Patents

Literature

194results about How to "Good transparency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

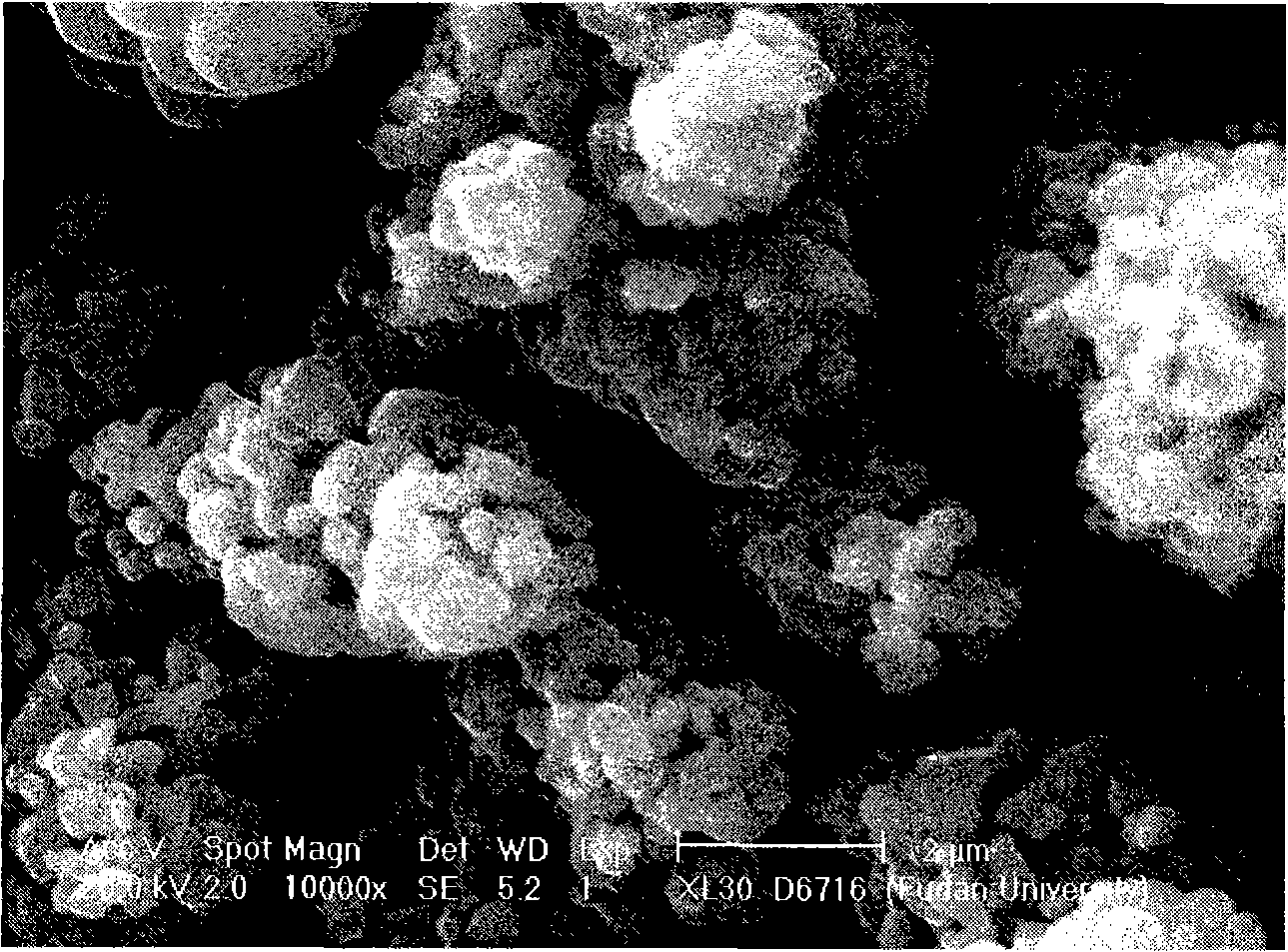

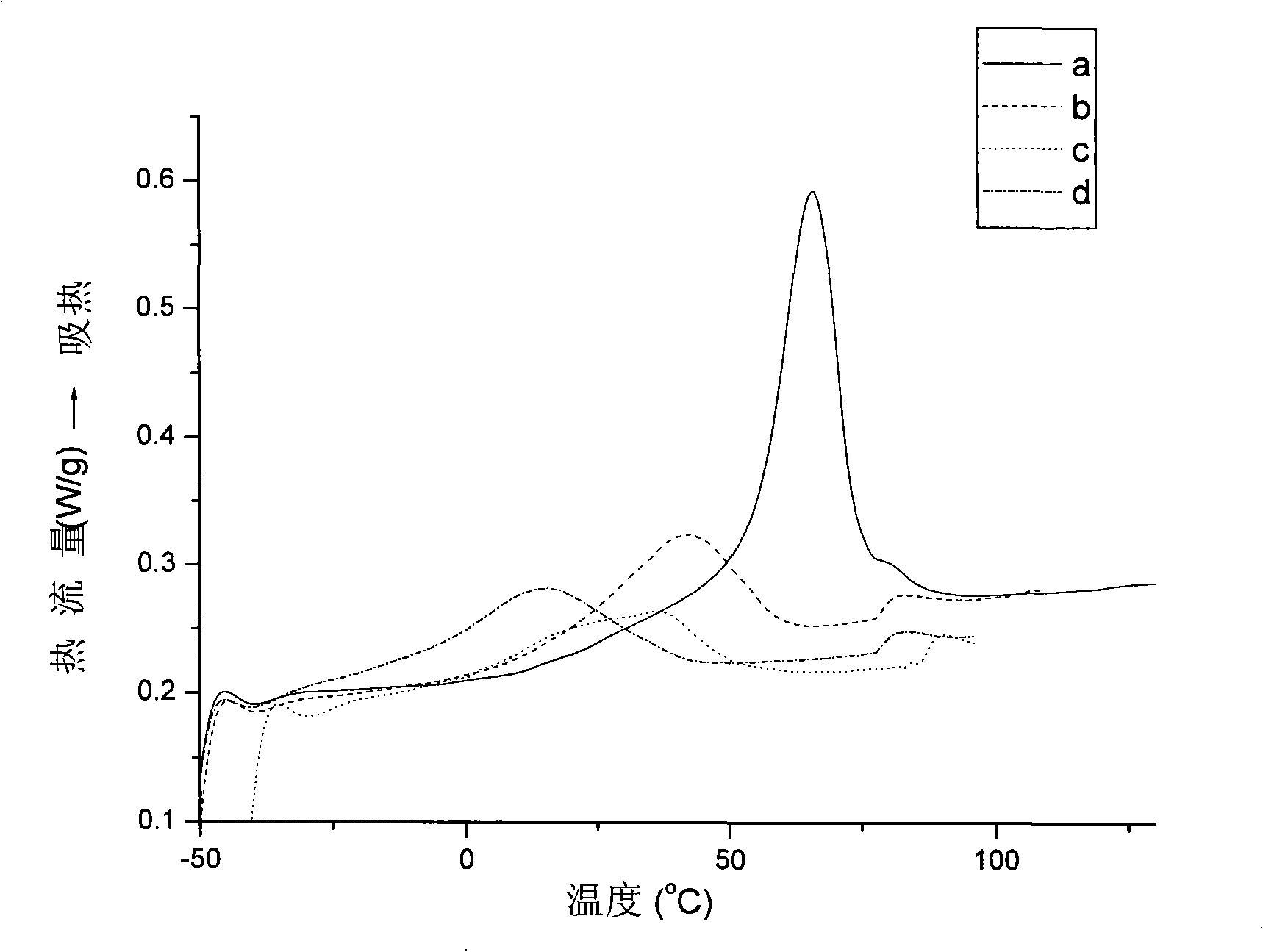

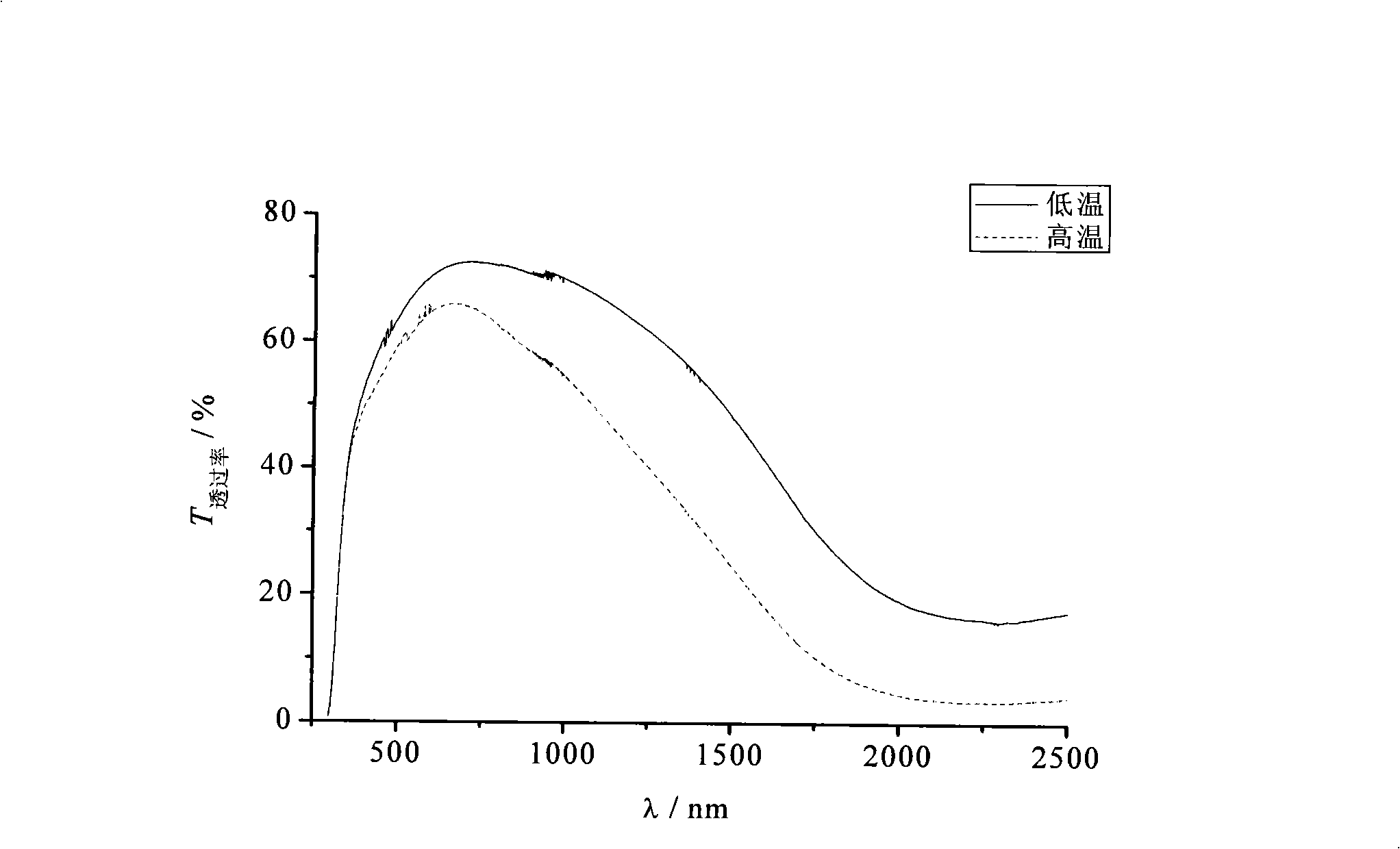

Intelligent heat-insulating film and its preparing process

InactiveCN101265374AGood transparencyEasy constructionFireproof paintsPolyurea/polyurethane coatingsTransmittanceHigh reflectivity

The invention relates to an intelligent heat-insulating film and a preparation method thereof. The invention adopts the mixture of phase transition intelligent nanometer powder in the rutile crystal structure and vanadium dioxide V1-XO2(X is more than 0 and less than 0.06) to uniformly disperse on a material which can be formed into films, thus preparing the intelligent heat-insulating film with the phase transition function. The intelligent heat-insulating film is a novel energy-saving material with the phase transition temperature adjustable within -10 DEG C to 70 DEG C. The film has high infrared transmittance and low reflectivity as well as excellent heat-insulating property at low temperatures. At high temperatures, the film has low infrared transmittance and high reflectivity as well as excellent heat insulating effect. The intelligent heat-insulating film can be used for heat-insulation and decorative-protection of the surfaces such as glass, plastic, metal, wood, concrete and so on.

Owner:FUDAN UNIV

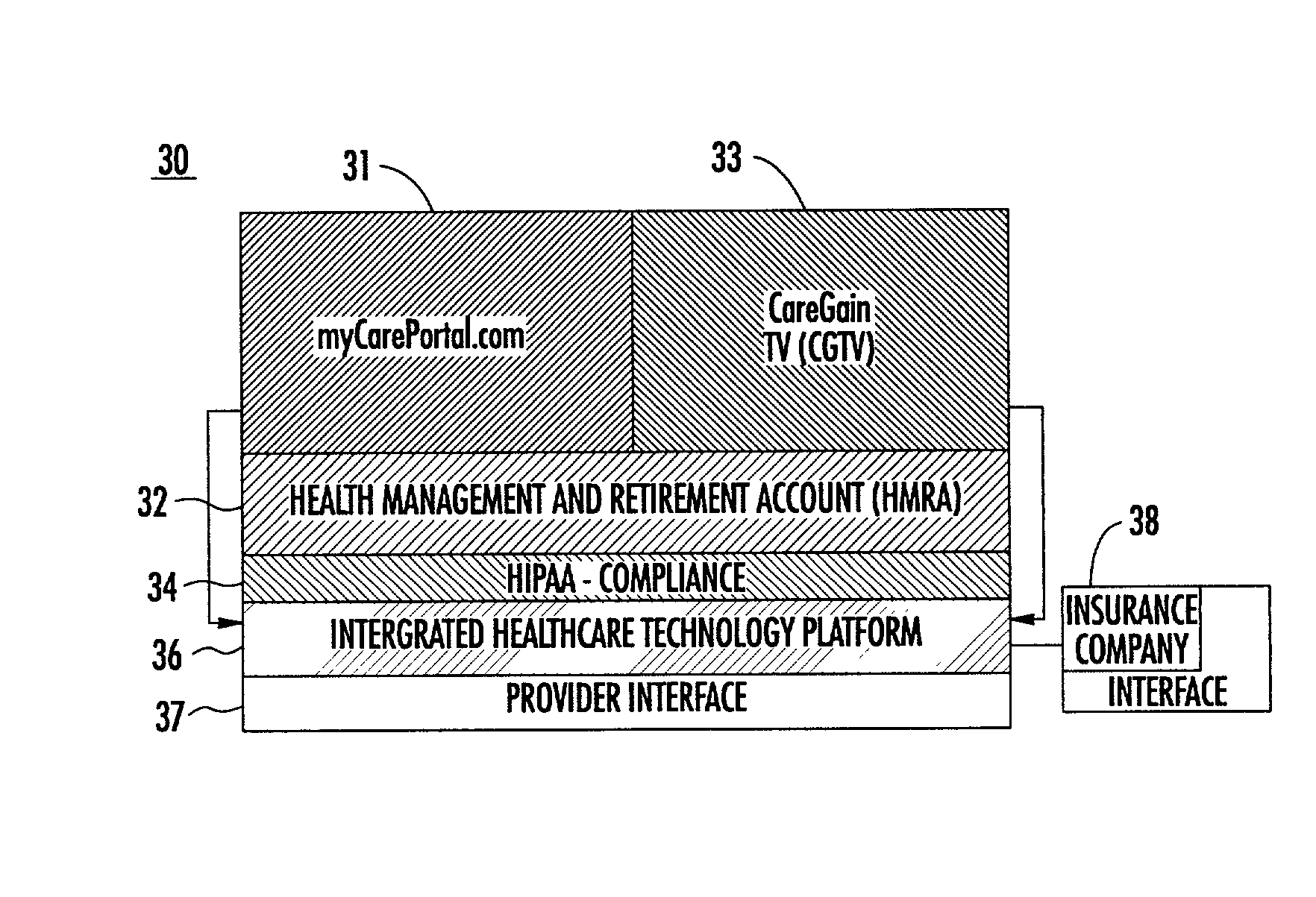

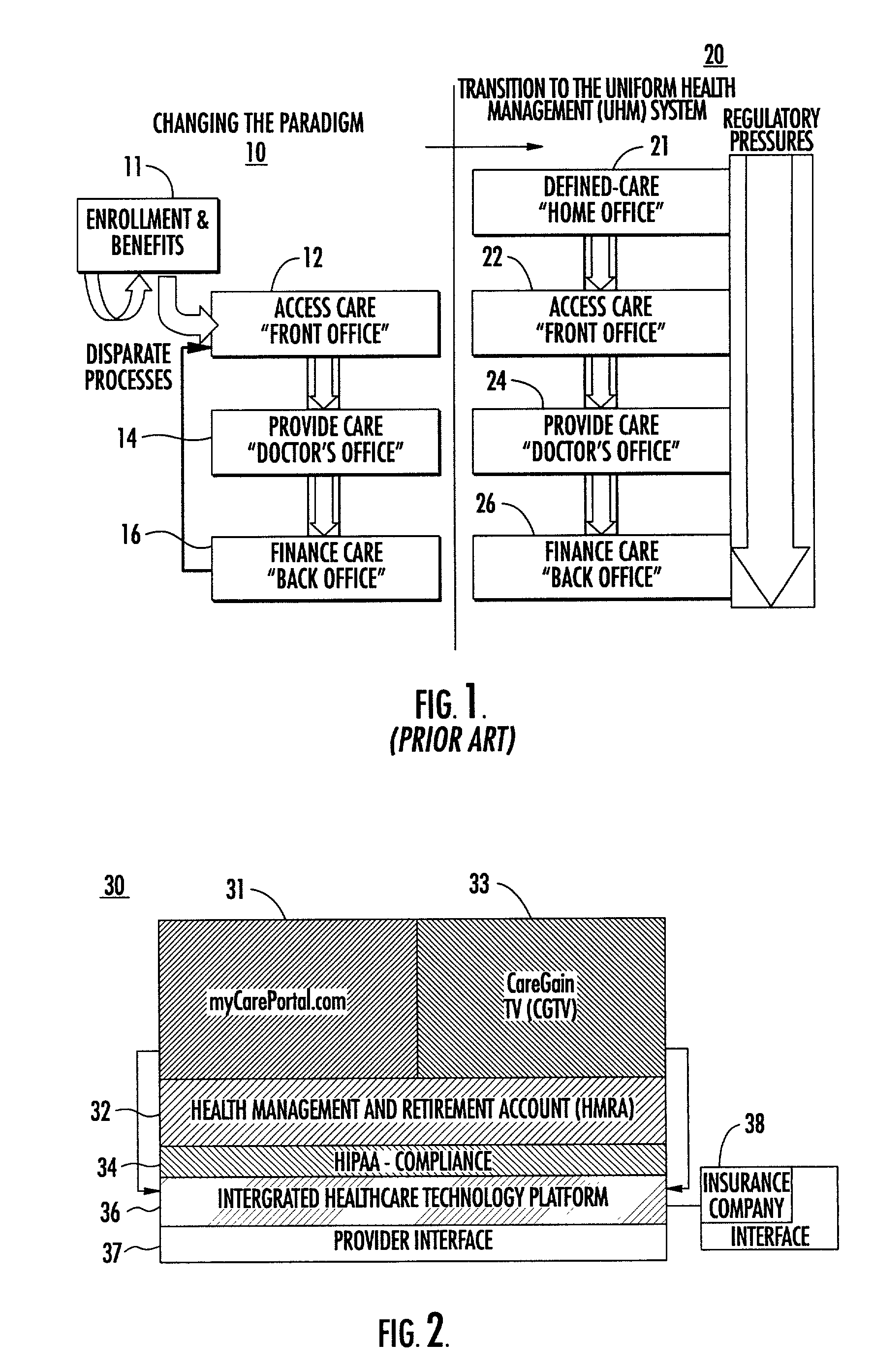

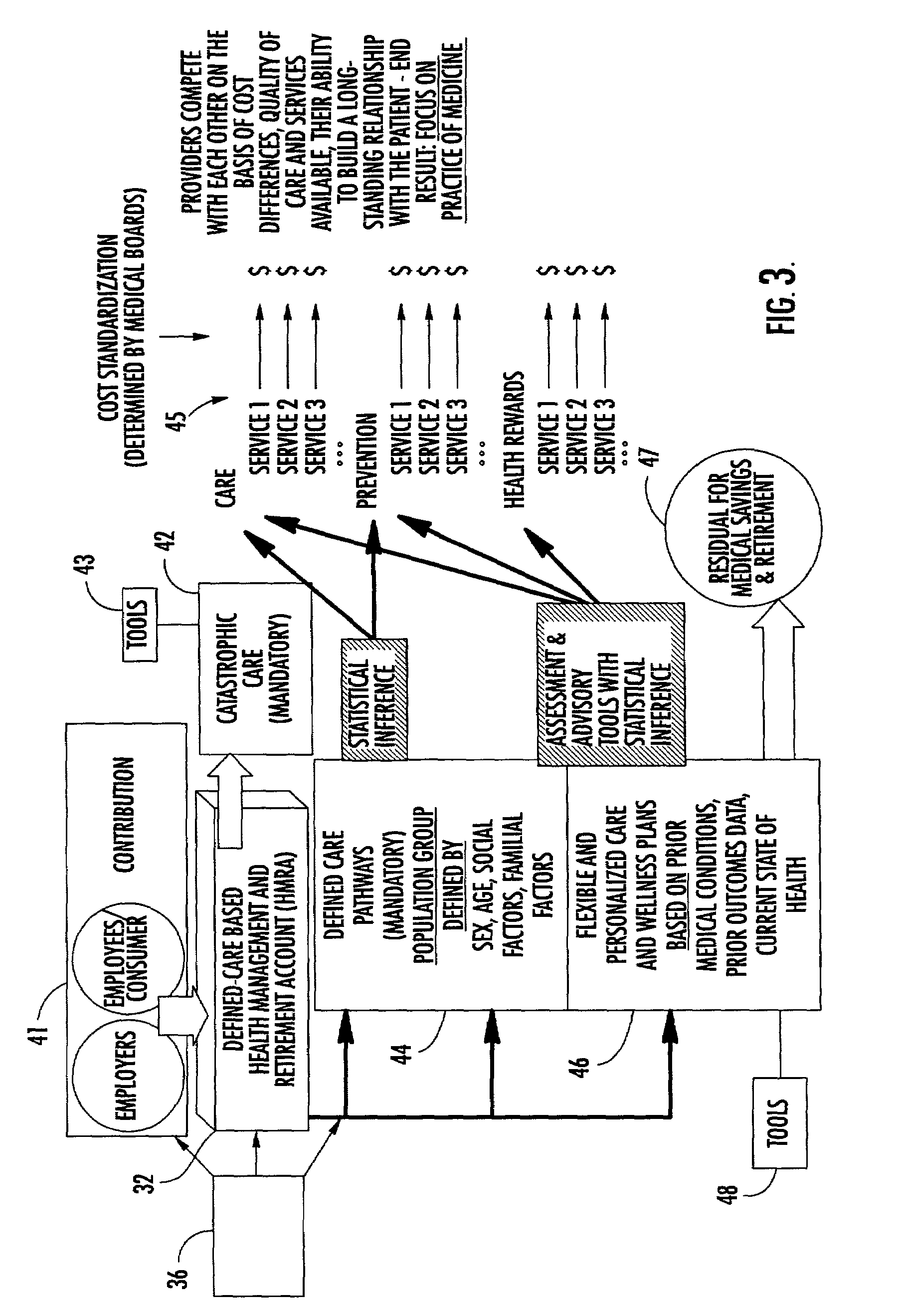

System and method for management of health care services

InactiveUS7493266B2Good transparencyMore flexibility and portabilityOffice automationElectric digital data processingHealth programPrimary component

The present invention is a system and method for management of consumer services such as health care services which combines new financial structure for health insurance and health benefit plan, payment methods, health plan design, benefit development algorithms, unique procurement methods for health care benefits with and without application to an individual consumer's personal state of health, and is integrated with financial services and asset management products, and benefits for an individual consumer's future medical and / or retirement savings, for healthcare needs. The method and system employs a combination of the defined benefit and defined contribution approaches which combination is referred to herein as “defined-care.” Defined-care model or the healthcare asset management model has two primary components, one which is referred to herein as a “health management and retirement account”, and the other of which is an infrastructure “connected portal” that interfaces through a technology platform with the health management and retirement accounts and the account holders. The foundation of this infrastructure according to the present invention is a technology platform across which a variety of processes are implemented. In the technology platform for the infrastructure of the present invention, the conventional processes and the new processes are integrated, thereby allowing a change to one process to be adopted by or otherwise accommodated by the other processes.

Owner:CANOPY ACQUISITION

Transparent flame retarding polyvinyl chloride (PVC) composite and preparation method thereof

The invention discloses a transparent flame retarding polyvinyl chloride (PVC) composite and a preparation method thereof. The composite is prepared as that the polyvinyl chloride (PVC), plasticizer, heat stabilizer, flame retardant and lubricant are melted and mixed in a certain proportion in an extruding machine. In the invention, liquid flame retarding plasticizer and nanometer powder flame retardant are used as the flame retarding system in order to fully develop the coordinative action of the organic flame retardant and the nanometer inorganic flame retardant, thereby the flame retarding performance of the soft polyvinyl chloride material is greatly improved and the soft polyvinyl chloride composite with flame retarding performance and good transparency is prepared; the preparation technique is simple and easy for operation.

Owner:NINGBO XIANFENG NEW MATERIAL

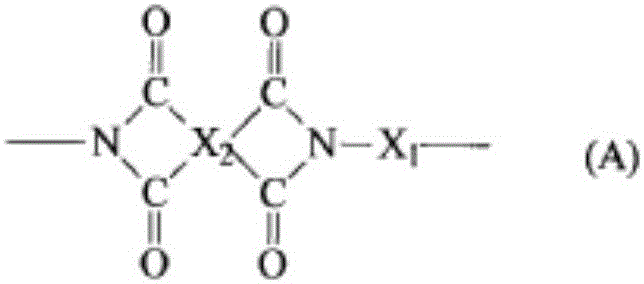

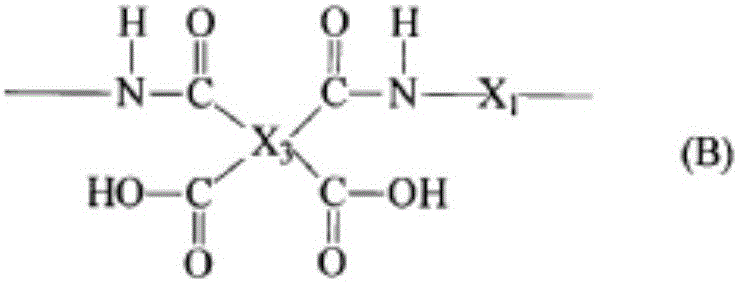

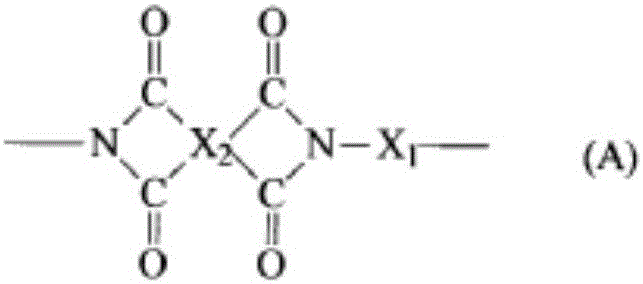

Polyimide precursor and resin composition containing same

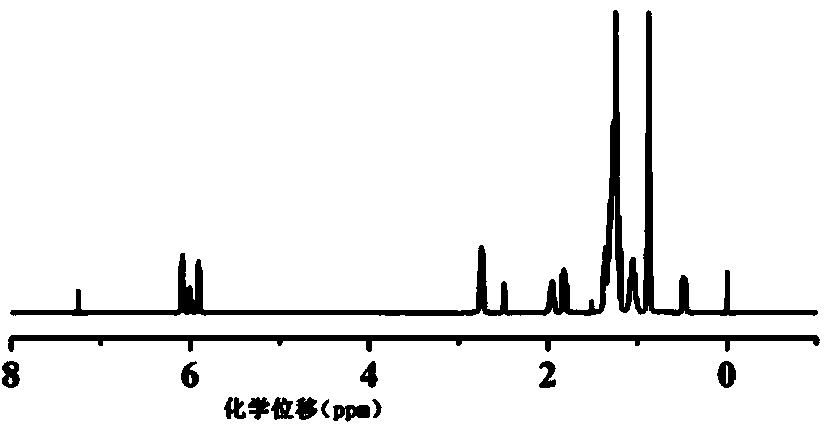

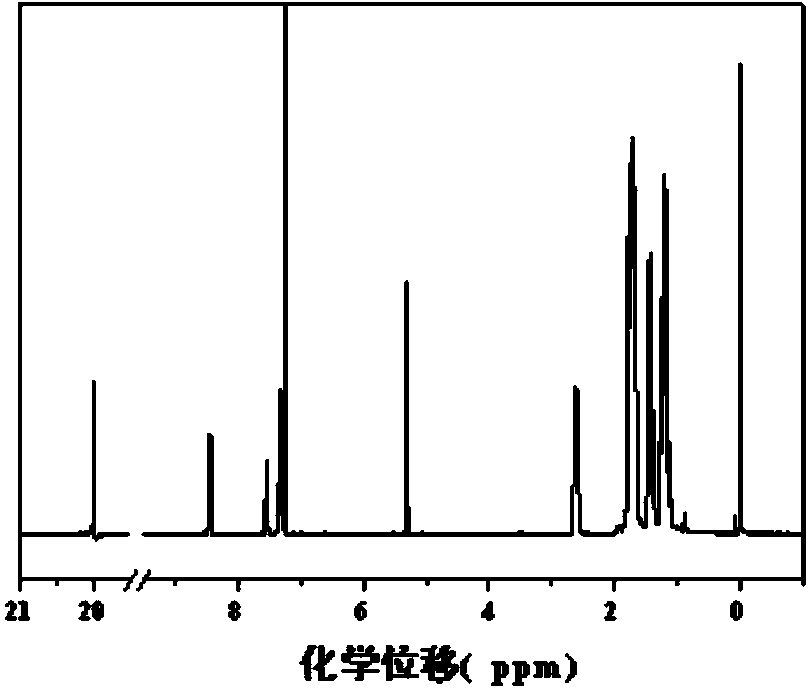

ActiveCN105916910AExcellent storage stabilityGood transparencySynthetic resin layered productsDiamineTrifluoromethyl

A polyimide precursor characterized by having a structure derived from 2,2'-bis(trifluoromethyl)benzidine (TFMB) or the like as a diamine-derived structure and also having both a structure derived from a specific alicyclic tetracarboxylic acid dianhydride and a structure derived from an aromatic tetracarboxylic acid dianhydride as structures each derived from a tetracarboxylic acid dianhydride, wherein the degree of imidation of an amide bond derived from the alicyclic tetracarboxylic acid dianhydride is 10 to 100%.

Owner:ASAHI KASEI KOGYO KK

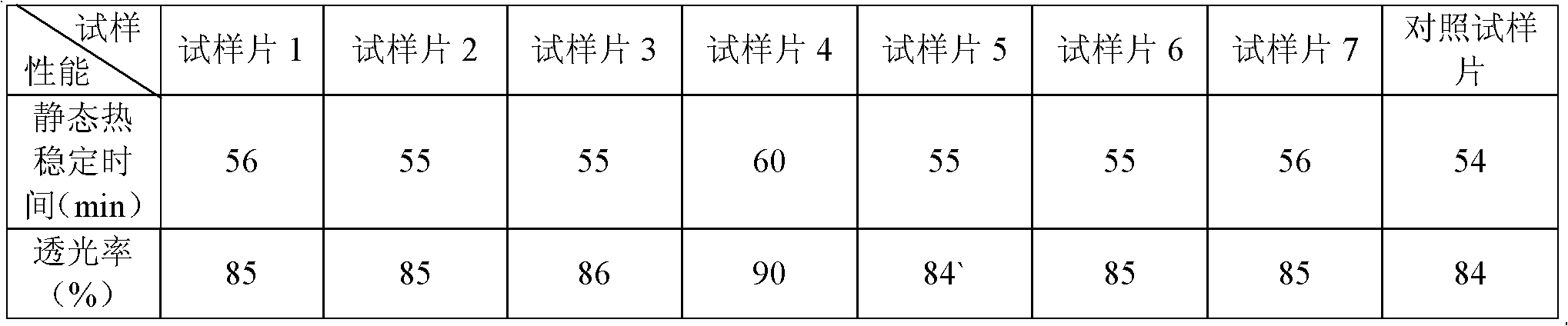

Pasty calcium-zinc composite heat stabilizer and preparation method thereof

InactiveCN102093648AImprove the thermal stability of PVCGood transparencyAntioxidantRefractive index

The invention provides a pasty calcium-zinc composite heat stabilizer and a preparation method thereof. The composite heat stabilizer comprises the following raw materials in a mass ratio: 2-10 parts of zinc stearate, 6-13 parts of calcium stearate, 45-52 parts of epoxy compound, 14-16 parts of chelating agent, 10-12 parts of beta-diketone, 6-8 parts of antioxidant and 2-4 parts of polyalcohol. The pasty calcium-zinc composite heat stabilizer provided by the invention conforms to environmental protection requirements, is applied to the fields of medical treatment and public health and has the main advantages that each component of the pasty calcium-zinc composite heat stabilizer system has appropriate calcium soap to zinc soap ratio and various auxiliary stabilizing groups. By means of the synergistic effect of the components, the zinc burning phenomenon of the system can be effectively delayed, and the thermal stability of PVC (Poly Vinyl Chloride) can be increased. Moreover, assistants selected for the system have closer refractive indexes to PVC resin, so that prepared PVC products have good transparency.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

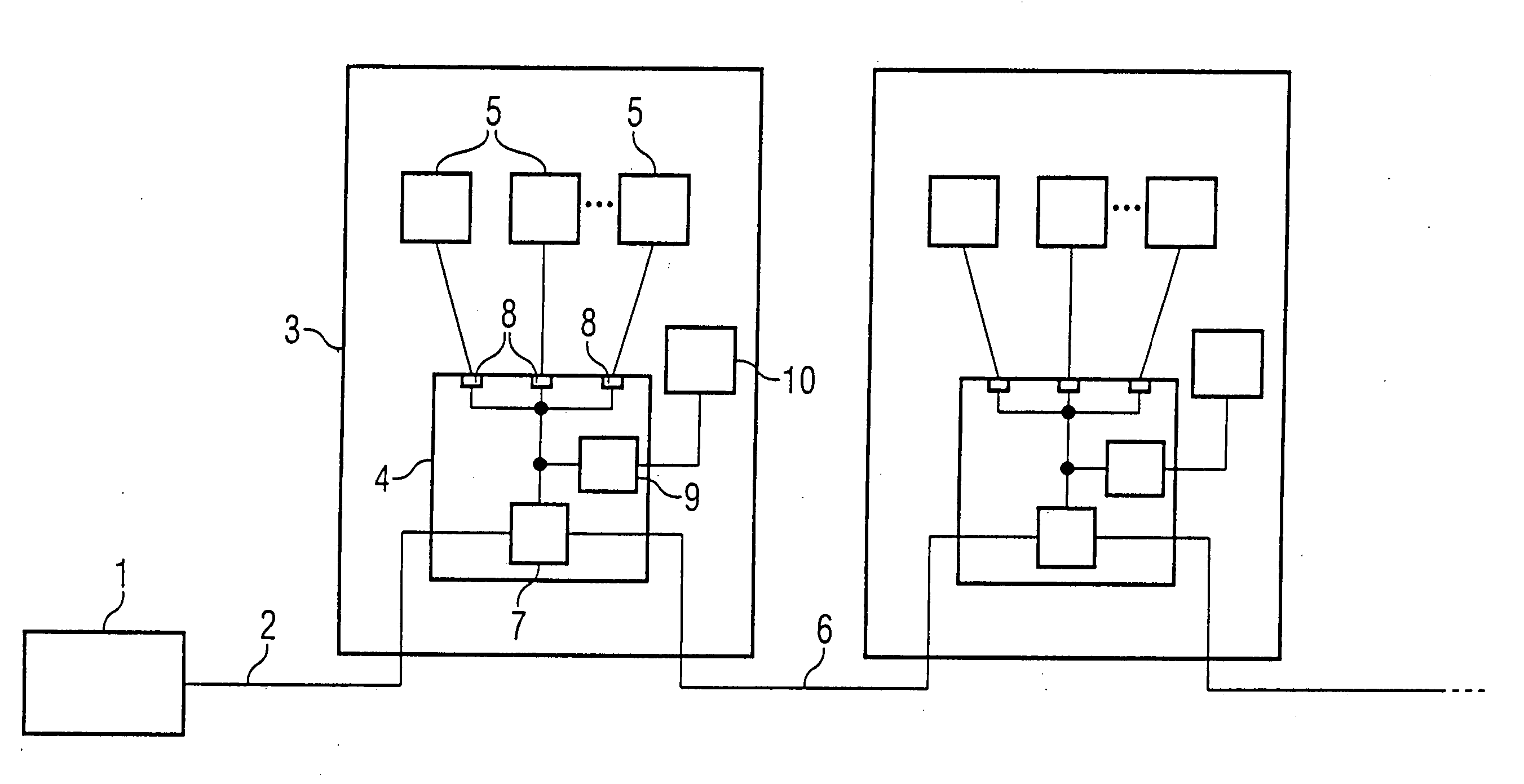

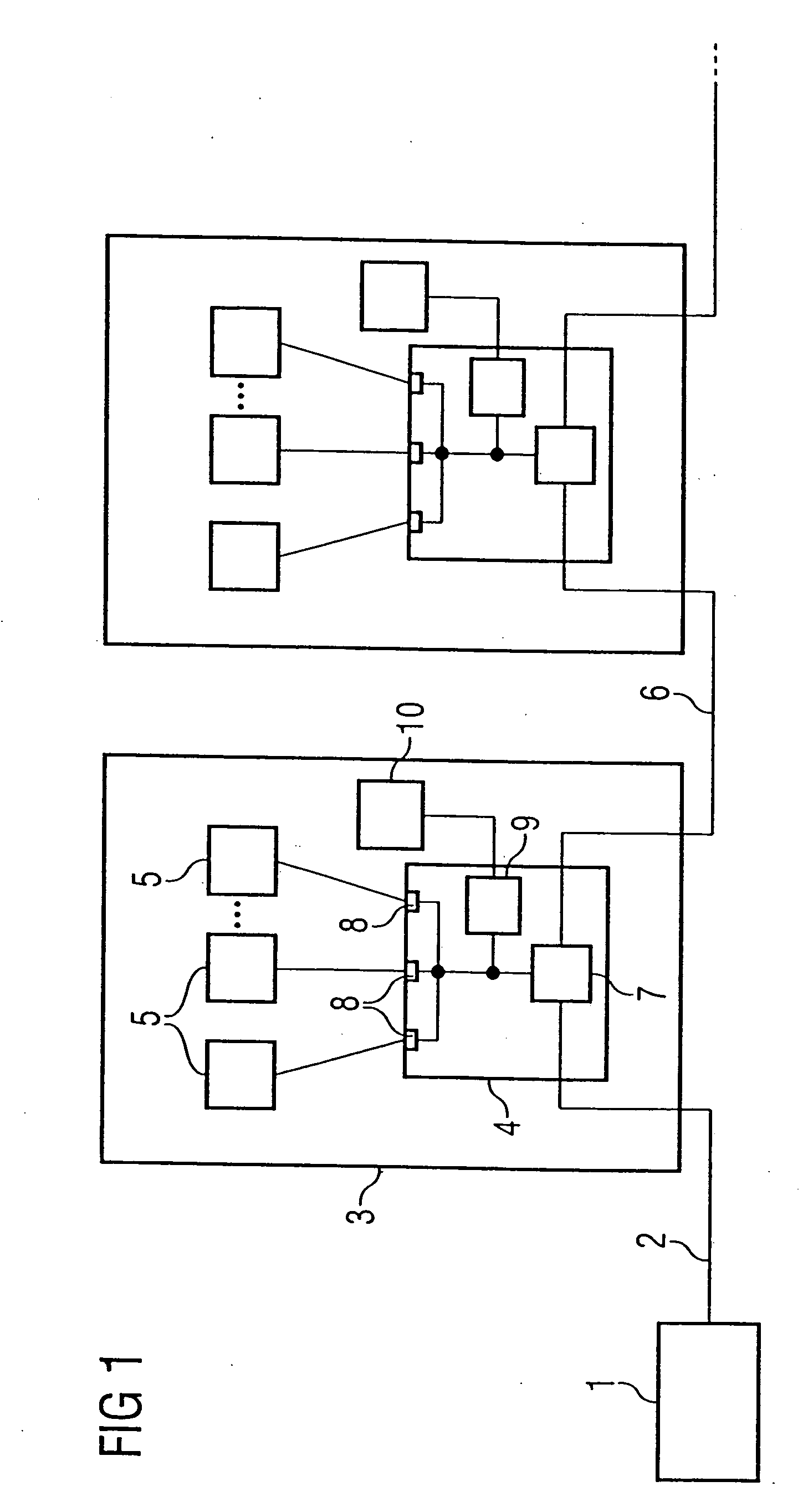

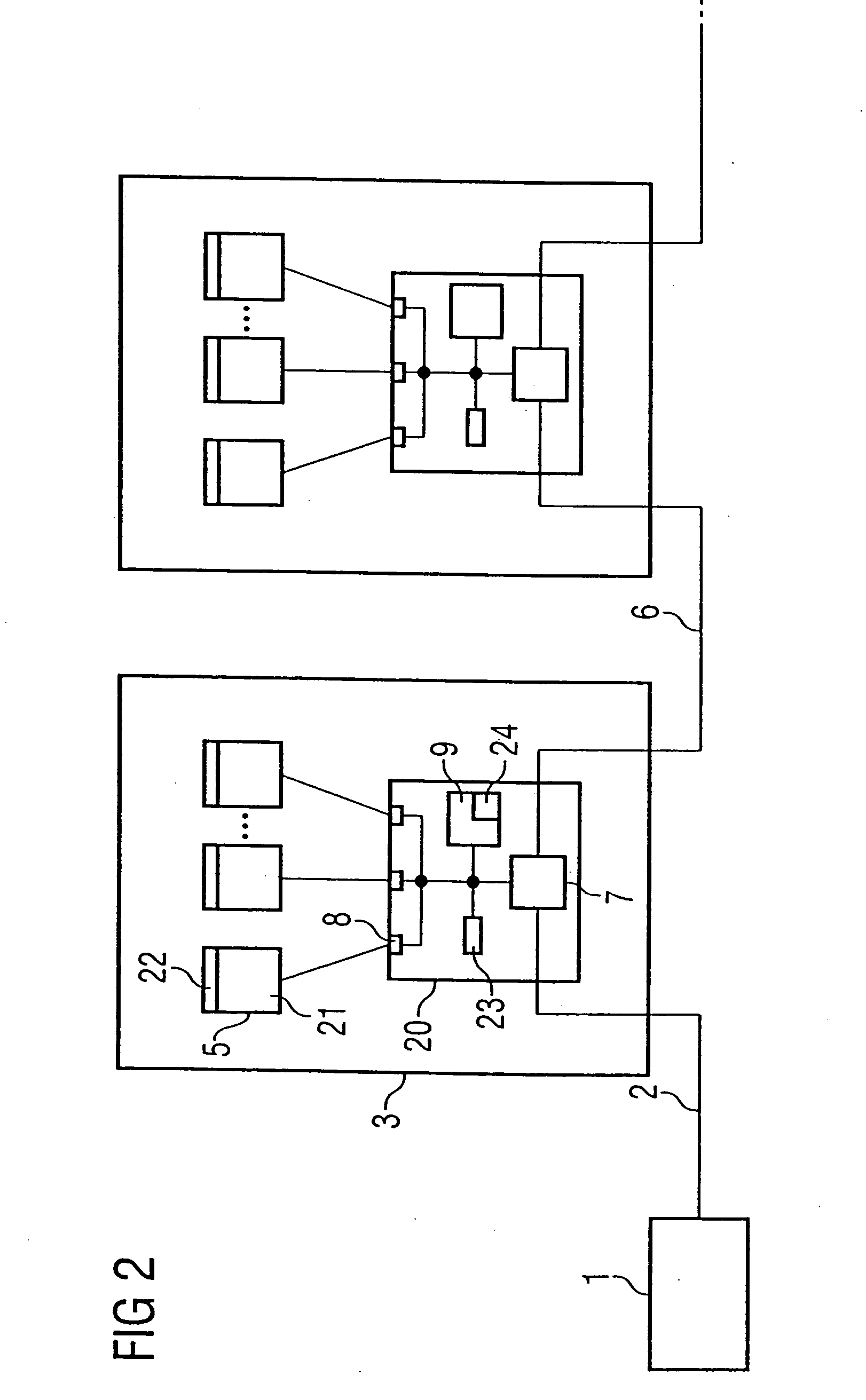

Hub chip for connecting one or more memory chips

InactiveUS20060190674A1Good level of reliabilityGood transparencyMemory adressing/allocation/relocationUnauthorized memory use protectionAddress decoderError identification

The invention relates to a hub chip for connecting one or more memory chips via a respective memory chip interface, having an address input for connecting the hub chip to an address bus and having an address output for connection to a further address bus, having an address decoder unit configured to use an address applied to the address input to address one of the connected memory chips or to apply the applied address to the address output, characterized by an error recognition unit configured to use provided checking data to detect an error in a memory area of the one or more memory chips.

Owner:INFINEON TECH AG

Temperature-sensitive chromic material

The invention discloses a temperature-sensitive chromic material. The temperature-sensitive chromic material is prepared from 0.5 to 2 percent of temperature-sensitive macromolecules by mass; 0 to 30 percent of film-forming monomers by mass; 0 to 5 percent of thickening agent by mass; 0 to 1 percent of dispersing agent by mass; 0 to 0.5 percent of cross-linking agent by mass; 0 to 3 percent of oxidizing agent by mass; 0 to 1 percent of reducing agent by mass, wherein a solvent of the temperature-sensitive chromic material is water. The temperature-sensitive chromic material according to the invention has the characteristic of intelligent light ray and heat adjustment according to temperature, not only can reduce heat penetrating through sunlight, but also can keep good transparency, and is applicable to various places such as dwellings, office buildings and greenhouses where temperature and light rays need to be adjusted.

Owner:CHONGQING HEWEI TECH CO LTD

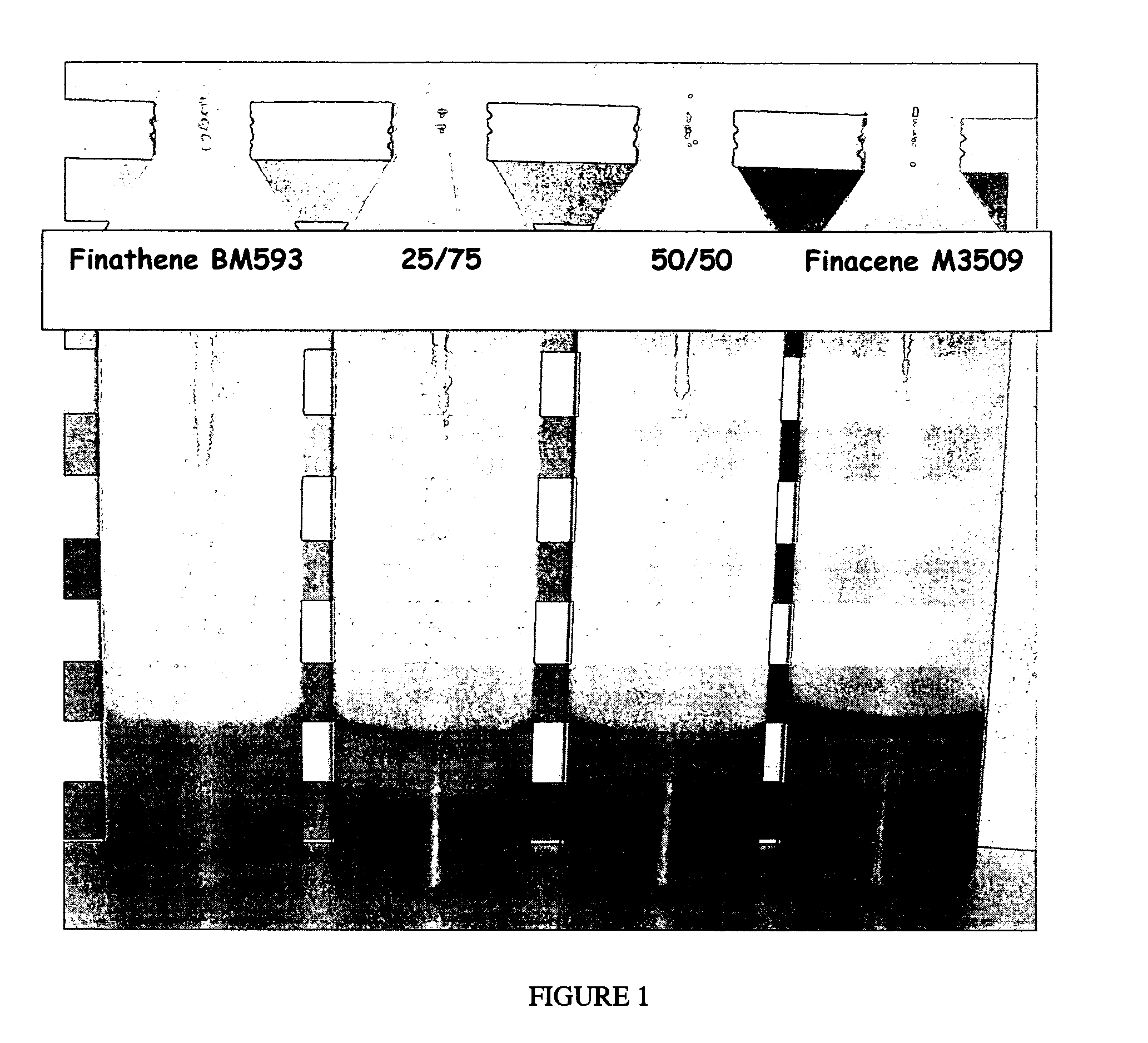

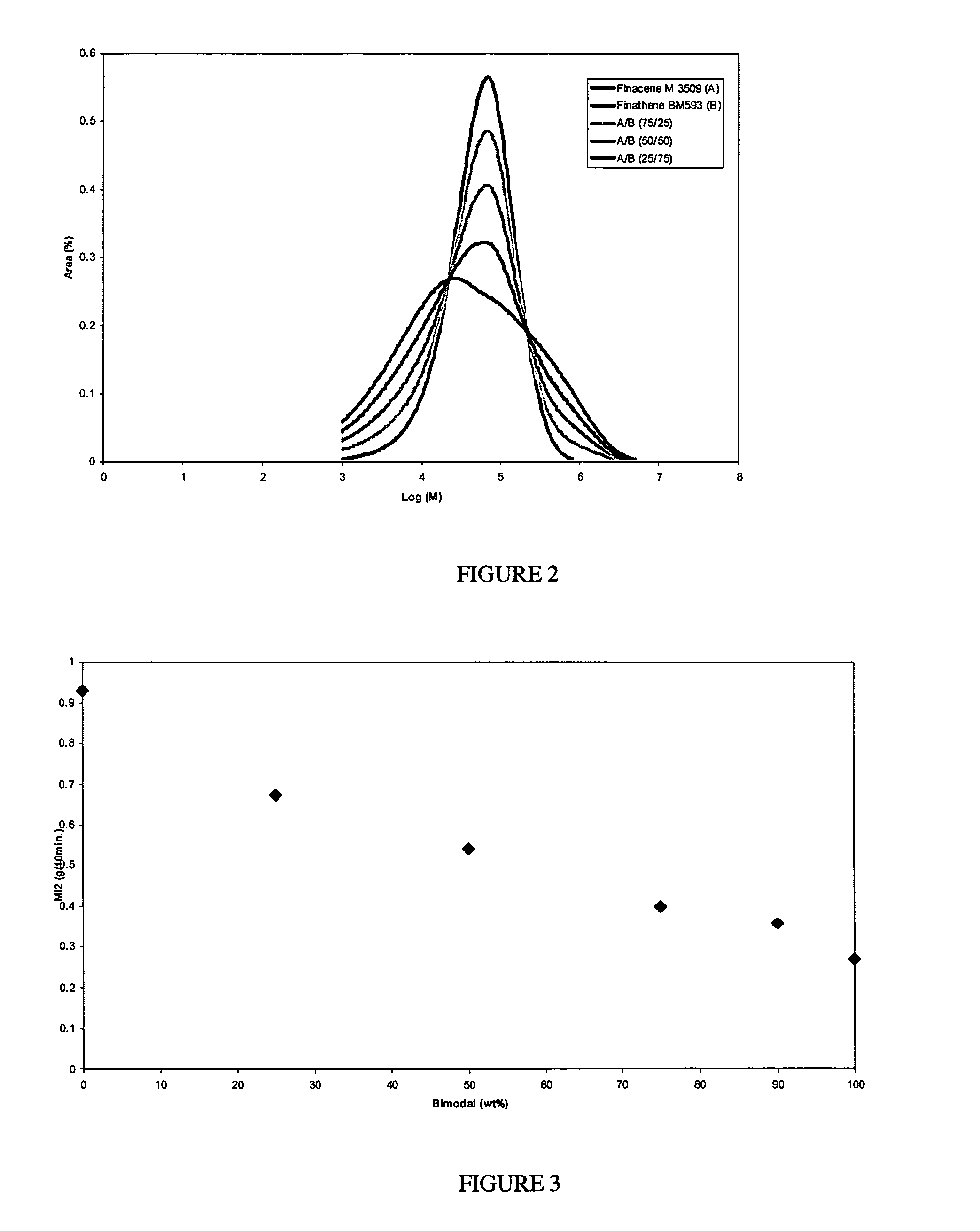

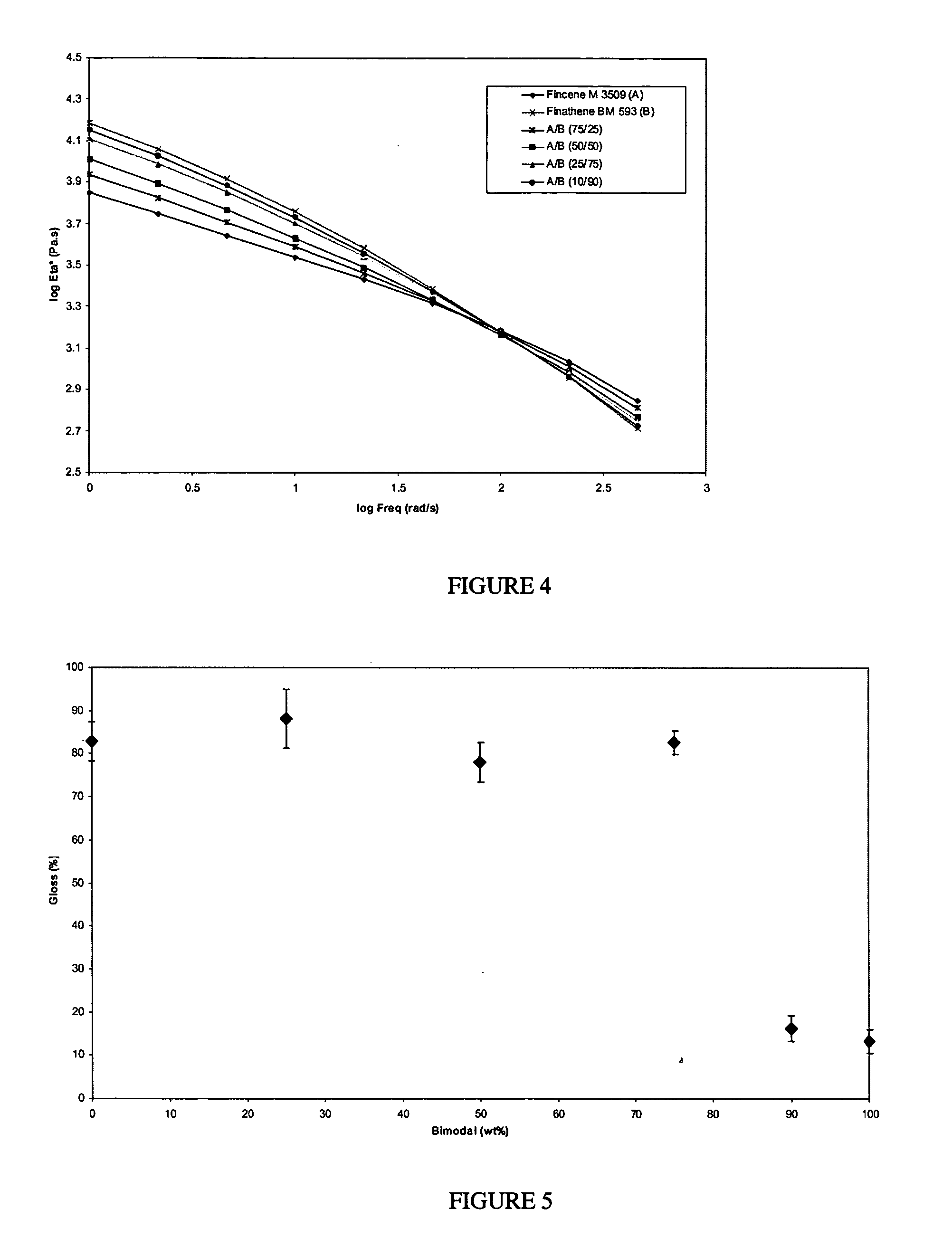

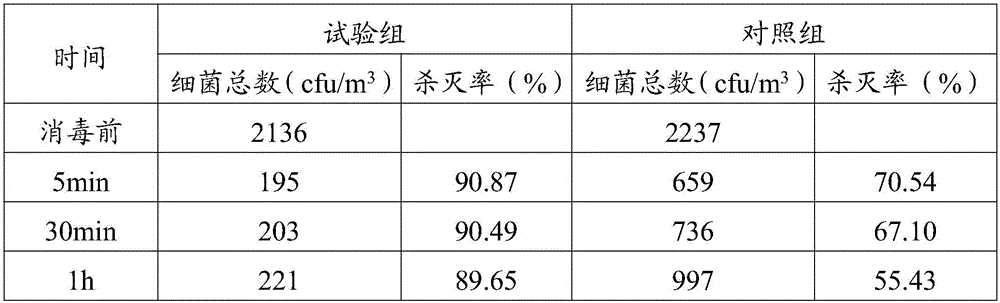

Polyethylene blends with good contact transparency

InactiveUS20050222338A1Good transparencyHigh stress crack resistanceHigh-density polyethylenePolymer blend

This invention discloses the production and use of a polyethylene composition comprising a metallocene-produced linear low density polyethylene and a multi modal high density polyethylene prepared from either a Ziegler-Natta or a metallocene catalyst system. The resulting polyethylene composition is suitable for preparing articles having improved environmental stress crack resistance, rigidity, contact transparency, gloss as well as good processing capabilities.

Owner:TOTAL RES & TECH FELUY

Air freshener and preparation method thereof

InactiveCN106310326ALong lasting fragranceGood transparencyBiocideDead animal preservationEugenolMethyl salicylate

The invention discloses an air freshener and a preparation method thereof. The air freshener comprises a plant essential oil mixture, wherein the plant essential oil mixture is prepared from, by weight, 10-97 parts of mint oil, 0.1-3.0 parts of eugenol type basil oil, 0-2 parts of camphor, 0-3 parts of borneol, 0-10 parts of menthol, 0-0.8 part of camphor wood oil, 0-0.6 part of star anise oil, 0-1.5 parts of methyl salicylate, 0-1.6 parts of turpentine, 0-10 parts of cinnamon oil, 0-0.8 part of eucalyptus oil, 0-2.5 parts of Blumea oil, 0-85 parts of lavender oil, 0-80 parts of lemongrass oil, 0-8 parts of citronella oil and 0-3.5 parts of tea tree oil. The air freshener is prepared from, by mass, 1-20% of the plant essential oil mixture. The air freshener contains plant essential oil, not only can clean air, but also can be cool and refreshing, refresh users and enable the users to recover from fatigue and breathe well.

Owner:GUANGDONG LUOFUSHAN SINOPHARM

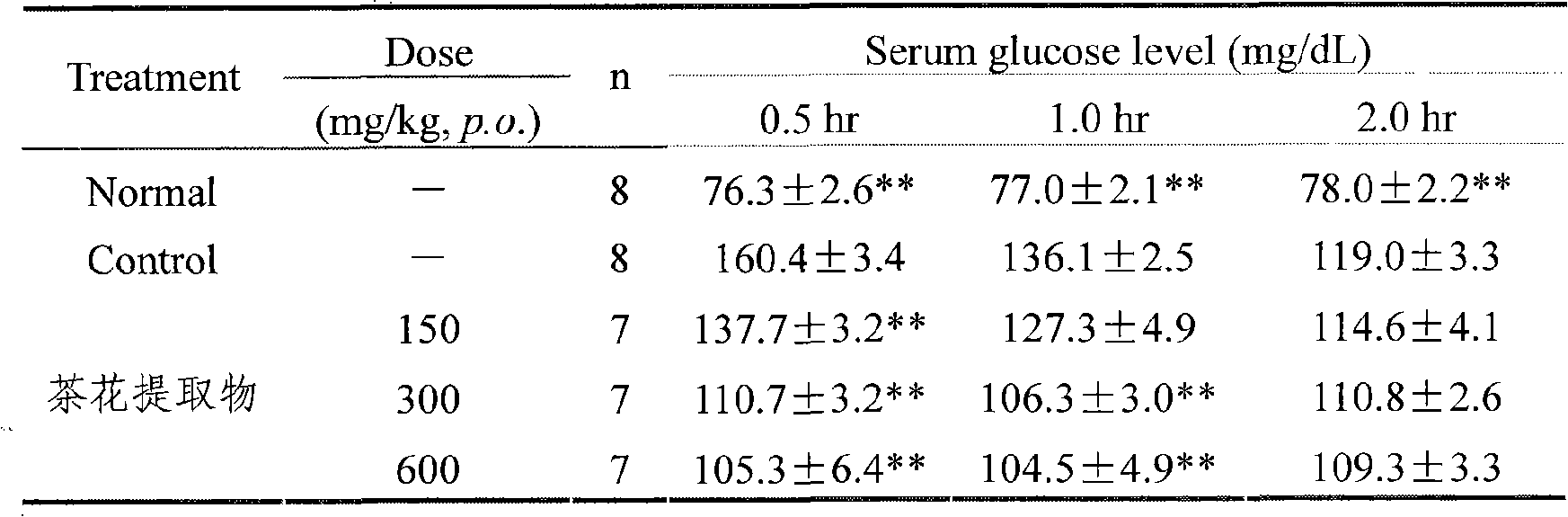

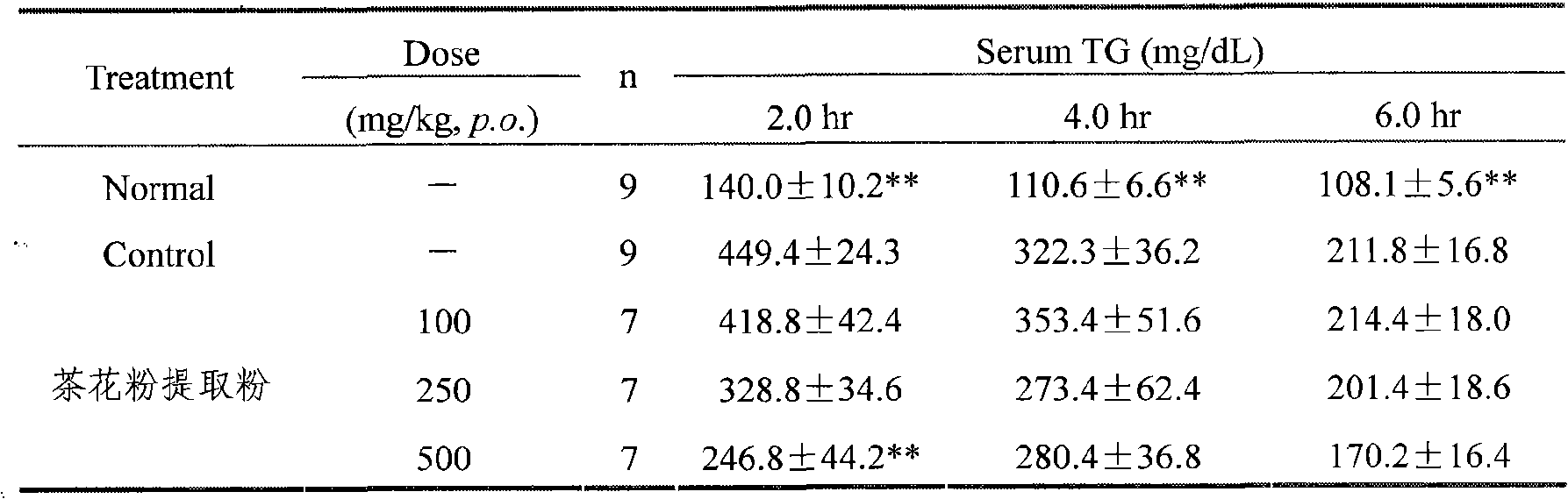

Camellia functional instant tea powder and preparation thereof

This invention belongs to the field of food technique, which relates to a functional instant tea flower powder and preparation thereof. This invention employs the tea flower as raw material and obtains the tea flower extracting solution by hot water infusion method; the tea flower extracting solution is manufactured to a tea flower concentrated solution by ultrafiltering, reverse osmosis concentrating, vacuum concentrating, sterilizing and aseptic packaging. The instant tea powder is produced by the method for spray drying or freeze drying. The functional instant tea flower powder prepared bythis invention is diffluent in cold water, the tea solution is transparent and the tea flavor is still primary taste. The tea flower powder not only is almost same as the tea infused directly by boiled water in smell, color and flavor, but also has high solubility and transparency. The processing of this invention has the advantages of high extracting efficiency, short extracting time and strong selectivity. The tea flower powder not only keeps the primary smell of tea flower and nutrition, but also has the effect of reducing blood sugar and triglyceride, is a new functional tea powder drink.

Owner:SHENYANG PHARMA UNIVERSITY

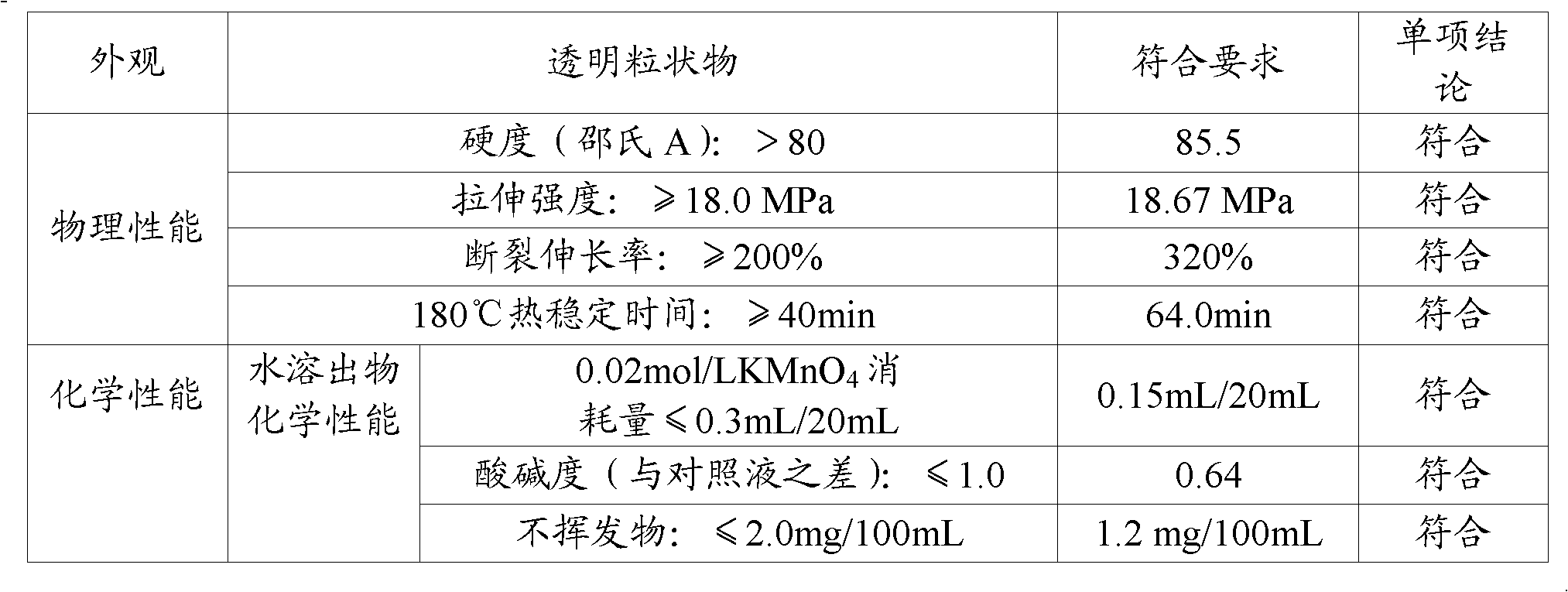

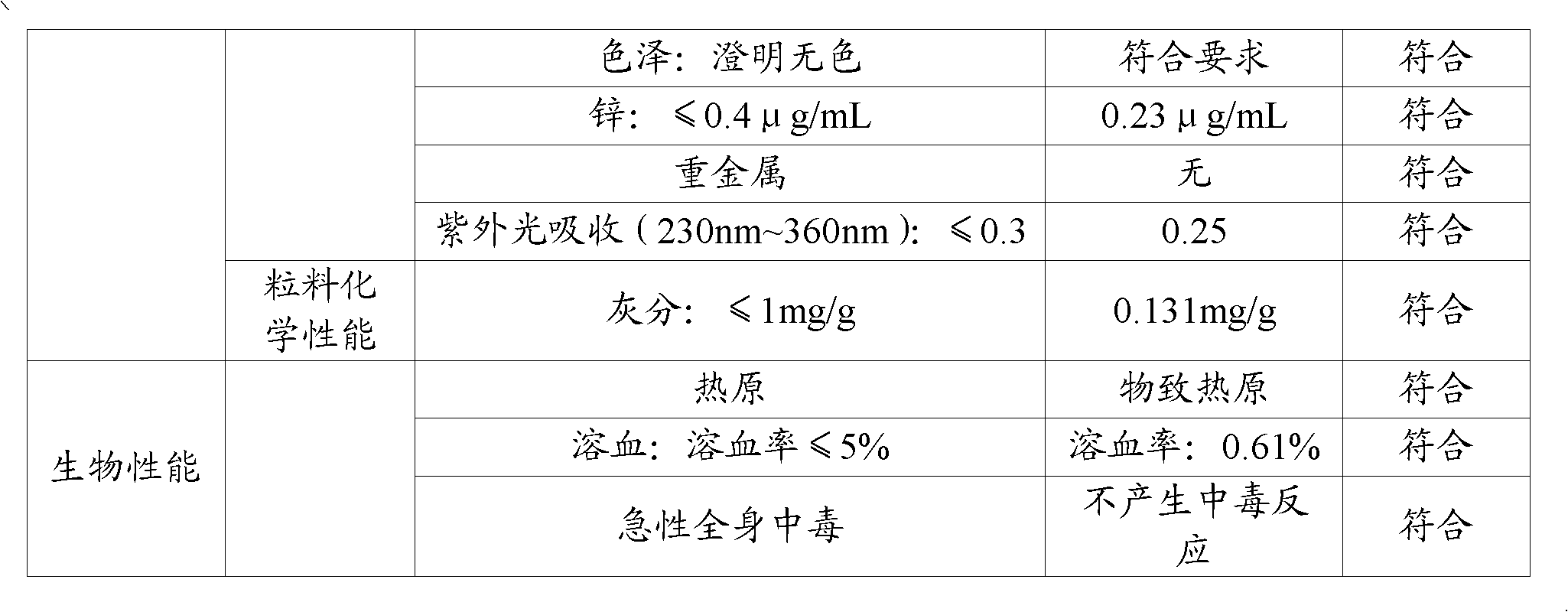

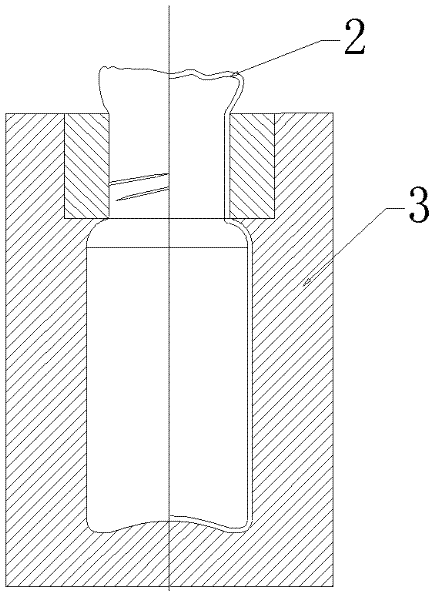

Pullulan polysaccharide capsule and preparation process thereof

InactiveCN104436204AStable performanceGood transparencyPharmaceutical non-active ingredientsCapsule deliveryWater contentDrug

The invention relates to a production method of a pharmaceutical capsule, namely a hollow pullulan polysaccharide capsule and a preparation process thereof. The pullulan polysaccharide capsule disclosed by the invention is characterized by being prepared from the following components in parts by weight: 80-99.5 parts of pullulan polysaccharide, 0.001-12 parts of gel, 0.1-5 parts of a coagulant aid, 0.1-5 parts of a cosolvent, 0.001-5 parts of a surface active agent, and 10-14 parts of water. The pullulan polysaccharide capsule and the preparation process thereof disclosed by the invention have the beneficial effects that the pullulan polysaccharide capsule is steady in property, good in transparency, difficult to become fragile, low in production cost, free from animal component and safe to use; the surface of the pullulan polysaccharide capsule cannot become fogged and yellow after being placed for a long time; the water content of the pullulan polysaccharide capsule is obviously lower than that of a gelatin capsule; therefore, the pullulan polysaccharide capsule is more suitable to be filled in hygroscopic drugs and aldehyde-containing drugs; the physicochemical indexes of the pullulan polysaccharide capsule accord with hollow shell capsule standards specified by the national formulary; the pullulan polysaccharide capsule satisfies requirements of different religious cultures; and therefore, the pullulan polysaccharide capsule has a wide market prospect and practical value.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

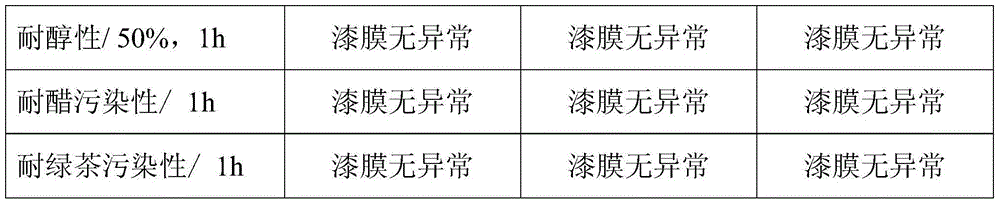

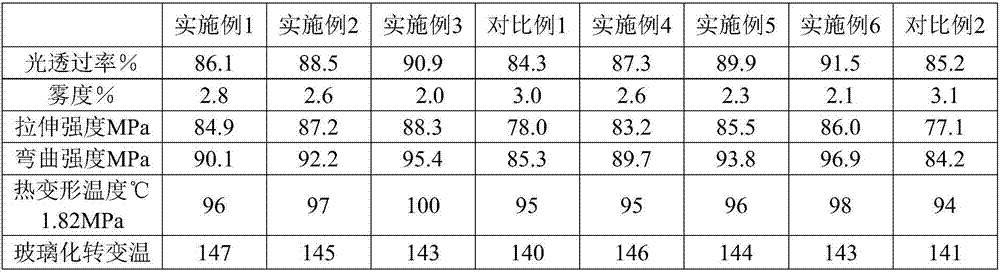

Non-ionic aqueous HDI polyurethane curing agent preparation method

ActiveCN105669947AGood scratch resistanceGood transparencyPolyurea/polyurethane coatingsSolventPolyester

The present invention relates to a non-ionic aqueous HDI polyurethane curing agent preparation method. The non-ionic aqueous HDI polyurethane curing agent mainly consists of HDI trimers, low molecular weight polyether polyols and an inert solvent. The obtained non-ionic aqueous HDI polyurethane curing agent is free of arene, glycol ethers and alkyl phenol, environmentally friendly, good in scratch resistance, good in transparency, excellent in chemical resistance, strong in pollution resistance, good in yellowing resistance, etc. A polyurethane paint prepared by an aqueous hydroxyl components is high in hardness and high in transparency, the paint film is good in scratch-resistant, and the polyurethane paint is good in flow leveling, high in fullness, good in compatibility, etc. The curing agent is a specific curing agent used for waterborne carpentry paint, waterborne industrial paint, waterborne plastic paint and various two-component waterborne polyester paint, waterborne polyurethane paint, waterborne epoxy paint, waterborne alkyd paint, waterborne polyurethane glue, etc.

Owner:UNION FOSHAN CHEM +1

Polymeric piezoelectric material, and process for producing the same

InactiveUS20140051825A1High constantGood transparencyPiezoelectric/electrostrictive device manufacture/assemblyChiral polymersChemistry

The invention provides a polymeric piezoelectric material including a helical chiral polymer having a weight-average molecular weight of from 50,000 to 1,000,000 and having optical activity, wherein a crystallinity of the material measured by a DSC method is from 20% to 80%, and a product of a standardized molecular orientation MORc measured by a microwave transmission type molecular orientation meter based on a reference thickness of 50 μm and the crystallinity is from 25 to 250.

Owner:MITSUI CHEM INC

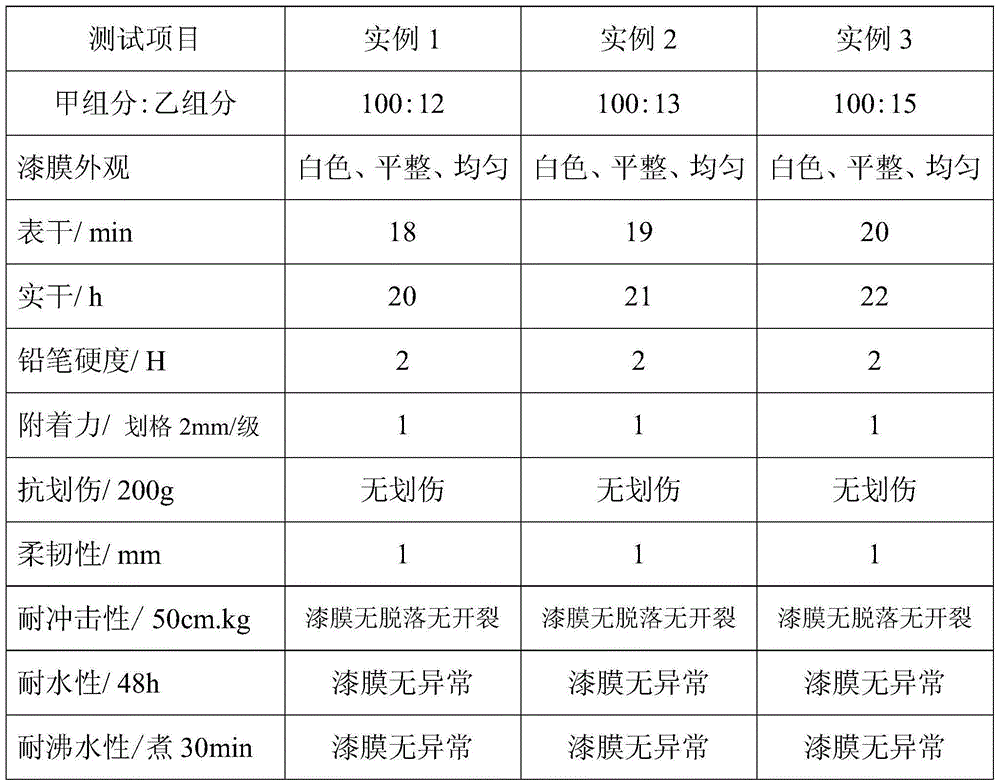

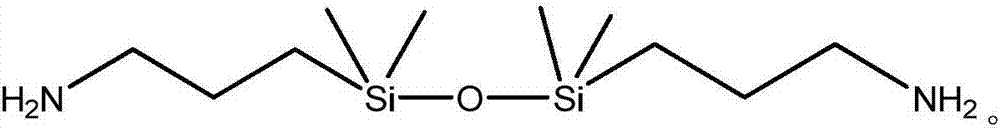

Copolymerization transparent nylon and preparation method for same

The invention discloses copolymerization transparent nylon which is mainly composed of a component A and a component B through condensation polymerization. The component A is a salt which is formed by polymerizing aromatic binary acid and 2-methyl pentanediamine; and the component B is a salt which is formed by polymerizing diaminosiloxane and aliphatic binary acid. The preparation method includes the steps of: adding the aromatic binary acid and the 2-methyl pentanediamine into an auto-control polymerization kettle with a stirrer to perform a reaction to obtain the component A; adding the aliphatic binary acid and the diaminosiloxane into the auto-control polymerization kettle with the stirrer to perform a reaction to obtain the component B; and feeding a catalyst, an initiator, the component A and the component B into a high-pressure reaction kettle to perform a polymerization reaction to produce the copolymerization transparent nylon. The copolymerization transparent nylon has better transparency, lower water absorption rate and higher heat resistance than semi-aromatic transparent nylon 6T / 6I and cycloaliphatic transparent nylon.

Owner:株洲时代工程塑料科技有限责任公司

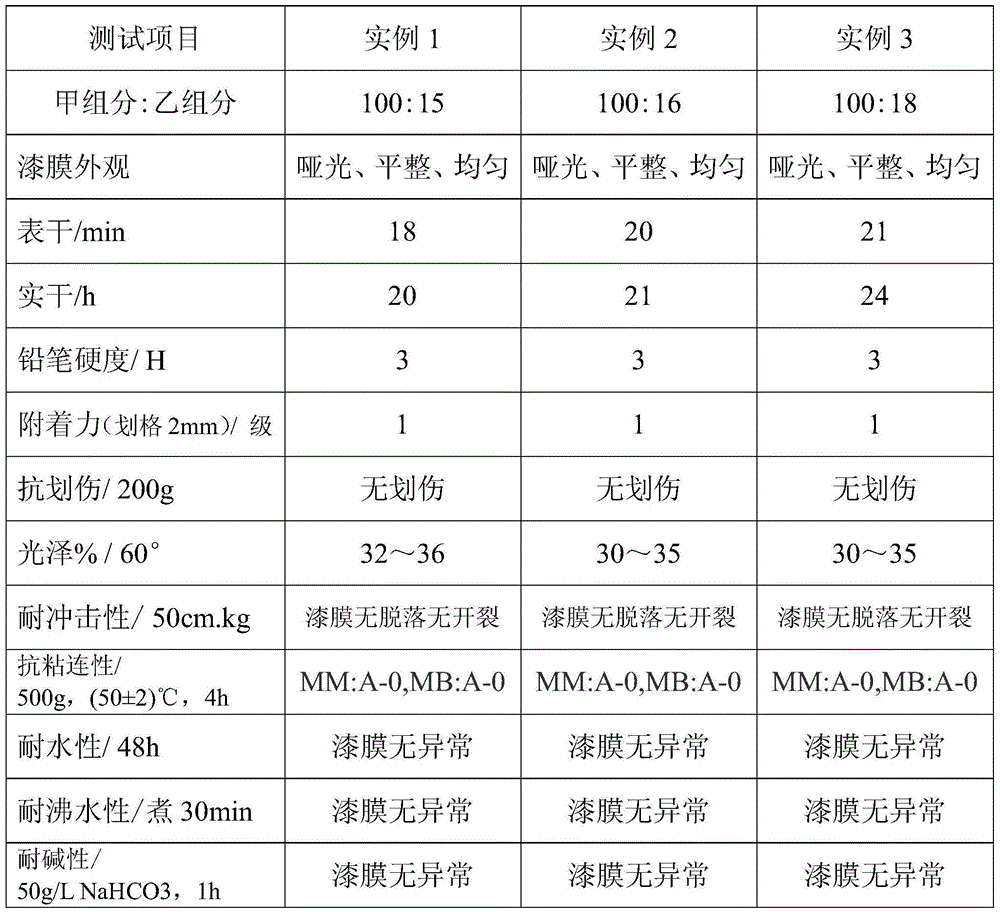

High-definition silky finish and preparation method thereof

ActiveCN104046225APollution ResistanceGood transparencyPolyurea/polyurethane coatingsEpoxy resin coatingsWaxChemistry

The invention discloses a high-definition silky finish and a preparation method thereof. The finish comprises the following components by weight fraction: 18-50% of easy-extinction resin, 0.1%-0.5% of a defoamer, 1%-3% of a dispersing agent, 1%-15% of yellow phase extinction powder, 1%-5% of wax powder, 5%-8% of an initiator, 0.1%-1% of a leveling agent, 1%-1.5% of anti-settling agent and the balance of monomer, wherein easy-extinction resin is at least one of polyurethane-acrylic resin, modified epoxy acrylic resin or polyester acrylic resin; yellow phase extinction powder is at least one of organic-phase-modified gas phase silicon dioxide or extinction wax; the wax power is at least one of polyethylene wax or fluorine-modified polyethylene wax. According to the invention, conventional surface scratch resistance and pollution performance are satisfied; meanwhile, by adjusting the ratio of easy-extinction resin, extinction powder or extinction wax and other materials, the film has good transparency, and the wood texture can be well exhibited; the surface of the film is fine and smooth and has a silky tactility.

Owner:JIANGSU HIMONIA TECH

Cationic type polypropylene carbonate waterborne polyurethane emulsion as well as preparation method and application

InactiveCN103435771AGood adhesionGood transparencyPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolypropylene carbonateIsocyanate

The invention belongs to the field of waterborne polyurethane and discloses a cationic type polypropylene carbonate waterborne polyurethane emulsion as well as a preparation method and the application thereof. The preparation method comprises the following steps: mixing polypropylene carbonate polyol with diisocyanate, raising temperature to 60 DEG C, adding a catalyst, gradually raising temperature to 80-90 DEG C, performing heat reaction for 2-3 h; reducing temperature to 40 DEG C, dropwise adding cationic hydrophilic chain extender, taking reaction for 3-4 h; raising temperature to 60 DEG C, adding small molecular chain extender, taking reaction for 1-2 h, and adding appropriate acetone to adjust the viscosity; when reducing temperature to 35-45 DEG C, adding a salt-forming agent to take reaction for 05-1 h; adding deionized water to emulsify the liquid, stirring the liquid at high speed, and evaporating to remove acetone, so as to obtain the cationic type polypropylene carbonate waterborne polyurethane emulsion. The cationic type polypropylene carbonate waterborne polyurethane emulsion is of excellent cohesiveness, and the obtained latex film has good transparency and good tear-resisting strength, so as to be taken as a waterborne coating and an adhesive.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

EVA (Ethylene vinyl-acetate) film and manufacturing method thereof

ActiveCN103205212AHigh transparencyGood transparencyFilm/foil adhesivesSynthetic resin layered productsPolyolefinSilane coupling

The invention provides an EVA (Ethylene vinyl-acetate) film used for laminated glass which is prepared from raw materials in percentage by weight as follows: 69-89.5% of ethylene-vinyl acetate copolymer, 10-30% of polyolefin plastomer, 0.2-0.4% of a silane coupling agent, 0.2-0.5% of an optical stabilizer and 0.1-0.4% of an antioxidant. The content of vinyl acetate in the ethylene-vinyl acetate copolymer is 32-33%. The EVA film consists of an upper layer, a middle layer and a lower layer, wherein the upper and lower layers are prepared from the ethylene-vinyl acetate copolymer, the silane coupling agent, the optical stabilizer and the antioxidant. The middle layer is prepared from the polyolefin plastomer. The EVA film provided by the invention is not only high in strength and transparency, but also good in sound insulating and shockproof performance. The invention further provides a preparation method of the EVA film, and the process is simple and easy to control.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD

No-sugar health wine and its making process

The making process of no-sugar health wine includes dissolving mangosteen triterpene glycoside extracted form alcoholized mangosteen into edible alcohol to obtain mangosteen triterpene glycoside solution; regulating the temperature of completely fermented grape juice as base wine to 18-28 deg.c; mixing the mangosteen triterpene glycoside solution and the fermented grape juice; and maintaining the mixture at 18-28 deg.c for over 2 hr to obtain the no-sugar health wine. The no-sugar health wine contains no monosaccharide, disaccharide and polysaccharide and is suitable for all people. It has the health functions similar to various grape wine as well as the health functions of clearing away heat of pharynx and larynx, moistening lung and relieving cough, like mangosteen.

Owner:张雨生

Air freshener and preparation method thereof

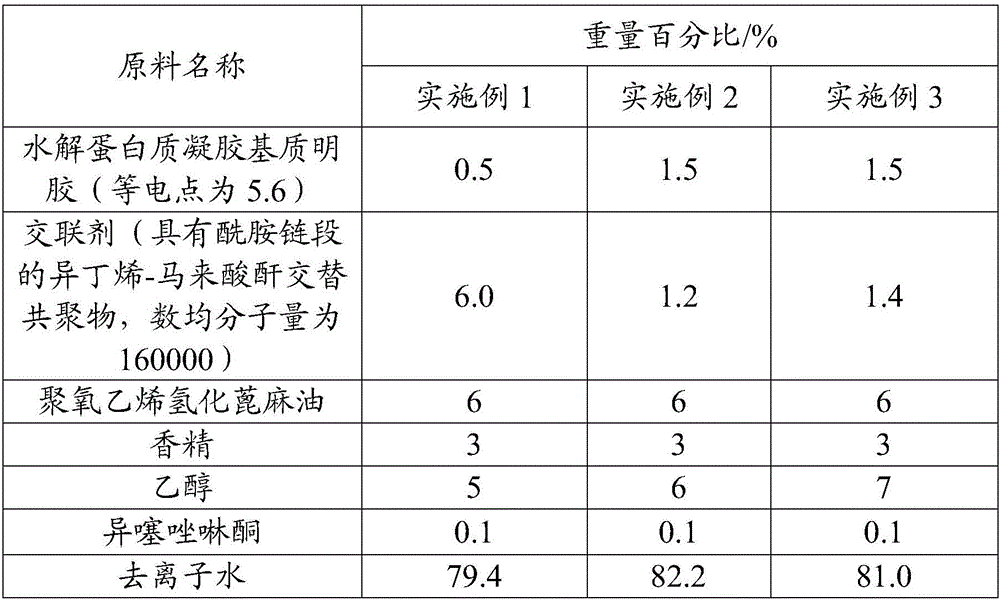

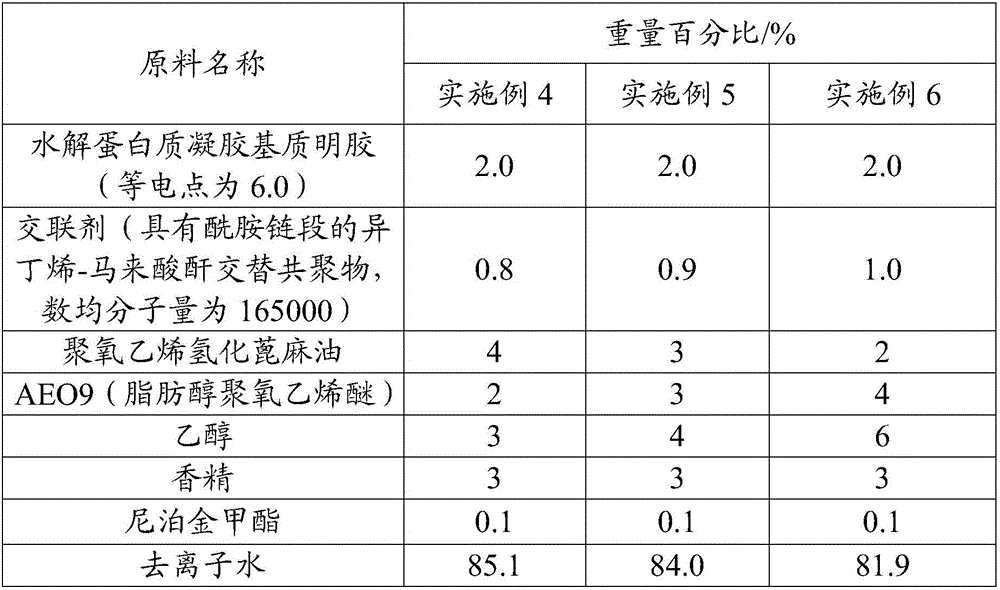

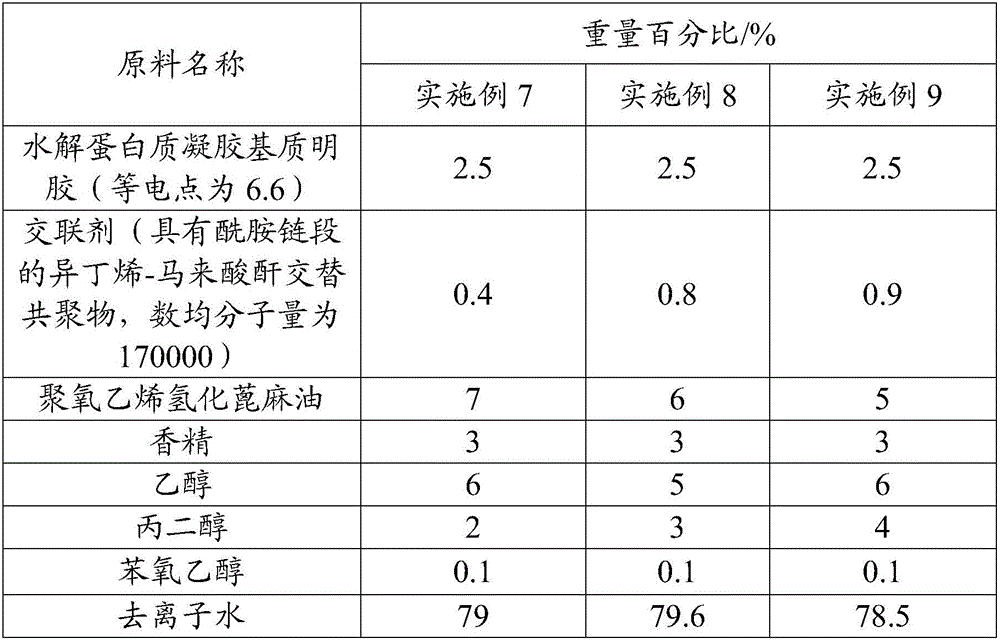

The invention relates to an air freshener and a preparation method thereof. The air freshener is prepared from the following components as raw materials by weight percent: 0.4%-6% of cross-linking agents, 0.5%-10% of gel, 1%-15% of solubilizers, 0.1%-15% of cosolvents, 0.05%-0.5% of preservatives, 0.5%-6% of flavor and fragrance and the balance of water. The air freshener provided by the invention is a gel solid with penetrating appearance, has good high temperature stability and excellent colloid elasticity, can slowly release, can have long-lasting fragrance and can please mind and body.

Owner:广州超威生物科技有限公司

PVC (polyvinyl chloride) heat shrinking film and preparation method thereof

The invention discloses a PVC heat shrinking film which is prepared by raw materials in parts by weight as follows: 90-100 parts of PVC resin, 1-5 parts of an assistant, 2-5 parts of a lubricating agent, 1-3 parts of a plasticizer and 2-5 parts of an antioxidant. The invention further discloses a preparation method of the PVC heat shrinkage film. The PVC heat shrinkage film obtained by adopting the preparation method has better transparency compared with a common PVC heat shrinkage film, and is uniform in shrinkage, high in shrink rate and environment-friendly; and the preparation method is simple and easy to operate, and can realize large-scale production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

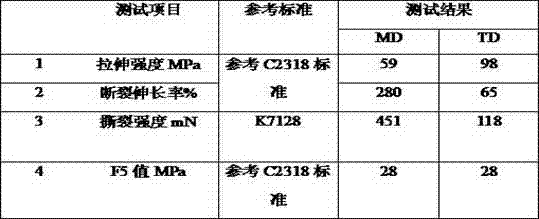

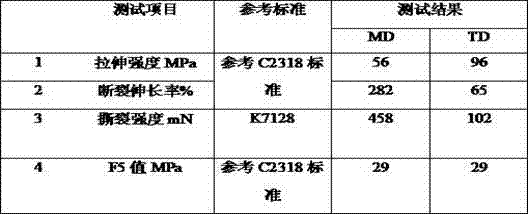

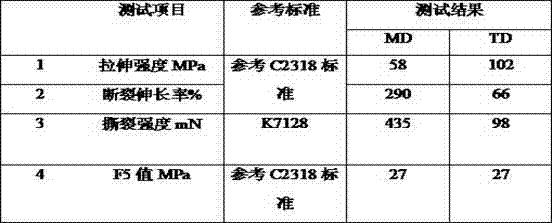

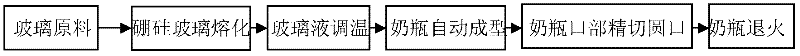

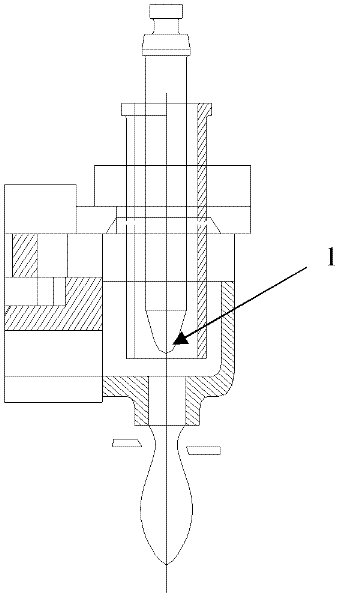

Production method for automatically machining borosilicate glass series feeding bottles

InactiveCN102503081AGood transparencyBright appearanceFeeding-bottlesPress and blow machinesMicrowave ovenConstant speed

The invention relates to a production method for automatically machining borosilicate glass series feeding bottles. The production method includes steps of (1), precisely metering various raw materials according to composition requirements of borosilicate glass, and sequentially pouring the raw materials into a mixing machine to mix the raw materials; (2), melting the borosilicate glass, feeding raw glass materials into a fully-electric melting furnace at uniform and constant speed to realize high-temperature melting, and homogenizing bubble-free glass melt in a homogenizing layer after a clarification process; (3), supplying materials to regulate the temperature of the glass melt, regulating the temperature of the glass melt in a glass material supply pipeline so that temperature required for forming feeding bottles is achieved; (4), forming and manufacturing the feeding bottles; (5), realizing precision cutting for round openings of the feeding bottles; and (6), realizing annealing treatment for the feeding bottles. The production method has the advantages that the glass of the feeding bottles is fine in transparency, appearances of the feeding bottles are smooth and bright, mold joint close lines are avoided, and the feeding bottles can be cleaned and checked easily. In addition, the feeding bottles can be boiled and sterilized at high temperature and cooled instantly by cold water to be used without breakage, can also be heated in a microwave oven, are fine in chemical stability and cannot be reacted to water, and acid and alkali substances after being used for a long time.

Owner:HANGZHOU AIJIA GLASS PROD

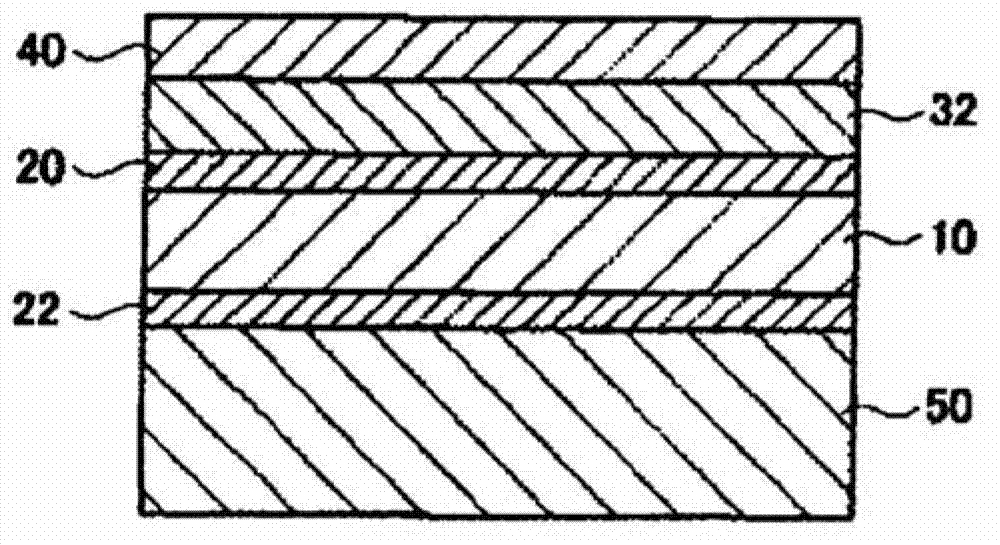

Optical adhesive resin composition, optical adhesive sheet, image display device, method for producing optical adhesive sheet, and method for producing image display device

InactiveCN103249796AGood transparencyExcellent handlingAdhesive processesNon-macromolecular adhesive additivesChemistrySide chain

The present invention is an optical adhesive resin composition containing (A) a (meth)acrylate polymer and (B) a side chain (meth)acrylic-modified (meth)acrylate polymer. The present invention can provide: the optical adhesive resin composition having excellent transparency, having sufficient step conformability, and being suitable for application in an image display device having superior handling characteristics and adhesion; an optical adhesive sheet that uses the optical adhesive resin composition; and an image display device that uses the optical adhesive sheet.

Owner:HITACHI CHEM CO LTD

Nuclear pore membrane composite medical dressing

InactiveCN1775301AGood mechanical strengthGood transparencyAbsorbent padsBandagesPressure sensitiveChemistry

The present invention relates to a nucleopore membrane composite type medical dressing. It includes basic membrane layer, said basic membrane layer is formed from single layer of nucleopore membrane or formed by superimposing several layers of nucleopore membranes, all the nucleopore membrane layers are successively up-down arranged according to the pore diameter from large to small, between membrane and membrane they are cohered together by means of pressure-sensitive adhesive, the pore diameter range of nucleopore membrane is 1-10 microns, its permeability range is 0.05%-50%, on one side of basic membrane layer directly-contacted with surface for wound a layer of skin friendly layer made up by selecting aquagel or silicon gel material is superimposed, on the side of basic membrane layer non-contacted with surface of wound a layer of reinforcing layer made up by using transparent porous semipermeable polymer material or non-woven fabric is superimposed.

Owner:长春吉原生物科技有限公司

Photosensitive graft polymer, and photosensitive resin composition comprising the same

InactiveCN101821299AGood dispersion stabilityGood transparencyPhotosensitive materials for photomechanical apparatusPolymer chemistryBenzyl group

Owner:SHOWA DENKO KK

Transparent ABS material and preparation method thereof

The invention discloses a transparent ABS material and a preparation method thereof. The transparent ABS material comprises the following components by weight percentage: 90-95 percent of ABS, 2-5 percent of main anti-static agent, 1-3 percent of auxiliary anti-static agent and 1-2 percent of high-temperature antioxidant. The transparent ABS material maintains the advantages of the ABS such as easy processing and formation, excellent corrosion resistance, excellent chemical resistance and the like, and also has the advantages of excellent transparency, excellent anti-static effect and permanent anti-static properties. Therefore, the transparent ABS material can substitute glass in various fields, and has broad application prospects in such industries as electrical appliances, instruments,automobiles, medical appliances and electronics.

Owner:SHENZHEN KEJU NEW MATERIAL

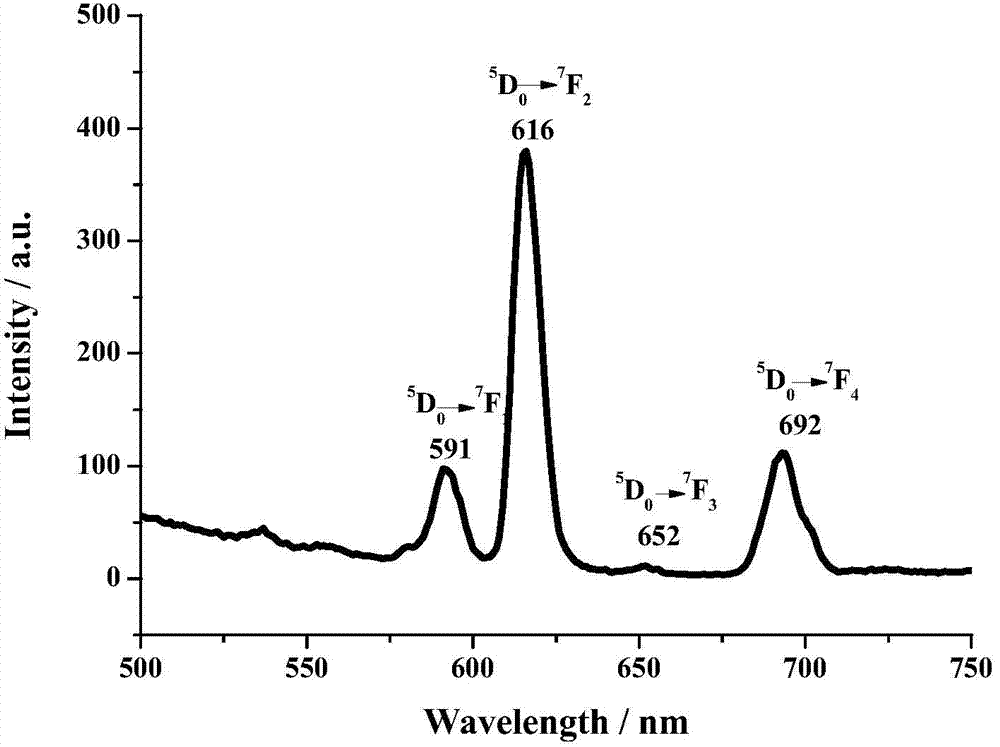

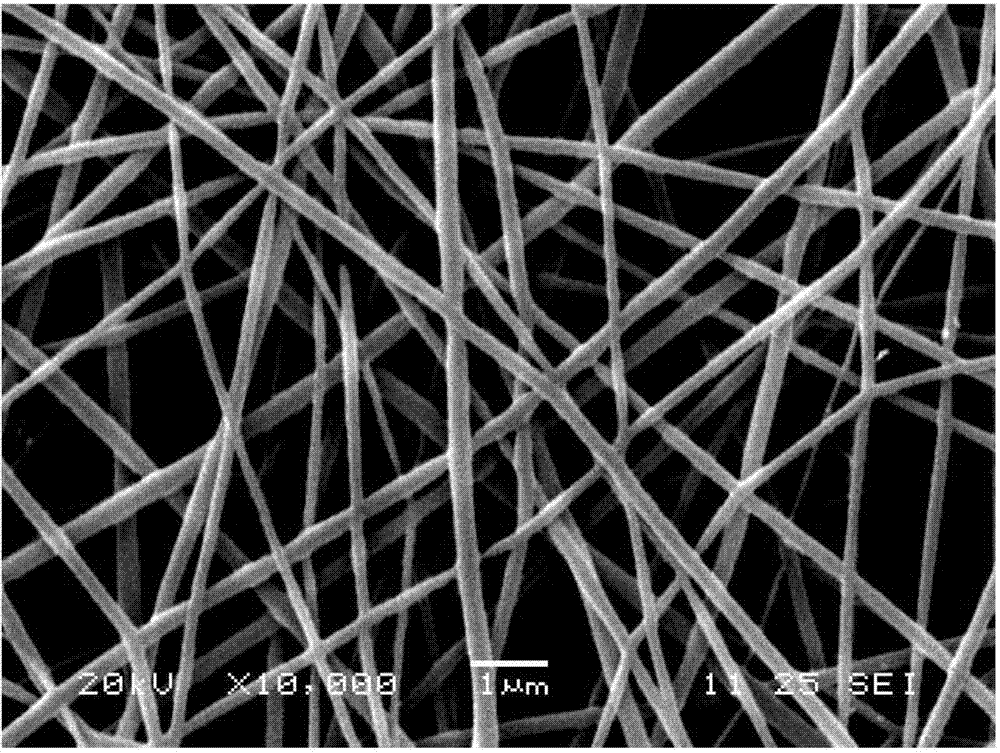

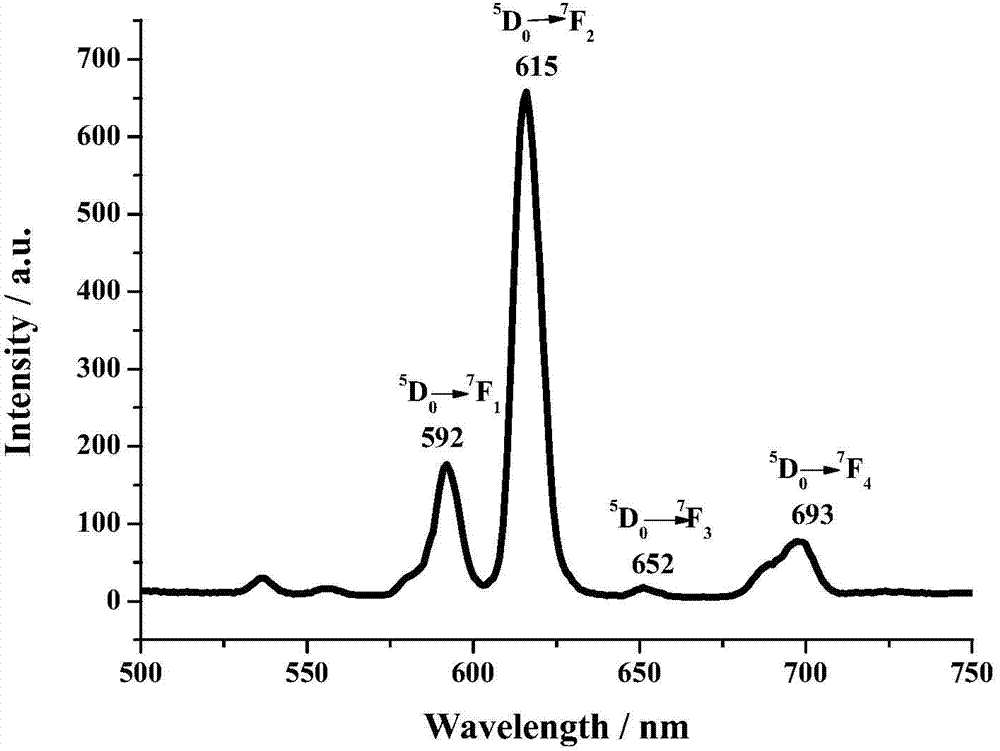

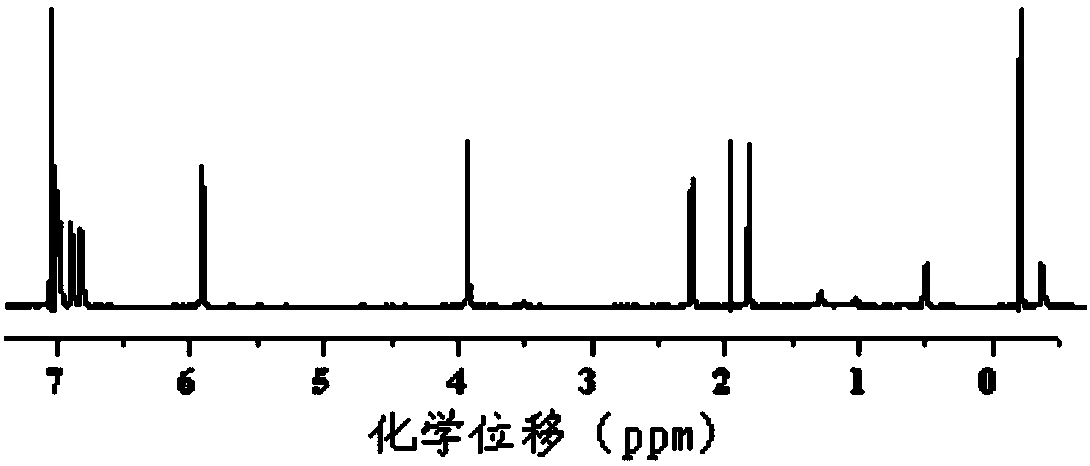

Side-hanging type polymethyl methacrylate rare earth complex luminescent material and preparation method thereof

InactiveCN104498032AEliminate concentration quenching effectsGood transparencyLuminescent compositionsConcentration quenchingSolubility

The invention discloses a side-hanging type polymethyl methacrylate rare earth complex luminescent material and a preparation method thereof, belongs to the field of high polymer materials, and in particular relates to a side-hanging type polymethyl methacrylate rare earth complex luminescent material and a preparation method thereof. The side-hanging type polymethyl methacrylate rare earth complex luminescent material is obtained by taking polymethyl methacrylate random copolymer of side-hanging aromatic carboxylic acid as a high polymer ligand and organic small molecules as a co-ligand to perform coordination with rare earth ions in an organic solvent. According to the side-hanging type polymethyl methacrylate rare earth complex luminescent material disclosed by the invention, because the luminescent center of the material is side-hung on a high polymer main chain, and flexible high polymers wrap the luminescent center and are separated from the luminescent center, a concentration quenching effect is effectively eliminated, and the fluorescence intensity of the luminescent material can be enhanced along with the increase of the rare earth content; and moreover, a matrix polymer has good transparency, has good solubility in various organic solvents, can be prepared into solid powder, a transparent film or nano fibers, can emit fluorescent light of various colors under ultraviolet irradiation, and can be applied to the fields of anti-counterfeiting mark materials, display materials and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Tuna coarse oil refining method

The invention provides a tuna coarse oil refining method. The method comprises the steps as follows: firstly, degumming; secondly, deacidification; thirdly, decoloration; fourthly, deodorization. According to the method, the degumming rate can reach as high as 5.35%, the degummed tuna oil is better in transparency, light in color, and has tinny fishy taste, and convenient for storage, and moreover, the technology required in the method is simple and convenient to realize, and has high practicability.

Owner:应夏英

Ultraviolet-curtain coating finish

InactiveCN102127364AHigh surface flatnessGood transparencyPolyurea/polyurethane coatingsEpoxy resin coatingsPliabilityDefoaming Agents

The invention discloses an ultraviolet-curtain coating finish. The finish comprises the following components in percentage by weight: 50 to 70 percent of 100 percent ultraviolet resin, 0.1 to 0.5 percent of defoaming agent, 1.0 to 2 percent of dispersing agent, 5 to 10 percent of filler, 3 to 8 percent of initiator, 0.1 to 1 percent of leveling agent, 1 to 1.5 percent of settling agent, and the balance of monomers, wherein the 100 percent ultraviolet resin is polyurethane acrylic resin, or modified epoxy acrylic resin or a mixture thereof; the monomers are acrylate monomers, modified acrylate monomers or a mixture thereof; and the filler is inorganic powder. The ultraviolet-curtain coating finish has high surface evenness, good transparency and high plumpness; and the formed film has high flexibility and scraping resistance, and can form a scraping-resistant protective layer on the surfaces of wood products such as wood furniture and wood floors, so as to durably protect the surfaces of the wood furniture and the wood floors.

Owner:JIANGSU HIMONIA TECH

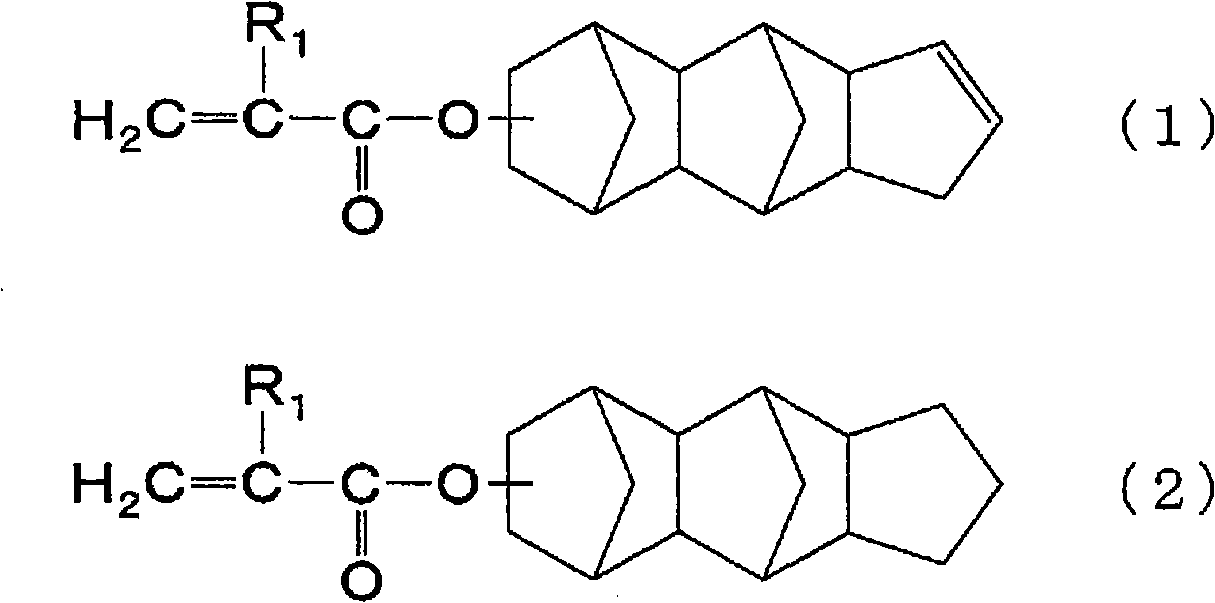

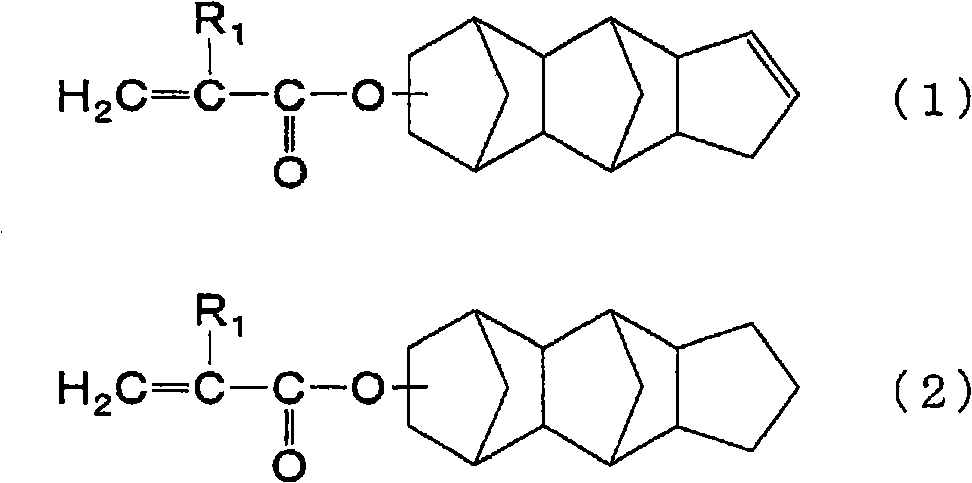

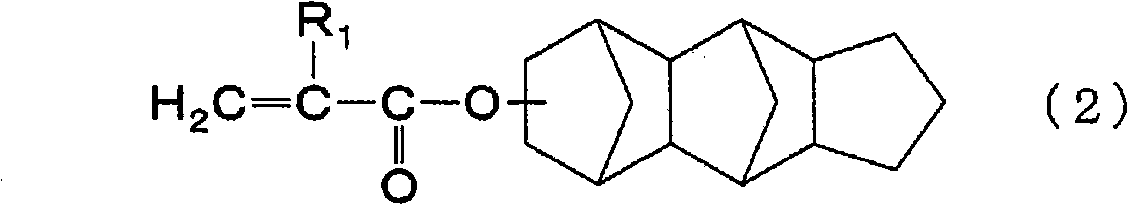

Cycloolefin copolymer and preparation method thereof

InactiveCN103965402AGood heat resistance and mechanical propertiesGood transparencyTransmittanceChemistry

The invention provides a cycloolefin copolymer with a structure shown in the formula I. In the formula I, x and y refer to polymerization degrees, wherein x is more than or equal to 250, and is less than or equal to 500; y is more than or equal to 20, and is less than or equal to 144. The cycloolefin copolymer provided by the invention has relatively good heat resistance and mechanical properties simultaneously. Experimental results show that the cycloolefin copolymer provided by the invention has the glass-transition temperature of 125-215 DEG C, the relatively good resistance, the tensile strength of 23-35MPa, the tensile modulus of 1000-1650MPa, the elongation at break of 3.7-4.9% and the relatively good mechanical properties. Moreover, the cycloolefin copolymer provided by the invention also has relatively good transparency. The experimental results show that the cycloolefin copolymer provided by the invention has the light transmittance of more than 90%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

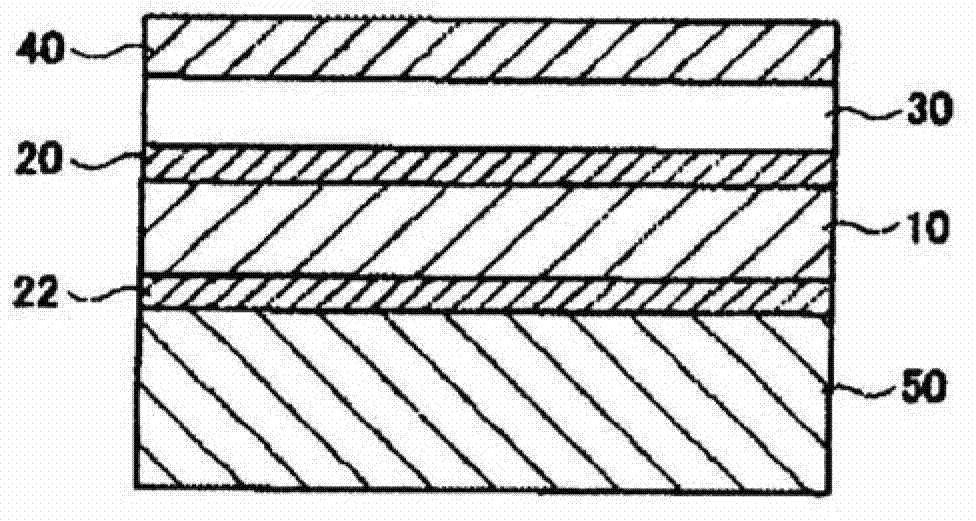

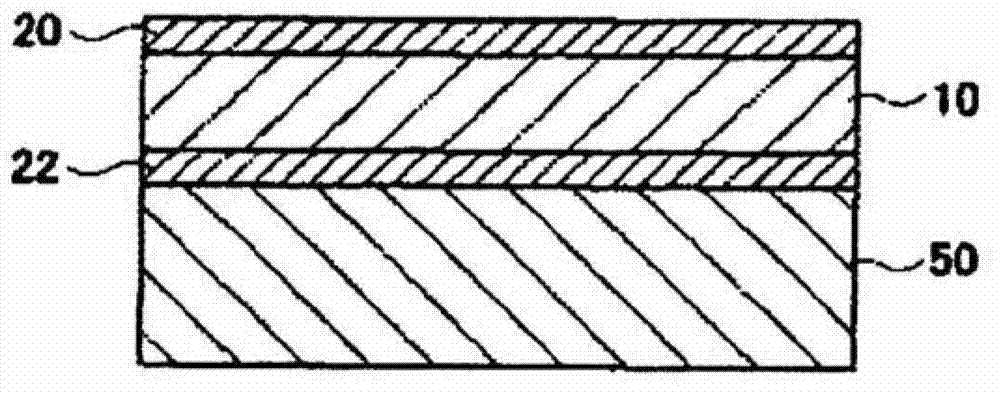

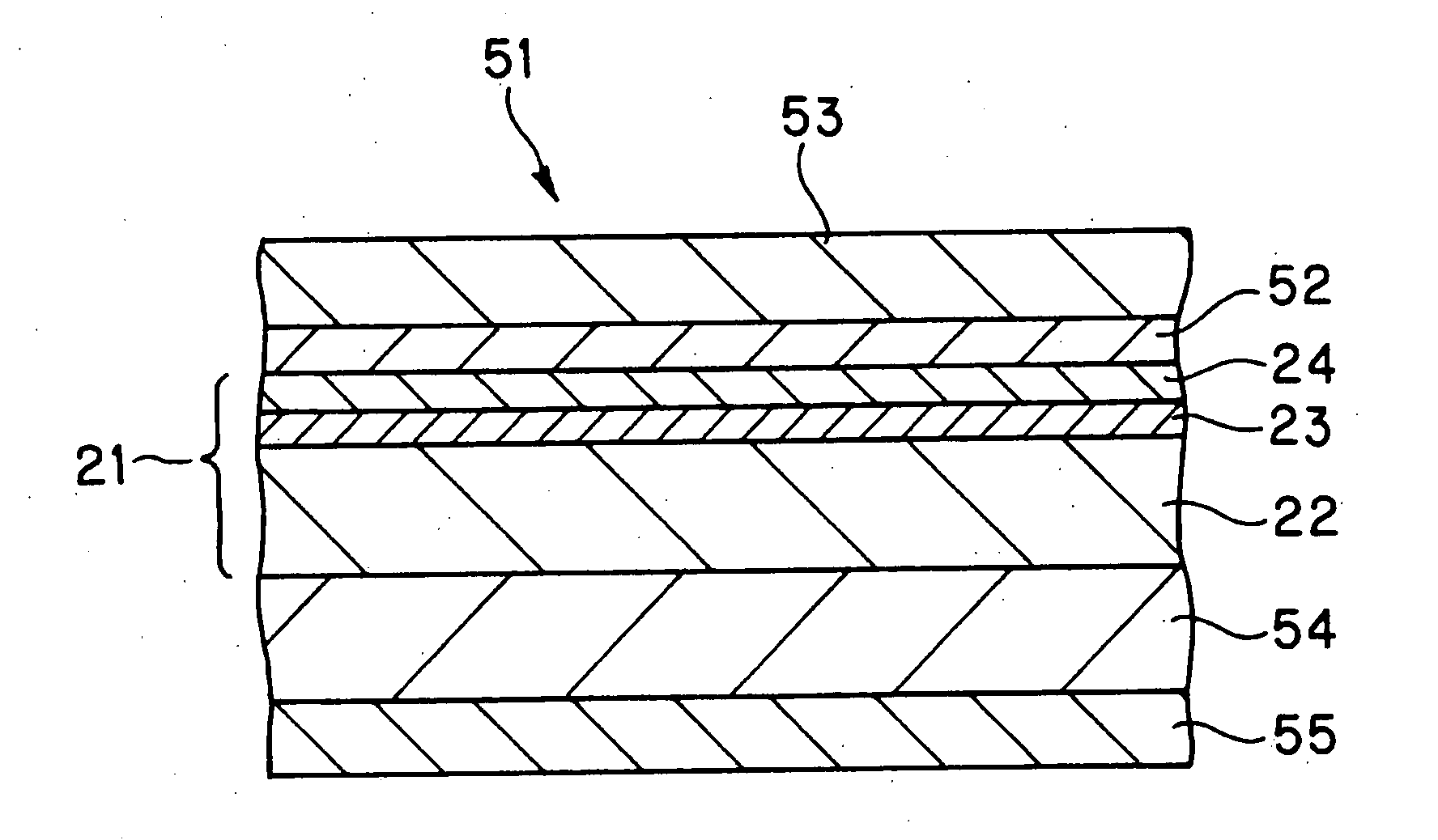

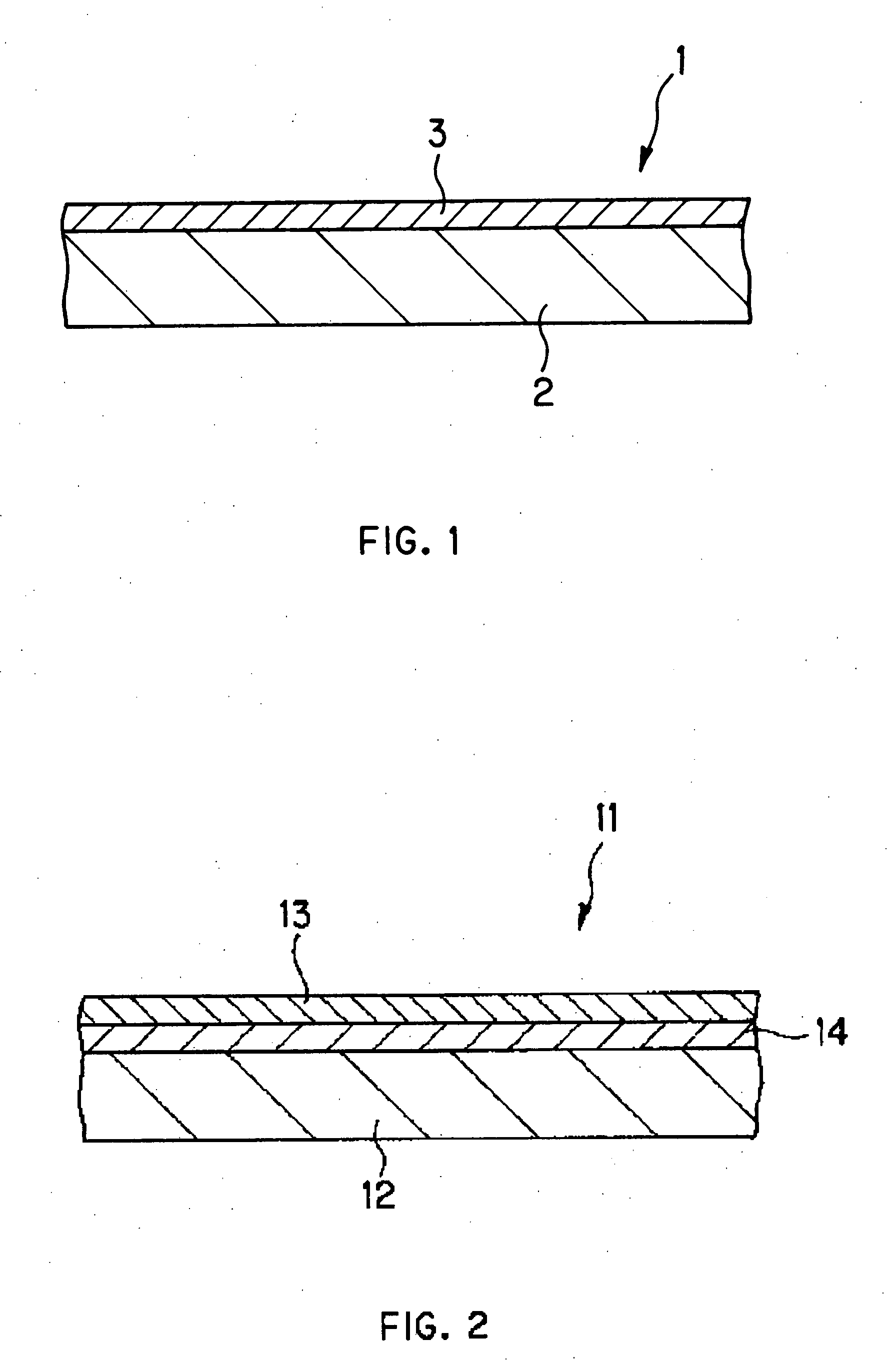

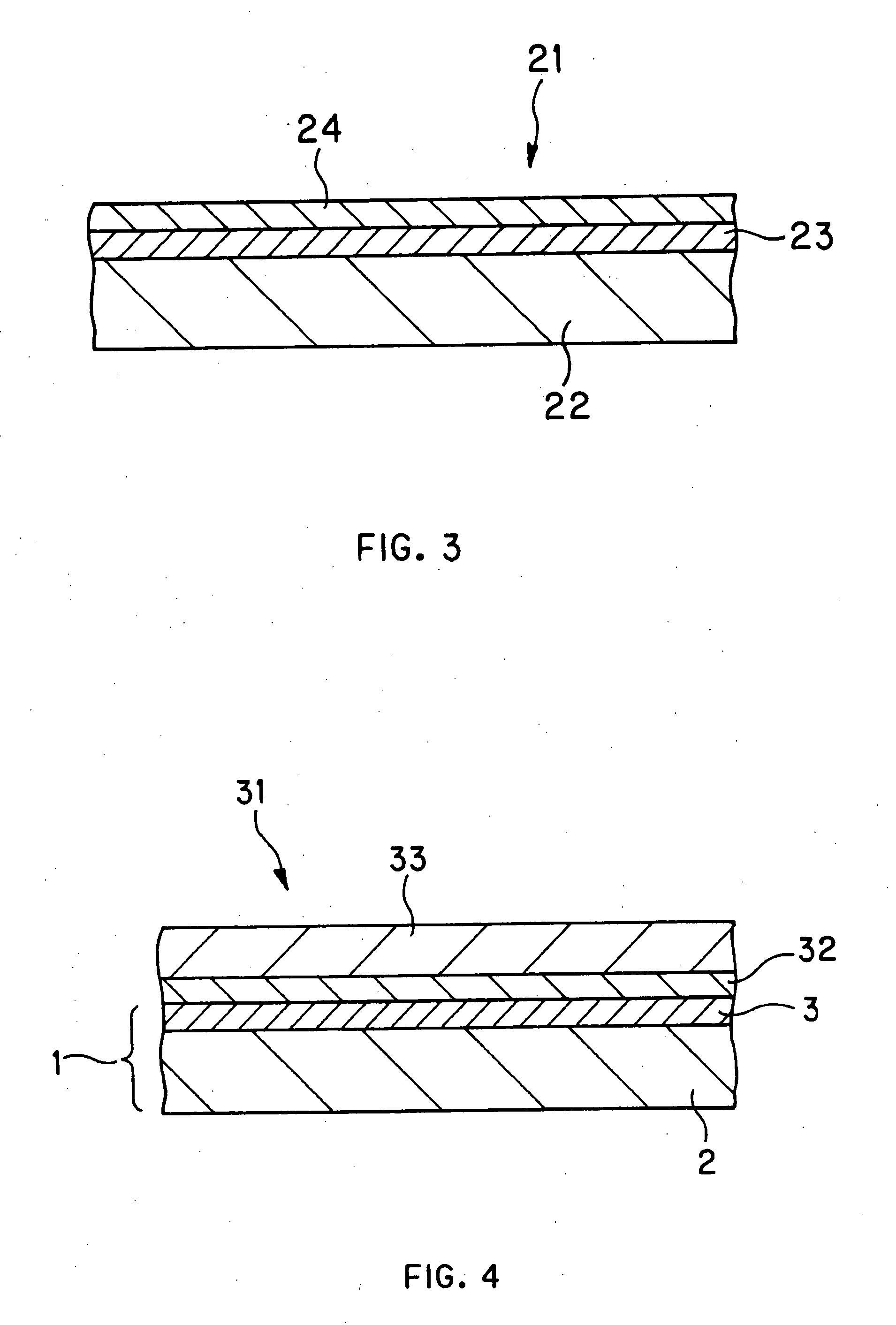

Barrier film and laminated material, container for wrapping and image display medium using the saw, and manufacturing method for barrier film

InactiveUS20080026198A1High barrier propertyGood transparencyLayered productsVacuum evaporation coatingCrystalliteInfrared

An object of the present invention is to provide a barrier film having the extremely high barrier property and the better transparency, a method for manufacturing the same, and a laminated material, a container for wrapping and an image displaying medium using the barrier film. According to the present invention, there is provided a barrier film provided with a barrier layer on at least one surface of a substrate film, wherein the barrier layer is a silicon oxide film having an atomic ratio in a range of Si:O:C=100:140 to 170:20 to 40, peak position of infrared-ray absorption due to Si—O—Si stretching vibration between 1060 to 1090 cm−1, a film density in a range of 2.6 to 2.8 g / cm3, and a distance between: grains of 30 nm or shorter. Still more, there is provided a barrier film provided with a barrier layer on at least one surface of a substrate film, has a composition wherein the barrier layer is a silicon oxi-nitride film, and the silicon oxi-nitride film has an atomic ratio in a range of Si:O:N:C=100:60 to 90:60 to 90:20 to 40, a maximum peak of infrared-ray absorption due to Si—O stretching vibration and Si—N stretching vibration is in a range of 820 to 930 cm−1, a film density is in a range of 2.9 to 3.2 g / cm3, and a distance between grains is 30 nm or shorter.

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com