Regulating nucleation method during crystallization of nickel-cobalt-manganese precursor

A nickel-cobalt-manganese and precursor technology, applied in chemical instruments and methods, nickel compounds, structural parts, etc., can solve the problems such as not being widely promoted and applied, the particle size distribution cannot be controlled, and the stability of the reactor fluid is poor, etc. Achieve significant nucleation effect, control the nucleation method is simple and efficient, and reduce the effect of process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

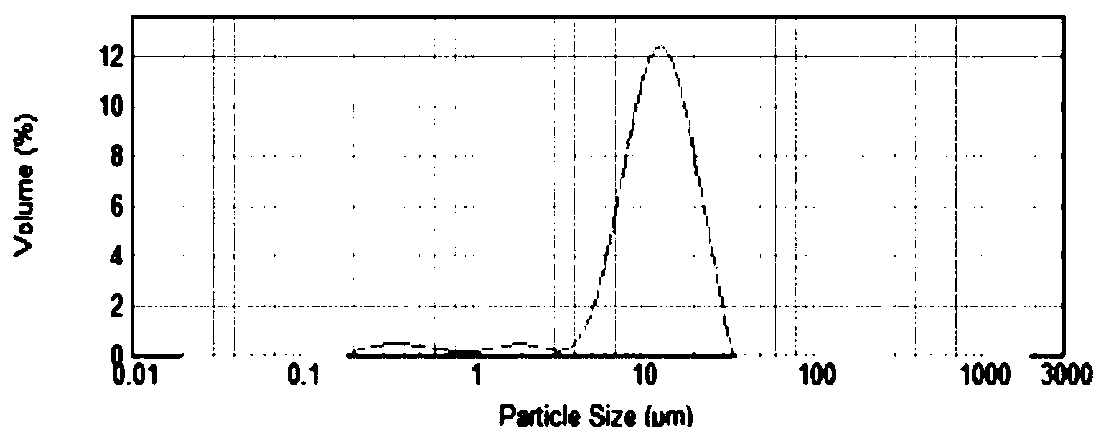

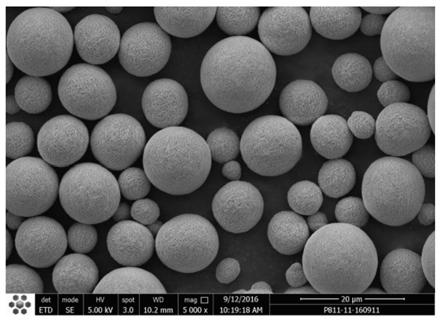

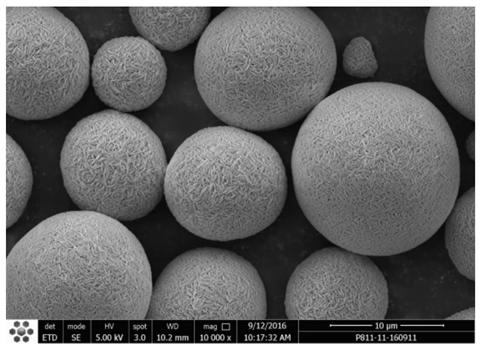

[0040] A nickel cobalt lithium manganate precursor, the molecular formula of the nickel cobalt lithium manganate precursor is Ni 0.8 co 0.1 mn 0.1 (OH) 2 , the particle size of the secondary particle aggregate of the nickel cobalt lithium manganese oxide precursor, D10=6.03 μm, D50=12.28 μm, D90=21.86 μm, particle size distribution span=1.29, and its preparation method includes the following steps:

[0041] (1) Under the protection of nitrogen, add the nickel-cobalt-manganese salt solution, ammonia solution and lye into the closed reaction kettle with bottom liquid to carry out stirring reaction; the specific operation is as follows: prepare nickel-cobalt-manganese salt solution, ammonia solution and Alkaline solution, wherein the nickel-cobalt-manganese salt solution is Ni:Co:Mn=8:1:1, a mixed solution of nickel salt, cobalt salt and manganese salt with a total metal ion concentration of 2mol / L, and the concentration of ammonia solution is 13mol / L, the lye is 10mol / L sodi...

Embodiment 2

[0052] A nickel cobalt lithium manganate precursor, the molecular formula of the nickel cobalt lithium manganate precursor is Ni 0.85 co 0.1 mn 0.05 (OH) 2 , the particle size of the secondary particle aggregate of the nickel cobalt lithium manganese oxide precursor, D10=6.36 μm, D50=12.4 μm, D90=20.68 μm, particle size distribution span=1.15, and its preparation method includes the following steps:

[0053] (1) Add nickel-cobalt-manganese salt solution, ammonia solution and lye into a closed reaction kettle equipped with bottom liquid to carry out stirring reaction; the specific operation is as follows: prepare nickel-cobalt-manganese salt solution, ammonia solution and lye, wherein, The nickel-cobalt-manganese salt solution is a mixed solution of Ni:Co:Mn=8.5:1:0.5, the total concentration of metal ions is 2mol / L, nickel salt, cobalt salt and manganese salt, the concentration of ammonia solution is 13mol / L, and the concentration of lye Before adding 10mol / L sodium hydroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com