Method for manufacturing high-purity vanadium battery electrolyte

A high-purity, electrolyte technology, applied in the direction of regenerative fuel cells, can solve the problems of increased impurity content, difficulty in ensuring product purity, and high production costs, so as to reduce the content of impurities, meet the use requirements, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

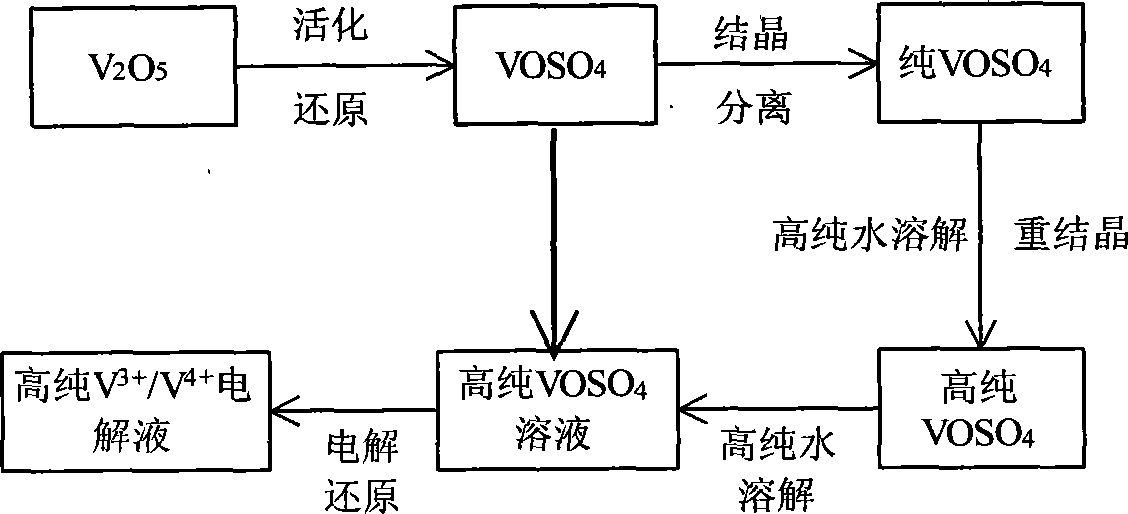

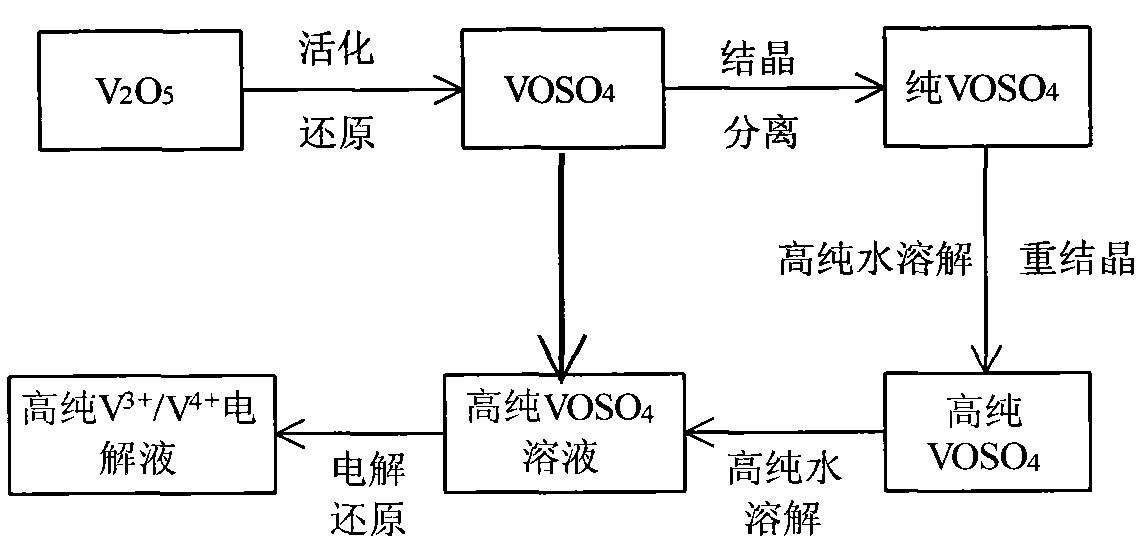

Image

Examples

Embodiment 1

[0034] A method for preparing a high-purity vanadium battery electrolyte, first dissolving 208g of vanadium pentoxide in 1000mL of sulfuric acid solution with a volume ratio of 1:1 and heating to 60°C for activation; The sulfur dioxide reducing agent is reduced to obtain a vanadyl sulfate solution; the resulting solution is electrolytically reduced in a diaphragm electrolytic cell to obtain high-purity V 3+ / V 4+ Mix the electrolyte.

Embodiment 2

[0036] A method for preparing a high-purity vanadium battery electrolyte, first dissolving 180g of vanadium pentoxide in 1000mL of sulfuric acid solution with a volume ratio of 1:1 and heating to 100°C for activation; Sulfur dioxide reducing agent is reduced to obtain vanadyl sulfate solution; the vanadyl sulfate solution is placed in a crystallization tank for crystallization, and then transferred to centrifugal separation equipment for centrifugal separation to obtain vanadyl sulfate crystals, and its purity is detected; after the crystal purity meets the requirements , dissolve the crystals in high-purity water, and adjust the concentration of sulfuric acid in the solution to 3mol / L with sulfuric acid. The resulting solution was electrolytically reduced in a diaphragm electrolytic cell to obtain high-purity V 3+ / V 4+ Mix the electrolyte.

Embodiment 3

[0038] A method for preparing a high-purity vanadium battery electrolyte, first dissolving 220g of vanadium pentoxide in 1000mL of sulfuric acid solution with a volume ratio of 1:2 and heating to 40°C for activation; The sulfur dioxide reducing agent is reduced to obtain vanadyl sulfate solution; the vanadyl sulfate solution is placed in a crystallization tank for crystallization, and then transferred to centrifugal separation equipment for centrifugation to obtain vanadyl sulfate crystals, and its purity is detected; if the vanadyl sulfate crystals If the purity does not meet the requirements after testing, the crystals can be dissolved in high-purity water and recrystallized in a recrystallization tank to obtain high-purity vanadyl sulfate crystals. Then dissolve the crystals meeting the purity requirements in high-purity water, and adjust the concentration of sulfuric acid in the solution to 1.5 mol / L with sulfuric acid. The resulting solution is electrolytically reduced in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com