Pigment drying device

A technology for drying devices and pigments, applied in drying, drying machines, heating devices and other directions, can solve the problems of high energy consumption of drums, difficult continuous production, and high energy consumption, and achieve increased heating area and water vapor emission. area, continuous drying operation, the effect of saving plant area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

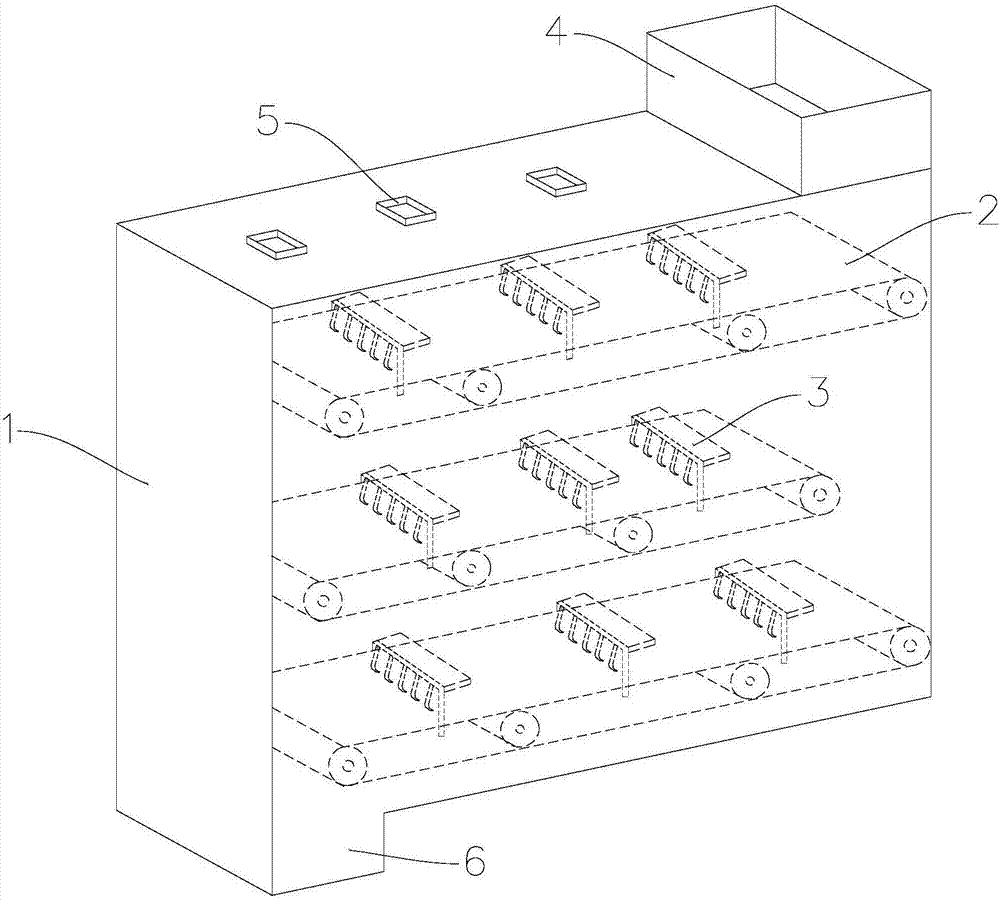

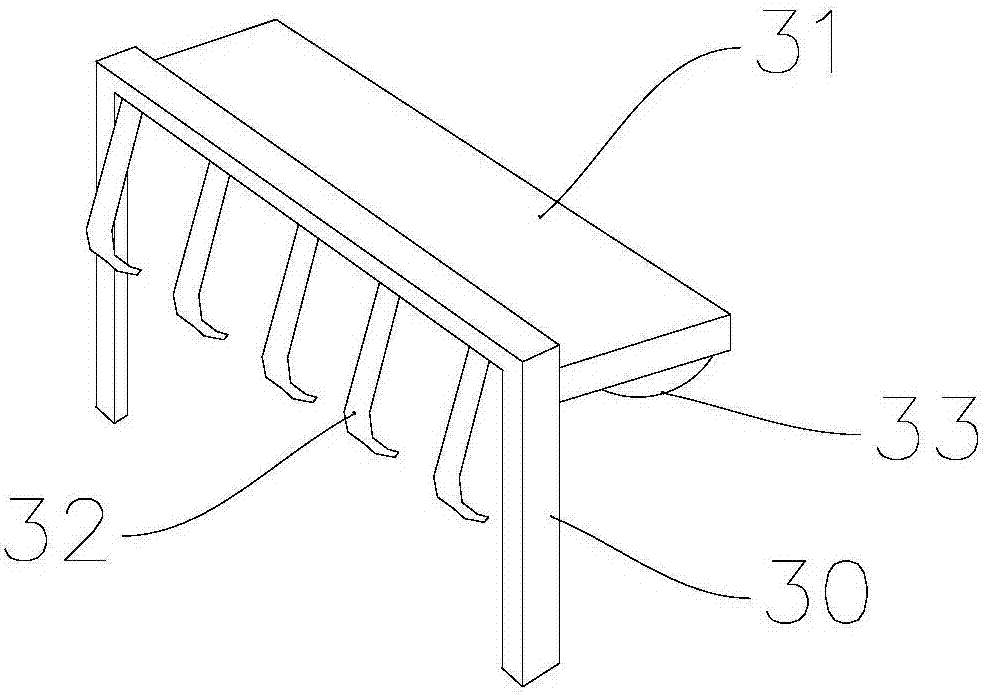

[0017] Such as Figures 1 to 2 As shown, the present invention provides a paint drying device, which includes an oven 1, in which there are multiple layers of conveyor belts 2 that are staggered from top to bottom for conveying paint in the horizontal direction, and the conveyor belts 2 on the lower layer It can accept the paint falling from one end of the conveyor belt 2 on the upper layer, each layer of the conveyor belt 2 is driven by an independently installed motor, and the upper part of each layer of the conveyor belt 2 is evenly spaced along its transmission direction. The drying structure 3 for spreading materials comprises a bracket 30, a drying plate 31 and a material spreading hook 32. The lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com