Modified vanadium dioxide dispersion as well as preparation method and application thereof

A technology of vanadium dioxide and dispersion, applied in vanadium oxide, coating and other directions, can solve the problems of poor dispersion stability of vanadium dioxide nano-powder, affecting specific performance, etc., and achieve excellent dispersion stability, short production cycle, and easy operation. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

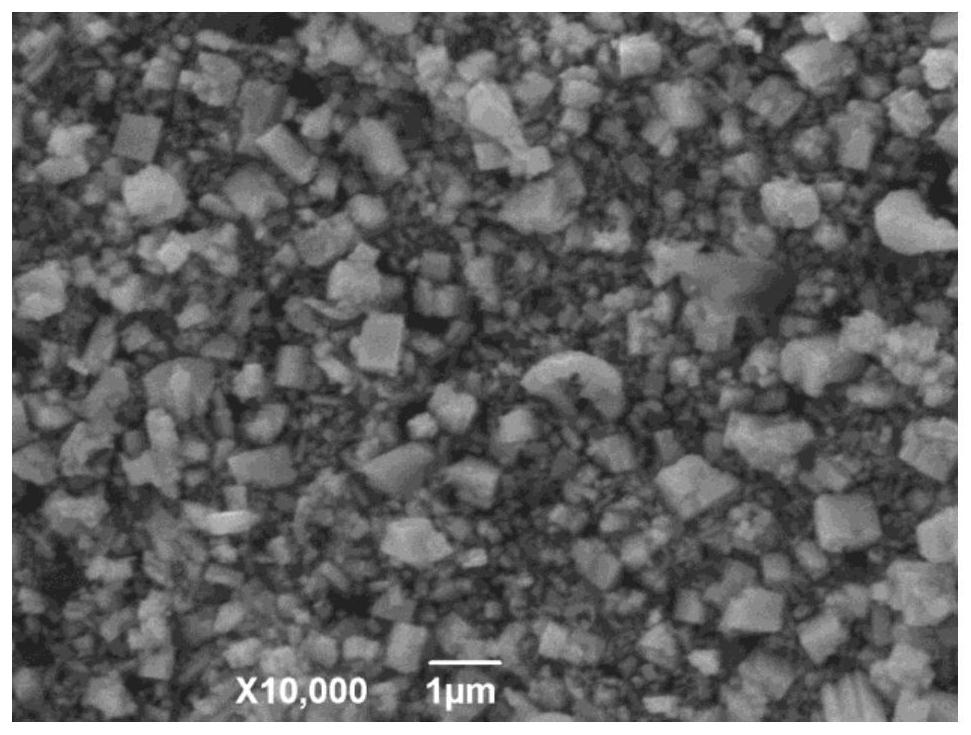

[0042] Add 100ml of deionized water to the beaker, then add 4gV 2 o 5 and 10ml of hydrochloric acid, stirred with a glass rod until completely dissolved, bathed in water at 60°C for 1 hour, then added 8g of oxalic acid, continued to heat until the solution turned blue, then injected nitrogen, added 5.85g of sodium hydroxide until the pH of the solution reached 7.5, washed with water and filtered, A gray precipitate was obtained. Transfer the gray precipitate to a 200ml reaction kettle, add 120ml of deionized water (60% filling), stir evenly, put it in an oven at 220°C for 48 hours, take out the reaction kettle and cool it to room temperature to obtain a dark blue turbid solution. The solution is washed, filtered and dried to obtain vanadium dioxide powder; and then continue to prepare a sufficient amount of vanadium dioxide powder according to the above method for future use. The prepared vanadium dioxide was annealed at 550°C for 1h. Add 30g of AC-3122 modified styrene acr...

Embodiment 2

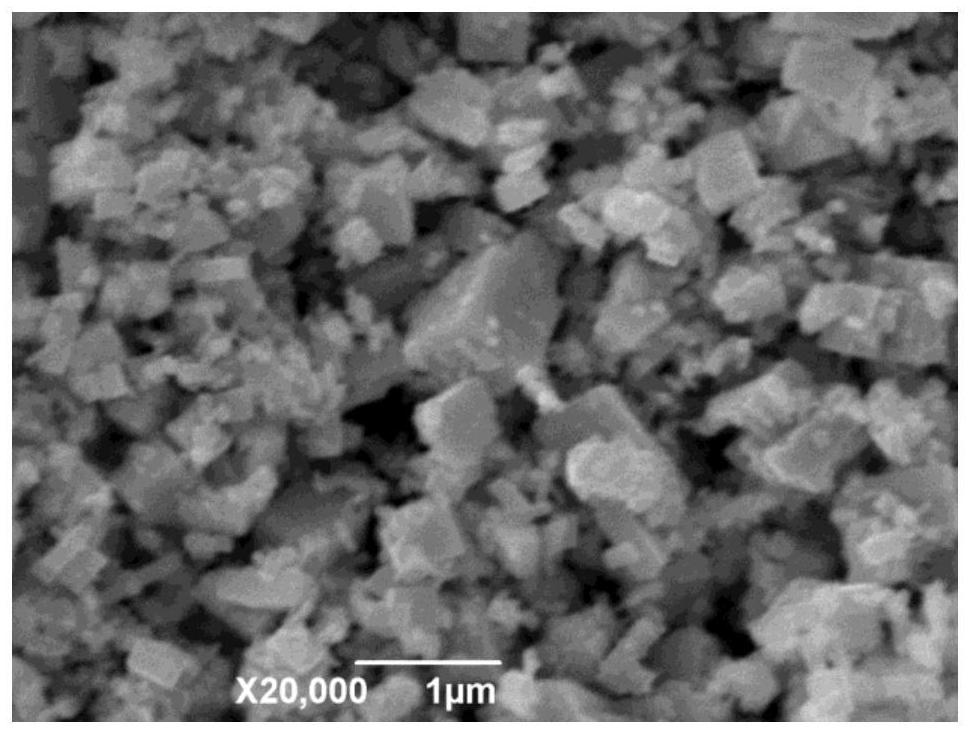

[0044] Add 100ml deionized water to the beaker, then add 5gV 2 o 5 and 14ml of hydrochloric acid, stirred with a glass rod until completely dissolved, bathed in water at 80°C for 1.5h, then added 10g of oxalic acid, continued to heat until the solution turned blue, then injected nitrogen, added 7.67g of sodium hydroxide until the pH of the solution reached 6.5, washed with water and filtered, A gray precipitate was obtained. Transfer the gray precipitate to a 200ml reactor, add 160ml of deionized water (filling degree is 80%), stir evenly, put it in an oven at 230°C for 48 hours, take out the reactor and cool it to room temperature to obtain a dark blue turbid solution, The solution is washed, filtered and dried to obtain vanadium dioxide powder; and then continue to prepare a sufficient amount of vanadium dioxide powder according to the above method for future use. The prepared vanadium dioxide was annealed at 600°C for 1.5h. Add 35g of AC-3122 modified styrene acrylic aci...

Embodiment 3

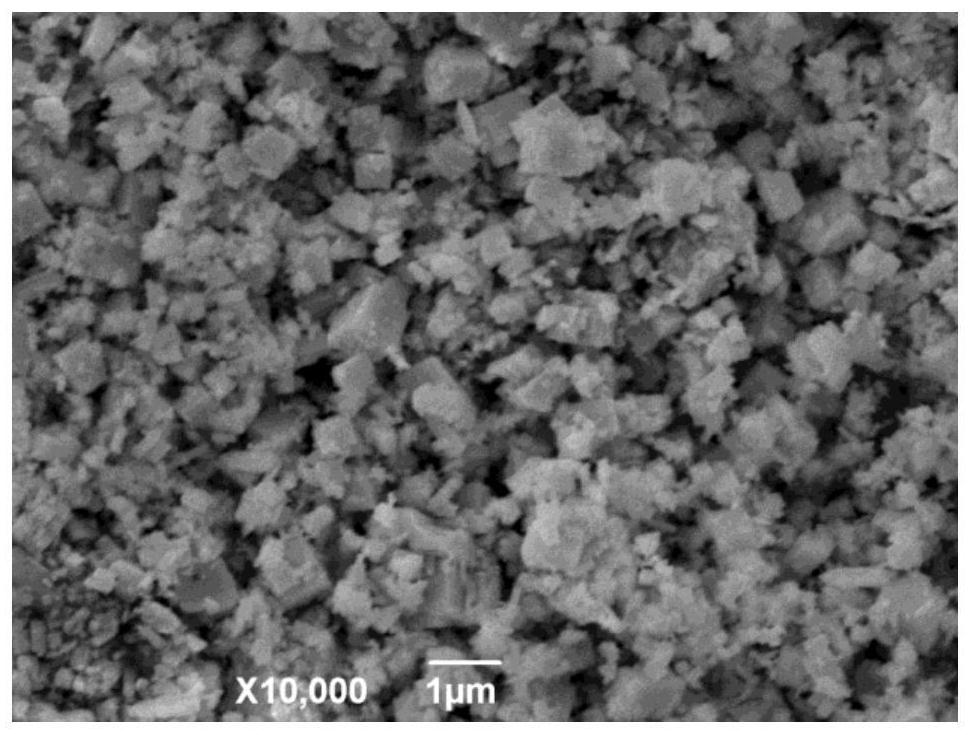

[0046] Add 100ml deionized water to the beaker, then add 4.5gV 2 o 5 and 12ml of hydrochloric acid, stirred with a glass rod until completely dissolved, bathed in water at 70°C for 1 hour, then added 9g of oxalic acid, continued to heat until the solution turned blue, then injected nitrogen, added 6.76g of sodium hydroxide until the pH of the solution reached 8.5, washed with water and filtered to obtain Gray precipitation. Transfer the gray precipitate to a 200ml reaction kettle, add 140ml of deionized water (70% filling), stir evenly, put it in an oven at 220°C for 48 hours, take out the reaction kettle and cool it to room temperature to obtain a dark blue turbid solution. The solution is washed, filtered and dried to obtain vanadium dioxide powder; and then continue to prepare a sufficient amount of vanadium dioxide powder according to the above method for future use. The prepared vanadium dioxide was annealed at 550°C for 1.5h. Add 40g of AC-3122 modified styrene acryli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com