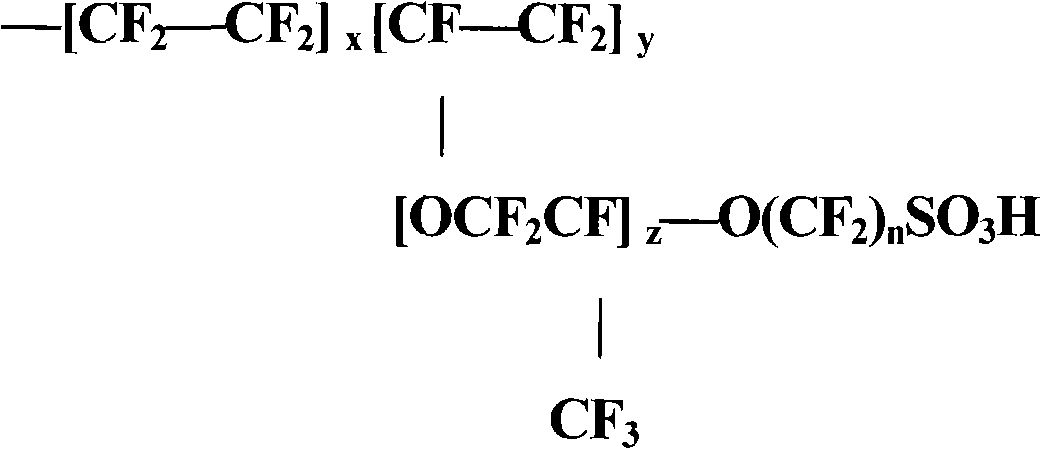

Nafion ion exchange membrane used for enhanced vanadium redox battery and preparation method thereof

A perfluorosulfonic acid ion, exchange membrane technology, applied in the direction of fuel cells, battery pack parts, fuel cell parts, etc., can solve the problems of low mechanical strength, low exchange capacity, high mechanical strength, and improve mechanical strength. , the effect of high exchange capacity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 1.89g perfluorosulfonic acid ion exchange resin (exchange capacity IEC=0.7mmol / g) in 20ml N, N 2 -In dimethylformamide (DMF), heat the reaction kettle to 140° C. for 3 hours to dissolve the resin, and obtain a uniform and clear film-forming solution as the film-forming solution.

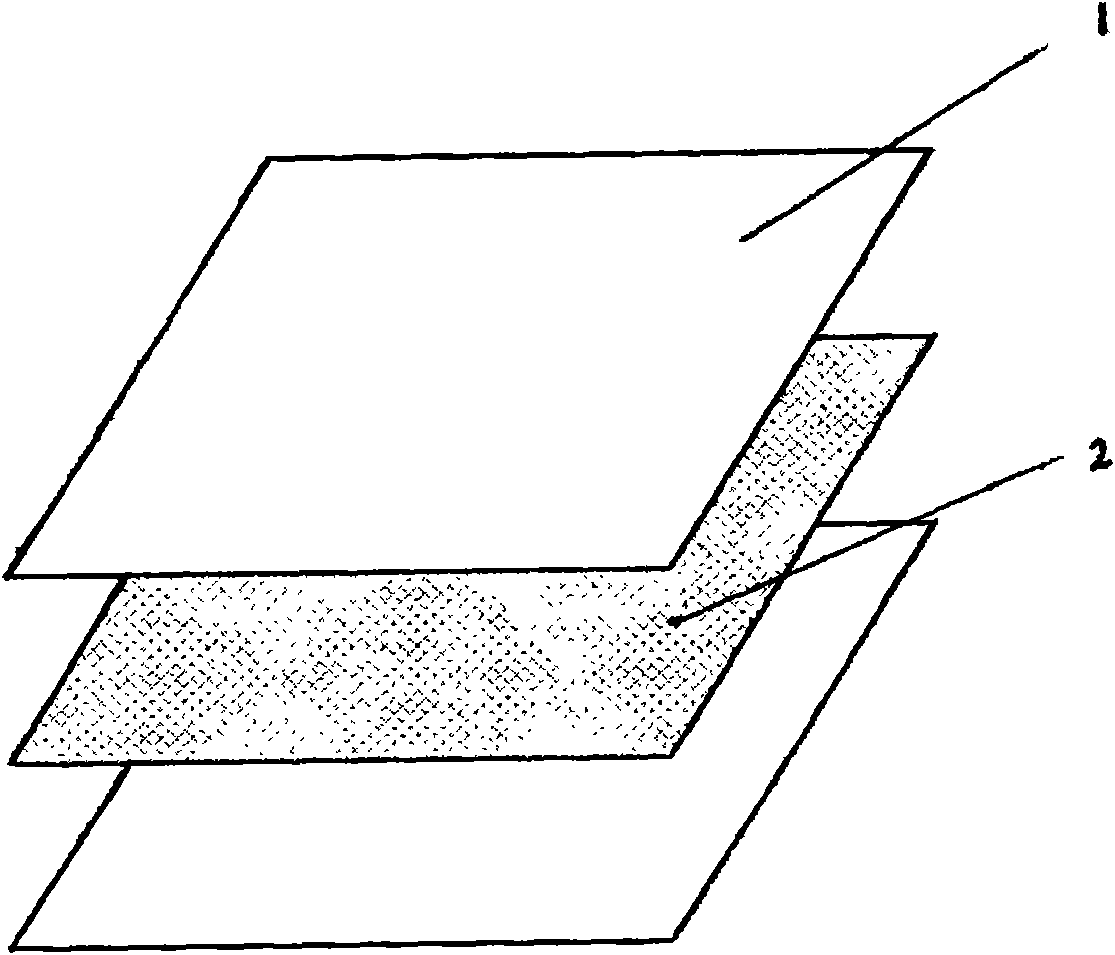

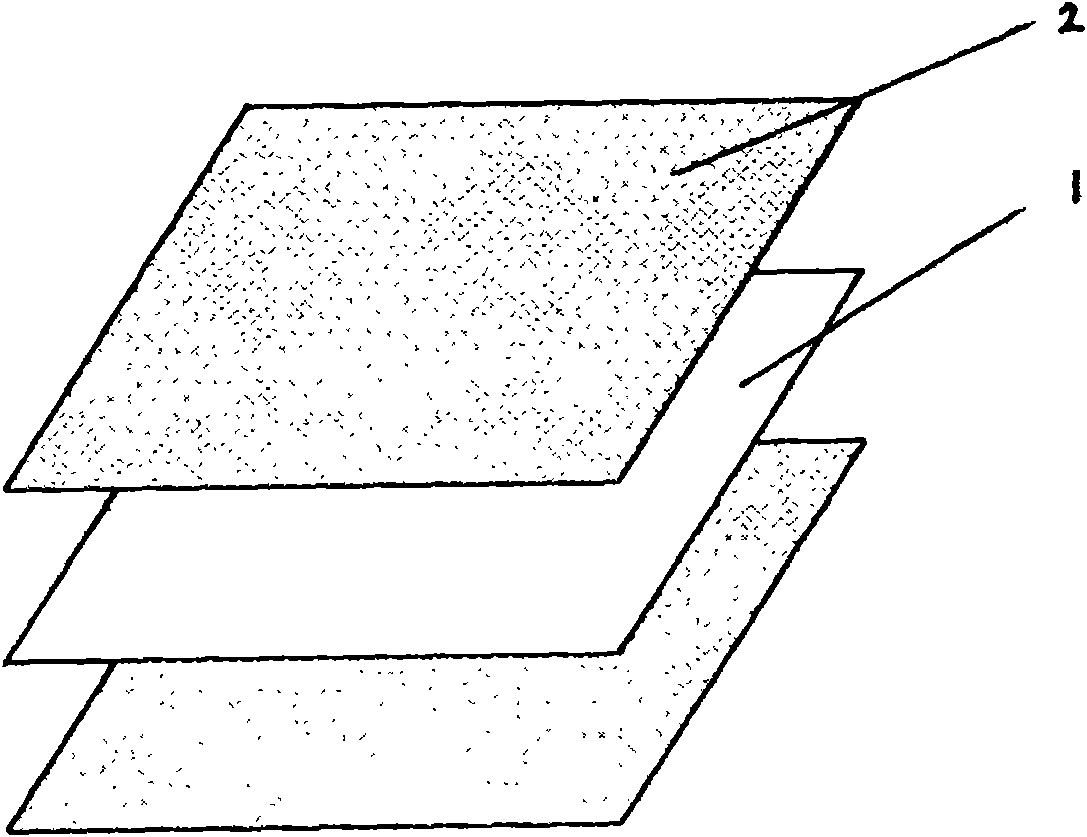

[0037] First, the prepared film-forming solution was vibrated in an ultrasonic oscillator for 1 hour to refine the solution and drive away tiny air bubbles therein. Then, take 10ml of the film-forming solution and cast it on a clean mold, heat it to 100° C., keep the temperature for 1 hour, and place the polytetrafluoroethylene (PTFE) mesh cloth 2 flatly on the film-forming solution. Finally, apply the remaining 10ml film-forming solution on the polytetrafluoroethylene (PTFE) mesh cloth 2, heat to 140°C, keep the temperature for 2h, and naturally cool to room temperature. A layer of film 1 was formed on each surface, and the obtained film was washed with distilled water and dried at ...

Embodiment 2

[0041] Substantially the same as example 1, the difference is that 0.63g perfluorosulfonic acid ion exchange resin is dissolved in 6.67mlN, N 2 - in dimethylformamide (DMF), as a film-forming solution.

[0042] In this embodiment, the reinforcing mesh is polytetrafluoroethylene (PTFE) mesh cloth, which is made of glass fiber as the base material woven into a mesh base cloth, and then coated with polytetrafluoroethylene resin. The grid of the mesh cloth is 0.5×0.5mm, and the thickness is 0.05mm.

Embodiment 3

[0044] Substantially the same as example 1, the difference is that 2.83g perfluorosulfonic acid ion exchange resin is dissolved in 30ml N, N 2 - in dimethylformamide (DMF), as a film-forming solution.

[0045] In this embodiment, the reinforcing mesh is polytetrafluoroethylene (PTFE) mesh cloth, which is made of glass fiber as the base material woven into a mesh base cloth, and then coated with polytetrafluoroethylene resin. The grid of the mesh cloth is 1×1mm, and the thickness is 0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com