Patents

Literature

31results about How to "Good dispersion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing organic silicon modified polyacrylic acid (polyacrylate) emulsion

The invention discloses a process for preparing organic silicon modified polyacrylic acid (polyacrylate) emulsion with high organic silicon content (15%-25%), wherein the ring-opening polymerization of epoxy silane is carried out simultaneously with the free radical polymerization of vinyl monomer, i.e., (1) ring-opening polymerization occurs to epoxy silane at the presence of catalyst, and organic (ring) siloxane containing unsaturated bonds polycondensation is carried out, thus producing organosilicon resin and organosilicon resin containing unsaturated double bonds, (2) at the presence of initiating agent, the free radical polymerization of vinyl monomer is carried out, and in-situ graft polymerization of organosilicon resin containing unsaturated bonds is carried out to prepare organic silicon-g polyacrylic acid (ester) grafted copolymer (as compatiblizing agent).

Owner:广东鸿昌化工有限公司

Multifunctional nano zinc oxide suspension and its prepn.

The invention discloses a kind of multifunctional naneo zinc oxide suspended liquor and its method of preparation, belonging to the technical field of chemical production. The multifunctional suspended liquor makes the denatured nano zinc oxide be the solid phase, it uses different surface-active agents and polymers to be the dispersed and stable phase, and it is prepared by being adopted the specific technical method make it suspended in the liquid phse of different organic solvents, water solvent and so on. The multifunctional suspended liquor made by using this method of preparation has stable disperse capability, consistent homogeneity and strong functionality, and it can be widely applied in the trades or fields of dope, ceramics, spinning and weaving, and so on.

Owner:骆天荣

Ultrasonic-assisted method for preparing polymer functionalized graphene

InactiveCN102516829AGood dispersionGood dispersion stabilityPigment treatment with macromolecular organic compoundsPigment physical treatmentSolventCvd graphene

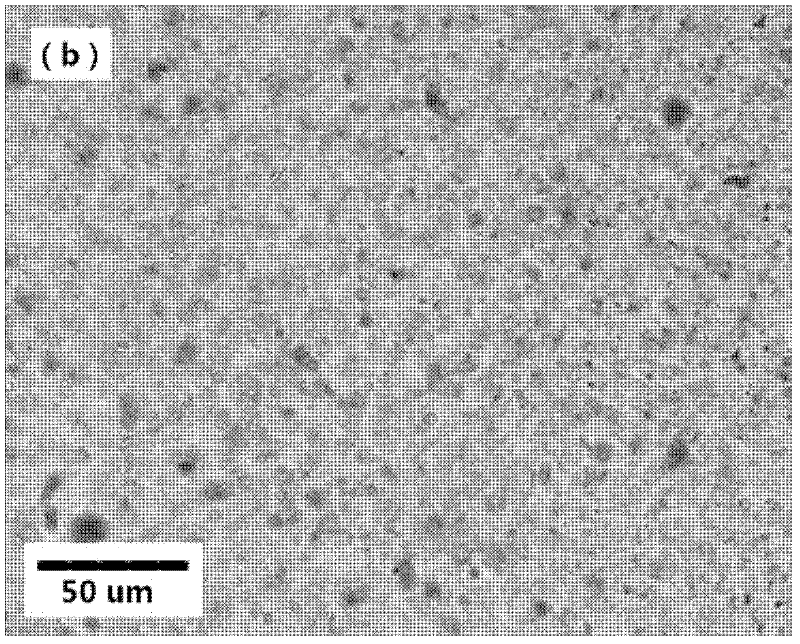

The invention discloses an ultrasonic-assisted method for preparing polymer functionalized graphene. According to the method, high-intensity ultrasonic equipment is adopted to carry out ultrasonic irradiation on a mixed solution of a polymer and graphene. By high-intensity ultrasound, on one hand, graphene layers are broken to induce the generation of a lot of reaction sites; on the other hand, a reactive macromolecular chain is generated by ultrasonic degradation of the polymer, and the reactive macromolecular chain is rapidly grafted on the graphene reaction sites, thus realizing in situ polymer functionalization of graphene. It is proved through experiments that the polymer functionalized graphene obtained by the method has high grafted polymer content and has good dispersibility and stability in a solvent and a polymer matrix. A polymer / functionalized graphene nanocomposite material prepared by the utilization of the polymer functionalized graphene has excellent mechanical properties. Therefore, in comparison with the prior art, the method is an ideal method for realizing polymer functionalization of graphene and has latent application values.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

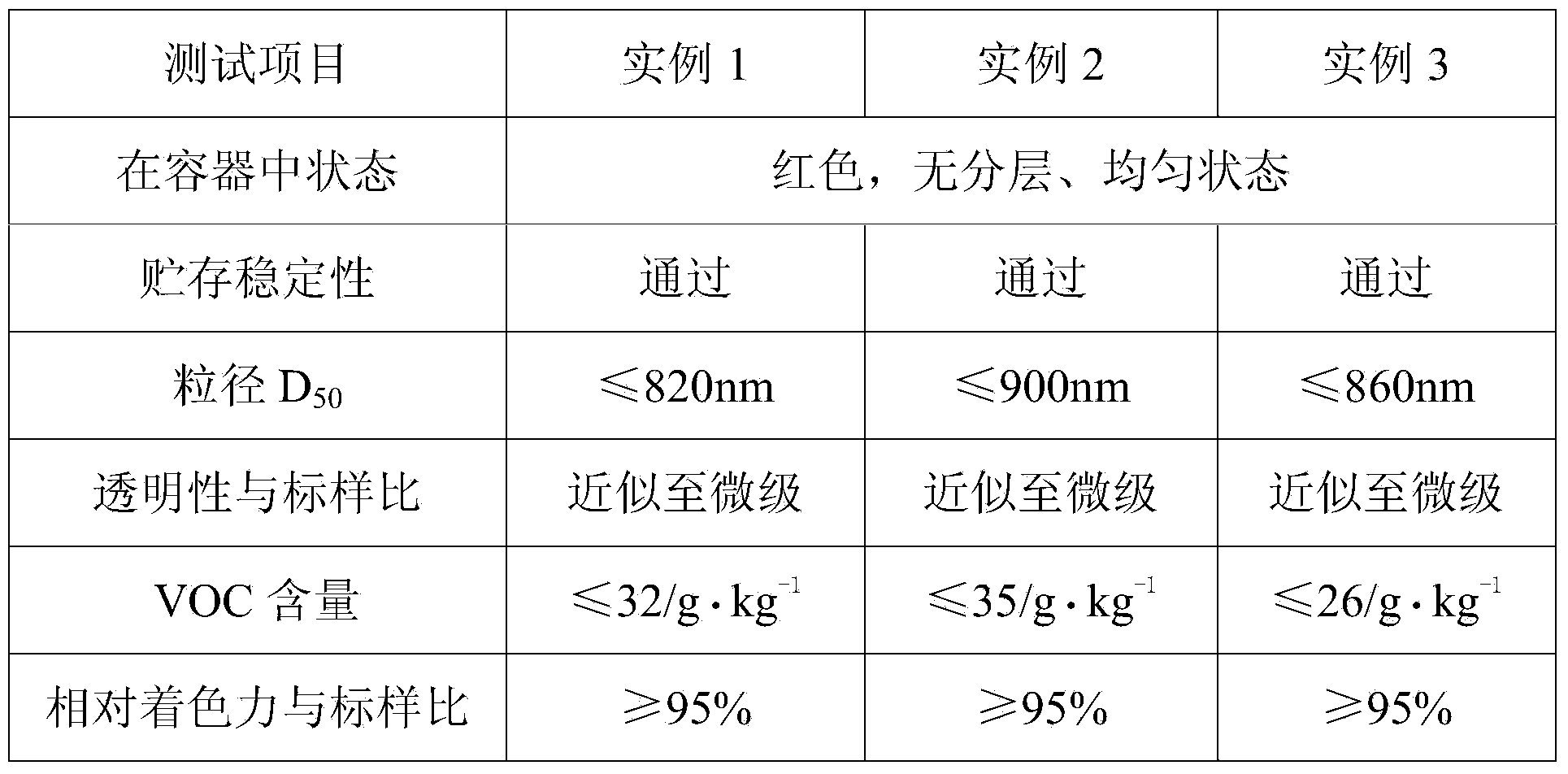

Preparation method of water and oil applicable, nano transparent iron oxide yellow paste

ActiveCN103351647AGood dispersion stabilityGood storage stabilityPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSolventIon

The invention relates to a preparation method of water and oil applicable, nano transparent iron oxide yellow paste. The yellow paste is composed of following raw materials in percentage by weight: 10% to 35% of deionized water, 3% to 10% of cosolvent, 1% to 3% of surface conditioning agent, 15 to 25% of dispersion resin, 8% to 20% of wetting dispersant, 0.1% to 0.6% of pH value conditioning agent, 20% to 40% of transparent iron oxide yellow, 0.1% to 1.0% of thickening and anti-settling agent, 0.1% to 0.3% of bactericide, and 0.2% to 1% of antifoaming agent. The particle size D50 of the water and oil applicable nano transparent iron oxide yellow paste is smaller than 1 [mu]m. The nano transparent iron oxide yellow paste has the characteristics of storage stability, transparency, compatibility and environmental-friendliness, is capable of replacing metal complex dye, and is widely applied to the areas of aqueous or oily woodenware paint, automobile finish, plastic paint, metal paint, construction paint, children toys, painting materials, high temperature glass printing ink, and the like.

Owner:英德科迪颜料技术有限公司

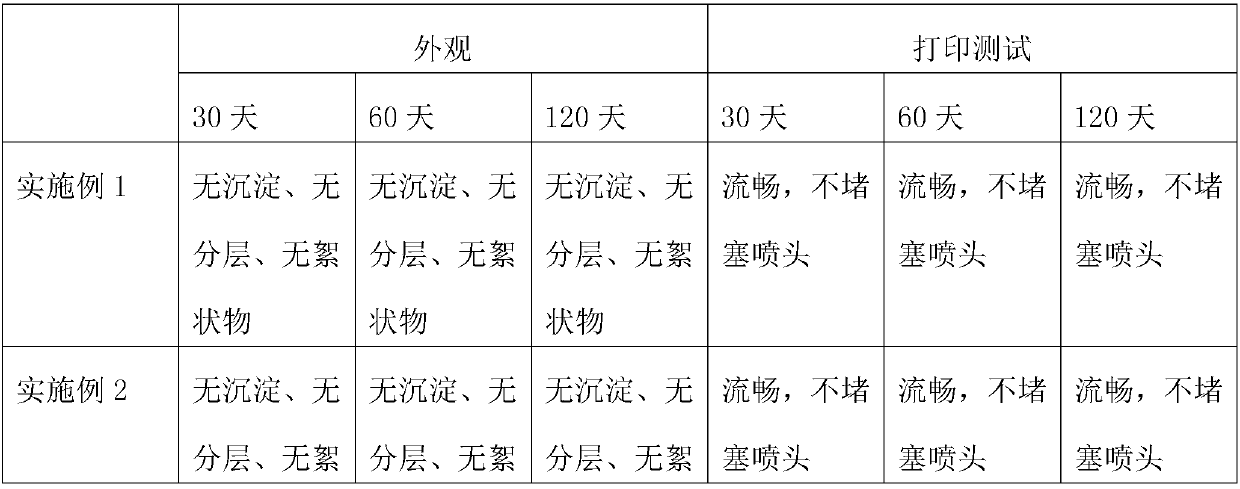

White ink pretreatment fluid as well as preparation method thereof and direct-injection digital printing process

ActiveCN107503197AGood dispersion stabilityImprove printing accuracyDyeing processDigital printingIon

The invention discloses white ink pretreatment fluid as well as a preparation method thereof and a direct-injection digital printing process, which belongs to the technical field of textile digital printing. The pretreatment fluid is prepared from the following components: 1 to 5 parts of cation colloidal silicon dioxide, 3 to 7 parts of adhesive, 2 to 6 parts of drying inhibitor, 3 to 8 parts of multivalence alkaline-earth metal salt, 3 to 8 parts of color bleeding prevention agent, 1 to 5 parts of cation mordant, 0.1 to 0.5 part of sterilizing agent, 0.1 to 0.5 part of wet defoaming agent, and 60 to 80 parts of deionized water. All raw materials are successively fed into a material machine and are respectively and uniformly stirred and filtered to obtain the white ink pretreatment fluid. The pretreatment fluid has good dispersion stability, is uniformly smeared when in use, is high in adhesive force, can prevent the seepage of the white paint direct-injection ink on the surface layer of a dark fabric, can also effectively improve the concealing capacity and adhesive force of the white paint direct-injection ink on the dark fabric, and can greatly enlarge the application range of the white paint direct-injection ink.

Owner:ZHUHAI HUACAI PRINTING SUPPLIES LTD

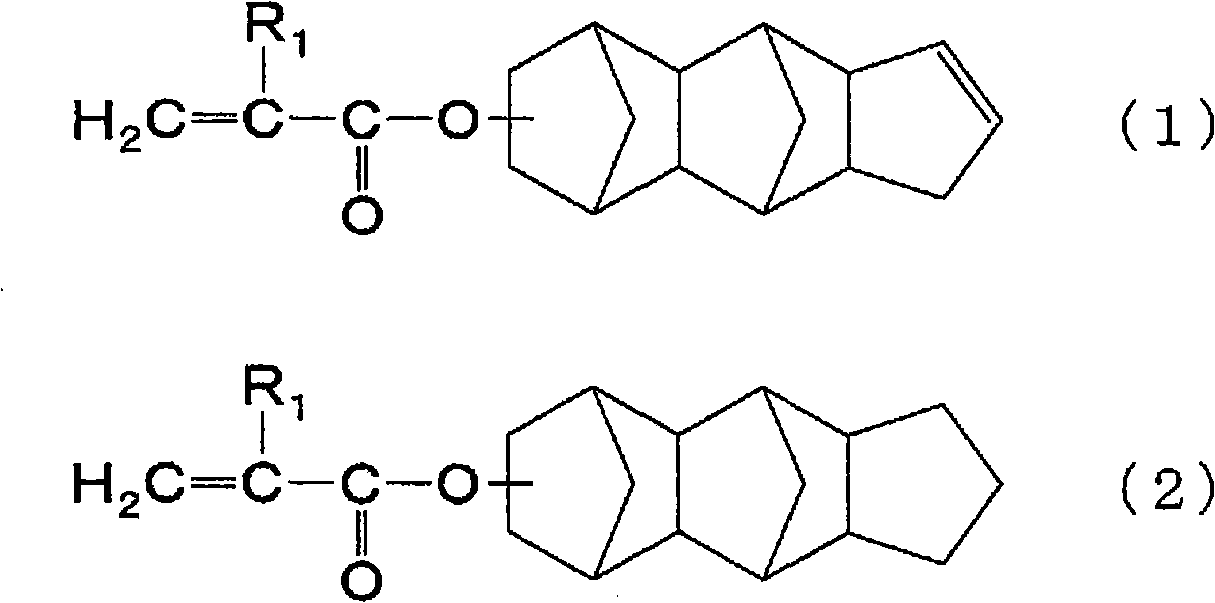

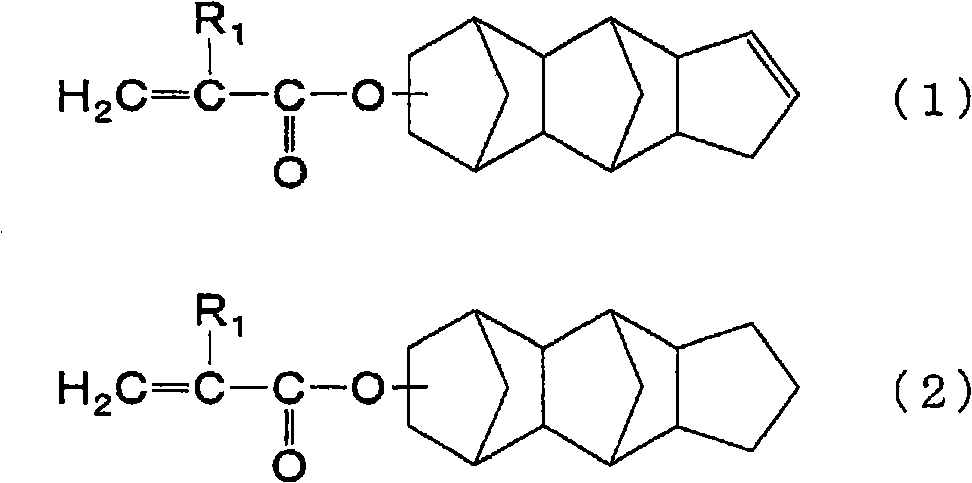

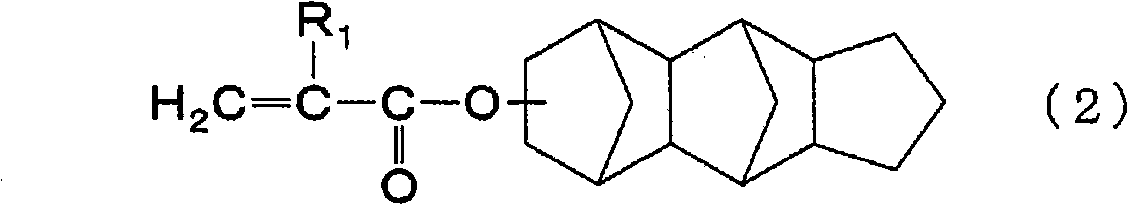

Photosensitive graft polymer, and photosensitive resin composition comprising the same

InactiveCN101821299AGood dispersion stabilityGood transparencyPhotosensitive materials for photomechanical apparatusPolymer chemistryBenzyl group

Owner:SHOWA DENKO KK

High precision composite polishing liquid, preparation method and use thereof

InactiveCN1919949AStrong suspensionGood dispersion stabilityPolishing compositions with abrasivesChemistryMonocrystalline silicon

The invention relates the high accuracy polishing liquid and its production method and usage. The method comprises the following steps: making the cerium oxide as suspending liquid, adding other nano oxidate friction material, stirring, adjusting the pH to 4-11, and getting polishing liquid. The polishing liquid can be used to polish silicon-containing compound, oxide compound, semi-conductor, conductor, glass, or monocrystalline silicon. It has advertises of high polishing efficiency and no damaging polisher.

Owner:孙韬

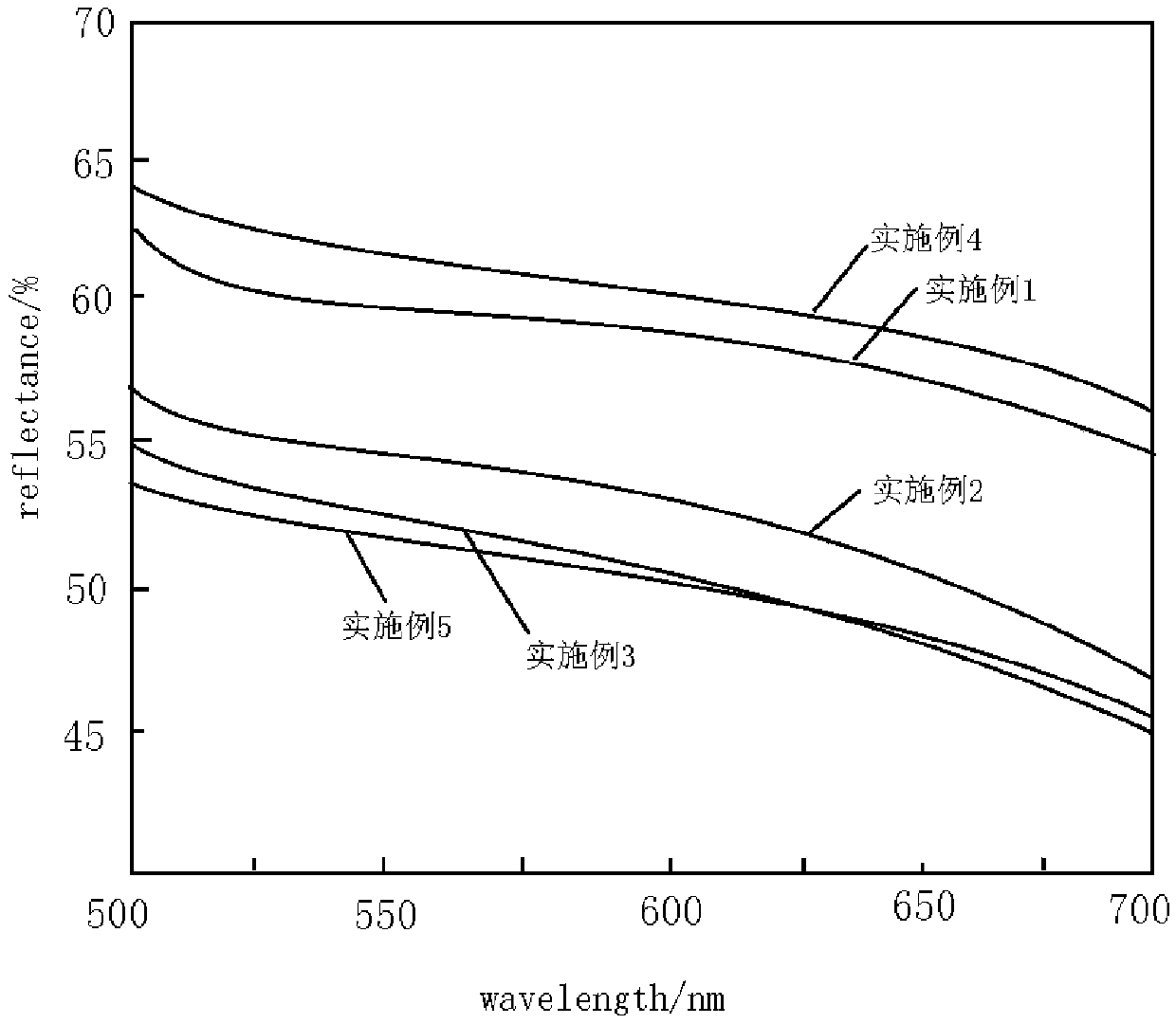

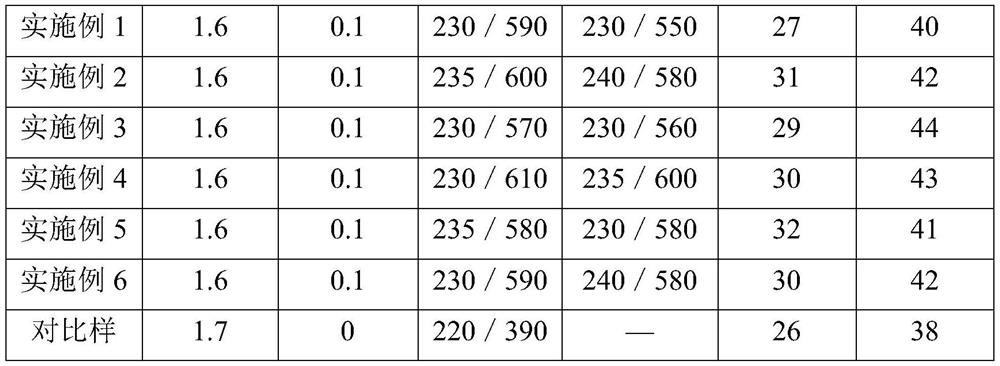

Black ceramic ink and preparation method thereof

The invention provides black ceramic ink and a preparation method thereof, and belongs to the technical field of ink preparation. The ceramic ink includes, by mass percentage, 25%-28% of a black pigment, 56%-60% of a solvent, 3%-6% of a dispersing agent BYK-2055, 3%-4.4% of organic bentonite, 0.3%-0.8% of a wetting agent Anti-terra-U, 5%-7% of a surfactant, and 0.4%-0.8% of an antifoaming agent. The black pigment is copper-chrome black doped with a small amount of aluminum oxide, and the mol ratio of the copper-chrome black to the aluminum oxide is 1 : 0.02-0.04. The ceramic ink takes the copper-chrome black as the pigment, so that the tinting strength of the ceramic ink can be enhanced through doping; through the blending of a dispersing system, excellent dispersing stability can be obtained; and through the controlling of formula composition and grinding parameters, the particle size and viscosity of the ink can accord with the requirements of an ink jet printer, so that a nozzle ofthe printer cannot be blocked.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of HA/collagen/PVP semi-interpenetrating polymer network scaffold

InactiveCN101612419AGood dispersion stabilityGood biocompatibilityProsthesisChemistryStructure and function

The invention discloses a preparation method of an HA / collagen / PVP semi-interpenetrating polymer network scaffold. The method comprises the following steps: thoroughly mixing in an alkali solution control system to form a sol system with the PVP content of 0.01-50% (by weight); aging and cleaning to obtain HA sol, and then mixing with blended solution with a mass ratio of PVP to collagen solute being 0.1-2.5:1; adding the obtained mixture containing the blended solution with the mass ratio of the solute to HA sol being 0.1-9:1 to a high-speed dispersion machine for mixing and crosslinking; and injecting the mixture into a mould, followed by post treatment to obtain the scaffold. HA prepared by the method is evenly distributed on a collagen / PVP semi-interpenetrating polymer network matrix and effectively linked with the matrix, and is in a directional arrangement, thus realizing effective combination of nano hydroxyapatite with the matrix in structure and function, and effectively solving problems existing in the collagen material. The preparation method has simple process and convenient operation and is easy to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH +1

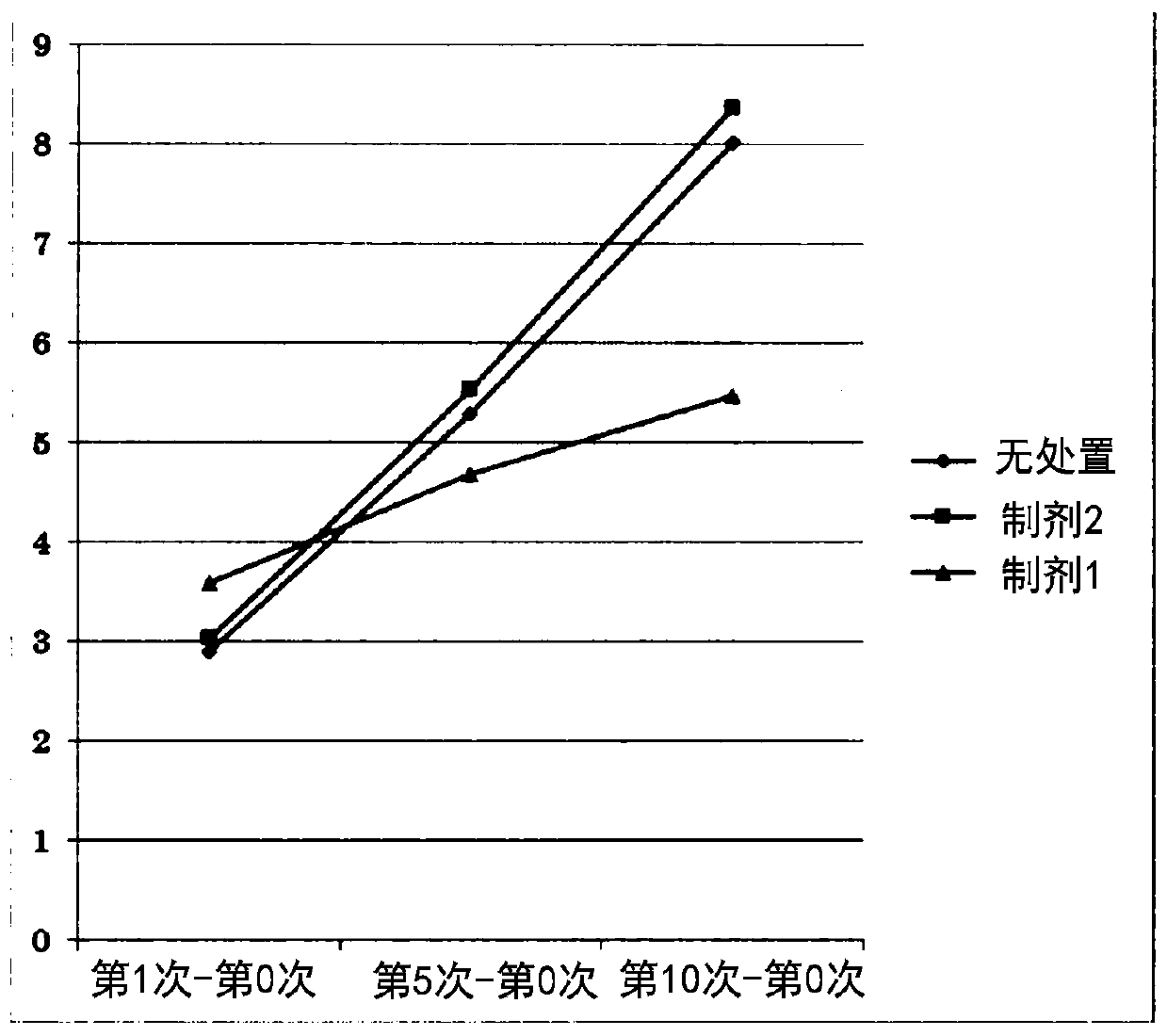

Fullerene-containing cosmetic composition

ActiveCN110769800AGood dispersion stabilityGood dispersionCosmetic preparationsHair cosmeticsComposite materialActive agent

Provided is a cosmetic composition that facilitates dispersion of fullerene in water. Also provided is a cosmetic composition which is used to prepare a fullerene-containing aqueous dispersion havinga transluscent appearance and excellent dispersion stability. A cosmetic composition containing (A) an oil agent containing 0.001-0.3% of fullerene dissolved therein, (B) a nonionic surfactant, (C) apolyvalent alcohol, (D) an oil agent, and (E) water is used. The composition preferably has a bicontinuous structure.

Owner:VITAMIN C60 BIORES

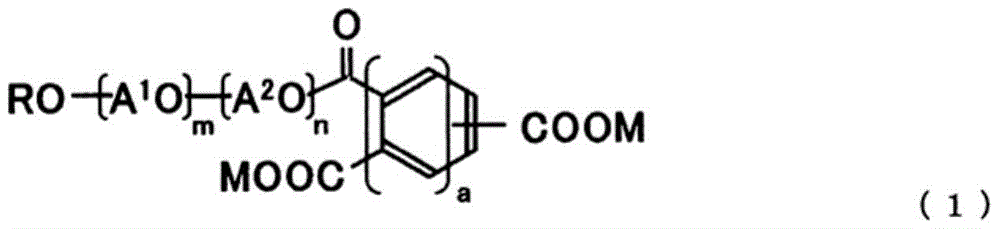

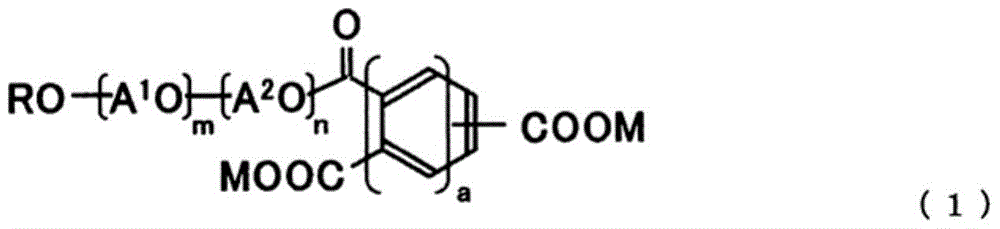

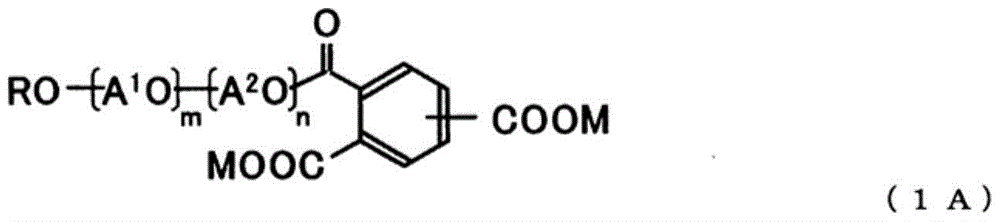

Nonaqueous dispersant and nonaqueous dispersion composition

ActiveCN105860054AGood dispersion stabilityImprove dispersion stabilityTransportation and packagingMixingSolventHigh concentration

The invention provides a non-aqueous dispersant allowing particle dispersoid to disperse into the non-aqueous solvent with high concentration, and excellent dispersion stability can be given to the particle dispersoid; the non-aqueous dispersant complies with the formula (1)(see description), wherein R refers to a linear chain or linear chain alkyl with 1-22 carbon atoms, A1O refers to oxygen ethylidene, and m is 1-30; A2O refers to oxygen alkylene with 3-4 carbon atoms, wherein n is 1-30; the following relation is complied with: 0.1<=m / n<=10 and 5<=m+n<=40, wherein a refers to aromatic nucleus number (1-2), and M refers to hydrogen atom, ammonio or alkanol ammonio.

Owner:NIPPON OIL & FATS CO LTD

Silicon carbide chemical mechanical polishing liquid with improved pH value stability, and applications thereof

ActiveCN109554119AGood dispersion stabilityDispersion stability Uniform dispersionSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesEnvironmentally friendlyMaterial supply

The invention provides a silicon carbide chemical mechanical polishing liquid with improved pH value stability, wherein the polishing liquid comprises an oxidizing agent, a high-hardness abrasive material and a pH value stabilizer, and the pH value stabilizer is aluminum nitrate. According to the present invention, the polishing liquid can well maintain the pH value stability during the chemical mechanical polishing, and has advantages of good dispersion stability and uniform dispersion; by adding the pH value stabilizer aluminum nitrate to the polishing liquid, the pH value stability of the polishing liquid during the chemical mechanical polishing is strong, and the polishing liquid is not easily subjected to hard agglomeration; and the polishing liquid is environmentally friendly, and can be used in a circulating material supply manner.

Owner:SICC CO LTD

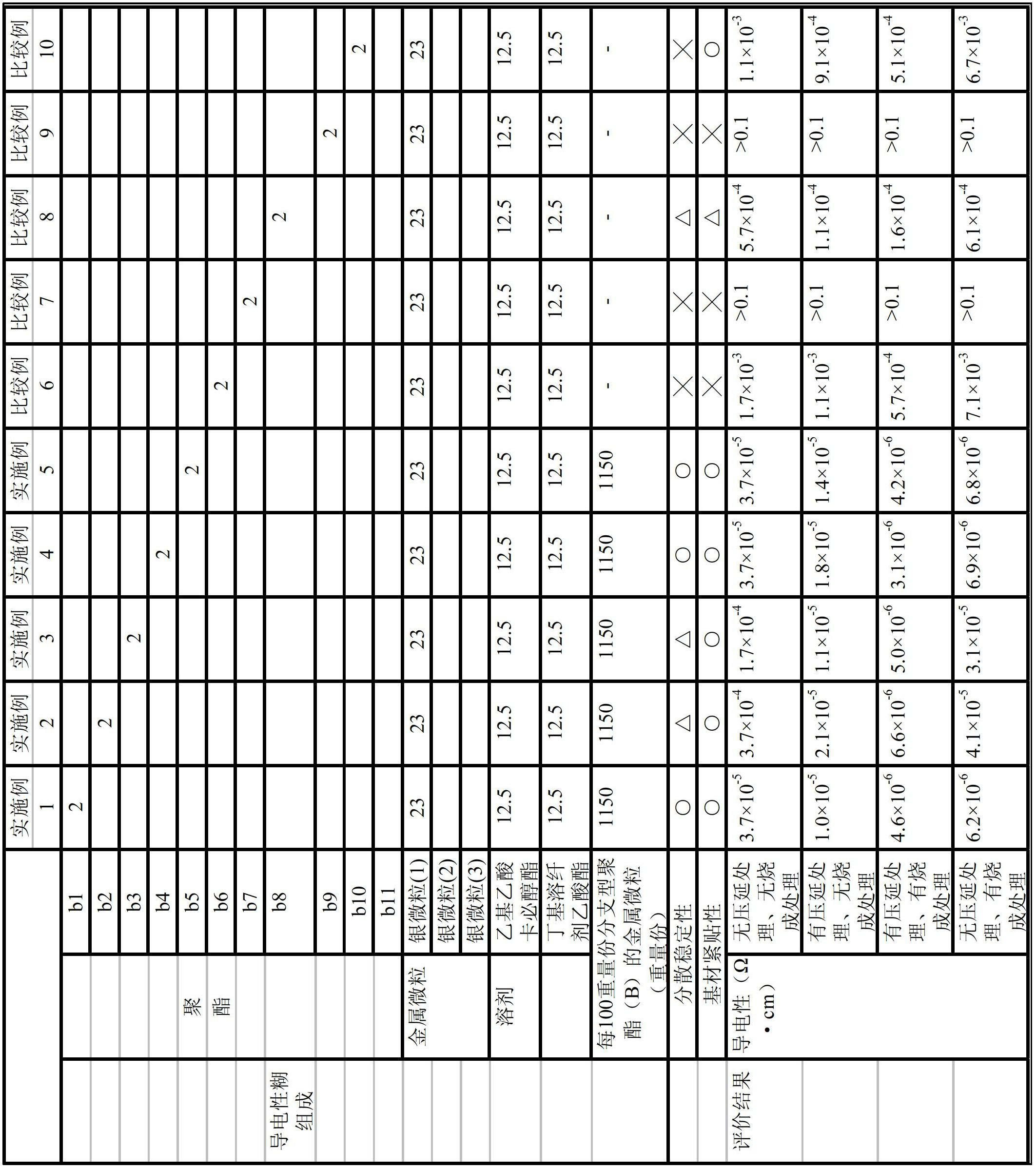

Electrically conductive paste and metal thin film

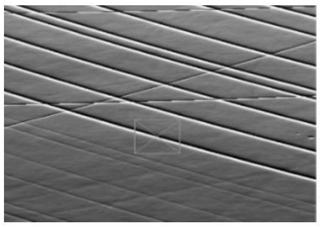

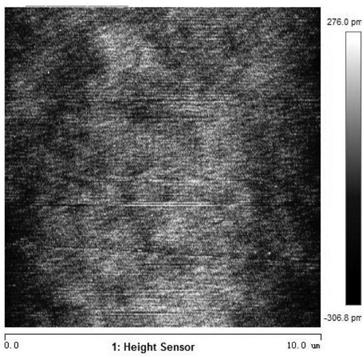

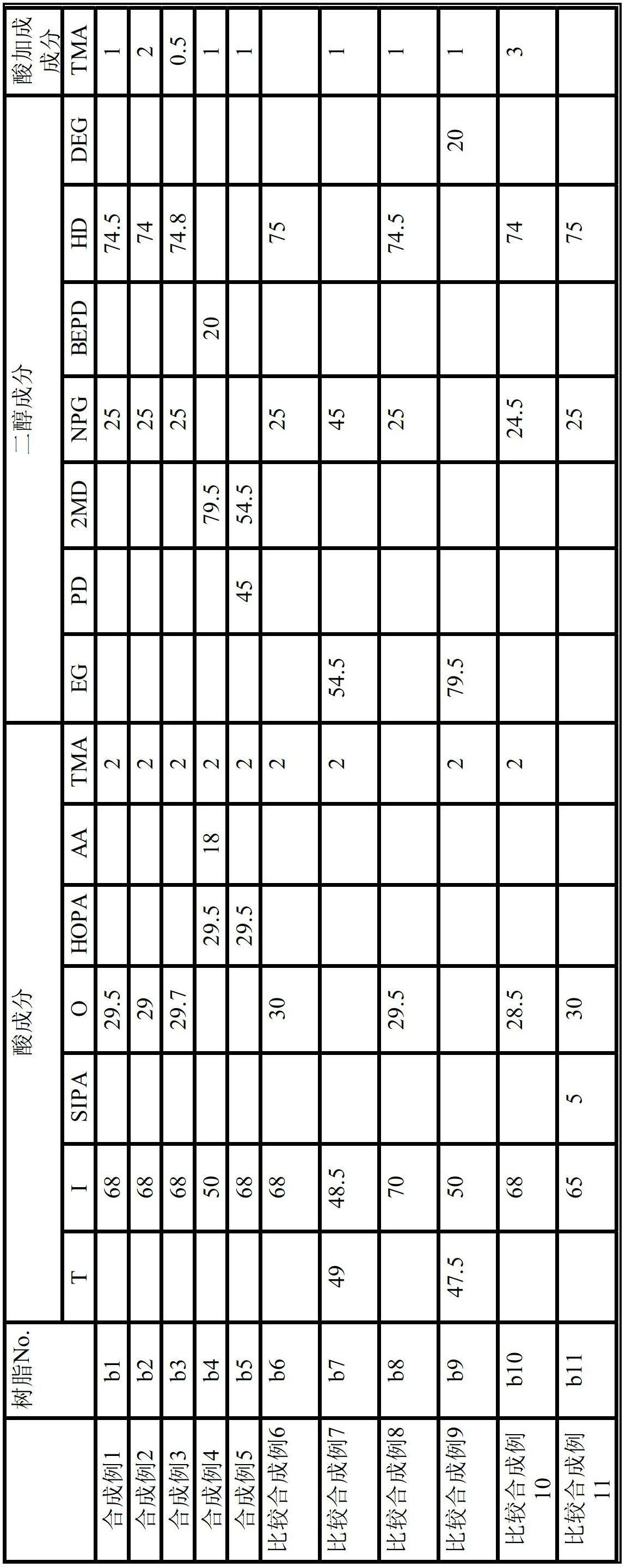

InactiveCN102696075AGood dispersion stabilityImprove dispersion stabilityConductive layers on insulating-supportsPrinted circuit aspectsDolicholOrganic solvent

An electrically conductive paste comprising metal microparticles, a branched polyester and an organic solvent, wherein the metal microparticles have an average particle diameter of 1*10-3 to 5*10-1 [mu]m inclusive, the branched polyester has a branching point derived from a polycarboxylic acid compound having a functionality of three or more and / or a polyol compound having three or more functionalities, the branched polyester has an acid value of 30 to 200 equivalents / 106 g inclusive, the branched polyester contains, as copolymerization components, at least one residue selected from an isophthalic acid residue, an ortho-phthalic acid residue and a cyclohexanedicarboxylic acid residue and a compound produced by substituting at least one hydrogen atom that is bound to a carbon atom contained in a linear alkyl diol having 3 to 5 carbon atoms by a linear alkyl group having 1 to 4 carbon atoms, the branched polyester has a glass transition temperature of lower than 40 DEG C, and the metal microparticles are contained in an amount of 600 to 1500 parts by weight relative to 100 parts by weight of the branched polyester.

Owner:TOYO TOYOBO CO LTD

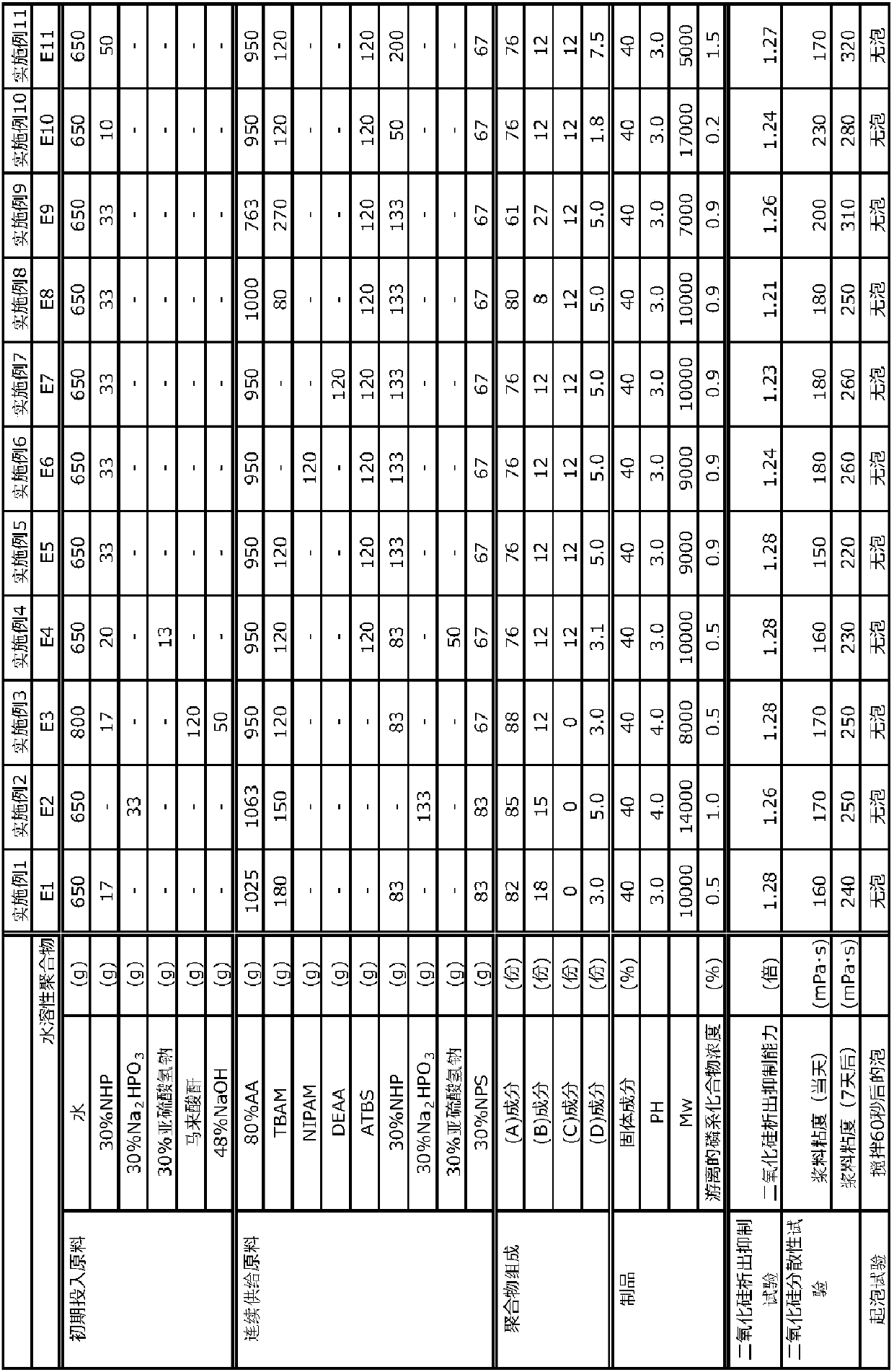

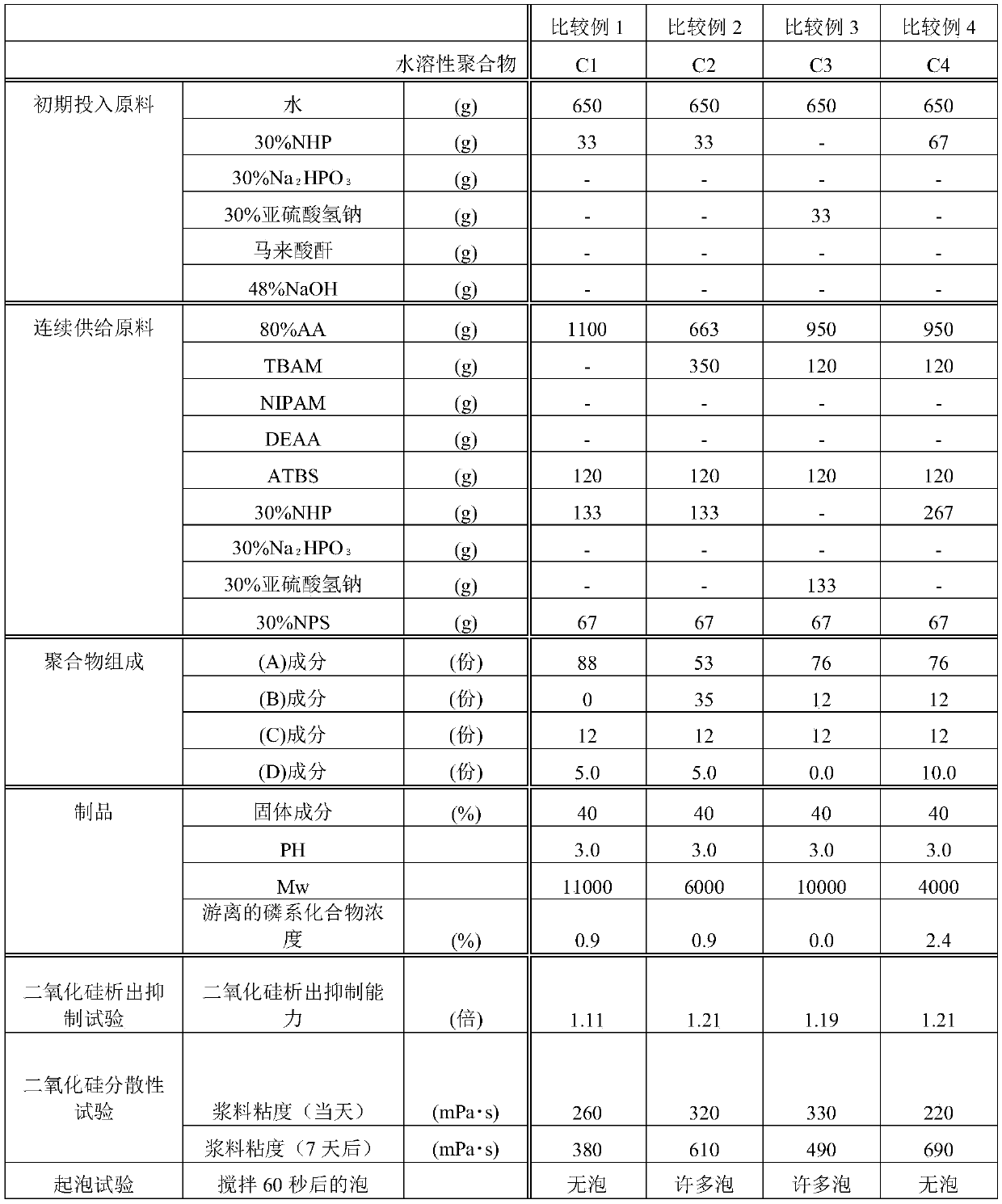

Water-soluble polymer composition, production method for water-soluble polymer composition, and application for water-soluble polymer composition

ActiveCN107849185AGood dispersion stabilityGood effectTransportation and packagingChemical industryWater soluble polymersWater soluble

A water-soluble polymer composition that includes a water-soluble polymer that includes 40-95 parts by mass of a structural unit (A) derived from a carboxyl-group-containing unsaturated monomer, 5-30parts by mass of a structural unit (B) derived from a (meth)acrylamide derivative that has a C1-8 alkyl group, and 0-35 parts by mass of a structural unit (C) derived from another monomer (provided that (A)-(C) total 100 parts by mass) and that is provided with a structural unit (D) derived from one or more compound selected from among phosphorous acid compounds and hypophosphorous acid compounds.The water-soluble polymer composition has a free phosphorus compound content of 2.0 mass% or less.

Owner:TOAGOSEI CO LTD

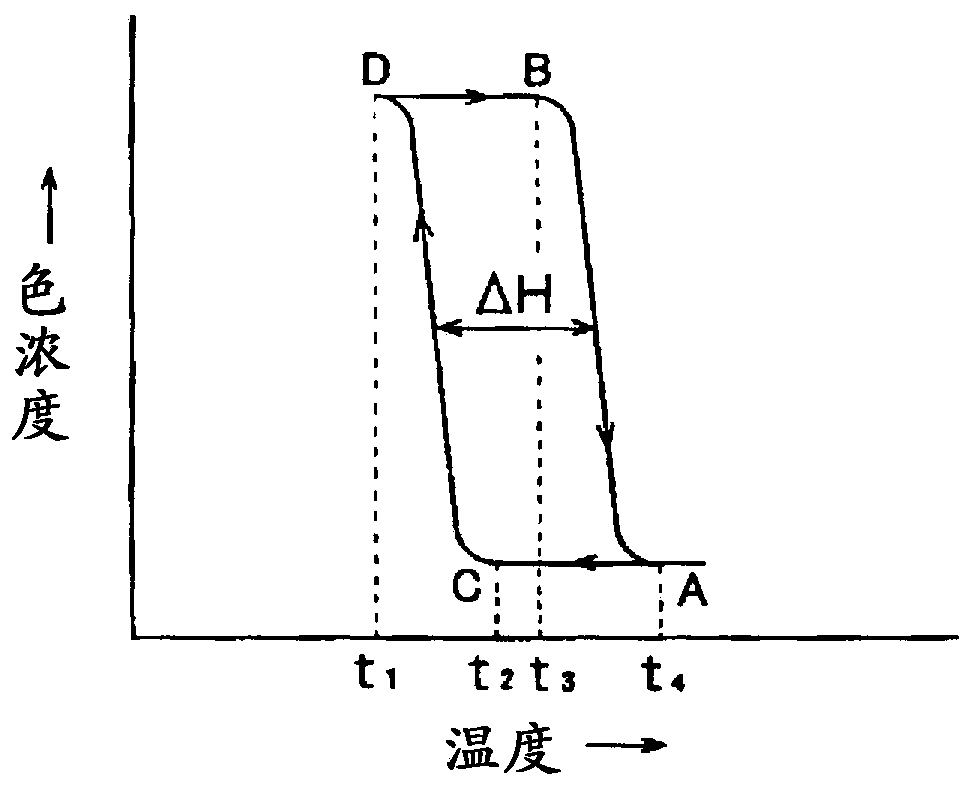

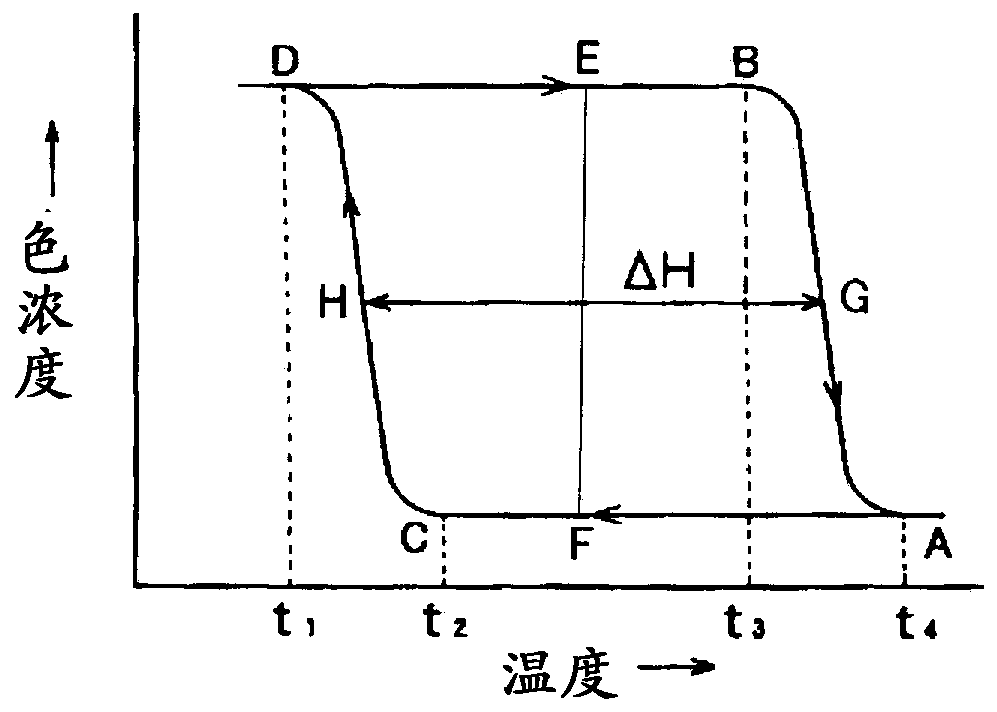

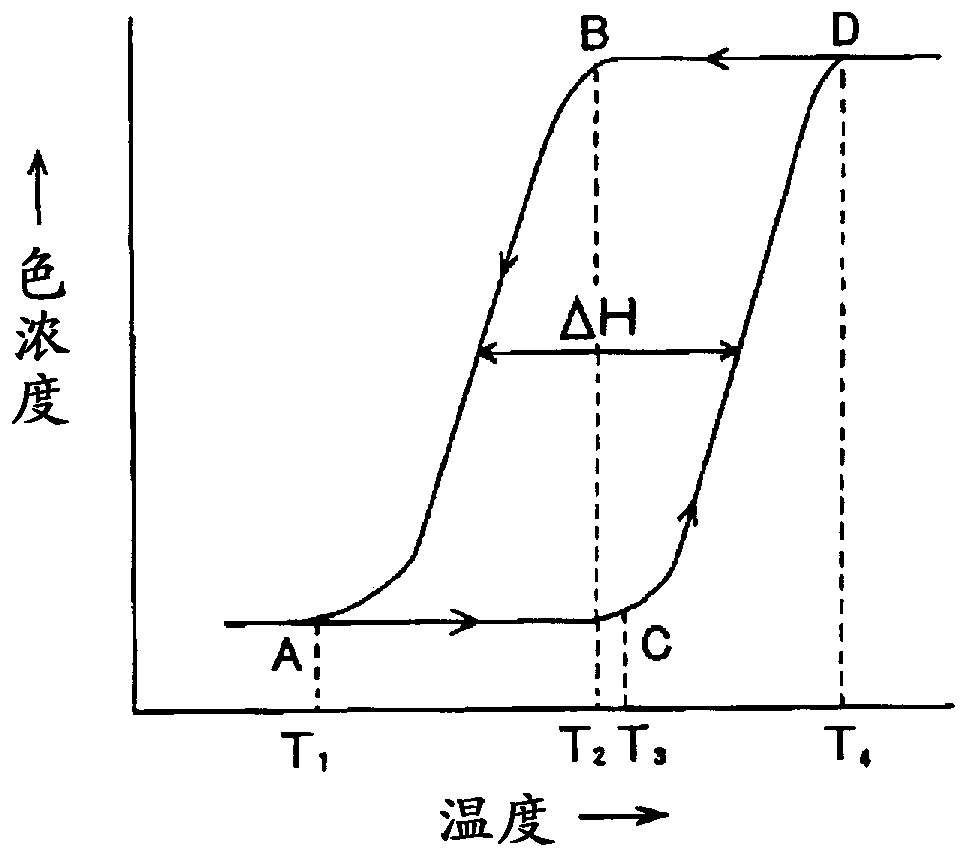

Reversible thermochromic aqueous ink composition and writing instrument using same

ActiveCN111263795AGood dispersion stabilitySettlement inhibitionInksOther pensColor reactionPolymer chemistry

To provide a reversible thermochromic aqueous ink composition that exhibits excellent dispersion stability of a reversible thermochromic microcapsule pigment; and a writing instrument using same. A reversible thermochromic aqueous ink composition that contains: a reversible thermochromic microcapsule pigment which is obtained by microencapsulating a reversible thermochromic composition containing(a) an electron-donating color-developing organic compound, (b) an electron-receiving compound, and (c) a reaction medium that determines the temperature at which a color-developing reaction between the component (a) and the component (b) takes place; and a vehicle that contains water and a specific gravity-adjusting agent selected from the group consisting of oxyacids of group 6 elements having atomic weights of 90-185 and salts thereof.

Owner:PILOT PEN CO LTD +1

Method for preparing lubricating oil through graphene and nano zinc borate whisker modified vegetable oil

InactiveCN109401824AGood dispersion stabilityGood anti-friction and anti-wear propertiesPolycrystalline material growthFrom normal temperature solutionsCvd grapheneChemistry

The invention discloses a method for preparing lubricating oil through graphene and nano zinc borate whisker modified vegetable oil. The method comprises the steps that methanol is added into the vegetable oil, stirring is conducted in a water bath, after a catalyst is added for a reaction, natural cooling is conducted, standing for layering is conducted, upper-layer vegetable oil methyl ester iscollected, washing is conducted, standing for layering is conducted for removing a water phase, an oil phase is dried, and thus vegetable oil methyl ester is obtained; the vegetable oil methyl ester is preheated in the water bath, glacial acetic acid and a catalyst are added, hydrogen peroxide is dropwise added while stirring, after a heat-preservation reaction is conducted, standing is conductedfor removing a water layer, an oil layer is washed with a hot sodium carbonate solution and then washed with saturated salt water to be neutral, decompressed rotary evaporation is conducted for removing moisture, and thus epoxidized vegetable oil methyl ester is obtained; and composite nano-powder modified by surface grafting, surface-treated nano-copper and graphene modified through combination of obtained oleic acid and stearic acid and a modified nano zinc borate whisker are added into the obtained epoxidized vegetable oil methyl ester, sufficient and uniform mixing is conducted, and thus the lubricating oil is prepared.

Owner:界首永恩机电科技有限公司

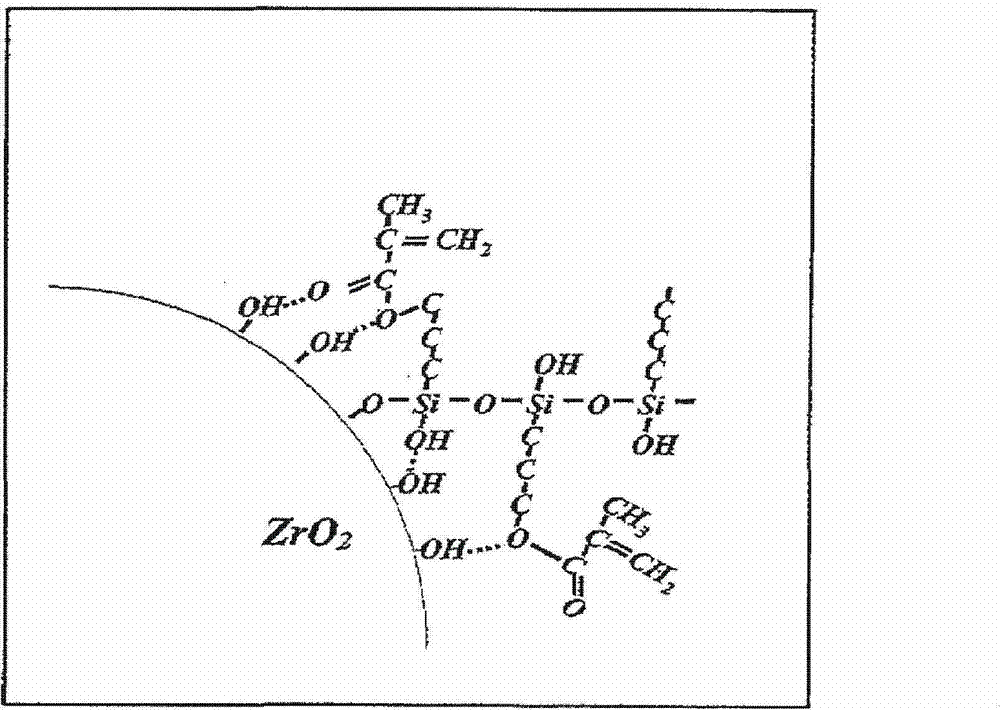

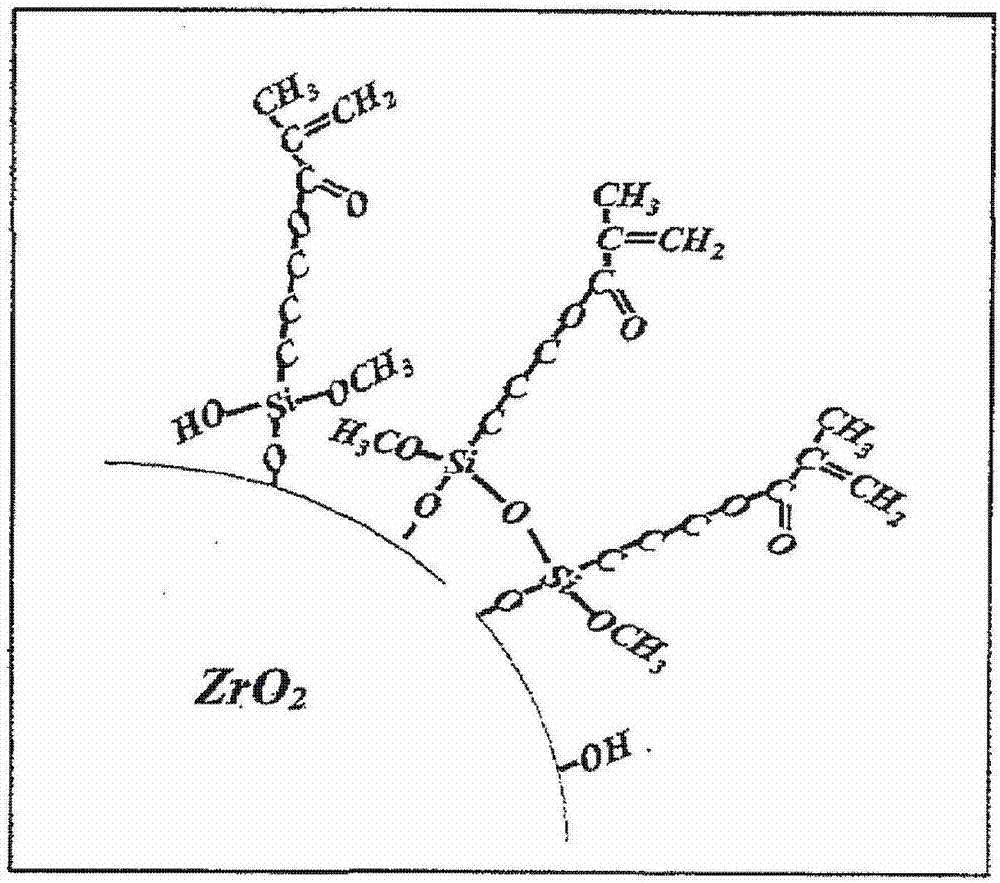

Modified zirconium oxide particle powder, modified zirconium oxide particle dispersed sol and making method thereof

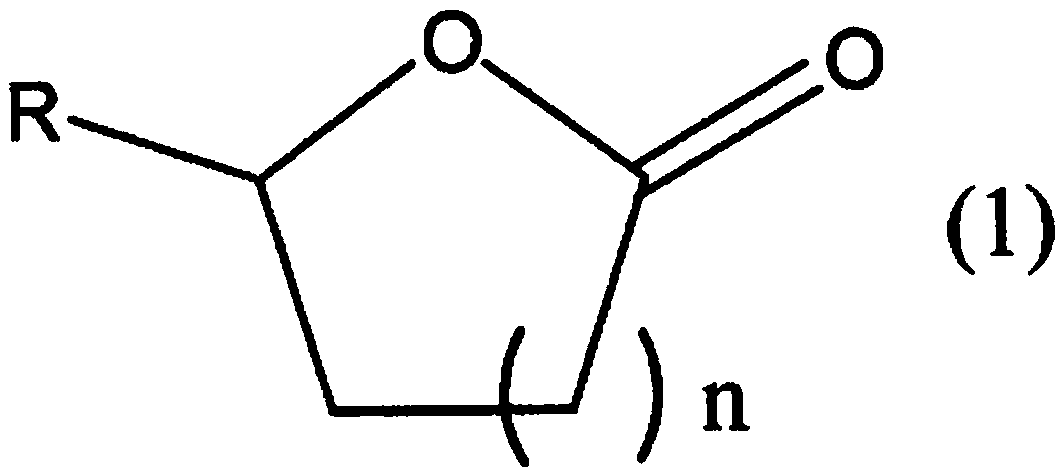

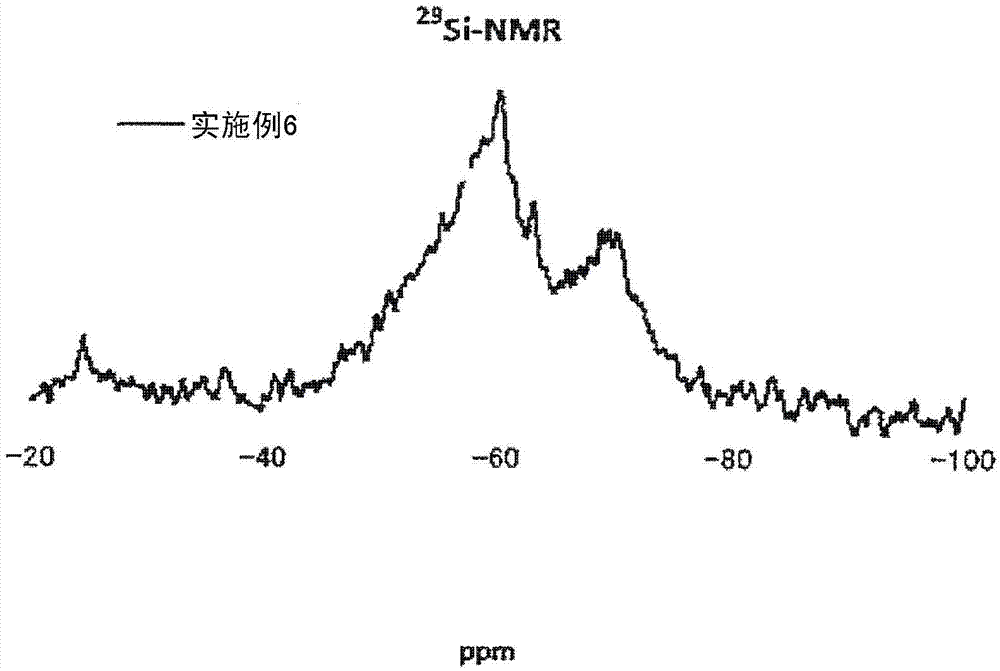

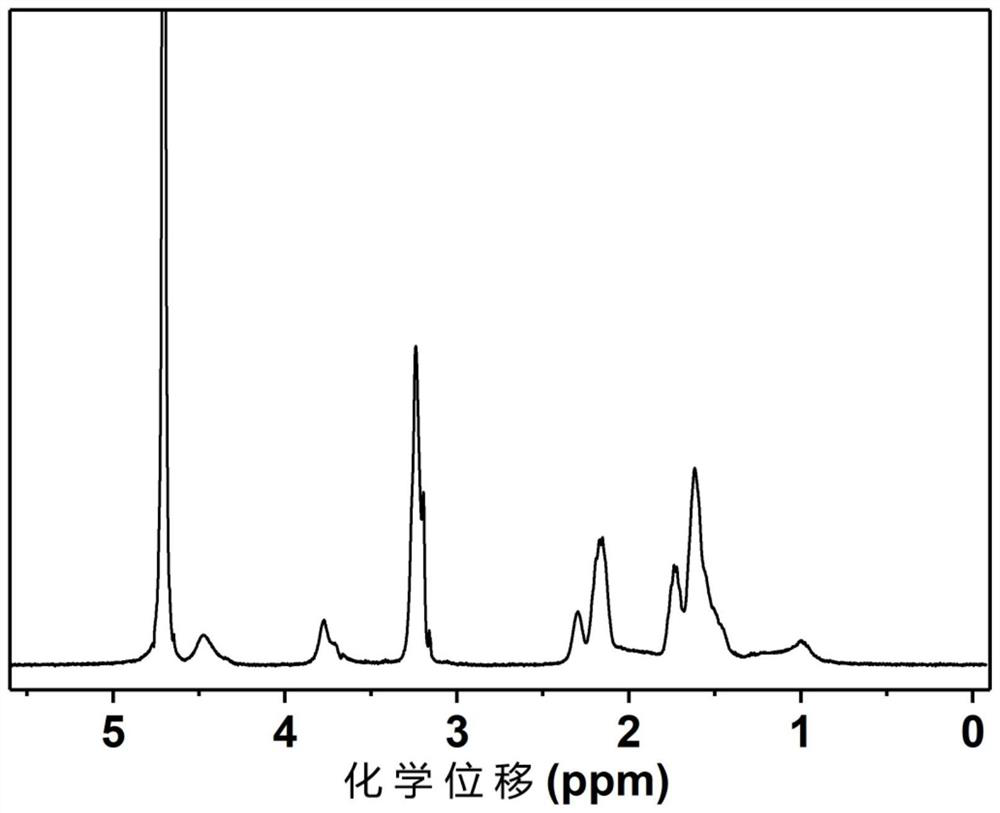

The invention provides modified zirconium oxide particle powder with excellent dispersibility and fluidity, a modified zirconium oxide particle dispersed sol and a making method thereof. Being the powder of modified zirconium oxide particles subjected to organosilicon compound surface treatment, the powder is characterized in that, an average secondary particle size (DM2) is in the range of 5-500nm, an average primary particle size (DM1) is in the range of 5-500nm, and the ratio (DM2) / (DM1) of the average secondary particle size (DM2) to the average primary particle size (DM1) is in the range of 1-10. The organosilicon compound is shown as the formula (1). The content of the organosilicon compound in the particle is, in terms of Rn-SiO(4-n) / 2( with n being an integer of 1-3), 1-50wt%, and the half width of the main peak of the <29>Si MAS NMR spectrum is in the range of 3-15ppm. Rn-SiX4-n (1) (In the formula, R is bstituted or substituted alkyl of C1-10, and can be the same to each other or different, X can be alkoxy, hydroxy, halogen and hydrogen of C1-4, and n is an integer of 1-3).

Owner:JGC CATALYSTS & CHEM LTD

Large-pore composite plugging system and preparation method thereof

ActiveCN103773342AGood dispersion stabilityImprove dispersion stabilityDrilling compositionLarge poreSurface-active agents

The invention provides a large-pore composite plugging system and a preparation method thereof, belonging to the technical field of oil exploitation. The large-pore composite plugging system comprises amphoteric polyacrylamide solution with concentration of 0.2-0.5wt%, a flocculation agent solution and inorganic granules, wherein the flocculation agent solution is a cationic polymer solution with concentration of 0.2-0.5wt% or cationic surface active agent with concentration of 1-4wt%. The large-pore composite plugging system has the advantages of high elasticity, high plugging capability, movability and good thermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acid polishing solution for surface machining of glass and silicon-contained compound

InactiveCN102649897AStrong suspensionGood dispersion stabilityPolishing compositions with abrasivesChemistryOxide

The invention relates to the technical field of acid polishing solution based on rear-earth oxide for surface machining of glass and a silicon-contained compound, in particular to acid polishing solution for surface machining of the glass and the silicon-contained compound, which contains cerium-contained rear-earth oxide polishing powder and carboxylic polymer with molecular weight of 100 to 4000 and containing anhydride or amide groups, and the pH value of the acid polishing solution is 2.0 to 5.0. The acid polishing solution is uniform to disperse and has high production efficiency and stable product quality. Meanwhile, due to the adoption of the acid polishing solution, the surface scratch of an article to be polished can be greatly reduced, the abrasion of a polishing machine can be reduced, and the service life of the polishing machine can be prolonged. When the polishing solution is prepared, less polishing powder is used, easiness in cleaning is realized, and environmental pollution can be reduced.

Owner:JIANGSU SINO KRYSTALS OPTROINCS

Nano-carbon molecular high-performance lubricating oil

The invention discloses a nano-carbon molecular high-performance lubricating oil. The lubricating oil is prepared by taking mineral oil, engine oil, trimethylolpropane trioleate and glycerol ester of hydrogenated rosin as main ingredients and adding nano polytetrafluoroethylene, acrylic resin, propyl p-hydroxybenzoate, cetyl alcohol, nano-carbon, alkoxyl phosphate, acetyl tributyl citrate, hydroxybenzotriazole, overbased sulfurized calcium alkyl phenolate, methyl 4-bromo-5-azaindole-2-carboxylate, diisobutylene and surface modifier through heating stirring, ultrasonic dispersion, heating insulating, defoaming, mechanical shearing and other processes. Therefore, the lubricating oil has excellent dispersion stability and heat resistance, does not easily cause adhesion, can meet the requirement of industry, and has a relatively good application prospect.

Owner:方珺

Ceramic polymer anti-abrasion polypropylene composite material and preparation method thereof

The invention relates to a ceramic polymer anti-abrasion polypropylene composite material. The ceramic polymer anti-abrasion polypropylene composite material is prepared from the following raw material components: polypropylene, a ceramic polymer, metal alloy powder, polysulfide rubber, epoxy octyl stearate, diisodecyl pentaerythritol diphosphite and zinc stearate, wherein the ceramic polymer is prepared by virtue of the reaction of silicic acid, titanic acid, tungstic acid, molybdic acid, gallic acid, dimethylaminoethyl acrylate, acrylamide and benzoin methyl ether, the metal alloy powder is prepared by virtue of the reaction of zinc stearate, calcium stearate, copper stearate, 1-ethyl-3-methylimidazolium ethylsulfate and modified potassium powder, and the modified potassium powder is prepared by virtue of the reaction of potassium powder, 1-ethyl-3-methylimidazolium ethylsulfate, sodium dodecyl benzene sulfonate and methyl methacrylate. The ceramic polymer anti-abrasion polypropylene composite material has excellent abrasion resistance and mechanical strength.

Owner:周佳瑜

Lubricating oil additive and preparation method thereof

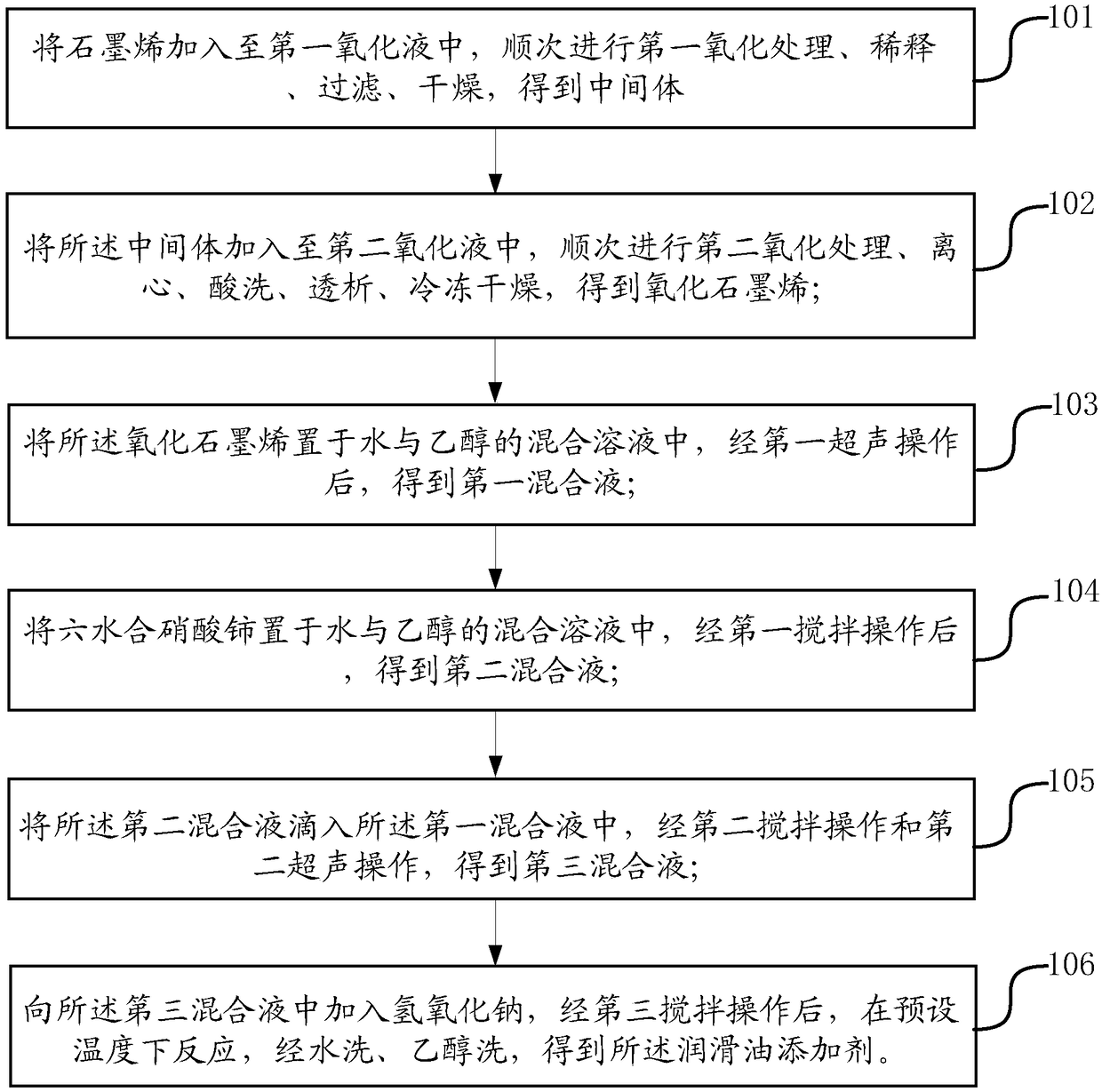

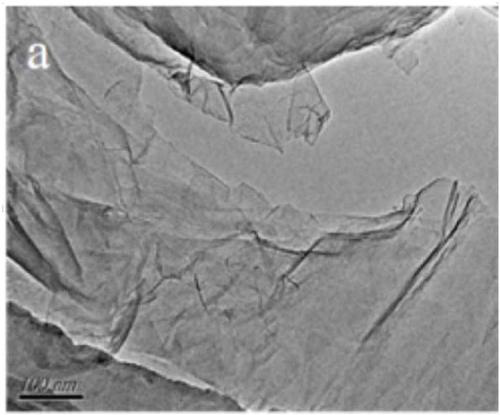

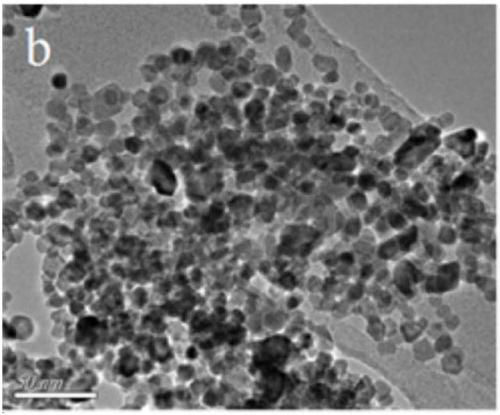

The invention discloses a lubricating oil additive and a preparation method thereof and belongs to the field of lubricating oil. The preparation method of the lubricating oil additive comprises stepsas follows: graphene is added to a first oxidation liquid for sequential primary oxidation treatment, dilution, filtration and drying, and an intermediate is obtained; the intermediate is added to a second oxidation liquid for sequential secondary oxidation treatment, centrifugation, acid pickling, dialysis and freeze-drying, and graphene oxide is obtained; the graphene oxide is placed in a waterand ethyl alcohol mixed solution, and a first mixed solution is obtained after primary ultrasonic operation; cerium nitrate hexahydrate is placed in the water and ethyl alcohol mixed solution, and a second mixed solution is obtained after primary stirring operation; the second mixed solution is dropped into the first mixed solution, and a third mixed solution is obtained through secondary stirringoperation and secondary ultrasonic operation; sodium hydroxide is added to the third mixed solution, after tertiary stirring operation, a reaction is realized at the preset temperature, and the pollution-free lubricating oil additive having the good lubricating effect is obtained through washing with water and washing with ethyl alcohol.

Owner:CHERY AUTOMOBILE CO LTD

Light-resistant graphene UV ink and preparation method thereof

InactiveCN113755051AGood dispersion stabilityExtended photoresponse rangeInksPhotoinitiatorEthylenediaminetetraacetic acid

The invention discloses light-resistant graphene UV ink and a preparation method thereof. The light-resistant graphene UV ink comprises light-resistant graphene UV ink; and the light-resistant graphene UV ink is prepared from polyurethane acrylic resin, photocatalytic modified graphene, pigment, a photoinitiator, a dispersing agent, an auxiliary and filler. The specific preparation process comprises the following steps: weighing a certain amount of Bi(NO3)3.5H2O, dissolving the Bi(NO3)3.5H2O in an HNO3 aqueous solution, adding ethylenediamine tetraacetic acid (EDTA) with a certain concentration, meanwhile, weighing a certain amount of NH4VO3, dissolving the NH4VO3 in deionized water, and conducting heating and stirring at 45 DEG C until the solution is clear, so as to obtain a BiVO4 precursor solution; step 2, preparing photocatalytic graphene UV ink, and conducting storing in a dark place; and step 4, filtering the photocatalytic graphene UV printing ink, adding the filtered photocatalytic graphene UV printing ink into an ink fountain, and carrying out PVC film unwinding, intaglio printing (coating), air box drying, UV curing, protective layer coating, air box drying and winding to obtain a finished product. A high-temperature and high-pressure reaction kettle is adopted for preparation, blending and storage are performed under the dark condition, the preparation process is simple, the yield is high, the product validity period is long, and the method is suitable for industrial production.

Owner:南通吉美装饰材料有限公司

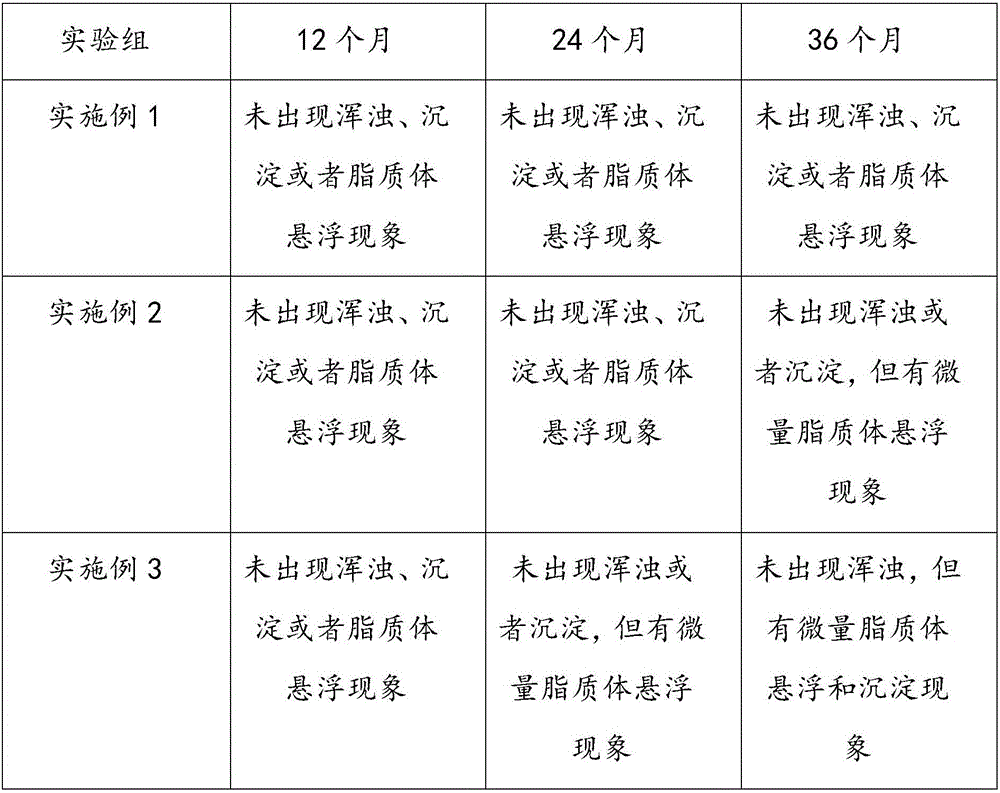

Liposome and preparation method thereof

InactiveCN106389334AGood dispersion, stabilityGood stabilityPharmaceutical non-active ingredientsLiposomal deliveryChemistryLiposome

The invention provides liposome and a preparation method thereof. According to the method provided by the invention, phospholipid and water are stirred and mixed; then, grinding and polishing are performed, so that the phospholipid can be effectively scattered in the water body, and can be mixed with the water body; further, the prepared phospholipid has high stability; in addition, the liposome can be stored for a long time at normal temperature without deterioration.

Owner:刘彦博

Method for preparing dispersant of coal-water slurry with fish sauce mix leavening product

The invention relates to a method for preparing a dispersant of coal-water slurry with fish sauce mix leavening product, and belongs to the technical field of dispersant preparation. The method comprises the steps of conducting mix fermentation on fish sauce extracting solution, plant and animal viscera, performing alkaline leaching and extraction on fermentation liquor, and obtaining the dispersant of coal-water slurry after concentration. According to the method for preparing the dispersant of coal-water slurry with the fish sauce mix leavening product, the prepared dispersant utilizes the combined action of rich amino acid in the fish sauce and humus produced from biomass fermentation, then uses lye to extract and obtain a long-chain surface active material lined with rich functional groups of carboxyl, phenolic hydroxy, amidogen, sulfonic acid group and the like, utilizes the hydrophobic group of the long-chain surface active material to be firmly absorbed on the surfaces of coal particles with hydrophilic radical exposed, forms shells on the particle surfaces, changes the surface wettability of the coal particles, enlarges the contact distance among particles at the same time, reduces the Van der Waals force effect among particles, improves the hydrophilia on the surfaces of the coal particles, enlarges surface streaming potential, accordingly makes the coal particles easy to disperse, forms even and stable low-viscosity coal-water slurry, and has a wide application prospect.

Owner:袁春华

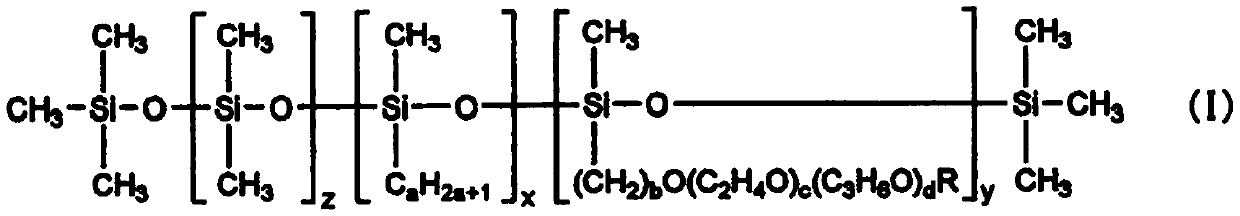

Water-in-oil type cosmetic emulsion preparation

PendingCN109922780AGood dispersion stabilitySuppress Color StreaksCosmetic preparationsBody powdersAmino acidMethyl palmoxirate

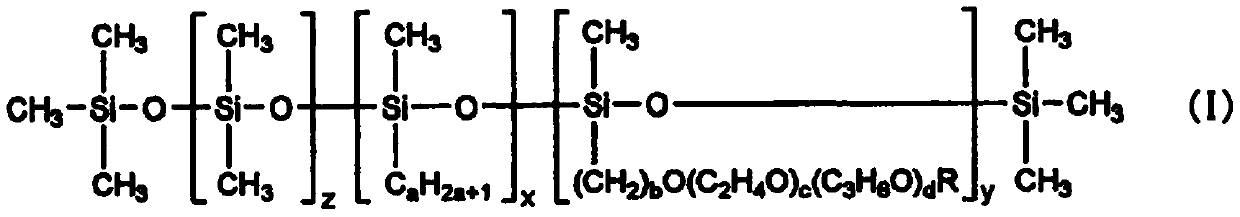

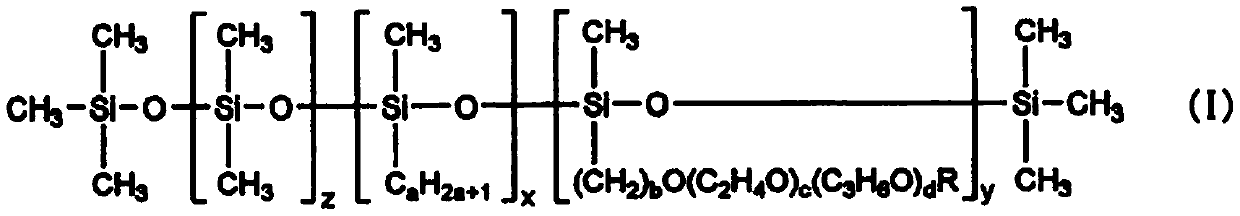

The purpose of the present invention is to provide a low-viscosity water-in-oil type cosmetic emulsion preparation which gives a smooth use feeling, lightly spreads when applied, and has excellent dispersed-powder stability. The cosmetic emulsion preparation of the present invention is characterized by comprising (A) a polar oil which is liquid at 25 DEG C and has an IOB value exceeding 0.1, (B) ahydrocarbon oil, (C) a polyoxyalkylene- and alkyl-modified organopolysiloxane represented by general formula (I), and (D) a powder surface-treated with both an N-acylamino acid and methylpolysiloxane. In formula (I), R represents a hydrogen atom or a C1-5 alkyl group, x is an integer of 5-50, y is an integer of 1-30, z is an integer of 20-200, a is an integer of 2-20, b is an integer of 1-5, c isan integer of 2-20, and d is an integer of 0-20.

Owner:SHISEIDO CO LTD

High-performance glass polishing solution

InactiveCN105778773AGood dispersion stabilityImprove flattening and polishing efficiencyPolishing compositions with abrasivesChemistryOxide

The invention relates to the technical field of daily chemical engineering, and concretely relates to a high-performance glass polishing solution. The glass polishing solution comprises, by weight, 1-10% of rare earth oxide, 0.5-10% of a polymer dispersant, 0.1-10% of a multifunctional group accelerator, 1-30% of potassium phosphate and 0.01-10% of a surfactant. The purpose of the invention is to provide the high-performance glass polishing solution in order to solve problems existing in the prior art.

Owner:王叶苗

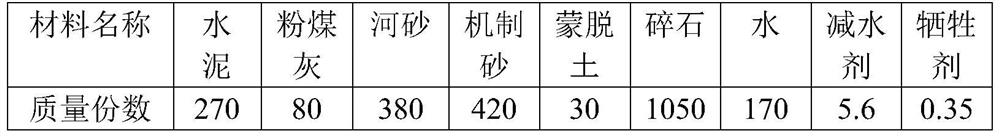

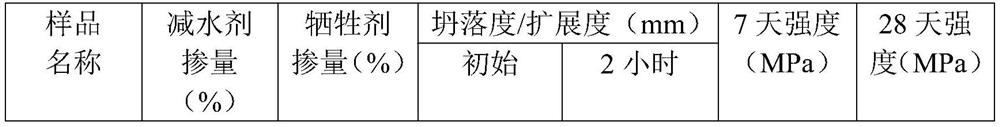

Soil sacrificial agent for polycarboxylate superplasticizer and preparation method of soil sacrificial agent

The invention discloses a soil sacrificial agent for a polycarboxylate superplasticizer and a preparation method of the soil sacrificial agent. The preparation method of the soil sacrificial agent forthe polycarboxylate superplasticizer comprises the following steps: (1) in a protective atmosphere, mixing and stirring styrene and ethanol, conducting heating to 40-45 DEG C, adding an initiator A in batches, simultaneously adding acrylic acid and methallyl alcohol for reaction, conducting heating to 88-92 DEG C after the reaction, and removing redundant ethanol and water to obtain an intermediate product; and (2) adding an initiator B into the intermediate product obtained in the step (1), conducting stirring and heating to 90-95 DEG C, adding ethylene oxide for reaction, adding water for dilution after the reaction is finished, and adjusting the pH value of the system to 5-7. The soil sacrificial agent can effectively inhibit soil from gradually absorbing water and expanding, so that the water demand of concrete is reduced, the problems of quick concrete loss and large pump loss are solved, and the problems of cracking, low strength, poor durability and the like after the concreteis hardened are further solved.

Owner:安徽海螺材料科技股份有限公司 +1

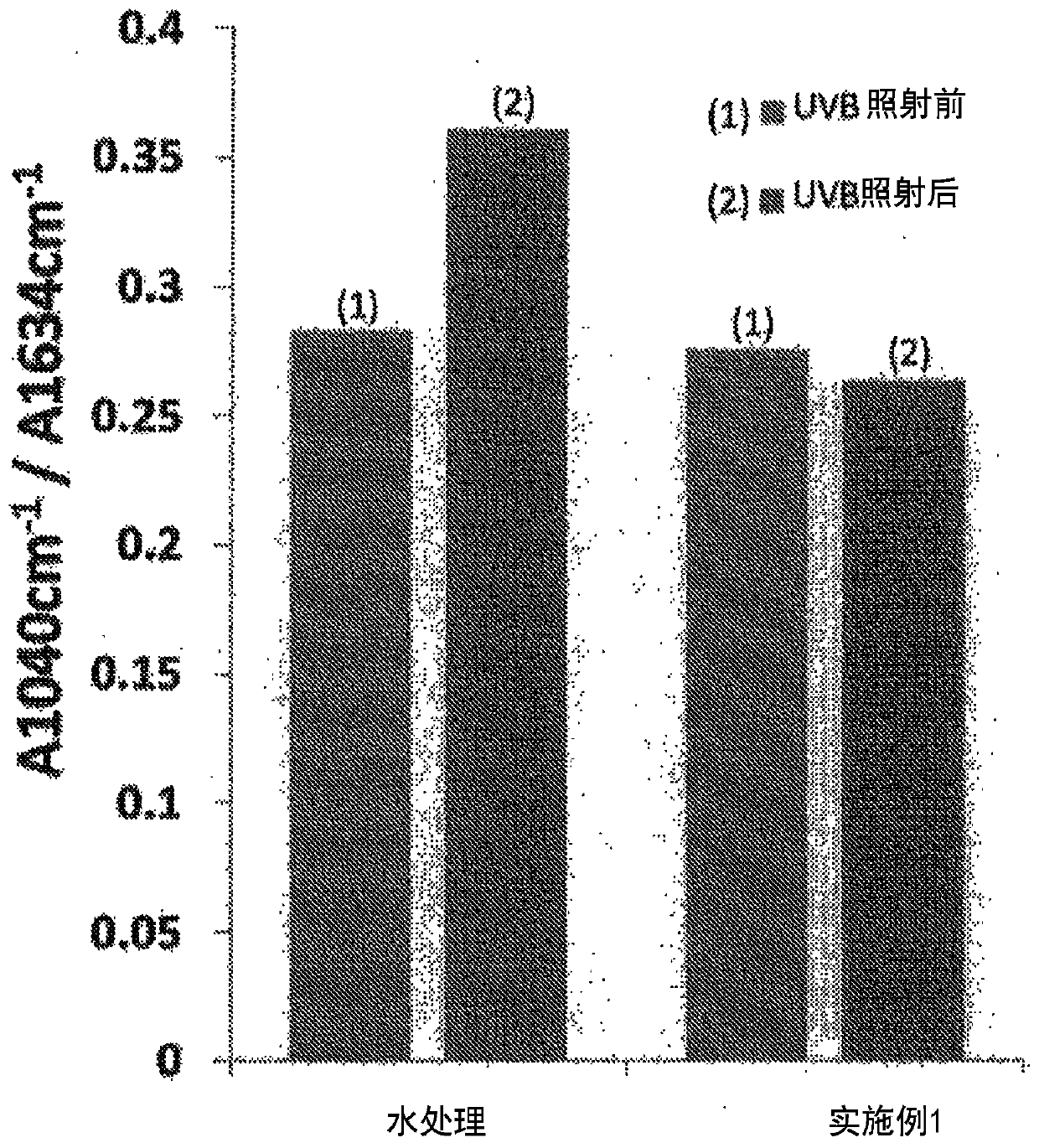

Modified vanadium dioxide dispersion as well as preparation method and application thereof

PendingCN114369321AGood dispersion stabilityImprove dispersion uniformityVanadium oxidesCoatingsChemistryVanadium dioxide

The invention belongs to the field of functional nano composite materials, and particularly relates to a modified vanadium dioxide dispersion as well as a preparation method and application thereof. The modified vanadium dioxide dispersoid is a dispersed particle system formed in a polyvinyl alcohol aqueous solution after vanadium dioxide is acted by a modifier, and the mass ratio of vanadium dioxide to the modifier is (1-5): 1; the obtained dispersion is excellent in dispersion stability, has a relatively strong infrared adjusting function, is simple in preparation process, short in production period, low in cost and easy for industrial production, and has great application value in the fields of water-based paint and coatings.

Owner:SHENZHEN MEIXINLONG CAN CO LTD

Preparation method of polyacrylamide aqueous dispersion

The invention discloses a preparation method of a polyacrylamide aqueous dispersion, which comprises the step of polymerizing a reaction system comprising acrylamide, an ionic monomer, a non-ionic monomer, a dispersion stabilizer, an inorganic salt and an initiator at a certain temperature for a period of time to obtain the polyacrylamide aqueous dispersion, wherein the dispersion stabilizer is acompound of an ionic polymer and an ionic polyacrylamide copolymer, and the non-ionic hydrophobic monomer and the initiator are added into the reaction system once or in several times. The prepared polyacrylamide aqueous dispersion has good stability and fluidity, the technological process is simple and convenient to operate, no organic solvent is added, and the polyacrylamide aqueous dispersion is green and environmentally friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com