Intelligent heat-insulating film and its preparing process

A technology of intelligent heat insulation and thermal insulation film, which is applied in coatings, fireproof coatings, polyester coatings, etc., can solve the problems of difficult film production, expensive equipment, difficult vanadium valence and crystal form, etc., to facilitate construction and reduce air conditioning Good energy consumption and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

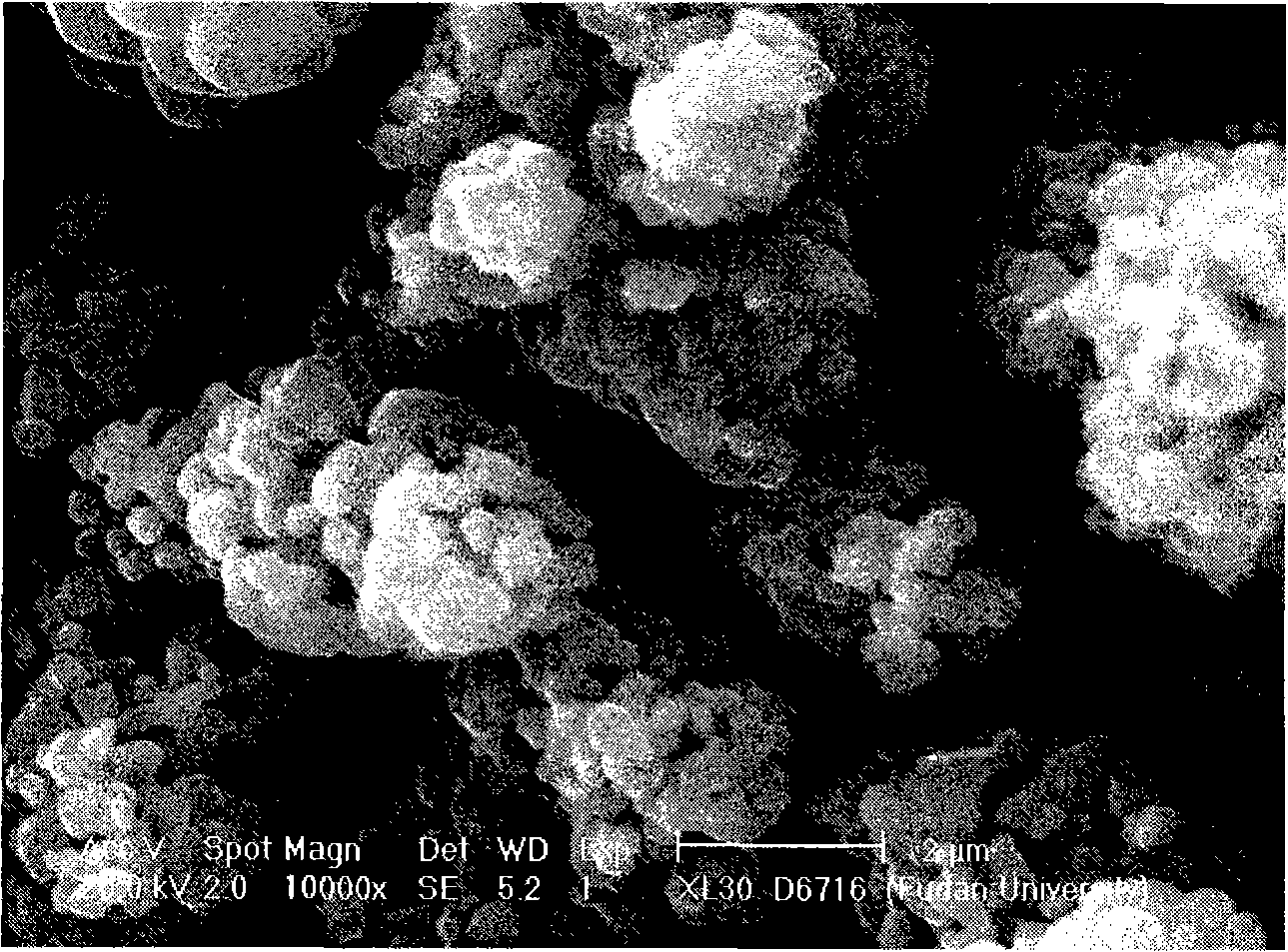

[0039] In a beaker, control the temperature at 50°C, and prepare 100ml of 0.5mol / L vanadyl sulfate aqueous solution, 100ml of 4mol / L sodium bicarbonate aqueous solution, and 30ml of 0.5mol / L potassium molybdate aqueous solution at 500rpm rotating speed. In a reaction kettle equipped with a stirrer, a dropping funnel, and a condenser, at a speed of 500 rpm, the temperature is controlled at 40-50°C, the vanadyl sulfate aqueous solution and the potassium molybdate aqueous solution are mixed and stirred for 20 minutes, and the temperature is maintained at 40-50°C. After adding sodium bicarbonate solution dropwise for 3-4 hours, a hydrated hydroxide precipitate was obtained, the precipitate was filtered and washed with water until no SO 4 2- , and then washed 1-2 times with methyl amyl ketone. In a nitrogen atmosphere, place the doped amorphous precursor in a muffle furnace, heat up to 400-500°C and sinter at a high temperature for 10 hours to obtain a doped Vanadium dioxide.

Embodiment 2

[0041] In a beaker, control the temperature at 10-20°C, and prepare 100ml of 0.1mol / L vanadyl sulfate aqueous solution, 200ml of 0.01mol / L sodium hydroxide aqueous solution, 40ml of 0.1mol / L ammonium tantalate, 40ml of 0.01mol / L aluminum chloride aqueous solution, in a reaction kettle equipped with a stirrer, dropping funnel, and condenser, at a speed of 500rpm, control the temperature at 10-20°C, mix vanadyl sulfate aqueous solution and ammonium tantalate aqueous solution and aluminum chloride aqueous solution were mixed and stirred for 20 minutes, and the temperature was maintained at 10-20°C. After adding dropwise sodium hydroxide aqueous solution for 5-6 hours, a hydrated hydroxide precipitate was obtained, and the precipitate was filtered and washed with water until there was no SO 4 2- , and then washed with ethanol for 1-2 times, the obtained doped amorphous precursor was dried in a vacuum oven at 40°C for 6 hours, placed in a muffle furnace in a nitrogen atmosphere, an...

Embodiment 3

[0043] In a beaker, control the temperature at 10-20°C, and prepare 100ml of 5mol / L vanadyl sulfate aqueous solution, 100ml of 10mol / L sodium acetate aqueous solution, 20ml of 1mol / L ammonia aqueous solution, and 1ml of 0.5mol / L aqueous ammonia solution at 1000rpm. L potassium tungstate, 1ml of 0.5mol / L titanyl chloride aqueous solution, 1ml of 0.1mol / L ammonium molybdate aqueous solution, in a reactor equipped with a stirrer, dropping funnel, and condenser, at 500rpm, Control the temperature at 70-80°C, mix and stir vanadyl sulfate aqueous solution, potassium tungstate aqueous solution, titanyl chloride aqueous solution, and ammonium molybdate aqueous solution for 20 minutes, keep the temperature at 70-80°C, and add sodium acetate aqueous solution dropwise in 1-2 hours Mixed solution with aqueous ammonia solution to get hydrated hydroxide precipitate, filter the precipitate, wash with water until no SO 4 2- , place the doped amorphous precursor in an oven at 80°C for 1 hour,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com