Preparation method of sulfonated polyimide/chitosan composite proton conducting film

A technology of sulfonated polyimide and proton conductive membrane, which is applied in the parts, circuits, electrical components of fuel cells, etc., can solve the influence of proton conductivity, poor water stability of five-membered ring sulfonated polyimide, etc. The problem is to improve the vanadium ion resistance performance, good proton selectivity, and improve the vanadium resistance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

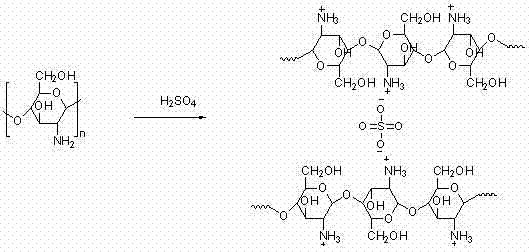

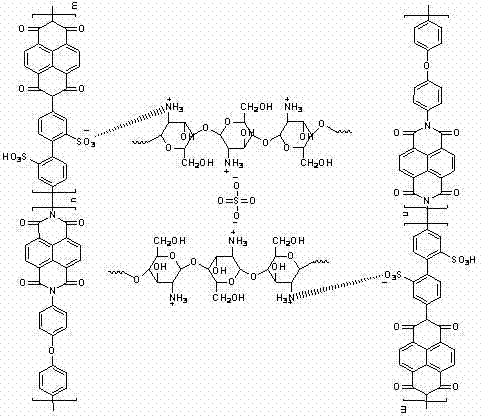

Method used

Image

Examples

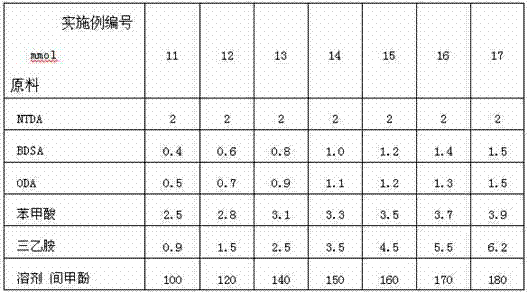

Embodiment 1

[0034] in N 2 Under protection, add 1.0 mmol BDSA, 10 mL m-cresol, 2.0 mmol triethylamine to a 100 mL three-neck flask, stir continuously at room temperature until BDSA is completely dissolved, add 2.0 mmol NTDA, 0.49 g benzoic acid and 1.0 mmol ODA, and continue stirring After a few minutes, the temperature of the system was raised to 80 °C for 4 hours, and then to 180 °C for 20 hours, and the heating was stopped to obtain a viscous polymer solution. When the temperature dropped below 80 °C, add 5 mL of m-cresol to dilute the reaction solution, continue stirring for several minutes, then pour acetone into it to obtain a flocculent polymer precipitate, filter it, and wash the precipitate repeatedly with acetone for several times to remove the residual solvent and untreated solution. The reactants were then dried at 80°C for 20 hours.

[0035] The sulfonated polyimide of the obtained triethylamine salt type is dissolved in the organic solvent m-cresol, and is prepared into a m...

Embodiment 2

[0041] in N 2 Under protection, add 1.2 mmol BDSA, 10 mL m-cresol, and 2.4 mmol triethylamine to a 100 mL three-neck flask, stir continuously at room temperature until BDSA is completely dissolved, add 2.0 mmol NTDA, 0.49 g benzoic acid and 0.8 mmol ODA, and continue stirring After a few minutes, the temperature of the system was raised to 80 °C for 4 hours, and then to 180 °C for 20 hours, and the heating was stopped to obtain a viscous polymer solution. When the temperature dropped below 80 °C, add 5 mL of m-cresol to dilute the reaction solution, continue stirring for several minutes, then pour acetone into it to obtain a flocculent polymer precipitate, filter it, and wash the precipitate repeatedly with acetone for several times to remove the residual solvent and untreated solution. The reactants were then dried at 80°C for 20 hours.

[0042] The sulfonated polyimide of the obtained triethylamine salt type is dissolved in the organic solvent m-cresol, and is prepared into...

Embodiment 3

[0048] in N 2 Under protection, add 1.0 mmol BDSA, 10 mL m-cresol, 2.0 mmol triethylamine into a 100 mL three-neck flask, stir continuously at room temperature until BDSA is completely dissolved, add 2.0 mmol NTDA, 0.49 g benzoic acid and 1.0 mmol ODA, continue stirring for several Minutes later, the temperature of the system was raised to 80 °C for 4 hours, and then to 180 °C for 20 hours, and the heating was stopped to obtain a viscous polymer solution. When the temperature dropped below 80 °C, add 5 mL of m-cresol to dilute the reaction solution, continue stirring for several minutes, then pour acetone into it to obtain a flocculent polymer precipitate, filter it, and wash the precipitate repeatedly with acetone for several times to remove the residual solvent and untreated solution. The reactants were then dried at 80°C for 25 hours.

[0049] The sulfonated polyimide of the obtained triethylamine salt type is dissolved in the organic solvent m-cresol, and is prepared into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com