Tea drying, sieving and separating device

A separation device and tea technology are applied in the directions of solid separation, sieving, tea treatment before extraction, etc., which can solve the problems of affecting the visual effect of tea leaves, affecting the quality of tea leaves, low drying efficiency, etc. Screening efficiency and net cleaning efficiency, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

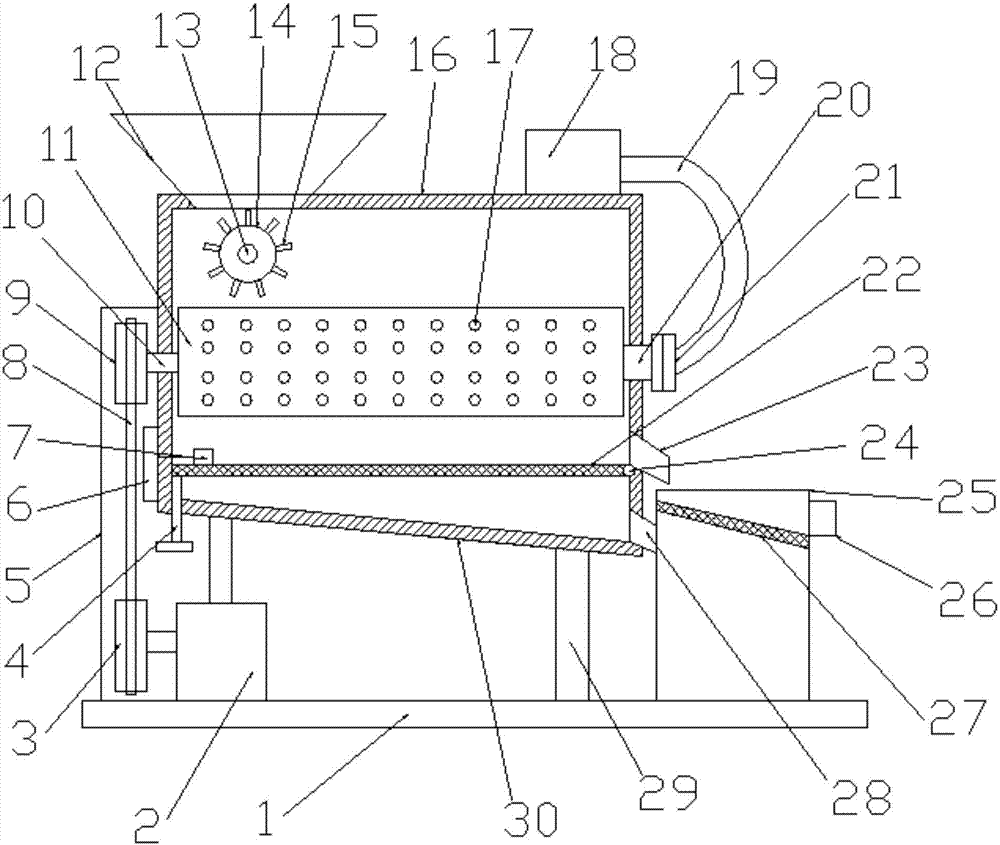

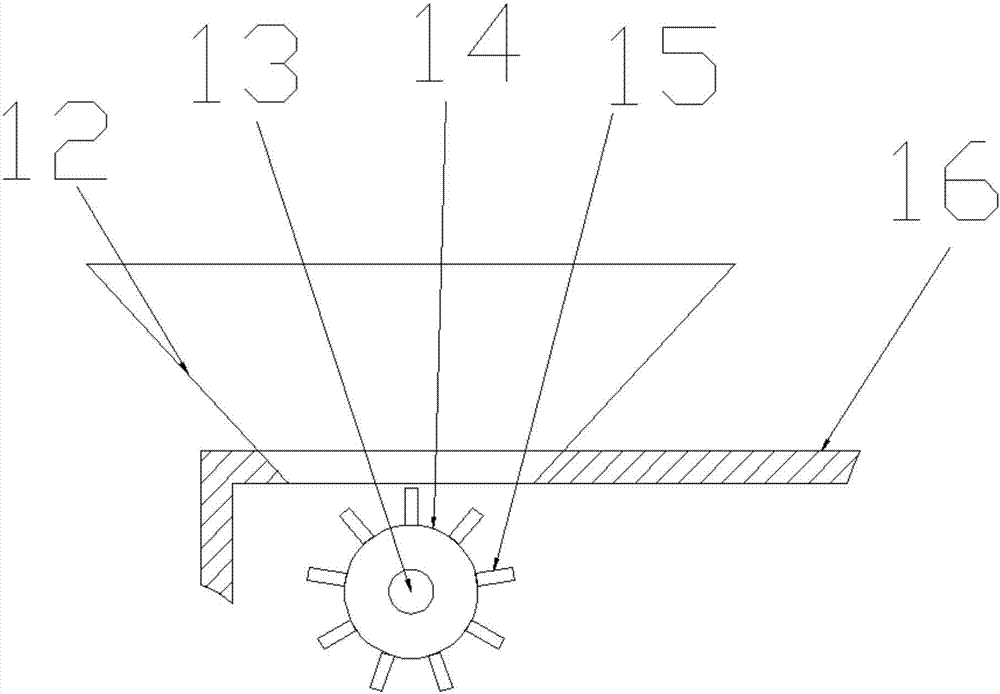

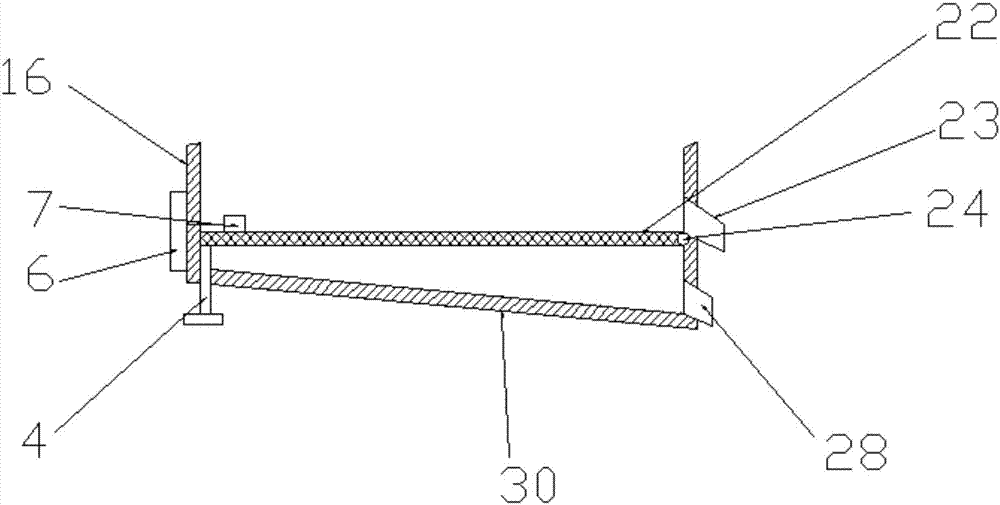

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0019] see Figure 1-3 , a tea drying, screening and separating device, comprising a fixed plate 1, an organic casing 16 is arranged on the fixed plate 1, a bracket 19 is arranged at the bottom end of the casing 16, and the casing 16 is fixed on the fixed plate 1 through the bracket 19 Above, the inside of the casing 16 is provided with a drying drum 11 horizontally. The drying drum 11 is a cylindrical shell structure. The drying drum 11 is provided with a number of air holes 12 communicating with its inner cavity. The left and right ends of the drum 11 are respectively provided with a left rotating shaft 10 and a right rotating shaft 20, and the left rotating shaft 9 and the right rotating shaft 17 are respectively sleeved on the bearings provided on the left and right side walls of the casing 16, and the left end of the left rotating shaft 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com