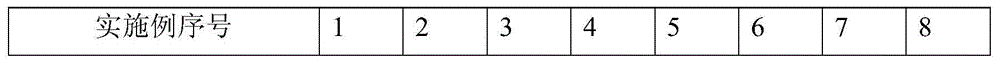

Patents

Literature

101results about How to "Controllable particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

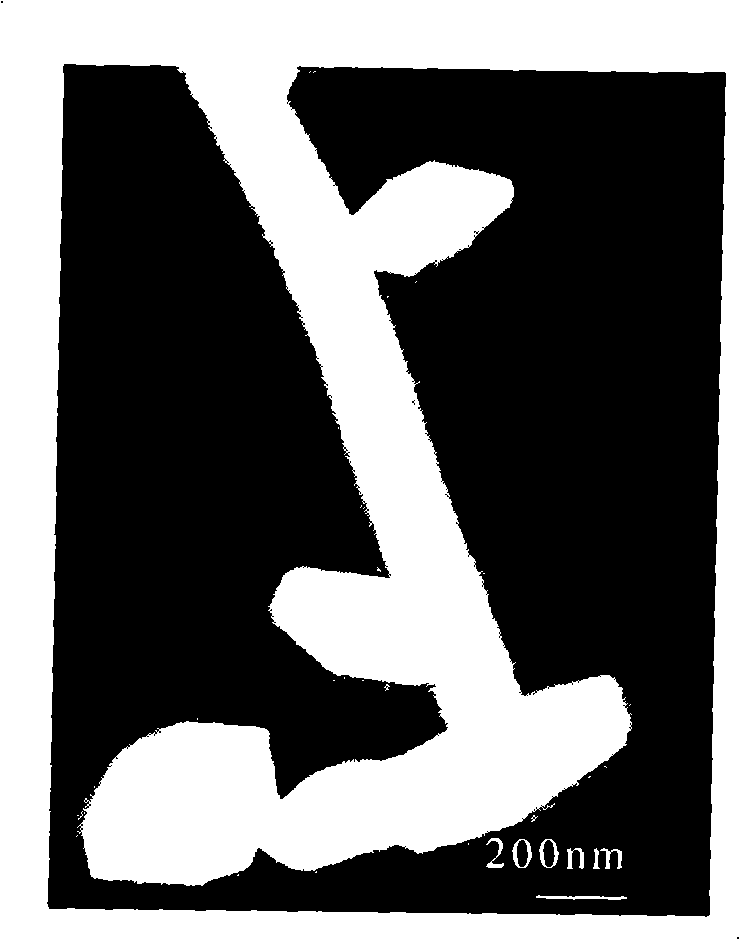

Magnetic composite microsphere with nucleocapsid structure and method for producing the same

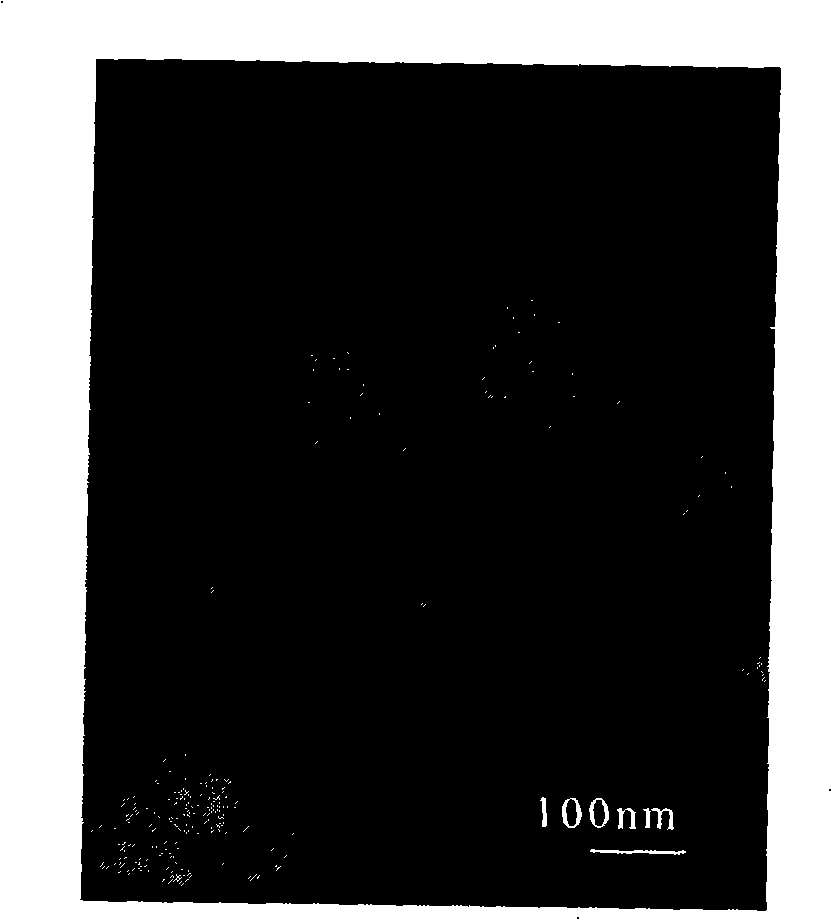

InactiveCN101220187AHigh magnetic contentNarrow particle size distributionInorganic material magnetismMicrosphereMagnet

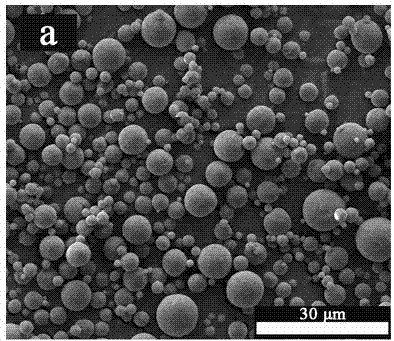

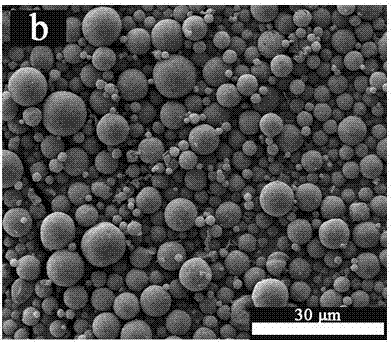

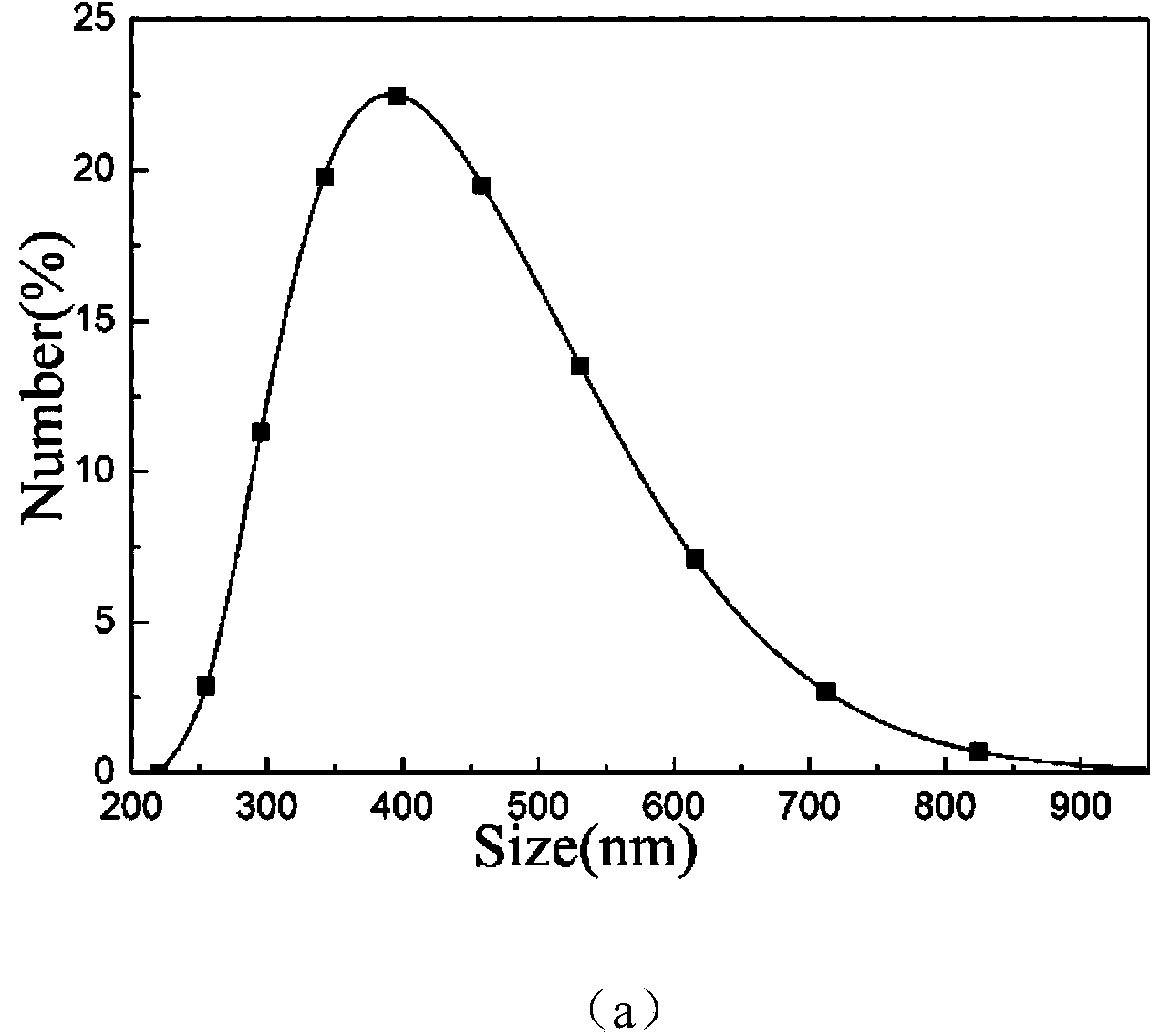

The invention belongs to the technical field of bioseparation material, in particular to a magnetic composite microsphere with nucleocapsid structure and a preparation method thereof. Nano ferroferric oxide decorated by oleic acid is firstly used as raw material, and is polymerized through template fine emulsion so as to prepare the monodisperse magnetic composite microsphere with high magnet content; and then the monodisperse micosphere is polymerized through seed emulsion and is added with different amount of shell monomer to prepare the magnetic composite microsphere with the nucleocapsid structure and the magnet content of 20wt percent to 80wt percent. The grain size of nucleocapsid composite microsphere is in narrow distribution, and the magnet content of the microsphere is controllable and the surface has functional reactive group; therefore, the microsphere of the invention can be surface-modified into a magnetic carrier of biological active molecule by chemical crosslinking to be applied in the biomedicine field. The method of the invention can be simply operated and the process of which can be controlled, thus having industrialized prospect.

Owner:FUDAN UNIV

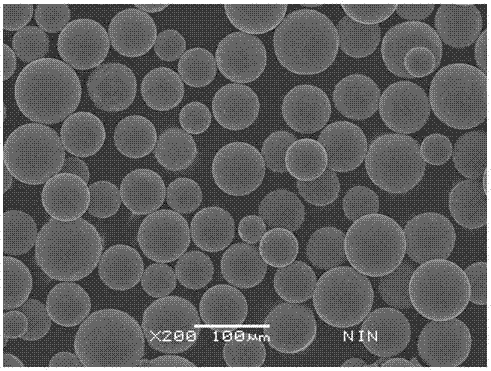

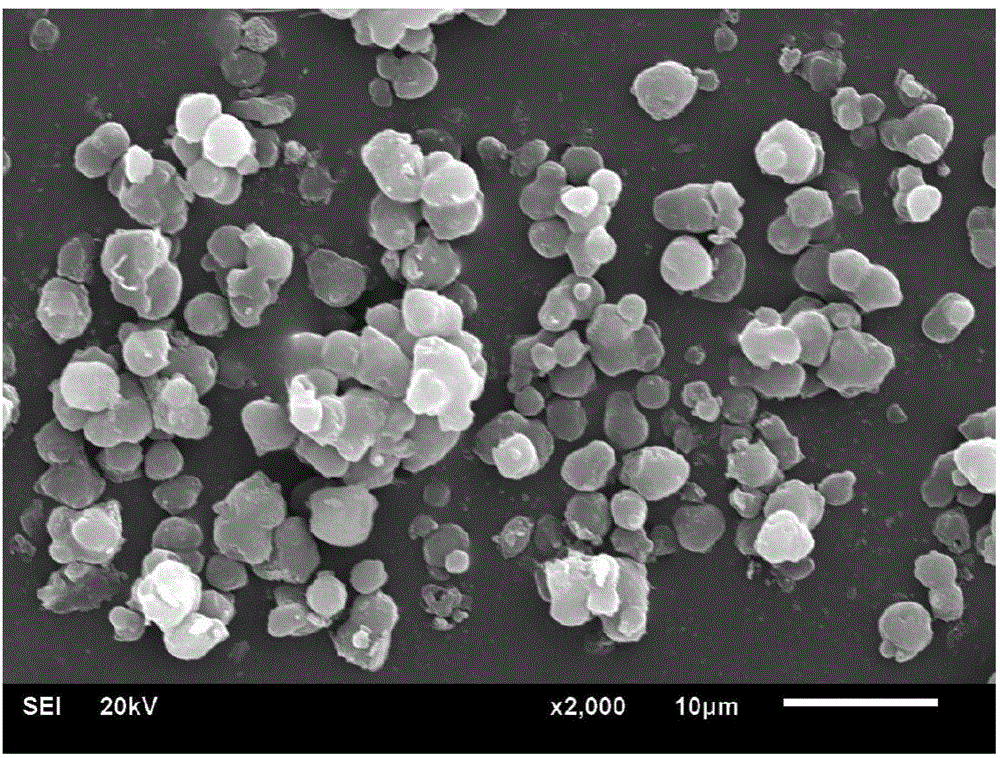

Method for preparing spherical active carbon employing water soluble bitumen

InactiveCN103693641ALow priceWide variety of sourcesCarbon compoundsSpray GranulationActivated carbon

The invention discloses a method for preparing spherical active carbon employing water soluble bitumen. The method comprises the following processes: washing commercial sulfonated asphalt to obtain a complete water-soluble material; preparing a bituminous solution from the obtained water-soluble material or water-soluble mesophase pitch and deionized water; carrying out spray granulation on the bituminous solution, so as to obtain a bituminous ball; carbonizing and activating the bituminous ball, so as to obtain the spherical active carbon. The method has the advantages that the commercial sulfonated asphalt and the water-soluble mesophase pitch are adopted, so that the spherical active carbon is low in price and wide in source, no organic solvent is added in the balling process, the bituminous ball is controllable in particle size distribution, the prepared spherical active carbon is large in specific surface area, and industrial production is easy to achieve.

Owner:TIANJIN UNIV

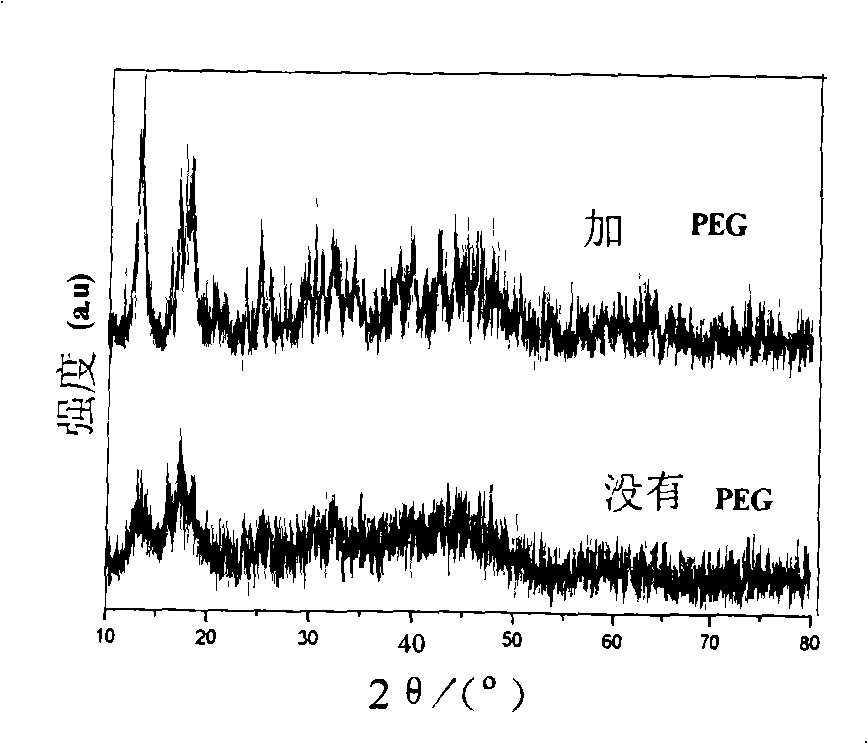

Method for preparing Nano silver grain, and prepared Nano silver grain

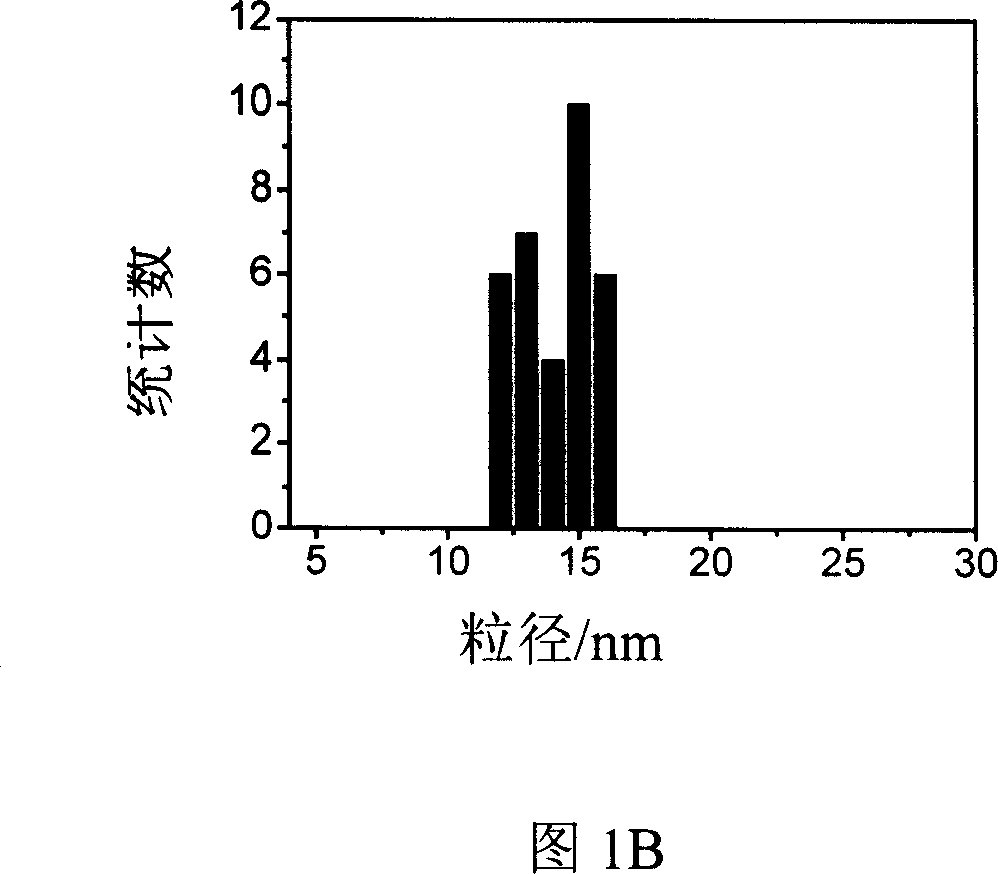

InactiveCN101050315ASmall average particle sizeGood uniformityBiocideCatalyst carriersAg nanoparticlesNanometre

This invention discloses a method for preparing Ag nanoparticles. The method comprises: (1) mixing acid solution of chitosan and AgNO3 solution to obtain a mixed solution; (2) adjusting the pH value to 3.0-5.0; (3) irradiating without oxygen. The deacetylation degree of chitosan is greater than or equal to 70%, and the average molecular weight is less than or equal to 20000. The concentration of chitosan in the mixed solution is 0.001-0.05 wt. %, and that of AgNO3 is 0.01-23.5 mM. The obtained Ag nanoparticles have such advantages as small average particle size, uniform particle size distribution, high solid content, high water solubility, and high biocompatibility.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for preparing flamazine/bacterial cellulose composite wound dressing

ActiveCN101905031ABroad spectrum antibacterialStrong antibacterial activityAbsorbent padsBandagesWound dressingMoisture absorption

The invention provides a method for preparing flamazine / bacterial cellulose composite wound dressing, which comprises the following steps of: performing pretreatment and purification treatment on a bacterial cellulose membrane to obtain purified bacterial cellulose; preparing flamazine suspension with the granularity of 50 to 5,000 nm under dark condition; reacting the bacterial cellulose membrane with the flamazine suspension to form a flamazine / bacterial cellulose composite membrane; and performing drying treatment to obtain a dry flamazine / bacterial cellulose composite membrane, or performing extruding dehydration to obtain a wet flamazine / bacterial cellulose composite membrane with different water content values to prepare the flamazine / bacterial cellulose composite wound dressing. The prepared flamazine / bacterial cellulose composite wound dressing has high mechanical performance, high antibacterial property, and high water and air permeability or good drainage and moisture absorption effects, can promote the drying, scabbing and healing of wound, and is used for preventing and treating the secondary wound infection of second-degree and third-degree burn or scald.

Owner:UNIV OF SCI & TECH BEIJING +1

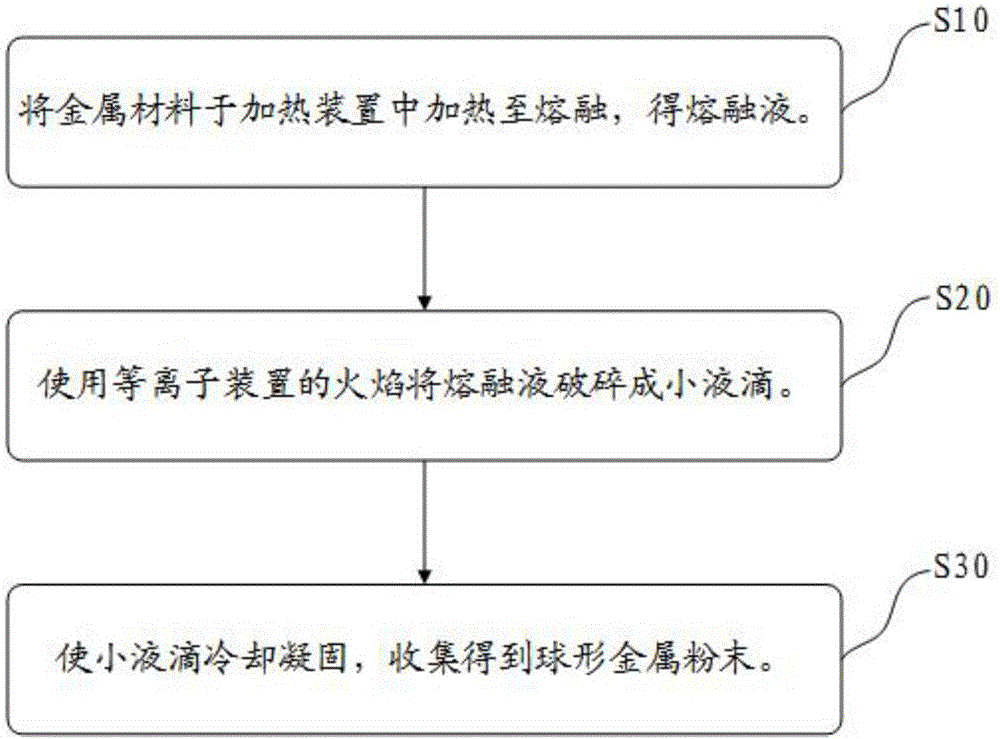

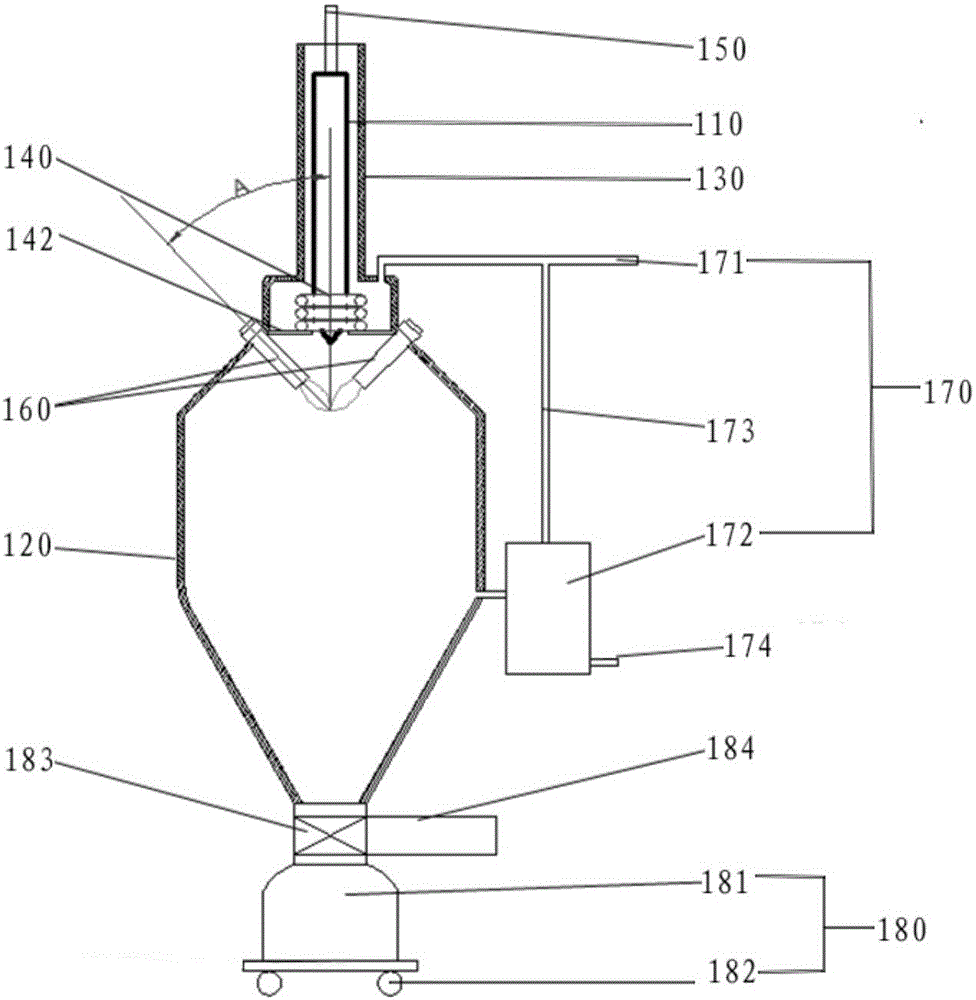

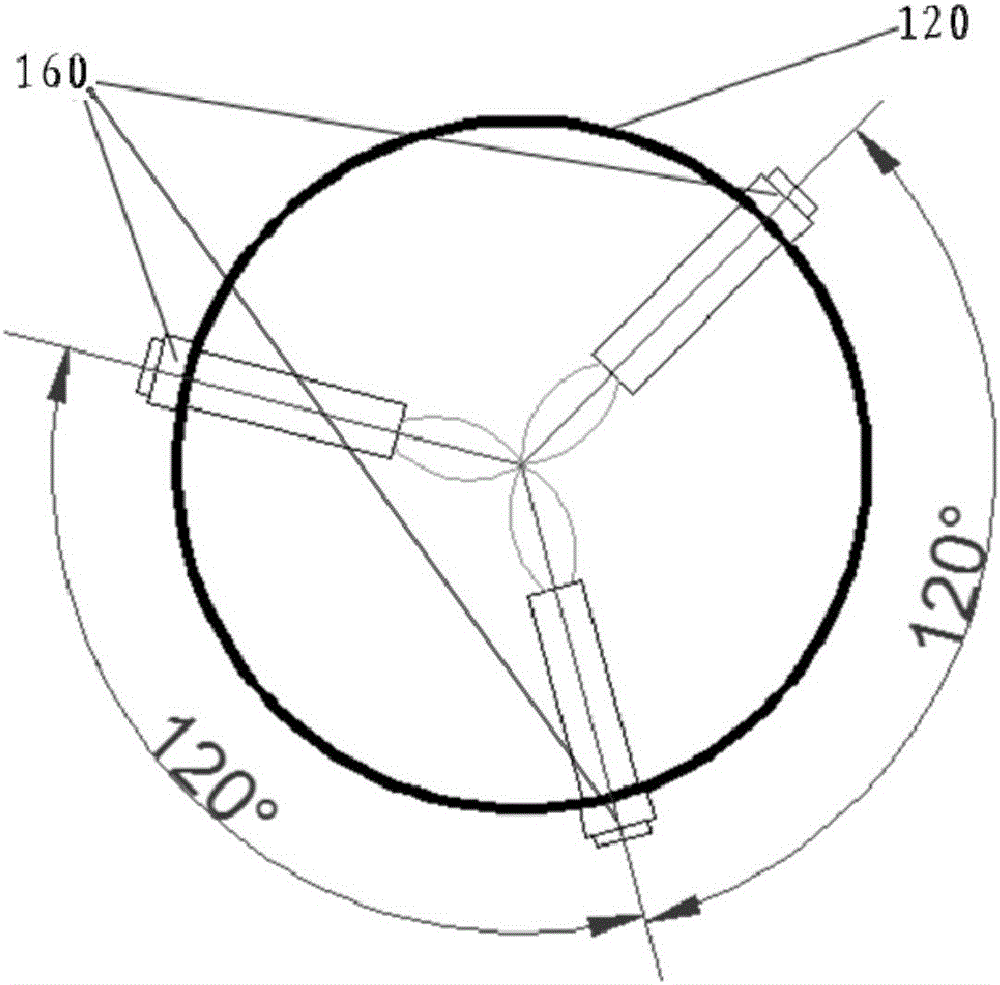

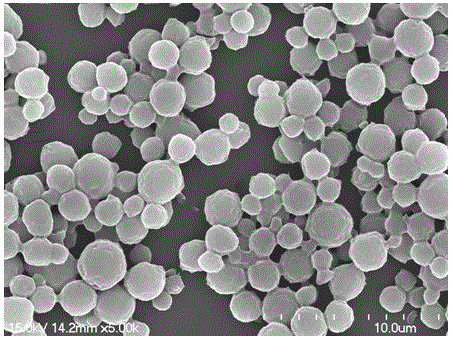

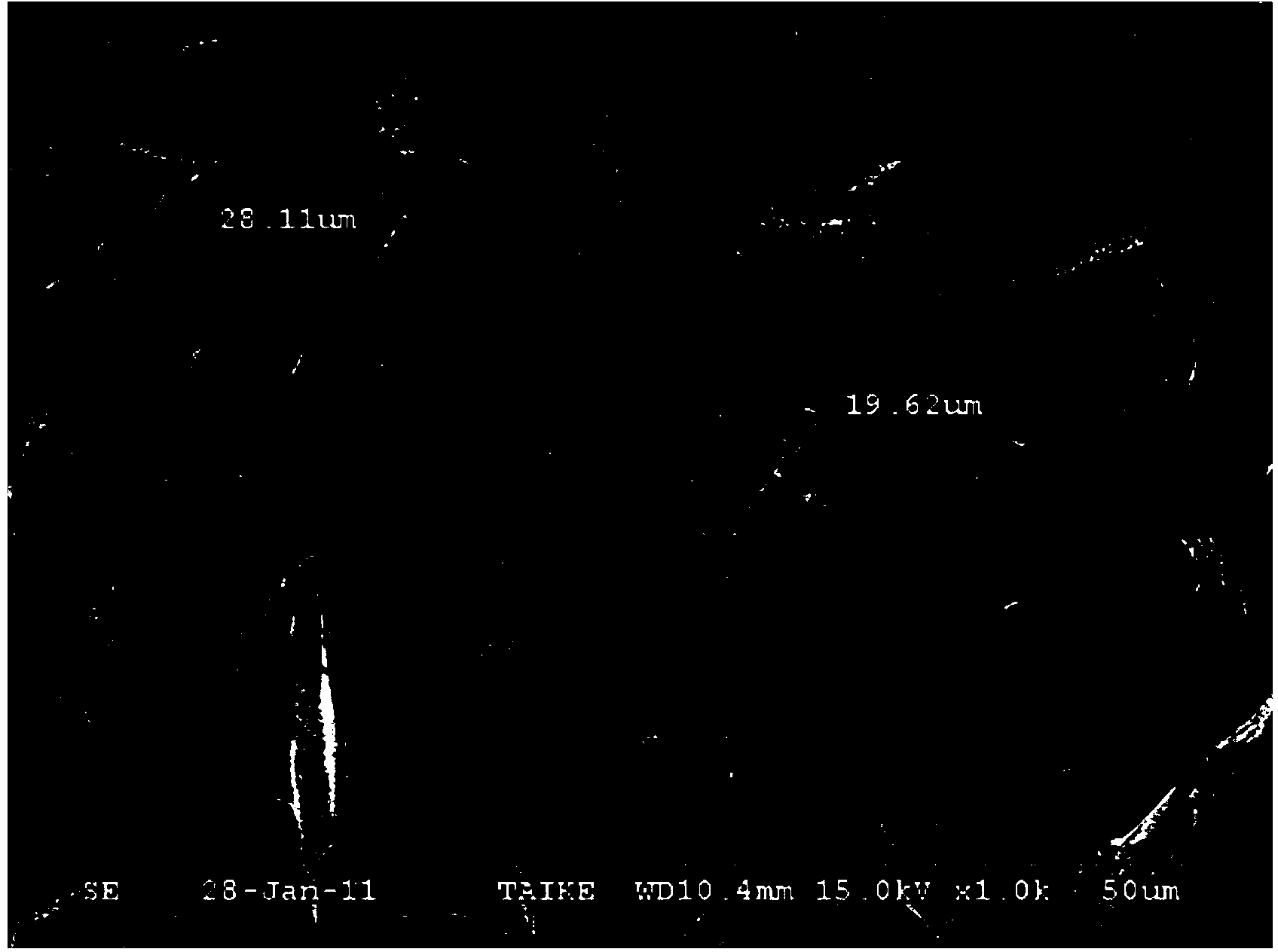

Spherical metal powder and preparation method thereof

ActiveCN105855560AReduce surface tensionReduce consumptionTransportation and packagingMetal-working apparatusSmall dropletPrill

The invention relates to a preparation method of spherical metal powder. The preparation method comprises the steps of heating a metal bar to melt in a heating device, so as to obtain melted liquid, and breaking the melted liquid into small droplets by using plasma as droplet breakage power, so that the small droplets are cooled and solidified and are collected so as to obtain the spherical metal powder. According to the spherical metal powder prepared by adopting the preparation method, almost no satellite particle exists, the oxygen content is less than 1200 ppm, and the occupancy of the powder below 53 mum reaches 90% according to weight percent; the spherical metal powder has the advantages of high degree of sphericity, narrow particle size distribution, low impurity content, good flowability, low oxygen content, no satellite particle, simple process, reliable technique, easiness in control over product particle size, high production efficiency and low inert gas consumption and is suitable for mass production, and the particle size distribution satisfies the 3D printing requirements.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

Wild antheraea pernyi silk fibroin microsphere and preparation method thereof

InactiveCN102977381AGuaranteed biocompatibilityIncrease productionCosmetic preparationsToilet preparationsDiseaseMicrosphere

The invention discloses a wild antheraea pernyi silk fibroin microsphere and a preparation method of the microsphere. The preparation method comprises the steps of degumming and dissolving tussah silk; subjecting the above processed tussah silk to dialysis treatment to obtain a solution of the wild antheraea pernyi silk fibroin; adjusting the concentration of the solution to 10-100mg / ml; adding in a citric acid solution or an acetic acid buffer solution at the temperature of 10-60 DEG C to adjust the pH value to 3-6; subjecting the resulting solution to ultrasonic oscillation and stirring treatment to obtain a suspension of the wild antheraea pernyi silk fibroin microsphere; centrifugalizing, freezing and drying the suspension to obtain the biodegradable wild antheraea pernyi silk fibroin microsphere, the diameter of which is 0.1-10mu m. The preparation method of the invention prepares the wild antheraea pernyi silk fibroin microsphere by means of in-situ self-assembly generation and is simple in process procedures; the prepared microsphere is uniform in size distribution, keeps the RGD sequence of the wild antheraea pernyi silk fibroin, promotes the cell recognition of the microsphere, improves the targeting property and bioavailability of drugs, can function as a carrier with bioactive substance to carry an enzyme drug, a nucleic acid drug, a polypeptide drug, a protein drug and the like, and can be applied to diagnosing and treating diseases and the like.

Owner:SUZHOU UNIV

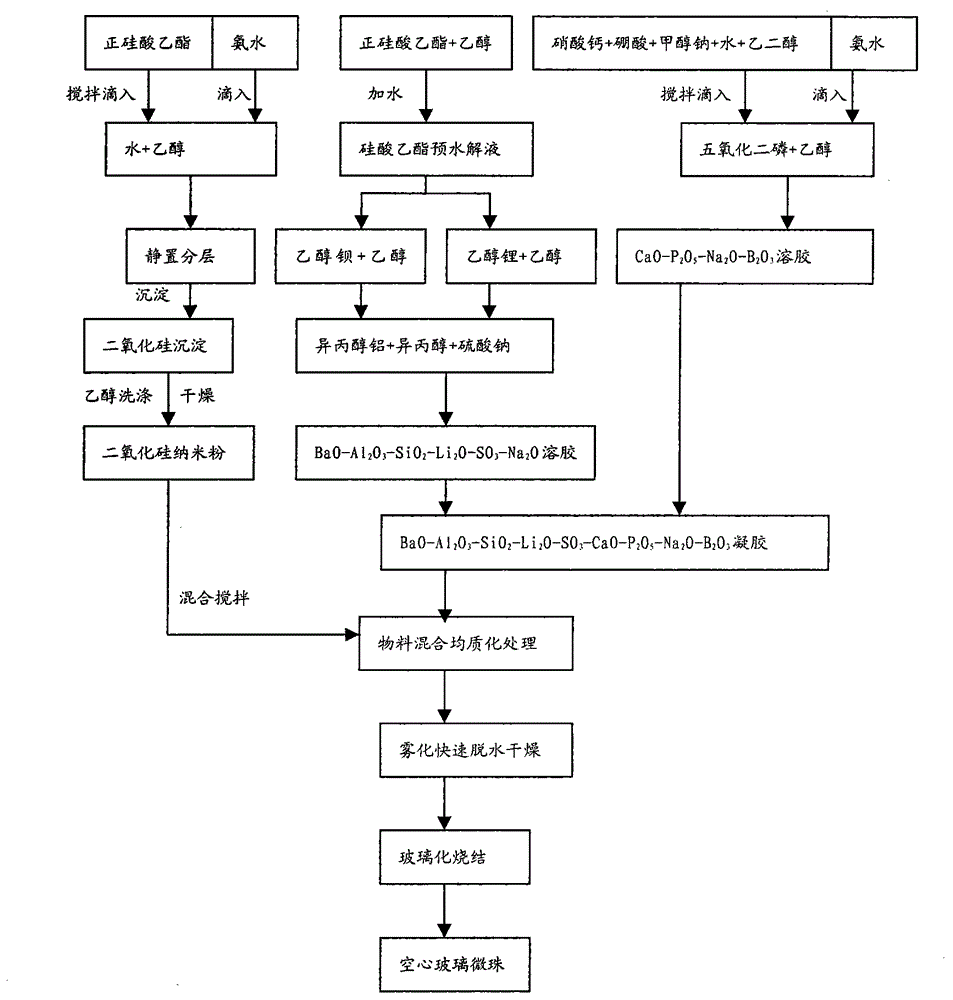

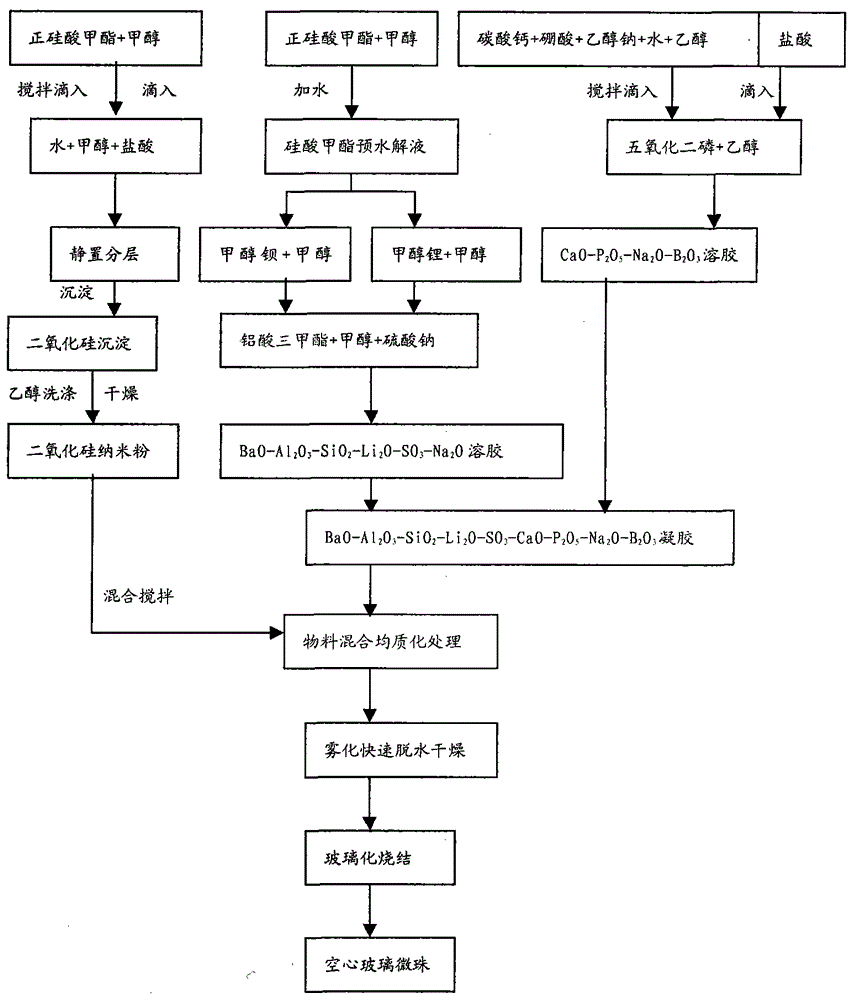

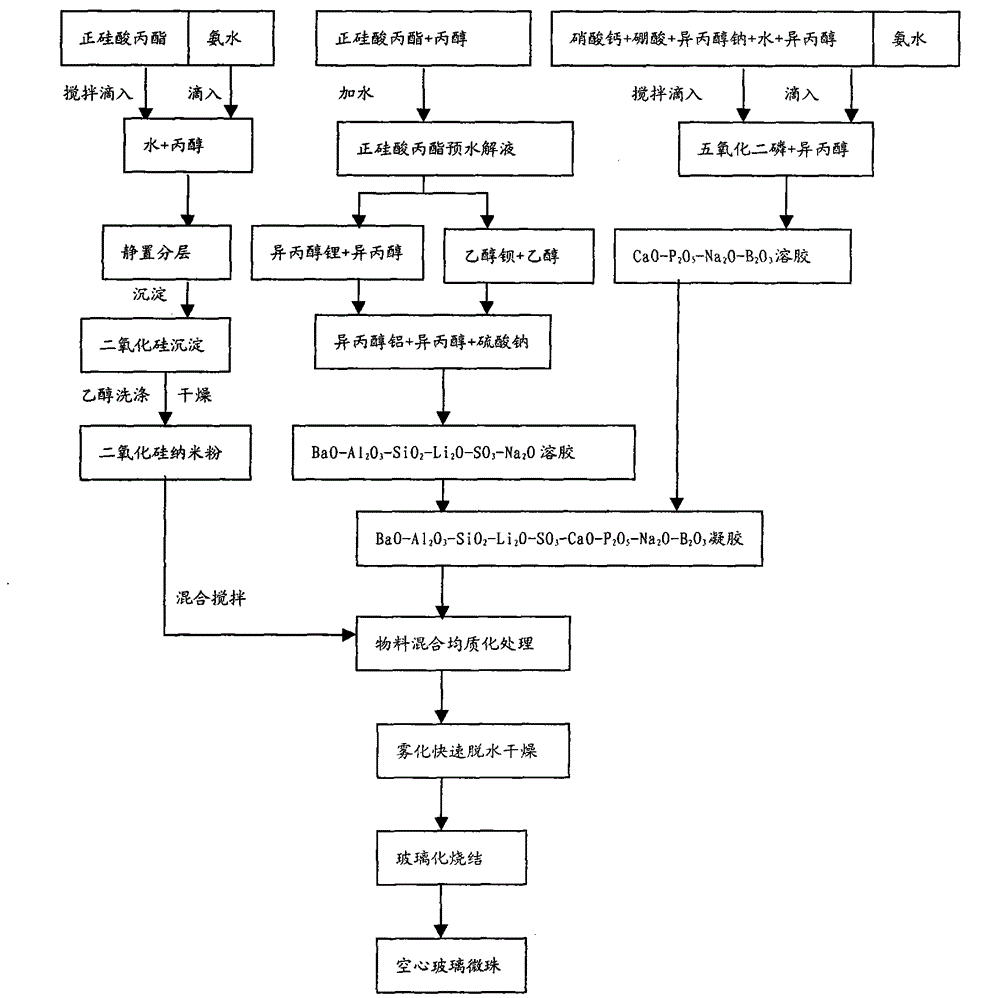

High-strength hollow glass beads and preparation method thereof

ActiveCN103979796AReduce energy consumptionPrevent volatilizationGlass shaping apparatusSpherical shapedHigh pressure

The invention discloses high-strength hollow glass beads, comprising the chemical components: 71-76.5% of SiO2, 1.5-2% of Al2O3, 4.5-5% of B2O3, 2.5-3% of Li2O, 0.2-0.5% of SO3, 5.5-6% of Na2O, 2.3-3.5% of BaO, 4.5-6% of CaO4 and 2.5-3% of P2O5, wherein the density is 0.4-0.8g / cm<3>, the compressive strength is 30-130MPa, the particle size is smaller than or equal to 80mum, the floatage rate is greater than or equal to 90%, and the softening temperature is greater than or equal to 700 DEG C. The preparation method comprises the following steps: preparing BaO-Al2O3-SiO2-Li2O-SO3-CaO-P2O5-Na2O-B2O3 gel by adopting a sol-gel method for hydrolyzing a polyhydric alcohol salt; preparing silica nano powder by using an alkoxide hydrolysis-precipitation method; quickly dewatering and drying to synthesize spherical precursor powder after stirring, mixing and homogenizing in an atomization manner; carrying out vitrification sintering. The high-strength hollow glass beads are applicable to high-temperature and high-pressure fields with special requirements, such as underwater solid buoyancy materials and deep well cementing cement in oil drilling.

Owner:白银金奇化工科技有限公司

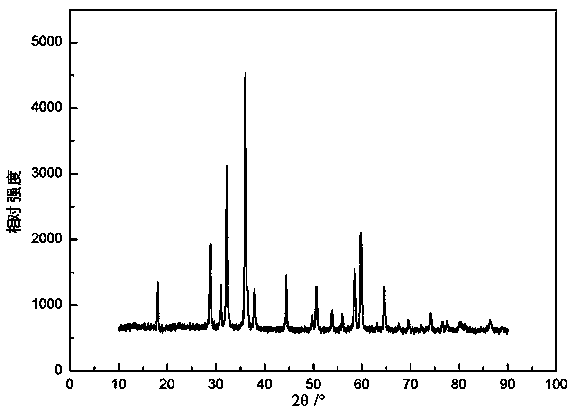

Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

ActiveCN101284952AReduce surface roughnessImprove flatnessPigmenting treatmentSemiconductor/solid-state device manufacturingCrystal systemInorganic salts

The invention relates to a chemical mechanical polishing abrasive particle CeO2 and a method for preparing the same, belonging to the rare earth powder material chemical preparation technical field. The invention is to prepare the CMP abrasive particle by utilization of cerous inorganic salt solution and homogeneous precipitation agent. The method comprises the following steps that: the cerous inorganic salt and the precipitation agent are prepared into solution with certain proportion; the solution is uniformly mixed through ultrasonic vibration; deposits are generated after the solution is heated to a certain temperature; serum is kept stand, aged, filtered and calcined, and then the CeO2 abrasive particle is prepared. The method also accelerates the nucleation rate through addition of surface active agent so as to reduce the reaction temperature, and simultaneously the nodulizing degree of the abrasive particle obtained is also good. The method prepares the CMP abrasive particle, wherein, the CMP abrasive particle belongs to the single-phase cubic crystal system; the space group is O<5>H-FM3M; the dispersibility is good; the grain fineness distribution is uniform; the shape is similar to a sphere; and the specific surface area BET is more than 0 and less than 50m<2> / g.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Preparation method of particle size distribution concentrated and controllable high-purity tantalum powder

The invention discloses a preparation method of particle size distribution concentrated and controllable high-purity tantalum powder. The method includes hydrogenating high-purity tantalum ingots into tantalum chips, placing the tantalum chips into a grinder for beating and grinding in an open manner prior to sieving, performing high-frequency oscillation classification on sieved tantalum powder, then subjecting the classified tantalum powder to low-temperature vacuum drying, and dehydrogenizing the dried tantalum powder. In the grinding and classification processes, all appliances in contact with the tantalum powder are made of tantalum with the purity more than 99.99%. Preferably, during classification, selection liquid is adopted as a medium. By means of the technology, in the production process of the tantalum powder, since high-purity media are adopted totally, few new impurities are brought in, subsequent pickling or other purification technologies are not required, technological process is shortened, and economy and environmental protection are realized; besides, the tantalum powder is low-carbon and low in oxygen and impurity; the liquid medium directly contacts with the tantalum powder during classification, and accordingly surface adhesion of coarse tantalum powder and fine tantalum powder is prevented; the classified tantalum powder is clean in particle and concentrated and controllable in particle size distribution.

Owner:TAIKE TECH SUZHOU

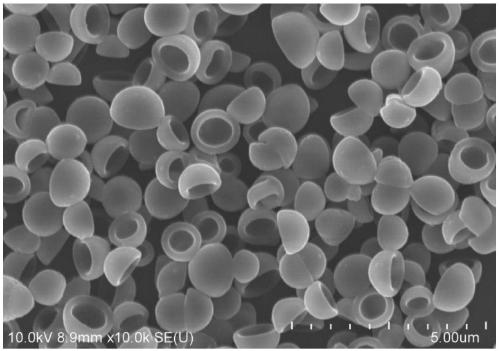

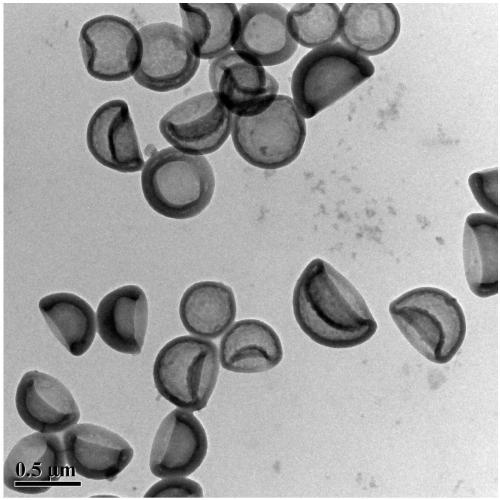

Preparation method of hollow carbon bowl powder

InactiveCN109553082AGood dispersionControllable particle size distributionMaterial nanotechnologyCarbon preparation/purificationIonBiological waste

The invention discloses a preparation method of hollow carbon bowl powder, and belongs to the technical field of preparation of inorganic materials. According to the method, a direct biological raw material or waste is adopted as a carbon source, a soft template is used as a template, and the hollow carbon bowl powder material with high dispersity, controllable particle size distribution and size,an inner hollow structure, morphology of a concave bowl-shaped structure, controllable wall thickness of the carbon bowl, and the like is prepared. The preparation method comprises the following steps: taking the carbon source, deionized water and the soft template agent as raw materials, respectively dissolving the carbon source and two surfactants in the deionized water to form three solutions,then mixing the three solutions according to a certain ratio, uniformly carrying out stirring to obtain a mixed solution, putting the mixed solution into a hydrothermal reaction kettle, and carryingout heating for a reaction to obtain a product. The method has the advantage that the direct biological raw material or biological waste is used as the carbon source, and aims to provide the novel utilization mode of biological wastes, so that emission of wastes is reduced, the wastes are converted into the functional carbon material, the process is simple, and the preparing and removing processesof a template in a hard template method is omitted.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of high-quality gamma-TiAl spherical powder

A preparation method of high-quality gamma-TiAl spherical powder comprises the following steps that (1) a gamma-TiAl alloy bar is smelted according to ingredient compounding of a gamma-TiAl base alloy; (2) the smelted gamma-TiAl alloy bar is subjected to forging so as to remove internal defects, and stress relief annealing is performed; (3) annealed gamma-TiAl alloy bar is subjected to finish turning processing to obtain a high-precision alloy bar; (4) the gamma-TiAl alloy bar is loaded to a reaction chamber, and the reaction chamber is vacuumized and filled with inert gas; (5) the end part of the high-precision alloy bar is heated by PREP powder making equipment, atomized drops are thrown away from the end part of the alloy bar, the drops are cooled rapidly into spherical particles in the inert gas environment, and the spherical particles fall into a collector; (6) prepared gamma-TiAl alloy powder is screened and packaged in the inert gas protection environment; (7) the gamma-TiAl alloy powder prepared with the method has the advantages that the degree of sphericity is high, the oxygen increase is low, no mixing exists, and the particle distribution is controllable.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

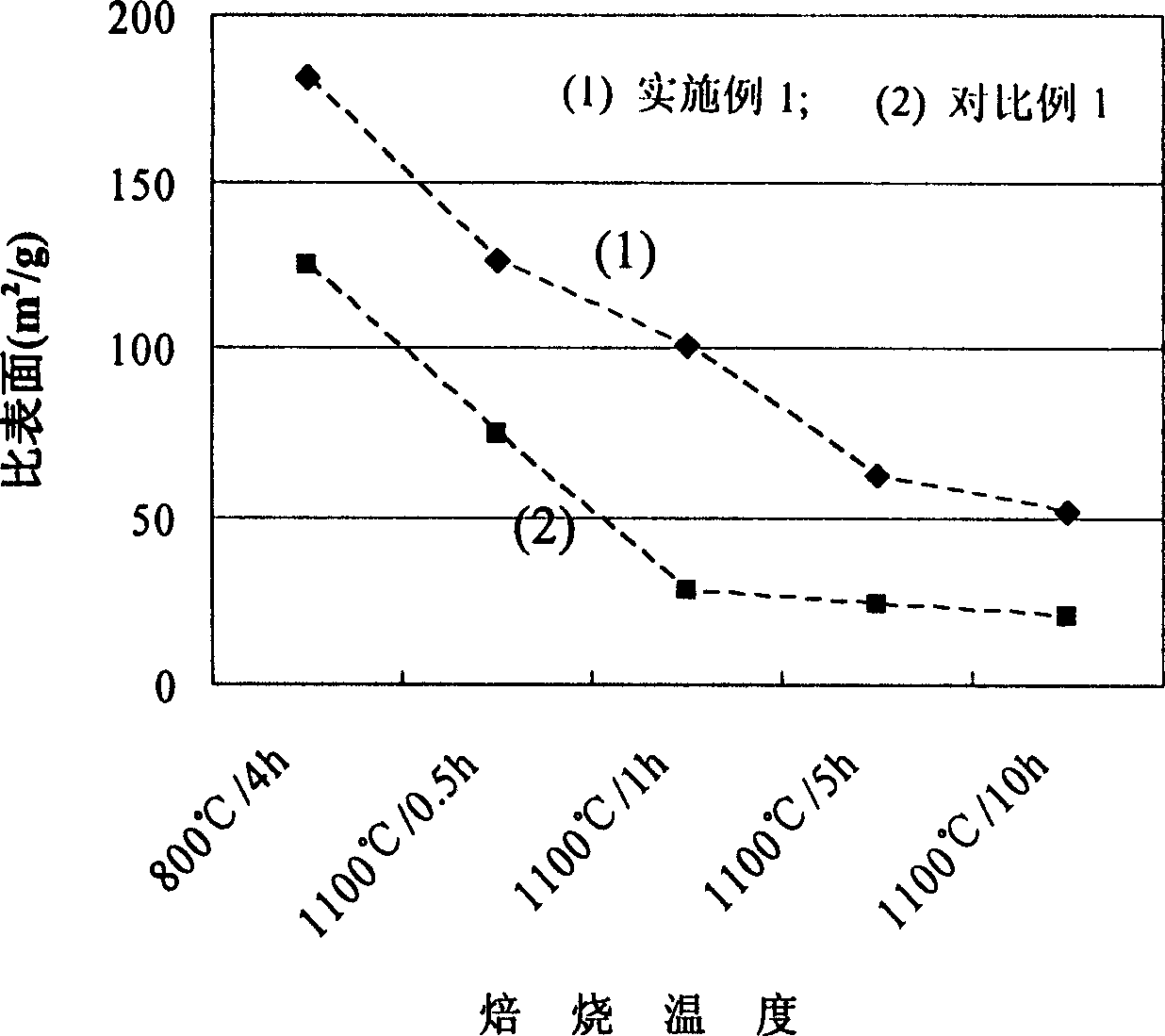

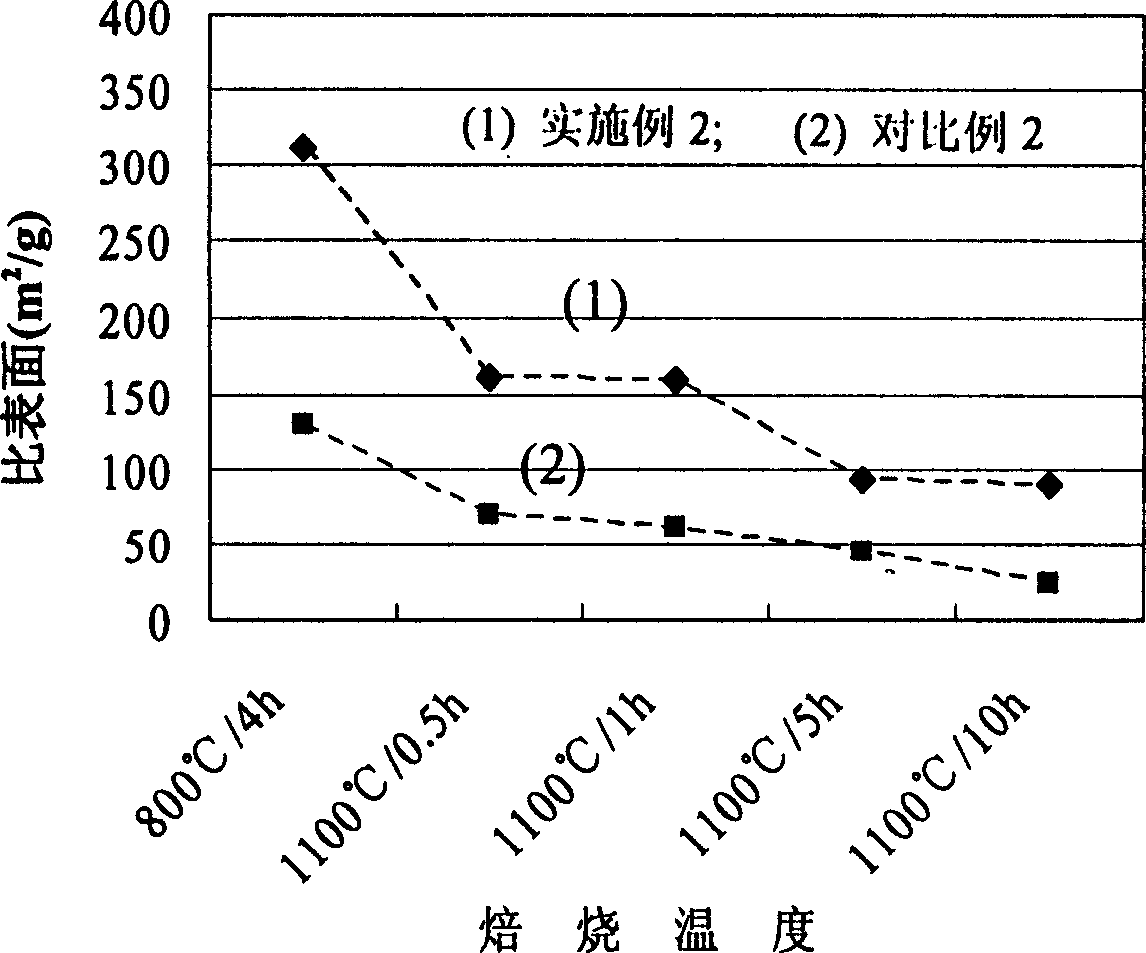

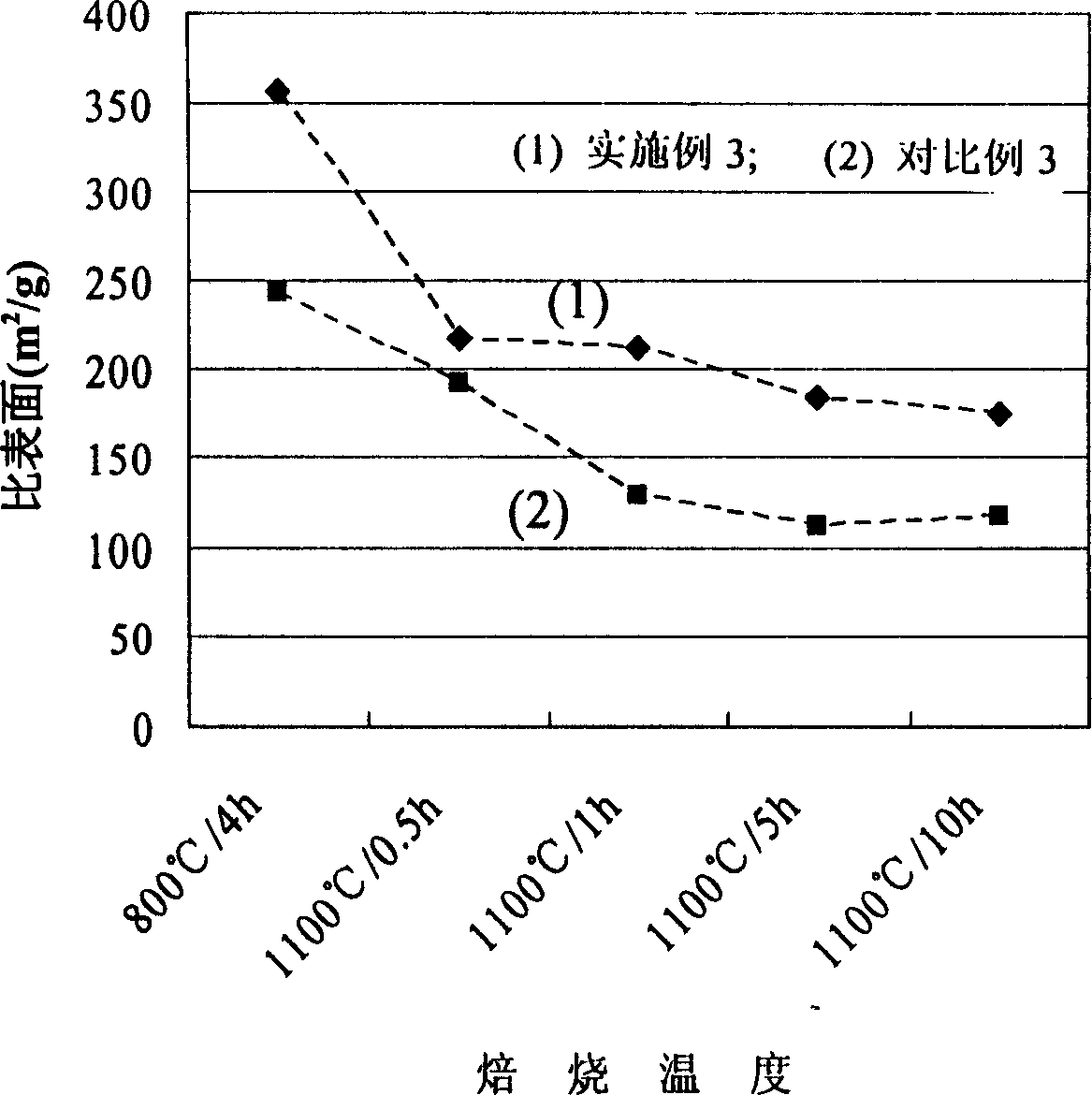

Method for preparing light temperature-resistance high surface area alumina and aluminiferous composite oxide

InactiveCN1528667AUniform particle size distributionParticle size controllableAluminium oxides/hydroxidesSurface-active agentsTemperature resistance

The invention discloses a method to prepare high-temperature high-surface area aluminum oxide and aluminous compound oxide. It uses surface-active agent, assistant surface-active agent, non-water soluble organic solvent, water, inorganic salt and basic material as raw materials to manufacture two reversed-phase microemulsions, then mixing the two microemulsions to react and produce sol, and then filtering, drying, baking, etc, to obtain high-thermal stability aluminum oxide and aluminous compound oxide. When they are baked at 1000 deg.C for 10h, their specific surface area are both kept at 50 sq m / g above, for an example, when the modified aluminum oxide is baked at 1100 deg.C for 10h, its specific surface area is 185.2 sq m / g. Their particle sizes are uniformly distributed and can be controlled. The raw materials are cheap and easy to obtain.

Owner:EAST CHINA UNIV OF SCI & TECH

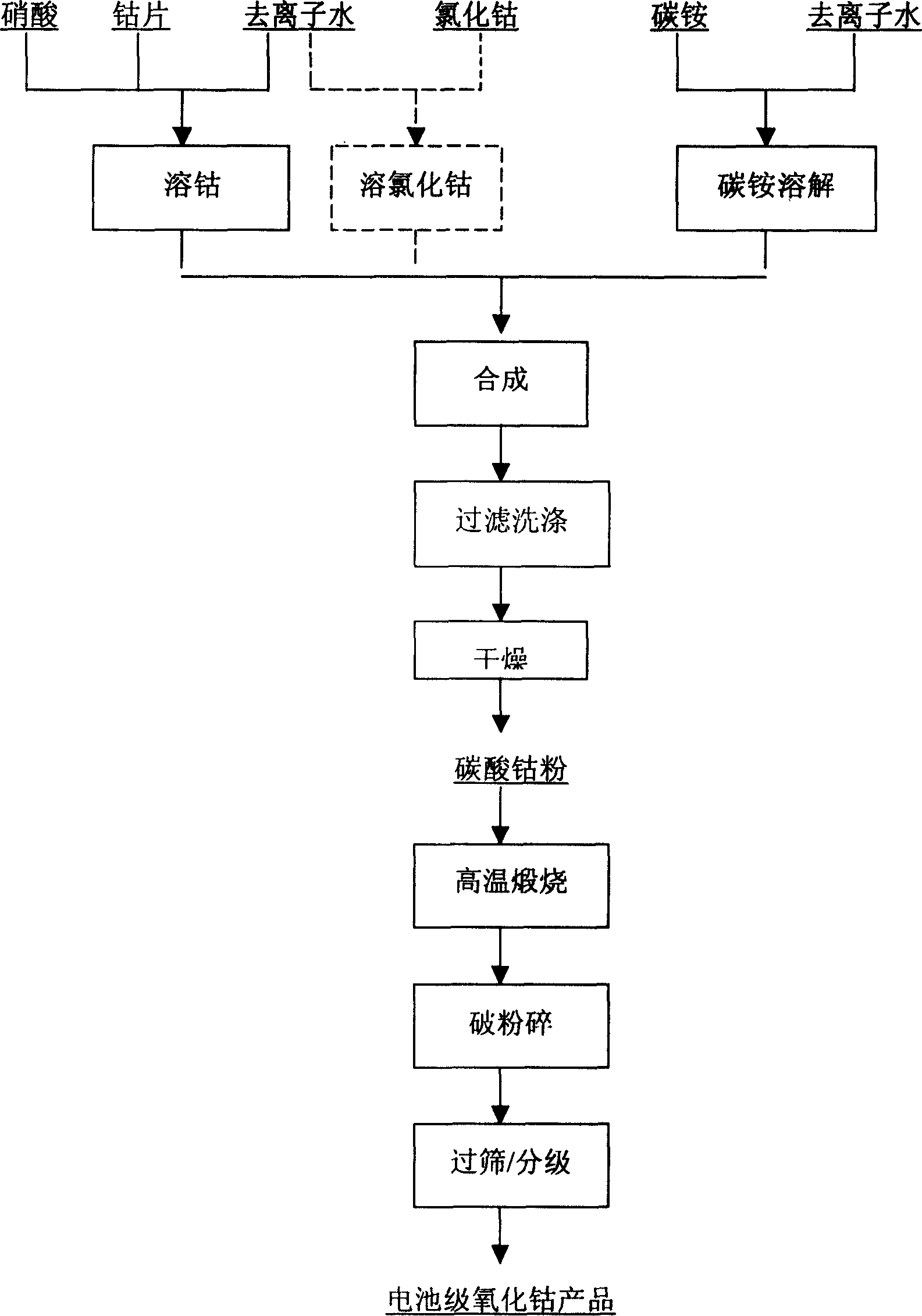

Cobalt oxide of lithium battery grade and its preparation method

ActiveCN1623909ANovel preparation processNo reportCobalt oxides/hydroxidesCobalt(II,III) oxideCarbonate

Owner:JIANGSU DANGSHENG MATERIAL TECH CO LTD

Method for preparing thermosetting amino resin microspheres

The invention relates to a method for preparing thermosetting amino resin microspheres. The invention aims to provide the method which can prepare amino resin microspheres with wide range of grain size and higher water resistance. The technical scheme I adopted by the invention is that the method for preparing the thermosetting amino resin microspheres comprises the following steps of: (A), adding an amino compound and an aldehyde compound into an aqueous solution of silica sol with an alkaline catalyst to obtain a prepolymer of water soluble amino resin, wherein the weight ratio of the amino compound to the aqueous solution of silica sol is 100: 0.5-100; (B), adding an acidic curing agent into the prepolymer of the water soluble amino resin to obtain amino resin microspheres; and (C), aging the microspheres, filtering, drying and grinding the microspheres to obtain a finished product. The amino compound may be one or more of tripolycyanamide, urea, thiourea, cyanuric acid and phenylated tripolycyanamide, and the aldehyde compound may be one or more of formaldehyde, paraformaldehyde, acetaldehyde, benzaldehyde and furfuraldehyde.

Owner:杭州精彩化工有限公司

Copper alloy coated composite powder and its preparation method

InactiveCN1868637AImprove performanceReasonable particle size distributionIron powderChemical composition

Owner:成都平和同心金属粉末有限公司

Method for preparing noble metal nano material with adjustable particle size by bacteria

The invention relates to a method for preparing noble metal nano material with adjustable particle size by bacteria, and belongs to the technical field of preparation of inorganic nano material. The method comprises the following steps of placing the bacteria in a culture liquid, uniformly mixing, and adding inorganic salts into the culture liquid to ferment, so as to obtain inorganic noble metal nano particles; or placing the bacteria in the culture liquid, culturing, fermenting, and adding the inorganic salts into the bacteria fermenting liquid to carry out reaction, so as to obtain the inorganic noble metal nano particles. The size of the nano particle is controlled by changing the adding amount of the inorganic salts. The bacteria are yeast and lactic acid. The inorganic salts are the inorganic salts of Cu (copper), Ag (silver), Pt (platinum) and Pd (palladium). The method has the advantages that the bacteria, the culture liquid and the inorganic salts are used as raw materials, the noble metal nano material is prepared by the bacteria fermenting, the size of the nano particle is controlled by changing the adding amount of the inorganic salts, and the composite noble metal nano particles different in the configuration are prepared by adding inorganic salts different in the type; and the preparation method is simple, quick and safe.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of carbon reinforced metal/metal oxide composite powder

The invention discloses a preparation method of carbon reinforced metal / metal oxide composite powder and belongs to the field of composite material preparation. The preparation method comprises the steps that a cavity is heated to reach metal salt decomposition temperature, then a metal salt solution and carbon dispersion liquid are mixed, the mixture is atomized into small liquid drops (generally nanoscale) by using a spraying device, the small liquid drops are led into the cavity, pyrolytic reaction instantly occurs under the high-temperature effect of the cavity to generate metal oxide and carbon composite powder, or the small liquid drops are led into the reduction atmosphere, while pyrolysis and reduction reactions occur to generate the metal oxide and carbon composite powder, and then the powder is collected through a dust collection device. The preparation method does not destroy original morphology of carbon, the prepared composite powder particles are smaller in size (can reach the nanoscale), size distribution is more controllable, the dispersity of the carbon in a matrix is more excellent, and the preparation method further has the advantages that the method is simple and convenient to operate, and large-scale batch production is easy to achieve.

Owner:KUNMING UNIV OF SCI & TECH

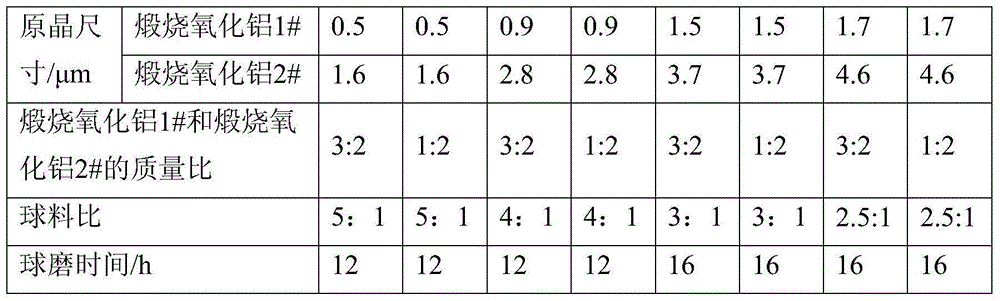

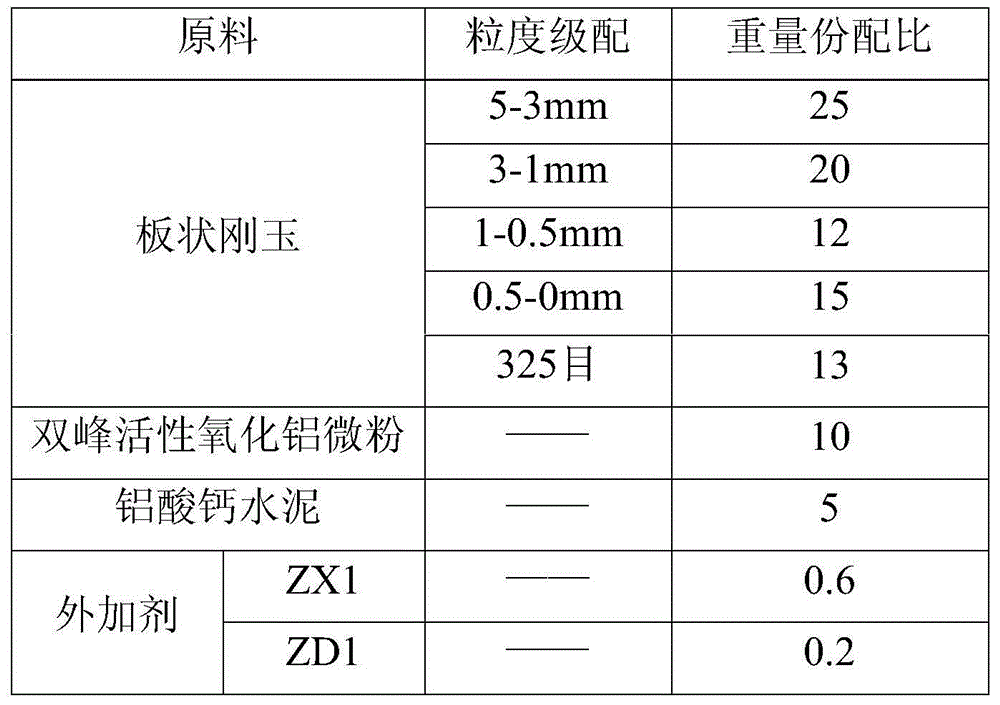

Bimodal active alumina micropowder and preparation method

The invention discloses a preparation method for bimodal active alumina micropowder. The method comprises the following steps: (1) calcining industrial alumina powder at different temperatures so as to obtain calcined alumina powders with a variety of original crystalline sizes; (2) selecting two calcined alumina powders with different original crystalline sizes and carrying out ball milling so as to obtain the bimodal active alumina micropowder, wherein the mass ratio of the two calcined alumina powders with different original crystalline sizes is 0.2-5: 1. The preparation method for the bimodal active alumina micropowder provided by the invention is simple and can obtain bimodal-distribution active alumina micropowder; and the obtained bimodal alumina micropowder can be used for refractory products and can improve performances like construction performance, compactness, slag resistance and mechanical strength of the refractory products.

Owner:浙江自立新材料股份有限公司

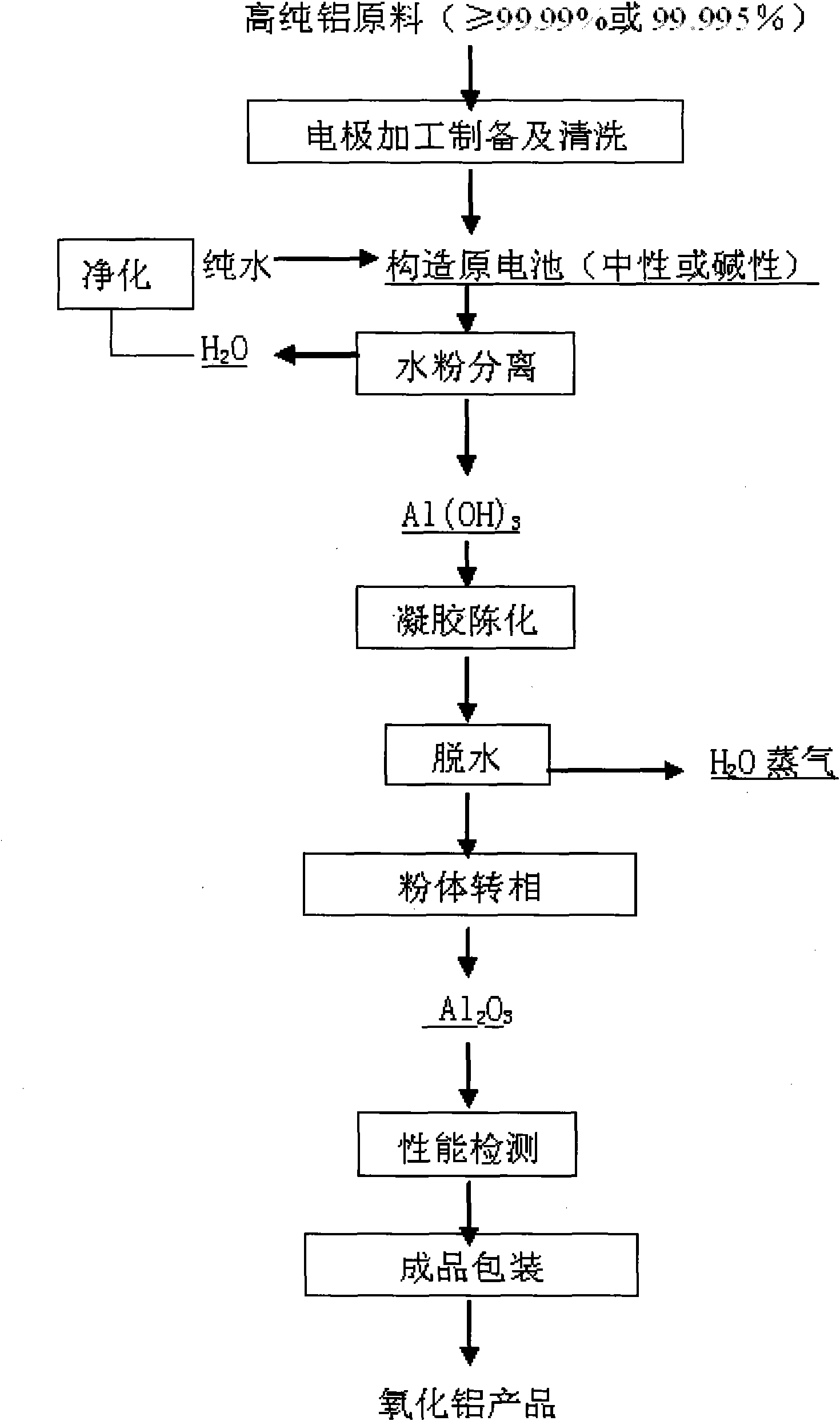

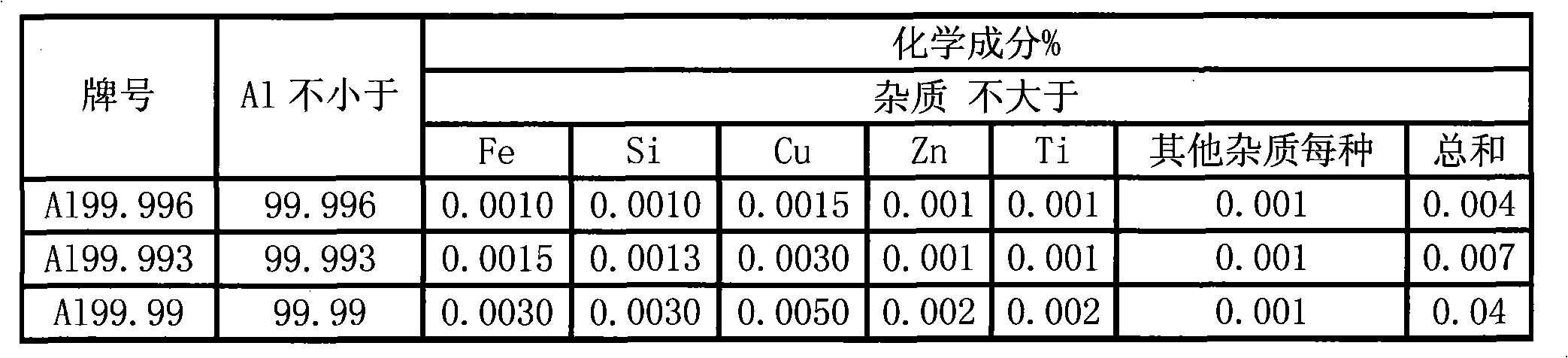

Method for preparing catalyst carrier Al2O3 powder by activating and hydrolyzing metallic aluminium under ultrasound-electric field coupling

InactiveCN101829607APromote activationThe principle is simpleCatalyst carriersCatalyst activation/preparationSpecific volumeAluminium

The invention discloses a new process for preparing high purity aluminum oxide powder. The processed is carried out based on the fundamental principle of ultrasound electrochemistry, wherein electrode reactions in primary cells between metallic aluminium and air is formed under ultrasound action in a pure water system, and in-situ activation is carried out on the surface of the high purity metallic aluminium by the cavitation of an ultrasonic field, which can promote the activation of the surface of the metallic aluminium and the primary cell reaction between the metallic aluminium and the air as well as the hydrolysis reaction of the metallic aluminium. The method has simple principle, concise process, short technological procedures, low specific volume and energy consumption, environmental protection and no pollution. As under the entire ultrasound-electric field coupling condition, the reaction is moderate and controllable, and the obtained high purity Al (OH) 3 gel has small primary particle size, uniform particle size distribution, high activity, good flowability, particle appearance approximate to sphere and easy purity control. The obtained Al (OH) 3 gel is processed then by thermal treatment, and the high purity aluminum oxide powder with different forms can be obtained at different thermal treatment temperatures. The product has high purity, excellent particle characteristics and incomparable advantages over the products prepared by other production methods in the aspects of purity and particle shape.

Owner:昆明珀玺金属材料有限公司

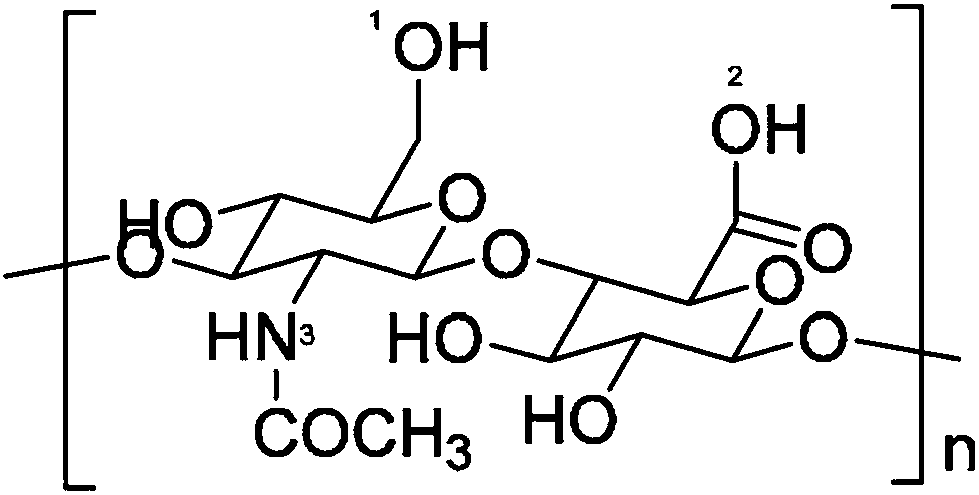

Preparation method and application of cross-linked hyaluronic acid gel microspheres

ActiveCN108478875AUniform crosslinkingThe particle distribution is round and uniformPharmaceutical delivery mechanismProsthesisCross-linkTissue repair

The invention discloses a preparation method and application of cross-linked hyaluronic acid gel microspheres. The preparation method comprises the steps that a hyaluronic acid alkaline solution withthe concentration being 5-30% g / ml is prepared, inorganic dispersants are added into organic phase cyclohexane under stirring, full stirring is conducted, and thus the inorganic dispersants are uniformly dispersed. By adopting the technical scheme, the preparation method is simple, products are controllable in particle size, intact in form, low in impurity content, high in purity and highly transparent, and meanwhile, the degradation period can also be controlled within the range of 30-300 days. In the preparation method and the application of the cross-linked hyaluronic acid gel microspheres,the cross-linked hyaluronic acid gel microspheres prepared through the preparation method can be used for producing medical or prevention products and used for injection, tissue repair and tissue strength in animals and especially in humans; and because of the extremely-low impurity content, the products have good biocompatibility and degradability, and clinical safety is ensured.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

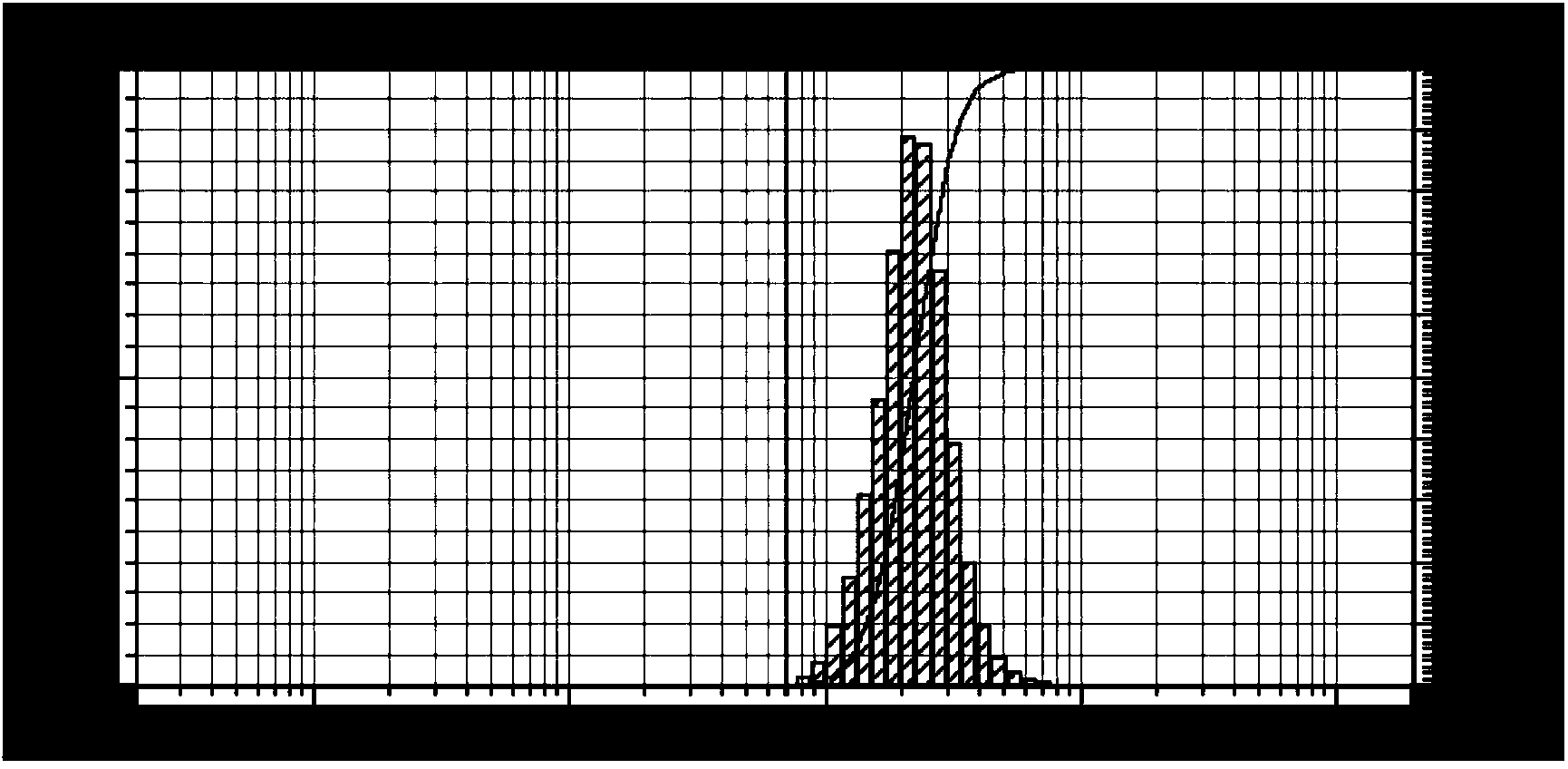

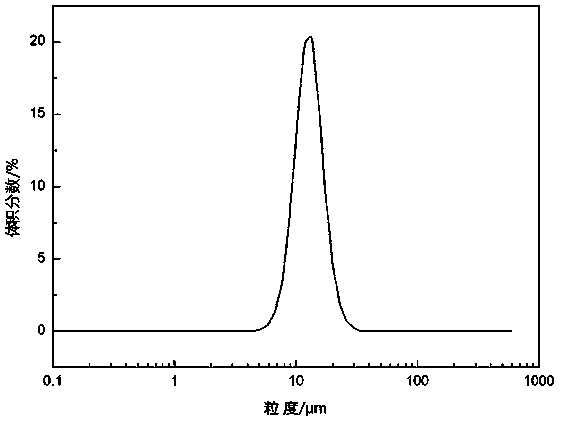

Method for preparing spheroid manganous-manganic oxide from manganese sulfate solution

InactiveCN110759384ALow impurity contentUniform particle size distributionManganese oxides/hydroxidesOxidizing agentAnalytical chemistry

The invention discloses a method for preparing spheroid manganous-manganic oxide from a manganese sulfate solution. The method includes the following steps that an electrolytic manganese metal sheet is dissolved, impurity-removed and purified to obtain the manganese sulfate solution with low impurity content; the manganese sulfate solution, ammonia water and additives are added into a reaction kettle in a parallel flow mode, a sufficient amount of an oxidizer is added for one-step oxidation under the stirring condition, and the reaction temperature is 50-90 DEG C; and after addition of the manganese sulfate solution is completed, the ammonia water is continued to be added for 6-10 h to control the pH value of a reaction system to be 4.5-9.5, adding of the ammonia water is stopped and thenstirring is continued, heat preservation and aging are conducted for 4-20 h, then a product is filtered and washed, and the spheroid manganous-manganic oxide is obtained by drying at 120 DEG C. The prepared spheroid erical manganous-manganic oxide D50 is 4-20 [mu]m, the tap density is greater than or equal to 2.0 g / cm<3>, and the Mn content is greater than or equal to 70.5%. The method is simple in process flow and low in production cost, and industrial production is easy to realize.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

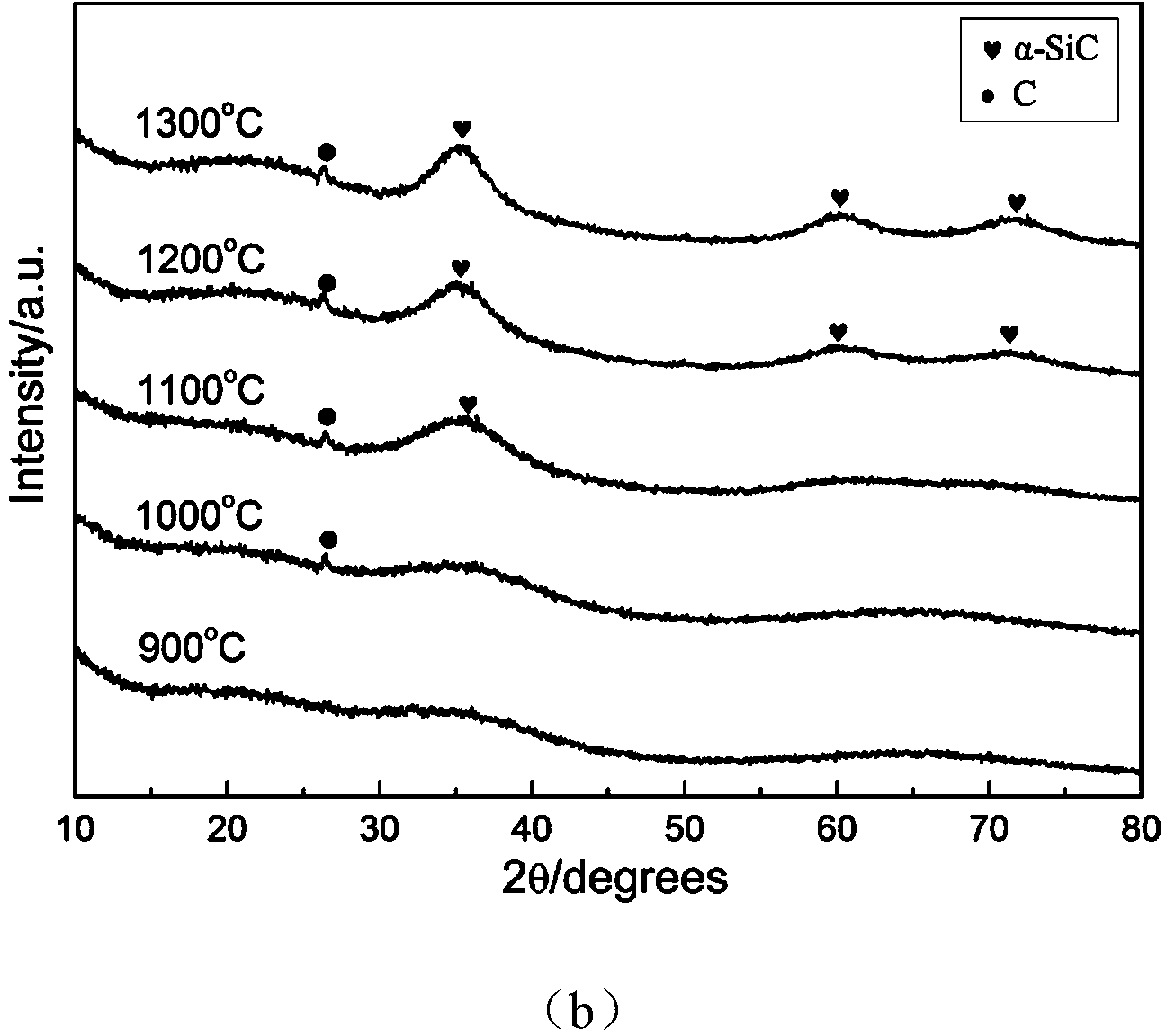

Preparation method of amorphous SiOC ceramic powder

ActiveCN104291791ASolve the high cost of raw materialsSimple preparation processCeramic particlePyrolysis

The invention discloses a preparation method of amorphous SiOC ceramic powder, which comprises the following steps: 1) carrying out low-temperature crosslinking curing on a precursor polymer, crushing the crosslinking curing product, and screening to obtain precursor particles, wherein the precursor polymer is linear polycarbosilane or a mixture of linear polycarbosilane and linear polysiloxane; 2) carrying out pyrolysis reaction on the precursor particles to obtain pyrolysis ceramic particles with irregular particle morphology, of which the particle size is 60 mu m-2mm; and 3) carrying out ball milling on the pyrolysis ceramic particles to obtain the amorphous SiOC ceramic powder. The amorphous SiOC ceramic powder has the characteristics of controllable Si, O and C element contents, controllable powder particle size and controllable crystallization temperature. The method has the advantages of simple preparation technique, low cost and the like, and is suitable for industrial production.

Owner:常州宇超钢管有限公司

Drug-loaded egg protein microspheres and preparation method thereof

ActiveCN104083770AHigh strengthEasy to packGranular deliveryMacromolecular non-active ingredientsEgg proteinMicrosphere

The invention relates to drug-loaded egg protein microspheres and a preparation method thereof, belonging to the field of drug controlled release. The invention aims at solving the technical problem of providing the drug-loaded egg protein microspheres and the preparation method thereof. A vector of the drug-loaded egg protein microspheres is egg protein. The preparation method comprises the following steps: mixing a surfactant with an oily component to obtain an oil phase; adding a mixed liquor of the egg protein and drugs to the oil phase to stir and emulsify, and then directly heating and solidifying or adding an aldehyde curing agent to carry out crosslinking solidification; demulsifying by using a petroleum ether after solidification is ended; and cleaning and centrifuging by using isopropyl alcohol, and carrying out freeze-drying, so as to obtain the drug-loaded egg protein microspheres. The microspheres disclosed by the invention have good biocompatibility and biological activity; the particle sizes are 0.2-20mu m, and can be adjusted according to different solidification methods; and the microspheres are good in controlled release effect, are applied to a plurality of drug-delivery ways, such as injection, oral administration and the like, and are wide in material source, low in price, simple and feasible in preparation process and low in production cost.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

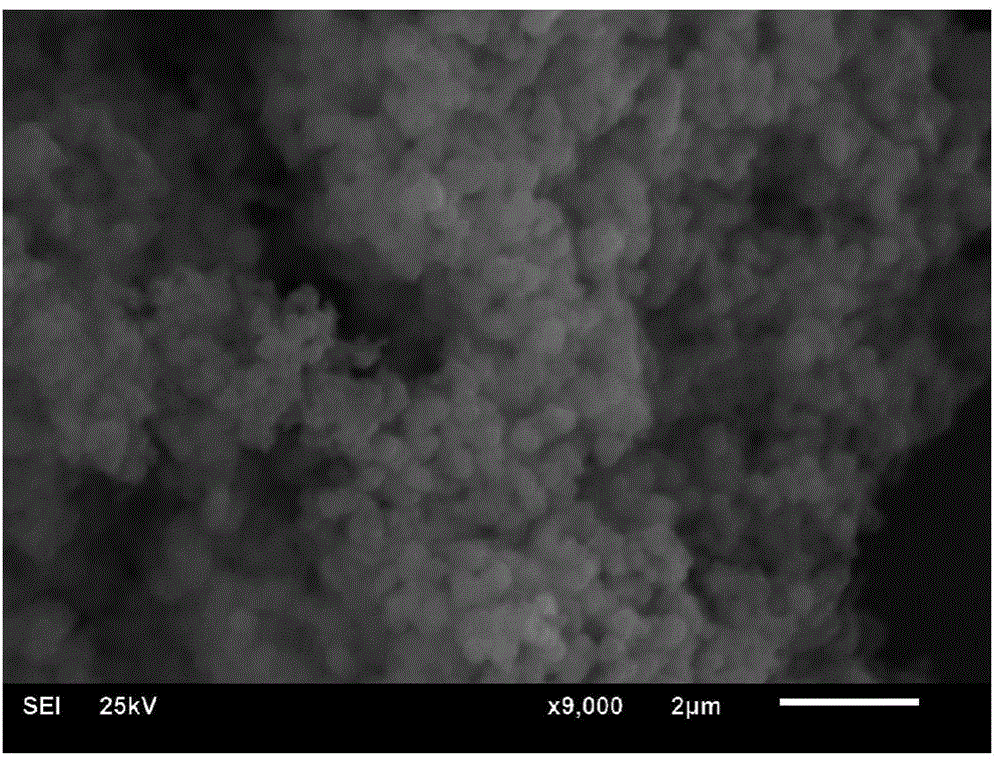

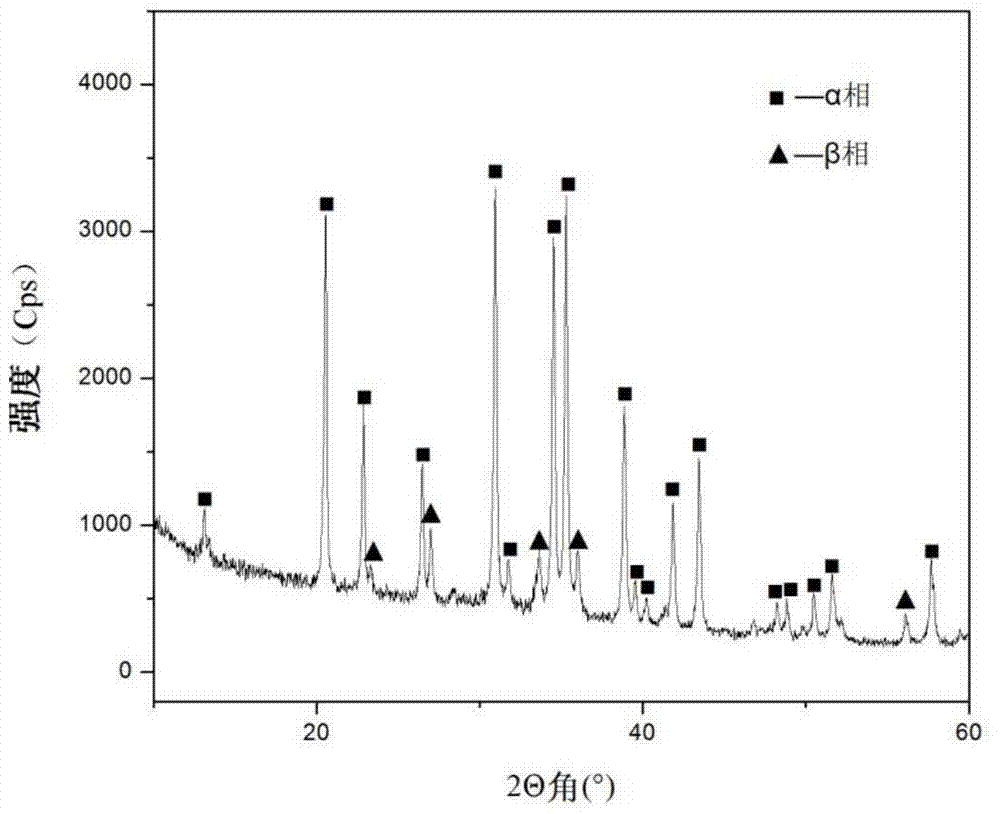

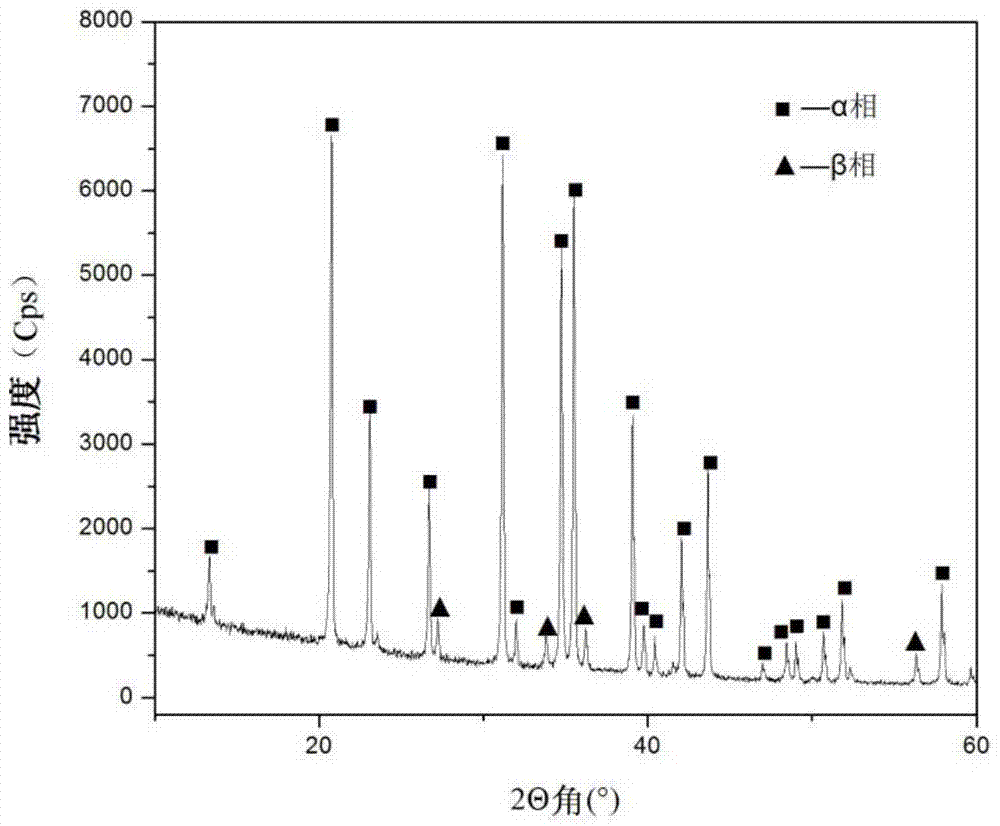

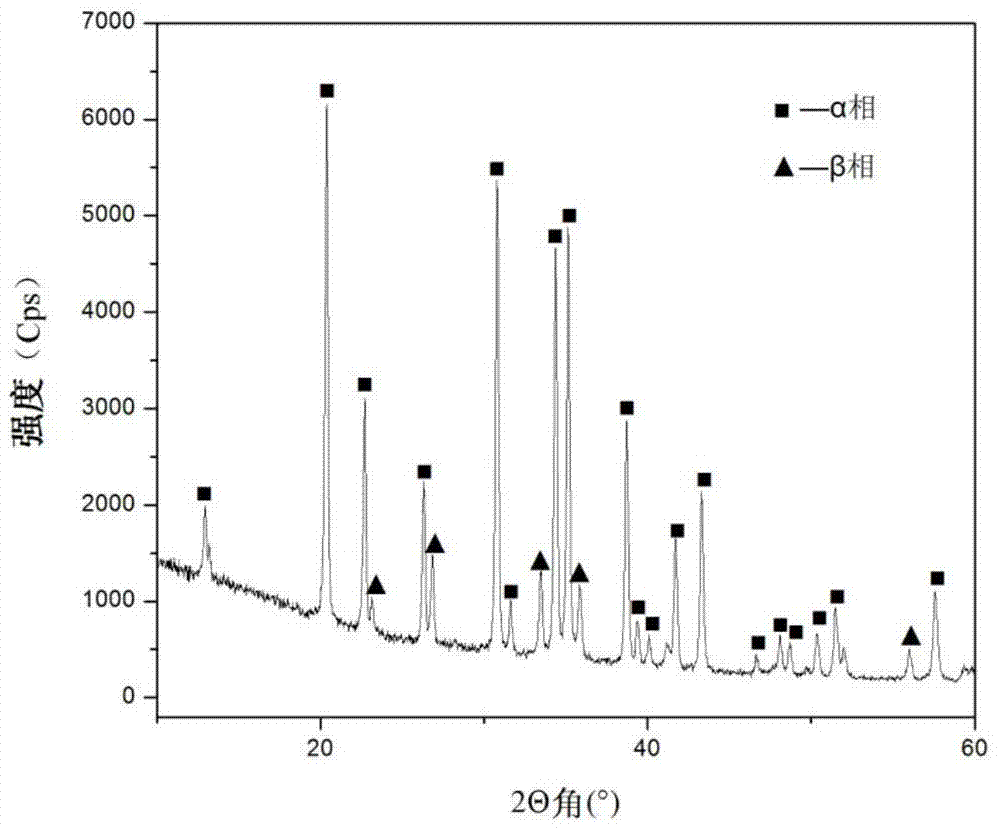

Method for preparing high alpha-phase silicon nitride by utilizing porous silicon

ActiveCN104495765AHigh alpha phase contentUniform particle size distributionNitrogen compoundsNitrogen atmosphereNitrogen gas

The invention discloses a method for preparing high alpha-phase silicon nitride by utilizing porous silicon. The method comprises the following steps: with the porous silicon as a raw material, in the nitrogen atmosphere, sequentially carrying out treatments including high-temperature calcination and grinding to obtain the high alpha-phase silicon nitride. With the adoption of the method of preparing the high alpha-phase silicon nitride by utilizing the porous silicon, the silicon nitride with high alpha phase content and uniform particle size distribution is efficiently prepared. The method is simple in process, controllable in performance, short in production period and low in cost, is capable of greatly lowering the production energy consumption and is suitable for large scale industrial production.

Owner:ZHEJIANG UNIV

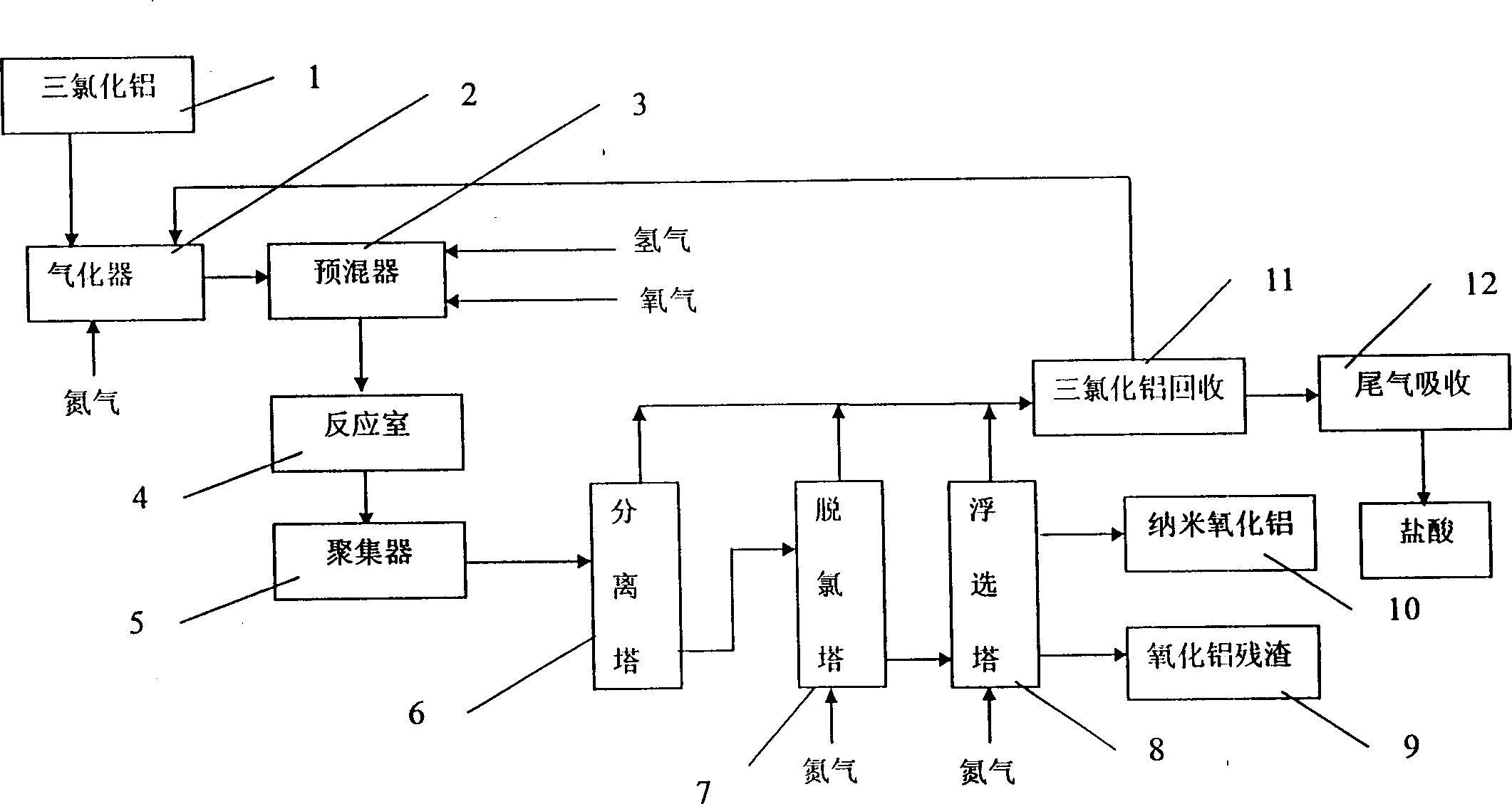

Continuous preparation process of high purity nanometer alumina

The continuous preparation process of high purity nanometer alumina includes the following steps: high temperature gasifying aluminum trichloride, continuous mixing with H2 and O2 in a re-mixer, high temperature hydrolysis and condensation reaction of aluminum trichloride in the high temperature generated through burning H2 inside a reactor, and aggregating the reaction product, gas-solid separation, dechlorinating, floating, etc. to obtain high purity nanometer alumina. By means of controlling the material ratio, the cooling rate in the reactor, and the length and temperature of the aggregator, nanometer alumina powder of different grain sizes may be obtained. By means of tail gas treatment, circular utilization of aluminum trichloride and absorption of HCl to prepare hydrochloric acid, the present invention realizes the best utilization of resource.

Owner:GUANGZHOU HUIFU RES INST CO LTD

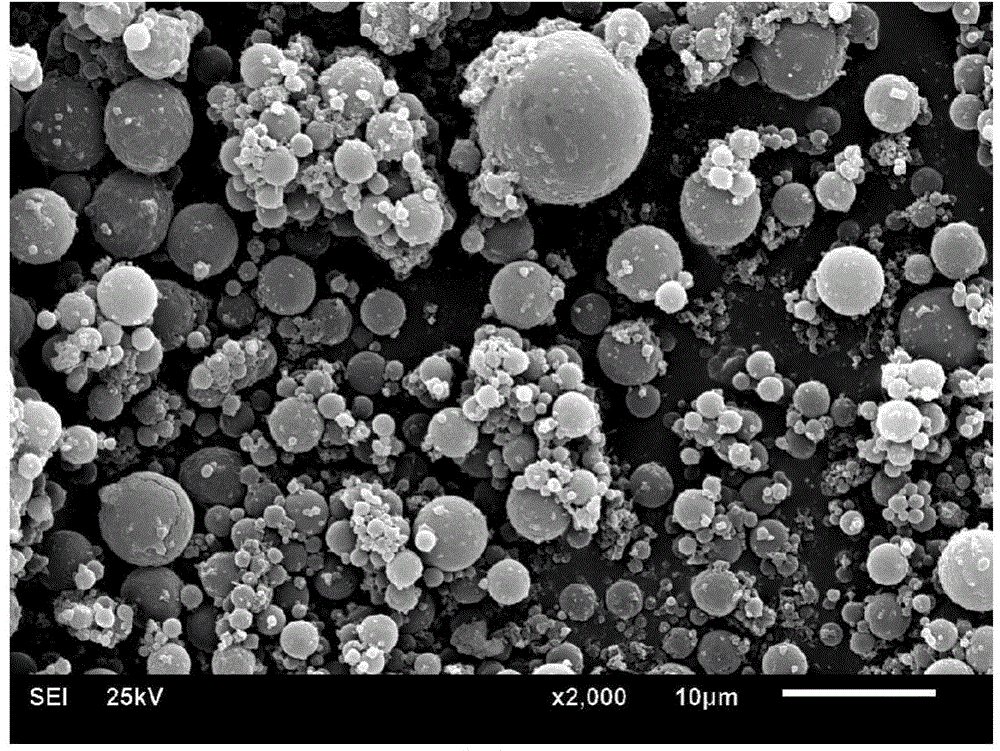

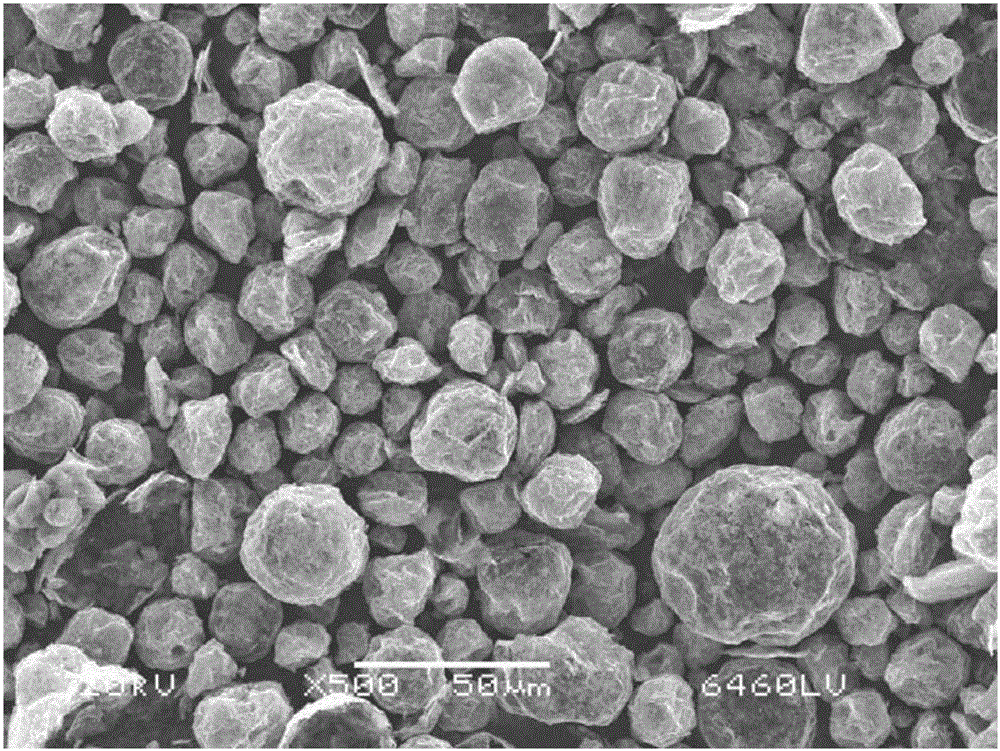

Preparation method for asphalt hard carbon negative electrode material for lithium ion battery

ActiveCN105836728ALow priceWide variety of sourcesCell electrodesSecondary cellsMicrosphereLithium-ion battery

The invention discloses a preparation method for an asphalt hard carbon negative electrode material for a lithium ion battery, wherein the preparation method comprises the following steps: 1) making commercial sulfonated asphalt and deionized water into an asphalt solution, and filtering out undissolved asphalt particles, to obtain a clarified water-soluble asphalt solution; 2) adding a graphite micro-powder to the asphalt solution obtained in the step 1); 3) carrying out spray granulation of the graphite asphalt solution obtained in the step 2), to obtain asphalt hard carbon microspheres with the particle size of 1-51[mu]m; and 4) heating the asphalt hard carbon microspheres obtained in the step 3) up, and drying to obtain the asphalt hard carbon negative electrode material for the lithium ion battery. The used raw materials are cheap in price and wide in sources; no any organic solvent requires to be added in the whole production process; the asphalt hard carbon particle size distribution can be controlled; the preparation process easily realizes industrialized production. The prepared asphalt hard carbon negative electrode material has excellent lithium intercalation and removal capacities, and is suitable for power lithium ion batteries.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

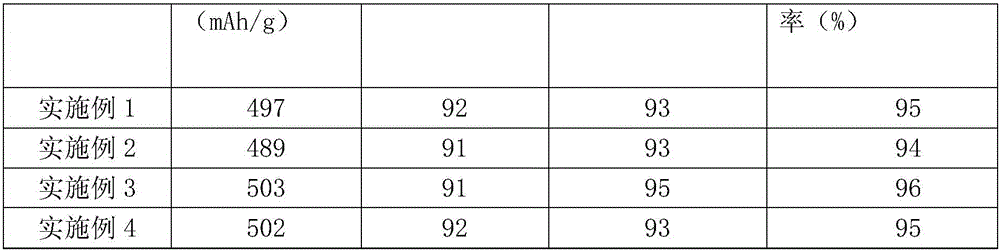

Positive electrode material precursor, preparation method and applications thereof

ActiveCN110817976AControllable particle size distributionMeets close-packed requirementsCell electrodesSecondary cellsElectrical batteryHigh energy

The invention discloses a positive electrode material precursor, a preparation method and applications thereof. The preparation method comprises:carrying out a three-stage co-precipitation reaction ona salt solution, an alkali solution and an ammonia solution to obtain a product, wherein each stage of the co-precipitation reaction comprises a seed crystal generation process under a high pH condition and a crystal grain constant-speed growth process under a low pH condition; and aging, washing and drying the product to obtain a positive electrode material precursor. According to the invention,the precursor material formed by mixing large and small secondary spherical particles, wherein the octahedral gaps and the tetrahedral gaps between the large particles are filled with the small particles so as to meet the close packing requirements of the material; compared with the conventional ternary precursor material, the material of the invention has the increased tap density of 2.2-2.5 g / cc, and easily meets the requirements of lithium ion batteries on high energy density at present; and the method is simple in process, controllable in productivity and easy for large-scale production and application.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

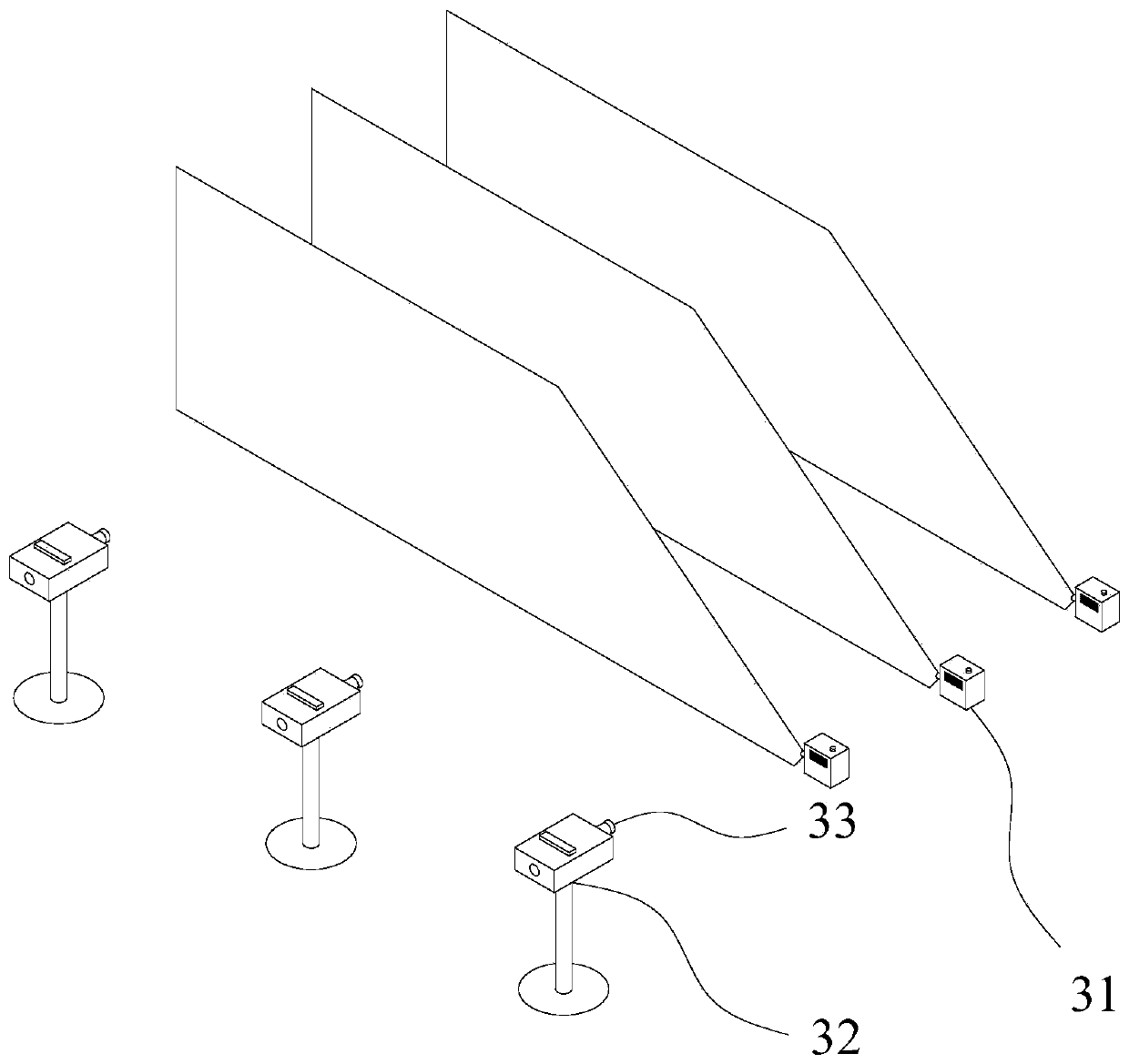

Fire disaster simulating experiment platform for underground traffic switching channel

The invention provides a fire disaster simulating experiment platform for an underground traffic switching channel. The platform comprises a model main body simulating the underground traffic switching channel, a combustor butted to the model main body and generating smoke, and a smoke imaging system, wherein the smoke imaging system comprises laser sheet light sources and image recording devicesrecording smoke distribution images; the plurality of laser sheet light sources are distributed in the model main body, and planar laser emitted by the laser sheet light sources is parallel to the flowing direction of smoke; the plurality of image recording devices are in one-to-one correspondence with the laser sheet light sources and are distributed outside an observation window of the model main body; and each laser sheet light source and each image recording device in pair which correspond to each other are provided with light filters filtering out laser with the same wavelength. The firedisaster simulating experiment platform for the underground traffic switching channel can conveniently research the horizontal spreading feature of the smoke, and is particularly suitable for simulating the fire disaster of the underground traffic switching channel.

Owner:ZHEJIANG UNIV

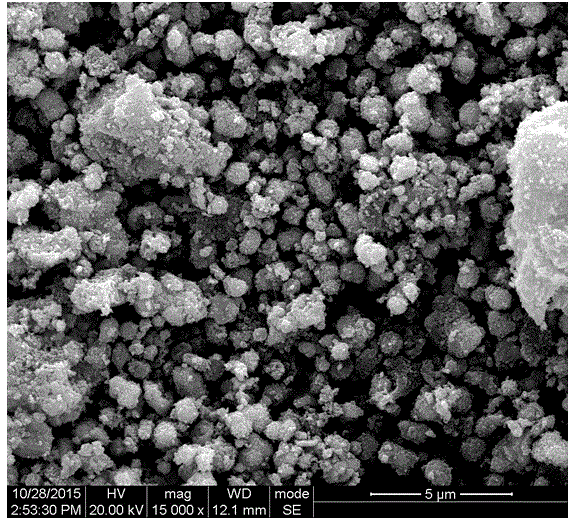

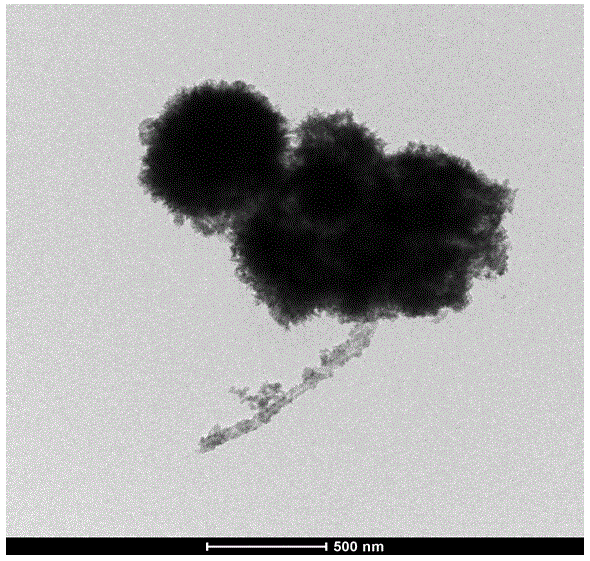

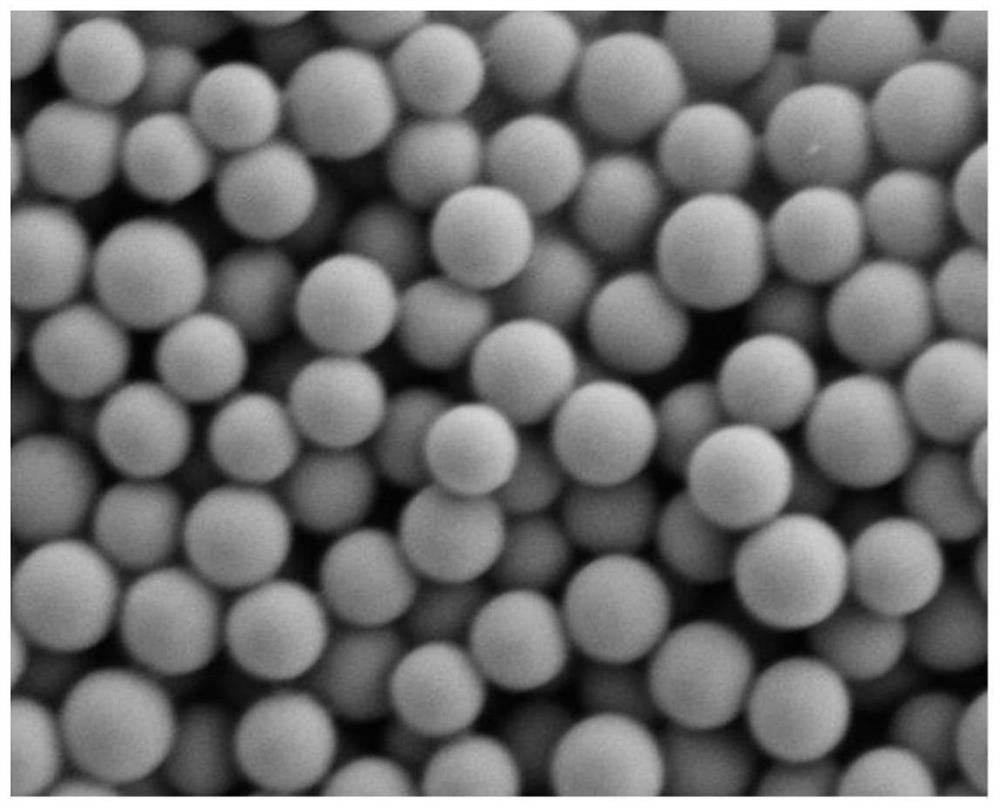

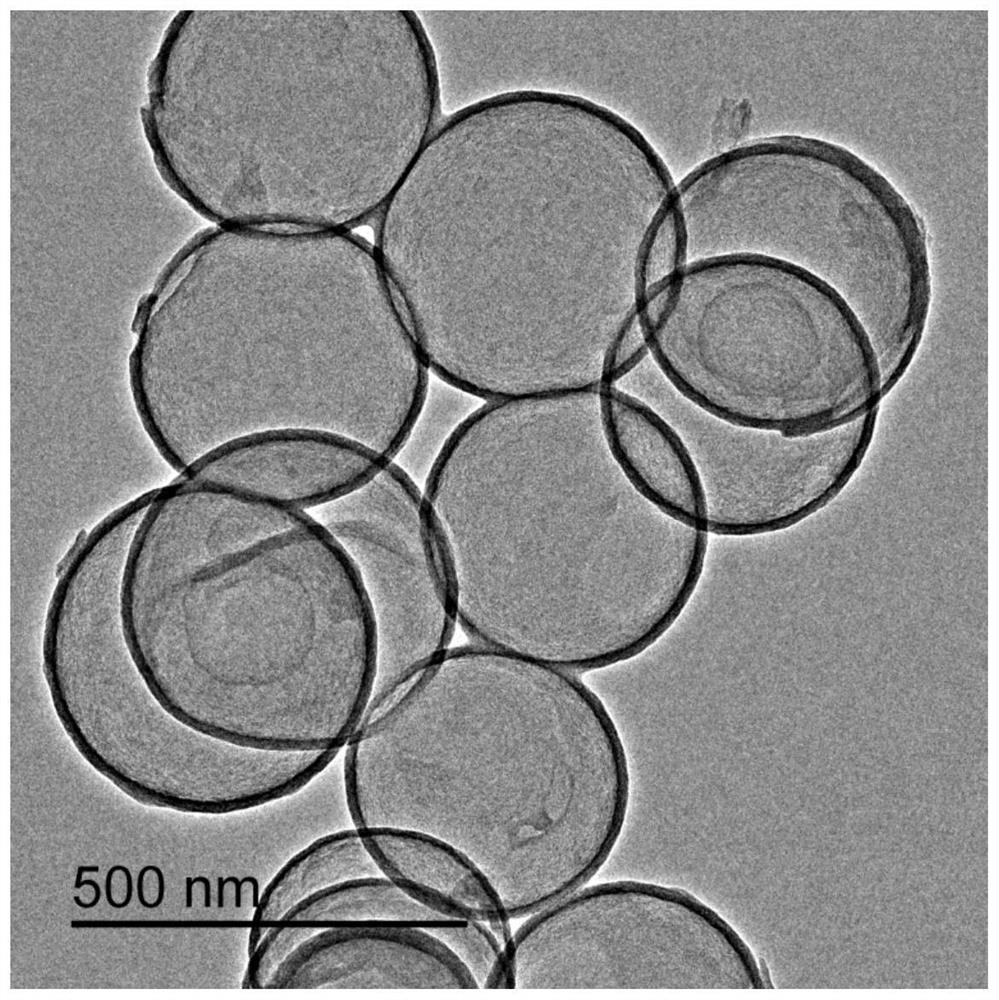

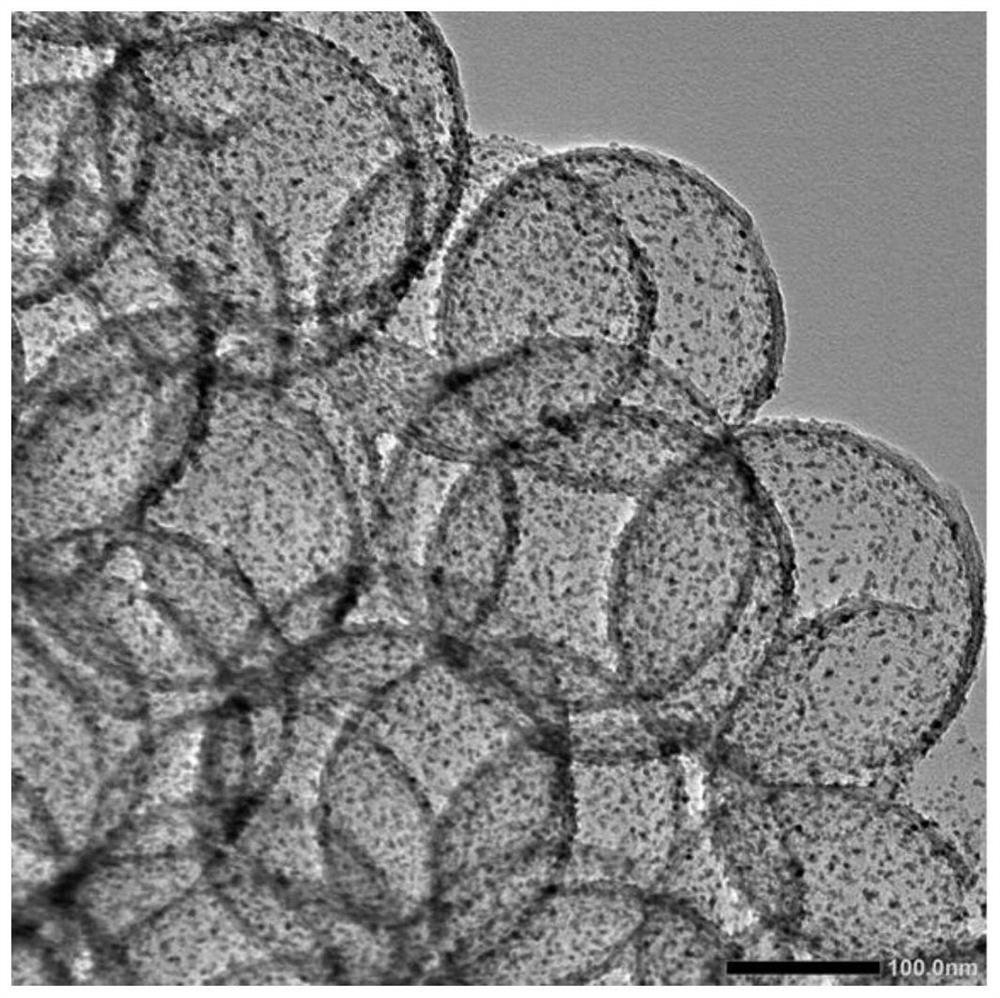

Nitrogen-doped mesoporous hollow carbon sphere loaded metal-based nano-catalyst and preparation method thereof

PendingCN114453000AInhibition of agglomerationHigh catalytic activityOrganic chemistryPhysical/chemical process catalystsNano catalystIridium

The invention discloses a nitrogen-doped mesoporous hollow carbon sphere loaded metal-based nano catalyst and a preparation method thereof. The catalyst is prepared through different methods, the expression of the catalyst is M (at) NHCS, NHCS is nitrogen-doped mesoporous hollow carbon spheres, and M is any one of metal nickel, copper, cobalt, iron, ruthenium, platinum, palladium, iridium, rhodium and gold. The hollow carbon spheres are used as a stable carrier, and metal can be loaded to realize a functionalization effect. Metal is loaded on the surfaces of the carbon spheres, so that metal particles are not easy to agglomerate, and more active sites can be provided. Besides, the hollow carbon sphere also has an adjustable pore structure and an easily modified surface, and the macroscopic size and the shell thickness can be adjusted by a synthesis method, so that the hollow carbon sphere material has huge performance potential.

Owner:SHAANXI UNIV OF SCI & TECH

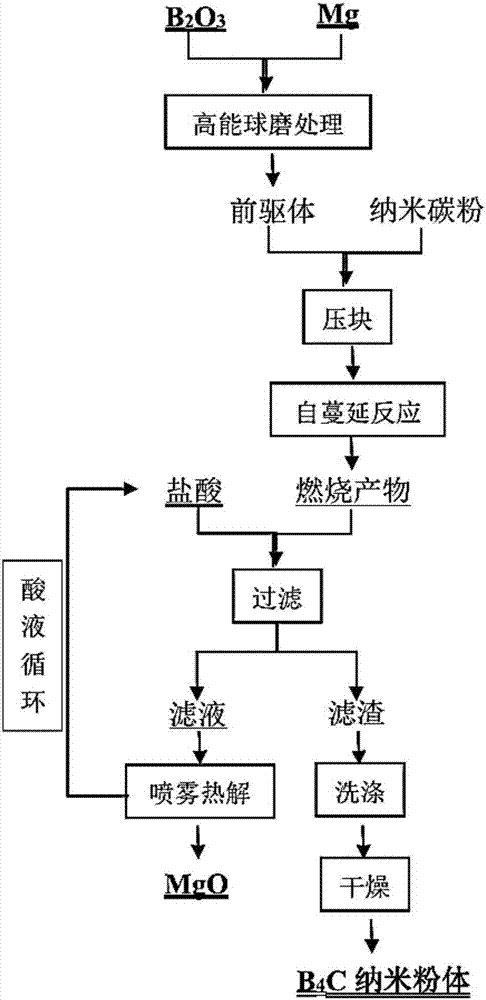

Method for preparing B4C nano-powder through in-situ combustion synthesis

InactiveCN106976883AHigh purityHigh activityCarbon compoundsChemical industryHigh energyBiological activation

The invention discloses a method for preparing B4C nano-powder through in-situ combustion synthesis, and belongs to the technical field of powdering in a powder metallurgy process. The method comprises the steps of mixing boron oxide and magnesium powder at a molar ratio, feeding into a high-energy ball mill for mechanical activation treatment; mixing with carbon nano-powder evenly at a molar ratio, putting into a mold, pressing into a block blank at 10-60MPa and then putting into a self-propagating reactor for triggering self-propagating reaction; immersing the product into diluted hydrochloric acid and carrying out intensified leaching in a closed reaction kettle; and finally carrying out spray pyrolysis to obtain a high-purity boron carbide nano-powder product. The high-purity and high-activity nano B4C powder is prepared through the method. The method is low in raw material cost, low in energy consumption, simple in operation, and low in requirement for technological conditions and instruments and equipment; and a foundation is laid for industrial production. By adopting high-energy ball milling activation, the disadvantages of a traditional magnesium heat reduction method are improved; and by adopting a self-propagating powder technology, the product has the advantages of high purity, controllable particle size distribution and high powder activity.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com