Preparation method of polyacrylamide aqueous dispersion

A polyacrylamide and water-based dispersion technology, applied in the field of water-based polymer preparation, can solve the problems of low molecular weight of polyacrylamide emulsion, unsatisfactory emulsion stability, increased synthesis cost, etc., and achieves high molecular weight, fast dissolution speed, and economical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

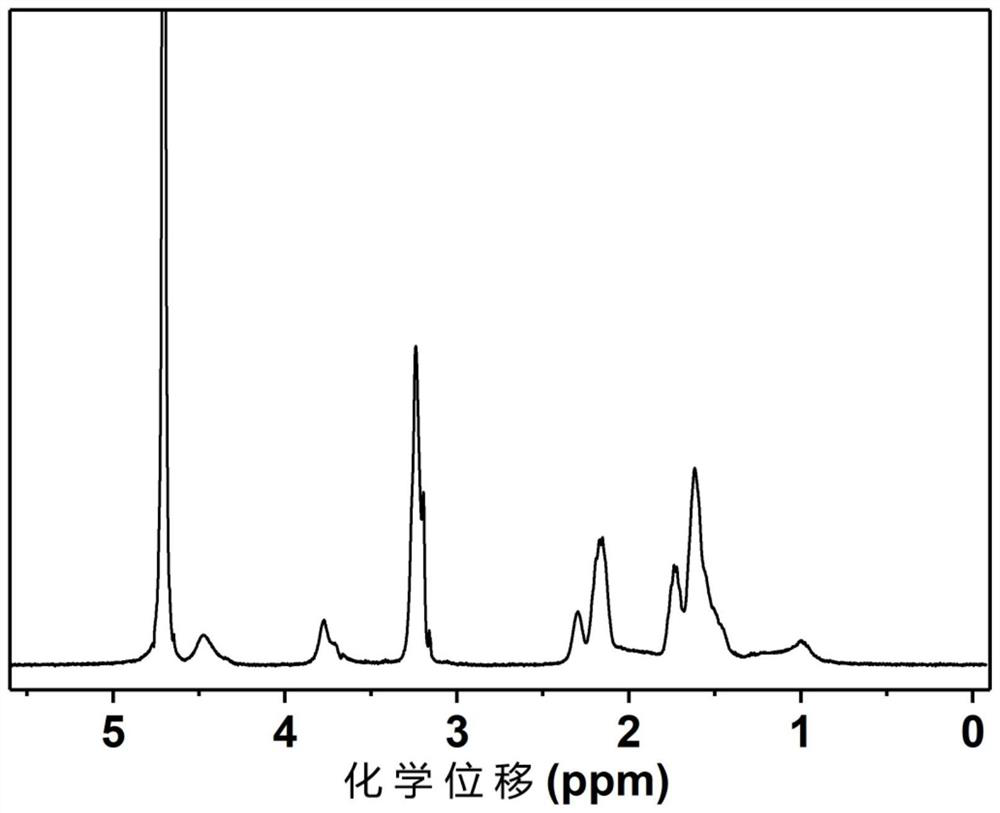

Image

Examples

Embodiment 1

[0026] (1) Preparation of cationic polymer:

[0027] Synthesis of polymethacryloyloxyethyltrimethylammonium chloride (A1): 80% aqueous solution of methacryloyloxyethyltrimethylammonium chloride (187.5g, 722mmol), VA-044 (0.15g, 0.46mmol) and water (1870g). After degassing and oxygen removal, react at 45°C for 7 hours. After cooling to room temperature, water (2620 g) was added to dilute to a 5 wt % aqueous solution of polymethacryloyloxyethyltrimethylammonium chloride.

[0028] Synthesis of polymethacryloyloxyethyl dimethyl benzyl ammonium chloride (A2): 80% aqueous solution (187.5g, 526mmol) of methacryloyloxyethyl dimethyl benzyl ammonium chloride was added in a flask , VA-044 (0.11 g, 0.33 mmol) and water (1870 g). After degassing and oxygen removal, react at 45°C for 7 hours. After cooling to room temperature, water (2620 g) was added to dilute to a 5 wt % polymethacryloyloxyethyl dimethyl benzyl ammonium chloride aqueous solution.

[0029] Synthesis of polyacryloxyet...

Embodiment 2

[0052] Synthesis of cationic polyacrylamide aqueous dispersion: at room temperature, add acrylamide (36g, 0.506mol), ammonium sulfate (210g, 1.59mol), methacryloyloxyethyl Trimethylammonium chloride 80% aqueous solution (1.8g, 6.93mmol), dispersion stabilizer 1 (216g), isooctyl methacrylate (2.0g, 10.07mmol) and water (243.3g), stirred until all added The substance is completely dissolved. After degassing and oxygen removal, the temperature was raised to 45°C, and VA-044 aqueous solution (1 mL, 6.0 mg / mL) was added. Continue the reaction for 30 minutes, then add isooctyl methacrylate (1.6g, 8.06mmol, 0.016eq.) and VA-044 aqueous solution (1mL, 8.0mg / mL), and the total volume of the reaction system is about 550mL. After continuing the reaction for 30 minutes, the heat source was removed to stop the reaction, and a cationic polyacrylamide aqueous dispersion with good fluidity was obtained. According to GB12005.1-89 polyacrylamide molecular weight determination method, the meas...

Embodiment 3

[0054] Except that the dispersion stabilizer used is dispersion stabilizer 2, other conditions are the same as in Example two, and the molecular weight of the obtained polymer is 6.12×10 6 Da. The aqueous dispersion can be stored at room temperature for 5 months without delamination, and the dispersion can be quickly and completely dissolved in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com