Patents

Literature

285 results about "Vanadyl sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadyl(IV) sulfate describes a collection of inorganic compounds of vanadium with the formula , VOSO₄(H₂O)ₓ where 0≤x≤6. The pentahydrate is common. This hygroscopic blue solid is one of the most common sources of vanadium in the laboratory, reflecting its high stability. It features the vanadyl ion, VO²⁺, which has been called the "most stable diatomic ion."

Preparation method of vanadium battery electrolyte solution with high purity and high concentration

InactiveCN103515642AHigh purityIncrease concentrationRegenerative fuel cellsHigh concentrationVanadyl sulfate

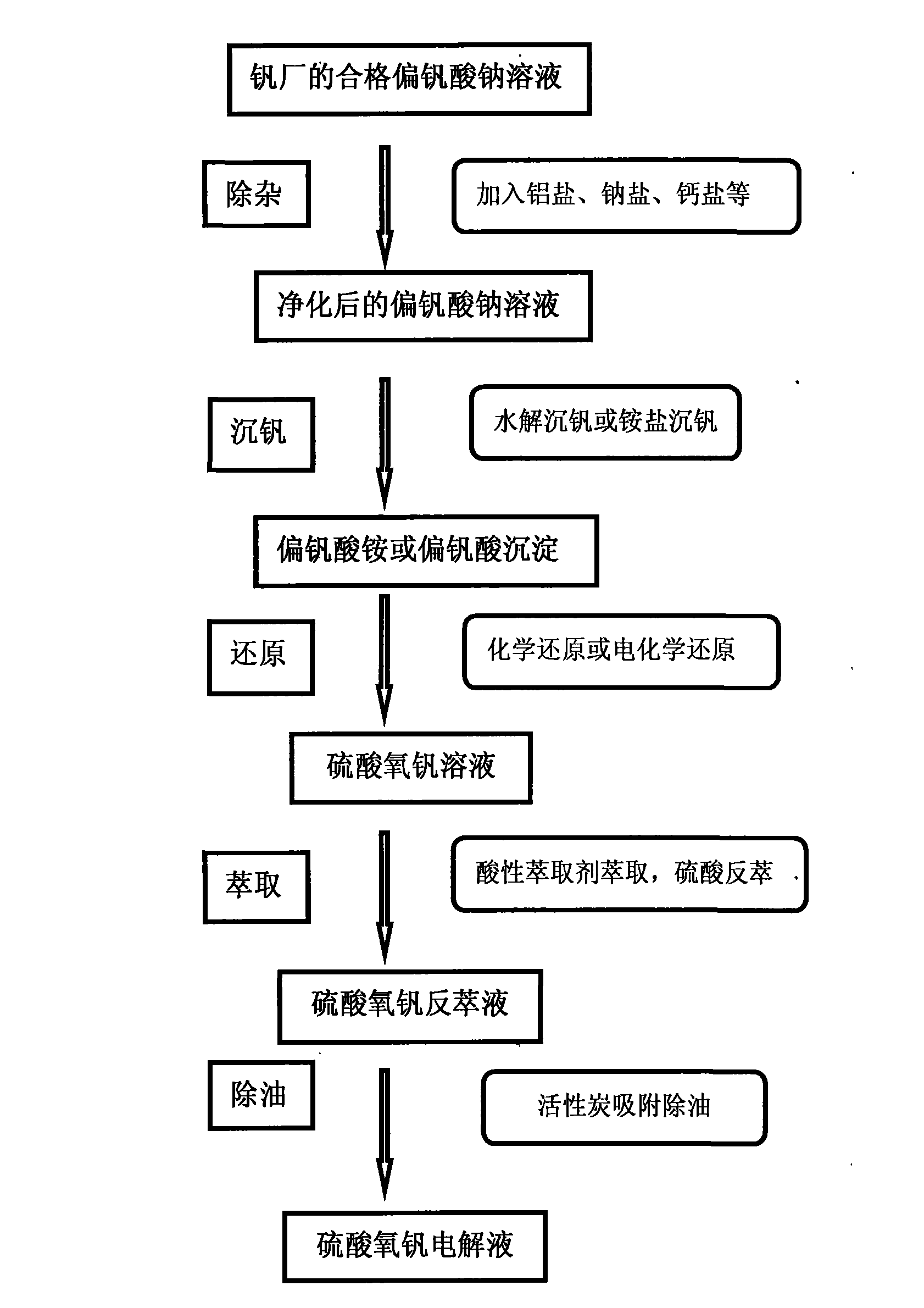

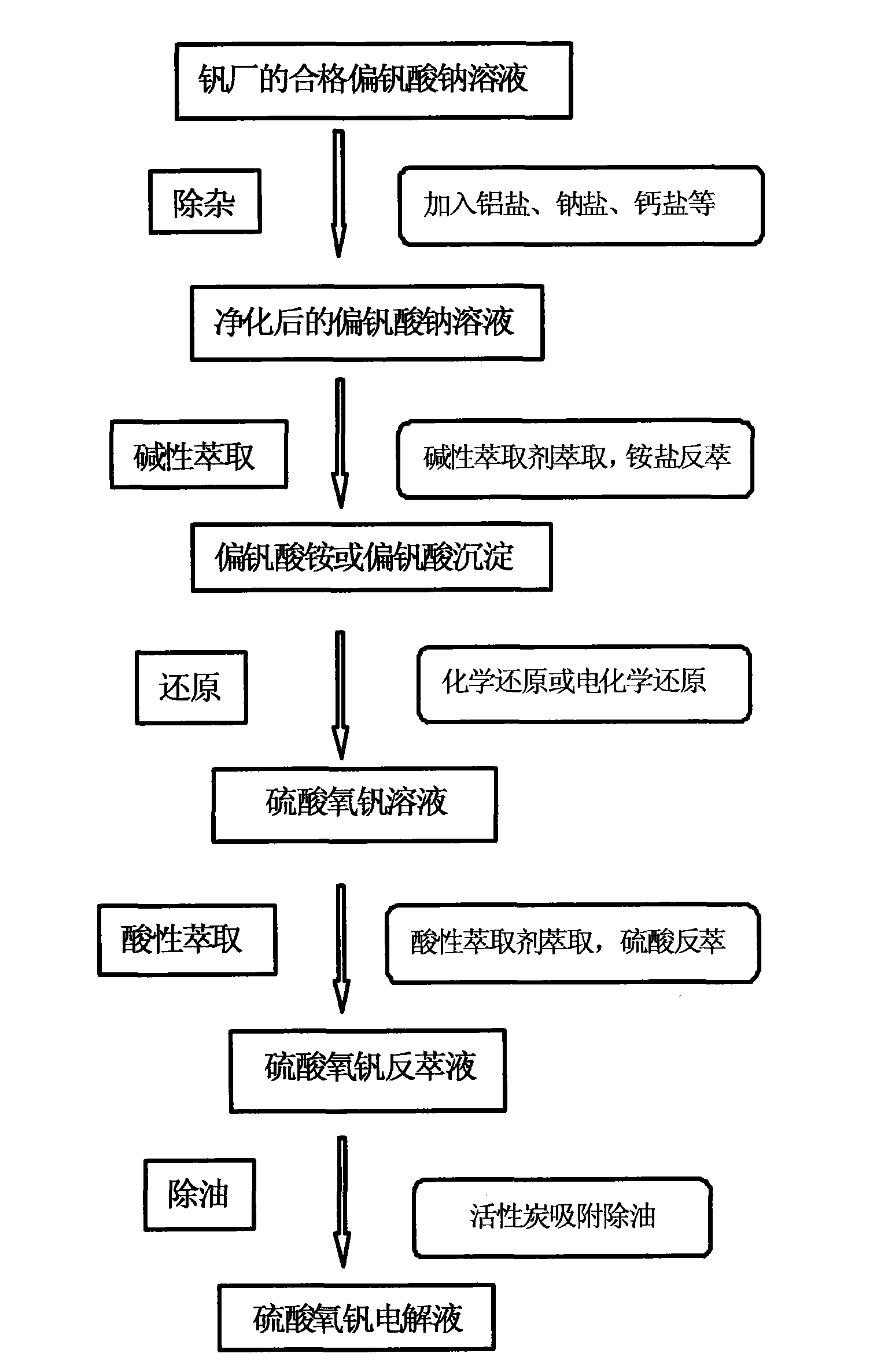

The invention relates to a preparation method of a vanadium battery electrolyte solution with high purity and high concentration. The vanadium battery electrolyte solution is different from a traditional vanadium electrolyte solution with vanadium pentoxide as raw material; through the method, a qualified vanadium solution produced by a vanadium factory is adopted as raw material, steps of removing impurities, precipitating vanadium, reducing, extracting and removing oil are carried out, after carrying out processes of four-step impurity removal and one-step reduction, the impurities in the electrolyte solution are effectively removed, and the all-vanadium solution flow battery vanadyl sulfate electrolyte solution with high purity and high concentration and with the concentration of 1-4 M is obtained. The method adopts the initial vanadium solution as the raw material, has the advantages of low cost, simple preparing procedures, and mild reaction conditions, allows the obtained electrolyte solution product to have high purity, and is suitable for application in an all-vanadium solution flow battery.

Owner:NO 63971 TROOPS PLA

Vanadium ion redox flow battery electrolyte, preparation method thereof and battery thereof

ActiveCN101635363ASimple production processReduce lossesRegenerative fuel cellsFuel cell detailsManufacturing technologyVanadyl sulfate

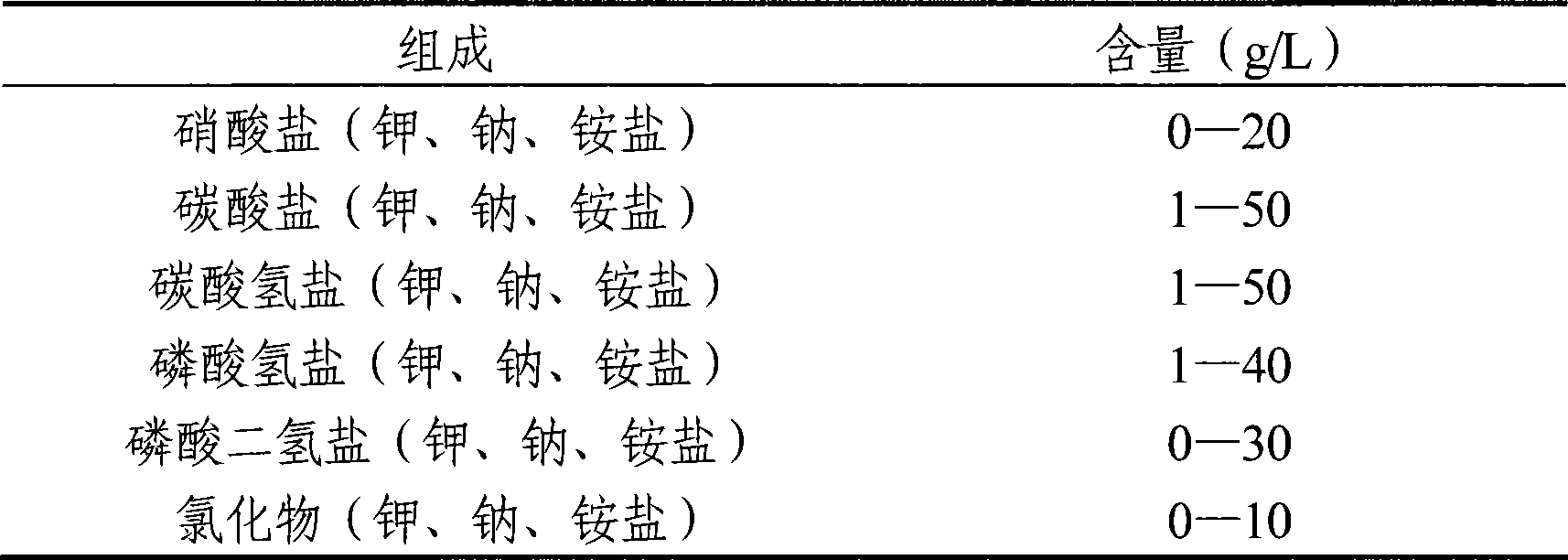

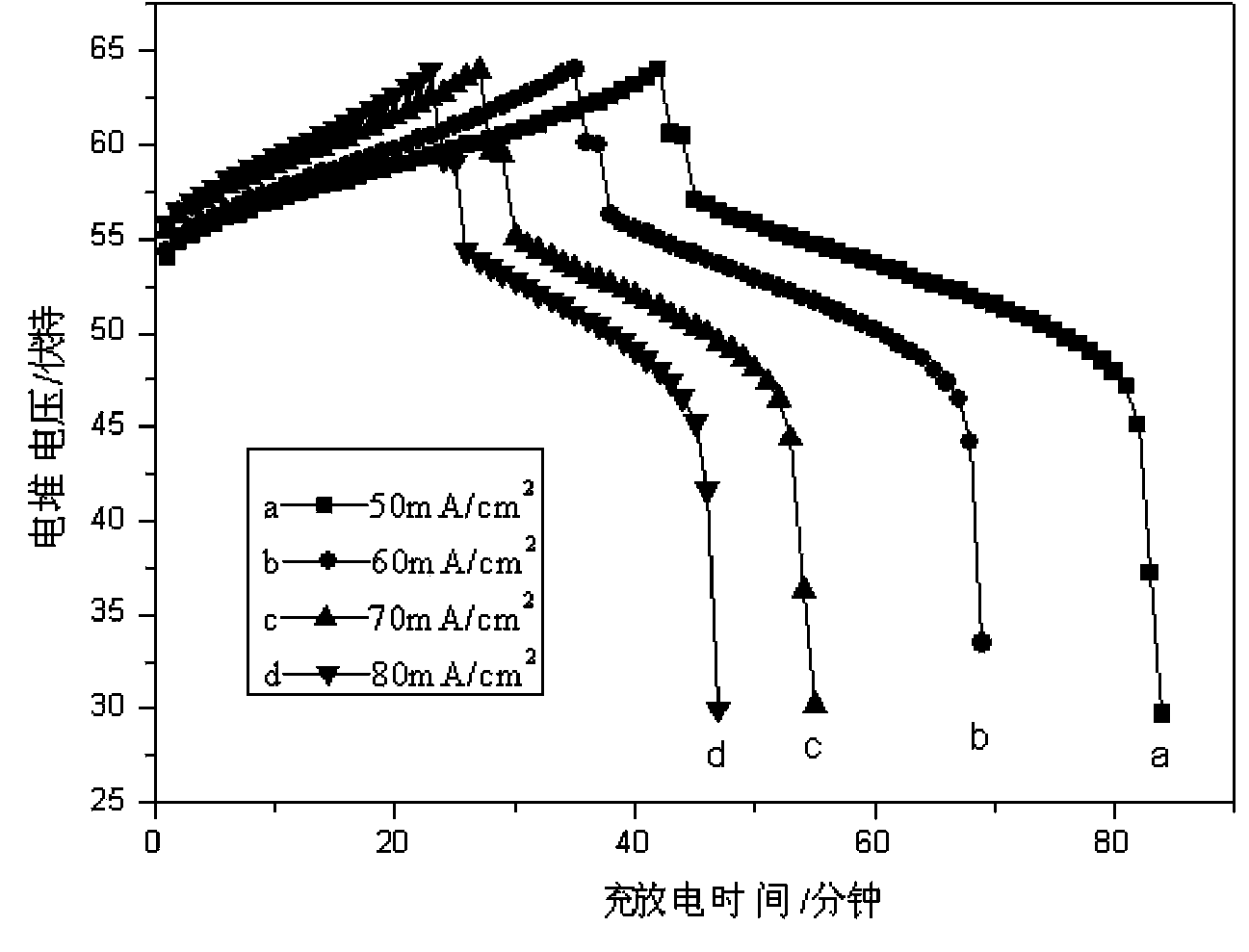

The invention provides vanadium ion redox flow battery electrolyte, comprising vandic salt, sulphuric acid, additive, deionized water and metal salt can be dissolved in a sulphuric acid system. The electrolyte can greatly improve the cathode system evolution overpotential of the vanadium battery and anode system evolution overpotential, greatly reduce the ratio of gas evolution in the electrolyte caused by various polarizations in the process of operating the vanadium battery, and improve the stability of the electrolyte in the process of charge and discharge. The invention further provides a preparation method of the vanadium ion redox flow battery electrolyte, which eliminates a step of electrolyzing the obtained vanadyl sulfate solution to obtain 50% of trivalent vanadium and 50% of tetravalent vanadium, greatly simplifies the manufacture technology of the vanadium electrolyte which can be directly used for charging and discharging, reduces the lose of the vanadium in the process of preparation, and reduces the preparation cost of the electrolyte.

Owner:BYD CO LTD

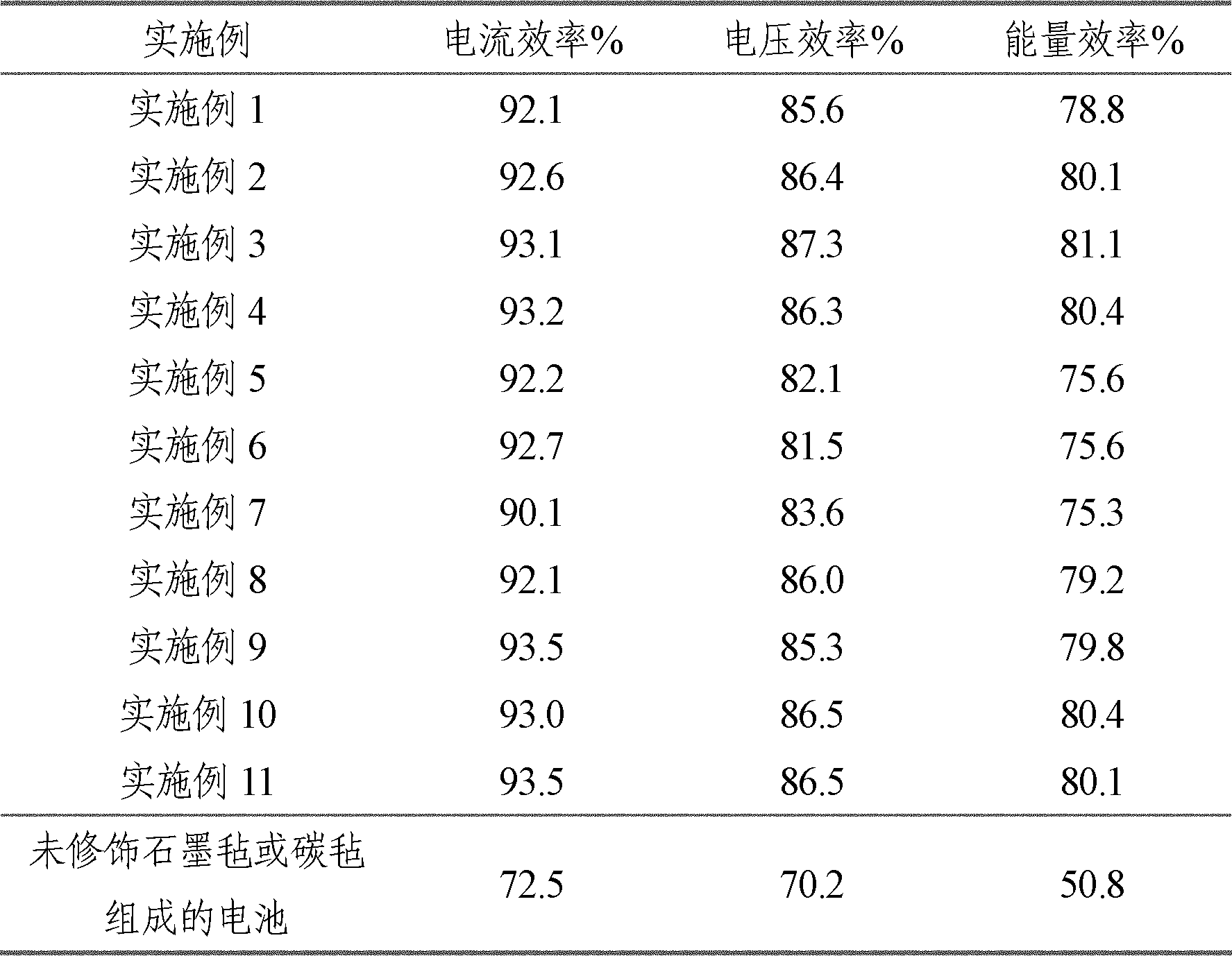

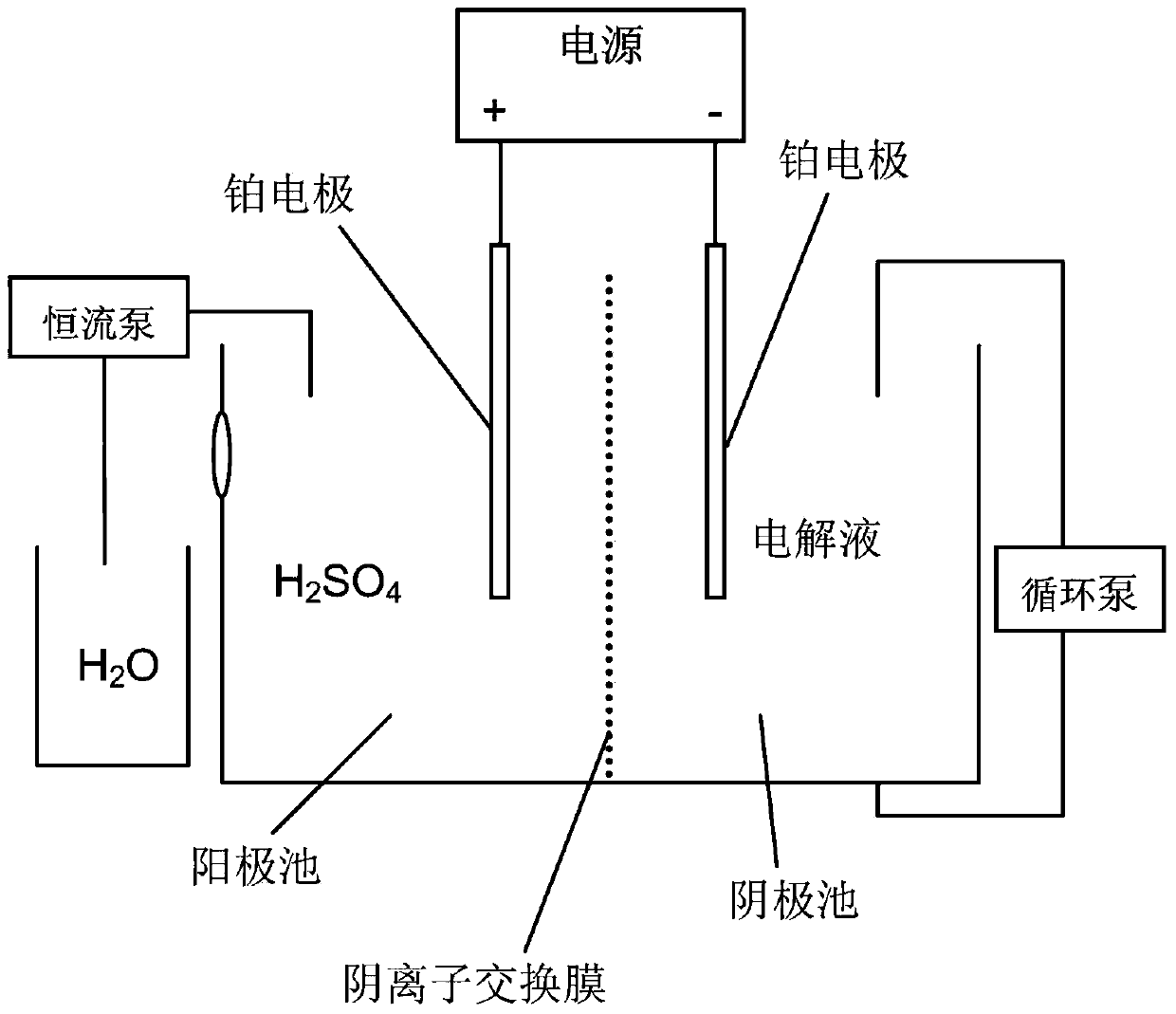

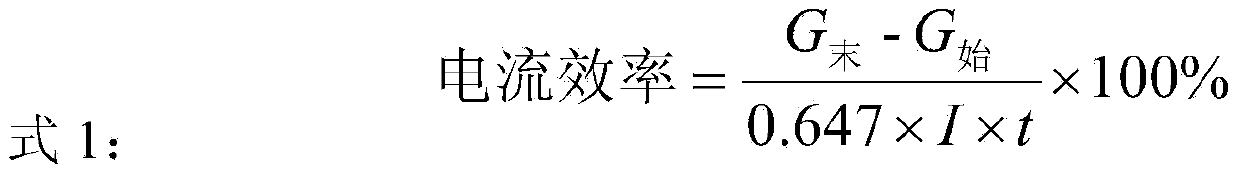

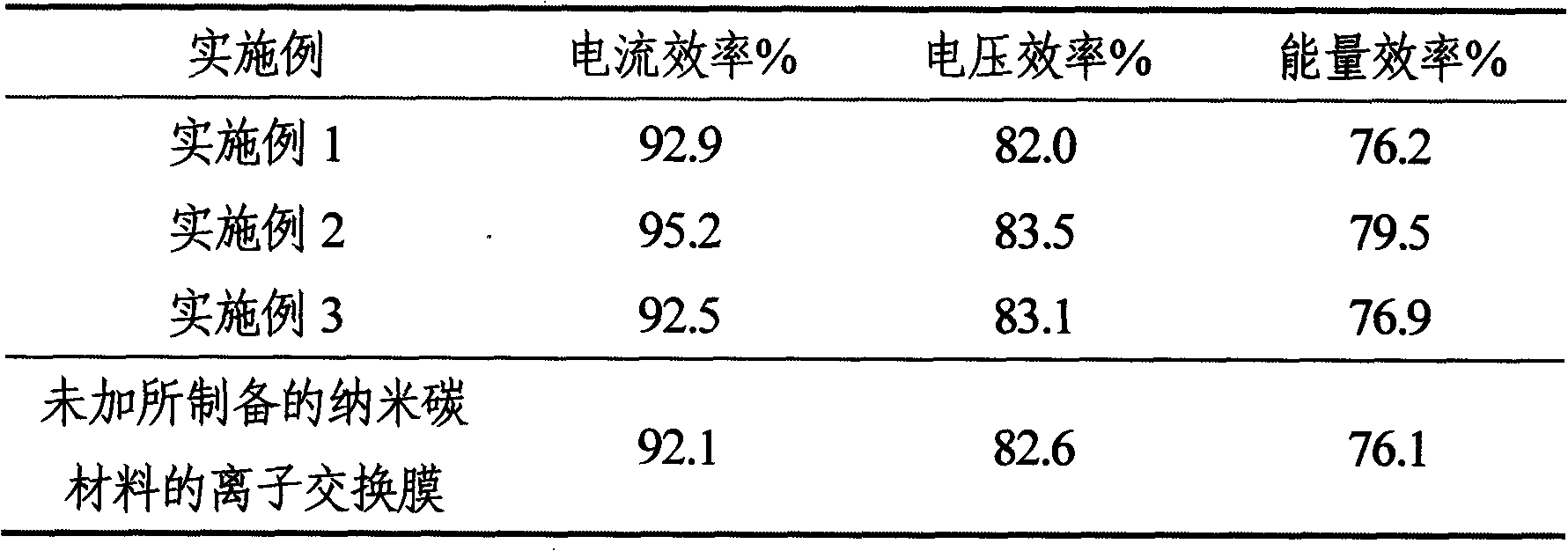

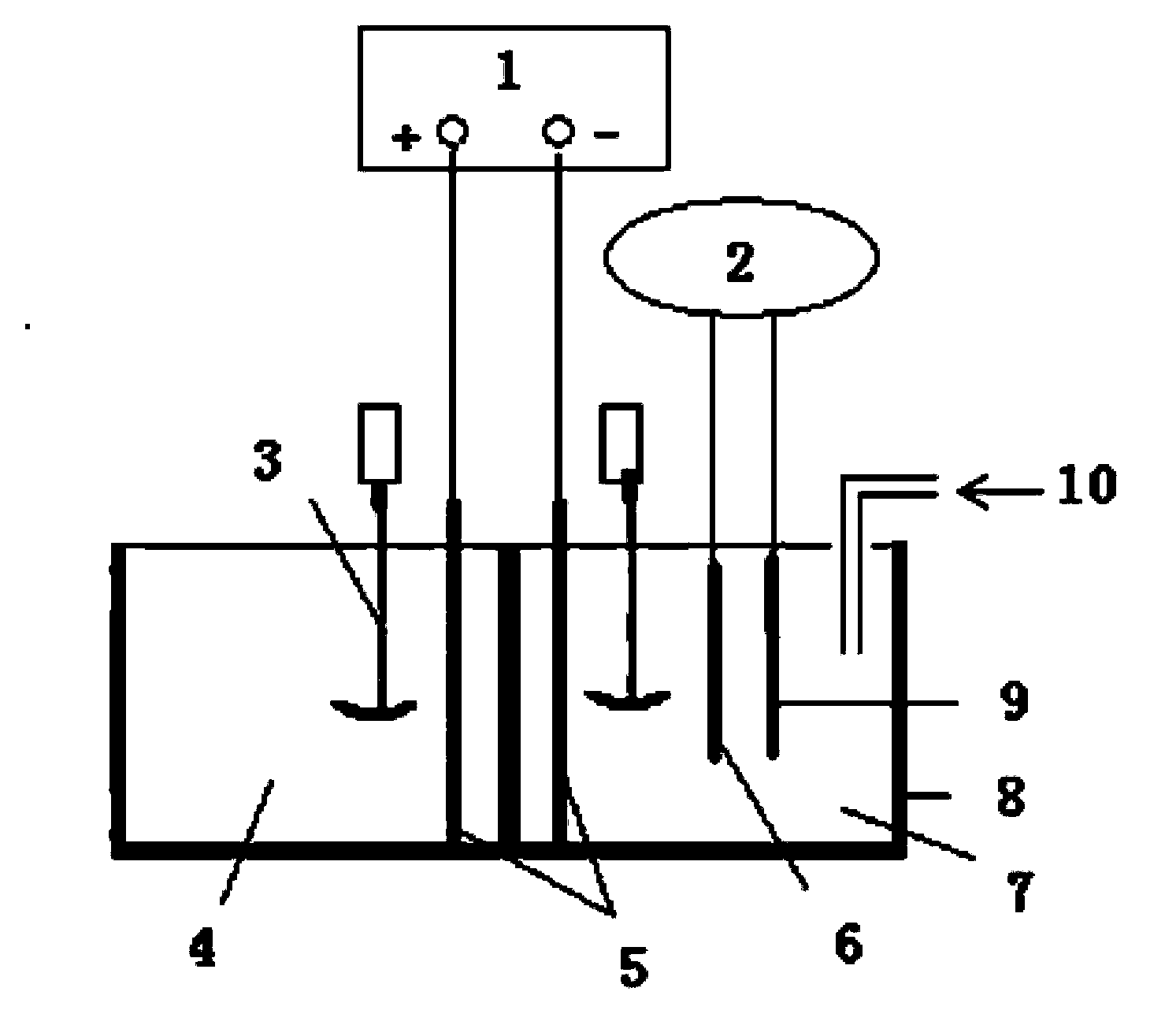

Electrochemical treatment method for improving vanadium cell electrode material activity

ActiveCN101465417AReduced stabilityShort lifeElectrode manufacturing processesRegenerative fuel cellsElectrolysisInternal resistance

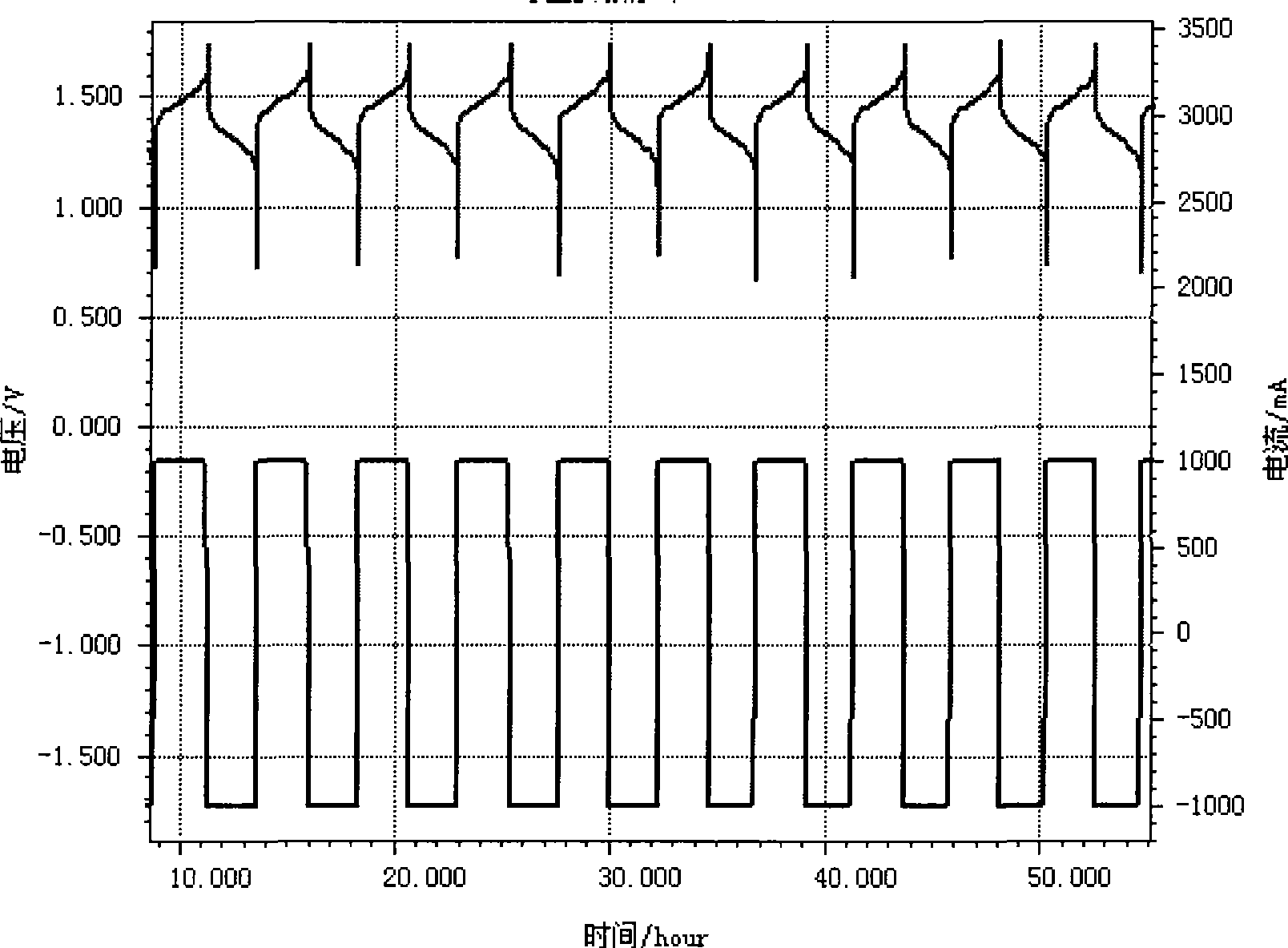

The invention relates to the field of battery manufacturing and energy storage, in particular to an electrochemical treatment method for improving the activity of vanadium cell electrode materials. Graphite felt or carbon felt which is used as anode is immerged in active electrolyte and carries out electrochemical active treatment in an electrobath with a certain current density and time, then the graphite felt or carbon felt is washed and dried for obtaining activated graphite felt or carbon felt electrode material. The method carries out moderate and controllable electrochemical anode activation treatment by choosing suitable activated electrolyte and current density, and overcomes the disadvantages that the stability of the electrode material is deceased owning to overoxidation of the material caused by heat and acid treatment and the service life of the battery is reduced; the method has simple process and low cost. The graphite felt or carbon felt treated by the method is used as electrode and takes a cation-exchange membrane as a diaphragm, and the anode and cathode electrolytes are 1.5M of vanadyl sulfate and 2M of sulphuric acid; after the battery is combined, the ohm internal resistance is greatly reduced, and the current efficiency, voltage efficiency and energy efficiency of the battery are obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for vanadyl sulfate electrolyte of all-vanadium flow battery

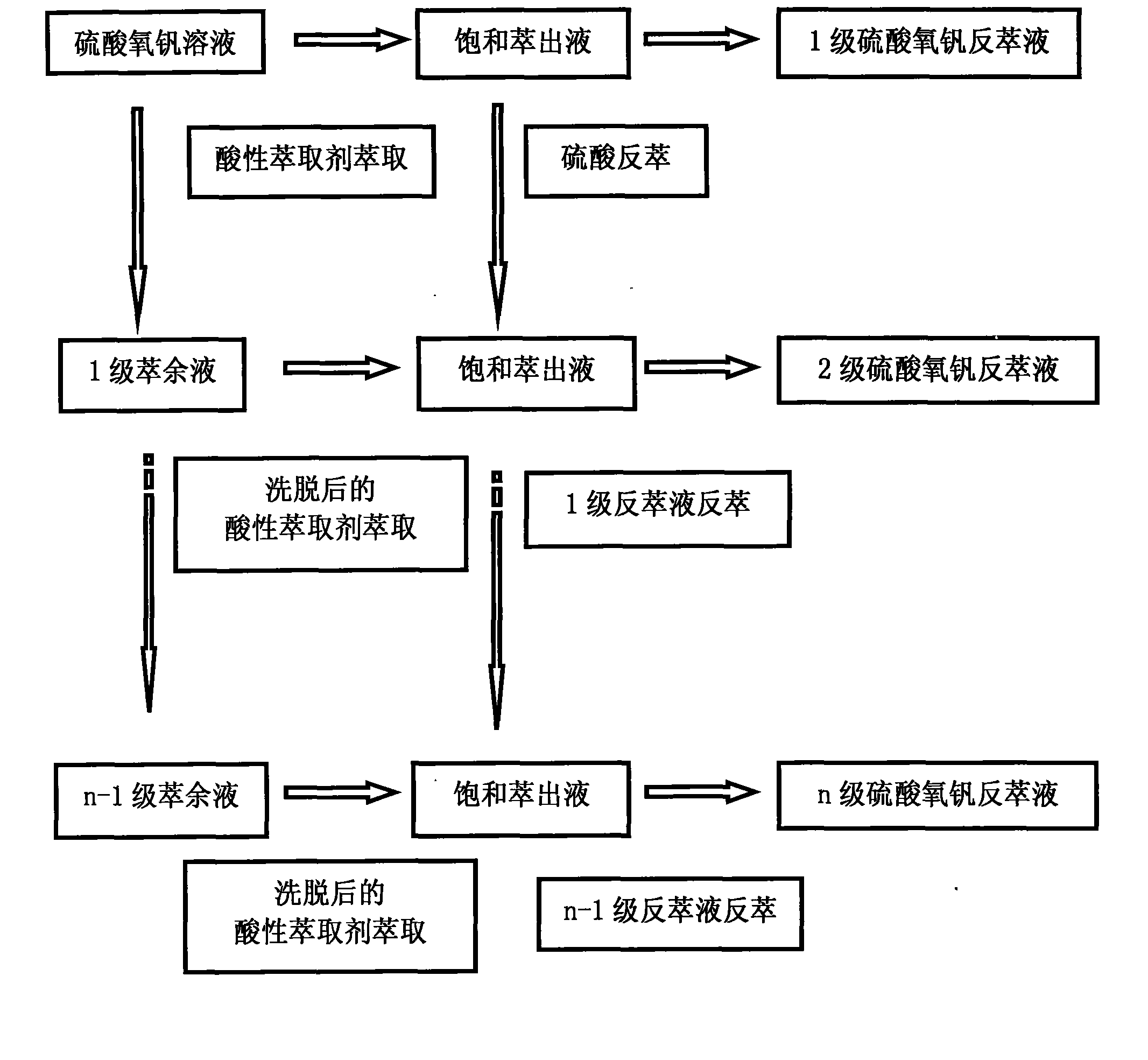

ActiveCN102683733AAchieve mass productionSimple processRegenerative fuel cellsVanadium compoundsAlkaline earth metalKerosene

The invention discloses a preparation method for vanadyl sulfate electrolyte of an all-vanadium flow battery. The preparation method is characterized by comprising the following steps of: adjusting pH value of vanadyl sulfate solution obtained from leaching vanadium slag and stone coal, back extracting and resin-analyzing treatments by using oxide or hydroxide of alkali metal or alkaline earth; adding an inorganic reducing agent; performing multi-grade counter-current extraction by using P204 or P507: TBP: sulfonated kerosene extracting agent; after the two-phase separation, washing the vanadium-loaded organic phase; performing 2-5 grades of multi-grade counter-current back extraction on the vanadium-loaded organic phase by using sulfuric acid solution to obtain the back extracting liquid of vanadyl sulfate; adjusting the pH value of the back extracting liquid of vanadyl sulfate, adding the organic reducing agent to adjust the potential value of the solution; extracting the solution by using the extracting agent; after the two-phase separation, washing the vanadium-loaded organic phase by using the sulfuric acid solution; performing multi-grade counter-current back extraction by using the sulfuric acid solution to obtain the vanadyl sulfate solution; and distilling until the concentration required for all-vanadium flow battery. The method provided by the invention can improve the purity, simplify the preparation procedure and reduce the cost.

Owner:GUANGDONG INST OF RARE METALS

Method for preparing electrolytes of all-vanadium flow battery

ActiveCN103401010AOmit the cooling dilution stepShorten production timeRegenerative fuel cellsHydrogenSulfate

The invention relates to preparation of electrolytes of flow batteries and particularly relates to a method for preparing electrolytes of an all-vanadium flow battery. The method comprises the steps of (a) reducing V2O5 powder into V2O4 powder and V2O3 powder in a hydrogen gas atmosphere; and (b) dissolving the reduced V2O4 powder into concentrated sulfuric acid so as to obtain a vanadyl-sulfate tetravalent vanadium solution which serves as an anode electrolyte of the vanadium battery, dissolving the reduced V2O3 powder into concentrated sulfuric acid so as to obtain a sulfate trivalent vanadium solution which serves as a cathode electrolyte of the vanadium battery, or enabling the reduced V2O4 and V2O3 powder to be subjected to evaporative crystallization in sulfuric acid with the concentration of 6-18.4 mol / l so as to obtain VOSO4 and V2(SO4)3 crystals, and dissolving the VOSO4 and V2(SO4)3 crystals into dilute sulfuric acid, thereby obtaining vanadium electrolytes of the all-vanadium flow battery. The method disclosed by the invention has the advantages that the steps of heating dissolution, cooling dilution and the like are omitted, the reaction conditions are mild, the process is simple, the cost is low, and the product quality is stable.

Owner:HUNAN YINFENG NEW ENERGY

Process for electrolyzing preparing electrolyte of full vanadium ion flow battery

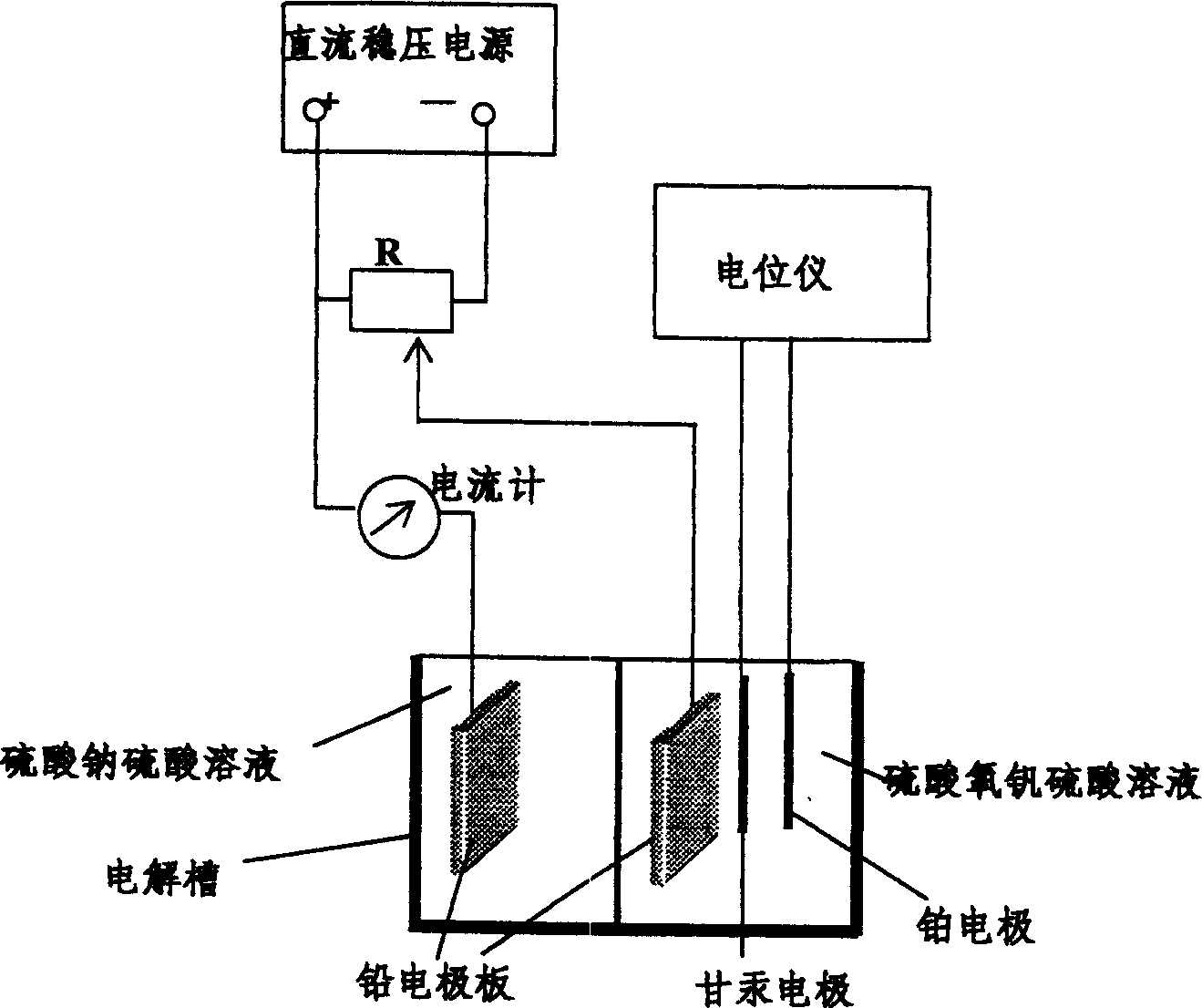

InactiveCN1598063ASimplify the assembly processExtended service lifeElectrolysis componentsLead-acid accumulatorsLiquid cellVanadyl sulfate

The invention relates to the field of the cell manufacturing and especially relates to a method of preparing the electrolyte of the vanadium ion liquid cell, making the 1:1 thin vitriol from the thick vitriol, adding the trioxid bi-vanadium and then the five-trioxid bi-vanadium to get the vitriol oxide vanadium; adding the Na2SO4, emulsification agent OP and other additive, placing the vitriol oxide vanadium at the cathode of the electrolytic cell and the same ion intension at the anticathode and electrolyse, getting the vitriol electrolyte used for vitriol batteries which includes half quadrivalence vanadium and half tervalent vanadium. The invention simplyfy the equipment of vitriol batteries and chemical procedure, enhance the work efficiency, extend the use time of the functional materials of vitriol batteries, such as the electrode and the dissepiment, needn't change the electrolyte of the anode, avoid wasting raw material, avail the producing by large scale.

Owner:攀枝花钢铁有限责任公司钢铁研究院 +1

Process for preparinbg vanadylic sulfate and use

The preparation process of vanadylic sulfate includes adding V2O3 and V2O5 into sulfuric acid, filtering and evaporating the filtrate, eliminating crystalline water to obtain light blue VOSO4 powder. Compared with available technological path, the said technological process of the present invention has less steps, mild reaction condition, simple technological process, low cost and stable product quality. The filtrate may be used as the material as electrolyte in vanadium cell.

Owner:攀枝花钢铁有限责任公司钢铁研究院

Dietary supplement system for multifunctional anti-aging management and method of use

A dietary supplement system includes a dietary supplement composition for oral administration by an individual in the morning, the composition, including (a) a telomere maintenance complex including: Purslane extract (aerial parts); Turmeric rhizome extract (95% curcuminoids); Quercetin dehydrate, Cayenne pepper fruit; Vanadium (as vanadyl sulfate); Fenugreek seed; Astragalus root extract, Omega fatty acid complex including linoleic acid; alpha-linolenic acid; oleic acid borage seed oil gamma-linolenic acid), evening primrose oil fish body oil (eicosapentaenoic acid; docosahexaenoic acid); (b) a calorie restriction mimetics and gene expression complex including Trans-resveratrol (from Polygonum cuspidatum root extract); Pterostilbene Fisetin 50% (Buxus microphlla Sieb (stem and leaf; Alpha lipoic acid, Coenzyme Q-10, Betaine HCl, Sulfur (from methylsulfonylmethane); L-Carnitine tartrate; L-Carnitine HCl, and (c) a free radical scavenger complex, including Green tea leaf extract catechin and polyphenols); Anthocyanins (from bilberry fruit and grape skin extracts).

Owner:LIFE SCI INT

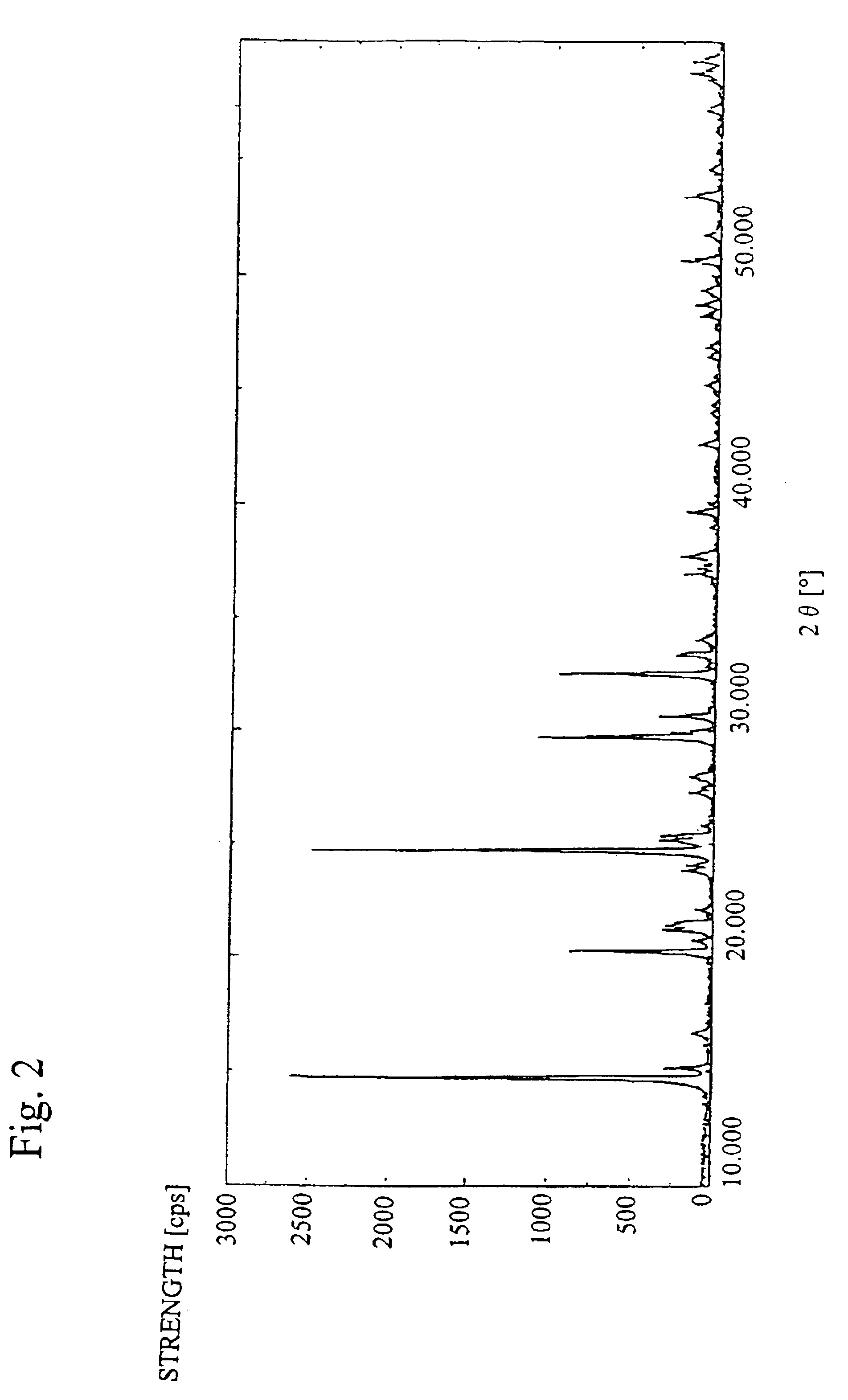

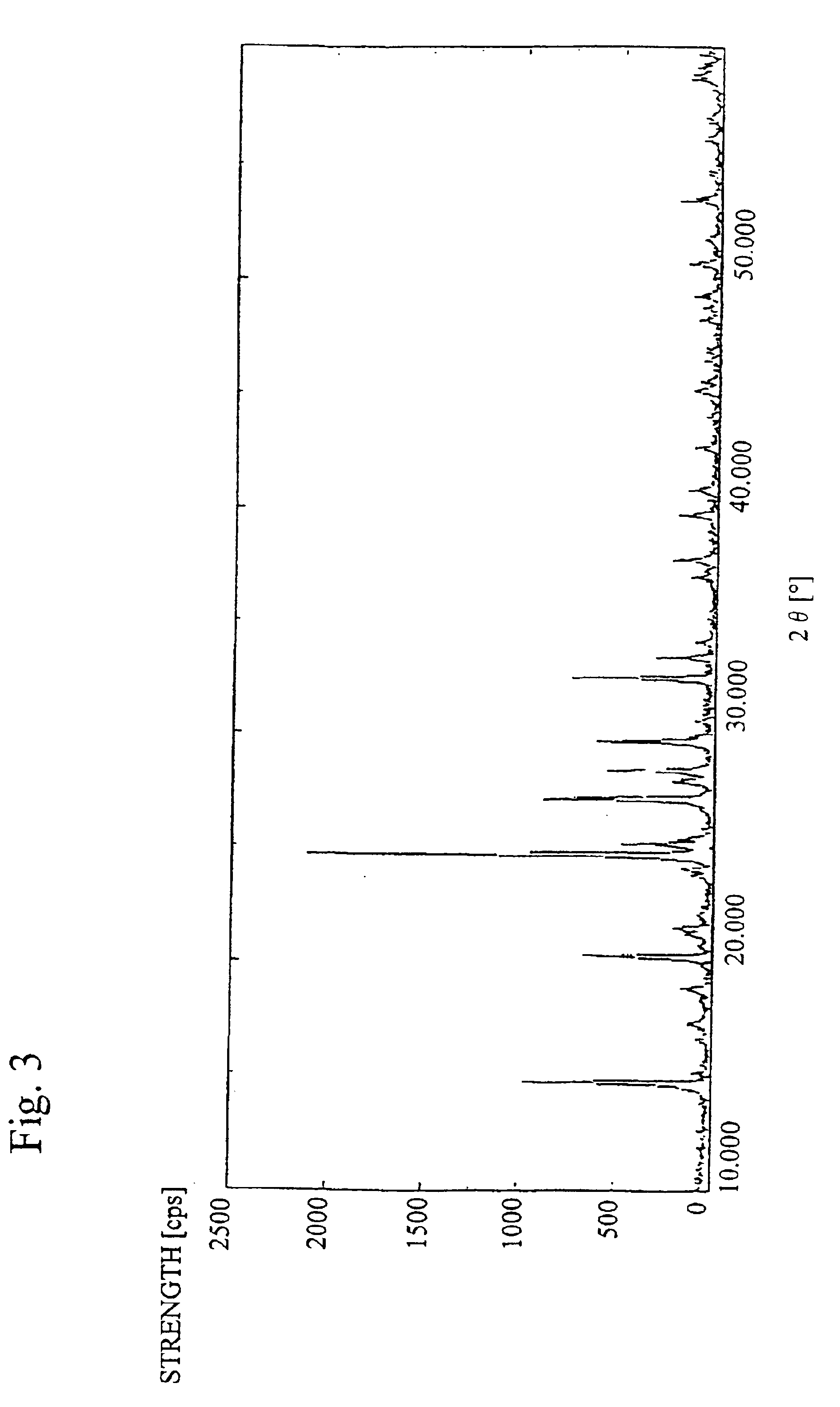

Modified vanadium compound, producing method thereof, redox flow battery electrolyte composite and redox flow battery electrolyte producing method

InactiveUS6872376B2Improve solubilityEasy to prepareCell electrodesRegenerative fuel cellsVanadium CompoundsSulfate

Owner:THE KANSAI ELECTRIC POWER CO +1

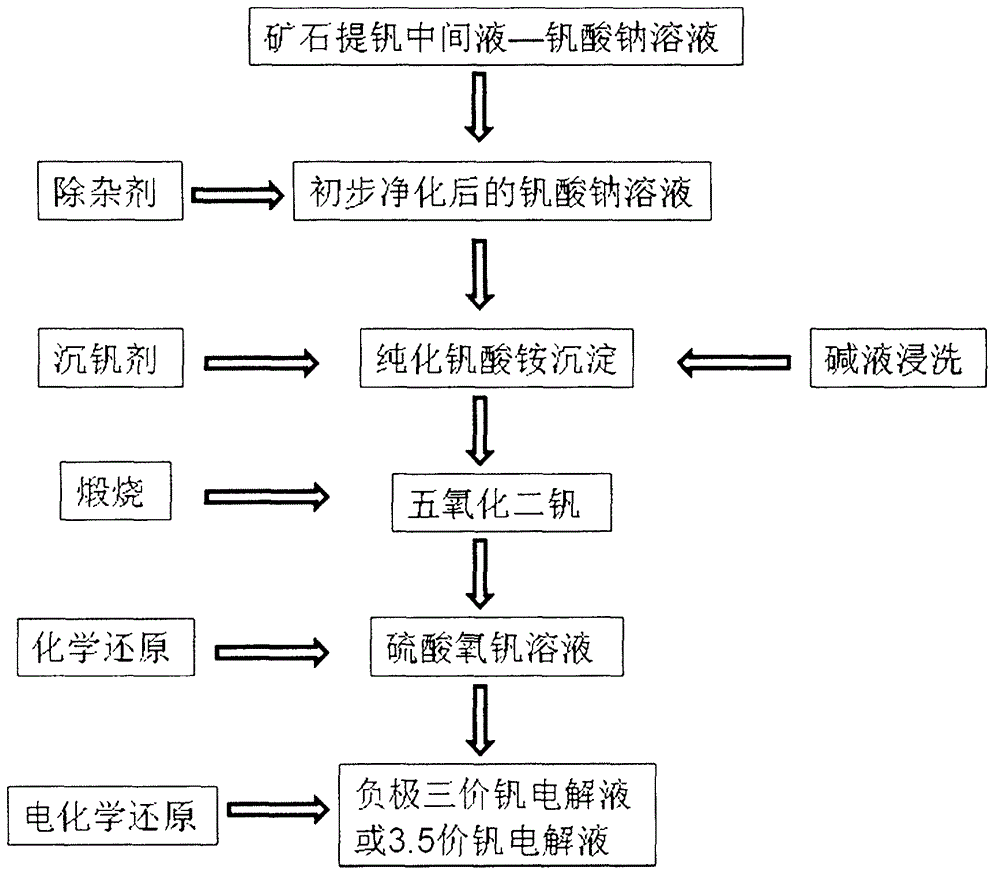

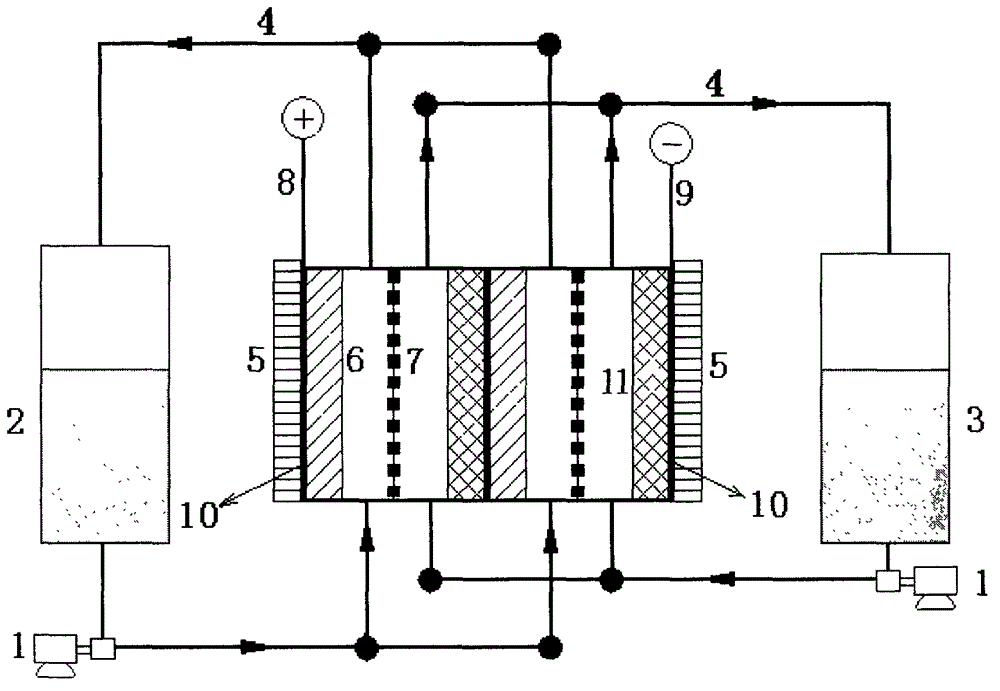

Combined chemical-electrochemical method for preparing vanadium redox flow battery electrolyte

InactiveCN104037439AEasy to operateHigh purityRegenerative fuel cellsVanadium compoundsHigh concentrationElectrolysis

The invention relates to a combined chemical-electrochemical method for preparing an all-vanadium redox flow battery electrolyte. The method adopts a solid or solution containing soluble vanadate, especially vanadium slag leachate obtained after steel-making with vanadic titano-magnetite, for production of a high-purity high-concentration vanadium electrolyte. The method is characterized in that a vanadyl sulfate electrolyte with a sulfuric acid concentration of 1 to 6 mol / L and a vanadium concentration of 1 to 5 mol / L can be prepared through impurity removal, acidic vanadium precipitation, multiple alkaline leaching and vanadium precipitation, calcination and reduction, an electrochemical process is cooperatively used so as to prepare a 3.5-valent or 3-valent vanadium electrolyte, and after electrolysis, the vanadium electrolyte of a positive electrode can be repeatedly used through chemical reduction. The method provided by the invention can treat the vanadium slag leachate and the solid or solution containing soluble vanadate and has the advantages of simple process flow, mild reaction conditions, substantially reduced cost, etc.; and the prepared high-purity high-concentration vanadium electrolyte is especially applicable to an all-vanadium redox flow battery.

Owner:NO 63971 TROOPS PLA +1

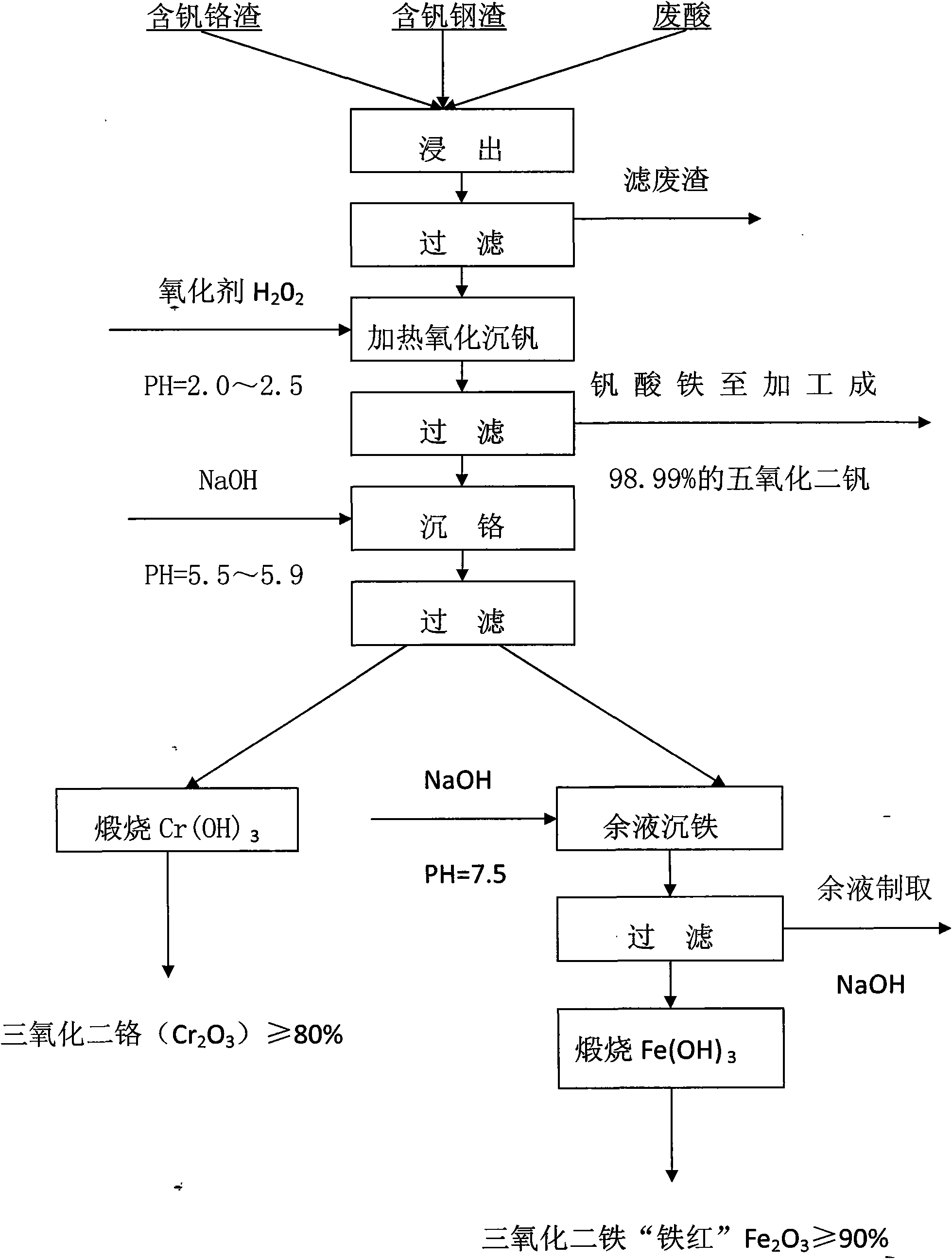

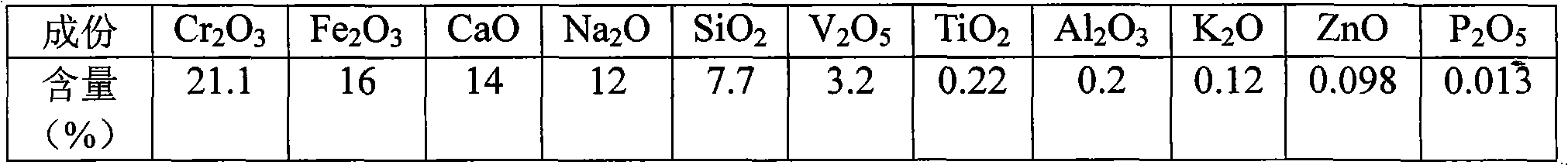

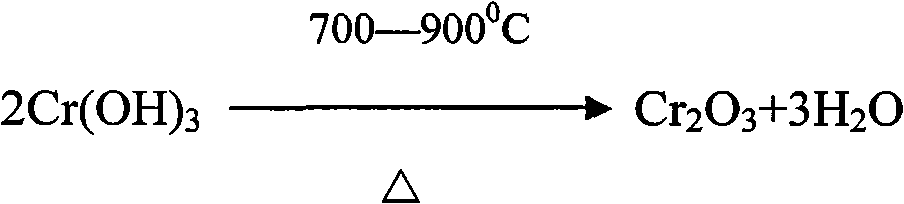

Process for extracting vanadium and chromium from chromic slag by using waste acid of titanium powder plant

InactiveCN101979683AFiltration process goes wellAchieve the purpose of separationProcess efficiency improvementChromium(III) hydroxideSlag

The invention discloses a method for separating and extracting vanadium and chromium. The method comprises the following steps of: (1) producing chromium fine sand (Cr2O3) of which the content is over 80 percent and ferric vandate of which the content is over 20 percent from two waste materials by taking waste acid of a titanium powder plant as a leaching agent and vanadium-chromium slag (containing 2.5 to 4.5 percent of vanadium and 14 to 25 percent of chromium) as a raw material; (2) putting the vanadium-chromium slag into the waste acid to allow the chromium and the vanadium in the slag to form chromium sulfate and vanadyl sulfate which can be dissolved in water very easily, wherein the leaching time is about 6 hours; (3) adding a certain amount of steel making steel slag during leaching to fulfill the aim of generating a great deal of calcium sulfate when a great deal of calcium oxide meets the acid during filtration, and wrapping, adsorbing or and stopping 'silica gel' formed by silicon dioxide in the chromium slag by the calcium sulfate which is used as a filter medium to ensure that the filtration is performed smoothly; (4) adjusting the pH value of the filtrate to be 2.5 by using sodium hydroxide, and then adding an oxidant and oxydol to ensure that the chromium in the solution is oxidized to be hexavalent, the iron is oxidized to be trivalent, and the vanadium is oxidized to be pentavalent; (5) heating the leaching solution to the temperature of between 70 and 90 DEG C to ensure that the vanadium and the iron is combined together to generate water-fast 'ferric vandate', wherein the time for thermal precipitation is about one hour, and the vanadium residual in the solution is not more than 0.4 g / L; (6) adding sodium hydroxide into the solution of which the ferric vandate is filtered out, and fully stirring the mixture until the pH value of the solution is between 5.5 and 5.9 to ensure that the chromium in the solution is completely converted into chromium.

Owner:PANZHIHUA SHUOSHENG IND & TRADING

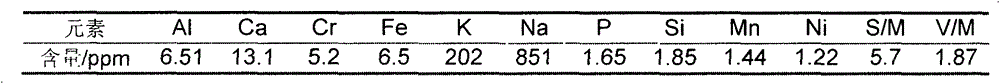

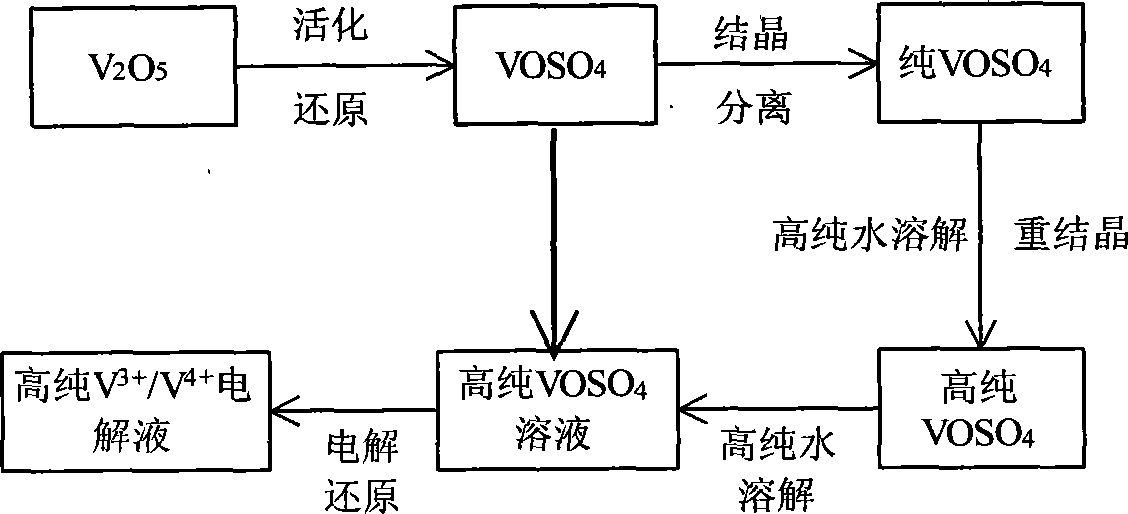

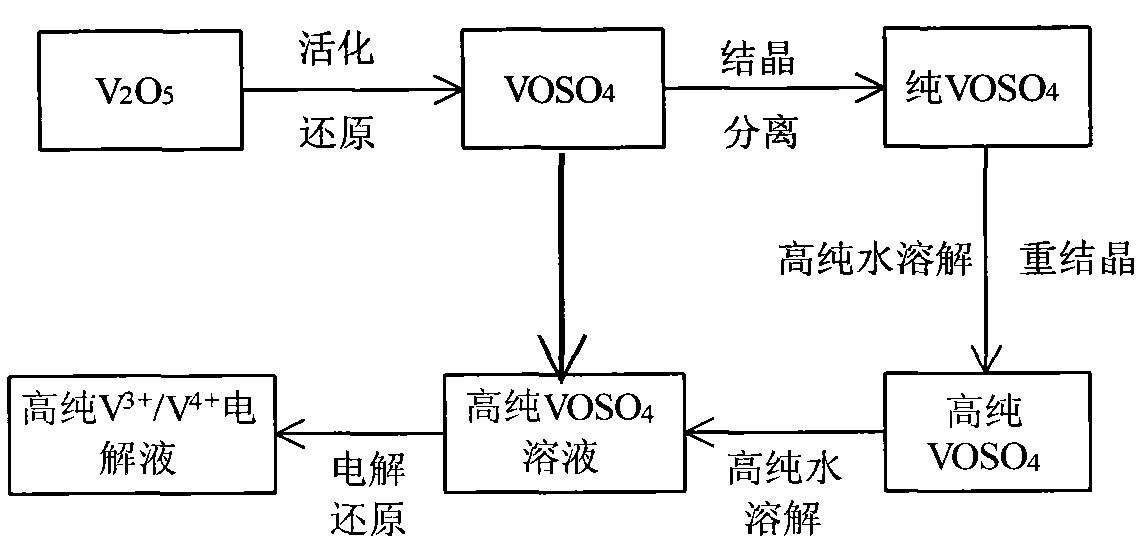

Method for manufacturing high-purity vanadium battery electrolyte

ActiveCN102354762AMeet the use requirementsHigh purityRegenerative fuel cellsElectrolysisVanadyl sulfate

The invention relates to a method for manufacturing a high-purity vanadium battery electrolyte, comprising the following steps of: firstly, adding vanadium pentoxide to a sulfuric acid solution for heating and activating; adding a high-purity reducing agent for reduction; and electrolyzing and reducing the obtained vanadicsulfate solution in a diaphragm electrolytic tank so as to obtain the high-purity vanadium battery electrolyte. In the high-purity vanadium battery electrolyte manufactured by the method, the impurity contents are controlled below 10ppm; the high-purity vanadium battery electrolyte can be used as the electrolyte of an anode and cathode of a vanadium battery and meets the use requirements of the vanadium battery; and the production cost of the electrolyte is reduced.

Owner:承德新新钒钛储能科技有限公司 +1

Method for separating vanadium and chromium solution and recycling vanadium and chromium

ActiveCN105861829AAchieve restorationAchieve reduction of vanadiumProcess efficiency improvementVanadium dioxideVanadyl sulfate

The invention discloses a method for separating a vanadium and chromium solution and recycling vanadium and chromium. A reducing agent is added to the vanadium and chromium solution under the condition that the pH value ranges from 8 to 14, and the temperature ranges from 20 DEG C to 100 DEG C, and pentavalent vanadium and hexavalent chromium are reduced into tetravalent vanadium and trivalent chromium; the trivalent chromium forms chromic hydroxide precipitate in situ, and a chromic hydroxide filter cake and vanadium-containing filtrate are obtained through filtering; the chromic hydroxide filter cake is used for preparing chromic oxide; and the vanadium-containing filtrate is used for preparing hydration vanadium dioxide or vanadyl sulfate or vanadium pentoxide. By means of the method, efficient separation and recovery of vanadium and chromium are achieved, the vanadium recovery rate reaches 96% or higher, the chromium recovery rate reaches 98% or higher, and the purity of vanadium and chromium products reaches 98% or higher. The method has the beneficial effects that the technological processes are short, the separation efficiency is high, the cost of raw materials and auxiliary materials is low, operation is easy and convenient, and the method can be used for large-scale industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

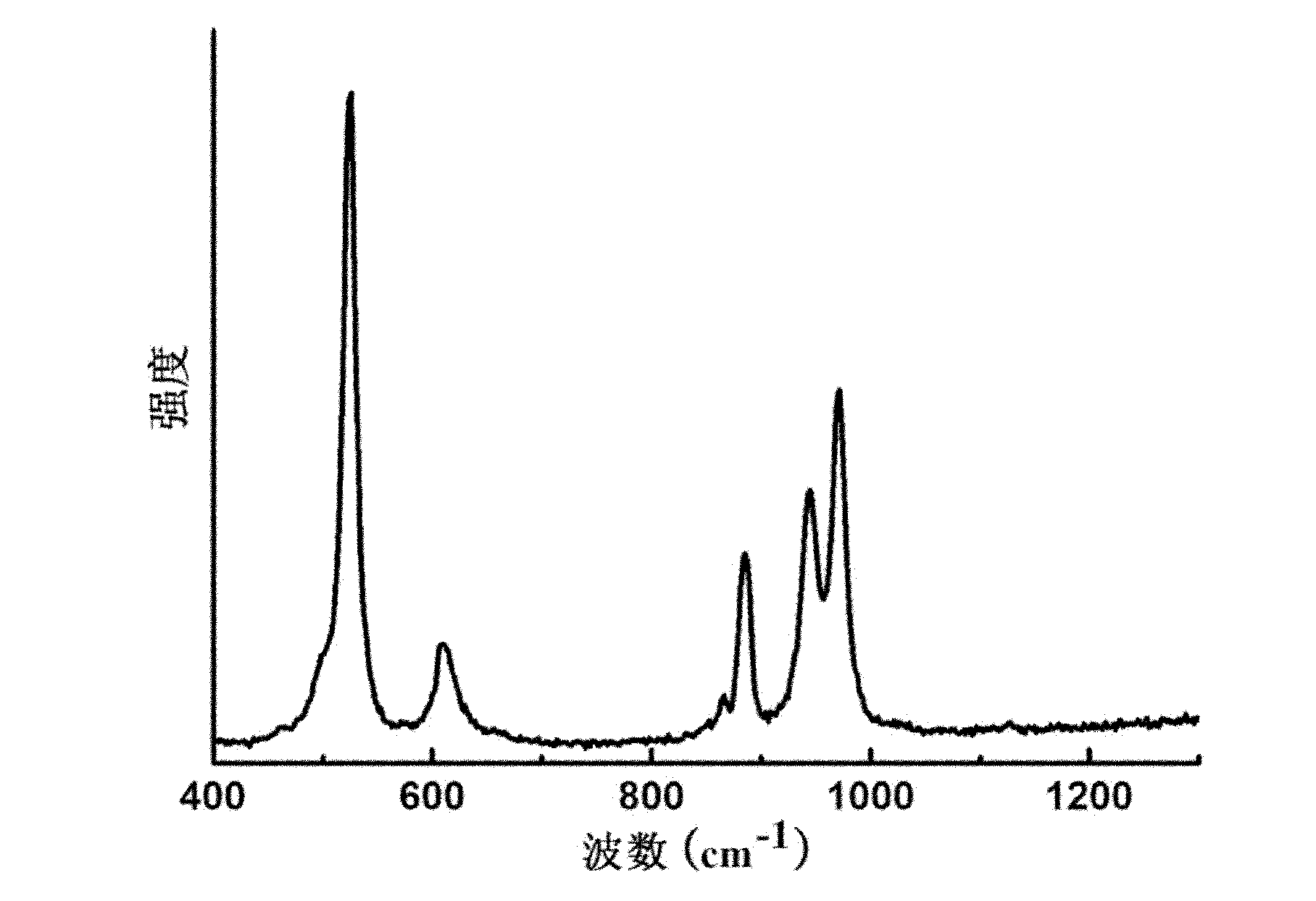

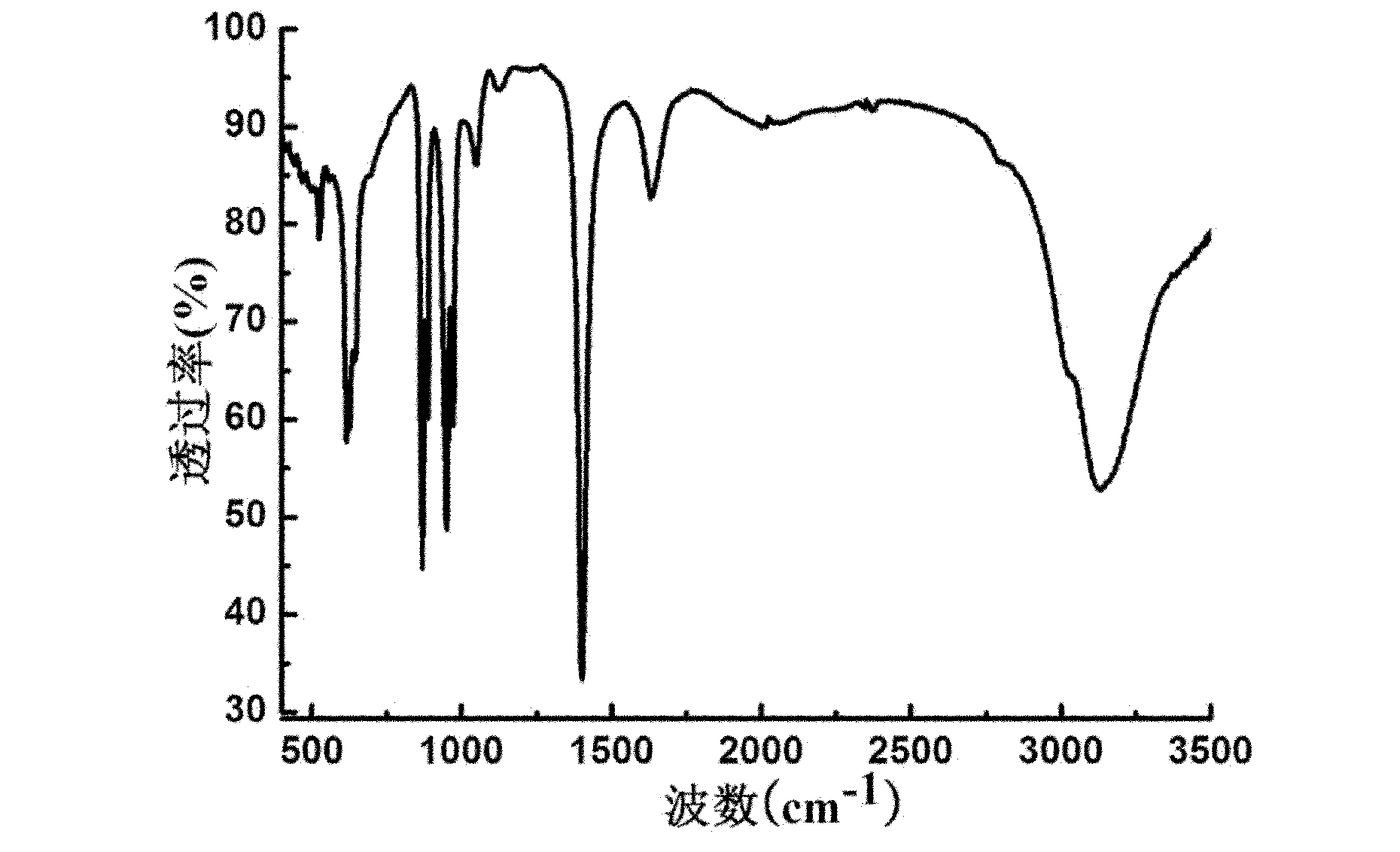

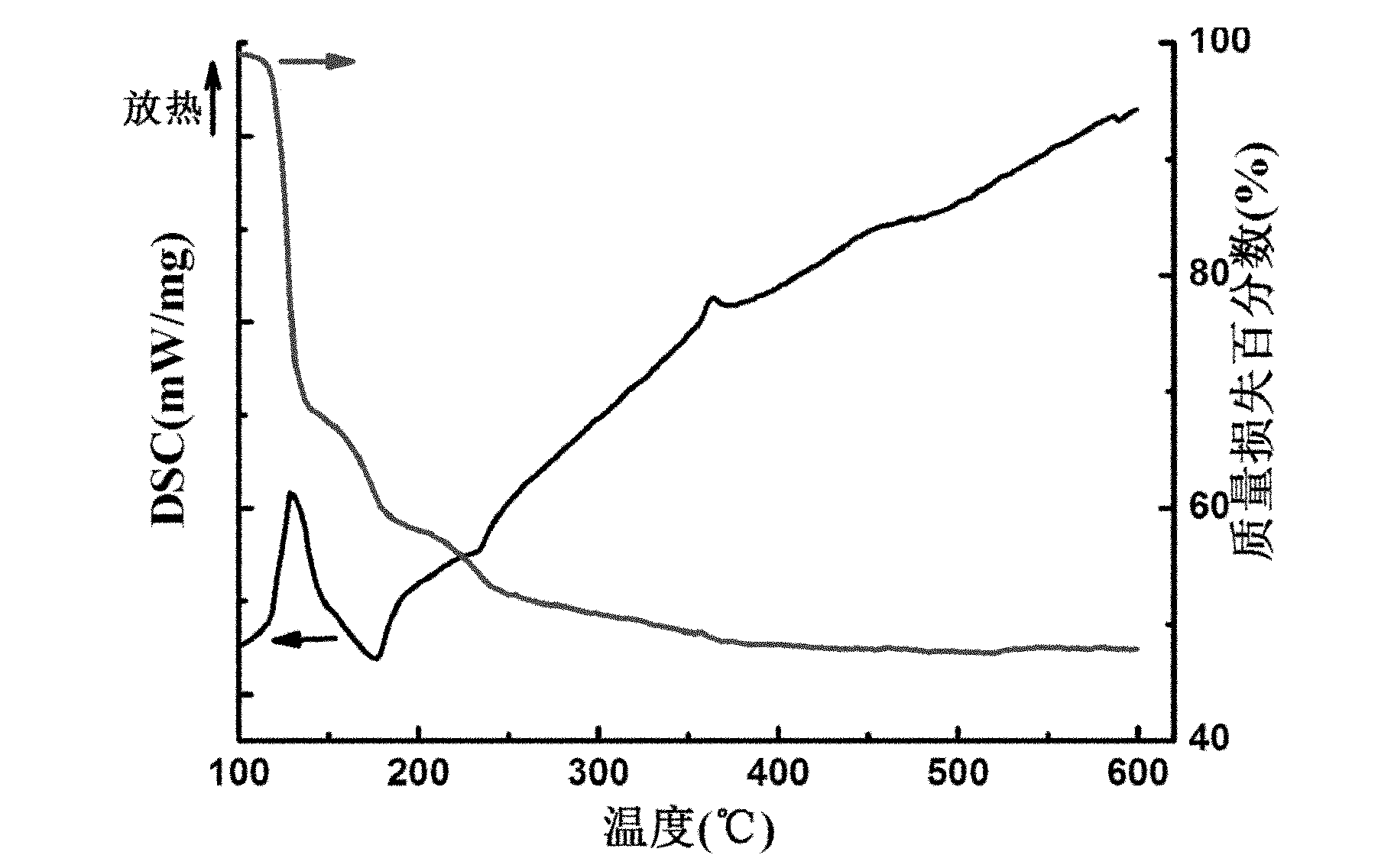

Mo-V-Te-Nb-O catalyst, preparation method and application thereof

ActiveCN101612564AHigh selectivityHigh catalytic activityCarboxylic preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsOxalateTelluric acid

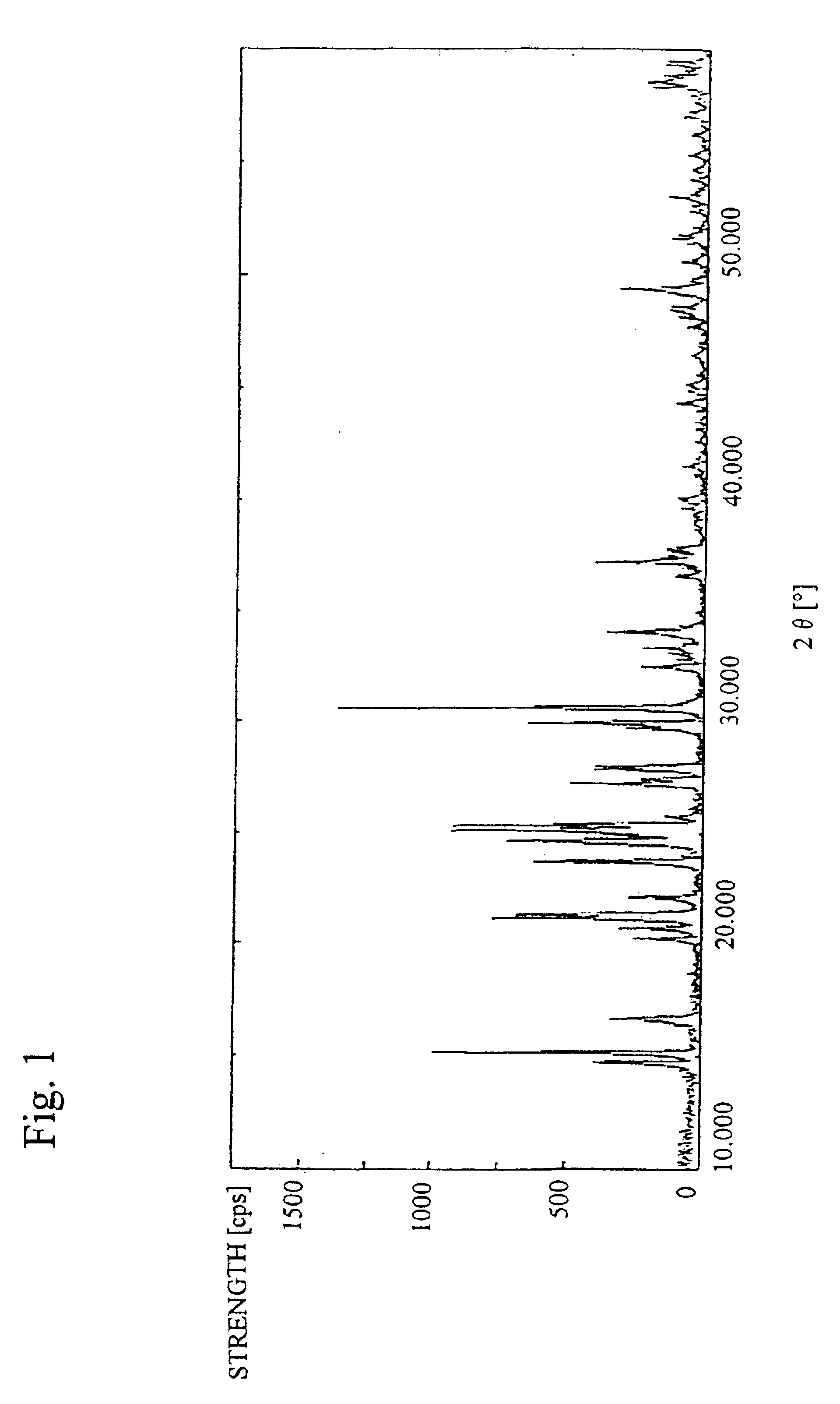

The invention provides a Mo-V-Te-Nb-O catalyst, a preparation method and application thereof. The catalyst takes ammonium molybdate, vanadyl sulfate, telluric acid and niobium oxalate as raw materials, and comprises the active ingredients of Mo, V, Te and Nb in a molar mixture ratio of 1:0.2-1.0:0.2-1.0:0.1-0.5. The method comprises the steps of preparing the ammonium molybdate, the vanadyl sulfate, the telluric acid and the niobium oxalate into mixed solution according to the mixture ratio, placing the mixed solution in a specially-made stainless steel reactor, raising the temperature from room temperature to between 160 and 230 DEGC through a program at a heating rate between 2 and 10 DEG C per minute, preserving heat for 2 to 20 hours, naturally cooling to room temperature, aging, taking out, performing pumping filtration, drying, roasting, grinding the obtained product to be 20 to 40 meshes and obtaining the catalyst. The Mo-V-Te-Nb-O catalyst prepared by adopting a temperature-programmed hydrothermal synthesis method shows high catalytic activity, catalyst stability and acrylic acid selectivity in reaction for preparing acrylic acid through propane selective oxidation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Two-stage extraction preparation method for high-purity vanadyl sulfate solution

InactiveCN103505903AHigh purityIncrease concentrationFinal product manufactureRegenerative fuel cellsHigh concentrationVanadyl sulfate

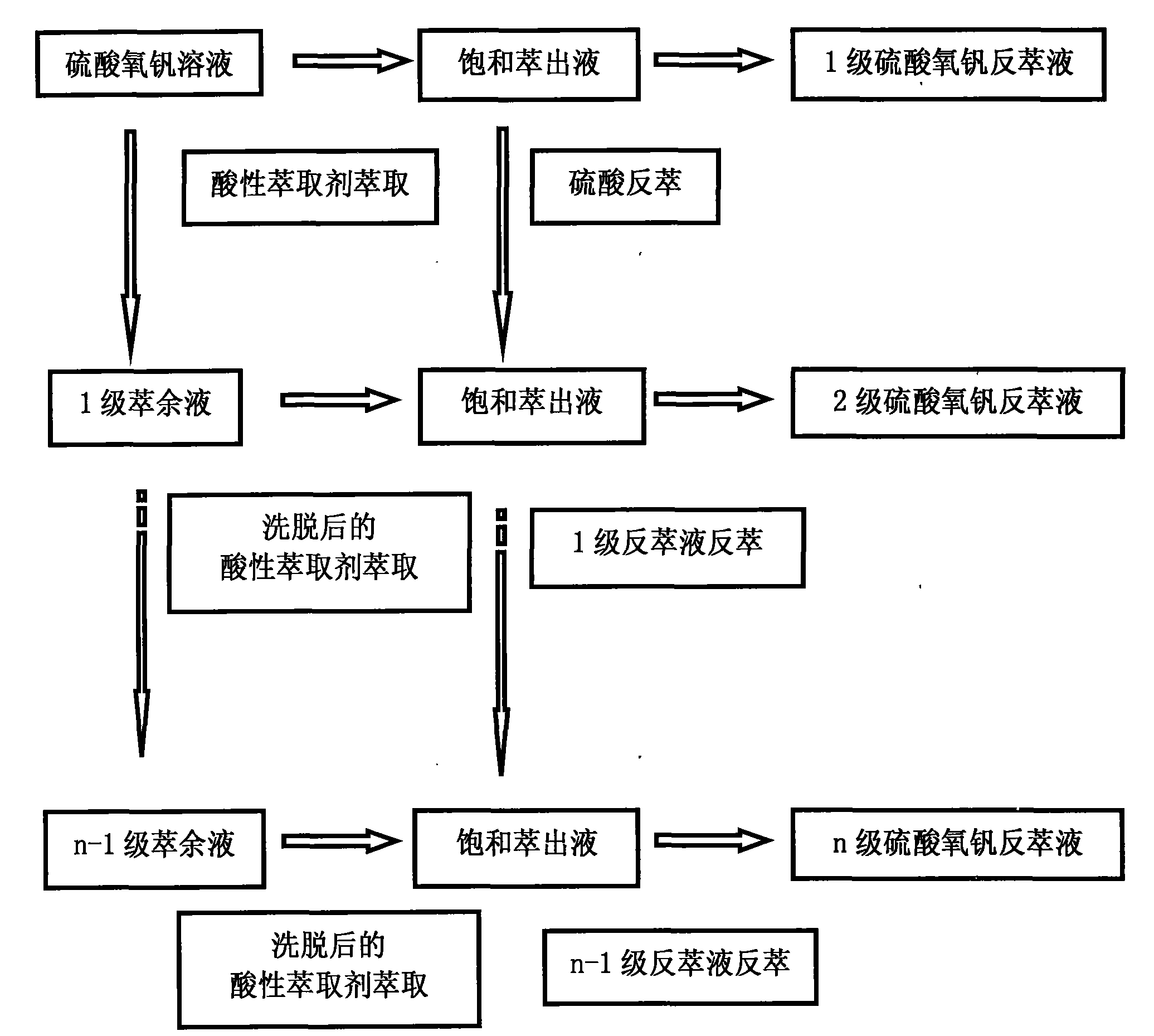

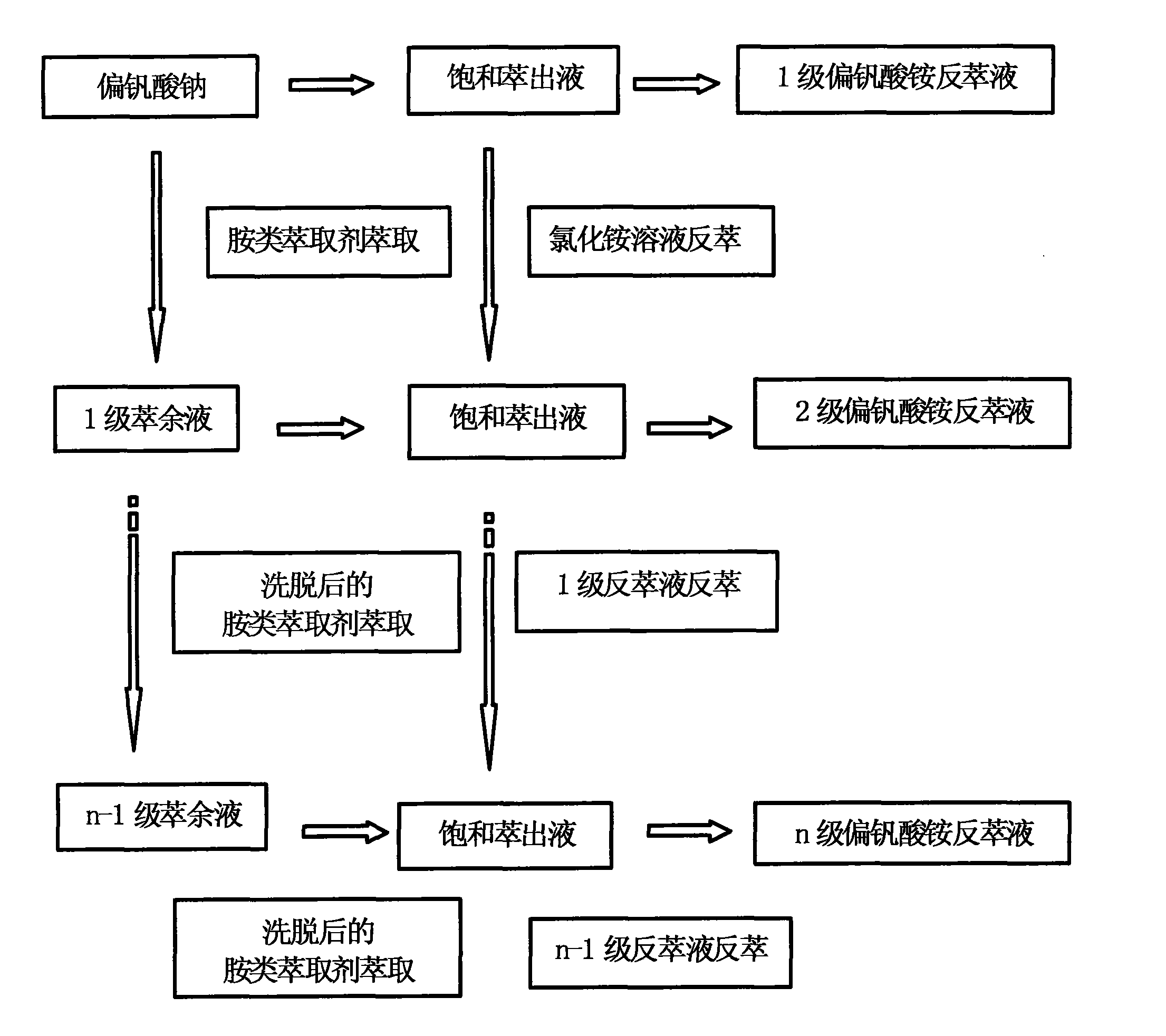

The invention relates to a two-stage extraction preparation method for a high-purity vanadyl sulfate solution, and is characterized in that the method comprises a series of steps: employing a qualified pentavalent vanadium solution produced by a vanadium factory, after purification by an initial impurity removal process, extracting pentavalent vanadium by an amine extractant, reducing pentavalent vanadium into tetravalent vanadium by adding a reductant, and extracting tetravalent vanadium by an acid extractant; the high-purity tetravalent vanadyl sulfate solution is prepared directly from the pentavalent sodium vanadate solution without a solid state process. The high-purity and high-concentration vanadyl sulfate electrolyte solution with the concentration of 1-4 M is obtained. The method adopts the qualified pentavalent vanadium solution as the raw material, the consumed reagents in the preparation process are commonly used, and the price is low; the extractants applied in the preparation process can be repeatedly used, and thus the cost is low; and the method has the advantages of simple preparation steps and mild reaction conditions, requires no high temperature, and enables the obtained electrolyte solution to have high purity.

Owner:NO 63971 TROOPS PLA

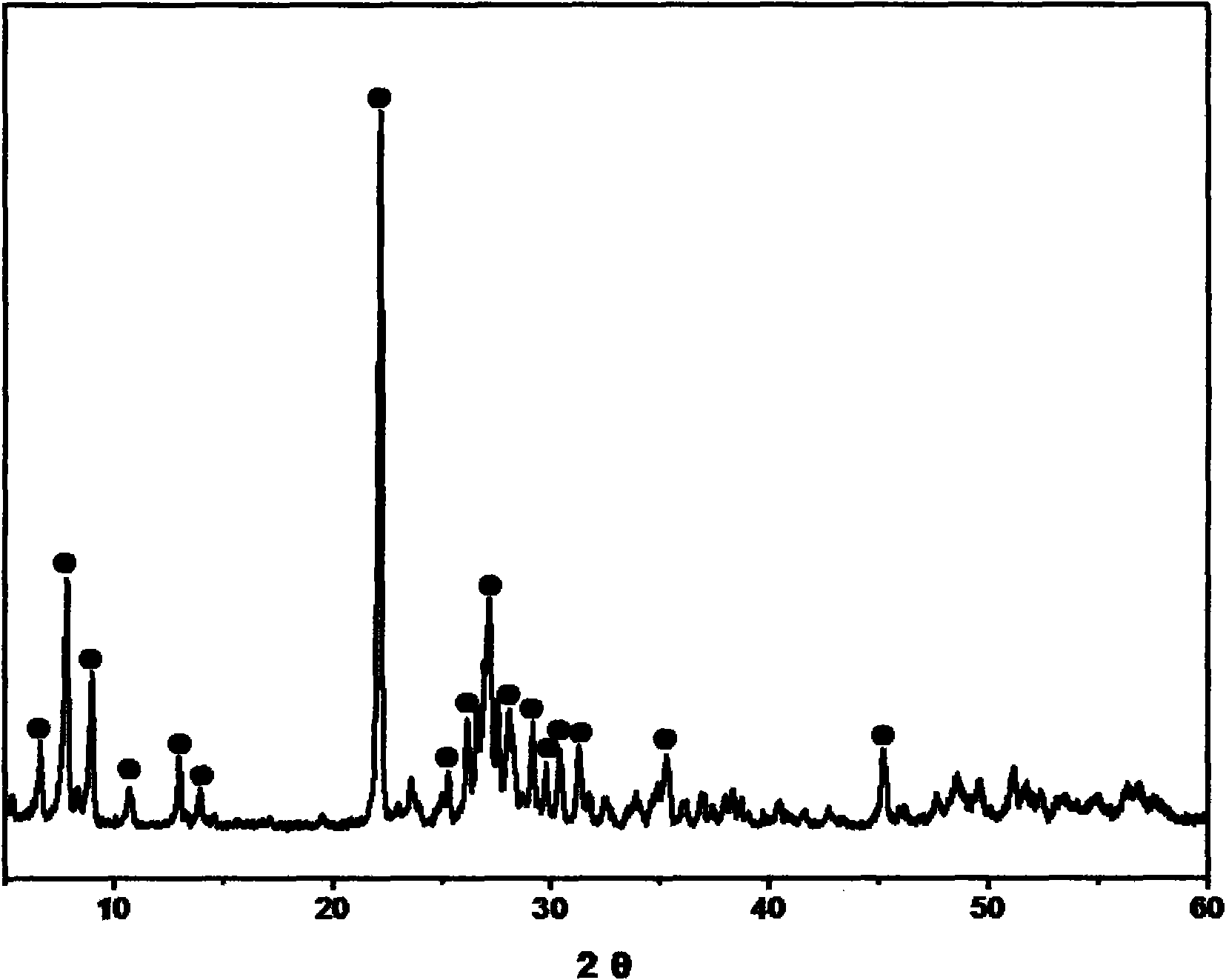

Preparation method of vanadyl sulfate

ActiveCN102951680AOvercome the disadvantage of lower purityHigh purityVanadium compoundsVanadyl sulfateDry basis

The invention discloses a preparation method of vanadyl sulfate, which comprises the following steps: (1) dissolving vanadium pentoxide with sulfuric acid to obtain an activated solution; (2) contacting the activated solution with a reducing agent to reduce pentavalent vanadium in the activated solution into tetravalent vanadium so as to obtain a reduction product; (3) adjusting the pH value of the reduction product by an alkali to precipitate the tetravalent vanadium in the reduction product so as to obtain a precipitate; (4) dissolving the precipitate with sulfuric acid, performing crystallization to obtain a vanadyl sulfate solid, wherein with respect to 1 mole of tetravalent vanadium in the precipitate, the using amount of the sulfuric acid is 0.9-1.1 moles. The vanadyl sulfate product prepared by the method provided by the invention has a dry basis content of up to 97 wt%.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

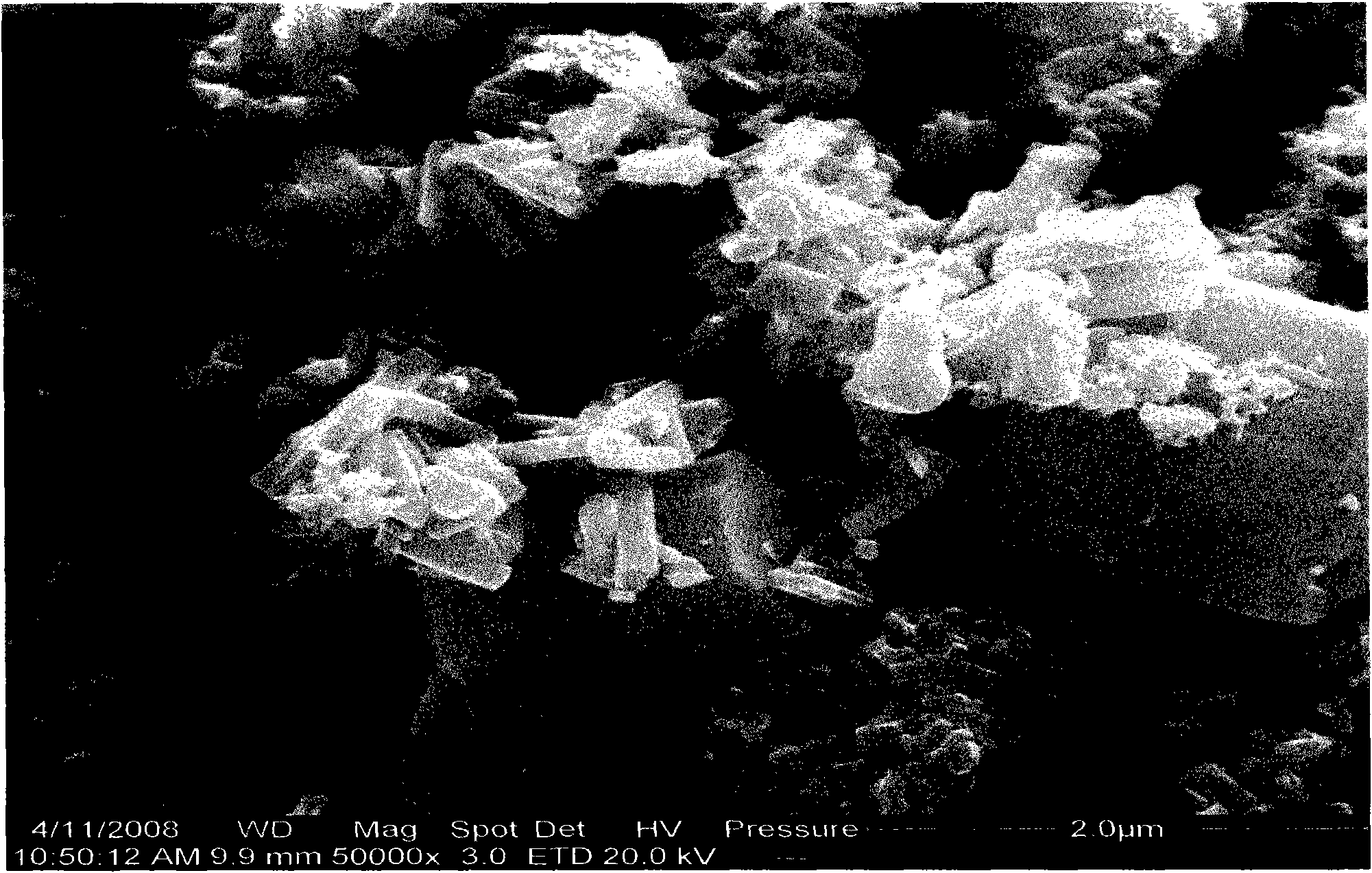

Vanadium dioxide powders and preparation method thereof

The invention discloses a preparation method of vanadium dioxide powders. The preparation method comprises the following steps: 1) dissolving carboxylic acid with hydroxyl in hydrogen peroxide, regulating pH value of the solution with ammonia water to be more than 7; adding vanadyl sulfate in the solution to obtain a reaction solution; after the completion of the reaction, adding an organic solvent in the solution, standing to generate precipitate, separating the precipitate from the solution to obtain peroxide complex of vanadium; 2) adding the peroxide complex of vanadium obtained in the step 1) and a reducing agent in water to form a water solution, and carrying out hydrothermal treatment to obtain vanadium dioxide powders. According to the invention, the preparation process is simple; the phase of product is adjustable; the powders of vanadium dioxide containing phase A are prepared, so that the material is provided for studying vanadium dioxide powders with phase A, and therefore, the preparation method is potentially significant for the scientific study.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing electrolyte for vanadium redox flow battery

InactiveCN1828991AImprove solubilityIncrease energy densityHybrid cell detailsRegenerative fuel cellsSolubilityAlkaline earth metal

The present invention relates to a preparation method for electrolyte of vanadum oxidation-reduction liquid stream. It contains 1, putting weight ratio 1.5-2.5 :1 vanadium trioxide and vanadium pentoxide powder in furnace and calcination at 200-700 degree centigrade, to make yellow powder became black powder to obtain multivalent vanadum compound, wherein quadravalence vanadum greater than total vanadum by 50 per cent, 2, adding distilled water in specific gravity 1.84 concentrated sulfuric acid to proceed 2 : 1 diluting then adding above-mentioned compound, according to mass fraction preparation to 65-75 per cent concentration vanadyl sulfate solution, wherein total vanadum concentration in 25-45 per cent, 3, adding 1-10 per cent concentration alkali salt or alkali salt and alkaline earth metal salt. Said invention adds additive in vanadyl sulfate solution, which not only raising vanadum ion solubility, preferably solving crystallizing jamming battery flow field problem in charge discharge process, but also reducing vanadium ion osmotic problem in film, greatly raising battery energy source efficiency.

Owner:缪强

Method of preparing electrolyte of vanadium ion redox flow battery

InactiveCN101552346ANothing producedShort processFinal product manufactureRegenerative fuel cellsVanadyl sulfateAmmonium metavanadate

The present invention relates to a method of preparing electrolyte of vanadium ion redox flow battery, the method use abundant stone coal in our country as raw material, direct acid dipping, liquid solid separation to obtain extract of tetravalent vanadium, after P204-TBP system extraction and sulfuric acid reextraction of the extract, obtaining a high pure vanadic sulfate solution with a concentration 1-5 mol / L. The invention provide method for preparing high pure vanadic sulfate solution is simple, comparing with other methods, there is no need to transfer the vanadium in the stone coal extract into deposition of poly-ammonium vanadate or ammonium metavanadate, then proceeding other complex process such as calcination, sulfuric acid dissolution etc. The method shorts preparation process of the electrolyte of vanadium ion redox flow battery, the extractant can be used circularly which reduces production cost greatly. The invention provides a novel process for preparing electrolyte of vanadium ion redox flow battery in short process and at low cost.

Owner:KUNMING UNIV OF SCI & TECH

Method for recycling failed vanadium electrolyte

ActiveCN106450371ASimple processEasy to operateFuel cells disposal/recyclingBattery recyclingSulfate radicalsPhysical chemistry

The invention provides a method for recycling failed vanadium electrolyte. The method includes steps of confirming vanadium ion concentration C1, averaged valence state M1 of vanadium ion and sulfate radical concentration Cs1 in the failed vanadium electrolyte; according to the volume ratio of the failed vanadium electrolyte, determining the quantity n1 of the vanadyl sulfate or vanadium sulphate as required; according to the vanadium ion concentration C2 and sulfate radical concentration Cs2 required by the regenerated vanadium electrolyte, confirming the volume V2 of the regenerated vanadium electrolyte and the quantity n2 of the vitriolic material as required; and then adding water and adjusting the volume of the obtained solution to V2, and thereby obtaining the regenerated vanadium electrolyte. Through recycling the recycled vanadium electrolyte, the electrolyte is regenerated; the recycle rate is up to 10%; moreover, the method is simple in process and easy to operate.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

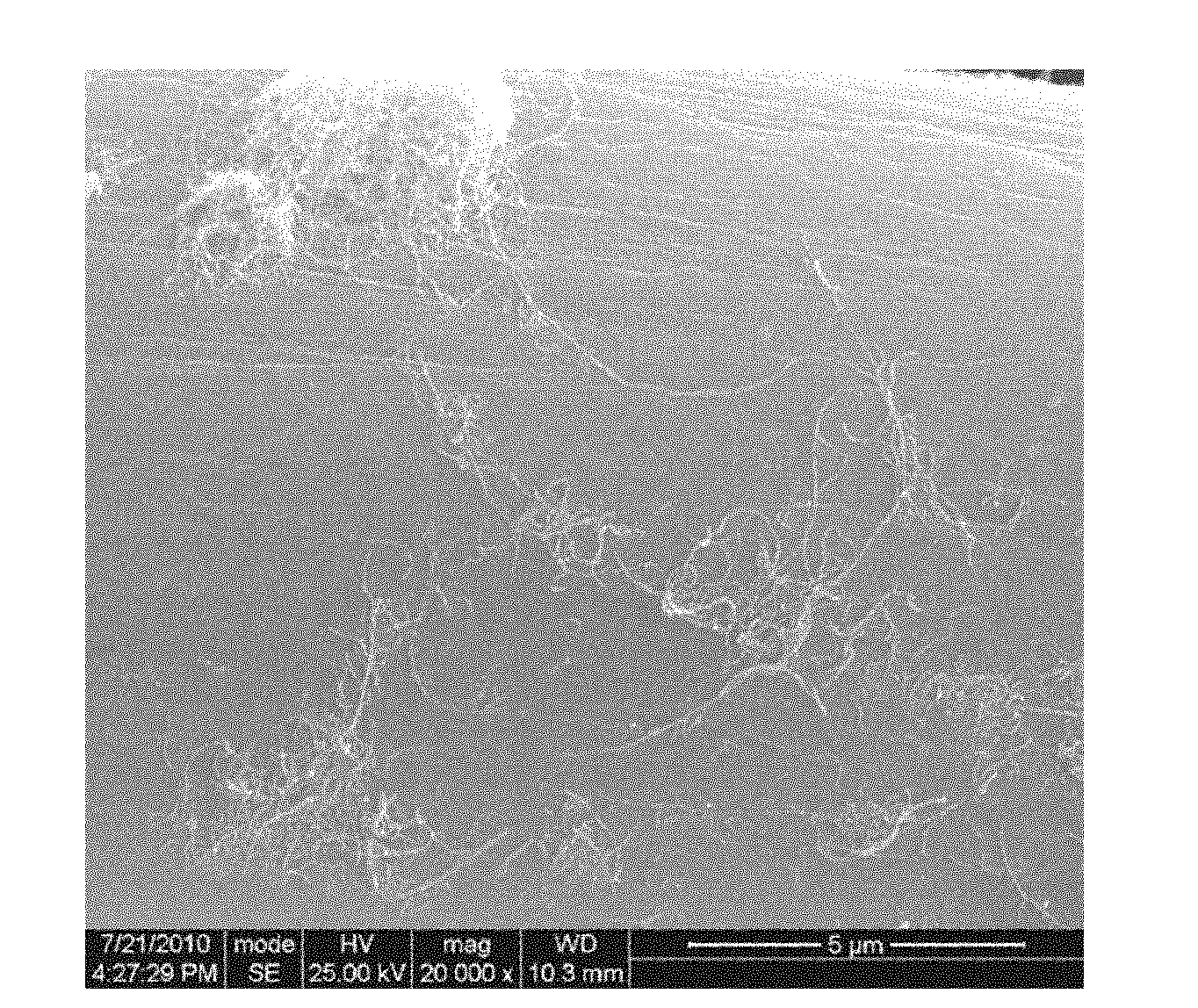

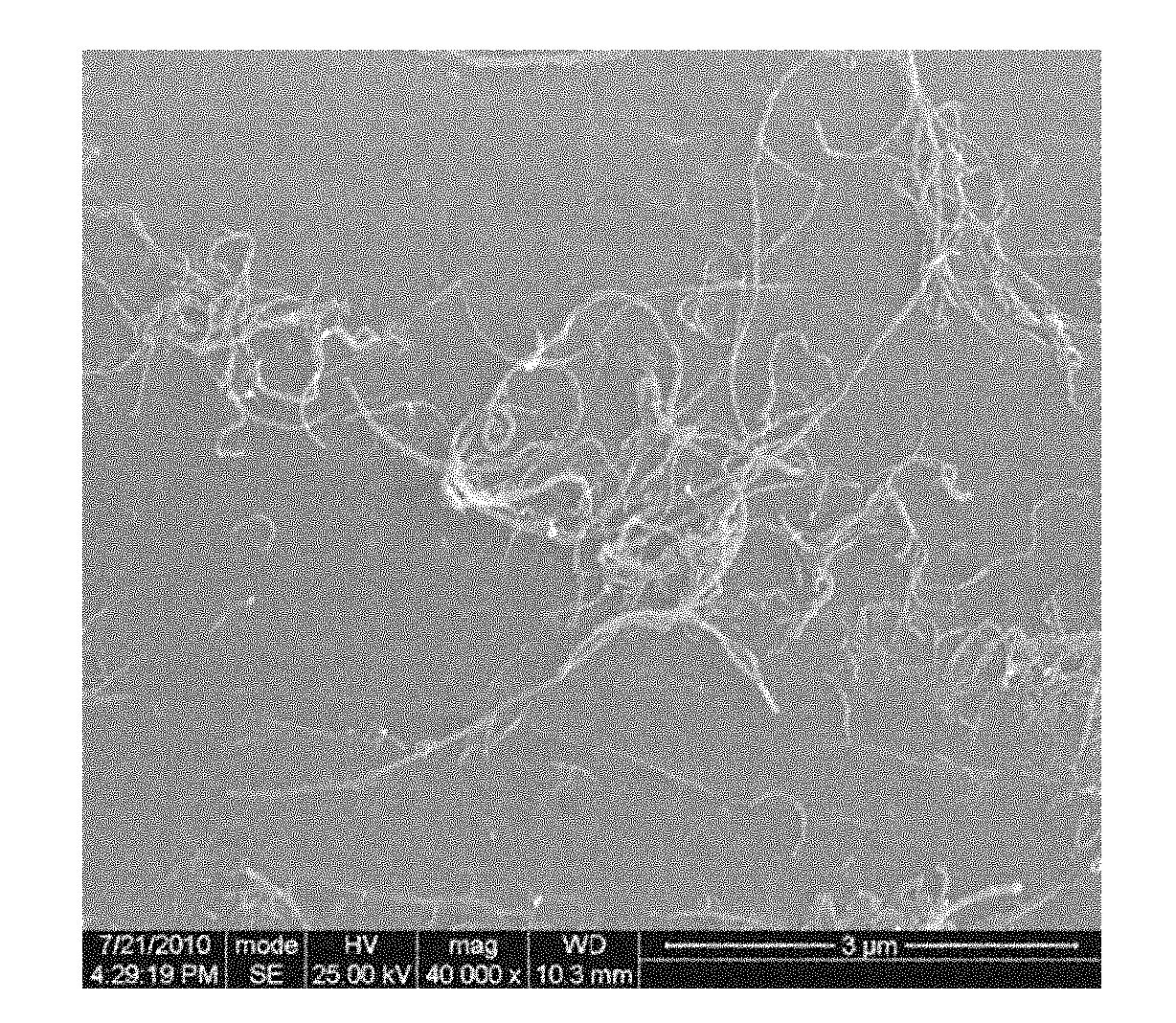

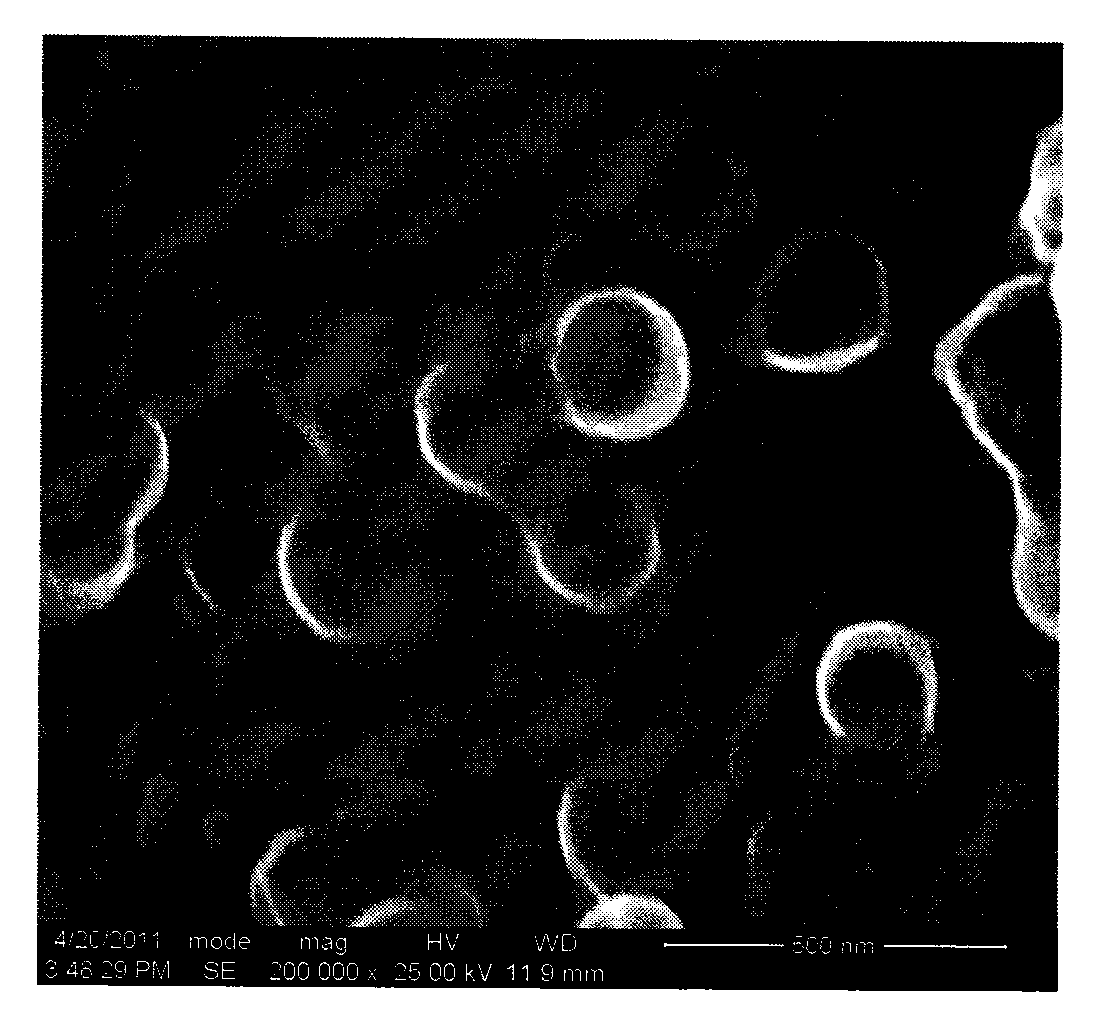

Surface modification treatment method for increasing activity of vanadium battery electrode materials

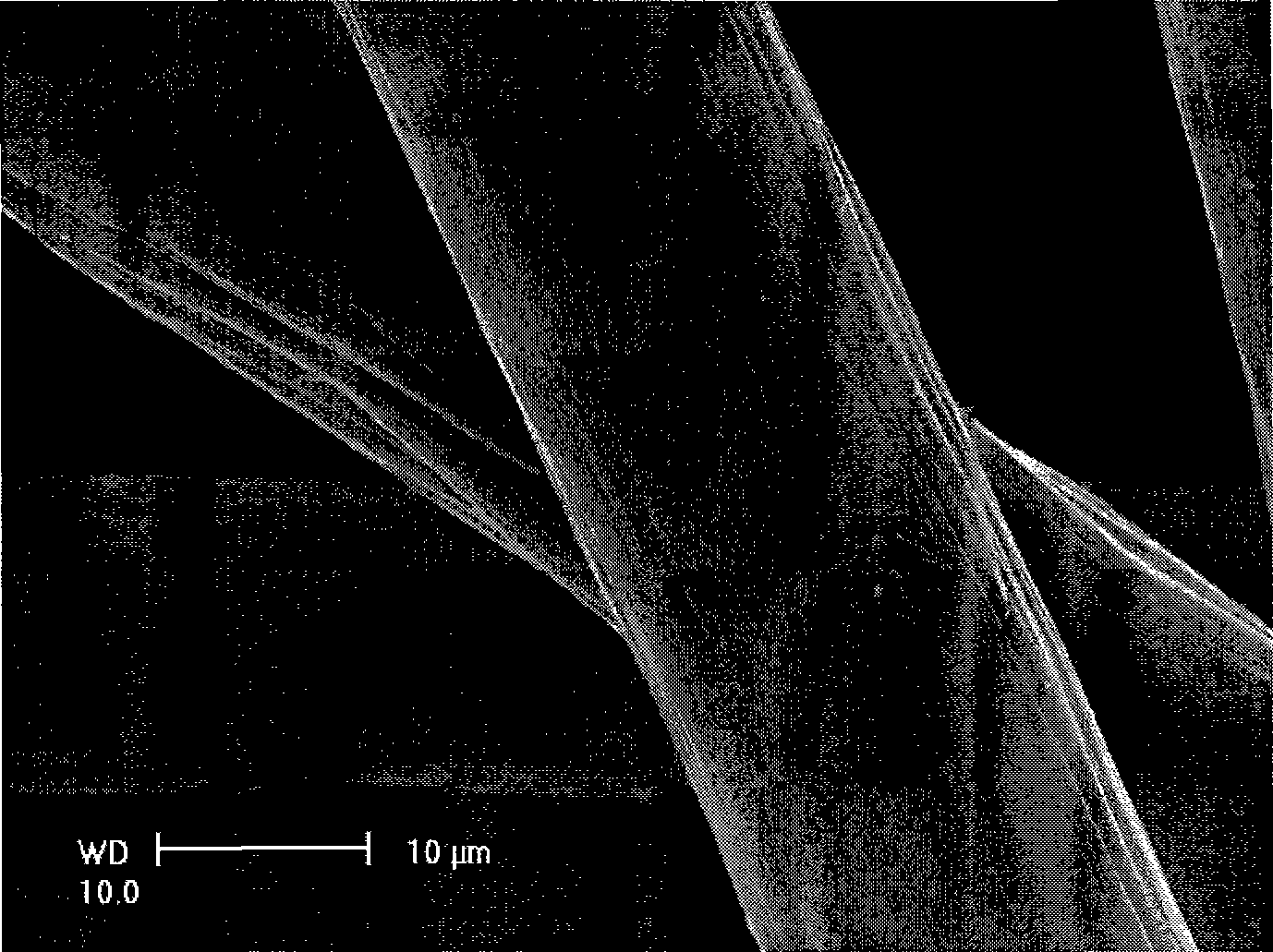

The invention, relating to the field of battery production and energy storage, discloses a surface modification treatment method for increasing the activity of vanadium battery electrode materials, comprising the following steps: immersing a graphite-felt or carbon-felt material in a dispersion liquid of multi-walled carbon nanotubes for soaking, then cleaning, drying to obtain a modified graphite-felt or carbon-felt electrode material. According to the invention, mild and controllable surface modification treatment on the electrodes is carried out by using the multi-walled carbon nanotubes, the disadvantages of stability reduction of electrode materials and battery life shortening caused by peroxidation of the materials due to heat treatment and acid treatment are overcome, the technology is simple, and the cost is low. According to the invent, the graphite-felt or carbon-felt treated by the method as electrodes, a cation-exchange membrane as a separator, and positive and negative electrolytes which both consist of 1.5 M vanadyl sulfate and 2 M sulfuric acid form a battery, and the current efficiency, voltage efficiency, and energy efficiency of the battery are all obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation and application method of immobilization double-tooth Schiff base vanadyl complex catalyst

InactiveCN102580776ARetain activityPreserve optionalityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereVanadyl sulfate

The invention belongs to the technical field of a vanadyl complex catalyst and particularly relates to an immobilization double-tooth Schiff base vanadyl complex catalyst as well as a preparation method and an application method thereof. The preparation method comprises the following steps: firstly, bonding double-tooth Schiff base genin on crosslinked polystyrene microspheres; and then performing the coordinating chelation reaction to the microspheres and vanadyl sulfate to prepare the crosslinked polystyrene microsphere immobilization double-tooth Schiff base vanadyl (IV) complex catalyst. According to the invention, a homogeneous catalyst is changed into a heterogeneous vanadyl (IV) complex catalyst; not only are the activity and the selectivity of the homogeneous catalyst reserved, but also a series of advantages are brought in, for example, the thermal stability of the catalyst is improved, the catalyst is convenient to separate from a reaction medium, and the catalyst is reused;and the efficiency of the catalyzing process is greatly promoted.

Owner:ZHONGBEI UNIV

Method for preparing vanadyl sulfate from electrolyte for failure vanadium cell

ActiveCN102983346ASimple processing methodRaw materials are easy to getFinal product manufactureRegenerative fuel cellsVanadyl sulfateEnergy storage

The invention relates to the field of cell recovery and energy storage, particularly relates to a method for preparing vanadyl sulfate from electrolyte for a failure vanadium cell, and solves the problem on waste liquid treatment aspect due to the fact that vanadium electrolyte can not be used as energy is imbalanced after the vanadium electrolyte is used for a plurality of times in the prior art. The failure vanadium electrolyte is taken as a material; the valence state of vanadium in the electrolyte is increased to pentavalence by charging of the cell; a vanadium precipitating agent with proper quantity is added; the pentavalent vanadium is precipitated; and then an organic reducing agent is added and cultivated at the normal temperature to prepare vanadyl sulfate crystals. According to the method, the technique is simple, materials can be easily available, and the vanadium recovery rate can be up to over 80%, so that the method is suitable for industrial mass production; and the operating cost of the vanadium cell is reduced.

Owner:辽宁科京新材料有限公司

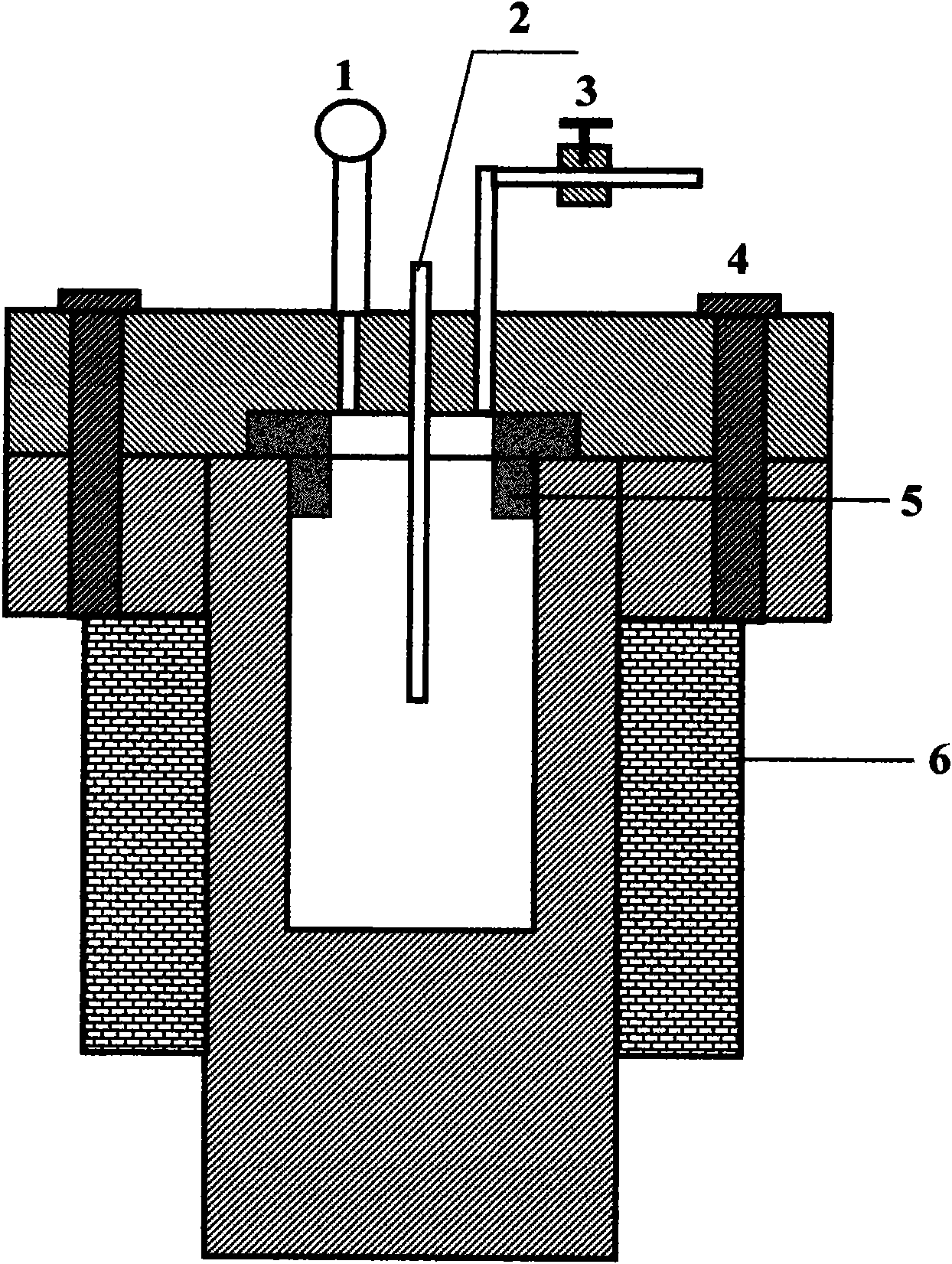

Preparation method of high-purity vanadyl sulfate, electrolyte prepared from high-purity vanadyl sulfate, and vanadium redox battery applying high-purity vanadyl sulfate

InactiveCN103466704ARegenerative fuel cellsVanadium compoundsVanadium redox batteryElectrolytic agent

The invention provides a preparation method of high-purity vanadyl sulfate, an electrolyte prepared from high-purity vanadyl sulfate, and a vanadium redox battery applying high-purity vanadyl sulfate. The preparation method comprises the following steps: coarse vanadium pentoxide is directly dissolved in concentrated sulphuric acid to form an activation-induced mixture, and the mixture is added in deionized water to be dissolved and filtered to obtain a solution containing pentavalent vanadium ions and sulfuric acid; the solution containing pentavalent vanadium ions and sulfuric acid is taken as a cathode electrolyte, a sulfuric acid solution is taken as an anode electrolyte, the pH value of the cathode electrolyte is controlled to be 2.2-2.4, and the impurity-removal constant-current electrolysis is carried out, so as to deposit chromium ions in the anode electrolyte on a cathode; chromium on the cathode is removed, and then is subjected to constant-voltage electrolysis to obtain a vanadyl sulfate solution; the vanadyl sulfate solution is evaporated to dryness to obtain vanadyl sulfate containing crystallization water. The preparation method has the advantages that the high-purity vanadyl sulfate crystal suitable for being applicable to the vanadium redox battery and is convenient to transport.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing V-Ti-Si-O composite catalyst used in methanol oxidation for synthesizing methylal

The invention provides a method for preparing a V-Ti-Si-O composite catalyst used in methanol oxidation for synthesizing methylal. The method comprises: taking vanadyl sulfate (VOSO4), titanium sulfate (Ti(SO4)2) and tetraethoxysilane (Si(OC2H5)4) as precursors; adding water for dissolution to form mixed solution; and taking aqueous solution of ammonia as precipitant and using a coprecipitation method to directly prepare the V-Ti-Si-O composite catalyst containing sulfate radicals. The introduction of SiO2 improves the thermal stability and molding capability of the catalyst, and as the catalyst contains the sulfate radicals which do not need to be introduced through second impregnation, the method is simple in preparation process. The catalyst is used in the selective oxidation of methanol for synthesizing methylal and has good performance.

Owner:NANJING UNIV

Gelled electrolyte of vanadium battery and vanadium battery

ActiveCN102005583AImprove cycle stabilityEliminate capillary exudationFuel cells groupingRegenerative fuel cellsVanadium redox batteryIndium

The invention provides gelled electrolyte of a vanadium battery and the vanadium battery employing the gelled electrolyte. The gelled electrolyte comprises sulfuric acid, vanadyl sulfate, gelatin and an additive, wherein the additive comprises one or more of silicon dioxide, sulfate of alkali metal and / or alkaline earth, glycerol, salt of metal indium, and C1-C4 ammonium ethoxylated alkyl sulfate. The gelled electrolyte can weaken the migration of water along with protons on two sides of a diaphragm of the vanadium battery to ensure that the phenomenon of unbalanced concentration and volume of electrolyte ions at positive and negative poles is improved, and also can weaken the migration of vanadium oxide ions along with the protons on the two sides of the diaphragm of the vanadium batteryto ensure that the self discharge of the vanadium battery is reduced; therefore, the cyclical stability of the vanadium battery can be improved, and the capillary seepage phenomenon of the electrolyte along with the diaphragm is stopped so as to avoid leakage.

Owner:BYD CO LTD

Method for preparing vanadyl sulfate

The invention discloses a method for preparing vanadyl sulfate. The process of the method mainly comprises: a) adding vanadium pentoxide to sulfuric acid; b) adding hydrazine or hydroxylamine; and c) performing evaporation and crystallization to obtain blue VOSO. xH2O crystals. Compared with the prior process route, the process route of the invention reduces the steps of heating, dissolving, cooling, diluting, electrolyzing and the like. The method has the advantages of mild reaction conditions, simple process, low cost, and stable product quality.

Owner:DALIAN RONGKE POWER

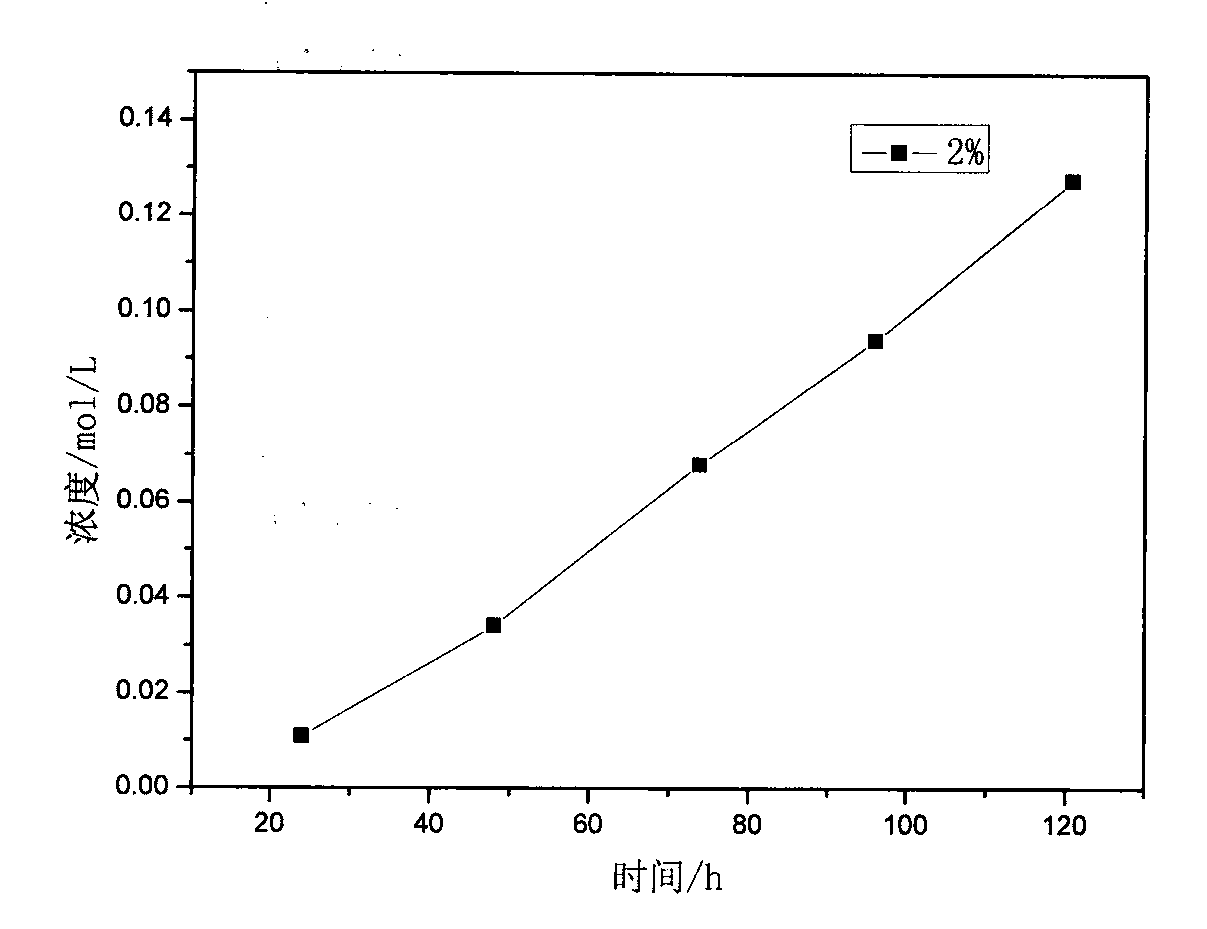

Enhanced ion-exchange membrane for enhanced vanadium cell and preparation method thereof

ActiveCN102723506AMild preparation conditionsPreparation conditions are easy to controlFinal product manufactureRegenerative fuel cellsVanadyl sulfateCell membrane

The invention, relating to the field of cell manufacturing and energy storage, discloses an enhanced ion-exchange membrane for a vanadium cell, solving the problems that Nafion membranes have low vanadium resistance and have influence on vanadium cell performances in the prior art. The preparation method is characterized by carrying out ultrasonic dispersion on the prepared nano carbon particles containing functional groups in a Nafion resin solution, and then conducting cast molding to obtain the enhanced membrane material. According to the method, by doping the nano carbon material whose surface contains functional groups (carboxyl or hydroxyl, etc.) in a matrix membrane material to enhance the vanadium resistance and ion exchange rate of the membrane material, thus the energy storage efficiency of the cell can be raised. The prepared ion-exchange membrane has outstanding stability. The cell performance is tested by using the prepared membrane material as a cell membrane and using 1.5M vanadyl sulfate and 2M sulfuric acid as an electrolyte, and the cell performance is obviously raised. The result of the test by vanadium resistance experiments shows that the vanadium resistance of the membrane is obviously raised.

Owner:辽宁科京新材料有限公司

Method for preparing vanadyl sulfate

The invention discloses a method for preparing vanadyl sulfate, comprising the following steps of: calcining ammonium metavanadate at the temperature of 540-600 DEG C in a closed reactor; adding sulphuric acid to a product obtained by calcining, and introducing an SO2 gas to carry out heating and stewing; and crystallizing a solution obtained after the heating and the stewing so as to obtain the vanadyl sulfate. The method for preparing the vanadyl sulfate does not generate a pollutant, i.e. an ammonia gas, and effectively utilizes the SO2 gas generated in industry, thereby having very well environmental benefits.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

Trivalent vanadium ion electrolyte and preparation method thereof, and vanadium battery

InactiveCN103515641AHigh purityImprove performanceRegenerative fuel cellsElectrolysisVanadyl sulfate

The invention provides a preparation method of a trivalent vanadium ion electrolyte, the trivalent vanadium ion electrolyte prepared with the method, and a vanadium battery. The trivalent vanadium ion electrolyte preparation method comprises the steps that: a sulfuric acid solution comprising vanadyl sulfate is adopted as a cathode, and a sulfuric acid solution is adopted as an anode, wherein the molar amount of the sulfuric acid of the anode equals that of the vanadyl sulfate in the sulfuric acid solution comprising vanadyl sulfate; constant-voltage electrolysis is carried out, such that the trivalent vanadium ion electrolyte with a molar ratio of trivalent vanadium to all vanadium higher than 0.98 is obtained. With the method provided by the invention, the trivalent vanadium ion electrolyte with relatively high purity can be stably obtained.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com