High-strength hollow glass beads and preparation method thereof

A hollow glass microsphere, high-strength technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of insufficient compressive strength of microspheres, high alkali metal content, and low chemical composition, etc., to achieve finished products The effect of high efficiency, lower preparation temperature, and prevention of volatilization of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

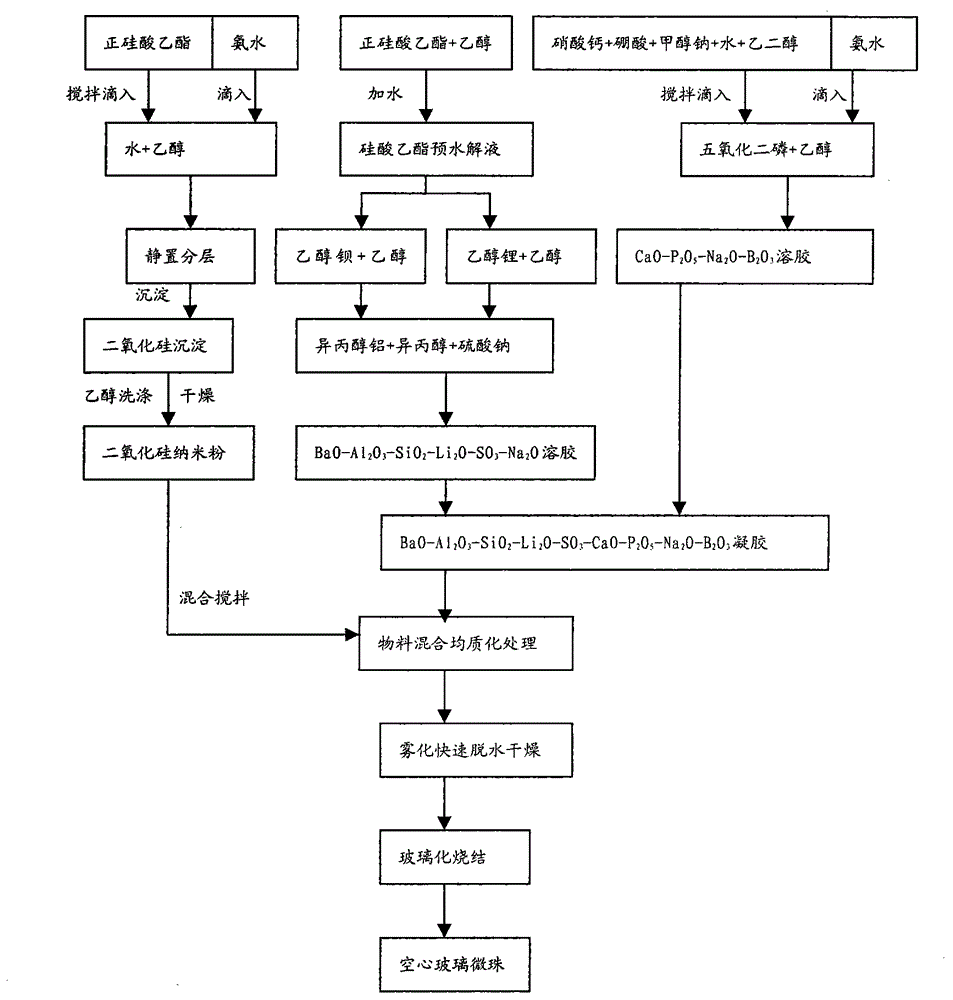

Embodiment 1

[0091] Step one is as follows:

[0092] Step 101: The raw materials used in the experiment are ethyl orthosilicate, sodium sulfate, absolute ethanol, and isopropanol, which are analytically pure; aluminum isopropoxide, barium ethoxide, and lithium ethoxide are self-synthesized by heating under reflux and vacuum distillation.

[0093] i. According to the mass percentage converted to oxides, 18% BaO, 16% Al 2 o 3 , 50% SiO 2 , 2%SO 3 , 14%Li 2 O Accurately weigh raw materials;

[0094] ii. Dissolve ethyl orthosilicate, barium ethylate and lithium ethylate with absolute ethanol, and dissolve aluminum isopropoxide and sodium sulfate mixture with isopropanol;

[0095] iii. Adopt step-by-step hydrolysis method, add a small amount of distilled water to the ethyl orthosilicate ethanol solution to partially hydrolyze in advance, add barium ethoxide ethanol solution, add lithium ethoxide ethanol solution, dissolve and then add the mixture of aluminum isopropoxide and sodium sulfate...

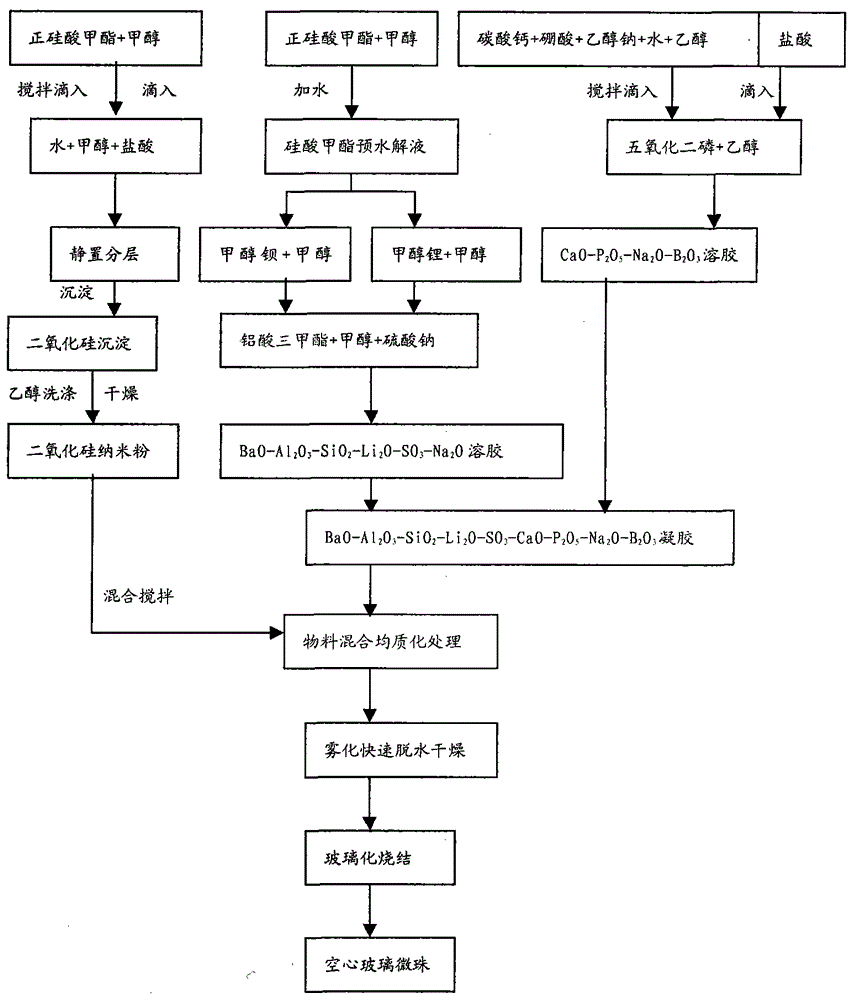

Embodiment 2

[0136] Step one is as follows:

[0137] Step 101: The raw materials methyl orthosilicate, sodium sulfate, and anhydrous methanol used in the experiment are analytically pure; trimethyl aluminate, barium methoxide, and lithium methoxide are self-synthesized by heating under reflux and vacuum distillation.

[0138] i. According to the mass percentage converted to oxides, 18% BaO, 16% Al 2 o 3 , 50% SiO 2 , 2%SO 3 , 14%Li 2 O Accurately weigh raw materials;

[0139] ii. Dissolve methyl orthosilicate, barium methylate, lithium methylate, trimethyl aluminate and sodium sulfate mixture with anhydrous methanol;

[0140] iii. Step by step hydrolysis method is adopted, methyl orthosilicate methanol solution is partially hydrolyzed in advance with a small amount of distilled water, barium methoxide methanol solution is added, lithium methoxide methanol solution is added, and methanol solution of trimethyl aluminate and sodium sulfate mixture is added after dissolution;

[0141] iv...

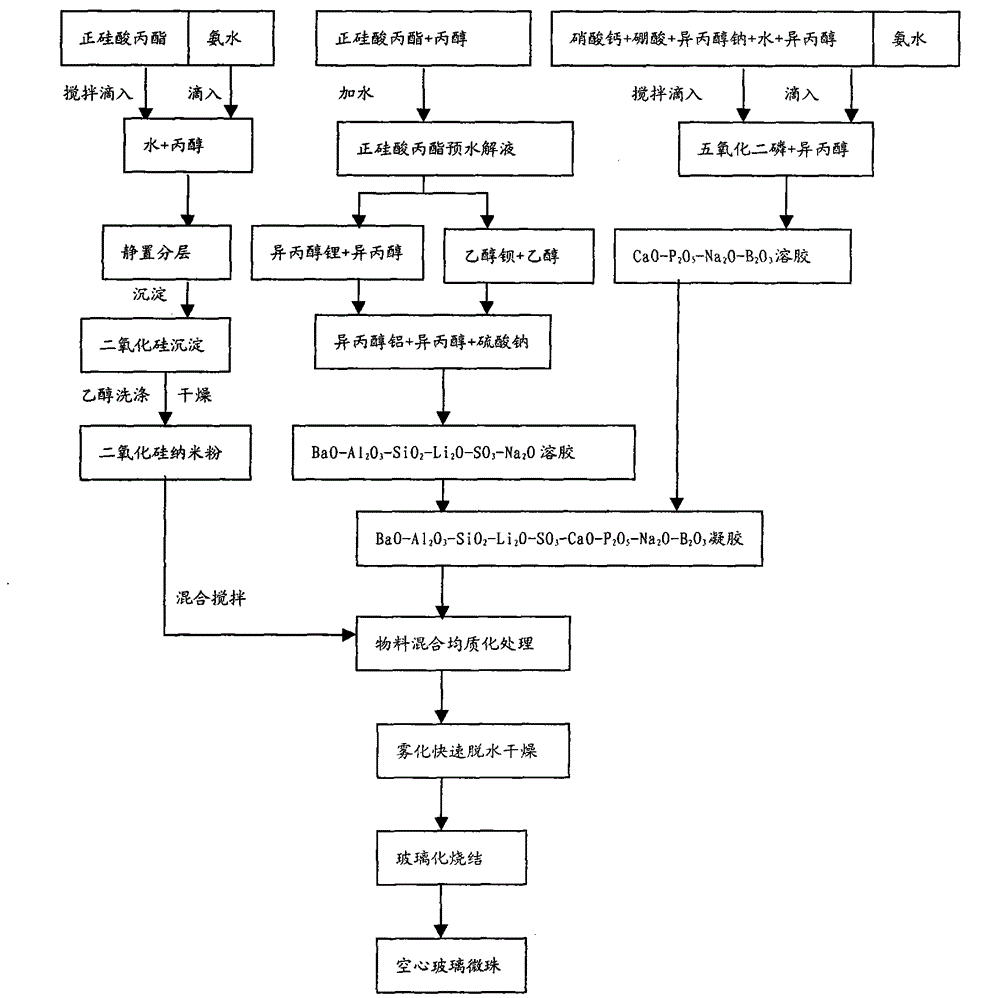

Embodiment 3

[0158] Step one is as follows:

[0159] Step 101: The raw materials of propyl orthosilicate, sodium sulfate, anhydrous propanol and isopropanol used in the experiment are analytically pure; aluminum isopropoxide, barium ethoxide and lithium isopropoxide are self-synthesized by heating under reflux and vacuum distillation.

[0160] i. According to the mass percentage converted to oxides, 18% BaO, 16% Al 2 o 3 , 50% SiO 2 , 2%SO 3 , 14% Li 2 O Accurately weigh raw materials;

[0161] ii. Dissolve propyl orthosilicate with anhydrous propanol, dissolve lithium isopropoxide, aluminum isopropoxide and sodium sulfate mixture with anhydrous isopropanol, and dissolve barium ethylate with absolute ethanol;

[0162] iii. Adopt step-by-step hydrolysis method, add a small amount of distilled water to the propyl orthosilicate propanol solution to partially hydrolyze in advance, add barium ethoxide ethanol solution, add lithium isopropoxide isopropanol solution, and then add aluminum is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com