Patents

Literature

49results about How to "Continuous in and out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spiral self-stirring dry fermenting device and method

ActiveCN102816690ARealize self-stirringReduced residence time required for anaerobic consumptionGas production bioreactorsWaste based fuelSlagSpray nozzle

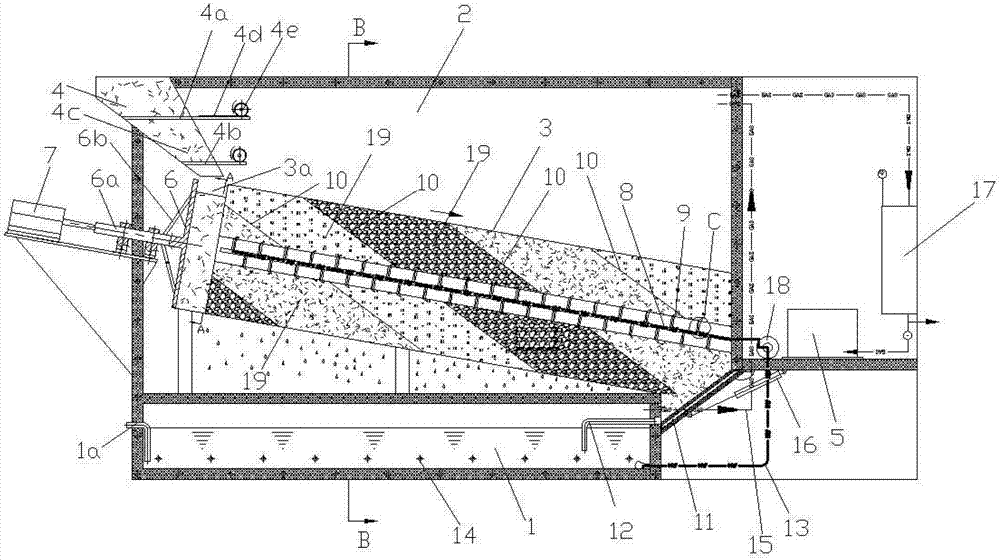

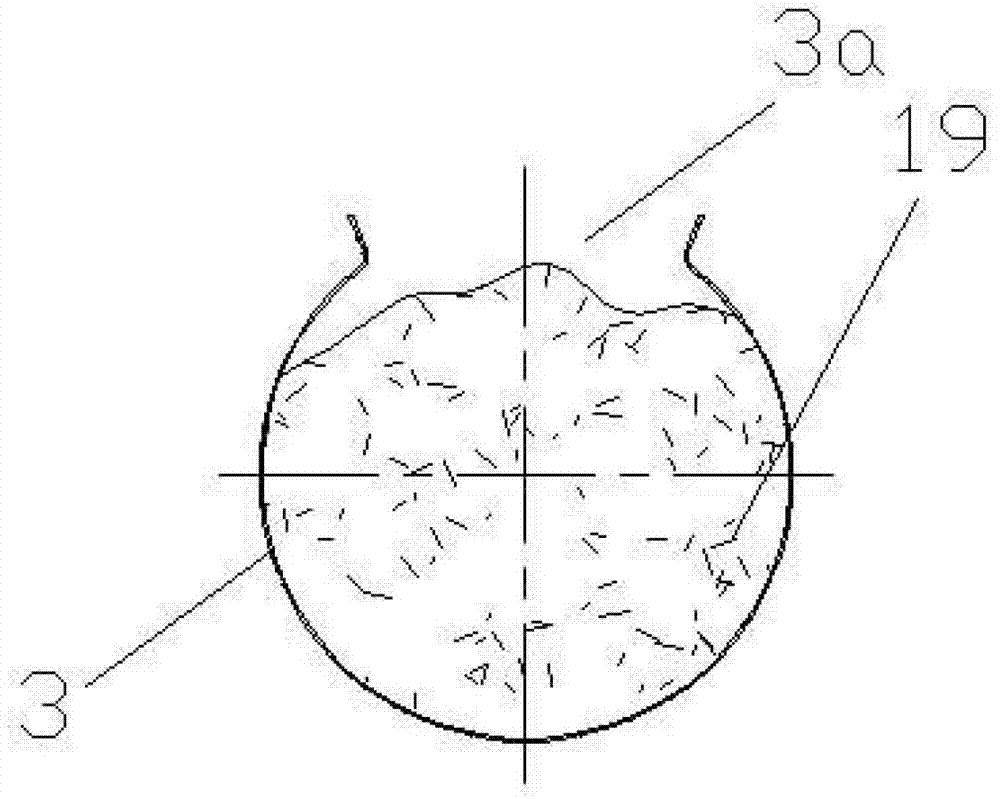

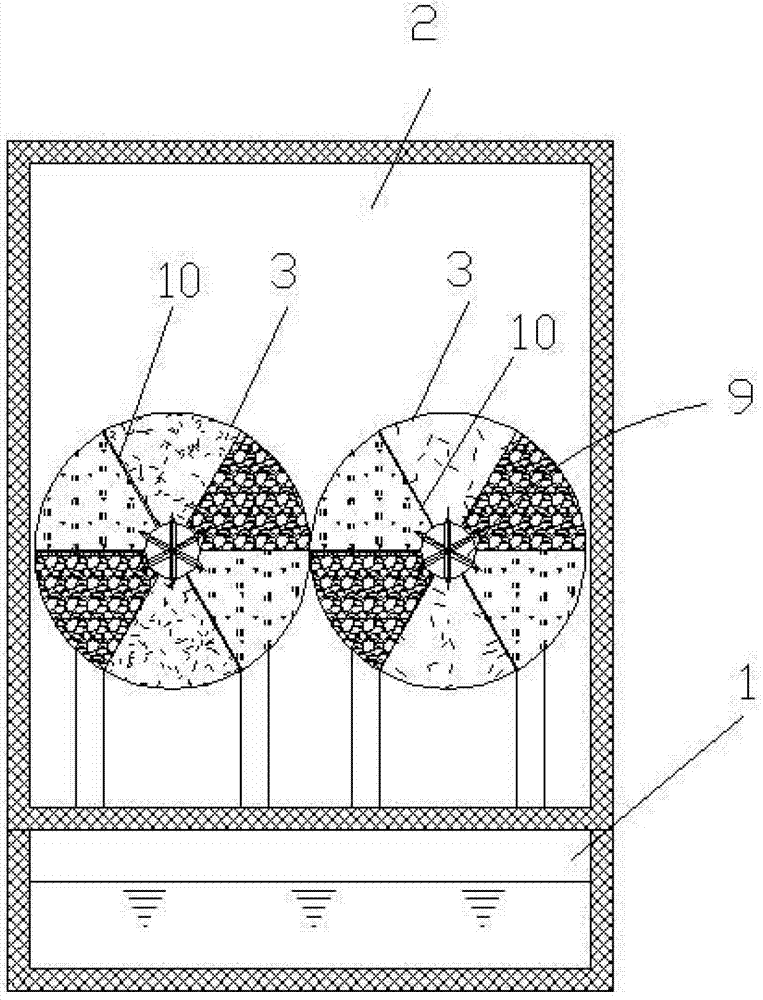

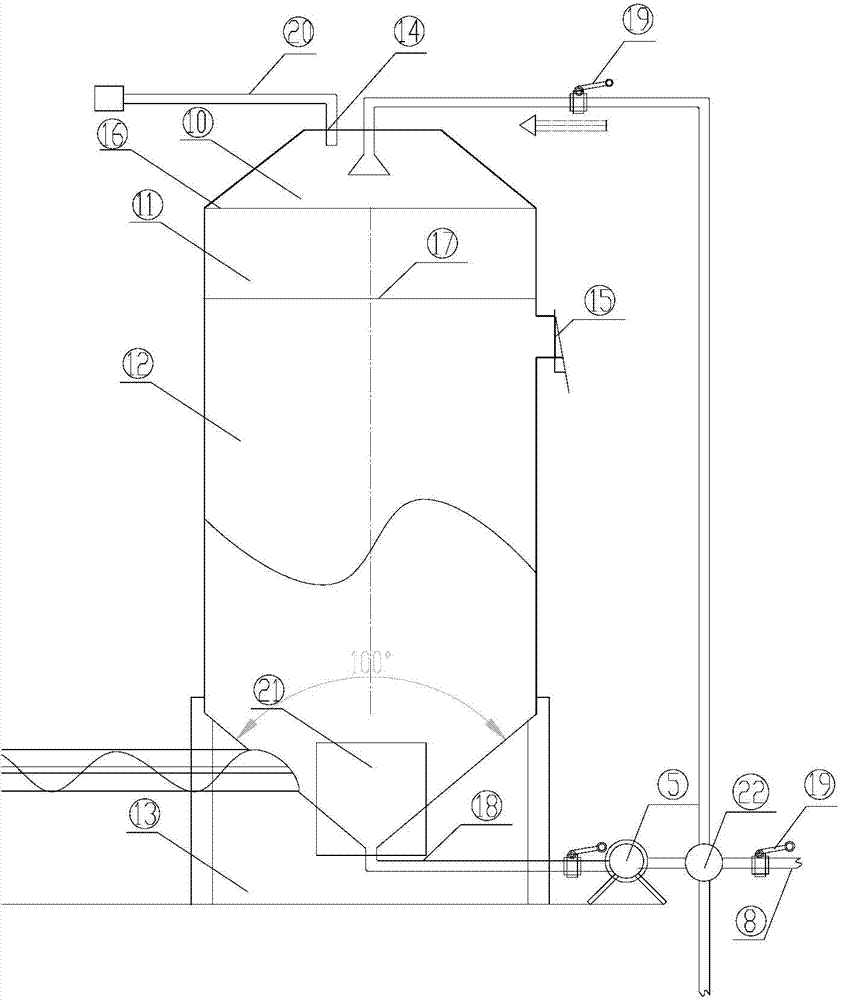

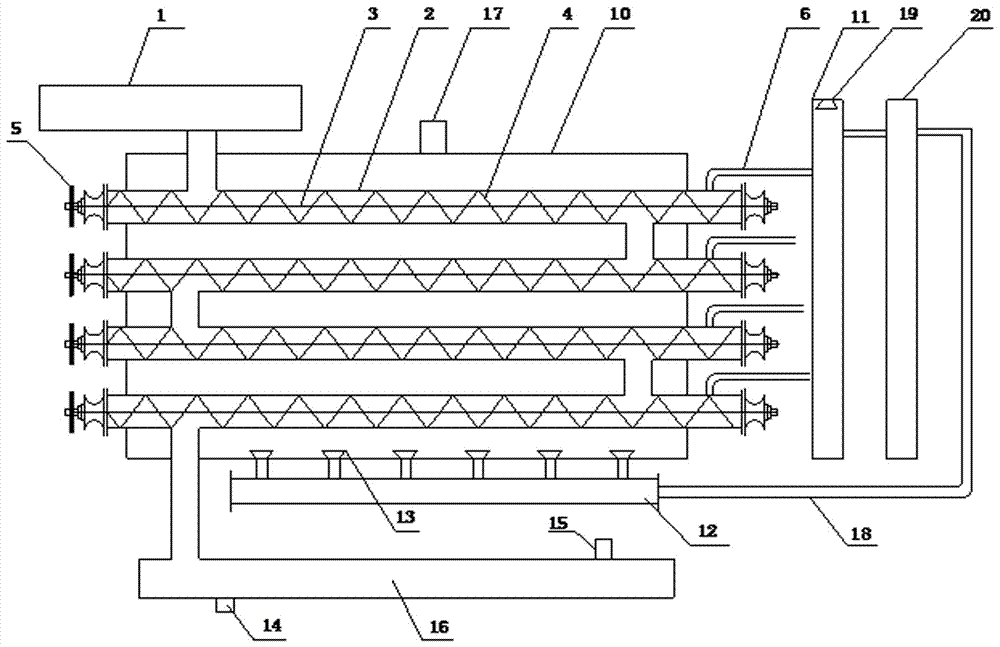

The invention discloses a spiral self-stirring dry fermentation device and a method. Fermentation cylinders are obliquely arranged at the bottom in a gas storage tank which is installed on a top board of a leachate holding tank; an enclosed inner cylinder is arranged at the central part in each fermentation cylinder along an axial direction; a leachate jet pipe is mounted in the inner cylinder; nozzles are distributed on the leachate jet pipe and extend out from the inner cylinder; spiral separator plates are distributed in each fermentation cylinder along an axial direction, and initiating terminals of the spiral separator plates are located behind a feed inlet; a lower end of each fermentation cylinder is provided with a material outlet, a slag removal opening communicating with the material outlet of the fermentation cylinder is mounted on a base plate of the gas storage tank, and a slag removal door is arranged on the slag removal opening; the leachate holding tank is provided with a leachate return pipe communicating with the gas storage tank and a pipeline communicating with a leachate inlet of the leachate jet pipe; electric heating pipelines are distributed in the leachate holding tank; and a biogas conveying pipeline communicating with the upper part of the gas storage tank is arranged at the upper part of the leachate holding tank. The invention also provides the method of using the device for fermentation.

Owner:CHONGQING ACAD OF AGRI SCI +1

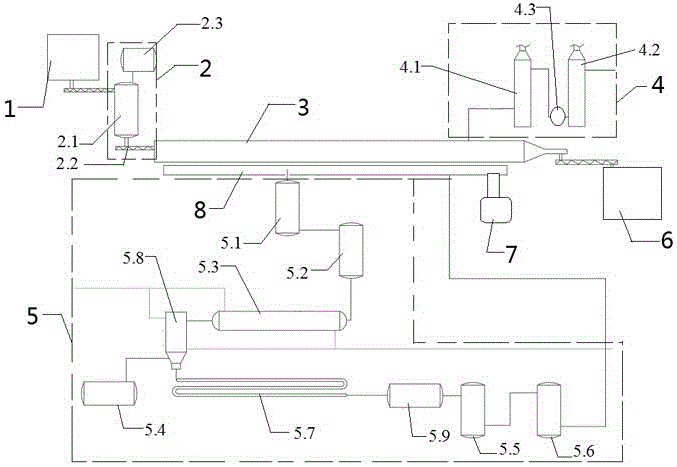

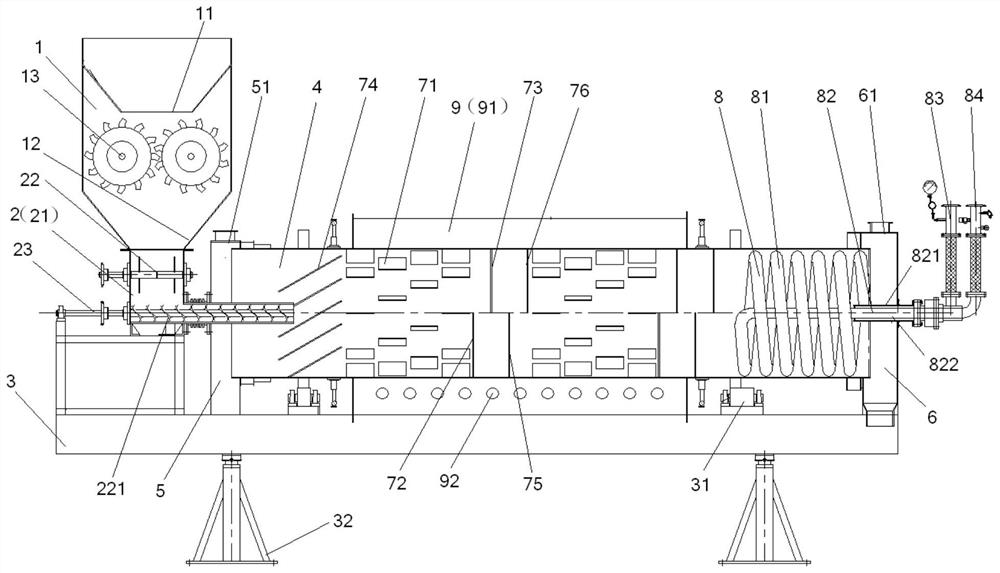

Waste tire low-temperature and normal-pressure continuous thermal cracking production device and technology

The invention relates to a waste tire low-temperature and normal-pressure continuous thermal cracking production device and technology. According to the technical scheme, the device comprises a preprocessing unit, a conveying and feeding unit, a thermal cracking unit, a desulfuration and atomization unit, an oil gas purifying and condensing unit, a carbon black deep processing unit, an oxygen supply air blower and a fuel gas spray gun, wherein the preprocessing unit, the conveying and feeding unit and the thermal cracking unit are connected in sequence, the desulfuration and atomization unit, the oil gas purifying and condensing unit, the carbon black deep processing unit, the oxygen supply air blower and the fuel gas spray gun are connected with the thermal cracking unit, a tail end outlet of the preprocessing unit is connected with the conveying and feeding unit, the thermal cracking unit mainly comprises a furnace body, the furnace body is connected with the oxygen supply air blower and the fuel gas spray gun, and the fuel gas spray gun comprises a natural gas spray gun and a waste gas spray gun. The waste tire low-temperature and normal-pressure continuous thermal cracking production device has the advantages that a full-sealed structure is adopted in the production process, and a strong atomization tower is adopted for performing cooling, dust removal and purification, so that environment pollution is lowered to the minimum; due to the fact that recycled combustible gas and cooling water is recycled, purified and secondarily utilized, energy is saved, the production cost is lowered, and the principle of energy conservation and emission reduction is met.

Owner:高义强

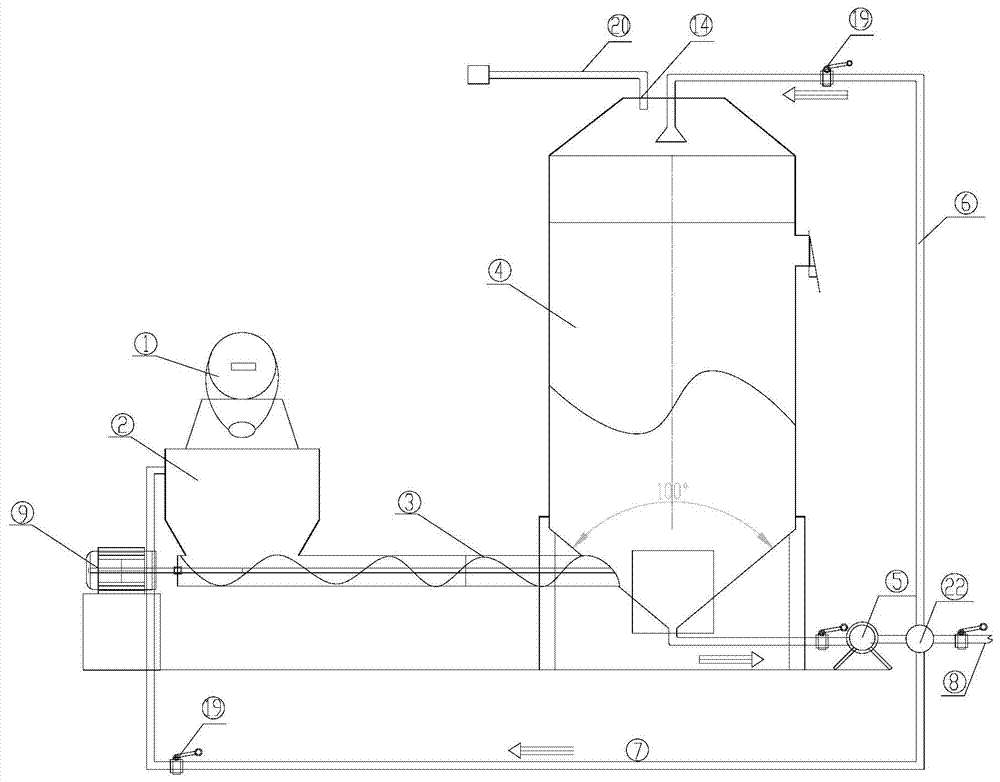

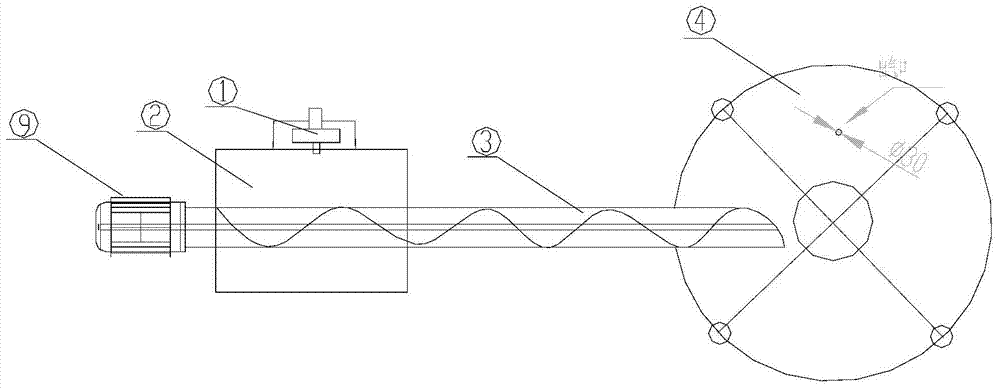

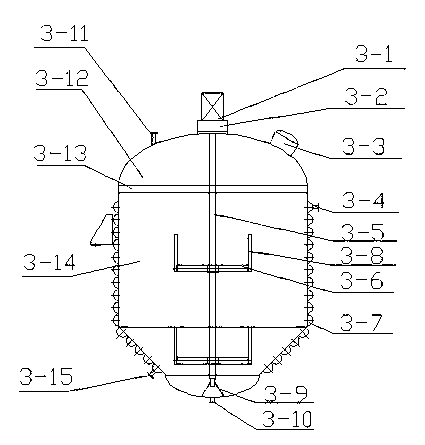

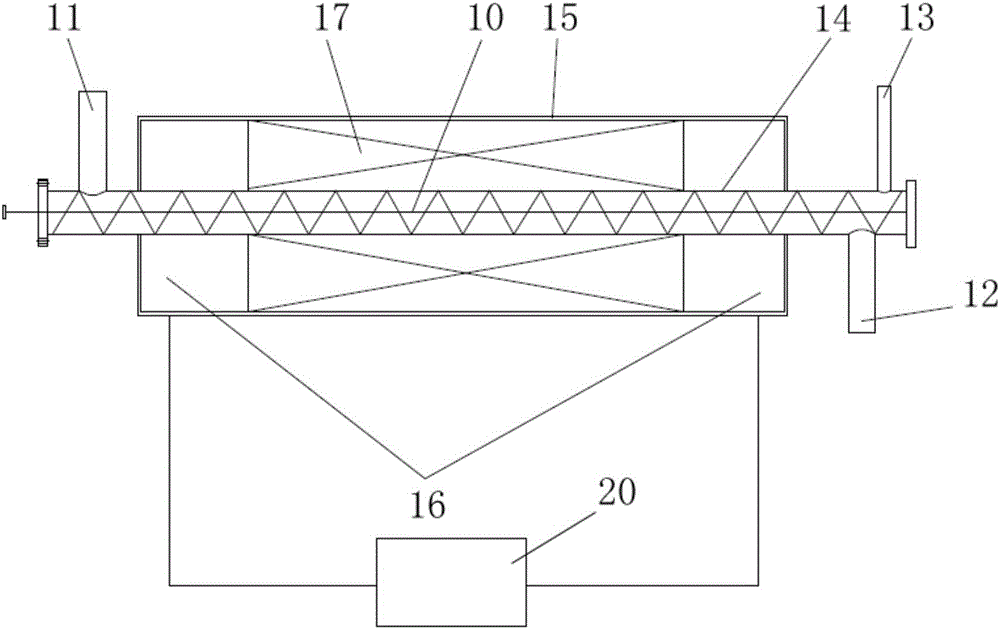

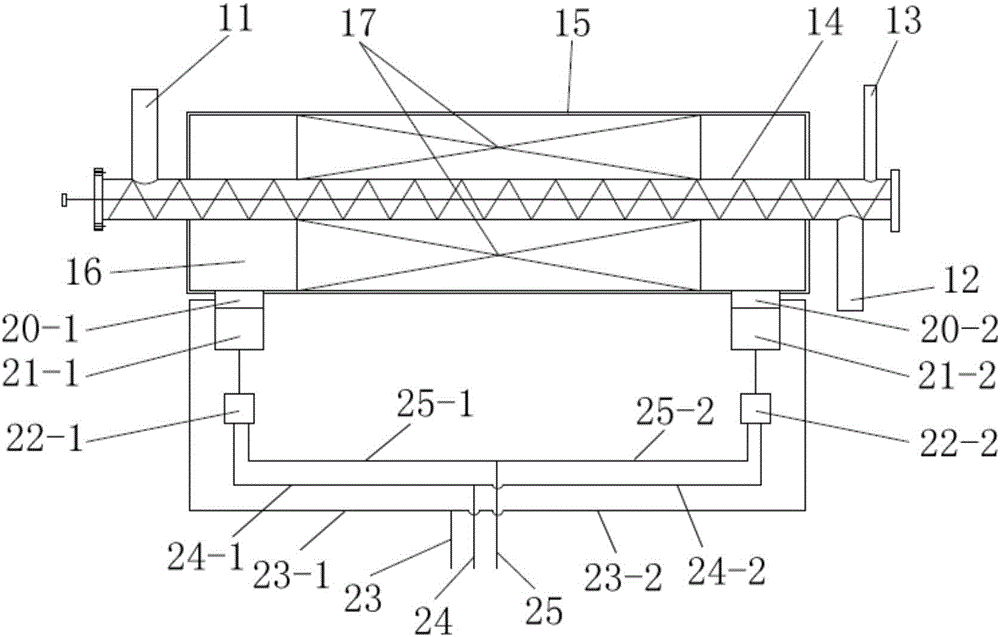

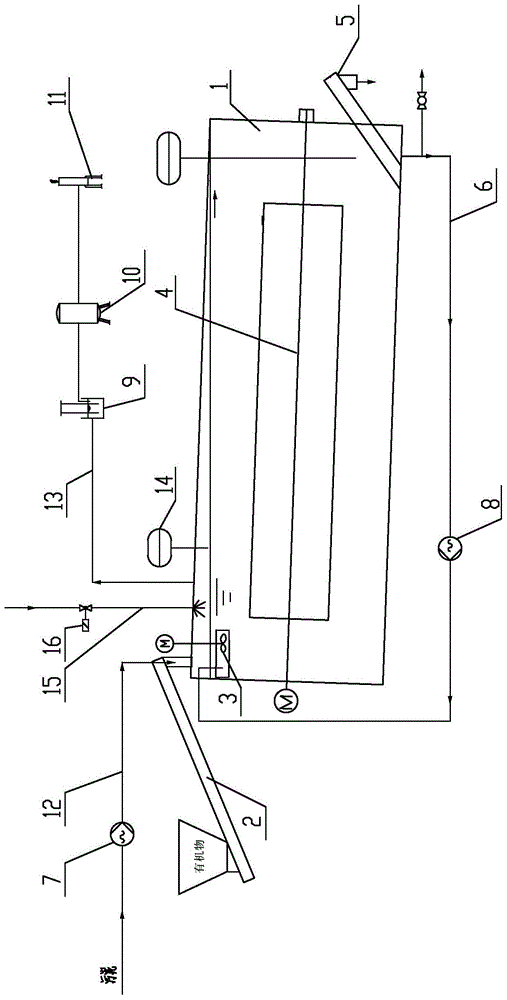

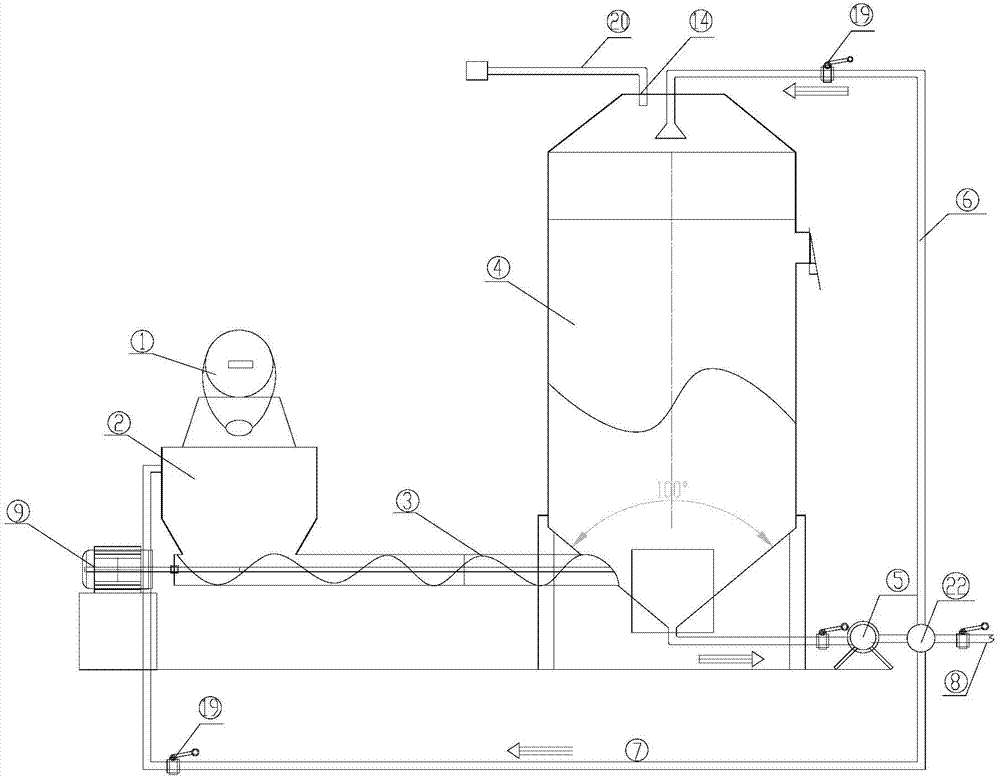

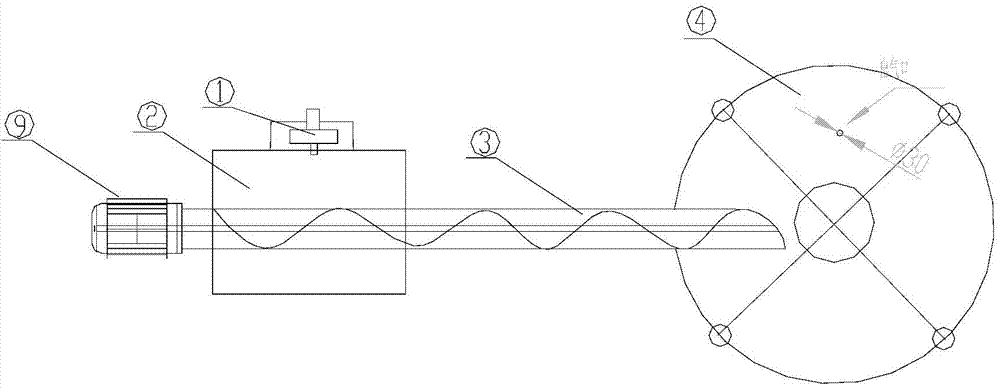

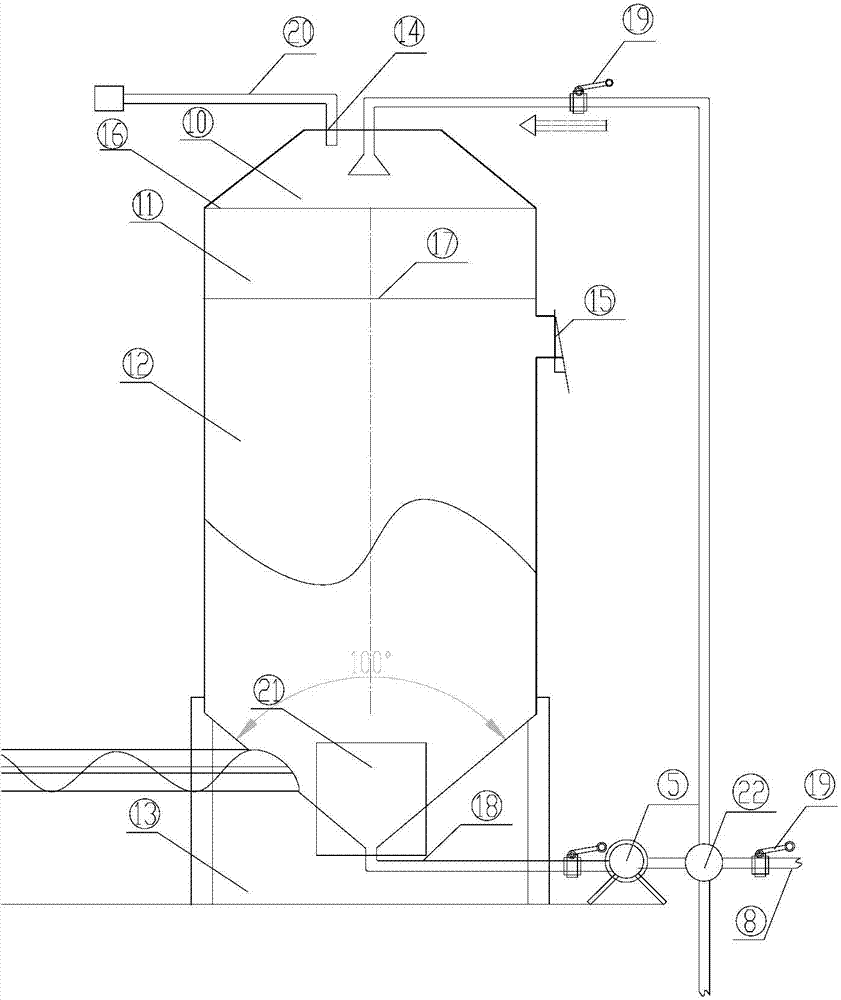

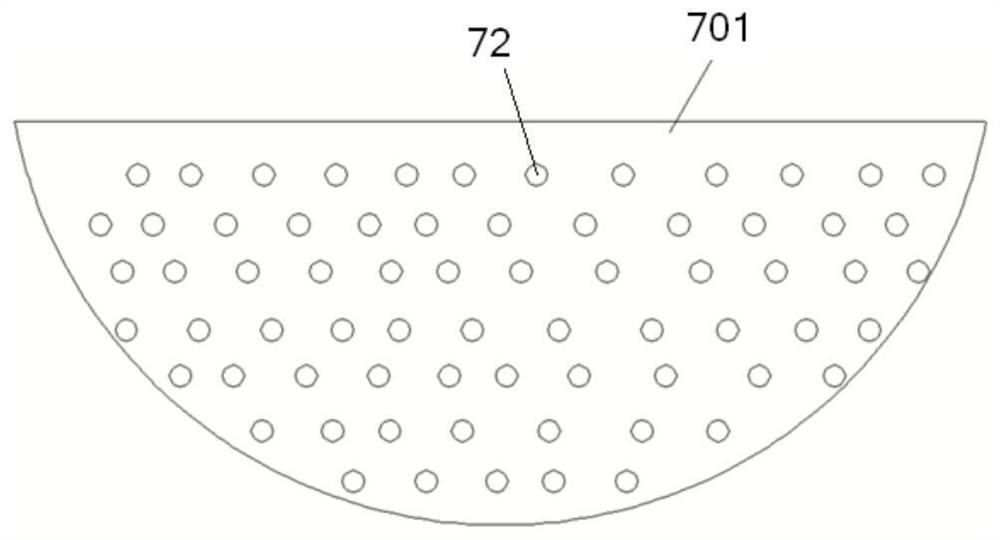

High-solid anaerobic reaction device and method for organic garbage

ActiveCN103614288AImprove processing efficiencyGuaranteed uptimeBiological substance pretreatmentsGas production bioreactorsPipe fittingSmall footprint

The invention relates to a high-solid anaerobic reaction device and method for organic garbage. The device comprises a pulverizer, a pretreatment pond and an anaerobic fermentation tank, wherein the pulverizer is arranged above the pretreatment pond; a spiral conveying device is arranged below the material outlet of the pretreatment pond and connected with the anaerobic fermentation tank; a liquid-collecting pipe is connected to the bottom of the anaerobic fermentation tank and connected to a four-way pipe fitting; the other three ports of the four-way pipe fitting are connected with a water draining pipe, a pretreatment pond backflow pipe and a biogas slurry spraying return pipe respectively; the anaerobic fermentation tank is internally sequentially provided with a spraying perforated plate and a sieve plate from top to bottom. According to the anaerobic reaction device for the organic garbage with the high solid content, the material pulverization, pretreatment and fermentation are integrated, the material uniformity is guaranteed, an anaerobic fermentation process is facilitated, the solid concentration and uniformity of a material are regulated through fermentation liquor backflow, and the stable fermentation of organic garbage is realized; the anaerobic reaction device has the characteristics of wide adaptability, high treatment efficiency, compact layout, stable operation, small land occupation area and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

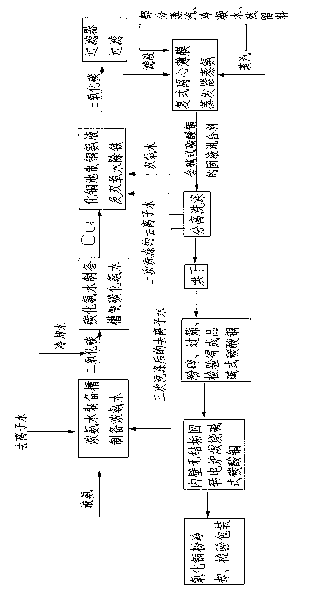

Method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate

InactiveCN103101958AGuaranteed purityOvercoming the disadvantages of static calcinationCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

The invention discloses a method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate. According to the method, pure copper, liquid nitrogen and high-purity carbon dioxide are taken as materials to prepare the high-purity basic cupric carbonate through a centrifugal film evaporator or a scraper reaction kettle; the problem of impurities such as chlorine which may be caused by production of the basic cupric carbonate material by the traditional method is avoided; the purity of the basic cupric carbonate is improved; the high-purity low-chorine electroplating grade copper oxide is burnt from the high-purity basic cupric carbonate through a rotary kiln; the defects of inactivation, a plurality of impurities, large labor intensity, un-continuous production, long period, high energy consumption, large cost and the like due to the fact that the basic cupric carbonate at the low-temperature part is not burnt thoroughly and the content is not enough when a pushed slab kiln statically burns while copper oxide at the high-temperature part is burnt to death are overcome; the product activity is ensured; and the method is high in product quality, less in energy consumption, small in cost and more environment-friendly.

Owner:TAIXING SMELTING PLANT

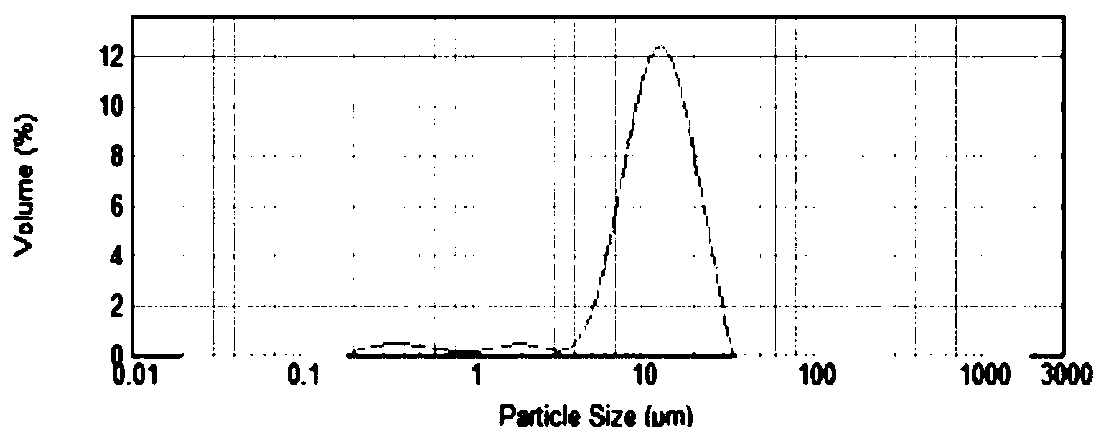

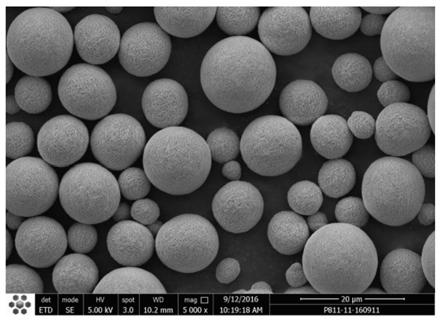

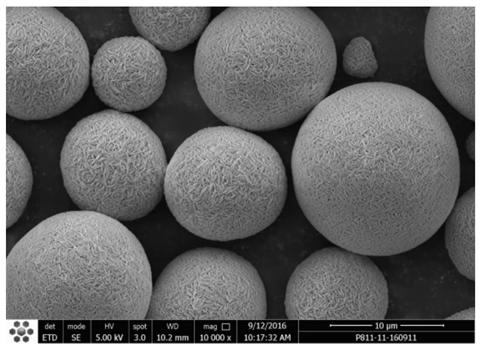

Regulating nucleation method during crystallization of nickel-cobalt-manganese precursor

ActiveCN109422297AParticle size distribution controlControlled nucleation method is simple and efficientCell electrodesSecondary cellsManganesePhysical chemistry

The invention discloses a regulating nucleation method during crystallization of a nickel-cobalt-manganese precursor. The method comprises the following steps: (1) adding a nickel-cobalt-manganese salt solution, an ammonia solution and an alkali solution into a closed reaction kettle containing a base liquid for a reaction; and (2) monitoring D50 and span values of particles generated in the reaction kettle; when the span value is smaller than 1, adding a nucleation feeding liquid to the reaction kettle, performing continuous stirring for the reaction, and monitoring the span value of the particles generated in the reaction kettle continuously; when the span value reaches a preset value, stopping adding the nucleation feeding liquid; and after the span value is lower than the preset value,adding the nucleation feeding liquid to the reaction kettle again, terminating the reaction until the D50 and span values of the particles generated in the reaction kettle reach a target particle size and the preset value separately, collecting materials, and then performing subsequent treatment so as to obtain the nickel-cobalt-manganese precursor, wherein the nucleation feeding liquid is a mixed solution of the nickel-cobalt-manganese salt solution and the ammonia solution, and span = (D90-D10) / D50.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Method for continuously preparing high-purity low-chloride electroplating copper oxide

InactiveCN103011251AHigh purityQuick responseCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

Owner:TAIXING SMELTING PLANT

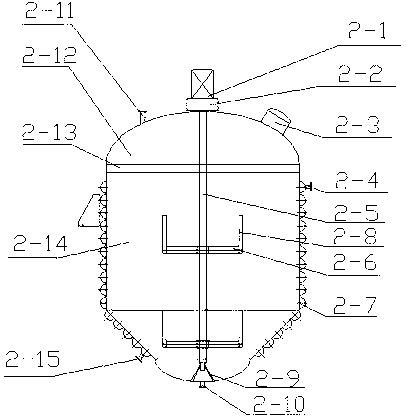

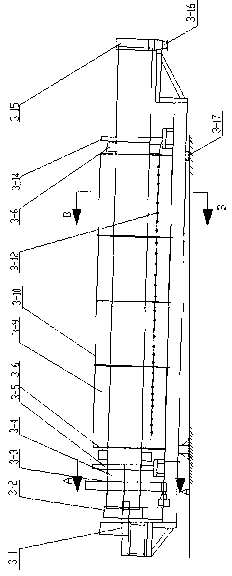

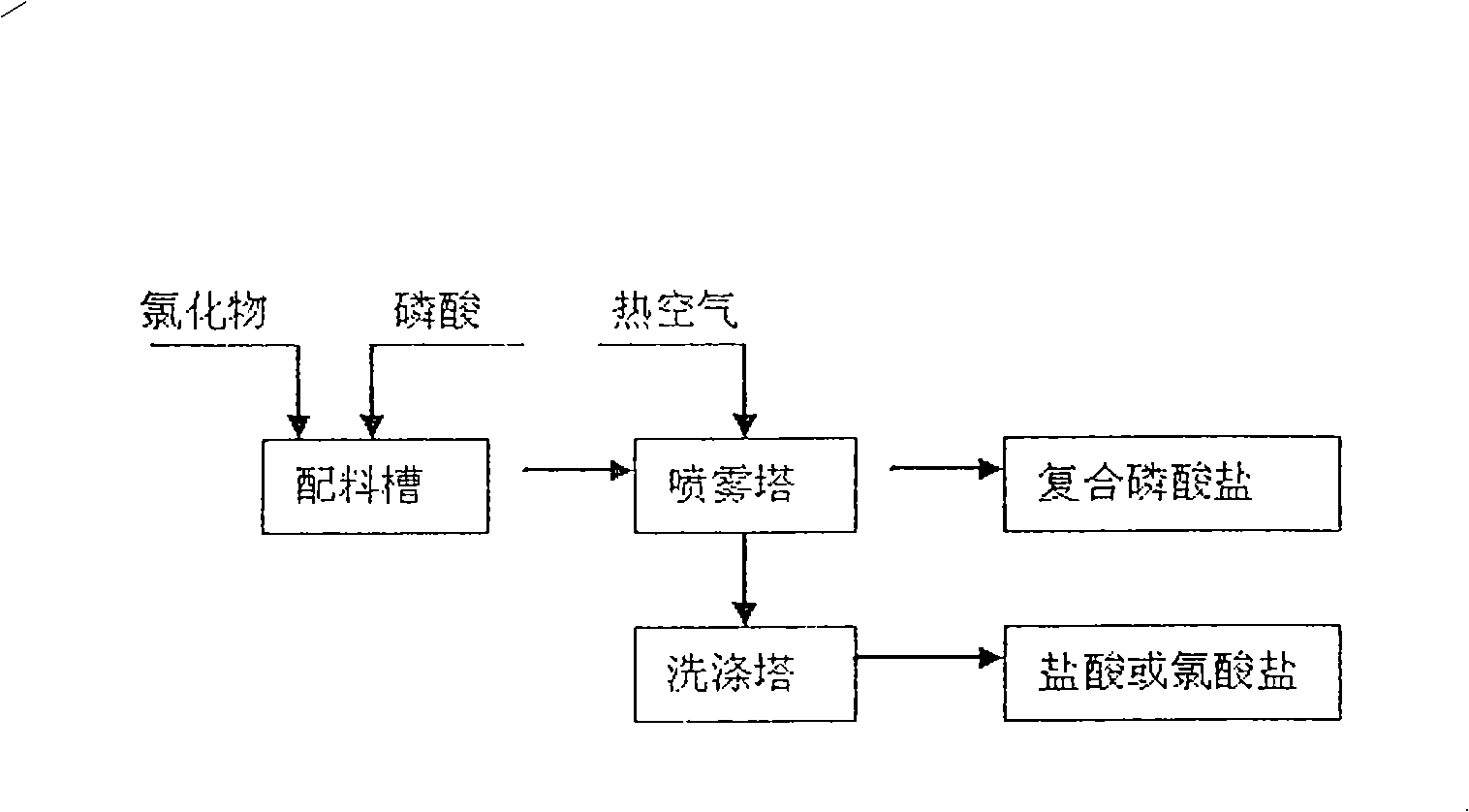

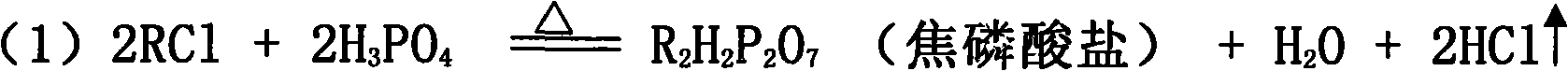

Method for preparing composite phosphate

ActiveCN101343053AReduce heat transfer rateLow mass transfer efficiencyPhosphatesState of artSmall droplet

The invention discloses a production method of composite phosphate, which essentially comprises steps as follows: firstly, chloride is mixed with excessive phosphoric acid in order to obtain material liquid; secondly, the material liquid is added into the spray dryer to atomize into tiny droplets; thirdly, the droplets are instantaneously contacted and heated with as much hot air as is sufficient to enable double decomposition reaction between chloride and phosphoric acid to happen, so that hydrogen chloride gas escapes, and the remaining things are reacted to obtain a compound phosphate product. The production method has technical advantages that the shortcomings of prior art can be overcome, the spray dryer is adopted as a core reactor to atomize the material liquid into small droplets to be contacted with the high-temperature hot air, the specific surface area of evaporation is maximum, so that the escaping time of HCl and the water vapor is 3 to 8 seconds only, the reaction conversion rate reaches up to 97 percent, the material liquid continues to be in and out, and large-scale industrialization production can be achieved.

Owner:GUIZHOU CHANHEN CHEM CO LTD

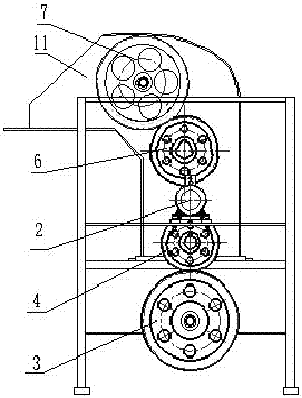

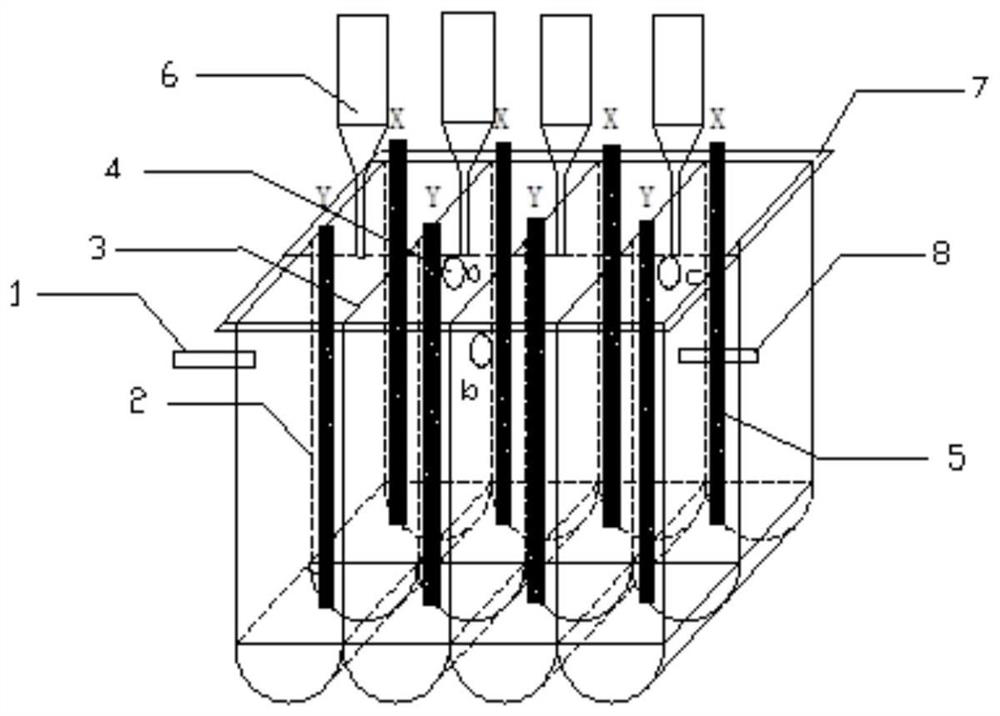

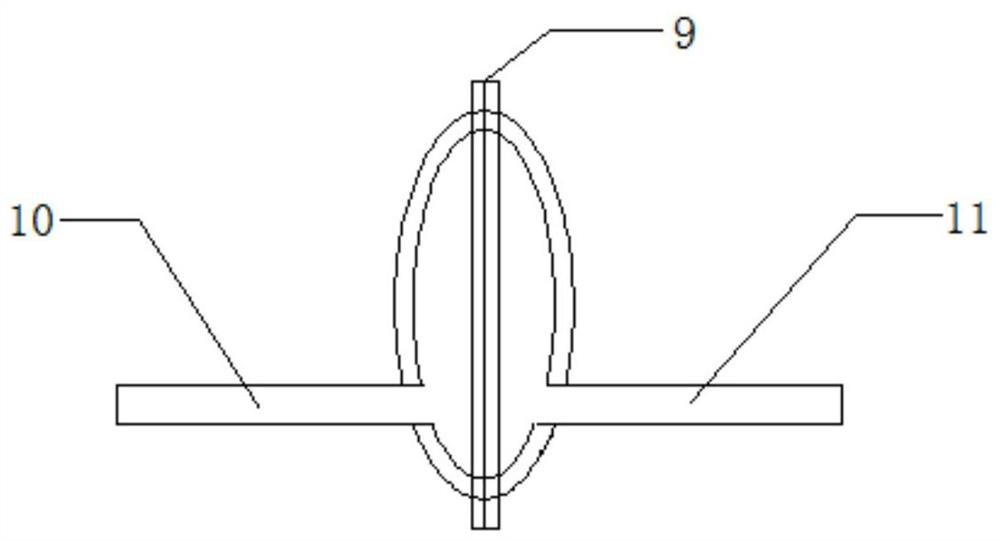

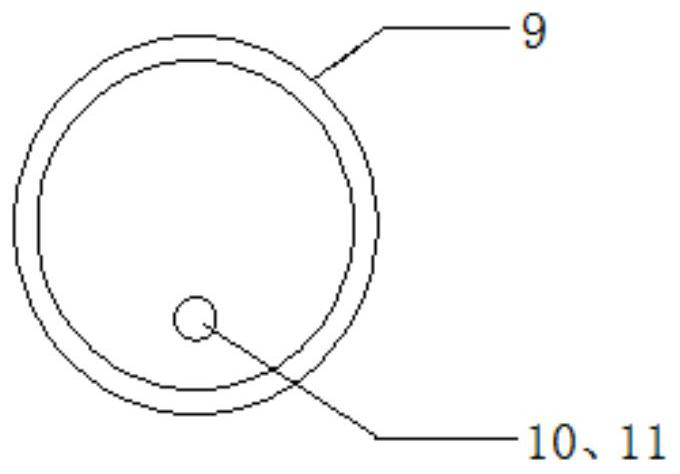

Carbonization device of rotten garbage treatment

PendingCN107513389AImprove purityReduce equipment costsTransportation and packagingSolid waste disposalSpray towerEngineering

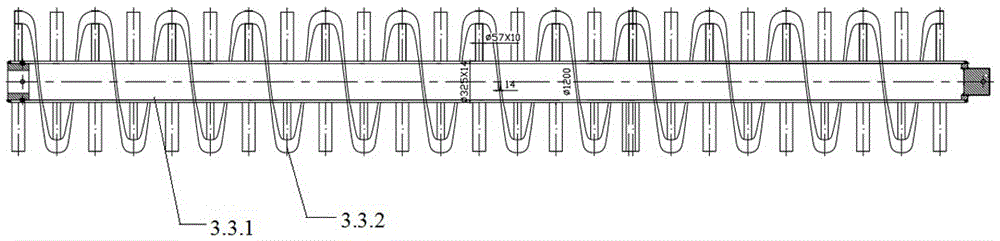

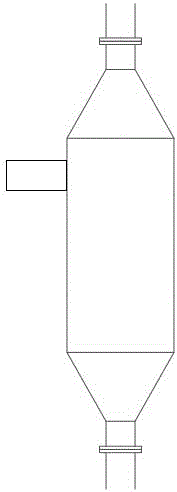

The invention discloses a carbonization device of rotten garbage treatment. The carbonization device comprises a feeding spiral device, a carbonizer, a spraying tower, a cooling tower, a combustible gas recycling tank, a conveying motor and a discharge spiral device, wherein a plurality of conveying tubes are mounted from top to bottom inside the carbonizer; rotating shafts are mounted inside the conveying tubes; spiral plates are mounted on the rotating shafts inside the conveying tubes; transmission wheels are mounted on rotating shafts outside the conveying tubes; transmission motors are used for driving a plurality of transmission wheels to rotate through chains; an upmost conveying tube is connected with the feeding spiral device; a lowermost conveying tube is connected with the discharge spiral device; the outlet of each conveying tube is connected with the inlet of the next conveying tube; gas outlet tubes are mounted at the end parts of the plurality of conveying tubes; the plurality of gas outlet tubes are sequentially connected with the spraying tower and a condensation tower; the gas outlet of the condensation tower is connected with a combustible gas recycling tank; and the combustible gas recycling tank is communicated with a gas stove mounted at the bottom of the carbonizer. After a combustible gas generated through a thermal decomposition reaction is treated, a heat source is provided to the carbonization device, and thus self-sufficiency of energy is achieved.

Owner:BEIJING HAOYE TONGYU TECH

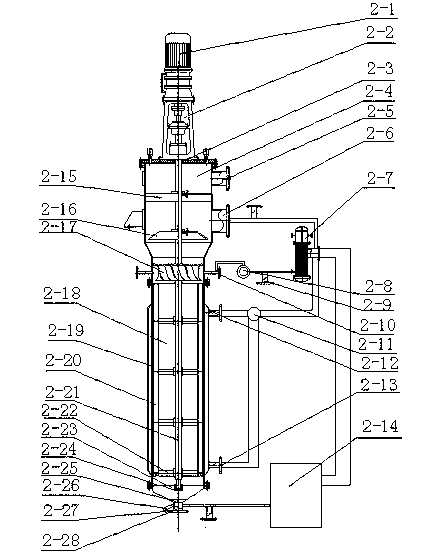

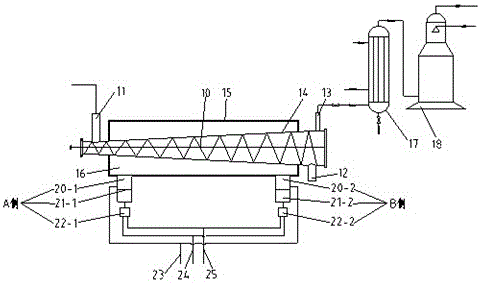

Heat accumulating type metal honeycomb gas electronic waste pyrolysis device and pyrolysis method

PendingCN106479532AFully pyrolyzedRealize the function of propulsion while pyrolysisIndirect heating destructive distillationSpecial form destructive distillationFlue gasHoneycomb

The invention discloses a heat accumulating type metal honeycomb gas electronic waste pyrolysis device. The heat accumulating type metal honeycomb gas electronic waste pyrolysis device comprises an electronic waste pyrolysis reactor and a heat accumulating type gas heating system. The electronic waste pyrolysis reactor comprises a reactor shell and a material pyrolysis assembly. The material pyrolysis assembly crosses the reaction shell. The heat accumulating type gas heating system comprises a metal honeycomb, a heat accumulating type combustion device and a flue gas channel. The flue gas channel is a closed space formed between the reaction shell and the material pyrolysis assembly in a matched mode, the flue gas channel is communicated with the heat accumulating type combustion device, the metal honeycomb is arranged in the flue gas channel, and the material pyrolysis assembly crosses the metal honeycomb. The invention further discloses a device for pyrolysis of electronic waste through the pyrolysis device. The method includes the two steps that a spiral shell is heated through the heat accumulating type gas heating system, and material pyrolysis is carried out. By means of the pyrolysis device and method, continuous material inflow and outflow can be achieved, the heat source stability is good, the pyrolysis process is simple, and the pyrolysis efficiency is high.

Owner:SHENWU TECH GRP CO LTD

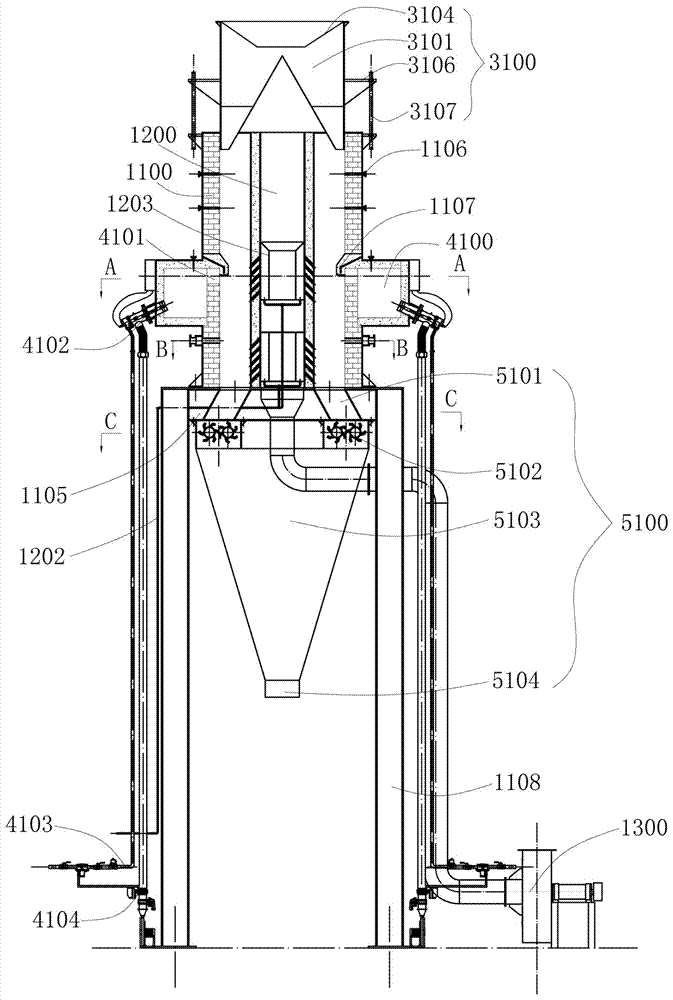

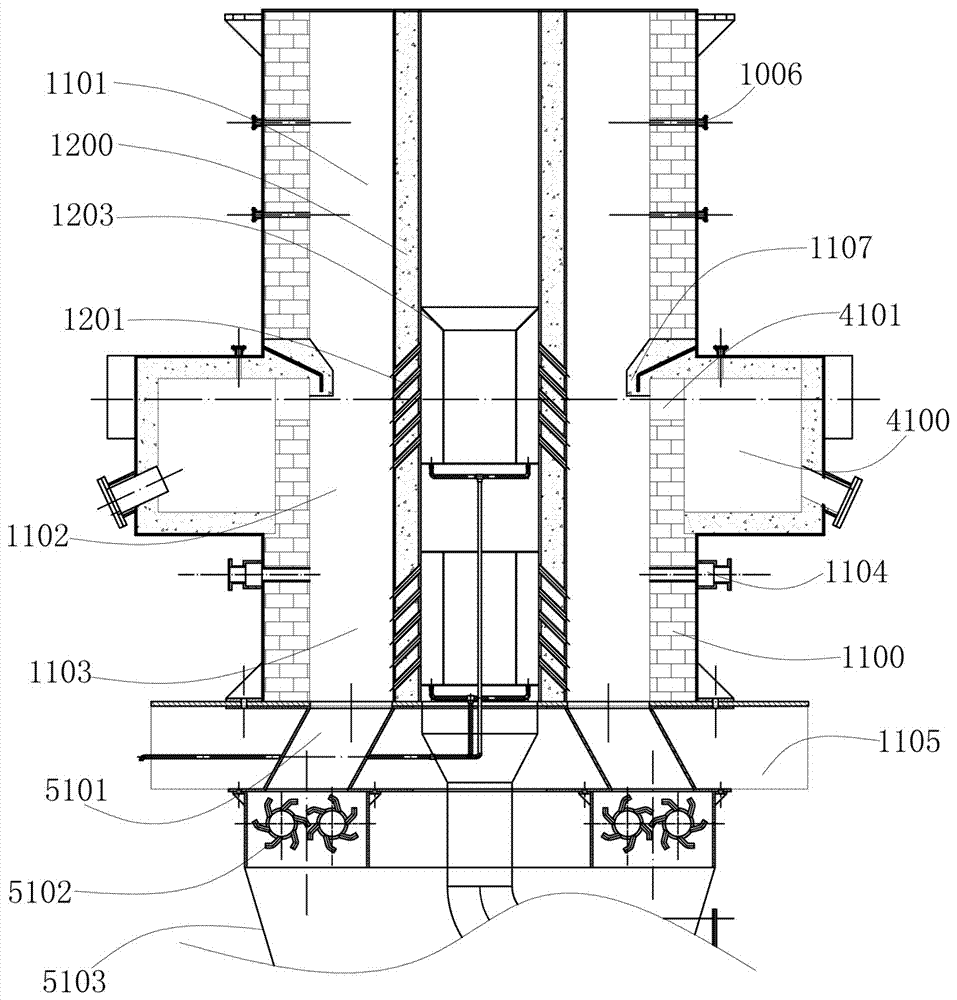

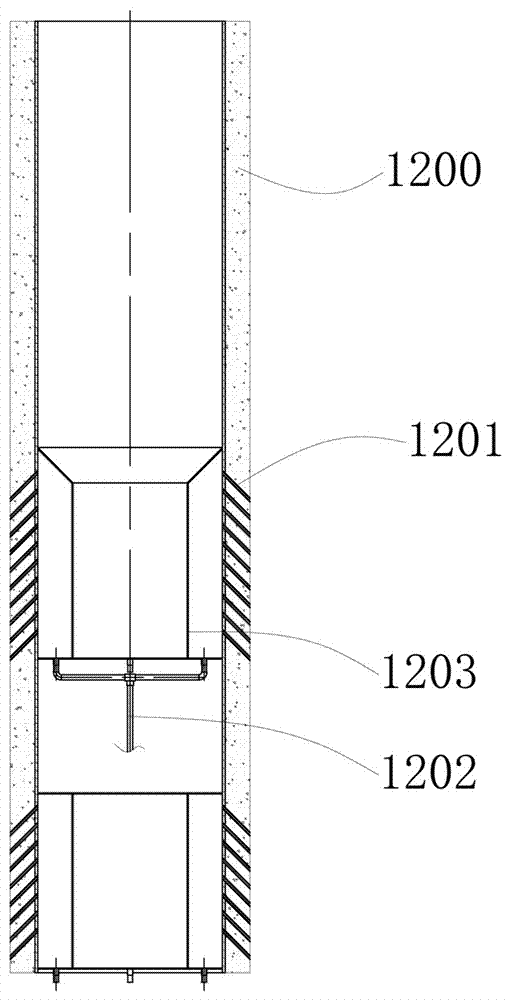

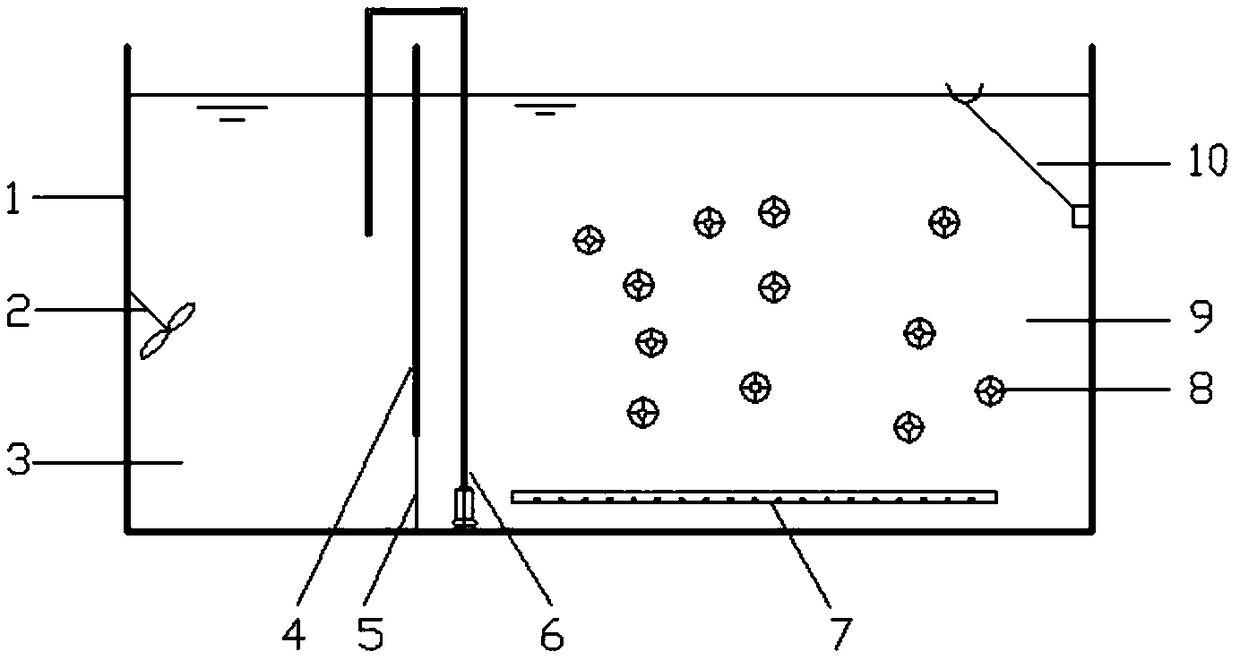

Anaerobic fermentation system and method for producing biogas by carrying out sludge digestion reaction through anaerobic fermentation system

ActiveCN104673629AGuaranteed long stayGuaranteed reflowBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeDigestion

The invention relates to the technical field of waste treatment and in particular relates to an anaerobic fermentation system and a method for producing biogas by carrying out a sludge digestion reaction through the anaerobic fermentation system. The anaerobic fermentation system comprises a fermentation tank, wherein the fermentation tank is of a sealed structure, and a horizontal stirring device is arranged inside the fermentation tank; a feeding end and a discharging end are respectively arranged at two ends of the fermentation tank in the horizontal direction; a biogas pipe is arranged on the top of the fermentation tank; a feeding hole is formed in the top, which is close to the feeding end, of the fermentation tank; the feeding hole is respectively connected with a feeding screw conveying device and a sludge conveying pipeline; a device for stirring and mixing the materials is arranged below the feeding hole and inside the fermentation tank; a discharge opening is formed in the discharging end and is connected with the screw conveying device; a return pipeline is arranged on one side of the discharging end; and the other end of the return pipeline is connected with the feeding end. The system has the advantages of small size, reasonable design, continuous operation and the like.

Owner:AQSEPTENCE GRP HANGZHOU CO LTD

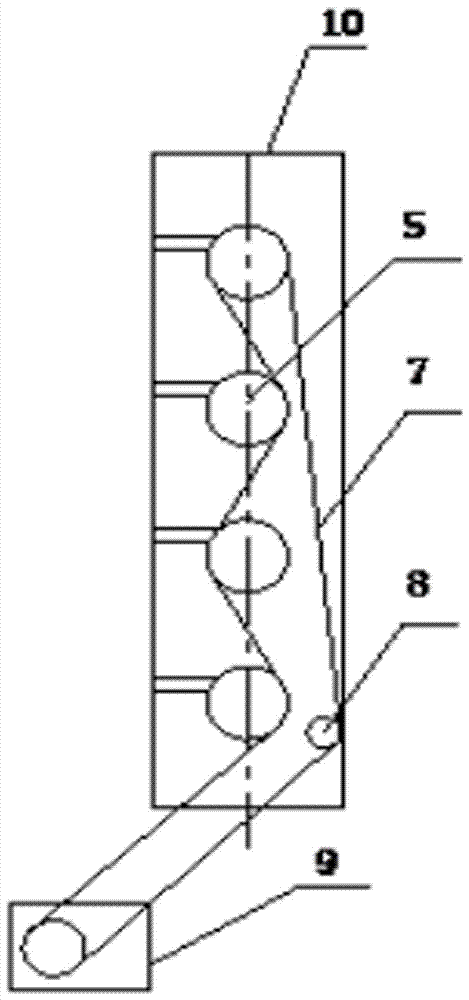

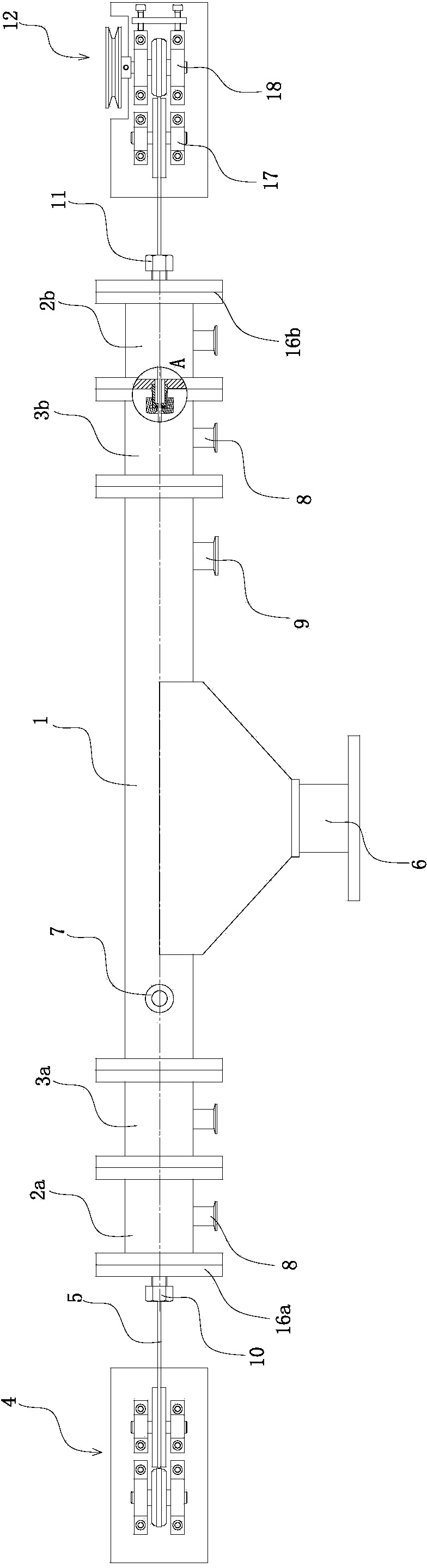

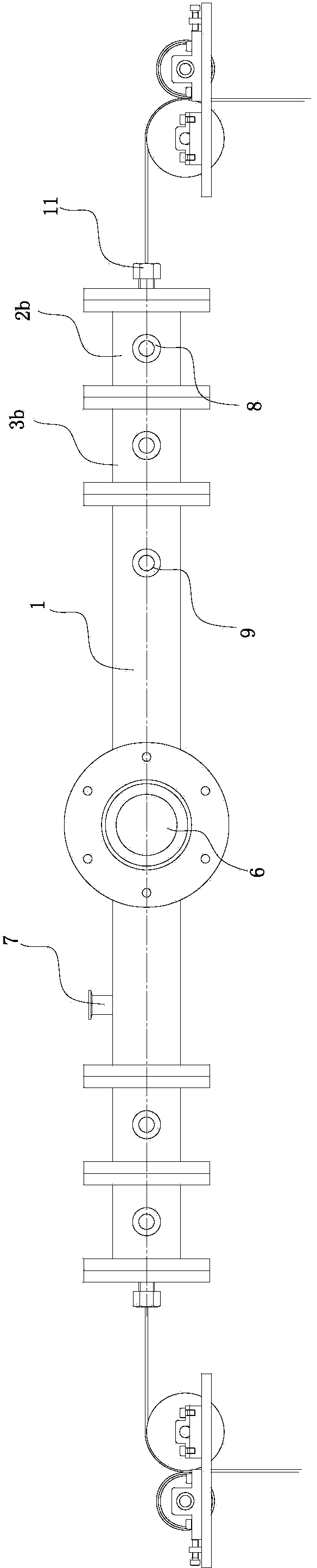

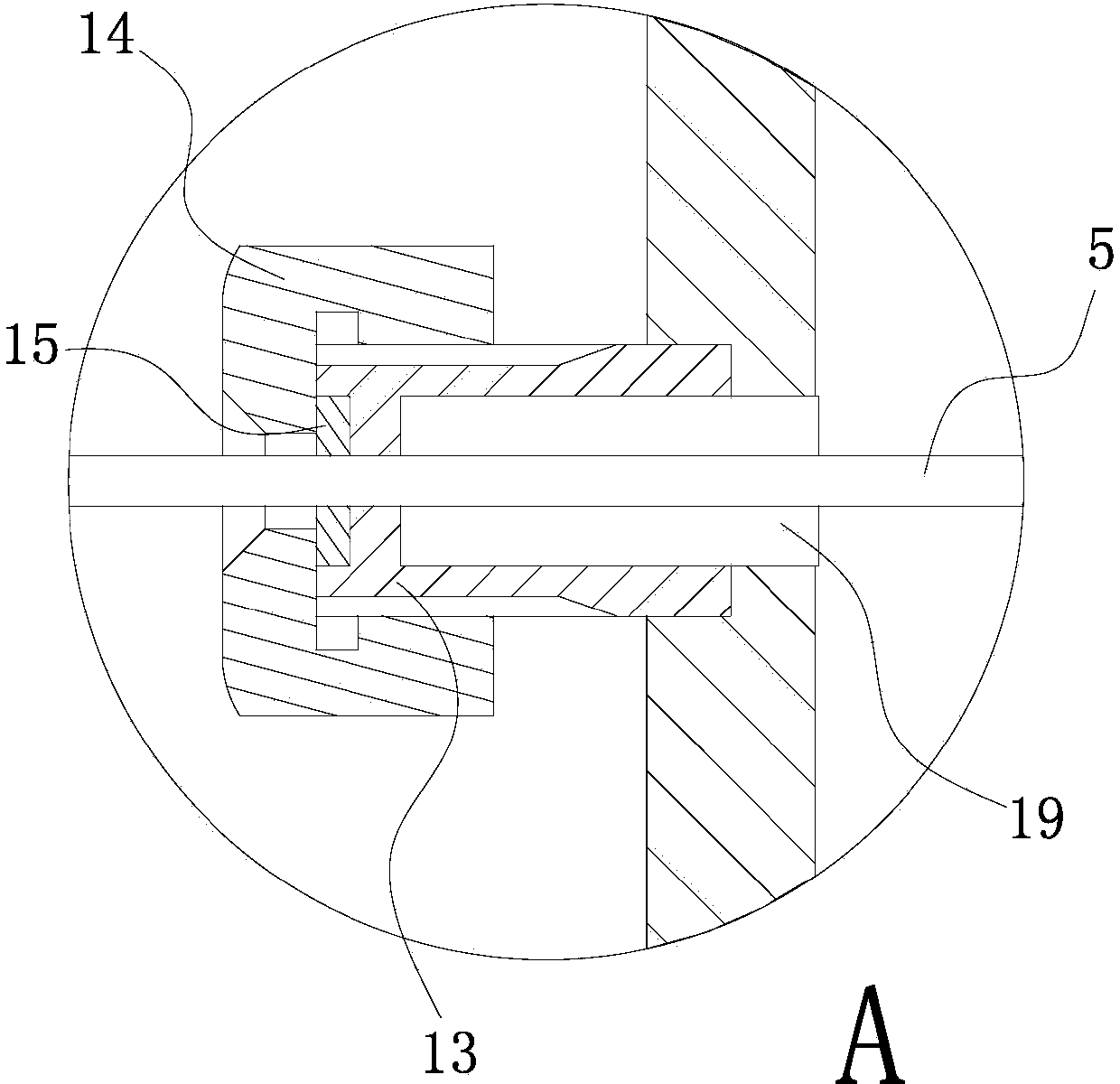

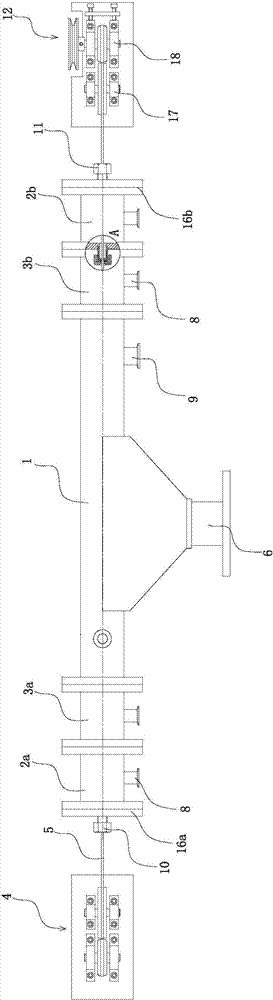

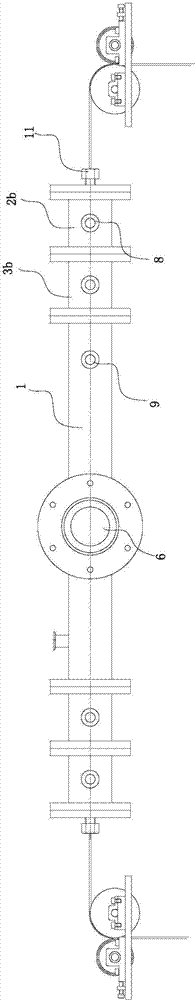

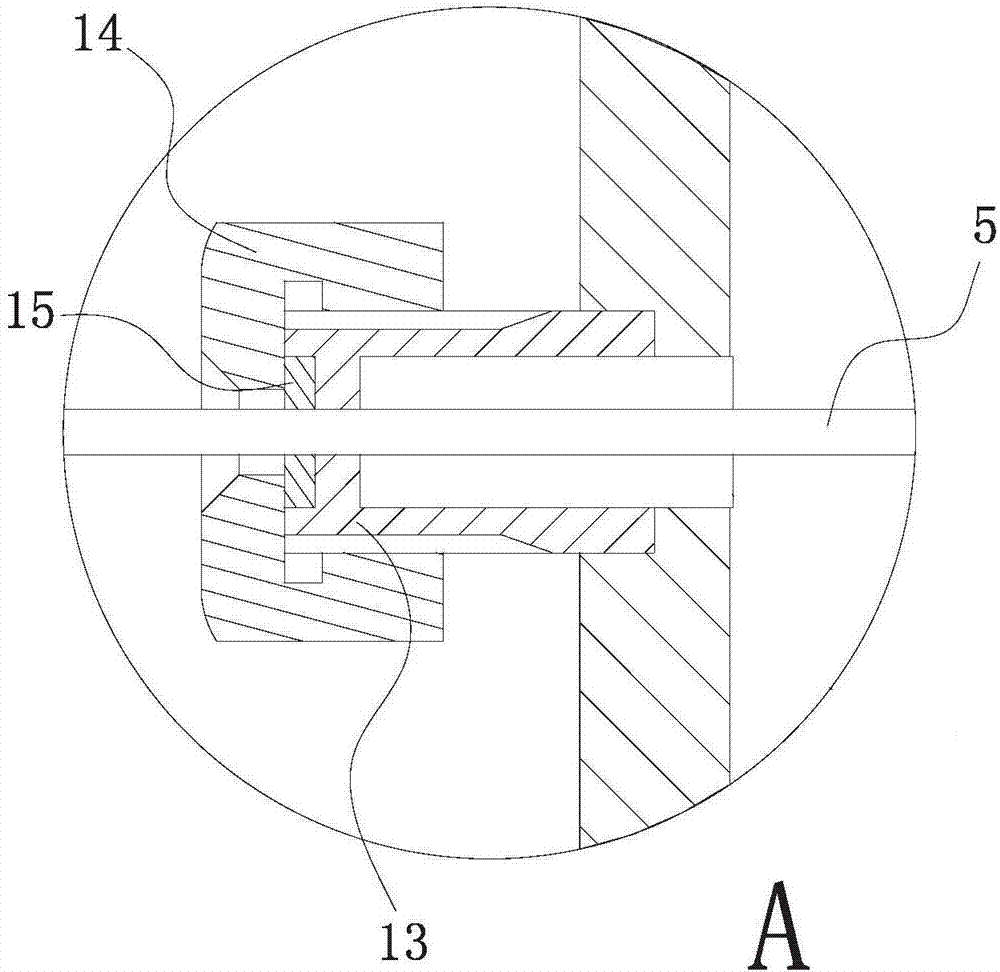

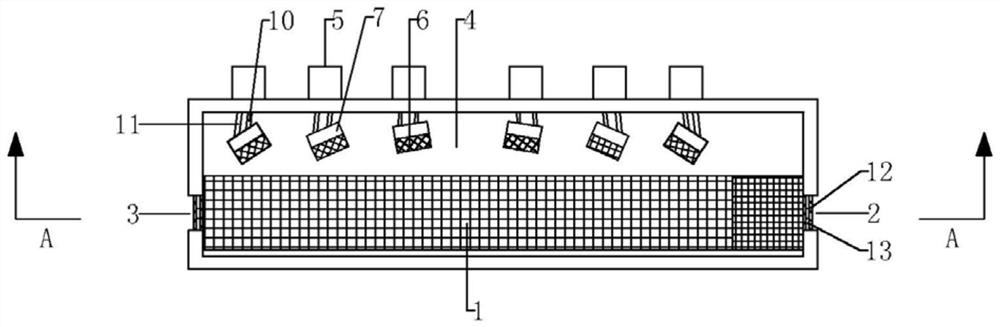

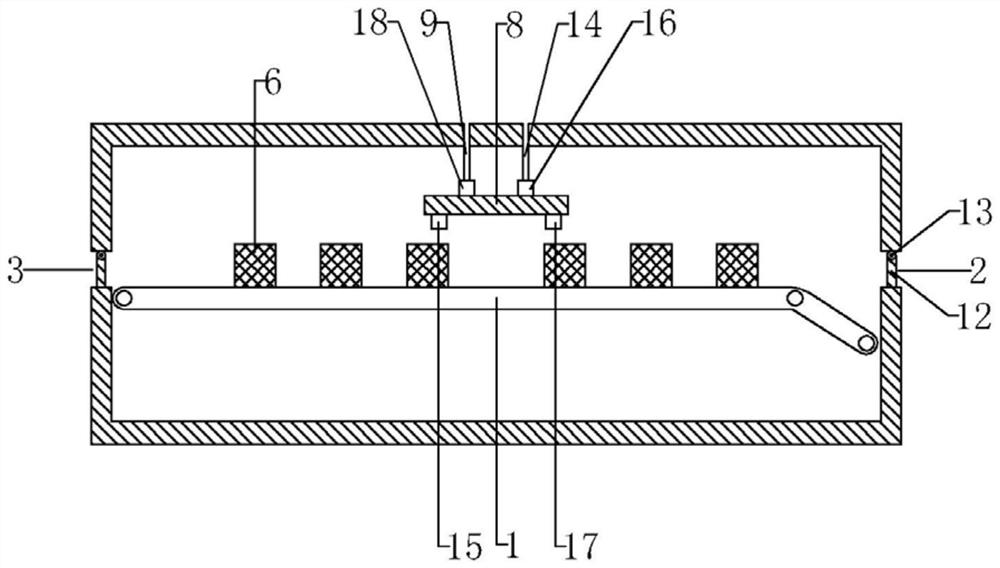

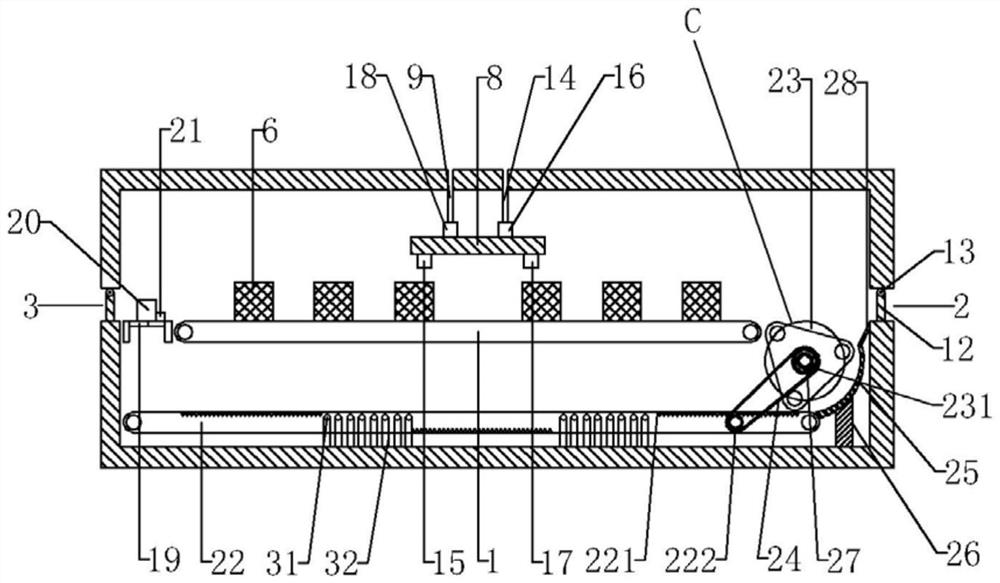

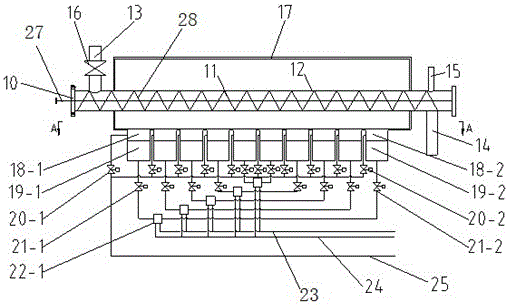

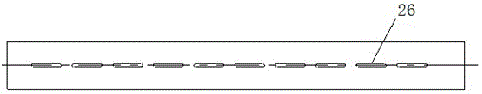

Continuous coating device for coating layer on surface of cable and method thereof

ActiveCN104213095AReduce pressure differenceContinuous in and outVacuum evaporation coatingSputtering coatingParyleneVacuum chamber

The invention discloses a continuous coating device for a coating layer on a surface of a cable and a method thereof. The coating device comprises a vacuum chamber, a pre-extracting chamber, a unwinding device and a winding device, wherein the pre-extracting chamber consists of upstream and downstream pre-extracting chambers at the upstream and downstream of the vacuum chamber; a cable inlet is formed at the front end of the upstream pre-extracting chamber near the unwinding device; a cable outlet is formed at the back end of the downstream pre-extracting chamber near the winding device; when the coating device is operated, a cable to be coated is released out by the unwinding device, and is leaded in the pre-extracting chamber and the vacuum chamber through the cable inlet and an opening in a baffle plate; when the cable is positioned in the vacuum chamber, a coating layer material is polymerized on the surface of the cable to form a coating layer; and the cable with a formed film is leaded out from the vacuum chamber and the pre-extracting chamber through the opening and the cable outlet, and is accommodated by the winding device. The continuous coating device enables the Parylene material coating to be changed from the intermittent single-furnace deposition to the continuous deposition, so that the coating efficiency is largely improved.

Owner:昆山彰盛奈米科技有限公司

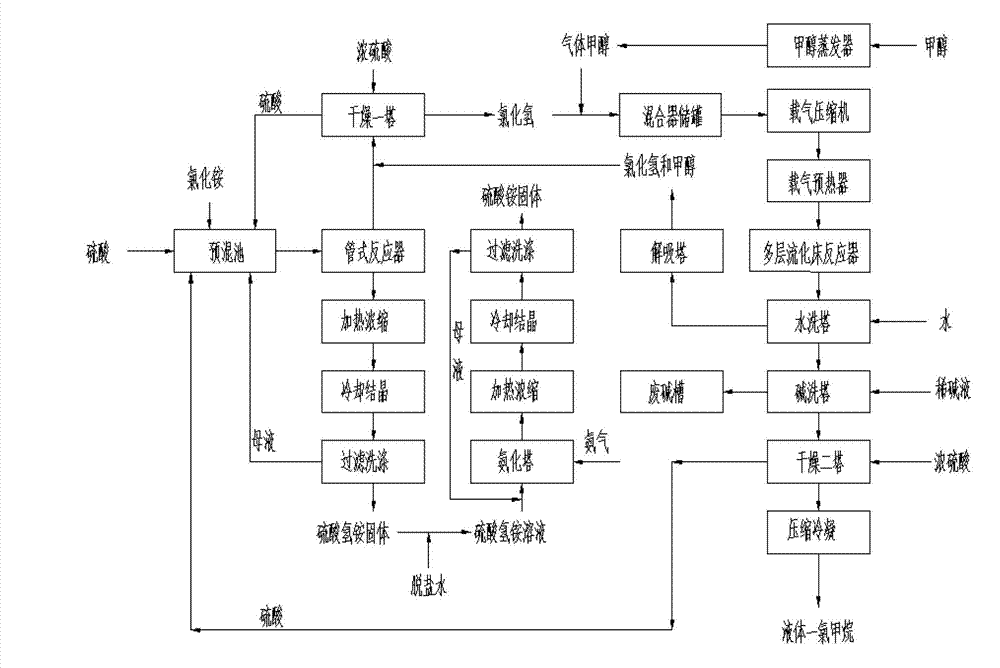

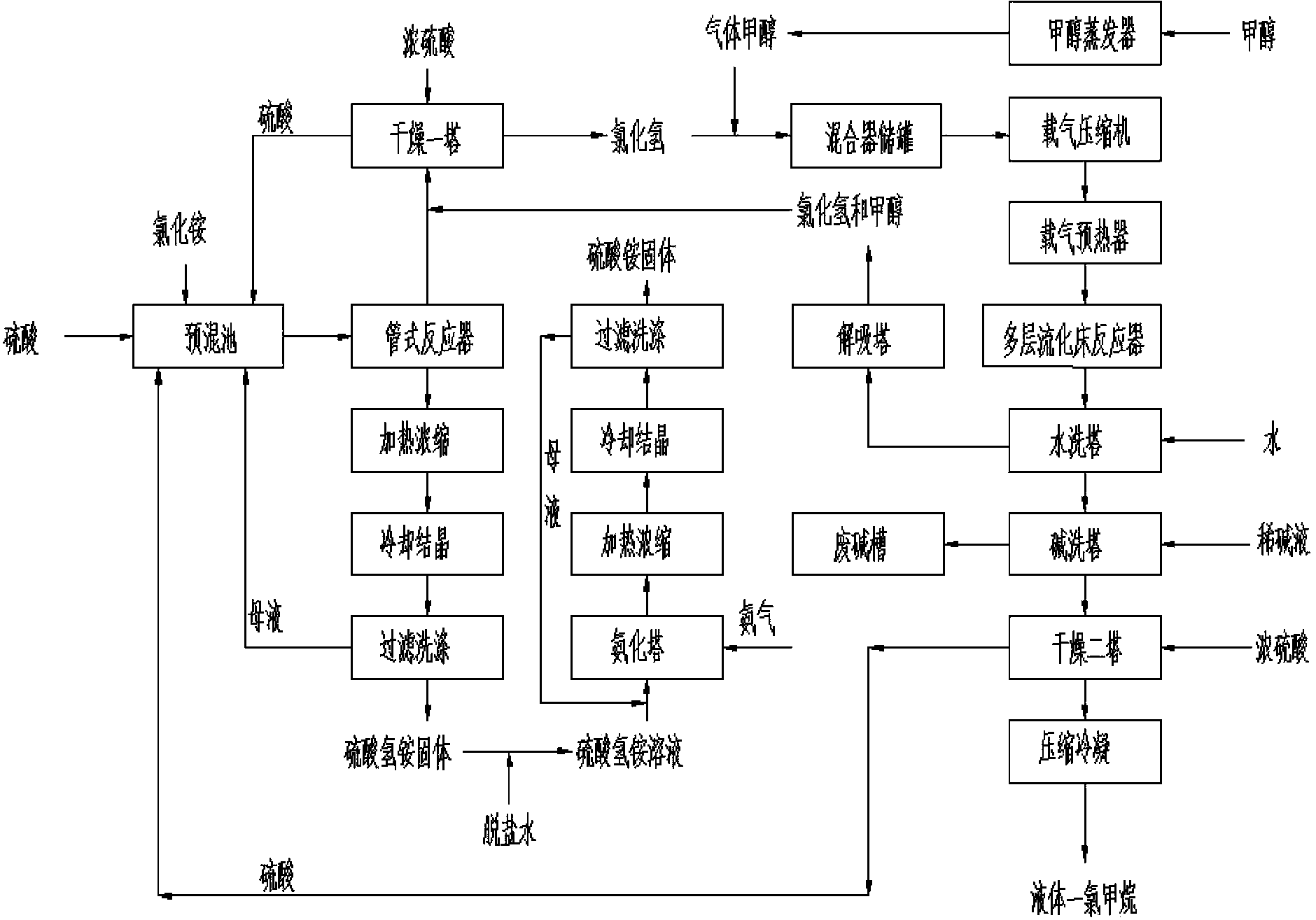

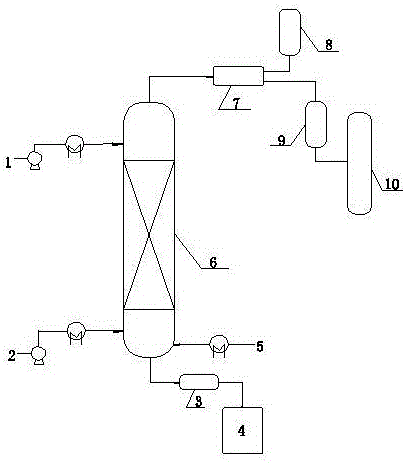

Technology for jointly producing ammonium sulfate and chloromethane

ActiveCN103193251AReduced purification stepsAvoid introducingHalogenated hydrocarbon preparationAmmonia compoundsFluidized bedAmmonium bisulfate

The invention relates to a technology for jointly producing ammonium sulfate and chloromethane. The technology specifically comprises steps of: S1, premixing ammonium chloride with sulfuric acid at normal pressure; S2, pumping the sulfuric acid solution of the ammonium chloride obtain in step S1 into a tubular reactor, and thus obtaining ammonium bisulfate and hydrogen chloride gas; S3, preparing the ammonium bisulfate obtained in step S2 to form aqueous solution, and performing ammonolysis reaction in an ammonification column so as to obtain ammonium sulfate; S4, guiding the hydrogen chloride gas obtained in step S2 into a drying column 1 to be dried, and filling the dried hydrogen chloride gas into a fluidized bed reactor together with gaseous methanol so at to obtain a chloromethane crude product; sequentially feeding the chloromethane crude product obtained in S4 into a water washing tower, an alkaline washing tower and a drying tower 2 so as to obtain pure chloromethane, and compressing and condensing the pure chloromethane to form high-purity liquid chloromethane. By utilizing the technology, ammonium and chlorine elements in ammonium chloride are fully and reasonably utilized, so that the joint production of ammonium sulfate and chloromethane is realized, the industrial structure is optimized, and a new method is provided for comprehensively utilizing the ammonium chloride.

Owner:BEIJING EDGEIN TECH +2

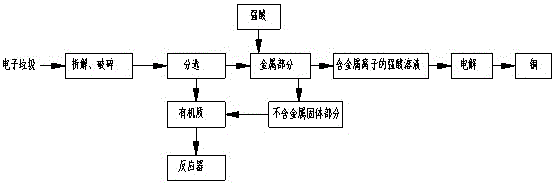

Conical screw heat accumulation type fuel-gas pyrolyzing system for electronic waste

PendingCN106497583AFully pyrolyzedRealize the function of propulsion while pyrolysisPhotography auxillary processesIndirect heating destructive distillationCooling towerProcess engineering

The invention relates to the technical field of the pyrolyzation of waste, and particularly relates to a conical screw heat accumulation type fuel-gas pyrolyzing system for electronic waste. The system comprises a raw material treating system, a metal recovering system and an electronic waste pyrolyzation reaction system, wherein the raw material treating system comprises a crushing device and a sorting device; the metal recovering system comprises an acid leaching tank and an electrolytic tank; the electronic waste pyrolyzation reaction system comprises an electronic waste pyrolyzation reactor, a heat accumulation type fuel-gas heating system and a cooling and separating system, wherein the electronic waste pyrolyzation reactor comprises a material pyrolyzing component and a reactor shell; the material pyrolyzing component comprises a conical screw shell and a conical boosting screw; the heat accumulation type fuel-gas heating system comprises a heat accumulation type combusting device and a fume passage; the cooling and separating system comprises an indirect heat exchanger and a cooling tower. The system has the advantages of being high in pyrolyzation efficiency, continuous in material feeding and discharging, saving energy, protecting environment and the like.

Owner:SHENWU TECH GRP CO LTD

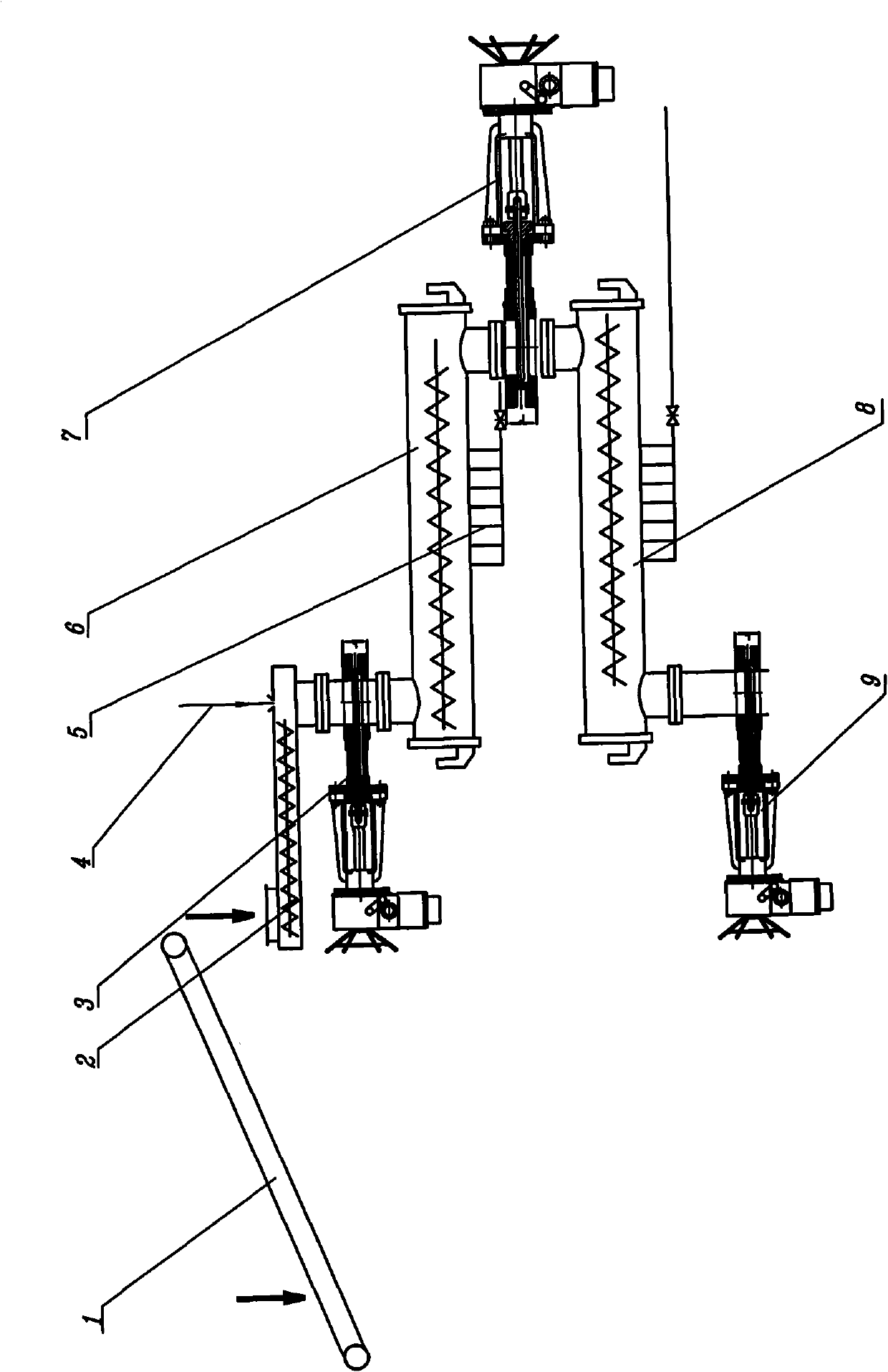

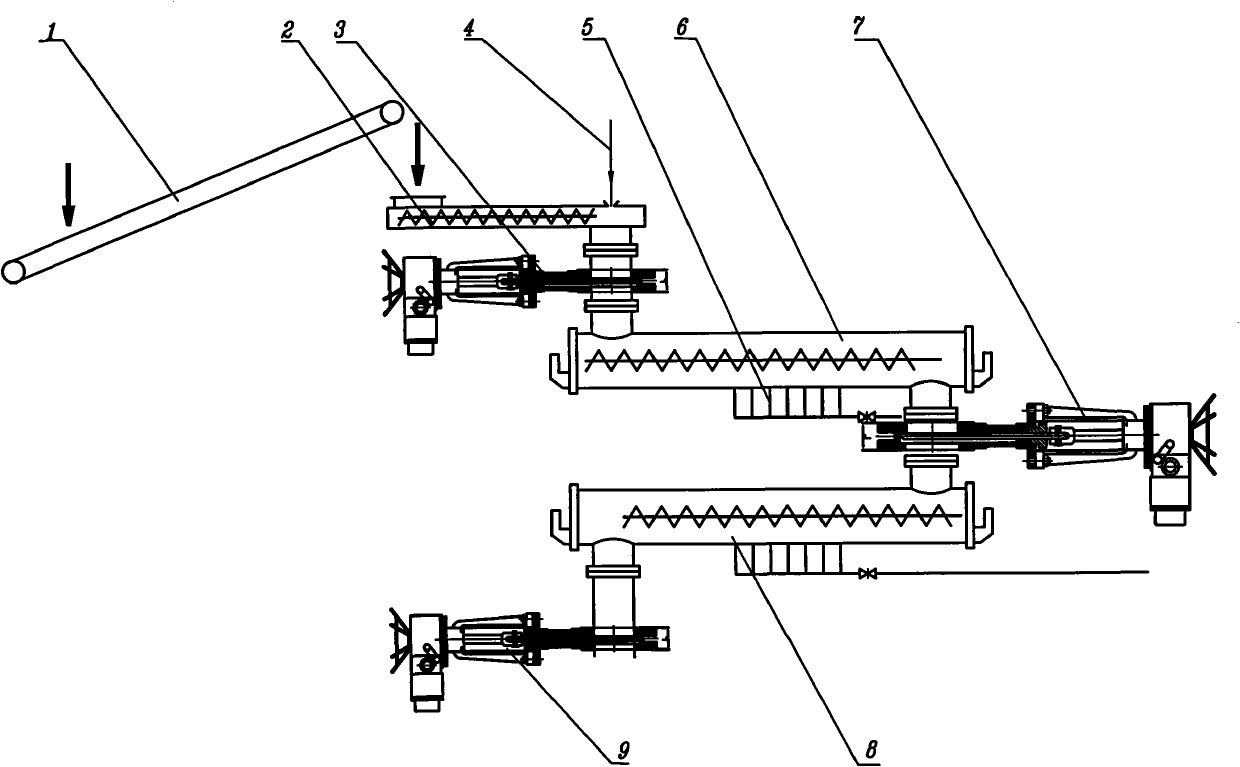

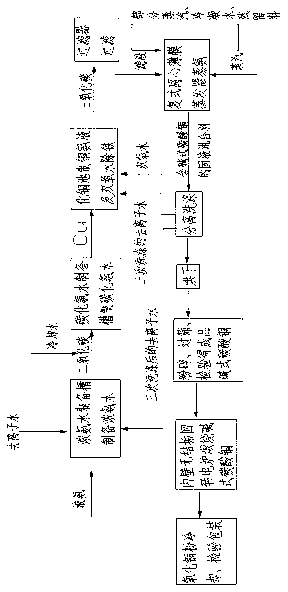

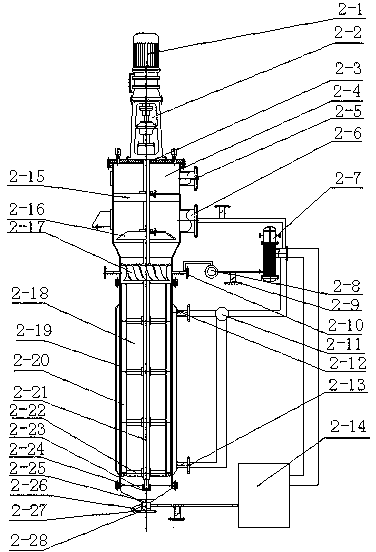

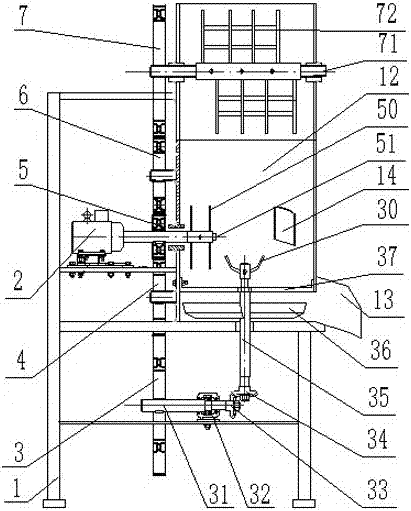

Two-stage type lignin steaming and cooking separation device

InactiveCN102000531ARealize normal pressure operationRealize two-stage cooking separationFeed devicesEngineeringSteaming

The invention relates to a two-stage type lignin steaming and cooking separation device, which comprises a charging mechanism, a steaming and cooking separation mechanism and a discharging mechanism, wherein the charging mechanism comprises a belt conveyor (1) and a spiral mixer (2). The two-stage type lignin device of steaming and cooking separation is characterized in that the steaming and cooking separation mechanism comprises a temperature rise storehouse (6) and a temperature preserving storehouse (8) which are connected in series by a gate valve (7); the temperature rise storehouse (6) is connected with the charging mechanism by a feeding gate valve (3); the temperature preserving storehouse (8) is connected with the discharging mechanism by a discharging gate valve (9); and the temperature rise storehouse (6) and the temperature preserving storehouse (8) are internally provided with spiral output mechanisms. By the sealing action of the gate valves (3), (7) and (9), the device realizes two-stage type steaming and cooking separation and normal pressure operation of charging and discharging.

Owner:浙江格义清洁能源技术有限公司

Rotary electric furnace and method thereof for preparing high-activity electro-plated copper oxide

InactiveCN103101959AGuaranteed purityOvercoming the disadvantages of static calcinationProductsReagentsHigh energyBasic copper carbonate

The invention discloses a rotary electric furnace and a method for preparing high-activity electro-plated copper oxide by using the rotary electric furnace. At least one percussion device is arranged on the outer wall of the furnace barrel of the rotary electric furnace, wherein the furnace barrel percussion device comprises a hollow cavity and a sphere; one end of the hollow cavity is open and the other end of the hollow cavity is closed, wherein the opening end is fixed on the outer wall of the furnace barrel; the sphere is movably arranged in the hollow cavity; the sphere moves up and down in the hollow cavity to form a clearance percussion status with the outer wall of the furnace barrel during the rotary process of the furnace barrel; the method for preparing the high-activity electro-plated copper oxide comprises the following steps of: preparing high-purity alkali type copper carbonate by adopting pure copper, liquid ammonia and high-purity carbon dioxide as materials; and obtaining the high-activity electro-plated copper oxide through roasting in the rotary electric furnace. According to the rotary electric furnace and the method for preparing the high-activity electro-plated copper oxide by using the rotary electric furnace, the defect that the low-temperature part is insufficient due to insufficient burning and the high-temperature part is burnt through during a static roasting process of the pushed slab kiln is overcome; moreover, the defects such as inactivity, a plurality of impurities, discontinuous production, long period, high energy consumption, high cost and the like are overcome, so that the activity of the product is ensured. Besides, the product quality is high, the energy consumption is less, the cost is low and the environment-friendliness is better.

Owner:TAIXING SMELTING PLANT

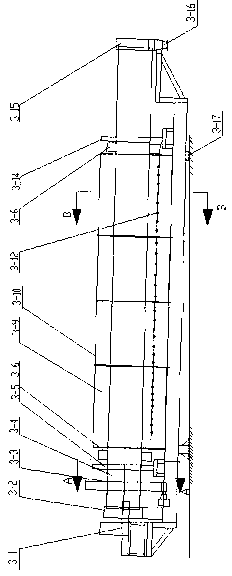

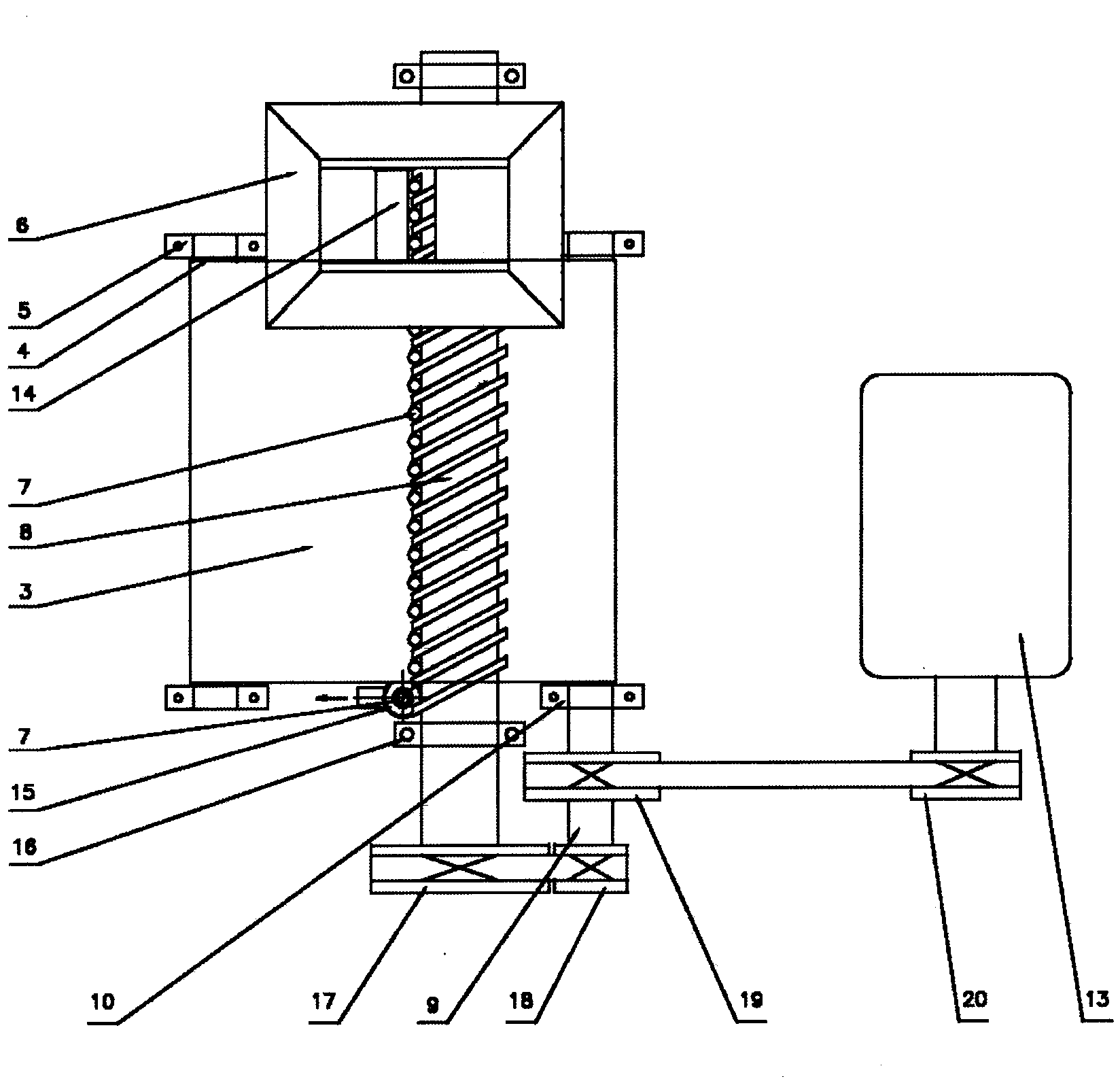

Vertical type gradient continuous sintering machine

ActiveCN107421332ANovel structural designRun smoothlyCharge manipulationFurnace typesFlueCombustion chamber

The invention belongs to the technical field of sintering ceramsite products and discloses a vertical type gradient continuous sintering machine which comprises a furnace body, an inner core tube, a feeding cabin, a plurality of combustion chambers, a discharging assembly and an external air distribution hole, wherein the inner core tube is arranged in the middle of the furnace body; a sintering cavity is formed between the furnace body and the inner core tube; the top of the inner core tube is open, and the bottom of the inner core tube communicates with a negative pressure air draft assembly; an internal air distribution hole is formed in the side wall of the inner core tube; the feeding cabin is arranged at the top of the furnace body; discharging holes of the feeding cabin are correspondingly formed between the furnace body and the inner core tube; a flow guiding air flue is arranged between the top of the inner core tube and the bottom of the feeding cabin; the combustion chambers are uniformly formed in the outer side of the furnace body in the circumferential direction; and combustion ports corresponding to the combustion chambers are formed in the furnace body. The vertical type gradient continuous sintering machine is novel in structural design and steady and reliable in operation, sinters under negative pressure and is small in energy consumption and high in yield. The breakage ratio of finished aggregate is low; and the product is excellent in particle shape, large in bulk density and low in powder passing rate.

Owner:ZHENGZHOU DESEN ENVIRONMENTAL SCI & TECH CO LTD

Method and device for microwave calcination of uranium chemical concentrate

The invention relates to a method and device for microwave calcination of a uranium chemical concentrate, and belongs to the technical field of microwave metallurgy. The method comprises leading the uranium chemical concentrate into high-temperature waste heat flue gas for preheating the cold uranium chemical concentrate, and performing three segments of calcination. The device is composed of a microwave generator, a spiral stirring device, a microwave control device, a temperature measuring device and a flue gas circulation purifying system. According to the method, industrial continuous production is realized; the high-temperature waste heat flue gas is fully utilized; and self-circulation treatment is implemented. The uranium chemical concentrate can be directly and fast heated; the heat loss of the material is reduced; and the energy utilization rate is increased. The uniformity of the product is improved; emission of harmful impurities and gas is avoided; and clean production is realized. The device is high in equipment automation degree and strong in controllability.

Owner:KUNMING UNIV OF SCI & TECH

Cable Surface Coating Continuous Coating Device and Method

ActiveCN104213095BReduce pressure differenceContinuous in and outVacuum evaporation coatingSputtering coatingParyleneEngineering

The invention discloses a continuous coating device for a coating layer on a surface of a cable and a method thereof. The coating device comprises a vacuum chamber, a pre-extracting chamber, a unwinding device and a winding device, wherein the pre-extracting chamber consists of upstream and downstream pre-extracting chambers at the upstream and downstream of the vacuum chamber; a cable inlet is formed at the front end of the upstream pre-extracting chamber near the unwinding device; a cable outlet is formed at the back end of the downstream pre-extracting chamber near the winding device; when the coating device is operated, a cable to be coated is released out by the unwinding device, and is leaded in the pre-extracting chamber and the vacuum chamber through the cable inlet and an opening in a baffle plate; when the cable is positioned in the vacuum chamber, a coating layer material is polymerized on the surface of the cable to form a coating layer; and the cable with a formed film is leaded out from the vacuum chamber and the pre-extracting chamber through the opening and the cable outlet, and is accommodated by the winding device. The continuous coating device enables the Parylene material coating to be changed from the intermittent single-furnace deposition to the continuous deposition, so that the coating efficiency is largely improved.

Owner:昆山彰盛奈米科技有限公司

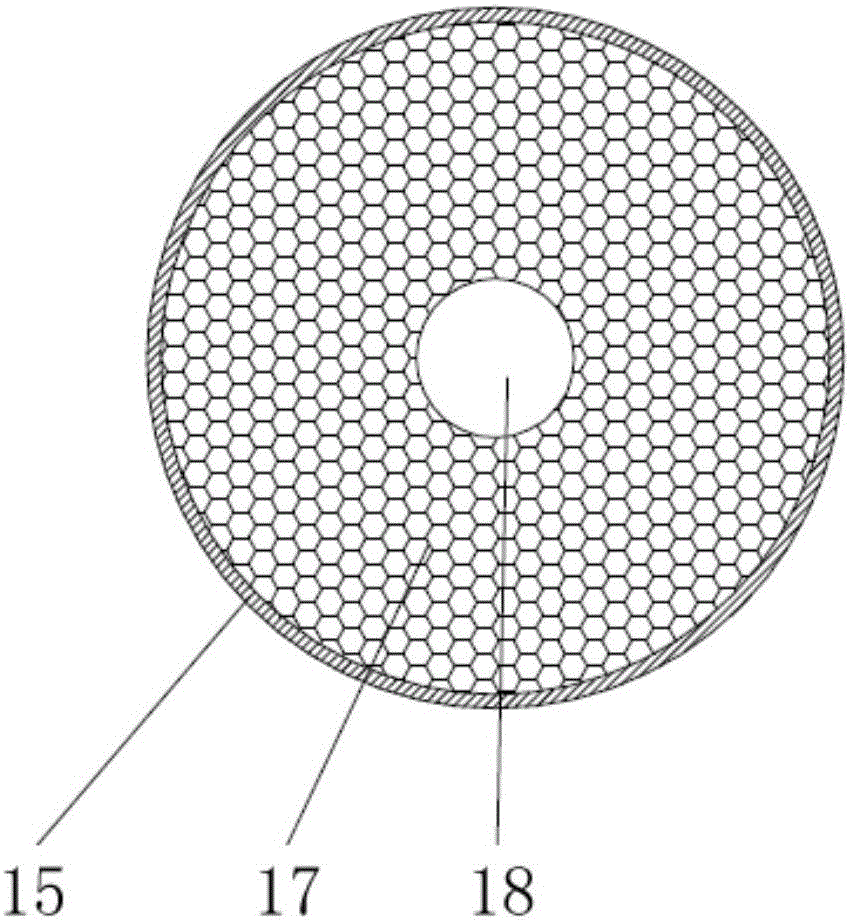

High-solid anaerobic reaction device and method for organic garbage

ActiveCN103614288BIt is convenient for subsequent feeding and dischargingFully contactedBiological substance pretreatmentsGas production bioreactorsTreatment pondProcess engineering

The invention relates to an organic waste high-solid anaerobic reaction device and an anaerobic reaction method. The device includes a pulverizer, a pretreatment tank and an anaerobic fermentation tank. The pulverizer is arranged above the pretreatment tank, and the discharge of the pretreatment tank There is a screw conveyor device below the opening, and the screw conveyor device is connected to the anaerobic fermentation tank; the bottom of the anaerobic fermentation tank is connected to a collecting pipe, which is connected to the four-way pipe fitting. The other three ports of the four-way pipe fitting are connected to the drainage pipe and pretreatment pipe respectively. The pool return pipe and the biogas slurry spray return pipe are provided with spray perforated plates and sieve plates from top to bottom in the anaerobic fermentation tank. The organic waste high solid anaerobic reaction device of the present invention collects the crushing and pretreatment of materials. The integration of treatment and fermentation ensures the uniformity of the materials, which is conducive to the anaerobic fermentation process. The solid concentration and uniformity of the materials are adjusted through the reflux of the fermentation liquid to achieve stable fermentation of organic waste. It has the characteristics of wide adaptability, high processing efficiency, compact layout, stable operation and small floor space.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

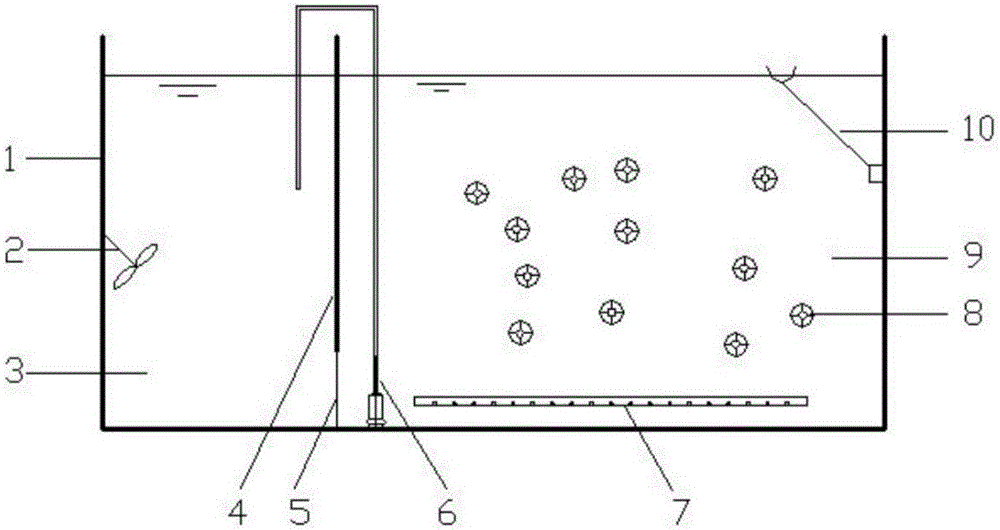

Sludge film composite SBR water treatment process

ActiveCN106186318AAchieve removalVersatileTreatment with aerobic and anaerobic processesRefluxSludge

The invention discloses a sludge film composite SBR water treatment process. Firstly, at a water entering stage, water enters from a region A of an SBR pond body, a stirring device is turned on while water enters, along with increasing of the amount of entered water, mixed liquid of water in the region A and raw sludge enters a region B through a water hole, an aerating device is turned on at the time, and a reflux device is turned on at the same time; then, at a reaction stage, water entering is stopped, the stirring device and the aerating device continue to be in a running state, the reflux device continues to run, and under the action of the reflux device, the mixed liquid in the region B flows back to the region A, and circulation is formed between the region A and the region B; precipitation is carried out, the stirring device, the aerating device and the reflux device are turned off, suspended filler, sludge and treated sewage are separated; water is drained, clean water obtained after treating is drained through a water decanter, and one running cycle is completed. Due to the fact that the SBR pond is partitioned, the sludge mixed liquid can circulate in the two regions under the action of the reflux device, and the process for treating sewage has the advantages that the volumetric loading is high and the water outlet effect is good.

Owner:QINGDAO SPRING WATER TREATMENT

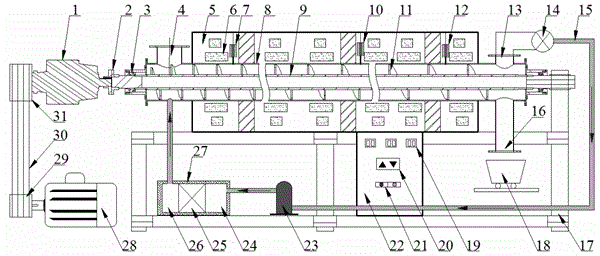

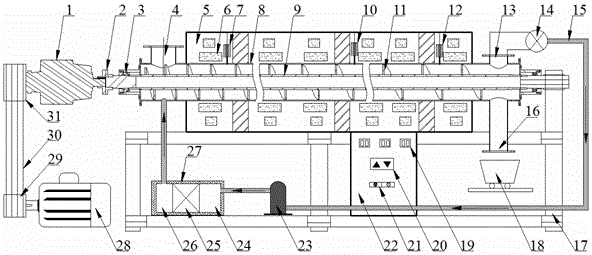

Air energy high-temperature heat pump tunnel type multifunctional drying production equipment

PendingCN112696910ASolve uneven heatingImprove drying effectDrying gas arrangementsDrying chambers/containersThermodynamicsProcess engineering

The invention relates to the field of drying devices, in particular to air energy high-temperature heat pump tunnel type multifunctional drying production equipment. The production equipment is provided with a rectangular hollow drying box, wherein a feeding port and a discharging port are formed in the two ends of a pipeline respectively; a conveying belt is arranged in the pipeline; a heat pump heating main machine is arranged along the conveying belt; the heat pump heating main machine is connected with a hot air exchanger through a heat supply pipeline; a cooling pipeline is connected between the heat pump heating main machine and the hot air exchanger; a fan is arranged and fixedly connected with the hot air exchanger; a moisture exhaust and air return fan is arranged above the conveying belt and connected with an air return duct; an opening of the air return duct penetrates through the outer wall of the drying box; and the outer wall of the air return duct is connected with the through position of the drying box in a closed mode. Materials are in a sealed state in the equipment, and can be continuously fed through the feeding port in the operation process of the equipment, so that the equipment can continuously work, and the problem that existing equipment can only conduct drying in batches in the working process is solved.

Owner:贵州九鼎新能源科技开发集团有限公司

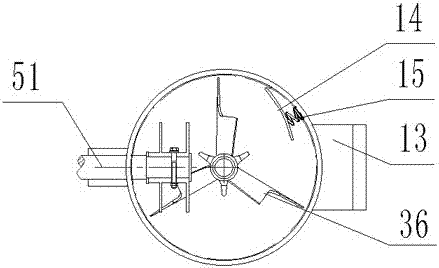

A straw crushing device

The invention discloses a straw crushing apparatus, comprising: a frame, a drive motor disposed on the frame, a feeding port to receive straws, a discharge port to discharge cut straws, a crushing barrel to crush and stir the straws, a feeding conveying assembly connected between the feeding port and the crushing barrel and connected to the drive motor, a stirring assembly disposed in the crushing barrel and connected to the drive motor, a crushing assembly disposed in the crushing barrel and connected to the drive motor, a guide assembly disposed in the crushing barrel and used to limit the straws in a range to contact with the crushing assembly, and a push assembly connected between the crushing barrel and the discharge port and connected to the drive motor. The straw crushing apparatus feeds and discharges material continuously to provide radial multi-dimensional cutting and axial multi-dimensional stirring and mixing, and axial multilayer guided three-dimensional crushing and cutting; therefore, the straws are homogenously crushed and mixed with high efficiency, and the straw crushing apparatus is long in service life, capable of automatic crushing and labor efficient.

Owner:NANJING INST OF TECH

Continuous feeding and discharging sintering rotary furnace

PendingCN112050624AAvoid enteringFull flip effectRotary drum furnacesCharge treatment typeEngineeringRotary furnace

The invention discloses a continuous feeding and discharging sintering rotary furnace. The continuous feeding and discharging sintering rotary furnace comprises a feeding bin, a feeder, a main frame,a furnace tube, a furnace head cover and a furnace tail cover, wherein the furnace tube is supported on the main frame; the furnace head cover and the furnace tail cover are arranged at the head end and the tail end of the furnace tube correspondingly; the feeder is arranged at a furnace head of the furnace tube and penetrates the furnace head cover to be in butt joint with the furnace tube; a first-level hopper and a second-level hopper are arranged in the feeding bin; a crushing roller couple is arranged between the first-level hopper and the second-level hopper; an outlet of the second-level hopper is in butt joint with the feeder; at least one material raising area and at least one material blocking area are arranged in the furnace tube and are alternately arranged at intervals in theaxial direction; each material raising area is provided with a plurality of circles of material raising plates, and each circle of material raising plates are provided with the multiple material raising plates arranged at intervals in the circumferential direction; and each material blocking area is provided with a first material blocking plate and a second material blocking plate, wherein the first material blocking plate and the second material blocking plate are oppositely arranged on the inner wall of the furnace tube, and a certain distance exists between the first material blocking plateand the second material blocking plate in the axial direction. The continuous feeding and discharging sintering rotary furnace has a crushing function, material overturning is sufficient, and the sintering time is accurate and controllable.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP +1

Technology for jointly producing ammonium sulfate and chloromethane

ActiveCN103193251BReduced purification stepsAvoid introducingHalogenated hydrocarbon preparationAmmonia compoundsFluidized bedEthyl Chloride

The invention relates to a technology for jointly producing ammonium sulfate and chloromethane. The technology specifically comprises steps of: S1, premixing ammonium chloride with sulfuric acid at normal pressure; S2, pumping the sulfuric acid solution of the ammonium chloride obtain in step S1 into a tubular reactor, and thus obtaining ammonium bisulfate and hydrogen chloride gas; S3, preparing the ammonium bisulfate obtained in step S2 to form aqueous solution, and performing ammonolysis reaction in an ammonification column so as to obtain ammonium sulfate; S4, guiding the hydrogen chloride gas obtained in step S2 into a drying column 1 to be dried, and filling the dried hydrogen chloride gas into a fluidized bed reactor together with gaseous methanol so at to obtain a chloromethane crude product; sequentially feeding the chloromethane crude product obtained in S4 into a water washing tower, an alkaline washing tower and a drying tower 2 so as to obtain pure chloromethane, and compressing and condensing the pure chloromethane to form high-purity liquid chloromethane. By utilizing the technology, ammonium and chlorine elements in ammonium chloride are fully and reasonably utilized, so that the joint production of ammonium sulfate and chloromethane is realized, the industrial structure is optimized, and a new method is provided for comprehensively utilizing the ammonium chloride.

Owner:BEIJING EDGEIN TECH +2

A kind of electrochemical preparation method of rhodium trichloride

ActiveCN108977834BThe preparation method is simple and advancedContinuous productionCellsDistillationElectrochemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

A method and device for microwave calcination of uranium chemical concentrate

The invention relates to a method and device for microwave calcination of a uranium chemical concentrate, and belongs to the technical field of microwave metallurgy. The method comprises leading the uranium chemical concentrate into high-temperature waste heat flue gas for preheating the cold uranium chemical concentrate, and performing three segments of calcination. The device is composed of a microwave generator, a spiral stirring device, a microwave control device, a temperature measuring device and a flue gas circulation purifying system. According to the method, industrial continuous production is realized; the high-temperature waste heat flue gas is fully utilized; and self-circulation treatment is implemented. The uranium chemical concentrate can be directly and fast heated; the heat loss of the material is reduced; and the energy utilization rate is increased. The uniformity of the product is improved; emission of harmful impurities and gas is avoided; and clean production is realized. The device is high in equipment automation degree and strong in controllability.

Owner:KUNMING UNIV OF SCI & TECH

Single-heat storage pulse type electronic waste heat treatment device

PendingCN106493153AFully pyrolyzedRealize the function of propulsion while pyrolysisTransportation and packagingSolid waste disposalCombustorCombustion chamber

The invention relates to the technical field of waste pyrolysis, and particularly relates to a single-heat storage pulse type electronic waste heat treatment device. The single-heat storage pulse type electronic waste heat treatment device comprises an electronic waste pyrolysis reactor and a single-heat storage type gas heating system, wherein the electronic waste pyrolysis reactor comprises a material pyrolysis assembly, and the material pyrolysis assembly comprises a spiral shell and a material auger; the single-heat storage type gas heating system comprises a heater shell, a single-heat storage type burning device and a fume channel of the heater shell, and the single-heat storage type burning device communicates with the heater shell and extends to the fume channel of the heater shell; and the single-heat storage type burning device comprises a plurality of groups of single-heat storage type burners, each group is composed of two single-heat storage type burners, and each single-heat storage type burner comprises a combustion chamber and a heat storage chamber. According to the device, a pulse type burning mode in pairs is adopted, so that a material accumulation section can be heated in real time, the heat utilization rate is high, and additionally, the load for the whole heating of equipment is reduced.

Owner:SHENWU TECH GRP CO LTD

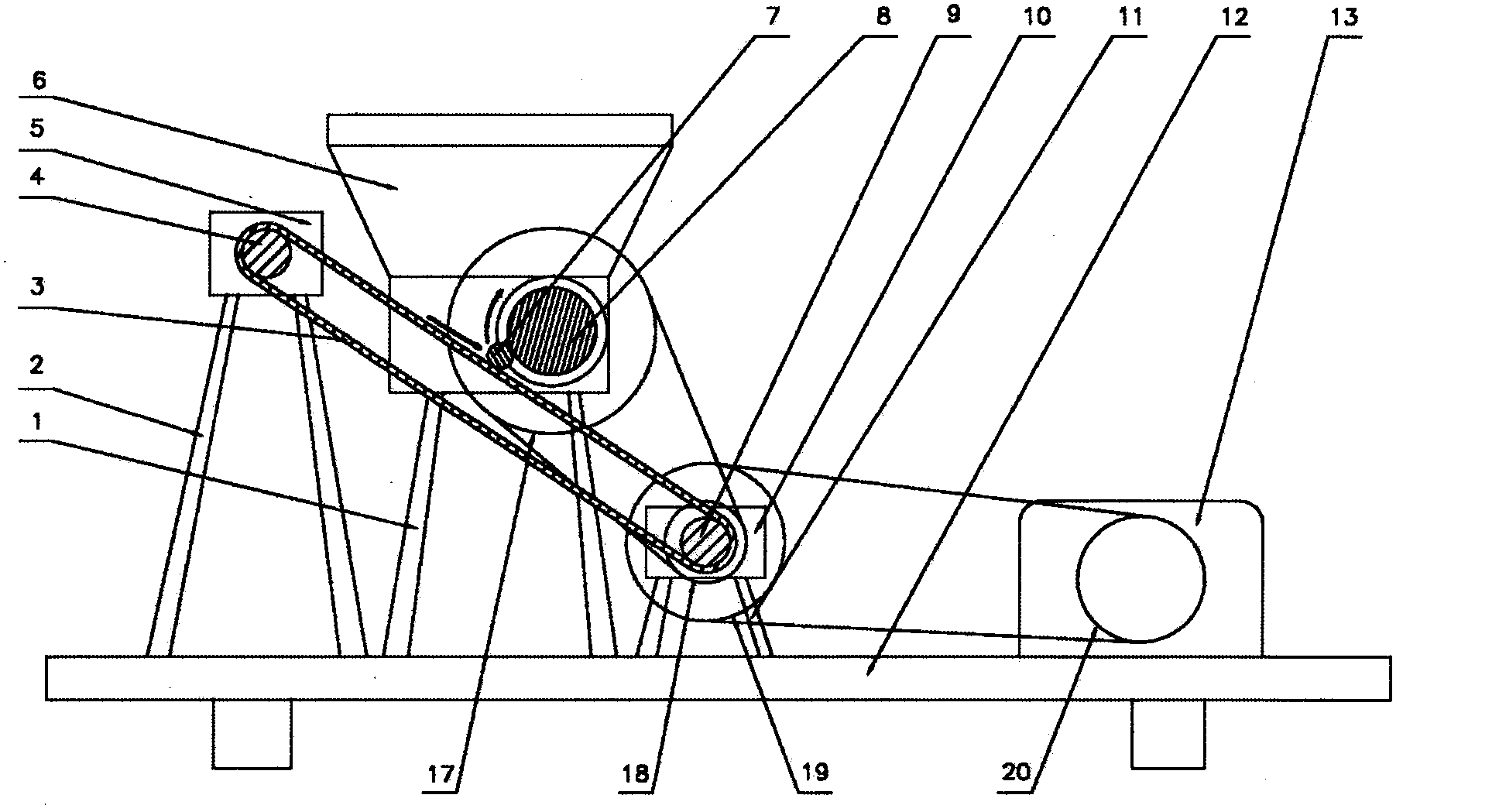

Lotus seed peel-grinding machine with abrasive belt

InactiveCN102669798BRealize grinding and peelingEfficient separationHuskingHullingEngineeringProcessing cost

The invention relates to lotus seed processing machinery, and particularly relates to a lotus seed peel-grinding machine with an abrasive belt. The lotus seed peel-grinding machine with the abrasive belt is composed of three parts, i.e., a drive device, a charge device and a peel-grinding device; and effective peel-grinding processing for lotus seeds is realized by virtue of a grinding principle, the elastoplasticity of the abrasive belt, and the relative movement of a screw conveying rod and the abrasive belt. The lotus seed peel-grinding machine with the abrasive belt disclosed by the invention has the advantages of being high in peeling rate, low in loss rate, simple and convenient in operation, low in manufacturing and processing costs, pollution-free to environment, and suitable for large-scale production.

Owner:XIANGTAN UNIV

Mud film composite sbr water treatment process

ActiveCN106186318BAchieve removalVersatileTreatment with aerobic and anaerobic processesRefluxSludge

The invention discloses a mud film composite SBR water treatment process. Firstly, in the water inlet stage, the water enters from the A area of the SBR tank body, and the stirring device is turned on at the same time as the water inlet. With the increase of the water inflow, the water in the A area The mixture of water and raw sludge enters zone B through the water hole. At this time, the aeration device is turned on, and the reflux device is turned on at the same time; then it enters the reaction stage, the water intake is stopped, the stirring device and the aeration device continue to be turned on, and the reflux device continues to Operation, under the action of the reflux device, the mixed liquid in the B area is refluxed to the A area, and the A and B areas form a cycle; the sedimentation, the stirring device, the aeration device and the reflux device are closed, and the suspended filler and sludge are separated from the treated sewage; Drainage, the treated clean water is discharged through the decanter, and one operation cycle ends. By partitioning the SBR tank, the sludge mixture can circulate in the two zones under the action of the reflux device. Using this process to treat sewage has the advantages of high volume load and good water discharge effect.

Owner:QINGDAO SPRING WATER TREATMENT

Method for removing water in continuous esterifying process

InactiveCN106631647AHigh purityReduce consumptionOrganic compound preparationCarboxylic acid esters preparationBoiling pointFixed bed

The invention discloses a method for removing water in a continuous esterifying process. According to the method, a used fixed bed reactor is partitioned into an upper segment, a middle segment and a lower segment, high-boiling-point substances are introduced into the fixed bed reactor from the upper segment, low-boiling-point substances are added from the lower segment, and the high-boiling-point substances and the low-boiling-point substances flow reversely in a fixed bed and are subjected to an esterification reaction under the action of a catalyst; carrier gas is introduced from the bottom of the fixed bed reactor, water generated in the esterification reaction and the low-boiling-point substances are introduced into a heat exchange along with the carrier gas from the top of the fixed bed, and a generated ester product is condensed and collected at the bottom of the fixed bed reactor; the water and low-boiling-point substances passing through the heat exchanger are introduced into a condenser for condensing, are introduced into a liquid recycling system in the form of liquid, and are introduced into a water-separating system to separate the low-boiling-point substances from the water. By adopting the method, water generated by the reaction is transferred out of a reaction system by using the carrier gas in order to promote the forward proceeding of the esterification reaction, so that continuous charging and discharging are ensured, the energy consumption is lowered, the product quality is stabilized, and a high-purity ester is obtained.

Owner:ZHONGRONG TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com