Enhanced ion-exchange membrane for enhanced vanadium cell and preparation method thereof

A technology of ion exchange membranes and vanadium batteries, which is applied in the direction of regenerative fuel cells, battery pack parts, fuel cell parts, etc., can solve the problems of low vanadium resistance and affect the performance of vanadium batteries, and achieve stable performance and physical Stable performance and chemical performance, good electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

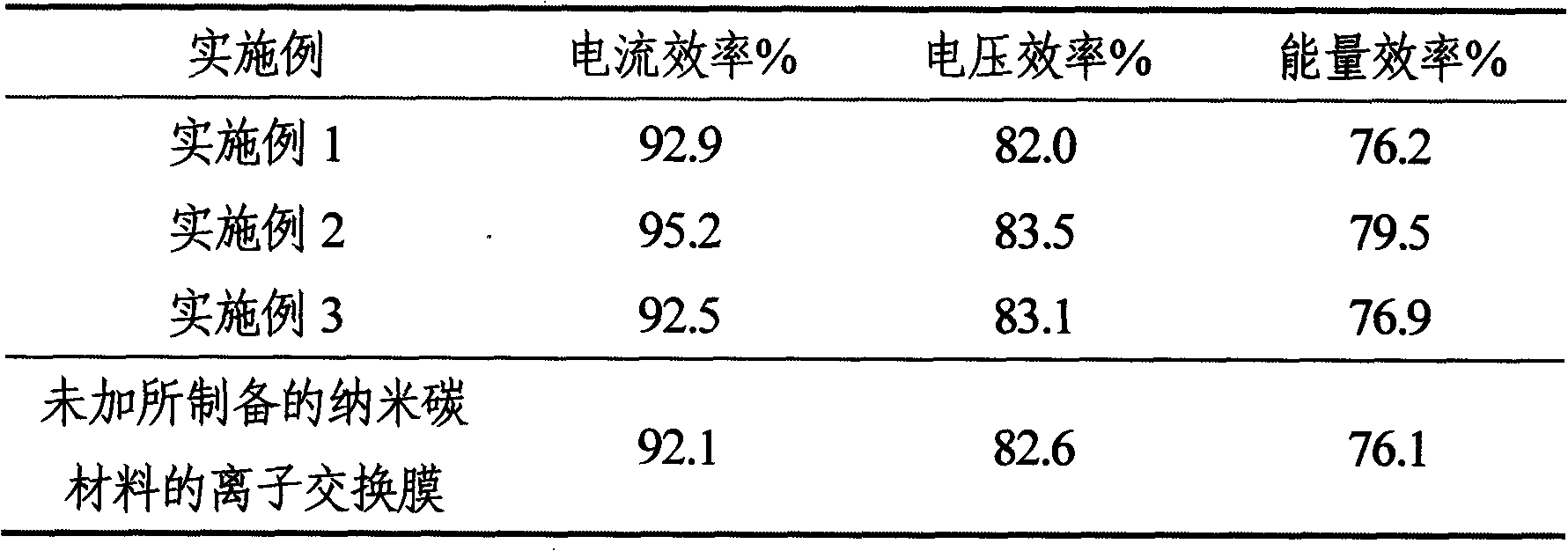

Embodiment 1

[0024] In this embodiment, the preparation method of the ion-exchange membrane for the enhanced vanadium battery is as follows:

[0025] (1) Weigh a certain amount of glucose powder and dissolve it in deionized water, configure it as a glucose aqueous solution with a weight concentration of 5%, then take a certain amount of glucose aqueous solution and place it in a high-pressure reactor, perform hydrothermal treatment, and treat at 200 ° C for 5 hours , and then filtered, washed, and dried to make nano-carbon material powder; in this embodiment, the particle size of the nano-carbon material powder is about 200nm.

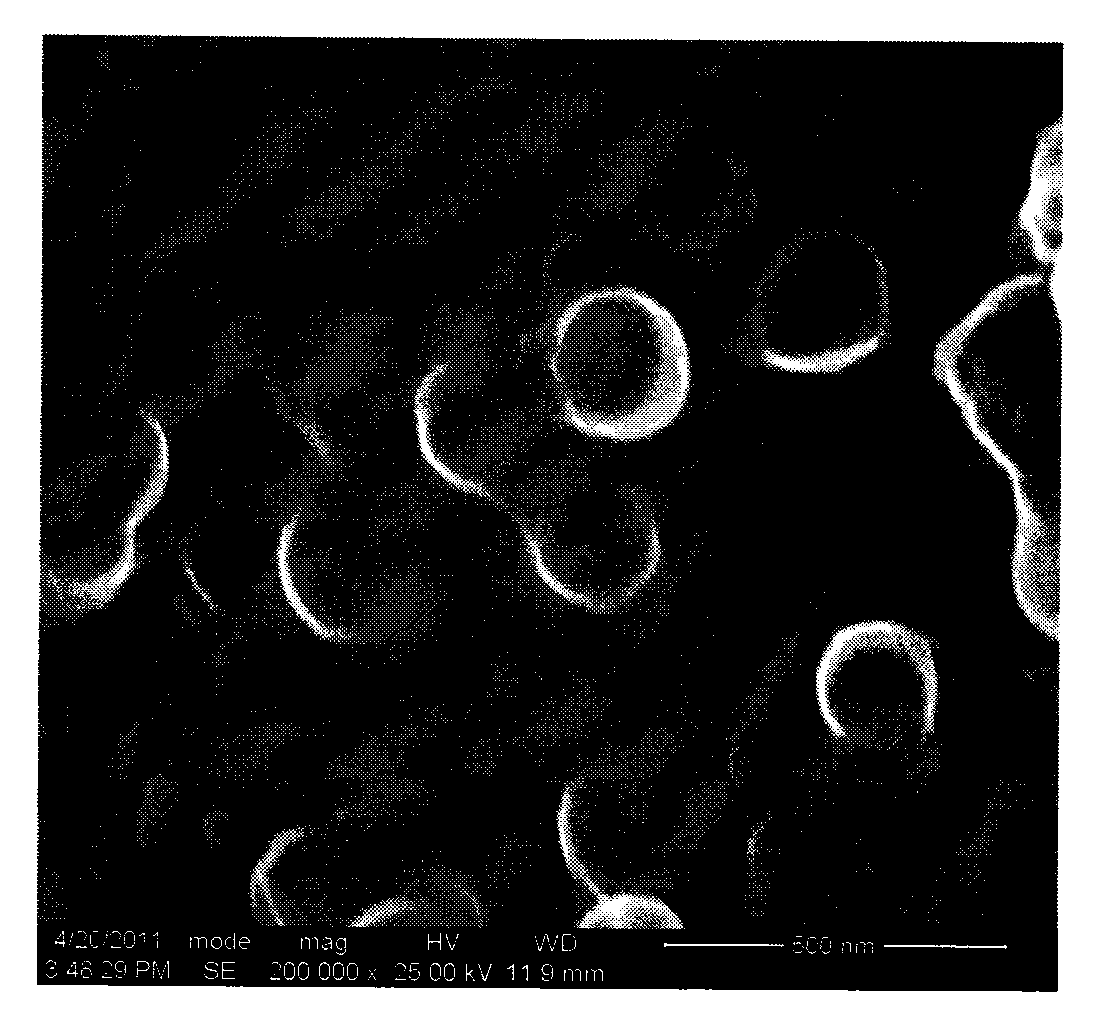

[0026] Such as figure 1 As shown, it can be seen from the SEM picture of the nano-carbon material that the particle size distribution of the prepared nano-carbon material is relatively uniform, concentrated at about 200 nanometers.

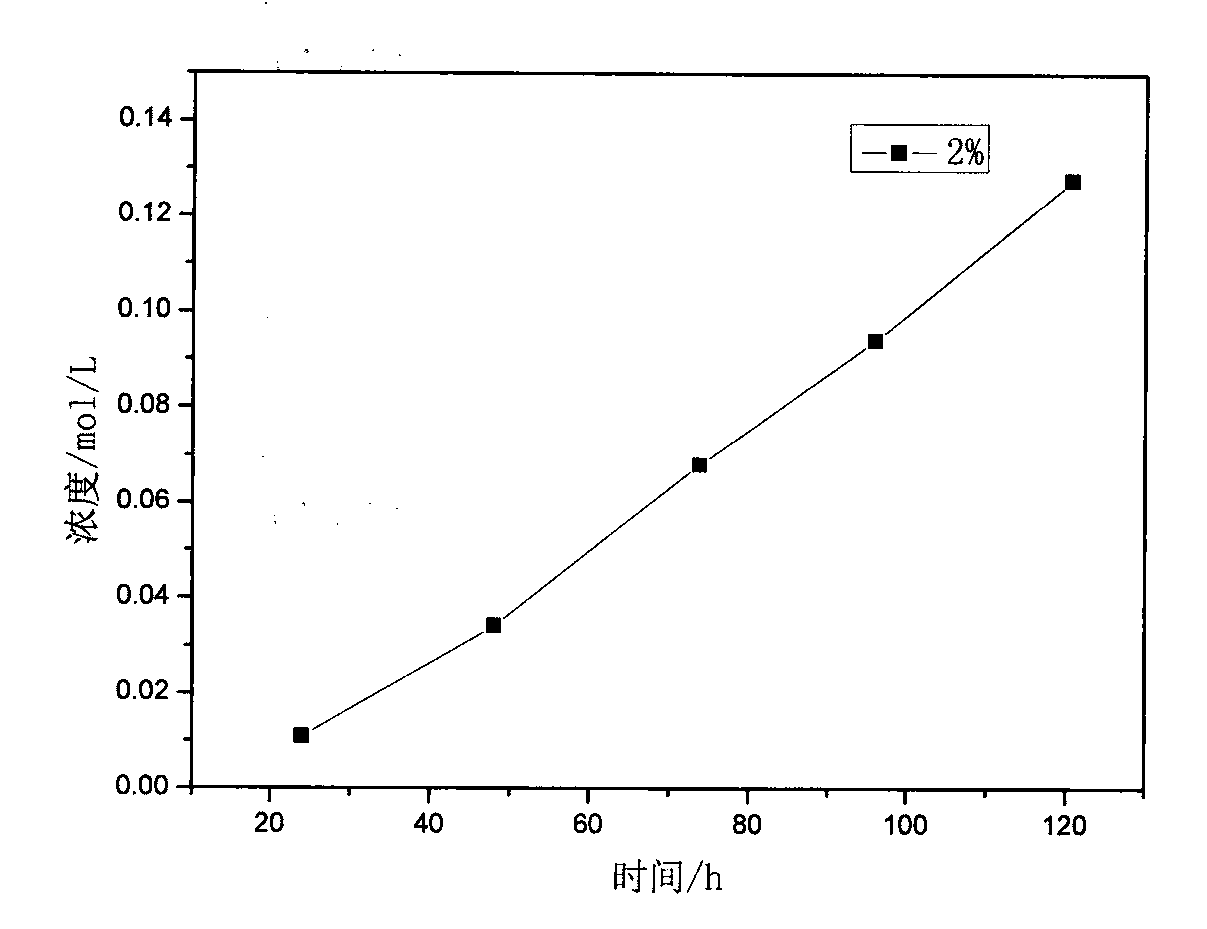

[0027] (2) The prepared nano-carbon material powder was ultrasonically dispersed in the dissolved perfluorosulfonic acid resin solut...

Embodiment 2

[0030] The difference from Example 1 is that in this example, the preparation method of the ion-exchange membrane for the enhanced vanadium battery is as follows:

[0031] (1) Take a certain amount of glucose powder and dissolve it in deionized water, and configure it into an aqueous glucose solution with a weight concentration of 5%, then take a certain amount of aqueous solution and place it in a high-pressure reactor, perform hydrothermal treatment, and treat at 200 ° C for 5 hours, Then filter, wash, and dry to make nano-carbon material powder; in this embodiment, the particle size of nano-carbon material powder is about 200 nanometers.

[0032] (2) The prepared nano-carbon material powder was ultrasonically dispersed in the dissolved perfluorosulfonic acid resin solution (mass of nano-carbon material: mass of perfluorosulfonic acid resin = 2:98), and the dispersion time was 1 hour.

[0033] (3) The dispersed solution was poured onto flat glass, and after drying at 140° C....

Embodiment 3

[0036] The difference from Example 1 is that in this example, the preparation method of the ion-exchange membrane for the enhanced vanadium battery is as follows:

[0037] (1) Weigh a certain amount of glucose powder and dissolve it in deionized water, configure it as an aqueous glucose solution with a weight concentration of 7%, then take a certain amount of aqueous solution and place it in a high-pressure reactor for hydrothermal treatment at 180°C for 8 hours, Then filter, wash and dry to make nano carbon material powder.

[0038] (2) The prepared nano-carbon material powder was ultrasonically dispersed in the dissolved perfluorosulfonic acid resin solution (mass of nano-carbon material: mass of perfluorosulfonic acid resin = 3:97), and the dispersion time was 2 hours.

[0039] (3) The dispersed solution was poured onto flat glass, and after drying at 120°C for 6 hours, the enhanced ion exchange membrane was prepared and assembled into a battery for battery performance test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com