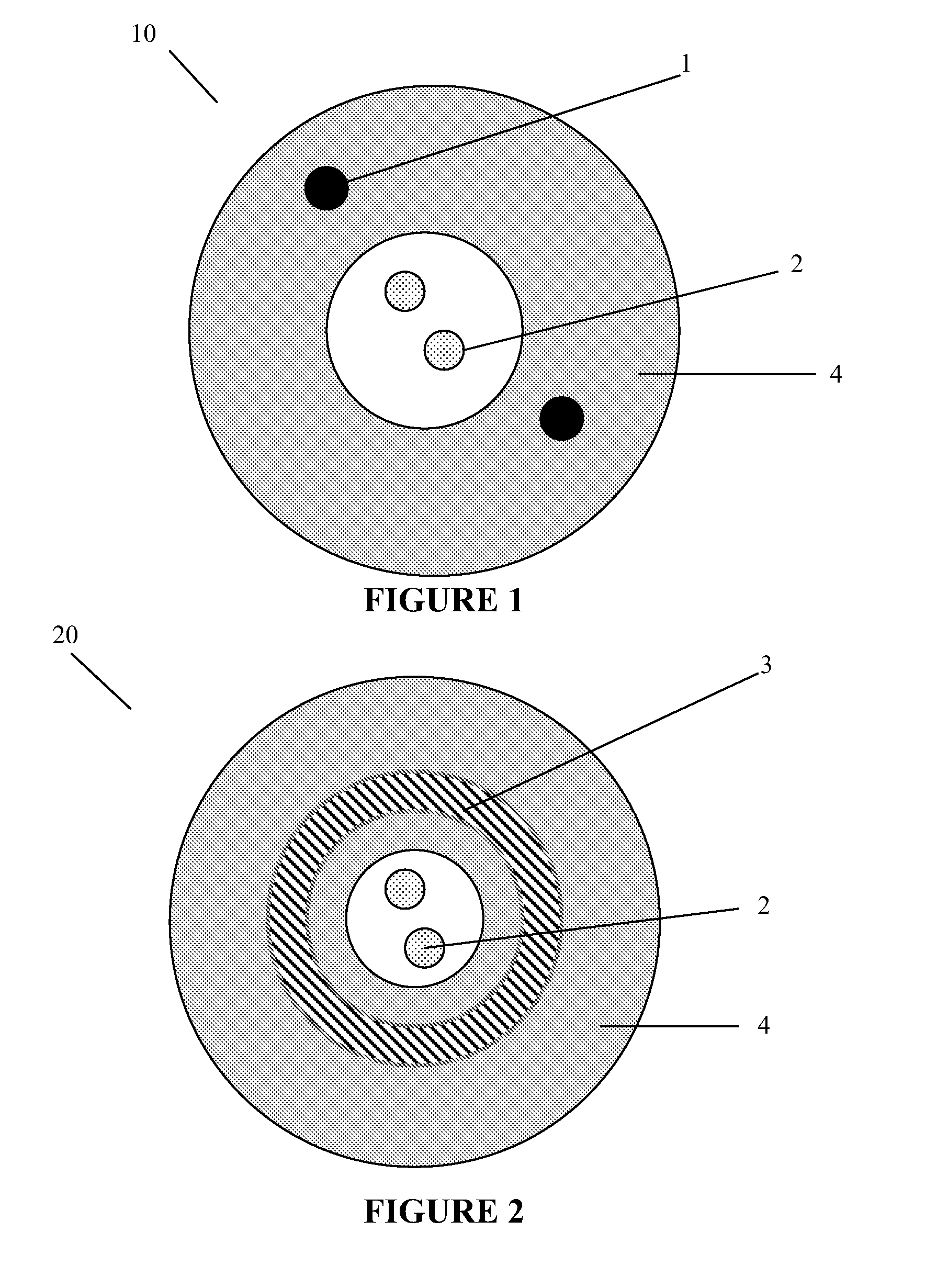

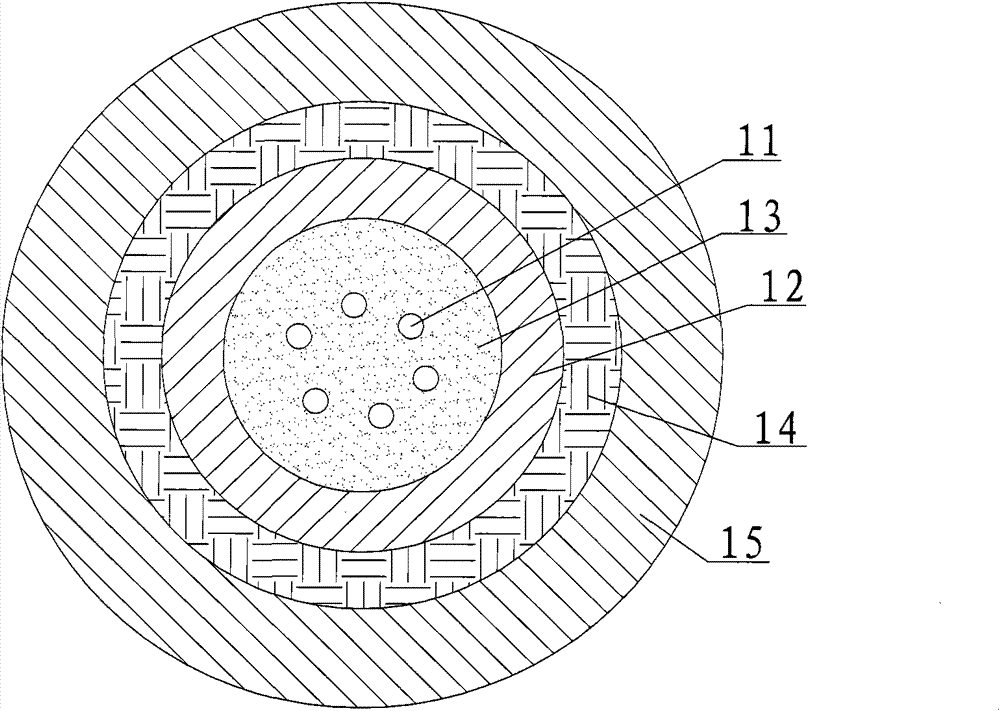

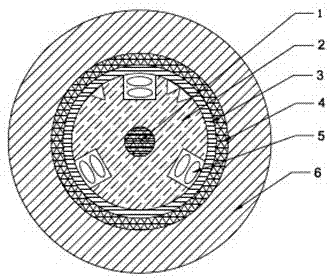

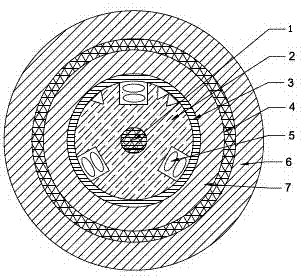

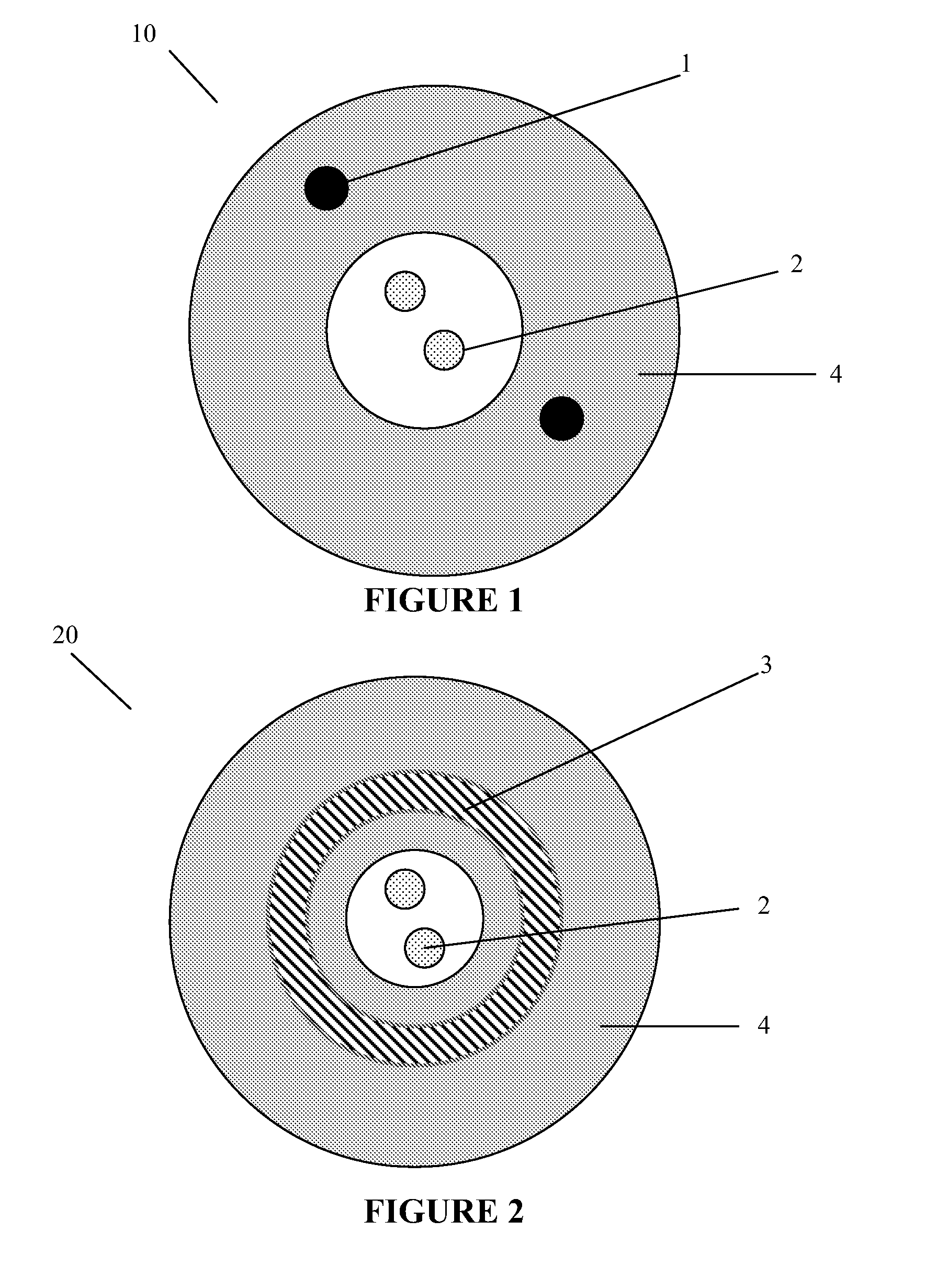

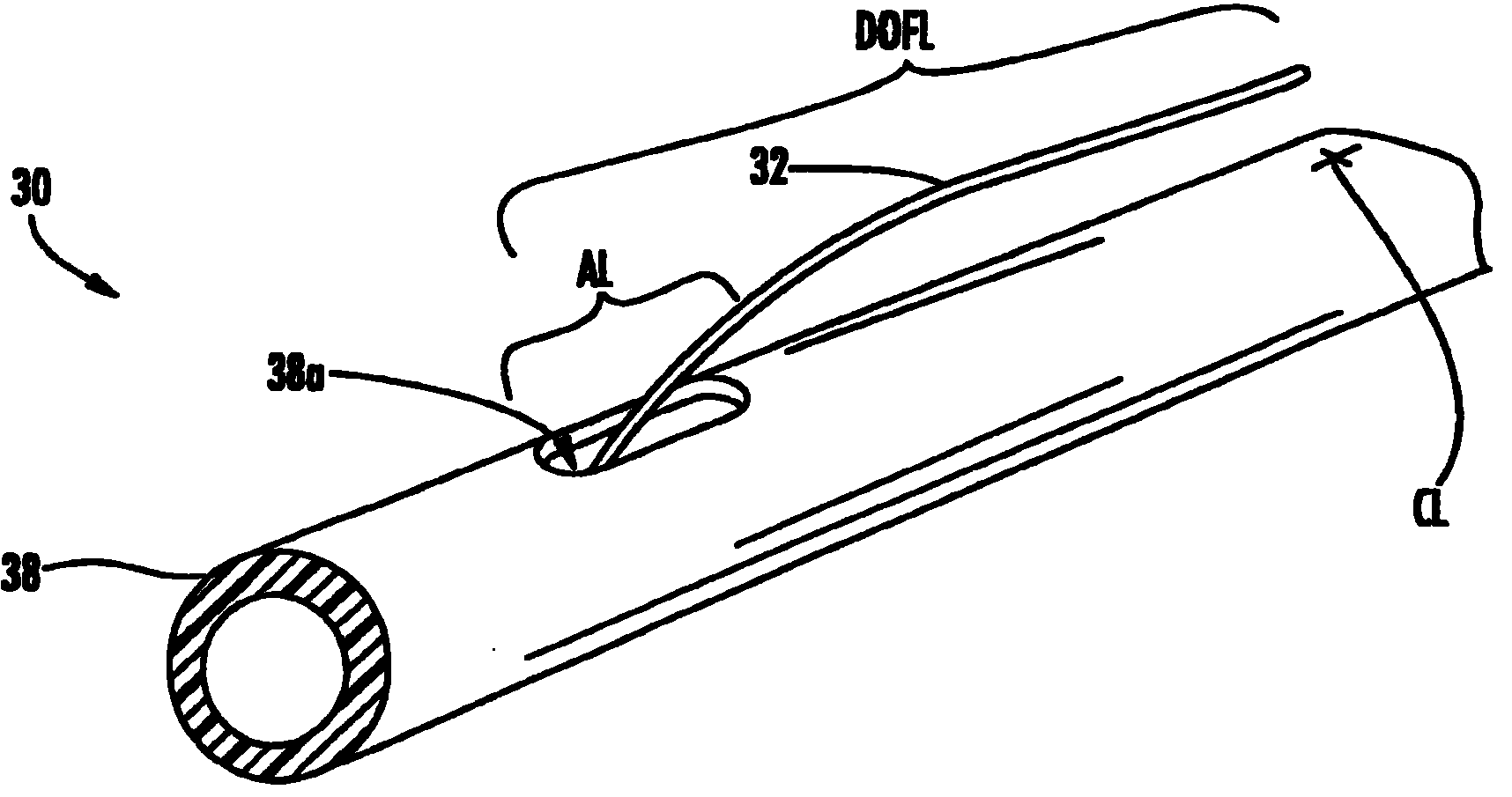

Strengthened Optical Waveguide Fiber Cable

The present invention relates to a loose tube optical waveguide fiber cable that is suitable for riser or plenum applications. The cable includes a protective tube that loosely surrounds two or more optical waveguides inside the hollow cavity defined by the tube. The protective tube has an inner surface and an outer surface and is a dry structure. Accordingly, the protective tube does not contain any gel-like compounds or other materials around the optical fibers positioned inside the protective tube. Strengthening members are disposed between the inner surface of the protective tube and the outer surface of the protective tube. The strengthening members are configured as embedded or layered strengthening elements and are disposed longitudinally along the length of the cable.

Owner:DRAKA COMTEQ BV

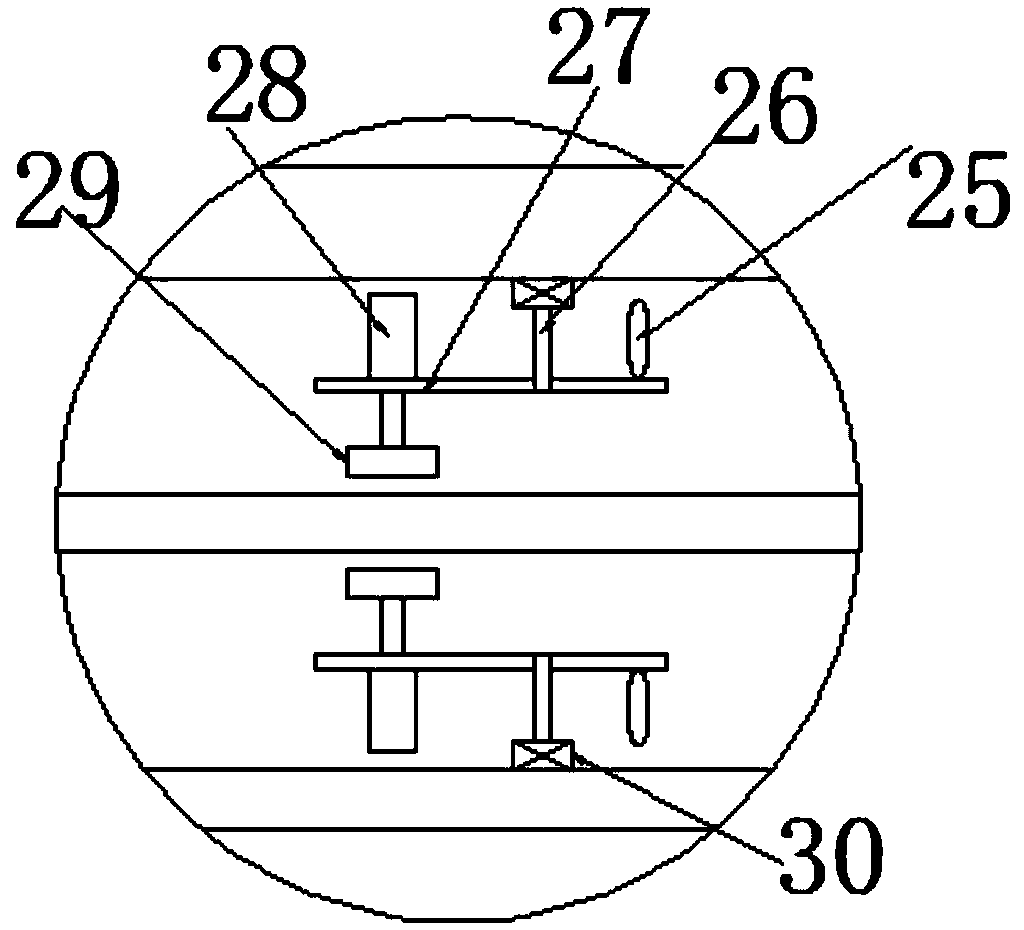

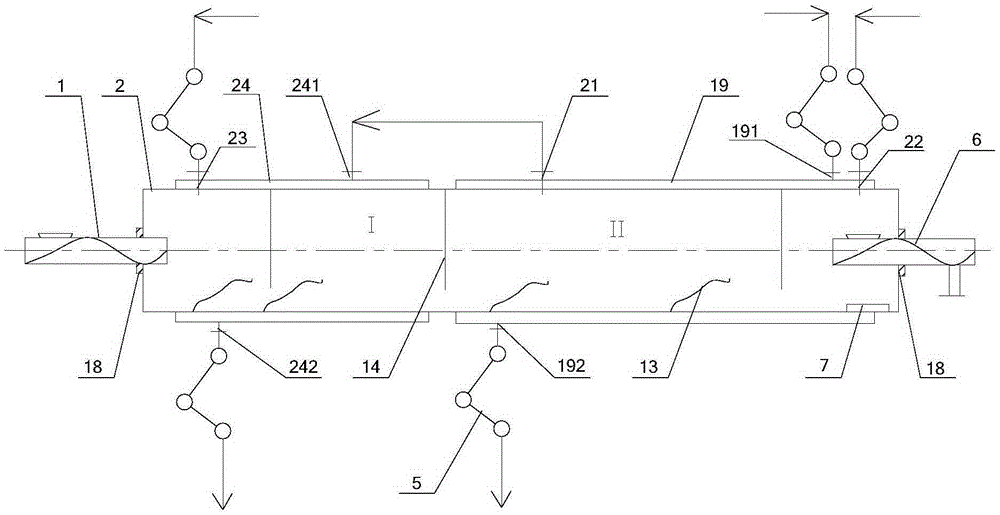

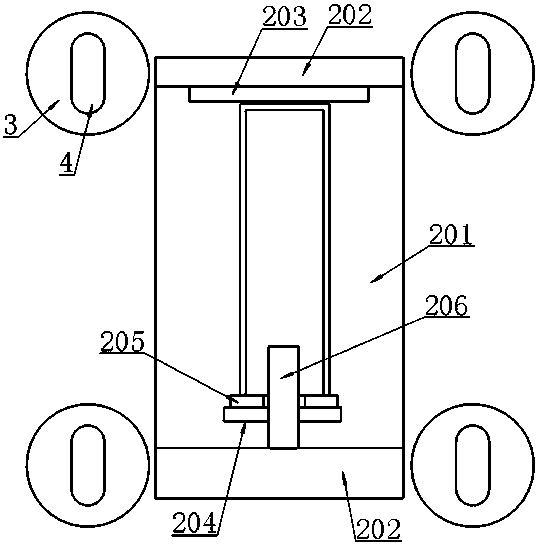

Rotary drying device and drying technology

ActiveCN105910414ASave energyHigh thermal efficiencyDrying solid materials with heatDrying gas arrangementsFailure rateDry structure

The invention discloses a rotary drying device, comprising a swing-type rotary furnace. The swing-type rotary furnace comprises a rotary drum, a driving device and a supporting device, a control device, and a heating jacket and / or dry hot gas inlet and outlet. The rotary drum is internally provided with a drying section. The cylinder wall of the vapor phase region of the drying section is provided with a steam outlet. The driving device and the supporting device are arranged out of the rotary drum, and are used to drive and support the rotary drum to swing back and forth around a rotating axis. The control device is connected with the driving device through a wire, and is used to control operation of the driving device. The heating jacket is arranged on the cylinder wall of the drying section. The heating jacket is provided with a hot medium inlet and a hot medium outlet which are connected with an external pipe through a moveable conduit assembly. Since the rotary drying device uses the swing-type rotary furnace, the rotary drum just swings back and forth in certain radian, and the cylinder wall of the rotary drum is provided with the heating jacket and the dry hot gas inlet and outlet. Compared with an existing built-in drying structure, the device is simple in structure, reduced in failure rate, and convenient in maintenance. The invention also discloses a drying technology.

Owner:HUNAN DINGJIU ENERGY & ENVIRONMENT TECH LTD

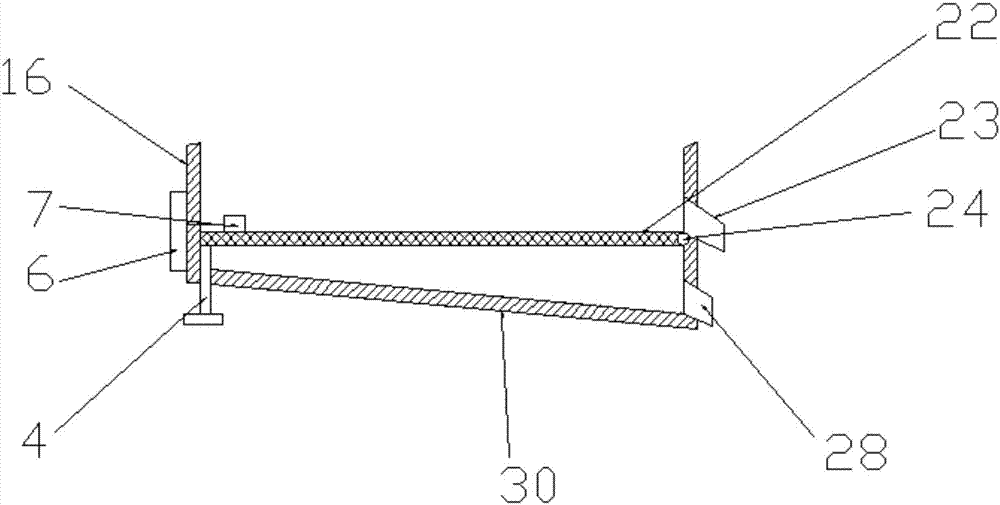

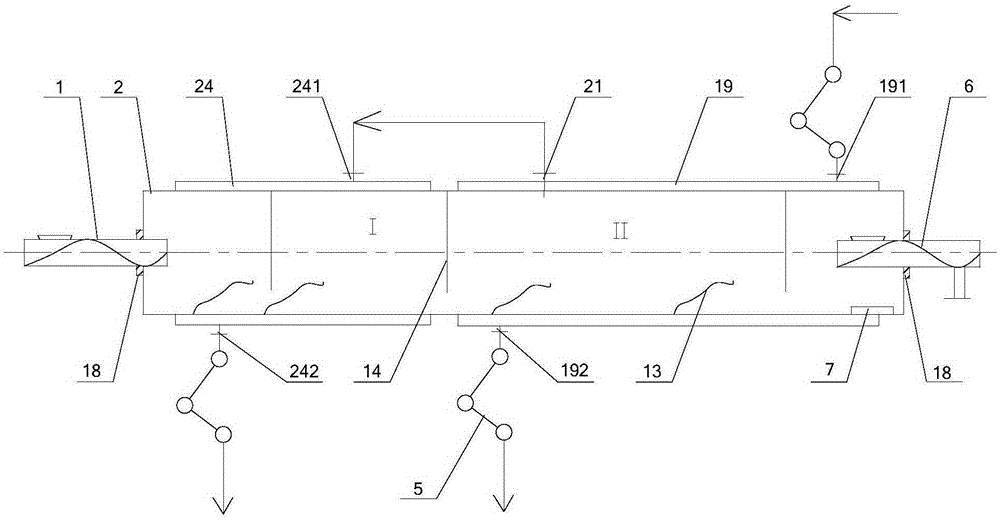

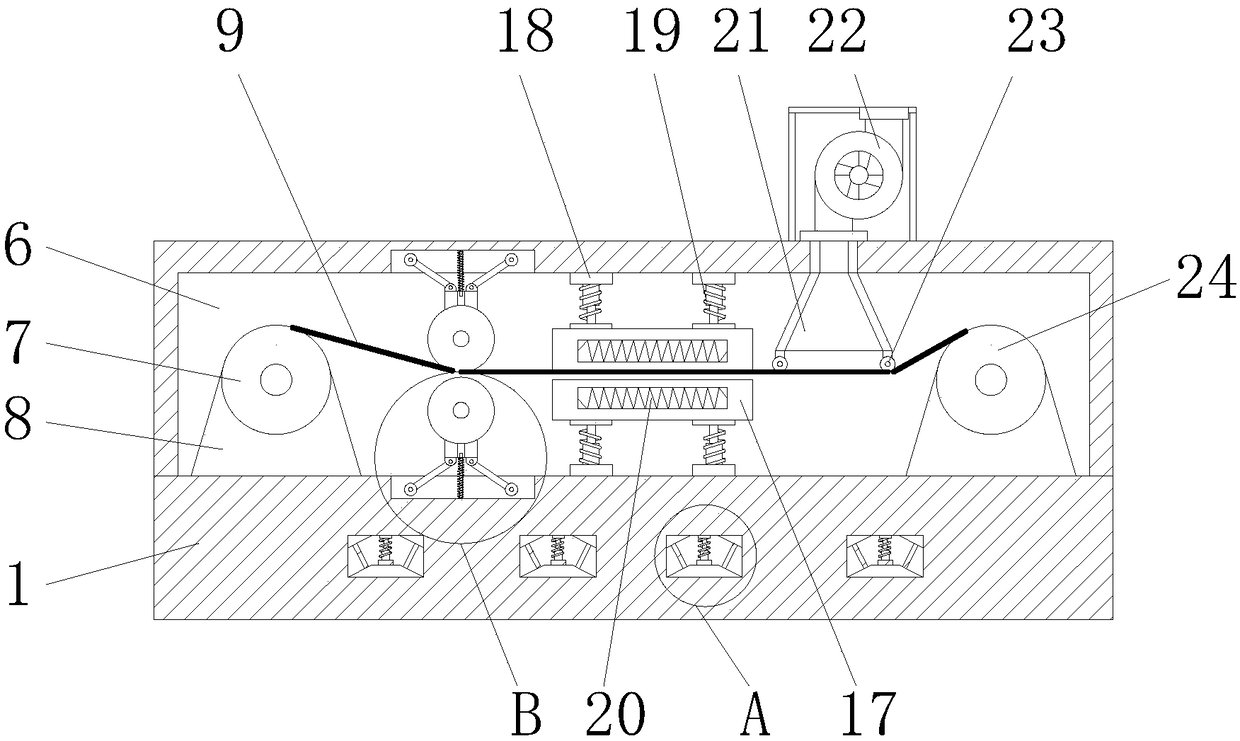

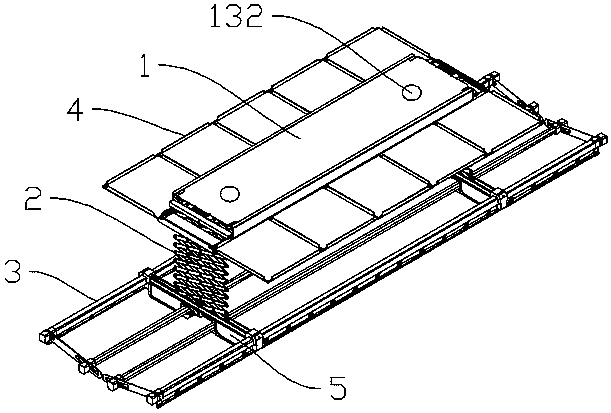

Conveying device with drying structure for garment printing and dyeing

InactiveCN109440350ARelieve stressRelieve pressureLiquid/gas/vapor removal by gas jetsTextile treatment carriersDry structurePulp and paper industry

The invention discloses a conveying device with a drying structure for garment printing and dyeing. The device comprises a box and an air outlet, an empty slot is formed in the lower end in the box, support columns are arranged at the left end and the right end of a support rod respectively, a launder is formed in the upper end in a box, and the left end of the launder is connected with a raw material roller through a support roller, and meanwhile a compression roller is arranged on the right side of the raw material roller, cloth wraps the periphery of the raw material roller, the compressionroller is connected with the box through a connecting block and a connecting rod, the lower end of the connecting rod is connected with the box through a rolling wheel and a sliding groove, a shaft column penetrates through the middle of the connecting block, a pressing plate is arranged on the right side of the compression roller and connected with the box through a connecting column and a connecting spring, and an air outlet is formed in the right side of the pressing plate. According to the conveying device with the drying structure for garment printing and dyeing, the printed and dyed cloth can be subjected to thermal drying and air-drying, and subsequent processing can be conducted on the cloth conveniently.

Owner:嘉兴铭皓服装有限公司

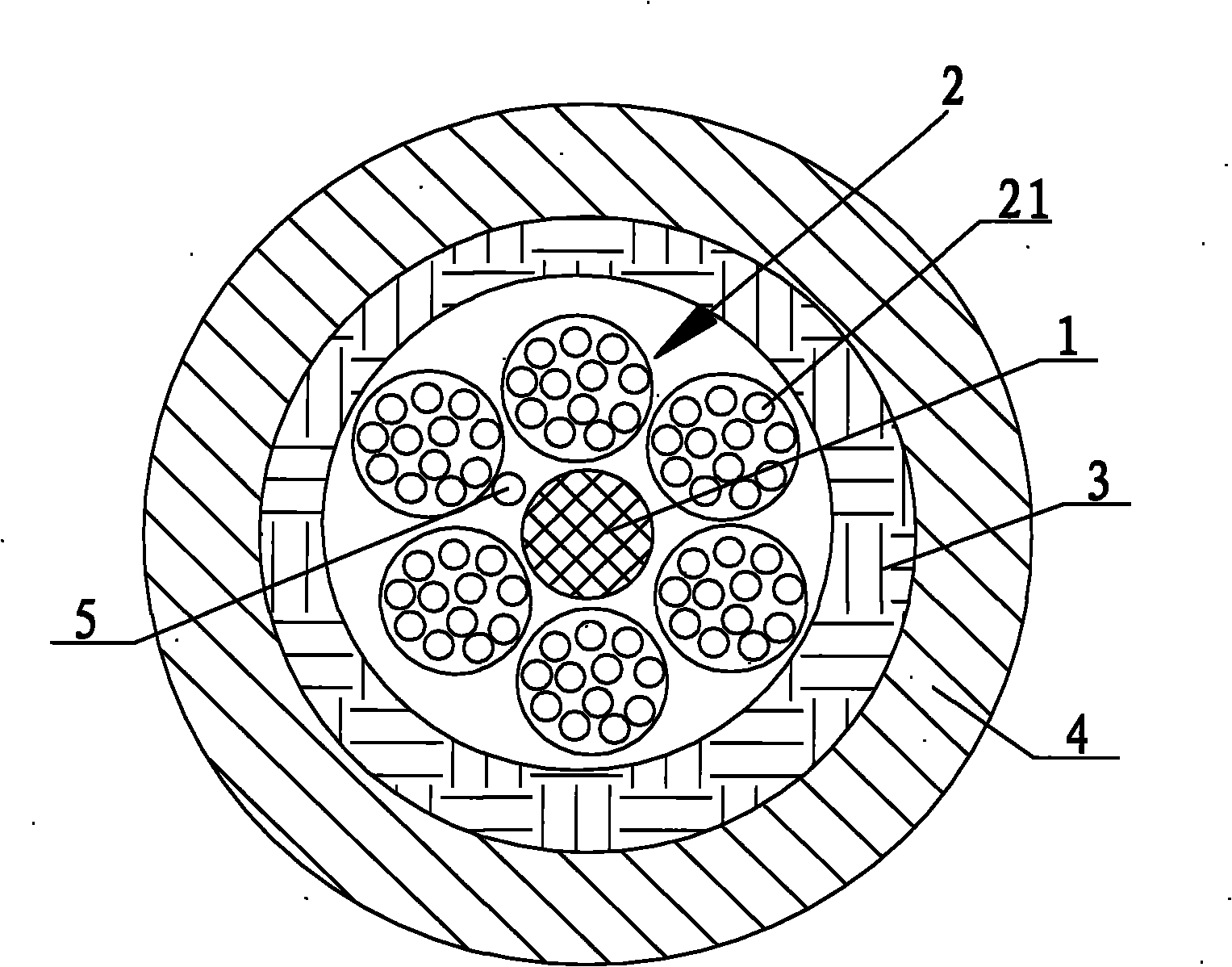

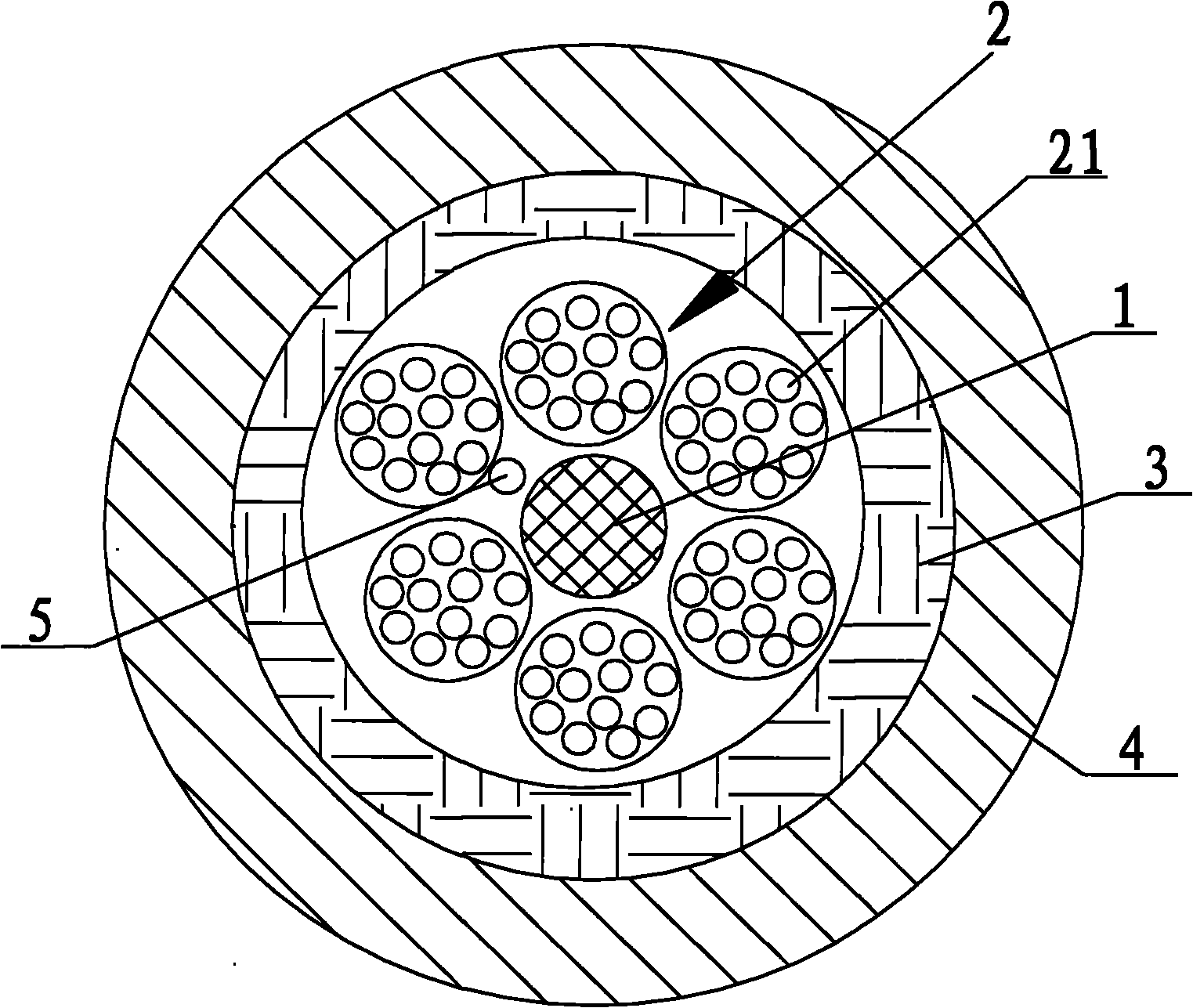

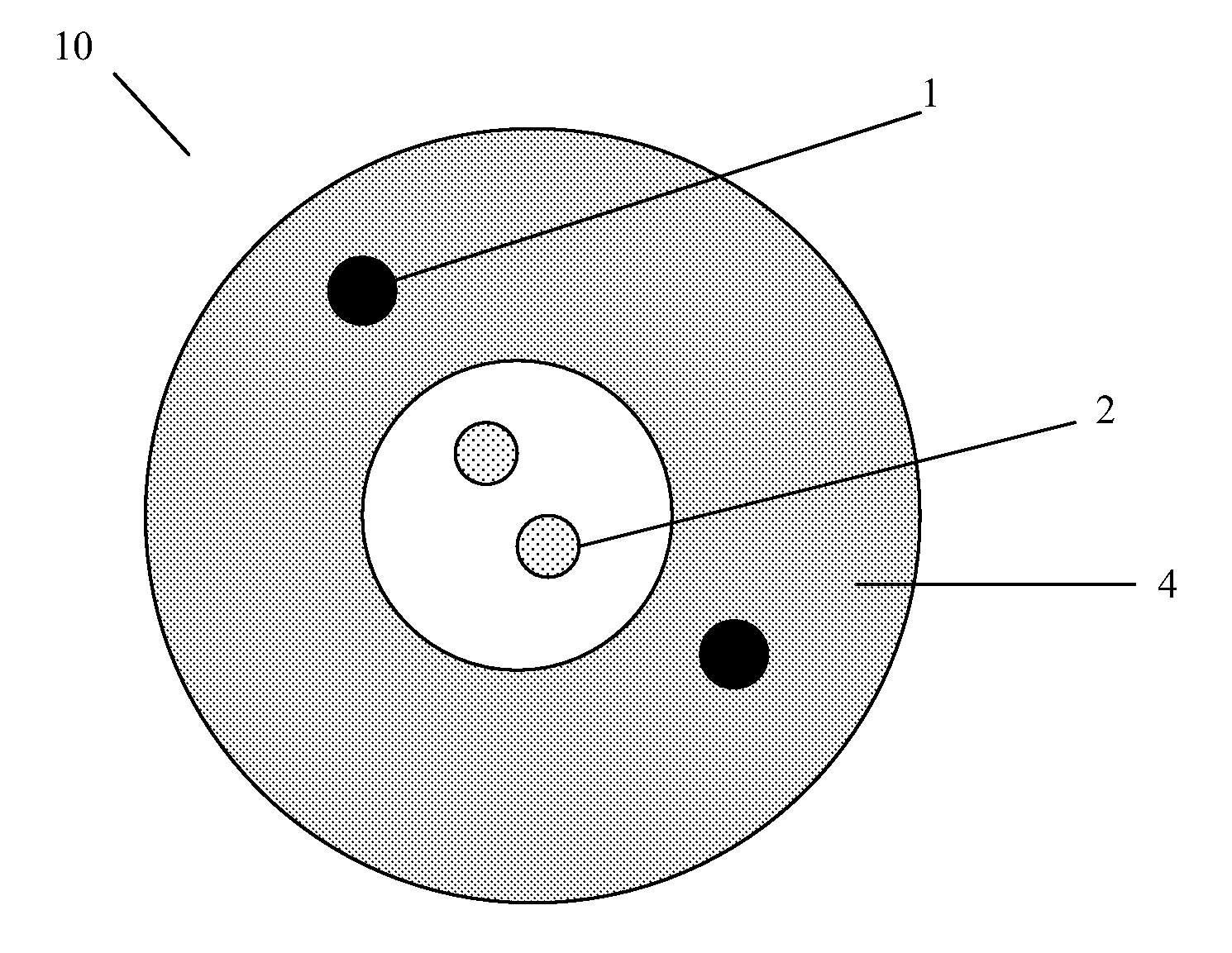

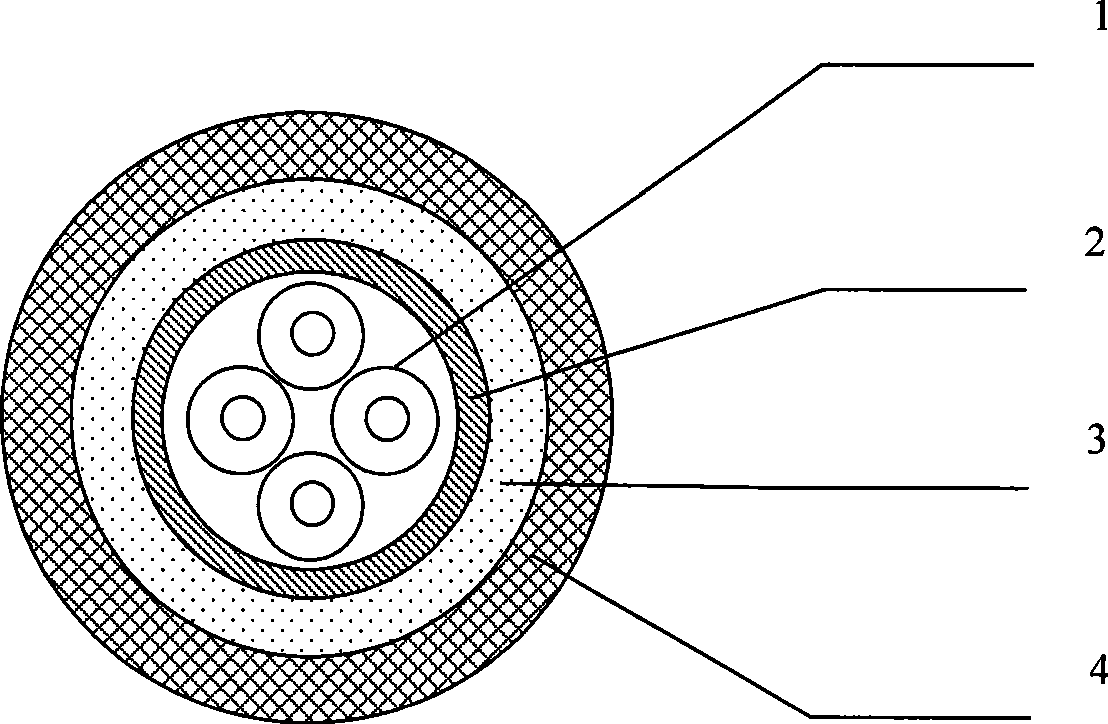

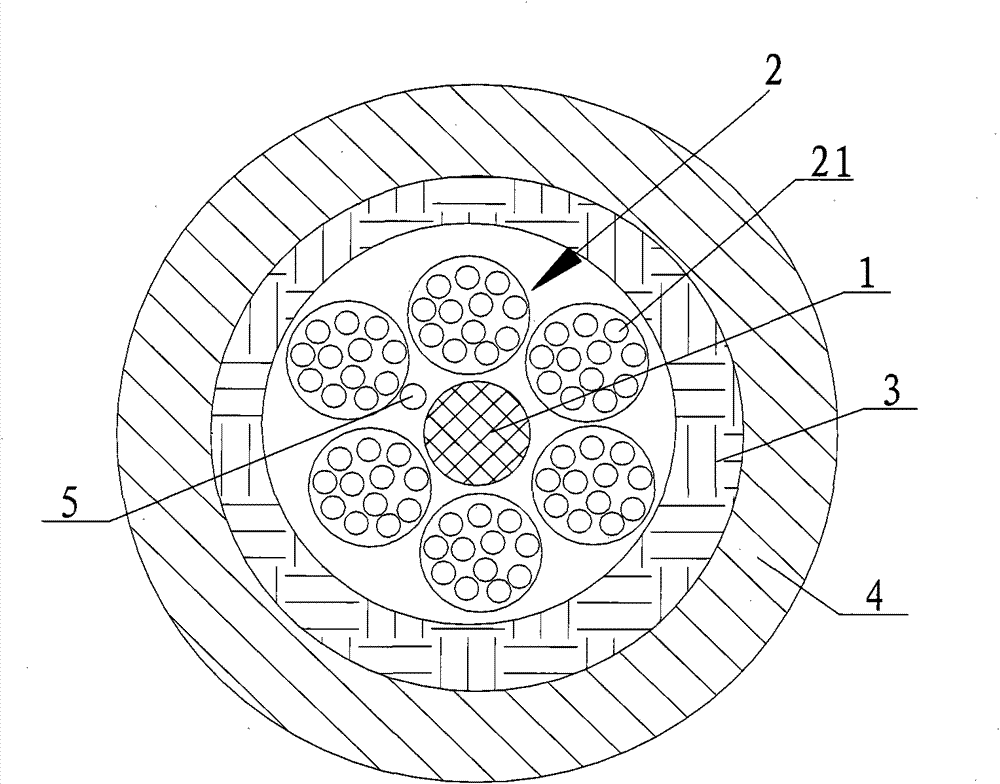

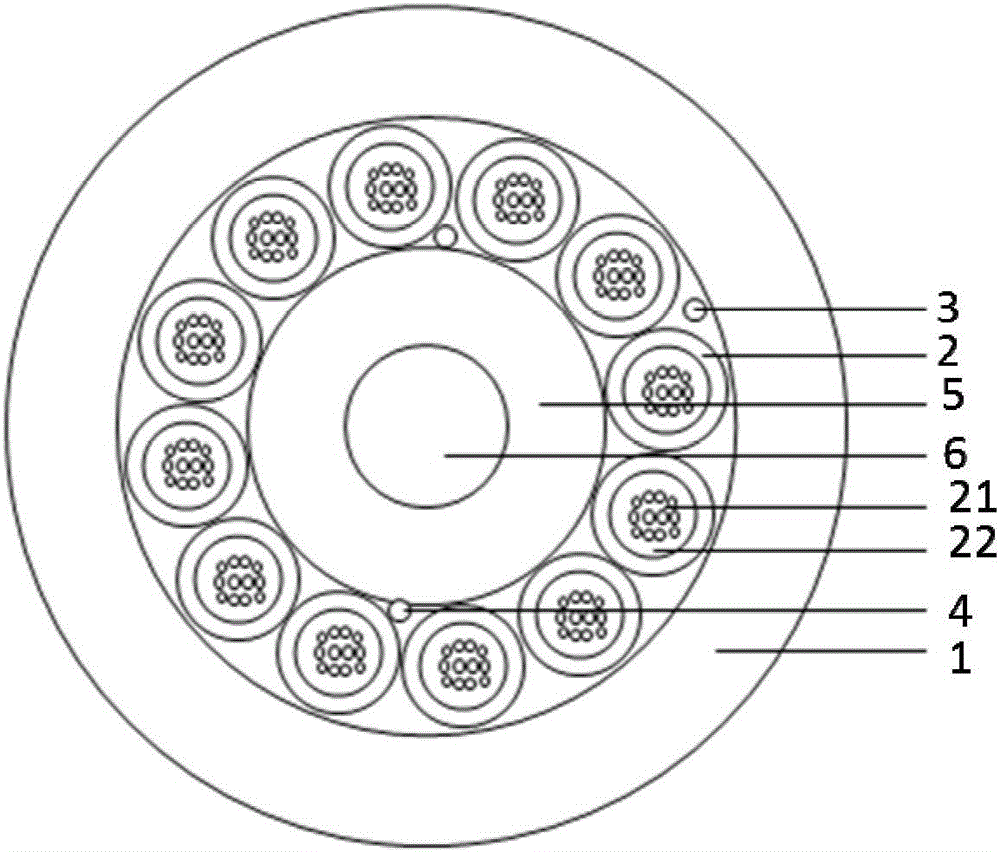

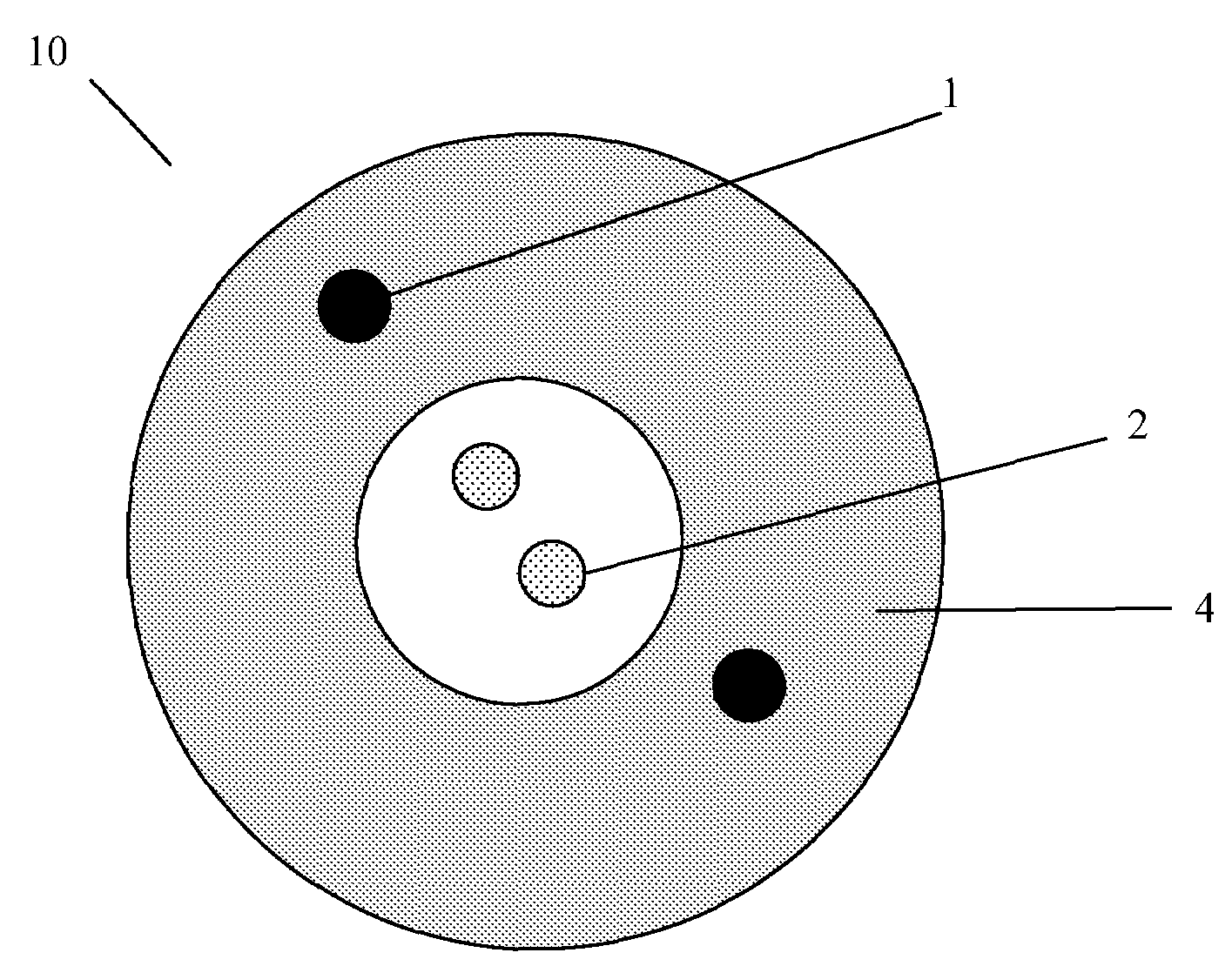

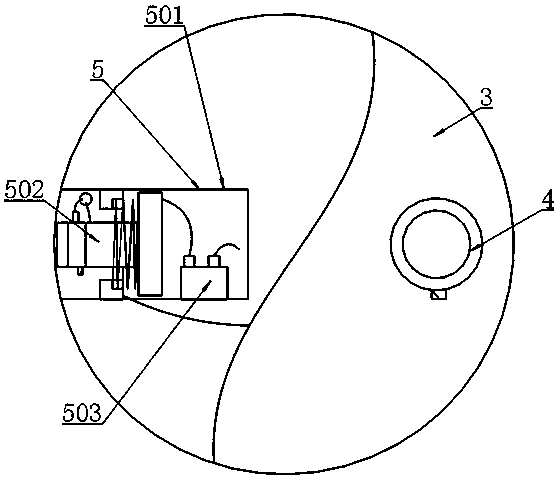

Optical cable for connection of 3G equipment

ActiveCN101393311ASolve the contradiction that cannot be used outdoorsSmall diameterFibre mechanical structuresDry structureConfidentiality

The invention relates to an optical cable for connecting 3G equipment, which comprises a plurality of sub-unit cables (1), a loosened sleeve (2), a reinforcer layer (3) and an outer sheath (4), wherein the plurality of sub-unit cables are directly arranged into the loosened sleeve (2); reinforcers are coated on the circumference of the loosened sleeve; the outside of the reinforcer layer is provided with the outer sheath; and the whole cable has a full-dry structure. The optical cable for connecting the 3G equipment is taken as a jumper for optical communication equipment in a building and outdoor optical terminals on the roof and so on, has the advantages of full-dry structure, good bending property, fire retardation, lightning protection, handiness, large transmission capacity, good confidentiality and so on; joints can be arranged on both ends of the cable in advance for convenient connection; and the invention is an optical cable for connecting the equipment aiming at 3G optical-fiber network construction.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

Full-dry high fiber count air-blowing micro-cable and optical fibre bundle processing method

ActiveCN102023357BThe number of fiber cores increasesGood flexibilityFibre mechanical structuresFiberDry structure

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

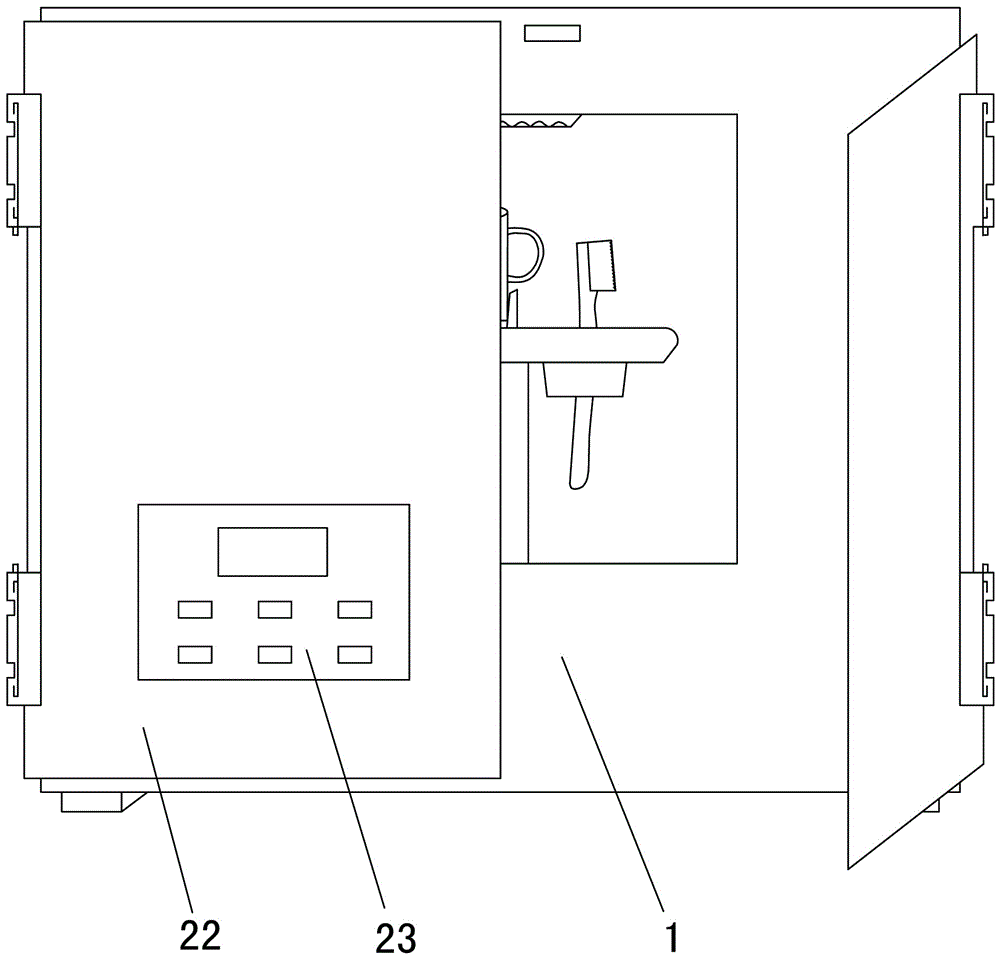

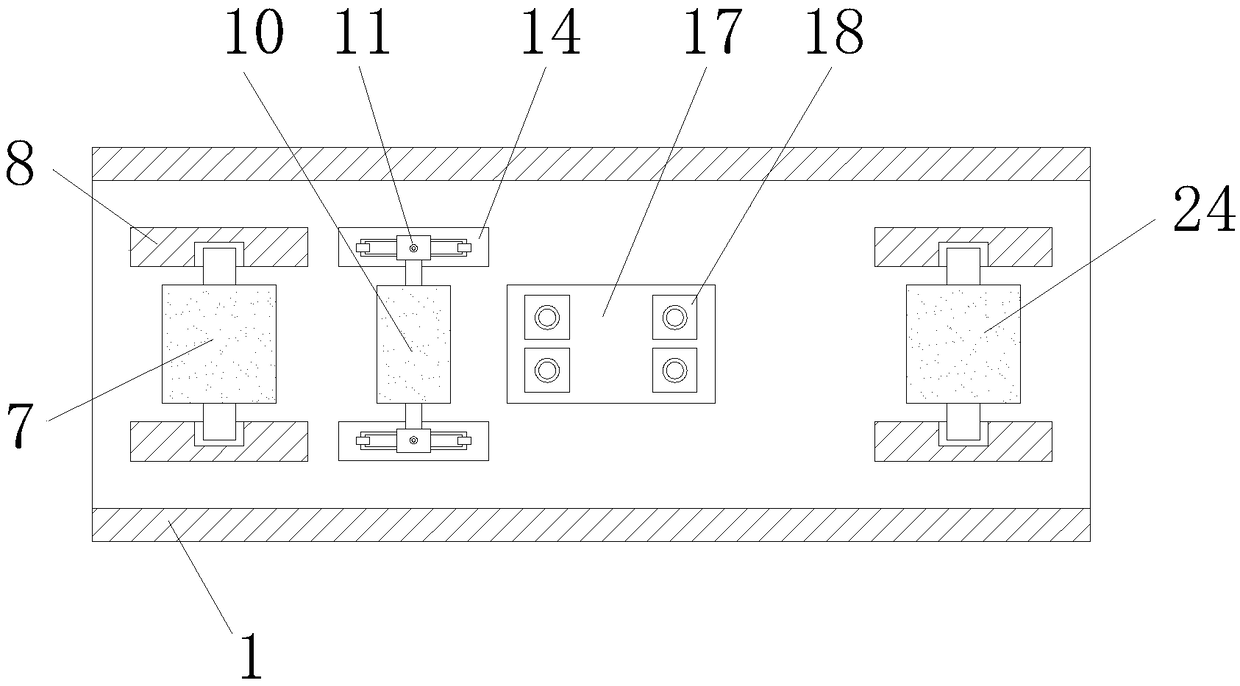

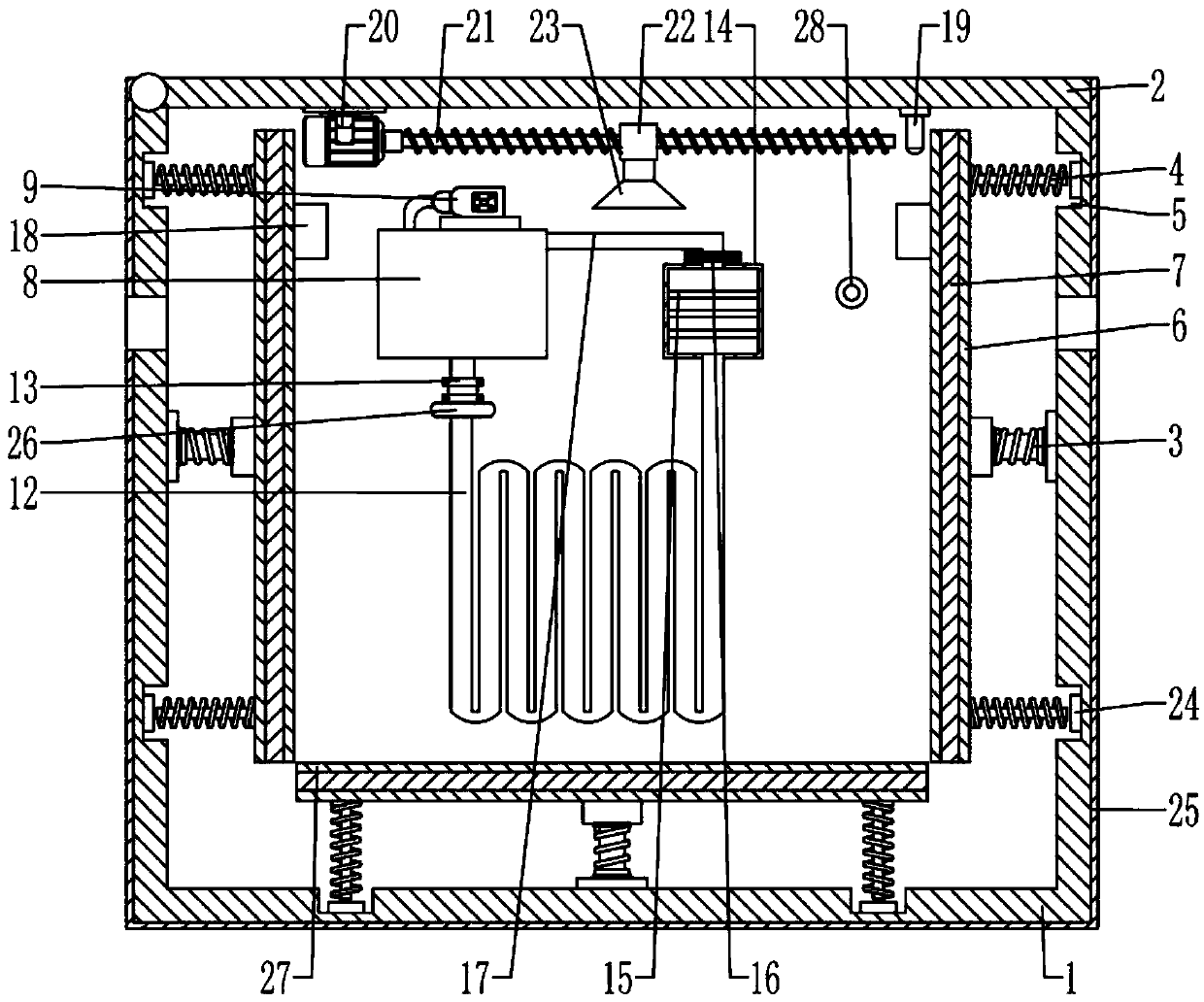

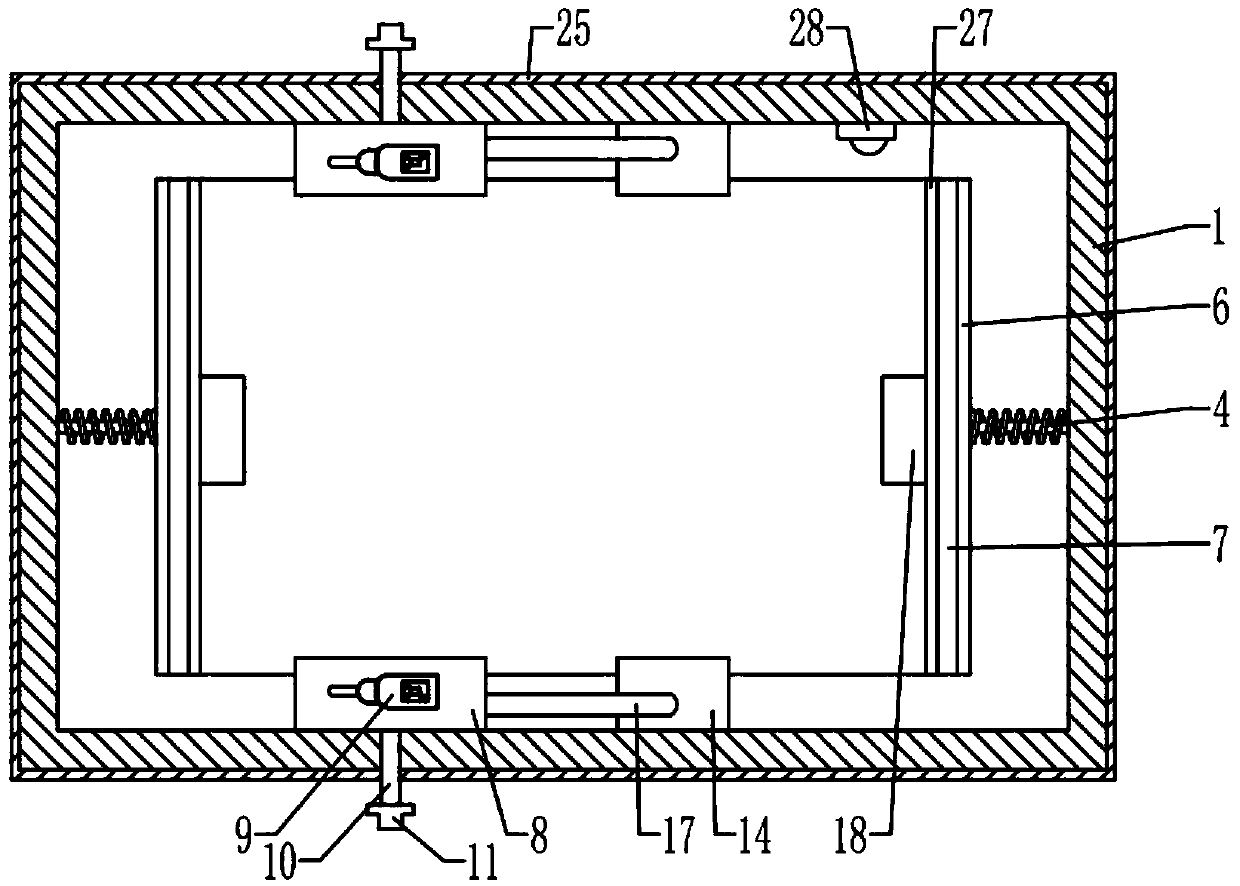

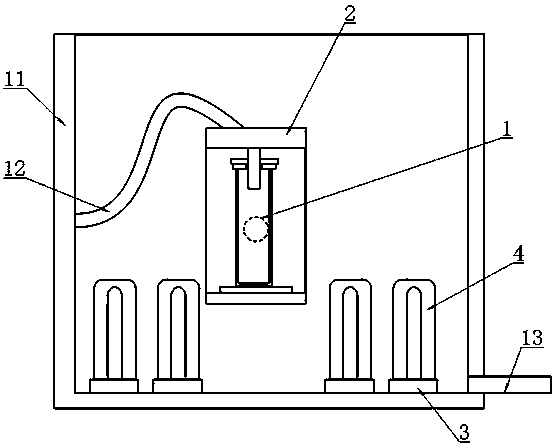

Battery storage device for new energy vehicles

The invention discloses a battery storage device for new energy vehicles, which comprises a box body and a movable door. Shock absorption structures are installed on the side walls and inner lower wall of the box body. A temperature regulating and monitoring structure is installed on the inner side walls of the box body. The movable door is arranged on the upper wall of the box body. A drying structure is installed on the inner lower wall of the movable door. The invention relates to the technical field of new energy vehicle batteries. The shock on a battery is absorbed by the shock absorptionstructures, the working temperature of the battery is detected by the temperature regulating and monitoring structure, heat is dissipated in time by means of water cooling, and the water on the surface of the battery is dried by the drying structure. Through the cooperation of the structures, the functions of battery shock absorption protection, temperature monitoring and operation environment drying are achieved.

Owner:INNER MONGOLIA JUNENG ENERGY SAVING SERVICE

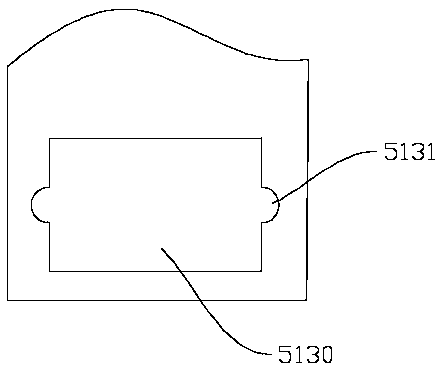

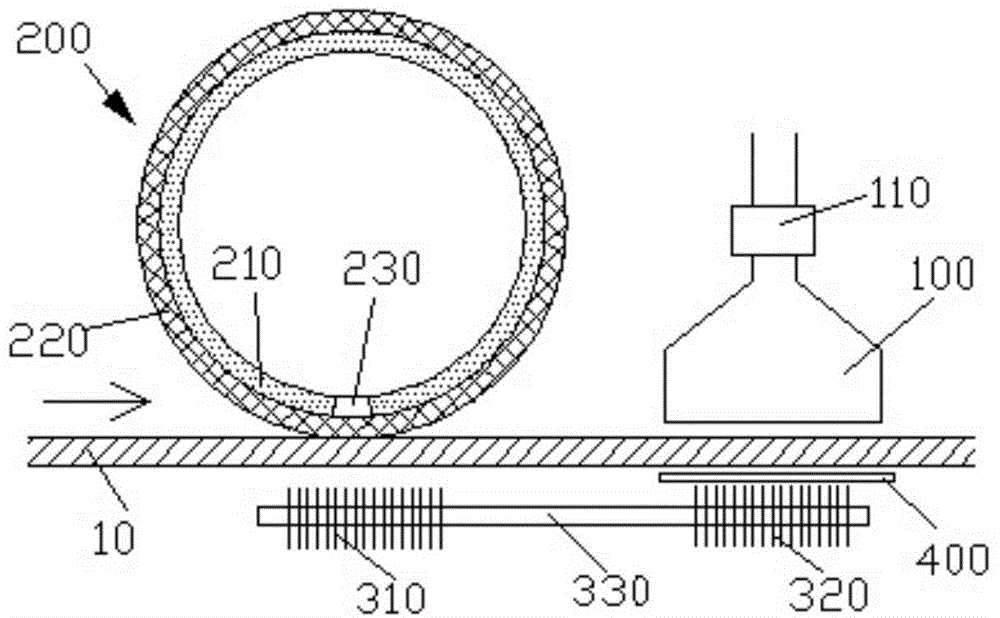

Center beam tube type optical cable, manufacturing method and fixing method of center beam tube type optical cable and plastic fixture

PendingCN106443918ASmall sizeAvoid destructionOptical fibre/cable installationFibre mechanical structuresFiberYarn

The invention provides a center beam tube type optical cable, a manufacturing method and a fixing method of the center beam tube type optical cable and a plastic fixture. The center beam tube type optical cable comprises an outer sheath, a plurality of loose tube sleeves located in the outer sheath and arranged in a circle, cable cores wrapped by the loose tube sleeves, a tear rope and water blocking yarn, wherein the tear rope and the water blocking yarn are located among the loose tube sleeves, and the cable cores comprise reinforcing part cushion layers wrapped by the loose tube sleeves and non-metallic reinforcing parts located in the reinforcing part cushion layers. By the adoption of the novel small-diameter optical cable, the optical cable size is effectively reduced; all materials of the optical cable are non-metallic materials, so that damage caused by thunderstorms to the optical cable is effectively avoided; besides, grounding for lightning protection in the construction process is omitted, so that construction efficiency is improved. A semi-dry structure is adopted for the cable cores, so that pollution caused by factice to the environment is reduced. The large number of the optical fiber cores meets the requirement of the access network layer for the number of optical fiber cores; in cooperation with the special non-metallic fixture, effective fixing is achieved in a connector box and a light splitting and fiber distribution box.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Full-dry nonmetal self-supporting skeleton-type optical cable

InactiveCN104849824AHigh strengthImprove tensile propertiesFibre mechanical structuresFiberLightning strokes

The invention relates to a full-dry nonmetal self-supporting skeleton-type optical cable, and the optical cable comprises an external sheath and a skeleton. The periphery of the skeleton is provided with longitudinal fiber slots at intervals, and the interior of each longitudinal fiber slot is provided with an optical communication unit. The optical fiber is characterized in that the center of the skeleton is provided with a nonmetal central reinforcing part in a passing-through manner; the periphery of the skeleton is sequentially wrapped by a waterproof part and a nonmetal reinforcing part; and the outermost layer is wrapped by the external sheath. The beneficial effects of the invention are that 1, the optical cable employs a skeleton-type optical cable structure, and the interior and exterior of the skeleton are provided with the nonmetal reinforcing parts, thereby enabling the optical cable to be high in strength, good in tensile property, and large in span; 2, the fiber filling density is high, and the relative diameter of the optical fiber is small; 3, the optical cable is easy for the setting of a separating window, and optical fibers can be separated and extracted from the separating window; the construction and connection are convenient, and a full-dry structure is more convenient for construction, connection and maintenance; 4, an all-dielectric structure can be used in a power transmission line, is resistant to lightning stroke, cannot be affected by electromagnetic interference, can be laid in a live-line manner, facilitates the separating and winding of the optical fibers, is high in laying success rate, and is low in cable consumption.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

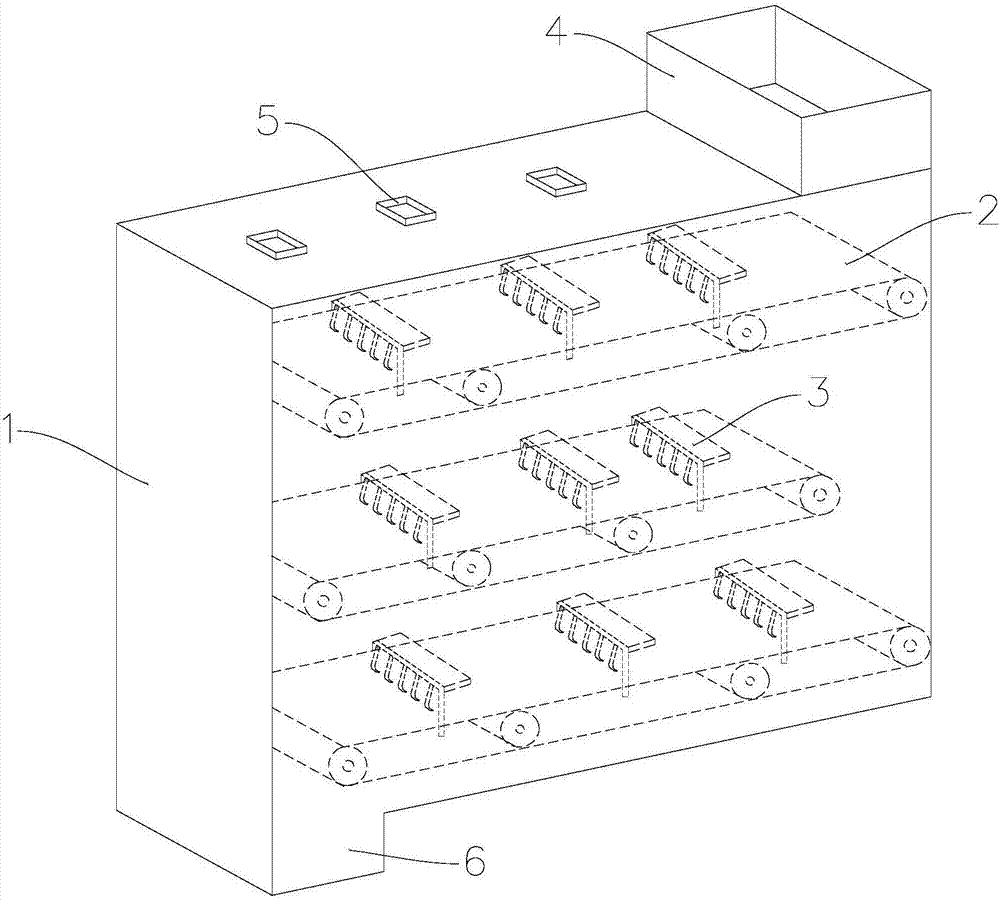

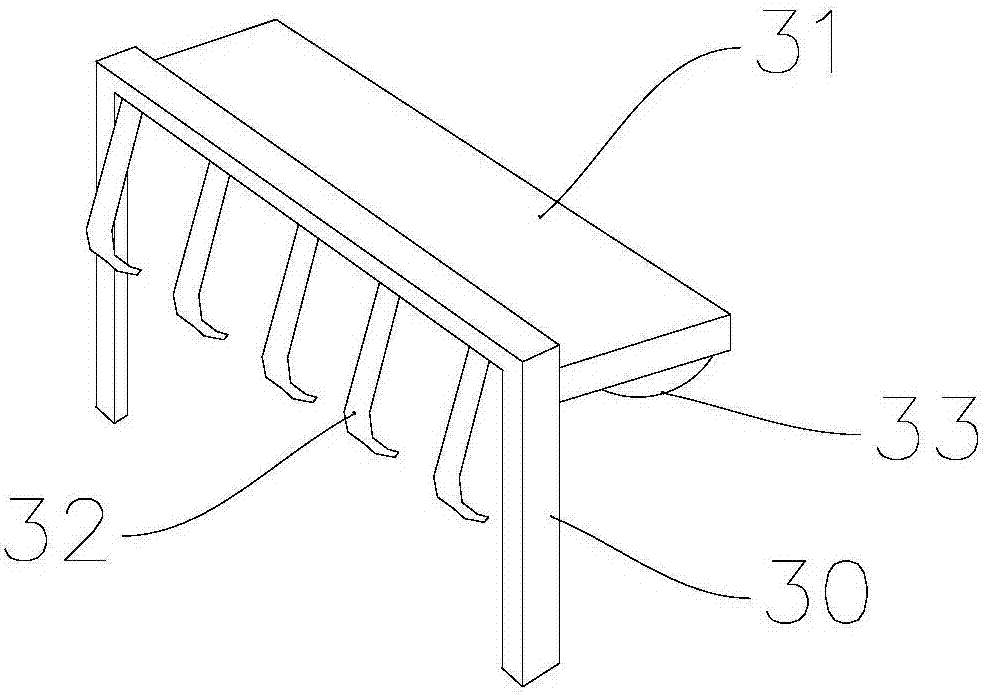

Suspended-ceiling-type multifunctional drying device

InactiveCN108149454ARealize the sterilization functionProtection securityTextiles and paperLaundry driersDry structureEngineering

The invention provides a suspended-ceiling-type multifunctional drying device, comprising a control box, telescoping mechanisms and a drying rack; the telescoping mechanisms are disposed on two sidesbetween the control box and the drying rack and are used for lifting the drying rack; an ultraviolet sterilizing device, a lifting control device, a hot air drying device and a water collector are disposed in the control box; the drying rack comprises connection cross arms; each connection cross arm includes an arm body, a side arm and a bottom arm, the side arm and the arm body are in pluggable connection, and the bottom arm and the arm body are in pluggable connection; the side arms are connected with drying bars, and the bottom arms are connected with connection shanks. The suspended-ceiling-type multifunctional drying device has the functions of sterilizing, sun drying, air drying, heat drying, dehumidifying, lighting and the like; the combination structure enables the sun drying structure to be more stable and more attractive in appearance.

Owner:嘉兴宸星环保科技有限公司

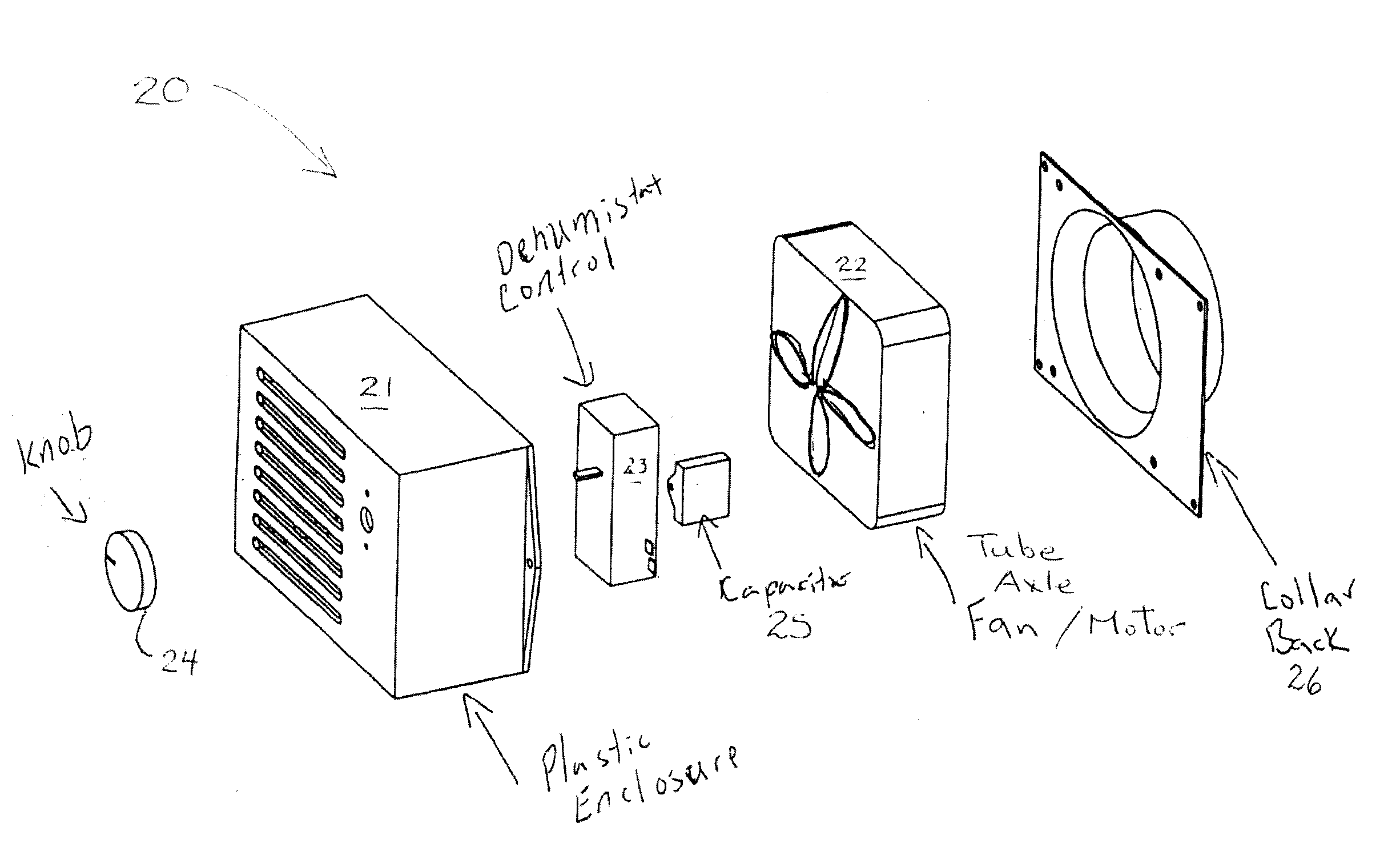

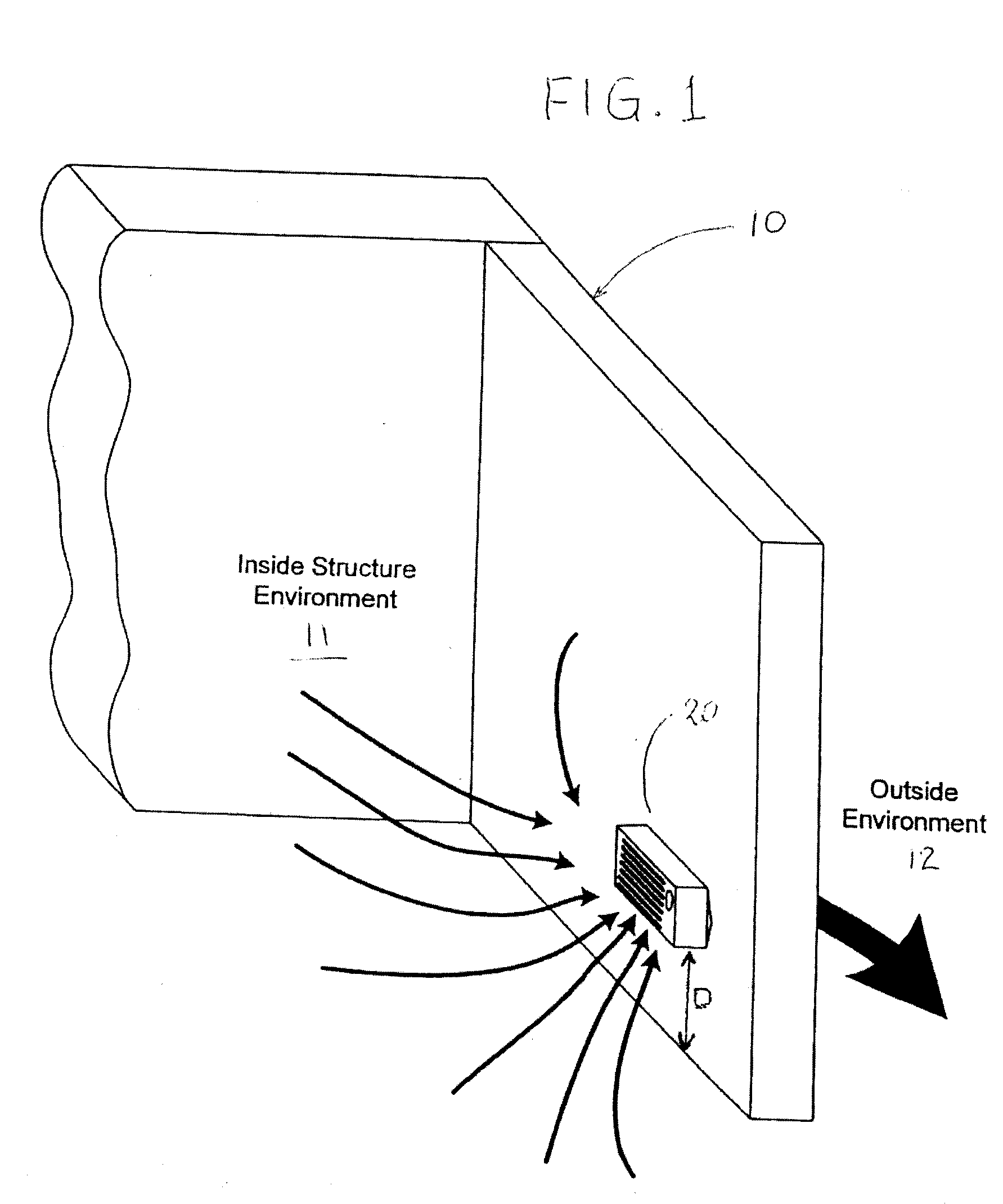

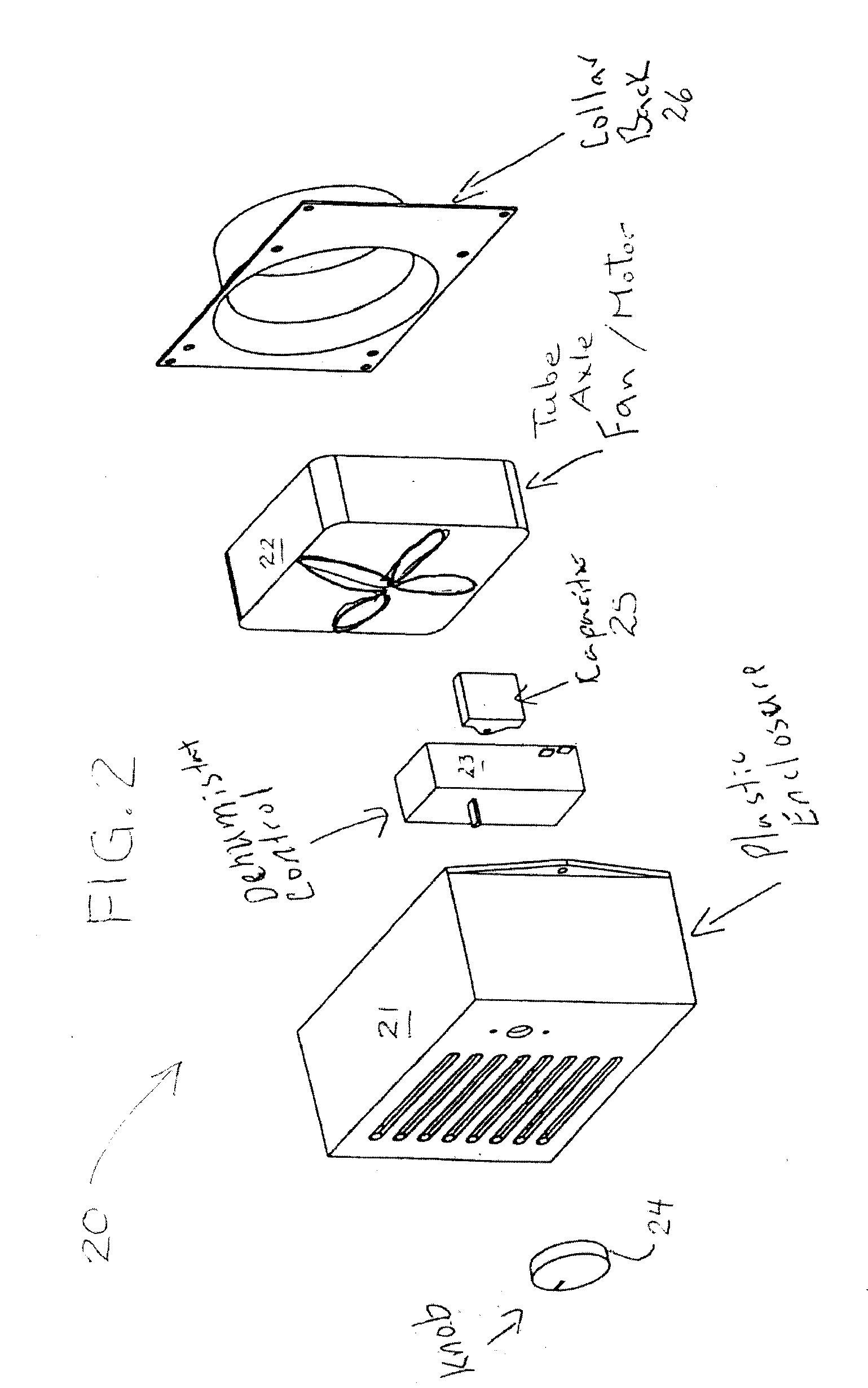

Ventilator Device For Dehumidification

InactiveUS20070158443A1Reduce humidityReduce condensationMechanical apparatusSpace heating and ventilation safety systemsMaximum ventilationGreenhouse

A ventilation device and the method of use thereof for dehumidification of residential attached or detached garages, sheds, greenhouses, RVs, motorhomes and other similar structures. This device and method uses an extraction ventilator to dry out the structure's environment, and reduce the interior humidity using a motorized fan to expel moisture latent air out of the structure. The fan continuously runs at minimal speeds to continuously exhaust interior air and ventilate the structure, thereby controlling the garage environment, while eliminating backdrafts, and preventing animals, snow and rain from entering the structure. The device uses a dehumidistat control to activate the fan to maximum ventilation capacity when the humidity reaches the set point, exhausting ambient air and extracting excess humidity from the structure. Once the humidity drops below the set point, the dehumidistat deactivates and returns the ventilator to minimum speed operator.

Owner:AIR TECH EQUIP

Strengthened optical waveguide fiber cable

The present invention relates to a loose tube optical waveguide fiber cable that is suitable for riser or plenum applications. The cable includes a protective tube that loosely surrounds two or more optical waveguides inside the hollow cavity defined by the tube. The protective tube has an inner surface and an outer surface and is a dry structure. Accordingly, the protective tube does not contain any gel-like compounds or other materials around the optical fibers positioned inside the protective tube. Strengthening members are disposed between the inner surface of the protective tube and the outer surface of the protective tube. The strengthening members are configured as embedded or layered strengthening elements and are disposed longitudinally along the length of the cable.

Owner:DRAKA COMTEQ BV

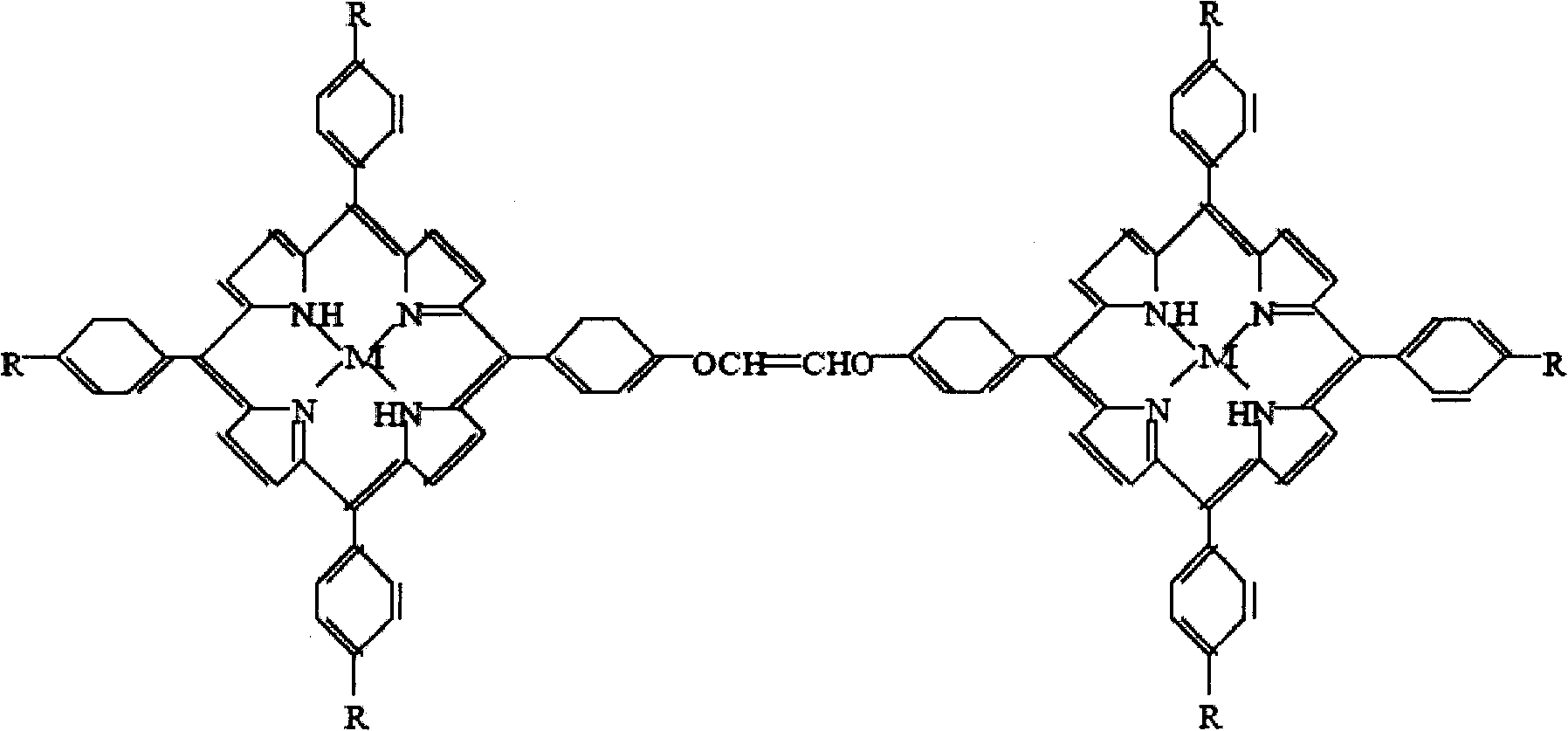

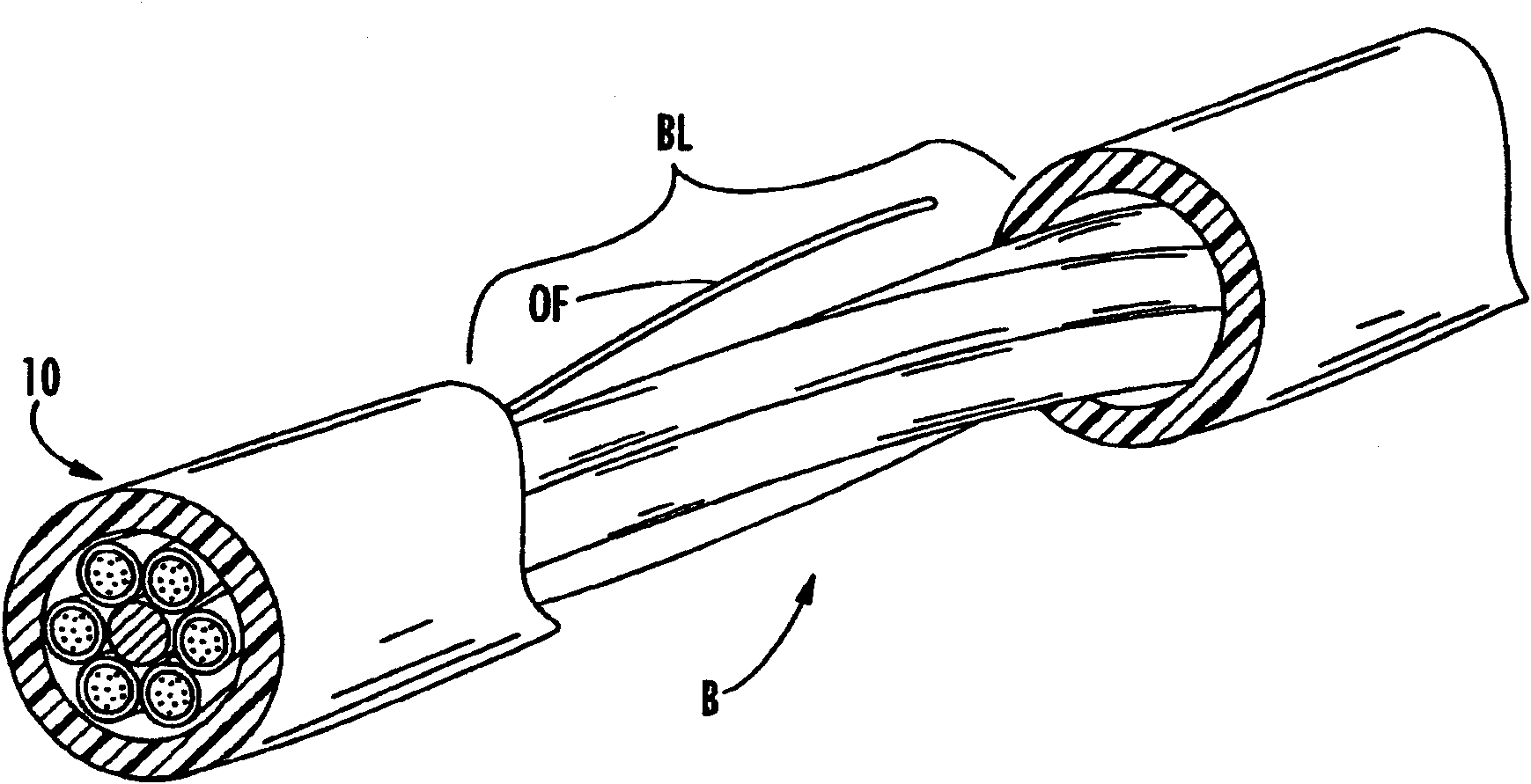

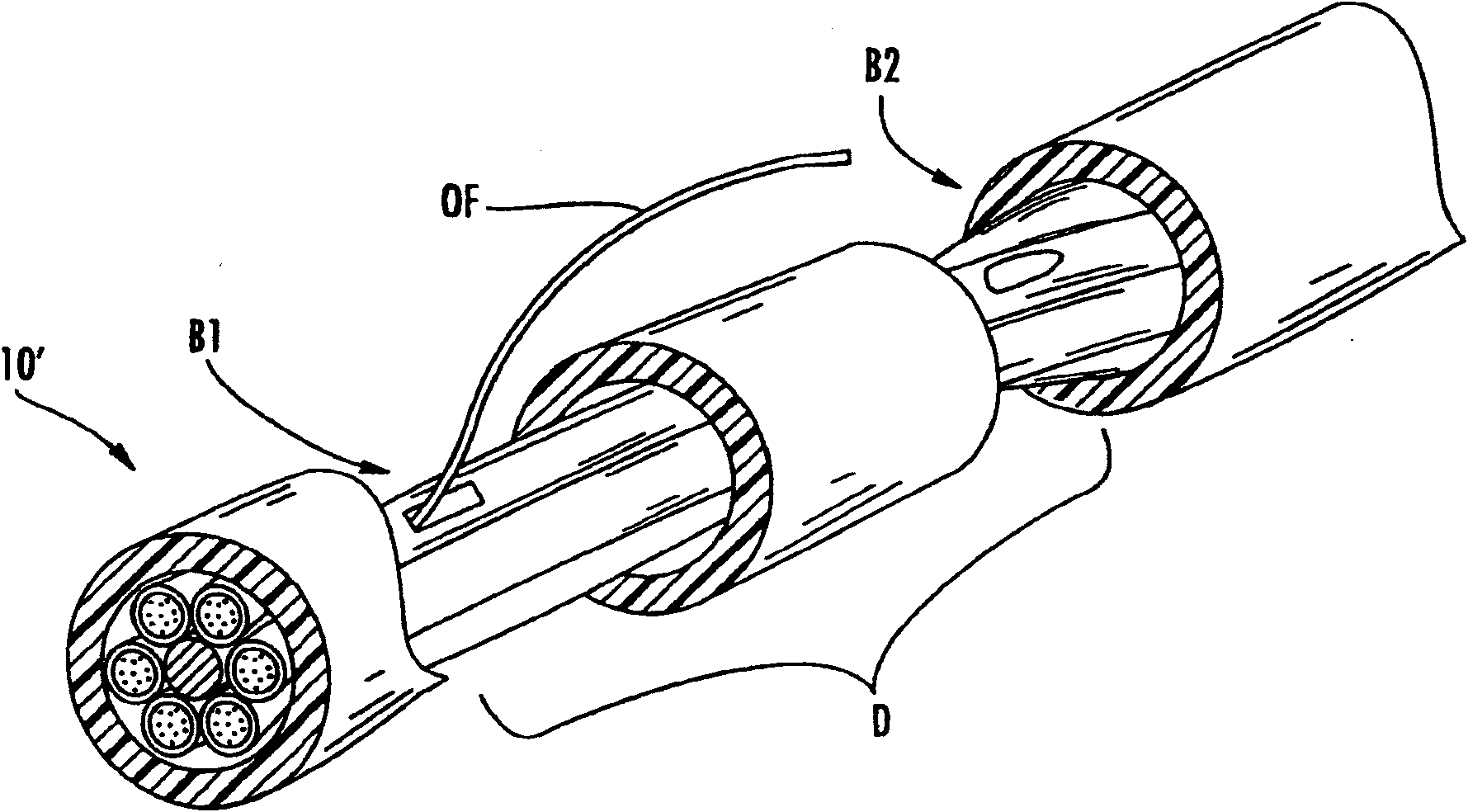

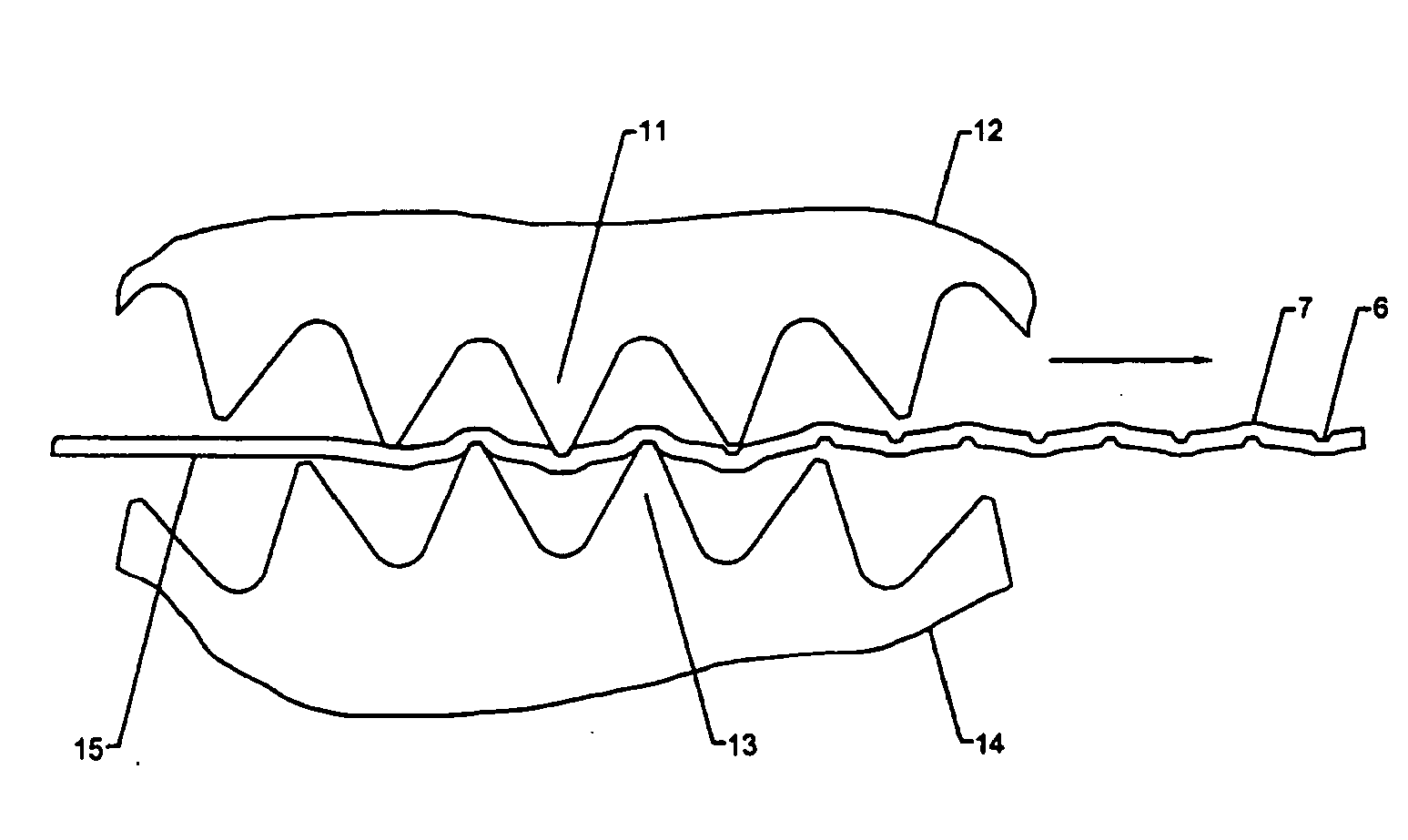

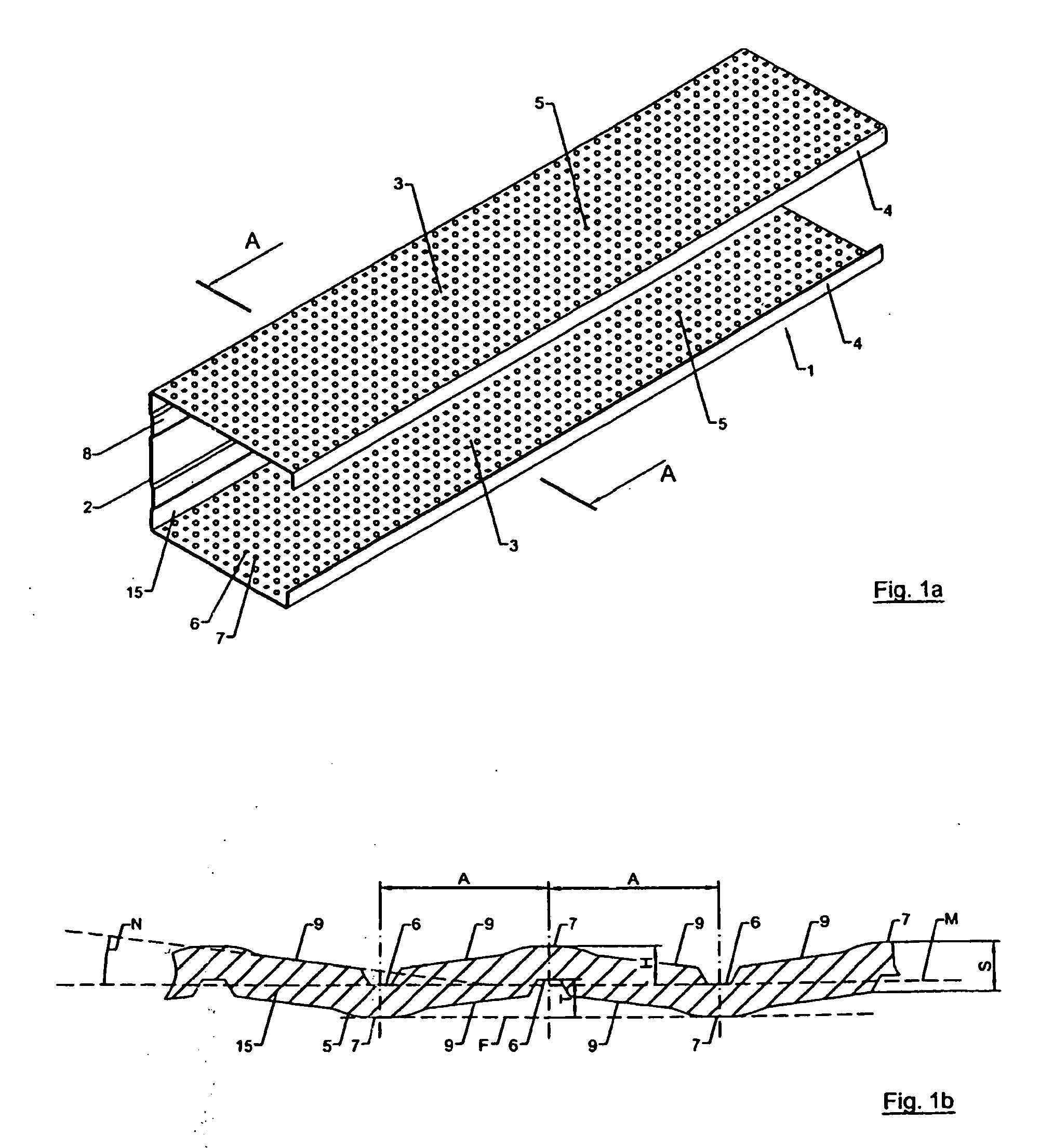

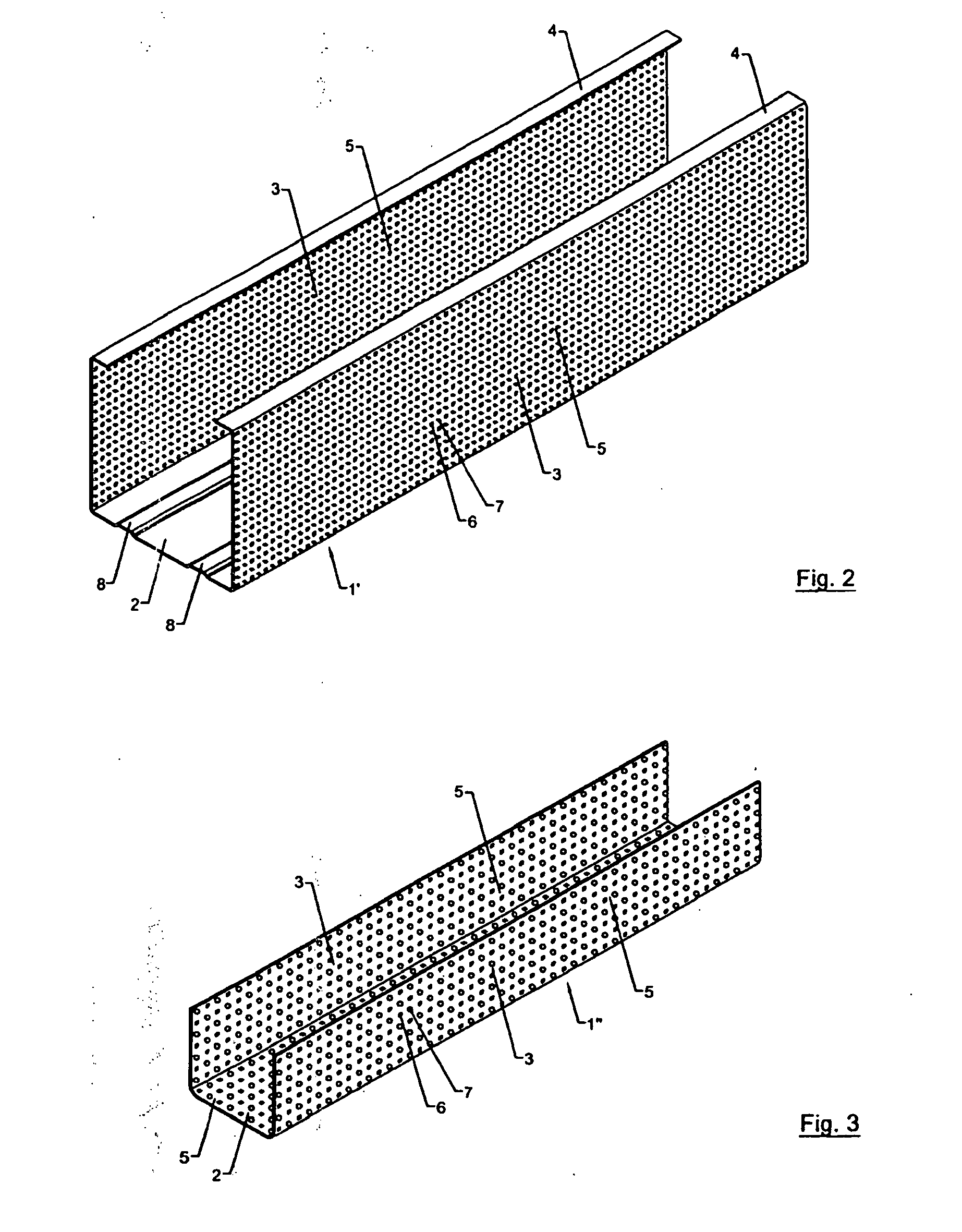

Fiber optic distribution cables and structures therefor

Fiber optic distribution cables and methods for manufacturing the same are disclosed. The fiber optic distribution cables present one or more optical fibers outward of the protective covering for distribution of the same toward the subscriber. In one fiber optic distribution cable, a length of distribution optical fiber that is removed from the distribution cable and presented outward of the protective covering is longer than the opening at access location. In another embodiment, a demarcation point is provided for inhibiting the movement (i.e., pistoning) of the distribution optical fiber into and out of the distribution cable. In still another embodiment, an indexing tube is provided for indexing a tether tube within the indexing tube for providing the distribution optical fiber with a suitable excess fiber length. Additionally, other embodiments may include a fiber optic distribution cable having a dry construction and / or a non-round cross-section.

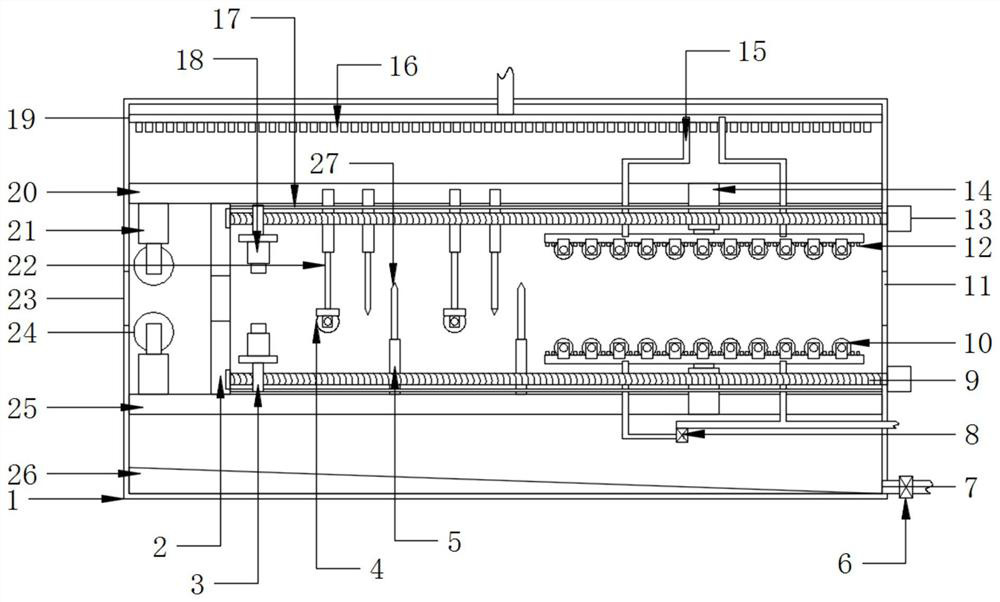

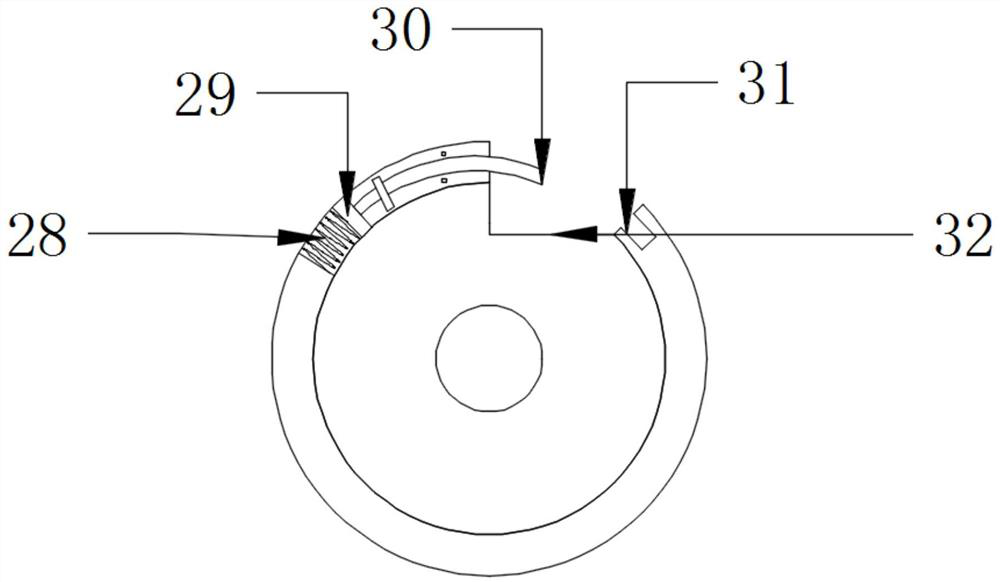

Pigment drying device

InactiveCN106931761AReduce areaLarge distribution areaDrying solid materialsHeating arrangementWater vaporDry structure

The invention relates to a paint drying device, which includes an oven, in which there are multiple layers of conveyor belts for conveying the paint along the horizontal direction, and the conveyor belts on the lower layer can receive the paint falling from one end of the upper layer of the conveyor belt. , the upper part of each layer of conveyor belt is evenly spaced along its conveying direction to set a plurality of spreading drying structures. The spreading drying structure includes a bracket, a drying plate and a spreading hook. The upper end of the bracket is connected with the drying plate, and the lower surface of the drying plate is An electric heating device for drying the paint on the conveyor belt below is provided, and a plurality of spreading hooks are provided on the lower surface of the drying plate for spreading the paint on the conveyor belt below to increase the heated area. The beneficial effect of the present invention is that the structure of the multi-layer conveyor belt in the oven can realize continuous feeding and discharging, and can realize continuous drying operation. Increasing the heating area and water vapor distribution area can greatly improve the drying efficiency.

Owner:湖北昇昊色彩科技有限公司

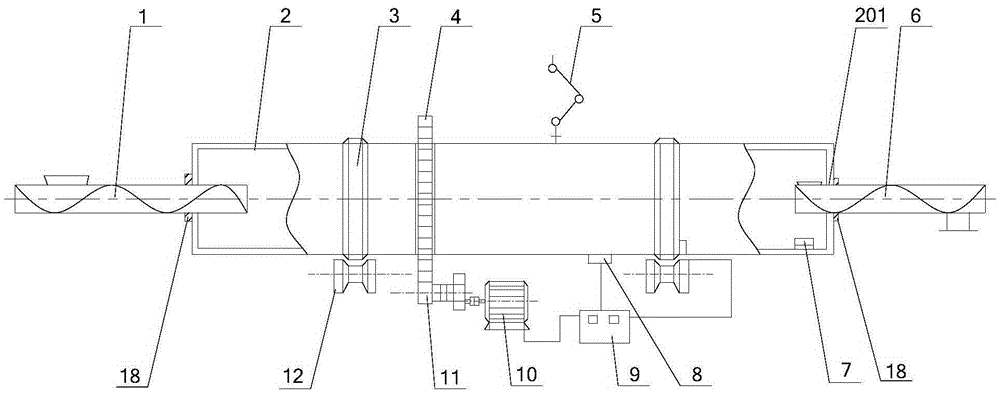

Drying device for non-woven fabric production

ActiveCN112577285AAutomatic pullImprove drying efficiencyDrying machines with progressive movementsDrying solid materialsWrinkle skinDry structure

The invention discloses a drying device for non-woven fabric production. The drying device for non-woven fabric production comprises a drying box body and a drying structure, and the drying structurecomprises an inlet, a cloth outlet, a cloth clamping and guiding structure, an inlet water squeezing structure, a middle water squeezing structure, an end drying structure and a winding structure. Themiddle water squeezing structure comprises a middle roller, a bottom telescopic rod, a scraping plate, a middle telescopic rod and an upper telescopic rod. According to the the device, through the arrangement of the water squeezing structure, waste water on a non-woven fabric is squeezed out firstly in the drying process, so that the drying efficiency is improved. The clamping guide structure isarranged on the device, so that the end part of the non-woven fabric can be automatically guided, the non-woven fabric can be automatically pulled to the position of the cloth outlet, and inconvenience caused by manual feeding is avoided. The device is provided with a communicating roll and a communicating nozzle, so that the cloth can be flattened and dried at the same time, and wrinkles are avoided.

Owner:ZHENGZHOU TEXTILE MACHINERY AUTOMATIC CONTROL EQUIP

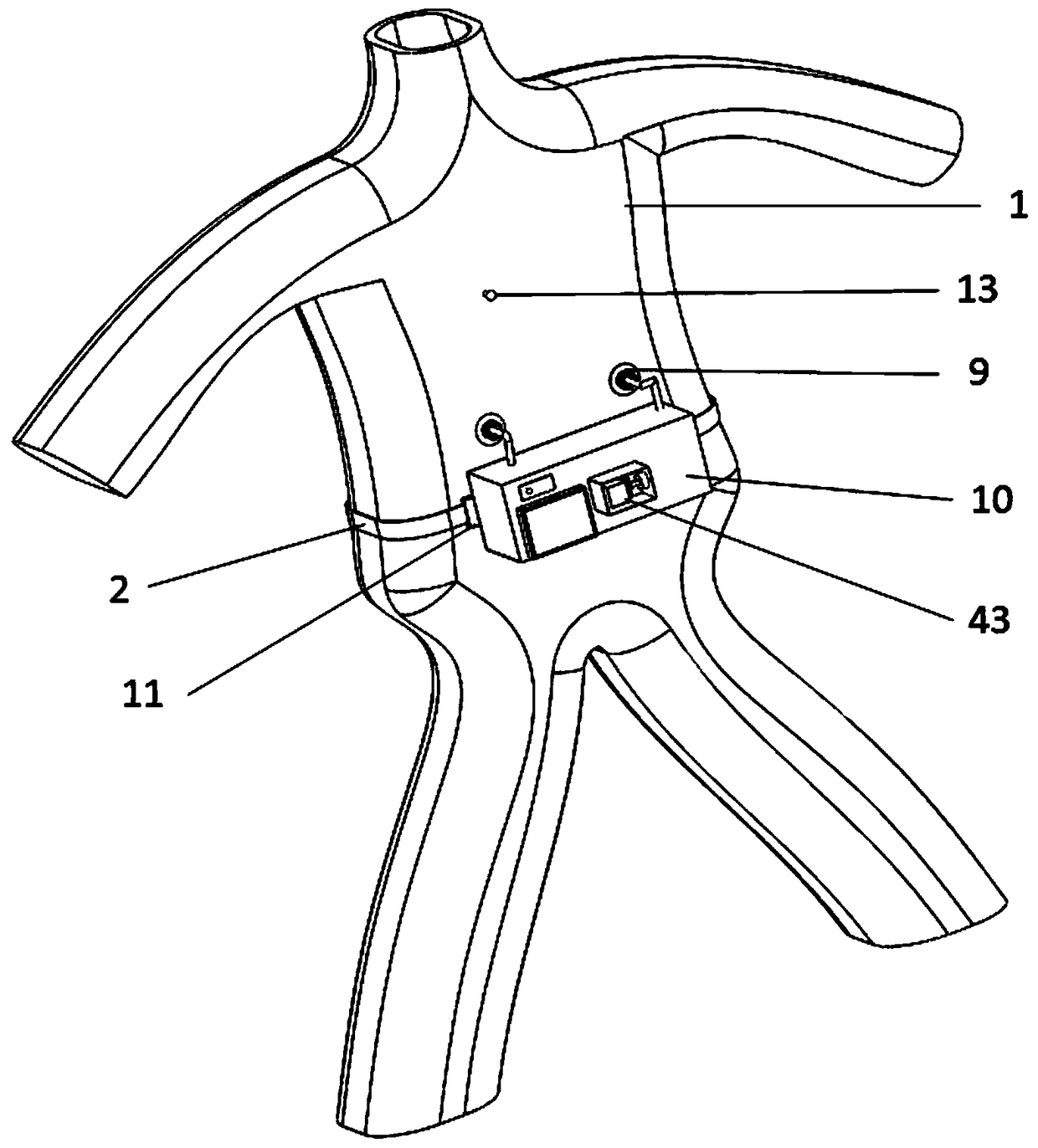

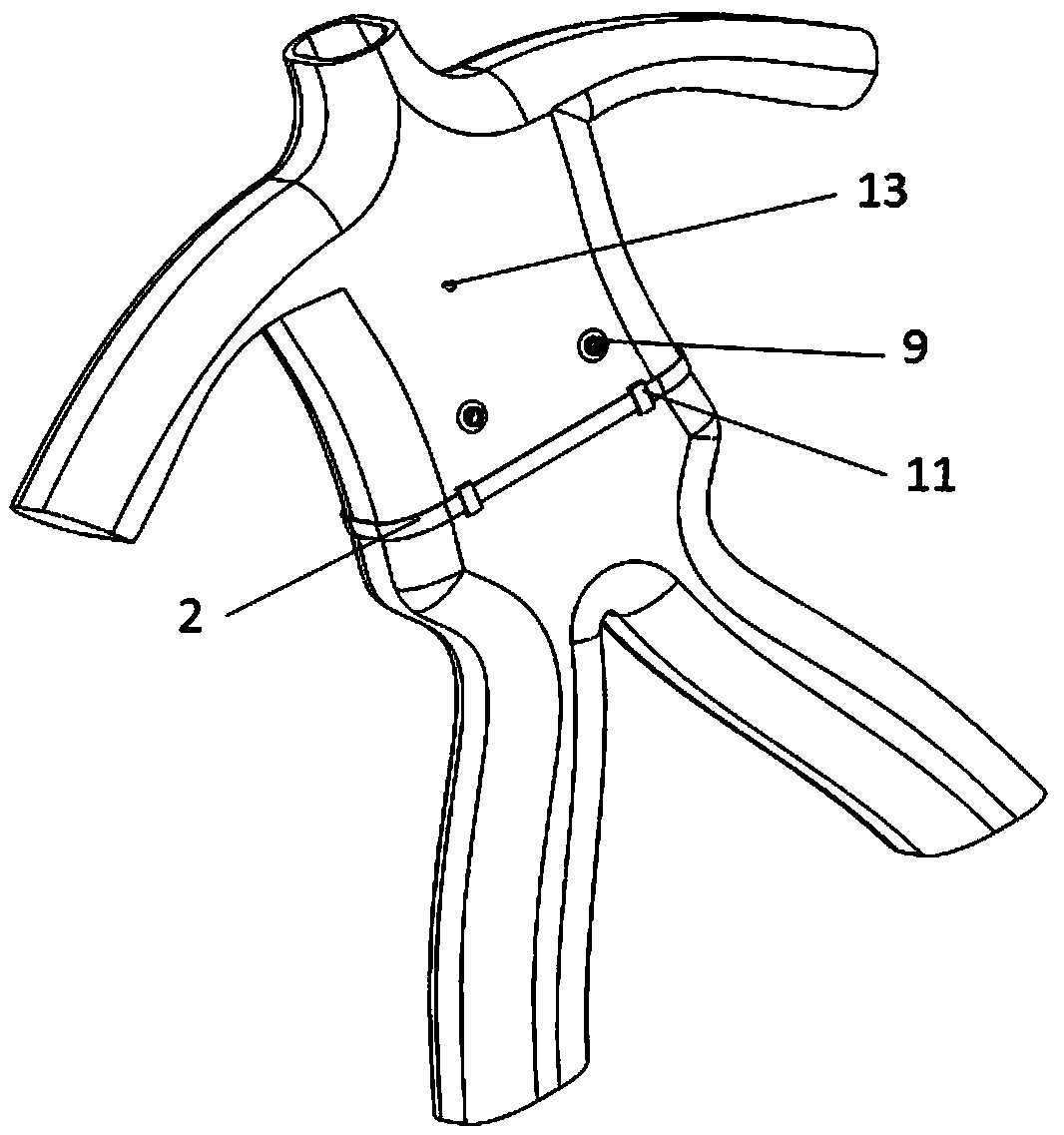

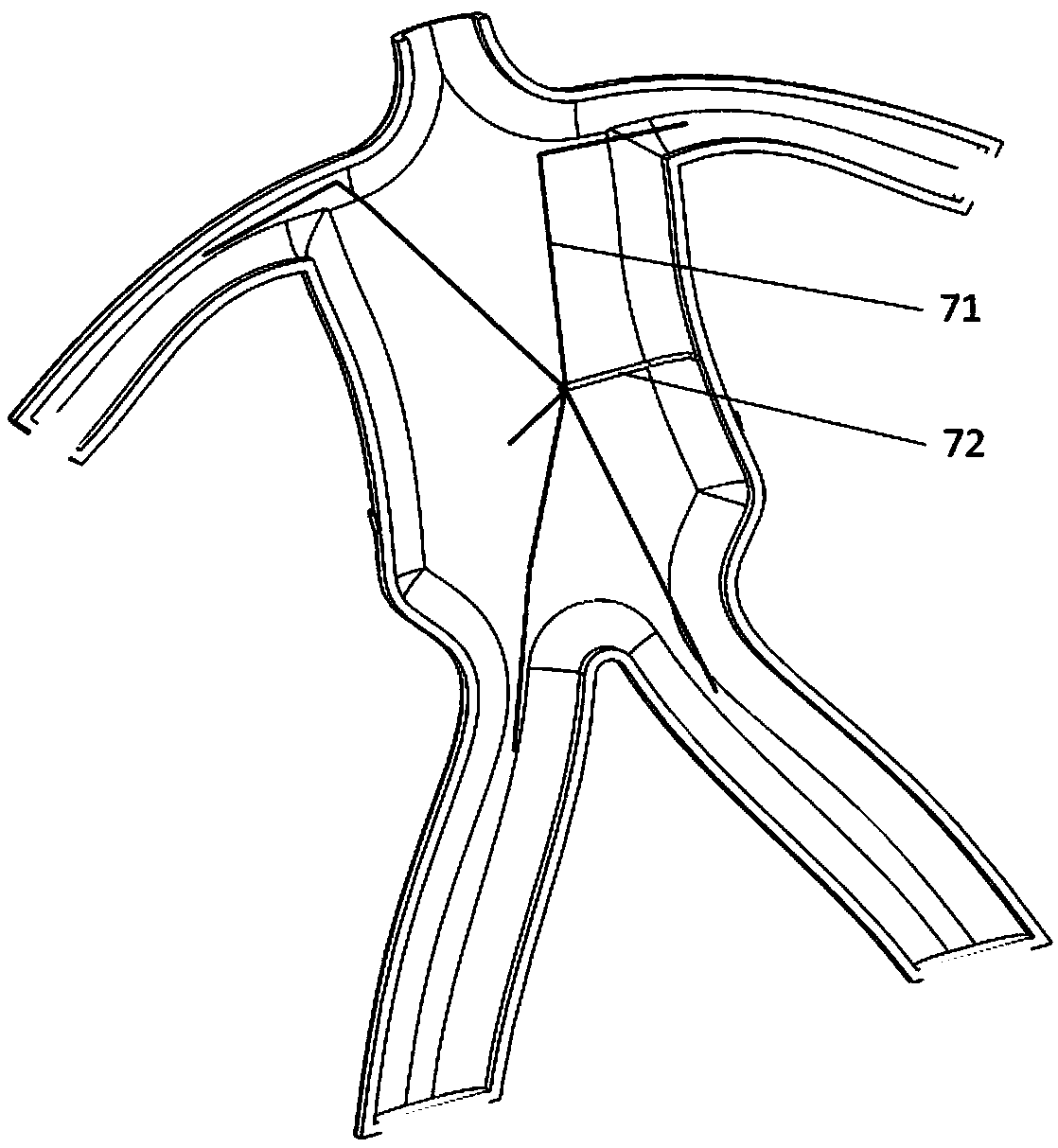

Device and method for preventing interior temperature and humidity of protection suit from being excessively high

A device for preventing interior temperature and humidity of a protection suit from being excessively high comprises a closed protection suit, a waist crotch belt, a miniature sucking pump, a coolingstructure, a drying structure, an air inlet tube, an air outlet tube, a power supply and a control structure and is characterized in that the wait portion of the closed protection suit is provide witha crotch belt fixing structure, the waist crotch belt is arranged on the protection suit through the crotch belt fixing structure, the miniature sucking pump, the cooling structure and the drying structure are all provided with air inlets and air outlets, sequential connection of the structures is achieved through connection of the air outlet of the previous structure and the air inlet of the later structure, the air inlet of the frontmost structure is connected with an air inlet tube, and the air outlet of the backmost structure is connected with an air outlet tube. The miniature sucking pump, the cooling structure and the drying structure are arranged on the waist crotch belt through hanging structures, and an orifice of the air inlet tube and an orifice of the air outlet tube are formed in different parts of the protection suit. It is achieved that high-temperature and high-humidity air is sucked into the device from all body parts and then the device delivers the high-temperatureand high-humidity air back to the body parts.

Owner:SHANDONG CENT FOR DISEASE CONTROL & PREVENTION

Drying device for traditional Chinese medicinal materials and low-temperature circulation drying method

ActiveCN107606882AEvenly heatedImprove drying qualityDrying gas arrangementsDrying solid materialsDry structureProcess engineering

The invention discloses a rapid low-temperature wind circulation intelligent drying device for traditional Chinese medicinal materials. The drying device comprises a hollow body, and the hollow body is internally provided with a drying chamber, an air duct and a moisture discharging cavity; and the device adopts a low-temperature circulation wind drying structure, and heating is uniform, the drying quality is improved. The invention further discloses a rapid low-temperature wind circulation drying method for the traditional Chinese medicinal materials and mainly comprises the steps of low-temperature circulation drying, temperature-rising drying and constant temperature drying and the like, too fast shrinkage of the surfaces of the medicinal materials due to too fast water loss is effectively prevented, so that the medicinal materials are in plump shapes; and the whole baking process is conducted in a relatively low temperature condition, and loss of volatile components is less.

Owner:HUNAN BESTCOME TRADITIONAL MEDICINE CO LTD

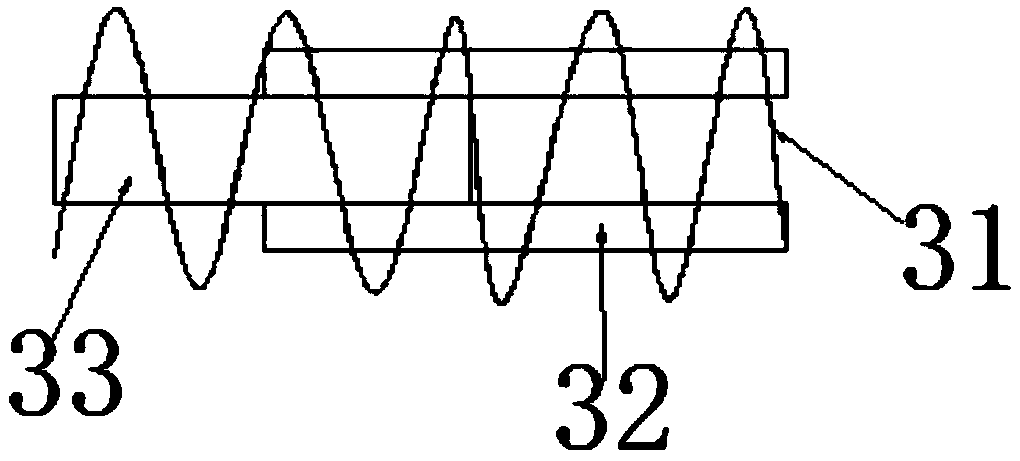

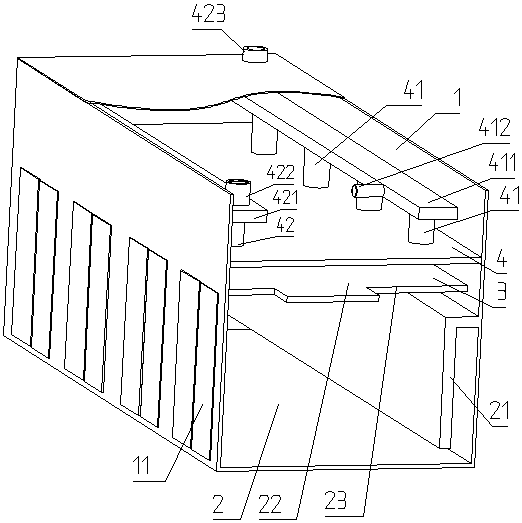

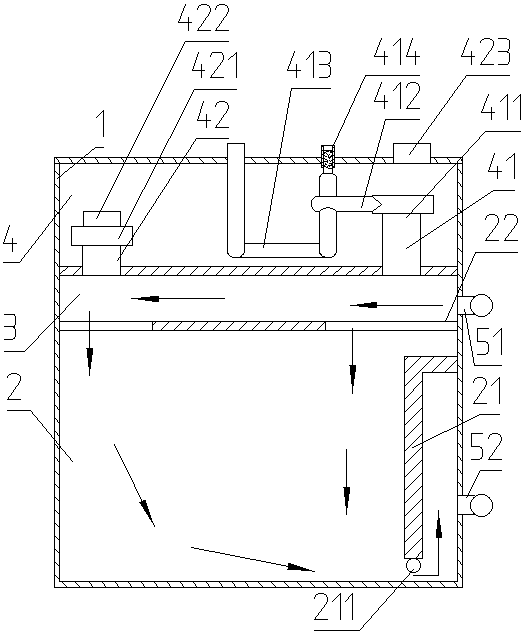

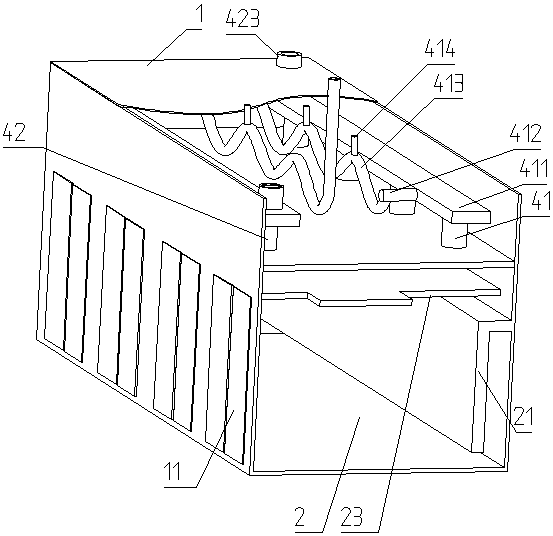

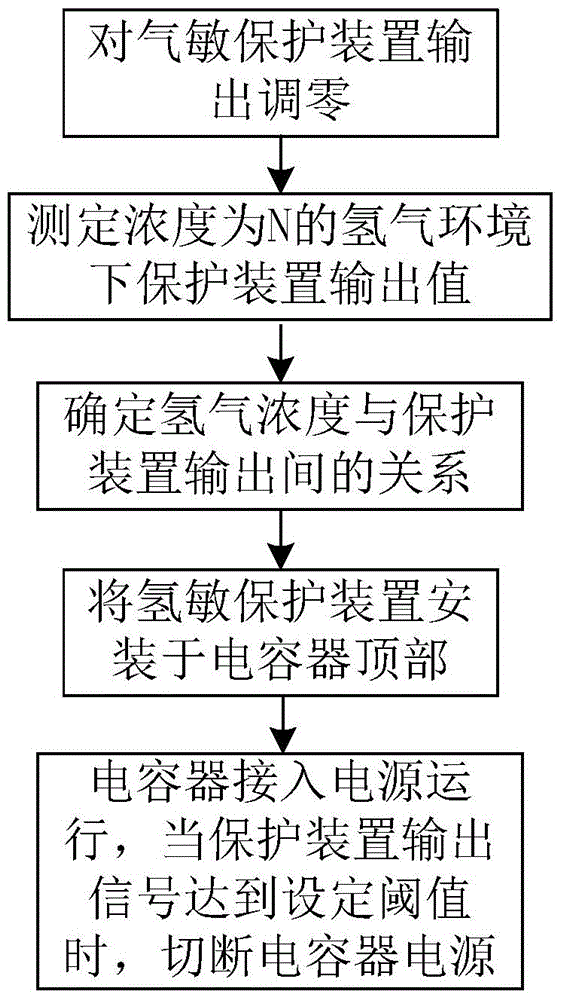

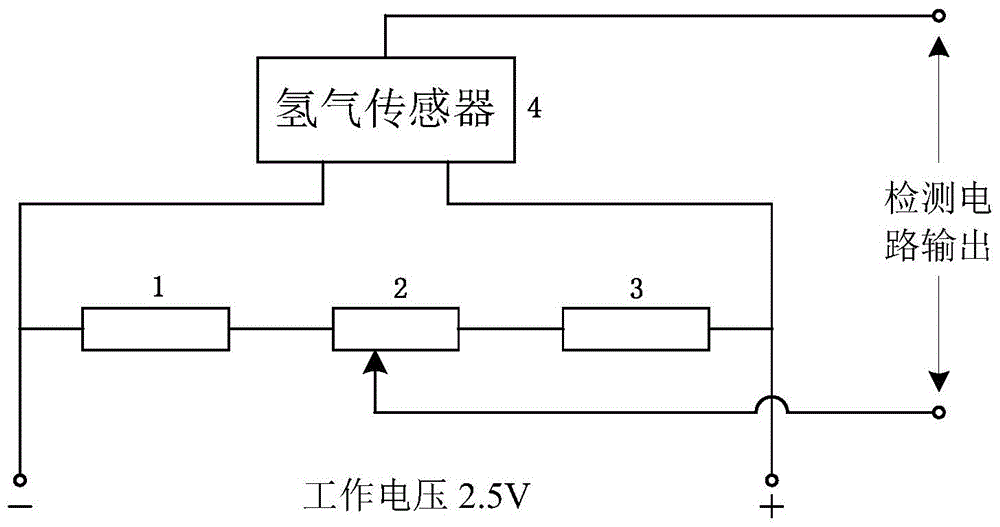

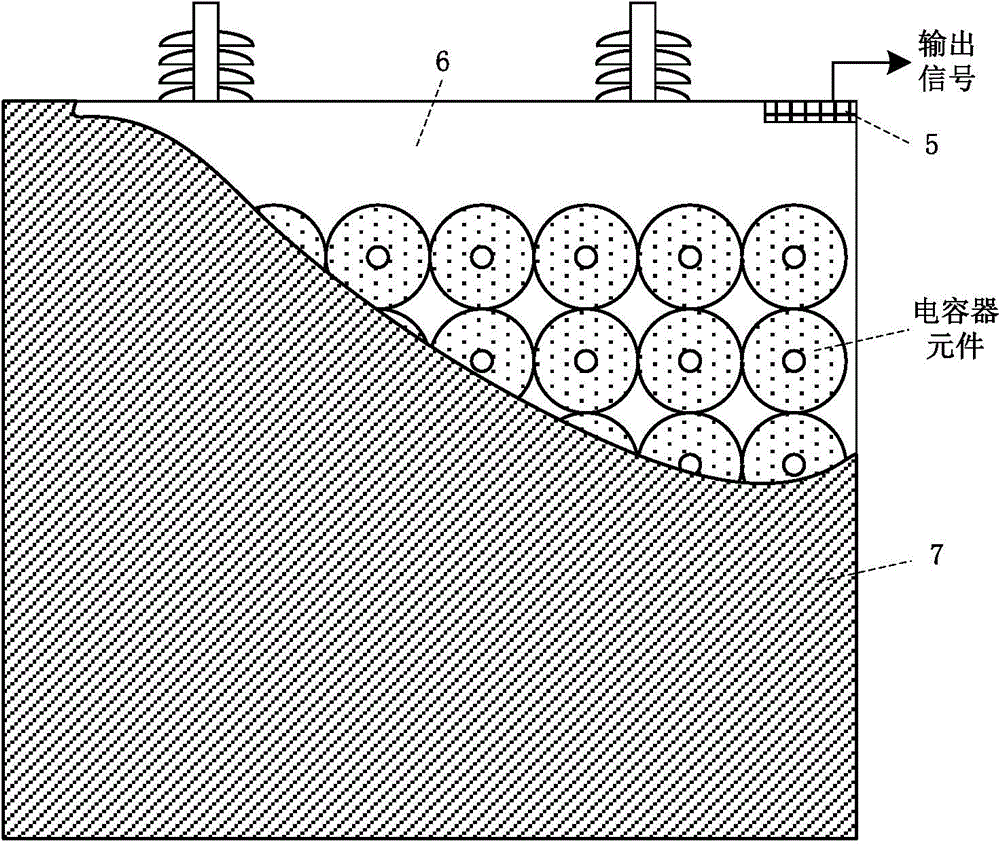

Gas-sensitive protection device and method for dry metallized film capacitor

ActiveCN104953553AThe detection method is simple and effectiveEasy to installEmergency protective circuit arrangementsDevice formDry structure

The invention discloses a protection device and method for a metallized film capacitor. The inside of the dry metallized film capacitor is not potted or adopts a potted dry structure, and a gap with certain height exists in the top of the capacitor. The gas-sensitive protection device formed by a thermal conductive hydrogen sensor and a detection circuit of the sensor is mounted at the top of the capacitor. When an element in the capacitor has a breakdown failure, a large amount of gas can be produced inside the element, escapes and can be gathered in the gap in the top of the capacitor finally. After the element produces the gas, the hydrogen volume accounts for about 85% through detection, thus, the produced gas can cause the concentration of hydrogen in the gap in the top of the capacitor to change, an output signal of the detection circuit can change, and the internal failure of the metallized film capacitor is detected. When a failure signal is detected, a power supply of the capacitor can be cut off from the outside, so that accidents such as capacitor explosions and the like caused by further development of the capacitor failure can be prevented, and failure detection and protection of the capacitor can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Drying structure of water jet loom

InactiveCN103981622ASpeed up evaporationDrying gas arrangementsDrying machines with progressive movementsHeat conductingDry structure

The invention provides a drying structure of a water jet loom. The drying structure of the water jet loom comprises a heating roller and a negative-pressure cover, which are orderly arranged in a fabric conveying direction; the heating roller and the negative-pressure cover are arranged perpendicular to the fabric conveying direction; the heating roller is made of a heat-conducting material; a pressure relief member is arranged on the heating roller; the negative-pressure cover is communicated with the heating roller by virtue of an air pump. Hot compressed air from the air pump in the drying structure of the water jet loom is used for heating the heating roller, the heating roller is used for heating the fabrics, and the moisture of the heated fabrics can be evaporated more quickly under the negative pressure of the negative-pressure cover.

Owner:SUZHOU DONGMAO TEXTILE IND

Efficient cleaning and drying device for chemical experimental apparatus

ActiveCN109959254AReasonable and effective cleaning and drying structureEasy to cleanDrying solid materials with heatCleaning using liquidsDry structureEngineering

The invention belongs to the technical field of chemical experiment equipment, and particularly relates to an efficient cleaning and drying device for a chemical experimental apparatus. A water inletpipe, a water outlet pipe, a mounting shaft, a rotary fixing unit, a lamp base plate, a lamp tube, a heating power source unit and an attraction electromagnetic unit are arranged on a cleaning box, the effective cleaning and drying effect of the chemical experimental apparatus can be achieved, and the advantages that the cleaning and drying structure is reasonable and effective, two-step cleaningis good, the lamp tube heating and drying structure is safe in vertical magnetic force attraction putting, during horizontal and vertical putting, the magnetic force attraction stability is high, in two states of idle and work, taking and putting are convenient, the dry position is heated, the amplitude is flexible and adjustable, and the whole cleaning and drying effect is good.

Owner:山东浩海天成智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com