Drying structure of water jet loom

A water jet loom and drying technology, which is applied in drying gas arrangement, progressive dryer, textile and other directions, can solve the problems of high energy consumption and insignificant drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

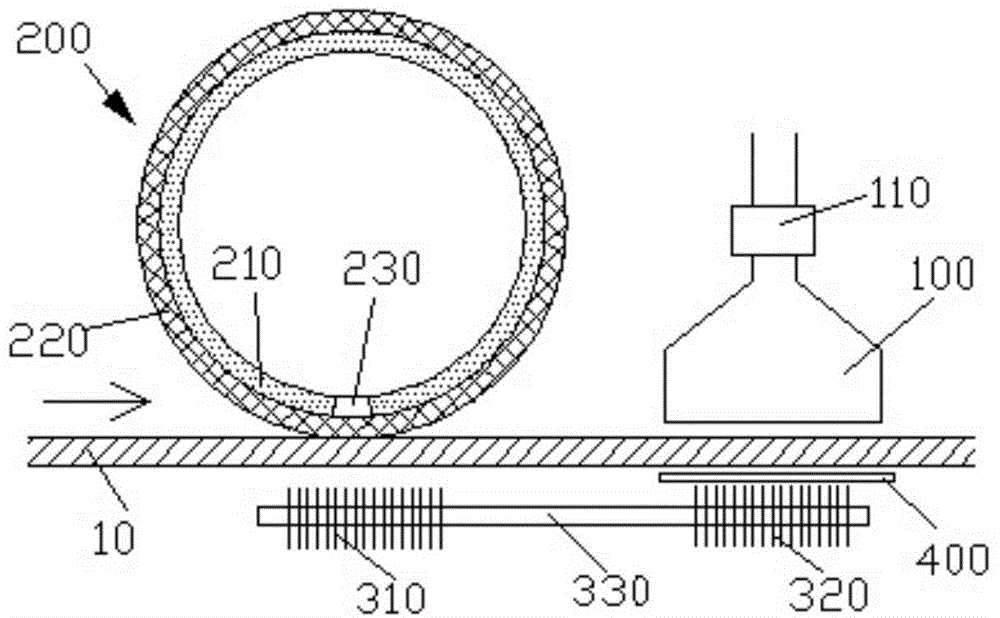

[0014] refer to figure 1 , in this embodiment, the drying structure of the water jet loom includes a heating roller 200 and a negative pressure cover 100 arranged in sequence in the direction of fabric 10 transmission, and the heating roller 200 and negative pressure cover 100 are perpendicular to the transmission of the fabric 10 direction, the heating roller 200 is made of thermally conductive material, the heating roller 200 is provided with a pressure relief member 230 , and the negative pressure cover 100 communicates with the heating roller 200 through an air pump 110 .

[0015] In the drying structure of the above-mentioned water jet loom, the other side of the negative pressure cover 100 relative to the fabric 10 is correspondingly provided with a filter screen 400 that restricts the passage of airflow, so that the negative pressure cover 100 receives air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com