Soil sacrificial agent for polycarboxylate superplasticizer and preparation method of soil sacrificial agent

A water reducing agent and polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of limited anti-sludge effect, staying in the experimental stage, and not yet realized industrial application, etc. Improve cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

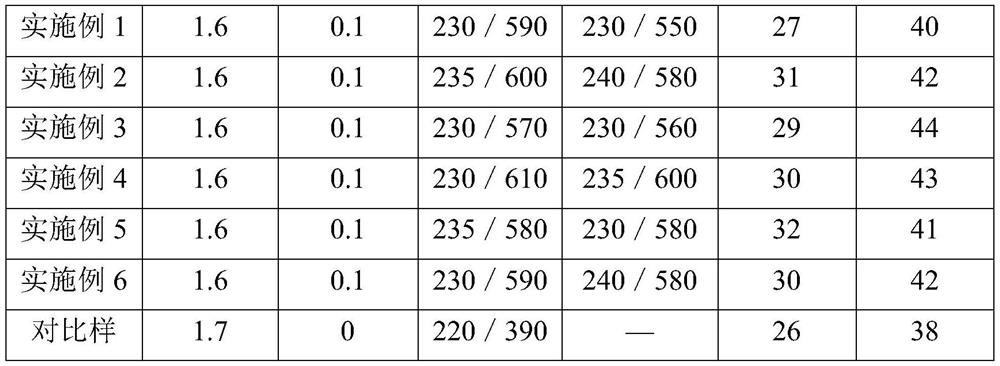

Examples

Embodiment 1

[0035] A preparation method for a soil sacrificial agent for a polycarboxylate water reducer, the steps are as follows:

[0036] In terms of parts by mass, put 230 parts of styrene and 55 parts of absolute ethanol into a reactor with stirring, nitrogen protection and reflux cooling pipe, turn on the nitrogen protection device, turn on the reflux cooling pipe to circulate cooling water, and start stirring to mix the materials evenly , the temperature of the material is controlled to 45°C, and one-third of the total amount of initiator A is added to the reaction system (the total amount of initiator A is 6 parts, and then the initiator is added to the reaction system at intervals of 1 hour. 1 / 3rd of A total amount), start dripping 90 parts of acrylic acid, 39 parts of methallyl alcohols at a constant speed; Acrylic acid and methallyl alcohols are added dropwise at a constant speed for 3 hours, continue to react after 1 hour after dropping, and will The temperature of the materia...

Embodiment 2

[0038] A preparation method for a soil sacrificial agent for a polycarboxylate water reducer, the steps are as follows:

[0039] In terms of parts by mass, put 230 parts of styrene and 55 parts of absolute ethanol into a reactor with stirring, nitrogen protection and reflux cooling pipe, turn on the nitrogen protection device, turn on the reflux cooling pipe to circulate cooling water, and start stirring to mix the materials evenly , the temperature of the material is controlled to 40°C, and one-third of the total amount of initiator A is added to the reaction system (the total amount of initiator A is 8 parts, and then the initiator is added to the reaction system at intervals of 1 hour. 1 / 3rd of A total amount), start dripping 95 parts of acrylic acid, 36 parts of methallyl alcohols at a constant speed; Acrylic acid and methallyl alcohols are added dropwise at a constant speed for 3 hours, continue to react after 1 hour after the dropwise addition ends, will The temperature ...

Embodiment 3

[0041] A preparation method for a soil sacrificial agent for a polycarboxylate water reducer, the steps are as follows:

[0042]In terms of parts by mass, put 230 parts of styrene and 55 parts of absolute ethanol into a reactor with stirring, nitrogen protection and reflux cooling pipe, turn on the nitrogen protection device, turn on the reflux cooling pipe to circulate cooling water, and start stirring to mix the materials evenly , the temperature of the material is controlled to 43°C, and one-third of the total amount of initiator A is added to the reaction system (the total amount of initiator A is 7 parts, and then the initiator is added to the reaction system at intervals of 1 hour) 1 / 3rd of A total amount), start dripping 93 parts of acrylic acid, 37 parts of methallyl alcohols at a constant speed; Acrylic acid and methallyl alcohols are added dropwise at a constant speed for 3 hours, continue to react after 1 hour after dropping, and will The temperature of the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com