Light-resistant graphene UV ink and preparation method thereof

A graphene and ink technology, applied in inks, household appliances, applications, etc., can solve the problems of affecting the appearance and service life of the film material, easy to generate static electricity, fading and other problems, and achieve a long product validity period, a large light response range, and a preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

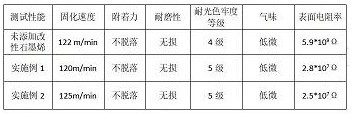

Examples

Embodiment 1

[0032] 1. Preparation of light-resistant graphene UV ink

[0033] (1) Raw material ratio is as follows (mass fraction):

[0034] Urethane Acrylic 42%

[0035] Photocatalytic modified graphene 4.0%

[0037] ITX photoinitiator 2.0%

[0038] Sodium polyacrylate 1.0%

[0039] Sodium Carboxymethyl Cellulose 0.1%

[0040] Calcium Stearate Emulsion 0.1%

[0041] Dimethicone 0.1%

[0042] Talc 16.0%

[0043] Solvent amount

[0044] (2) According to Bi(NO 3 ) 3 .5H 2 O, EDTA and NH 4 VO 3 The molar ratio is 1:0.3:1 ratio, weigh Bi(NO 3 ) 3 .5H 2 O dissolved in HNO 3 In the aqueous solution, heat and stir at 85°C for 15 minutes until clear, then add ethylenediaminetetraacetic acid (EDTA); at the same time, weigh the corresponding NH 4 VO 3 Dissolve in deionized water, heat and stir at 45°C for 15 minutes until clarified; mix the above two solutions under constant stirring, adjust the pH to 4.0, and obtain BiVO 4 Precursor solution, spare;

...

Embodiment 2

[0050] 1. Preparation of light-resistant graphene UV ink

[0051] (1) Raw material ratio is as follows (mass fraction):

[0052] Urethane Acrylic 36%

[0053] Photocatalytic modified graphene 5.0%

[0054] Chrome Yellow 4.0%

[0055] 184 Photoinitiator 1.5%

[0056] Sodium polyacrylate 1.0%

[0057] Sodium Carboxymethyl Cellulose 0.1%

[0058] Calcium Stearate Emulsion 0.1%

[0059] Dimethicone 0.1%

[0060] Talc 20.0%

[0061] Solvent amount

[0062] (2) According to Bi(NO 3 ) 3 .5H 2 O, EDTA and NH 4 VO 3 The molar ratio is 1:0.3:1, weigh Bi(NO 3 ) 3 .5H 2 O dissolved in HNO 3 In the aqueous solution, heat and stir at 85°C for 15 minutes until clear, then add ethylenediaminetetraacetic acid (EDTA); at the same time, weigh the corresponding NH 4 VO 3 Dissolve in deionized water, heat and stir at 45°C for 15 minutes until clarified; mix the above two solutions under constant stirring, adjust the pH to 4.0, and obtain BiVO 4 Precursor solution, spare;

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com