High-heat-conductivity fluorine-containing resin based prepreg and copper-clad plate prepared with same

A technology of fluorine-containing resin and prepreg, which is applied in the field of communication materials, can solve the problems of low thermal conductivity and limit wide application, and achieve the effects of simple operation process, low production cost and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

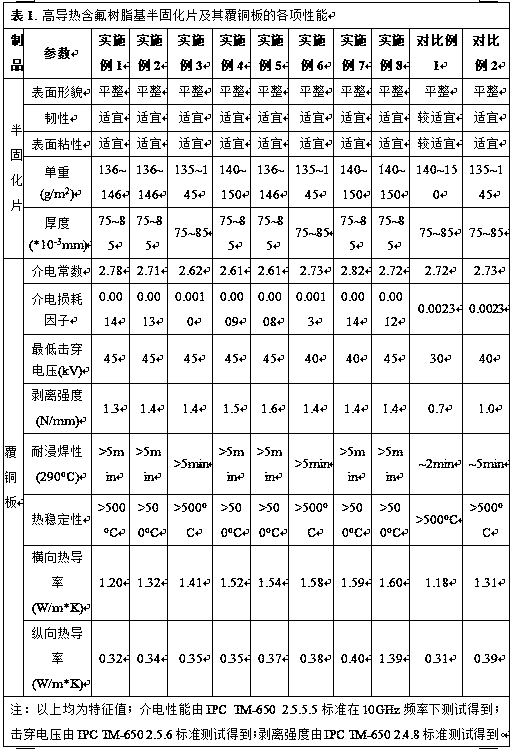

Examples

Embodiment 1

[0026] Add 20 parts of SiC (particle size 6 μm) to a mixed solvent composed of 800 parts of ethanol and 200 parts of water, stir well and add 2 parts of Al 2 o 3 (particle size 200nm), further stir evenly; then, add 0.04 parts of coupling agent KH550, stir at 80°C for 0.5h; add 20 parts of SiC (particle size 6μm) again, so that the SiC concentration increases to 4wt / v%, stir After uniformity, add 2 parts of Al again 2 o 3 (particle size 200nm), further stir evenly; then, add 0.04 parts of coupling agent KH550 again, and stir at 80°C for 0.5h; repeat the above operation until the concentration of SiC reaches 10wt / v%; Drying at ℃ to obtain high thermal conductivity SiC / Al 2 o 3 Composite inorganic filler; Weigh 60 parts of polytetrafluoroethylene emulsion (DuPont Teflon ® PTFE DISP30, solid content 60%) and 40 parts tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer emulsion (DuPont Teflon ® PFAD 335D, solid content 60%), after mixing evenly, add 80 parts of high ...

Embodiment 2

[0028] Add 10 parts of BN (particle size 10 μm) and 10 parts of SiC (particle size 6 μm) to a mixed solvent composed of 800 parts of ethanol and 200 parts of water, stir well and then add 2 parts of Al 2 o 3 (particle size 200nm), further stir evenly; then, add 0.04 parts of coupling agent KH550, stir at 80°C for 0.5h; then add 10 parts of BN (particle size 10μm) and 10 parts of SiC (particle size 6μm), so that The concentrations of BN and SiC were respectively increased to 2wt / v%, and after stirring evenly, 2 parts of Al were added again 2 o 3 (particle size 200nm), further stir evenly; then, add 0.04 parts of coupling agent KH550 again, and stir at 80°C for 0.5h; repeat the above operation until the concentrations of BN and SiC reach 6wt / v% respectively; after removing the solvent by filtration, The solid was dried at 110°C to obtain high thermal conductivity BN / SiC / Al 2 o 3 Composite inorganic filler; Weigh 50 parts of polytetrafluoroethylene emulsion (DuPont Teflon ® ...

Embodiment 3

[0030] Add 20 parts of BN (particle size 10μm) to a mixed solvent composed of 850 parts of ethanol and 150 parts of water, stir well, then add 2 parts of MgO (particle size 500nm), and stir evenly; then, add 0.04 parts of coupling agent KH550 , stirred at 80°C for 0.5h; then added 20 parts of BN (particle size 10μm) in order to increase the BN concentration to 4wt / v%, after stirring evenly, added 2 parts of MgO (particle size 500nm) again, and further stirred evenly; then , add 0.04 parts of coupling agent KH550 again, and stir at 80°C for 0.5h; repeat the above operation until the concentration of BN reaches 12wt / v%; filter to remove the solvent, and dry the solid at 110°C to obtain high thermal conductivity BN / Al 2 o 3 Composite inorganic filler; Weigh 50 parts of polytetrafluoroethylene emulsion (DuPont Teflon ® PTFE DISP30, solid content 60%) and 60 parts perfluoroethylene propylene emulsion (DuPont Teflon ® FEPD121, solid content 54%), after mixing evenly, add 80 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com