Preparation method of high-purity vanadyl sulfate, electrolyte prepared from high-purity vanadyl sulfate, and vanadium redox battery applying high-purity vanadyl sulfate

A vanadyl sulfate, high-purity technology, applied in the field of vanadium batteries, can solve the problems affecting the performance of electrolyte, affecting the performance and service life of vanadium batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

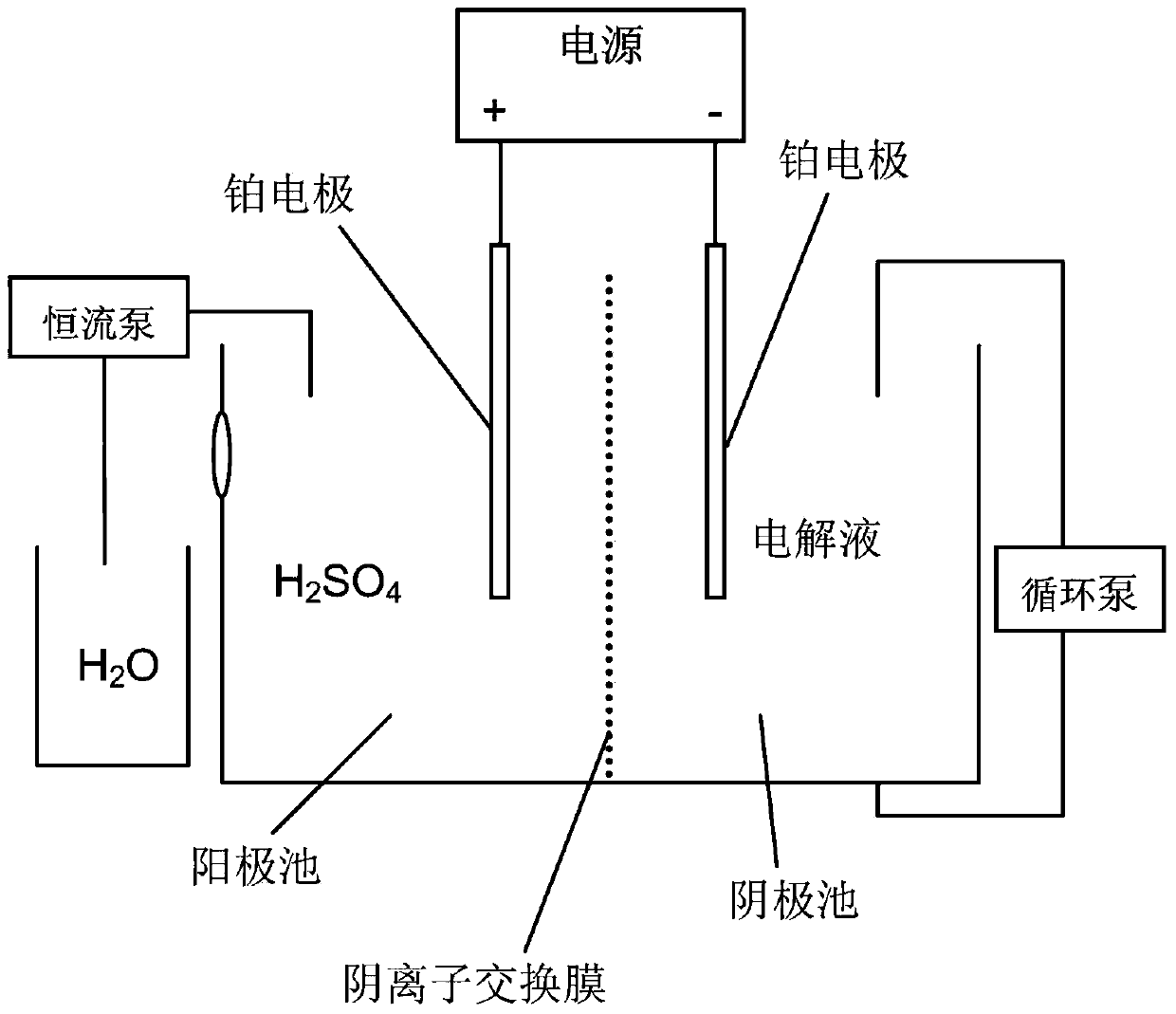

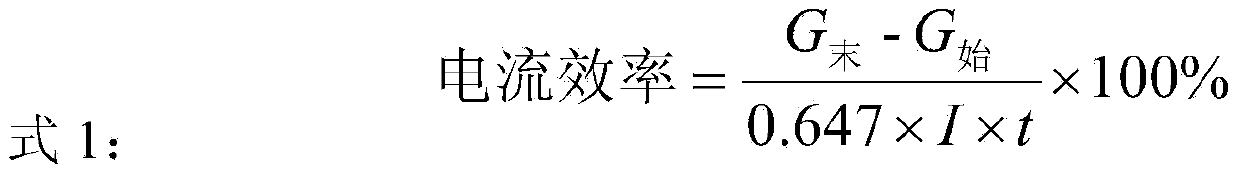

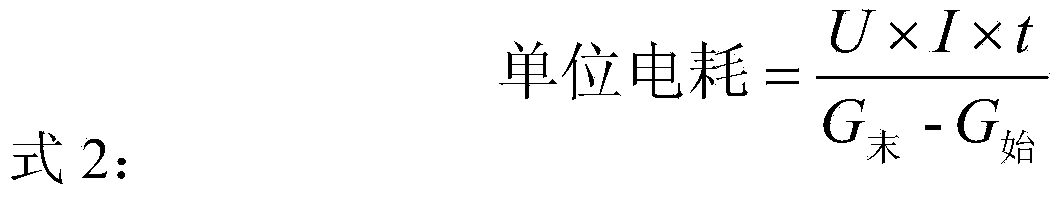

[0016] The preparation method of high-purity vanadyl sulfate according to one aspect of the present invention comprises the following steps: directly dissolving crude vanadium pentoxide in concentrated sulfuric acid to form an activated mixture, adding the mixture to deionized water for dissolving and filtering to obtain A solution containing pentavalent vanadium ions and sulfuric acid; the solution containing pentavalent vanadium ions V (V) and sulfuric acid is used as the negative electrode electrolyte, and placed in the cathode chamber, and the sulfuric acid solution is used as the positive electrode electrolyte, and placed in the anode chamber , control the pH value of the negative electrode electrolyte to 2.2-2.4 and perform impurity removal constant current electrolysis (for example, the current can be constant at a certain point in the range of 10-12A), so as to deposit chromium ions in the negative electrode electrolyte on the cathode; Remove the chromium deposited on t...

example 1

[0033] Prepare related materials. Among them, the composition of crude vanadium in Panzhihua Iron and Steel Co., Ltd. is: 93wt% V 2 o 5 , 7wt% of chromium oxide, others less than 10ppm. Concentrated sulfuric acid is analytically pure, d=1.84g / mL (d means density). (NH 4 ) 2 SO 4 It is analytically pure, and its ammonium sulfate content is above 99.0wt%.

[0034] Weigh 65g of crude vanadium pentoxide from Panzhihua Iron and Steel Co., Ltd., dissolve it in 30mL of concentrated sulfuric acid, and activate it for 10 minutes. Under the condition of stirring, slowly add the activated muddy mixture into deionized water, add water to dissolve to 400mL, and filter to obtain Add 14 g of ammonium sulfate to the solution containing sulfuric acid and pentavalent vanadium ions (abbreviated as vanadium solution).

[0035] Measure 30 mL of concentrated sulfuric acid, slowly add it into deionized water with stirring, and dissolve to obtain 400 mL of sulfuric acid solution. The vanadium...

example 2

[0041] Prepare related materials. Among them, the composition of crude vanadium in Panzhihua Iron and Steel Co., Ltd. is: 90wt% V 2 o 5 , 10wt% of chromium oxide, and the content of other components is less than 10ppm. Concentrated sulfuric acid is analytically pure, d=1.84g / mL. (NH 4 ) 2 SO 4 It is analytically pure, and its ammonium sulfate content is above 99.0wt%.

[0042] Weigh 67g of crude vanadium vanadium pentoxide from Panzhihua Iron and Steel Co., Ltd., dissolve it in 30mL of concentrated sulfuric acid, and activate it for 15 minutes. Under the condition of stirring, slowly add the activated muddy mixture into deionized water, add water to dissolve to 400mL, and filter to obtain 16 g of ammonium sulfate was added to a solution containing sulfuric acid and pentavalent vanadium ions.

[0043] Measure 30 mL of concentrated sulfuric acid, slowly add it into deionized water with stirring, and dissolve to obtain 400 mL of sulfuric acid solution. The vanadium soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com